Environmentally Oriented Analysis of Benefits and Expenditures in the Life Cycle of a Wind Power Plant

Abstract

1. Introduction

2. Materials and Methods

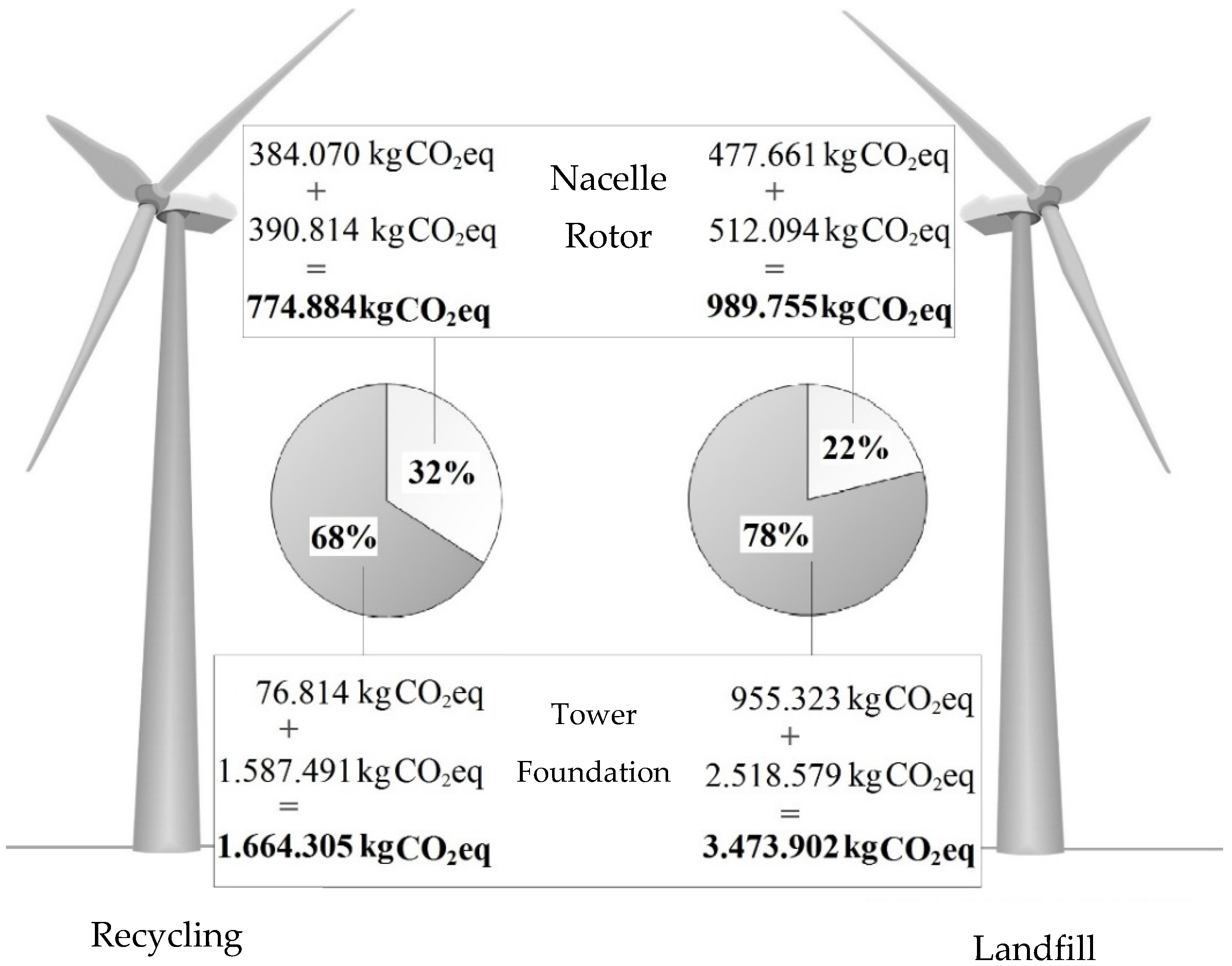

3. Results

4. Discussion

- −

- use of materials with the lowest possible negative impact on the environment for production,

- −

- using fewer resources during the production process,

- −

- reduction of the amount of pollution and by-products,

- −

- ensuring an adequate service life,

- −

- facilitating the re-use of materials, components and/or workgroups,

- −

- striving to reduce the impact of post-consumer development on the environment.

5. Conclusions

- −

- development and implementation by manufacturers of wind turbines using technology that allows for the replacement of faster-wearing elements, e.g., nacelles and rotors or their parts after the first life cycle, while leaving slower-wearing elements, e.g., foundations and towers, for the second life cycle, as this will allow for the second life cycle to reduce environmental inputs;

- −

- use of pro-environmental construction materials;

- −

- designing structures that enable easy post-use separation of materials and elements;

- −

- minimization of energy consumption, material consumption and emission intensity of production processes, use and post-consumer disposal of materials, materials and elements of a wind power plant;

- −

- optimization at the stage of designing the consumption of the materials (mainly steel) used to build wind farms that have the highest environmental impact;

- −

- development of comprehensive, pro-environmental standards regarding the method of post-consumer management of plastics, materials and elements of a wind power plant.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McCarthy, J. Reflections on: Our planet and life, origins and futures. Science 2009, 326, 1646–1655. [Google Scholar] [CrossRef] [PubMed]

- Mielczarski, W. Electricity Markets—Selected Technical and Economic Issues; Warsaw, Poland, 2000. [Google Scholar]

- Oexmann, J. Post-Combustion CO2 Capture: Energetic Evaluation of Chemical Absorption Processes in Coal-Fired Steam Power Plants; Cuvillier: Hamburg, Germany, 2011. [Google Scholar]

- Ragas, A.M.J. Towards a sustainability indicator for production system. J. Clean. Prod. 1995, 3, 123–129. [Google Scholar] [CrossRef]

- Udo, V.; Pawłowski, A. Human progress towards equitable sustainable development—Part II: Xmpirical Exploration. Probl. Sustain. Dev. 2011, 6, 33–62. [Google Scholar]

- Danielak, M. New Possibilities of Heat and Cold Accumulation; Polski Instalator: Warszawa, Poland, 2014; Volume 10. [Google Scholar]

- Mitchell, R.B. Technology is not xnough: Climate change, population, affluence and consumption. J. Environ. Dev. 2012, 21, 24–27. [Google Scholar] [CrossRef]

- Pawłowski, A. Sustainable development In contemporary civilization. Part 1: The environment and sustainable development. Probl. Sustain. Dev. 2008, 3, 53–65. [Google Scholar]

- Raupach, M.R. Global and regional drivers of accelerating CO2 emissions. Proc. Natl. Acad. Sci. USA 2007, 104, 10288–10293. [Google Scholar] [CrossRef] [PubMed]

- Tytko, R. Renewable Energy Devices and Systems; Publishing and Printing House of the Society of Slovaks: Kraków, Poland, 2013. [Google Scholar]

- Arachchige, S.P.R.; Mohsin, M.; Melaaen, M.C. Optimized CO2-flue gas separation model for a coal fired power plant. Int. J. Energy Environ. 2013, 4, 39–48. [Google Scholar]

- Duran, J.; Golušin, M.; Ivanović, O.M.; Jovanović, L.; Andrejević, A. Renewable energy and socio-economic development in the xuropean Union. Probl. Sustain. Dev. 2013, 8, 105–114. [Google Scholar]

- Krawiec, F. The Role of Renewable Energy Sources in Solving the Global Energy Crisis; Difin SA: Warsaw, Poland, 2010. [Google Scholar]

- Lewandowski, W.M. Pro-Ecological Renewable Energy Sources; Scientific and Technical Publishing House: Warsaw, Poland, 2007. [Google Scholar]

- Martens, P. Health and Climate Change. Modeling the Impacts of Global Warming and Ozone Depletion; Xarthscan Publications: London, UK, 1998. [Google Scholar]

- Purgał, P.; Orman, Ł.J. Using Renewable Energy Sources; Wydawnictwo Politechnika Świętokrzyska: Kielce, Poland, 2012. [Google Scholar]

- Indicators of Pollutant Emissions from Fuel Combustion; National Center for Emission Balancing and Management: Warsaw, Poland, 2015.

- Assaki, K.; Kato, M.; Uemoto, H. Influence of temperature and CO2 concentration on the CO2 absorption properties. J. Mater. Sci. 2005, 40, 5017–5019. [Google Scholar] [CrossRef]

- Jabłoński, W.; Wnuk, J. Renewable Energy Sources in the Energy Policy of the European Union and Poland; Eeffective Investment Management—Case Studies: Sosnowiec, Poland, 2004. [Google Scholar]

- Piasecka, I.; Bałdowska-Witos, P.; Flizikowski, J.; Piotrowska, K.; Tomporowski, A. Control the System and Environment of Post-Production Wind Turbine Blade Waste Using Life Cycle Models. Part 1. Environmental Transformation Models. Polymers 2020, 12, 1828. [Google Scholar] [CrossRef] [PubMed]

- Piasecka, I.; Bałdowska-Witos, P.; Piotrowska, K.; Tomporowski, A. Eco-Energetical Life Cycle Assessment of Materials and Components of Photovoltaic Power Plant. Energies 2020, 13, 1385. [Google Scholar] [CrossRef]

- Dmowski, A.; Przybyszewski, M. DC Microgrids in Renewable Distributed Energy, International Conference of xnergii xco-xuro-xnergia, 2 Renewable energy Sources in the Countries of the European Union as a Source of Energy Benefits—Fiction, Stagnation or Development; SAWO Bydgoszcz Fair: Bydgoszcz, Poland, 2005. [Google Scholar]

- Hadjipaschalis, I.; Poullikkas, A.; Xfthimiou, V. Overview of current and future energy storage technologies for electric power applications. Renew. Sustain. Energy Rev. 2009, 3, 1513–1522. [Google Scholar] [CrossRef]

- Jaksch, C. Environmental performance evaluation and indicators. J. Clean. Prod. 2000, 8, 79–88. [Google Scholar] [CrossRef]

- Zwierzycki, W. Forecasting the Reliability of Wearing Machine Parts; Publishing House of the Institute of Operating Technology: Poznań-Radom, Poland, 1999. [Google Scholar]

- Popczyk, J. Electricity Security in a Post-Industrial Society on the Example of Poland; Publishing House of the Silesian University of Technology: Gliwice, Poland, 2009. [Google Scholar]

- Alberts, H. Recycling of wind turbine rotor blades—Fact or fiction? Dewi. Mag. 2009, 2, 32–41. [Google Scholar]

- Brondsted, P.; Lilholt, H.; Aage, L. Composite materials for wind power turbine blades. Annu. Rev. Mater. Res. 2005, 35, 505–538. [Google Scholar] [CrossRef]

- Piotrowska, K.; Piasecka, I.; Bałdowska-Witos, P.; Kruszelnicka, W.; Tomporowski, A. LCA as a Tool for the Environmental Management of Car Tire Manufacturing. Appl. Sci. 2020, 10, 7015. [Google Scholar] [CrossRef]

- Griffin, D.A. Blade System Design Studies Volume 1: Composite Technologies for Large Wind Turbine Blades; Sandia National Laboratories: Albukerque, NM, USA, 2002. [Google Scholar]

- Kasner, R.; Kruszelnicka, W.; Bałdowska-Witos, P.; Flizikowski, J.; Tomporowski, A. Sustainable Wind Power Plant Modernization. Energies 2020, 13, 1461. [Google Scholar] [CrossRef]

- Gasiński, L.; Kłos, Z.; Żak, J. Problems of Shaping the Operational Quality of Vehicles and Other Technical Facilities; Poznań University of Technology Publishing House: Poznań, Poland, 1994. [Google Scholar]

- Legutko, S. Xcology of Machines; Publishing House of the Poznań University of Technology: Poznań, Poland, 2007. [Google Scholar]

- Merkisz-Guranowska, A. Aspects of the Development of Recycling in Poland; Publishing House of the Institute of Operating Technology: Poznań-Radom, Poland, 2005. [Google Scholar]

- Nadolny, K.; Bieńczak, K. Fundamentals of Modeling the Reliability of Consumables; Publishing House and Department of Printing of the Institute of Utilization Technology: Poznań-Radom, Poland, 1999. [Google Scholar]

- Bilitewski, B.; Härdtle, G.; Marek, K. Manual of Waste Management; Theory and Practice; Seidel Przywecki Publishing House: Warsaw, Poland, 2006. [Google Scholar]

- Powierża, L. Outline of Bioagrotechnical Systems Engineering. Part I. Fundamentals; Publishing House and Department of Printing, Institute of Utilization Technology: Radom-Płock, Poland, 1997. [Google Scholar]

- Guineé, J. Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Springer: Berlin, Germany, 2002; pp. 395–644. [Google Scholar] [CrossRef]

- Hauschild, M.; Rosenbaum, R.K.; Olsen, S. Life Cycle Assessment. Theory and Practice; Springer: Dordrecht, The Netherlands, 2018; pp. 9–55. [Google Scholar] [CrossRef]

- Curran, M.A. Goal and Scope Definition in Life Cycle Assessment; Springer: Dordrecht, The Netherlands, 2017; pp. 1–167. [Google Scholar] [CrossRef]

- Ulgiati, S.; Raugei, M.; Bargigli, S. Overcoming the in adequacy of single-criterion approaches to Life Cycle Assessment. Ecol. Modell. 2006, 3, 432–442. [Google Scholar] [CrossRef]

- Basosi, R.; Cellura, M.; Longo, S.; Parisi, M.L. Life Cycle Assessment of Energy Systems and Sustainable Energy Technologies; Springer: Basel, Switzerland, 2019; pp. 3–15. [Google Scholar] [CrossRef]

- Werner, F. Ambiguities in Decision-Oriented Life Cycle Inventories; Springer: Dordrecht, The Netherlands, 2005; pp. 27–133. [Google Scholar] [CrossRef]

- Finkbeiner, M. Special Types of Life Cycle Assessment; Springer Science + Business Media: Dordrecht, The Netherlands, 2016; pp. 115–178. [Google Scholar] [CrossRef]

- Schleisner, L. Life Cycle Assessment of a Wind Farm and Related Externalities. Renew. Energy 2000, 20, 279–288. [Google Scholar] [CrossRef]

- Ardente, F.; Beccali, M.; Cellura, M.; Lo Brano, V. Energy performances and life cycle assessment of an Italian wind farm. Renew. Sustain. Energ. Rev. 2008, 12, 200–217. [Google Scholar] [CrossRef]

- Alexandra, B.; Laurent, A.; Olsen, I.S. Life cycle assessment of onshore and offshore wind energy-from theory to application. Appl. Energy 2016, 180, 327–337. [Google Scholar] [CrossRef]

- Martínez, E.; Sanz, F.; Pellegrini, S.; Jiménez, E.; Blanco, J. Life Cycle Assessment of Multi-Megawatt Wind Turbine. Renew. Energy 2009, 34, 667–673. [Google Scholar] [CrossRef]

- Wagner, H.J. Life cycle assessment of the offshore wind farm alpha ventus. Energy 2011, 36, 2459–2464. [Google Scholar] [CrossRef]

- Al-Behadili, S.H.; El-Osta, W.B. Life Cycle Assessment of Dernah (Libya) wind farm. Renew. Energy 2015, 83, 1227–1233. [Google Scholar] [CrossRef]

- Oebels, K.B.; Pacca, S. Life cycle assessment of a non-shore wind farm located at the north eastern coast of Brazil. Renew. Energy 2013, 53, 60–70. [Google Scholar] [CrossRef]

- Kabir, M.R.; Rooke, B.; Dassanayake, G.M.; Fleck, B.A. Comparative life cycle energy, emission, and economic analysis of 100 kW nameplate wind power generation. Renew. Energy 2012, 37, 133–141. [Google Scholar] [CrossRef]

- Alsaleh, A.; Sattler, M. Comprehensive life cycle assessment of large wind turbines in the US. Clean Technol. Environ. Policy 2019, 21, 887–903. [Google Scholar] [CrossRef]

- Vargas, A.V.; Zenón, E.; Oswald, U.; Islas, J.M.; Güereca, L.P.; Manzini, F.L. Life cycle assessment: A case study of two wind turbines used in Mexico. Appl. Therm. Eng. 2015, 75, 1210–1216. [Google Scholar] [CrossRef]

- Chipindula, J.; Botlaguduru, V.S.V.; Du, H.; Kommalapati, R.R.; Huque, Z. Life cycle environmental impact of onshore and offshore wind farms in Texas. Sustainability 2018, 10, 2022. [Google Scholar] [CrossRef]

- Spreafico, C.; Landi, D. Investigating students’ eco-misperceptions in applying eco-design methods. J. Clean. Prod. 2002, 342, 130866–130874. [Google Scholar] [CrossRef]

| No. | Element | Material | Weight [kg] | % Content in Wind Power Plant | Aluminum [kg] | Copper [kg] | Steel [kg] | Cast Iron [kg] | Polymer Materials [kg] | Concrete [kg] | Oil [kg] | Other [kg] | Data Source |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | NACELLE | ||||||||||||

| 1.1 | Generator with a cooler | copper | 1430 | 0.08 | x | 1430 | x | x | x | x | x | x | Vestas |

| cast iron | 3920 | 0.22 | x | x | x | 3920 | x | x | x | x | |||

| steel | 2090 | 0.12 | x | x | 2090 | x | x | x | x | x | |||

| other | 60 | 0.00 | x | x | x | x | x | x | x | 60 | x | ||

| total: generator | 7500 | 0.43 | x | x | x | x | x | x | x | x | Vestas | ||

| 1.2 | Gearbox | high-quality steel | 2620 | 0.15 | x | x | 2620 | x | x | x | x | x | Vestas |

| cast iron | 14060 | 0.80 | x | x | x | 14,060 | x | x | x | x | |||

| oil | 280 | 0.02 | x | x | x | x | x | x | 280 | x | |||

| other | 40 | 0.00 | x | x | x | x | x | x | x | 40 | x | ||

| total: gearbox | 17,000 | 0.97 | x | x | x | x | x | x | x | x | Vestas | ||

| 1.3 | Transformer | steel | 4150 | 0.24 | x | x | 4150 | x | x | x | x | x | Siemens |

| aluminum | 860 | 0.05 | 860 | x | x | x | x | x | x | x | |||

| other | 80 | 0.00 | x | x | x | x | x | x | x | 80 | x | ||

| total: transformer | 5090 | 0.29 | x | x | x | x | x | x | x | x | Siemens | ||

| 1.4 | Main shaft with body | high-quality steel | 9520 | 0.54 | x | x | 9520 | x | x | x | x | x | own measurement |

| cast iron | 1795 | 0.10 | x | x | x | 1795 | x | x | x | x | |||

| other | 20 | 0.00 | x | x | x | x | x | x | x | 20 | x | ||

| total: main shaft | 11,335 | 0.65 | x | x | x | x | x | x | x | x | own measurement | ||

| 1.5 | Coolers | aluminum | 960 | 0.05 | 960 | x | x | x | x | x | x | x | own measurement |

| 1.6 | Hydraulic system | oil | 360 | 0.02 | x | x | x | x | x | x | 360 | x | own measurement |

| steel | 2660 | 0.15 | x | x | 2660 | x | x | x | x | x | |||

| aluminum | 420 | 0.02 | 420 | x | x | x | x | x | x | x | |||

| other | 200 | 0.01 | x | x | x | x | x | x | x | 200 | x | ||

| total: hydraulic system | 3640 | 0.21 | x | x | x | x | x | x | x | x | own measurement | ||

| 1.7 | Switchboards, converters, connections | steel | 340 | 0.02 | x | x | 340 | x | x | x | x | x | own measurement |

| copper | 240 | 0.01 | x | 240 | x | x | x | x | x | x | |||

| aluminum | 180 | 0.01 | 180 | x | x | x | x | x | x | x | |||

| other | 120 | 0.01 | x | x | x | x | x | x | x | 120 | x | ||

| total: switchboards and converters, | 880 | 0.05 | x | x | x | x | x | x | x | x | own measurement | ||

| 1.8 | Nacelle platform | cast iron | 14,590 | 0.83 | x | x | x | 14,590 | x | x | x | x | Vestas |

| steel | 3750 | 0.21 | x | x | 3750 | x | x | x | x | x | |||

| total: nacelle platform | 18,340 | 1.04 | x | x | x | x | x | x | x | x | |||

| 1.9 | Nacelle case | steel | 1100 | 0.06 | x | x | 1100 | x | x | x | x | x | own measurement |

| polymer materials | 1815 | 0.10 | x | x | x | x | 1815 | x | x | x | |||

| other | 340 | 0.02 | x | x | x | x | x | x | x | 340 | x | ||

| total: nacelle case | 3255 | 0.19 | x | x | x | x | x | x | x | x | own measurement | ||

| Total: nacelle | 68,000 | 3.87 | 2420 | 1670 | 26,230 | 34,365 | 1815 | 0 | 640 | 860 | Vestas | ||

| 2 | ROTOR | ||||||||||||

| 2.1 | Blades | steel | 1750 | 0.10 | x | x | 1750 | x | x | x | x | x | Vestas |

| polymer materials | 18,250 | 1.04 | x | x | x | x | 18,250 | x | x | x | |||

| total: blades | 20,000 | 1.14 | x | x | x | x | x | x | x | x | |||

| 2.2 | Hub | cast iron | 17650 | 1.00 | x | x | x | 17,650 | x | x | x | x | Vestas |

| polymer materials | 200 | 0.01 | x | x | x | x | 200 | x | x | x | |||

| other | 150 | 0.01 | x | x | x | x | x | x | x | 150 | x | ||

| total: hub | 18,000 | 1.02 | x | x | x | x | x | x | x | x | Vestas | ||

| Total: rotor | 38,000 | 2.16 | 0 | 0 | 1750 | 17,650 | 18,450 | 0 | 0 | 150 | Vestas | ||

| 3 | TOWER | ||||||||||||

| 3.1 | Tower rings | steel | 253,775 | 14.45 | x | x | 253775 | x | x | x | x | x | Vestas |

| aluminum | 1295 | 0.07 | 1295 | x | x | x | x | x | x | x | |||

| copper | 380 | 0.02 | x | 380 | x | x | x | x | x | x | |||

| other | 550 | 0.03 | x | x | x | x | x | x | x | 550 | x | ||

| Total: tower | 256,000 | 14.57 | 1295 | 380 | 253,775 | 0 | 0 | 0 | 0 | 550 | Vestas | ||

| 4 | FOUNDATIONS | ||||||||||||

| 4.1 | Reinforcement | steel | 54,545 | 3.10 | x | x | 54,545 | x | x | x | x | x | construction project |

| 4.2 | Concrete | cement | 209,050 | 11.90 | x | x | x | x | x | x | x | x | |

| aggregate | 1,036,775 | 59.01 | x | x | x | x | x | x | x | x | |||

| water | 90,400 | 5.15 | x | x | x | x | x | x | x | x | |||

| other | 3390 | 0.19 | x | x | x | x | x | x | x | x | |||

| total: concrete | 1,339,615 | 76.25 | x | x | x | x | x | 133,961 | x | x | |||

| 4.3 | Other | 650 | 0.04 | x | x | x | x | x | x | x | 650 | x | |

| Total: foundations | 1,394,810 | 79.39 | 0 | 0 | 54,545 | 0 | 0 | 1,339,615 | 0 | 650 | construction project | ||

| TOTAL: WIND POWER PLANT | 1,756,810 | 100.00 | 3715 | 2050 | 336,300 | 52,015 | 20,265 | 1,339,615 | 640 | 2210 | x | ||

| % content of materials in wind power plant | 0.21 | 0.12 | 19.14 | 2.96 | 1.15 | 76.25 | 0.04 | 0.13 | |||||

| Impact Category | Unit | Production | Use | Landfill | Recycling |

|---|---|---|---|---|---|

| Carcinogens | DALY | 2.25 × 10−1 | 1.06 × 10−1 | 1.55 | −7.94 × 10−2 |

| Respiratory organics | DALY | 2.86 × 10−3 | 2.23 × 10−4 | 5.07 × 10−4 | −6.77 × 10−4 |

| Respiratory inorganics | DALY | 7.33 | 3.38 × 10−1 | 3.55 × 10−2 | −1.43 × 10−1 |

| Ionizing radiation | DALY | 1.93 × 10−2 | 3.19 × 10−4 | 2.97 × 10−4 | 0.00 |

| Ozone layer depletion | DALY | 1.17 × 10−3 | 1.59 × 10−5 | 5.91 × 10−6 | −8.72 × 10−5 |

| Land use | PDF·m2/r | 3.34 × 104 | 3.96 × 103 | 2.92 × 103 | 0.00 |

| Minerals | MJ | 1.28 × 106 | 2.91 × 104 | 1.04 × 103 | −3.13 × 104 |

| Non-renewable energy | MJ | 2.47 × 106 | 2.09 × 105 | 6.65 × 104 | −3.74 × 105 |

| Substance | Influence Area | Production | Use | Landfill | Recycling |

|---|---|---|---|---|---|

| Arsenic | Air | 5.68 × 10−3 | 1.12 × 10−3 | 8.59 × 10−5 | × |

| Benzo (α) pyrene | Air | 1.68 × 10−4 | × | ||

| Cadmium | Air | 4.16 × 10−2 | 1.97 × 10−3 | 3.59 × 10−4 | −4.77 × 10−3 |

| Dioxins, measured as 2,3,7,8-tetrachlorodibenzo-p-dioxin (TCDD) | Air | 2.74 × 10−4 | × | × | × |

| Metals, unspecified | Air | 1.28 × 10−4 | × | × | 3.97 × 10−3 |

| Nickel | Air | 7.32 × 10−4 | × | × | −2.22 × 10−5 |

| PAHs, polycyclic aromatic hydrocarbons | Air | 3.98 × 10−4 | × | 6.56 × 10−6 | −2.52 × 10−5 |

| Solid particles, <2.5 µm | Air | 3.62 × 10−4 | 9.35 × 10−2 | × | × |

| Arsenic, ions | Water | 1.62 × 10−1 | 7.93 × 10−3 | 7.03 × 10−2 | −7.33 × 10−2 |

| Cadmium, ions | Water | 1.12 × 10−2 | 2.13 × 10−4 | 1.47 | −2.09 × 10−3 |

| Metal ions, unspecified | Water | 2.24 × 10−5 | × | × | −2.95 × 10−3 |

| PAHs, polycyclic aromatic hydrocarbons | Water | 2.66 × 10−3 | × | × | −2.15 × 10−4 |

| Arsenic | Soil | 7.92 × 10−5 | × | × | × |

| Cadmium | Soil | × | 2.13 × 10−4 | × | × |

| DALY | 0.225 | 0.106 | 1.545 | −0.794 |

| Substance | Influence Area | Production | Use | Landfill | Recycling |

|---|---|---|---|---|---|

| Acetaldehyde | Air | 1.30 × 10−6 | × | × | × |

| Benzene | Air | 2.95 × 10−6 | 1.04 × 10−6 | 4.32 × 10−8 | −2.27 × 10−7 |

| Ethylbenzene | Air | 2.14 × 10−6 | 1.89 × 10−8 | × | |

| Butane | Air | 1.64 × 10−5 | 1.15 × 10−6 | 4.18 × 10−7 | × |

| Butene | Air | 1.64 × 10−6 | × | × | × |

| Ethane | Air | 8.54 × 10−6 | 4.61 × 10−7 | 7.04 × 10−8 | × |

| Ethanol | Air | 1.54 × 10−6 | × | × | × |

| Eten | Air | 3.74 × 10−5 | 2.93 × 10−7 | 8.50 × 10−8 | × |

| Formaldehyde | Air | 5.67 × 10−6 | 5.03 × 10−7 | 2.53 × 10−7 | × |

| Heptan | Air | 4.48 × 10−6 | 2.76 × 10−7 | 1.36 × 10−7 | × |

| Hexane | Air | 8.71 × 10−6 | 7.42 × 10−7 | 2.79 × 10−7 | × |

| Aliphatic hydrocarbons, alkanes, unspecified | Air | 7.73 × 10−6 | 1.12 × 10−6 | 7.34 × 10−8 | × |

| Aliphatic hydrocarbons, alkenes, unspecified | Air | 4.77 × 10−6 | 2.64 × 10−6 | × | × |

| Aromatic hydrocarbons | Air | 2.92 × 10−6 | 1.68 × 10−7 | 1.43 × 10−7 | 2.08 × 10−6 |

| Hydrocarbons, unspecified | Air | 2.20 × 10−7 | × | × | 2.73 × 10−6 |

| Methane | Air | 7.90 × 10−5 | 4.52 × 10−7 | 4.33 × 10−4 | −3.91 × 10−5 |

| Methane, fossil | Air | 1.12 × 10−5 | 1.71 × 10−5 | 2.12 × 10−5 | × |

| NM VOC, non-methane volatile organic compounds | Air | 2.59 × 10−3 | 1.81 × 10−4 | 5.01 × 10−5 | −6.42 × 10−4 |

| PAH | Air | 4.92 × 10−6 | × | 1.82 × 10−8 | −3.11 × 10−7 |

| Pentane | Air | 2.33 × 10−5 | 2.07 × 10−6 | 5.98 × 10−7 | × |

| Propane | Air | 1.03 × 10−5 | 7.69 × 10−7 | 2.18 × 10−7 | × |

| Propene | Air | 5.84 × 10−6 | 3.79 × 10−7 | 6.80 × 10−8 | × |

| Toluene | Air | 5.90 × 10−6 | 1.02 × 10−6 | 1.78 × 10−7 | × |

| Xylene | Air | 1.45 × 10−5 | 1.05 × 10−5 | 2.03 × 10−7 | × |

| Unit | DALY | 0.0029 | 0.0002 | 0.0005 | −0.0007 |

| Substance | Influence Area | Production | Use | Landfill | Recycling |

|---|---|---|---|---|---|

| Ammonia | Air | × | 1.92 × 10−4 | × | × |

| Nitric oxide | Air | 3.90 × 10−1 | 8.53 × 10−2 | 1.73 × 10−2 | −6.47 × 10−2 |

| Solid particles | Air | 1.82 × 10−3 | 2.44 × 10−4 | × | −1.26 × 10−2 |

| Solid particles, <10 µm (mobile) | Air | 1.86 × 10−2 | × | × | × |

| Solid particles, <10 µm (stationary) | Air | 4.39 × 10−1 | 4.35 × 10−4 | × | × |

| Solid particles, <2.5 µm | Air | 2.59 × 10−2 | 9.99 × 10−2 | 1.23 × 10−2 | × |

| Solid particles, >2.5 µm and <10 µm | Air | 1.89 × 10−2 | 9.70 × 10−3 | 1.41 × 10−3 | × |

| Sulfur dioxide | Air | 3.00 × 10−2 | 1.36 × 10−1 | 4.22 × 10−3 | × |

| Sulfur oxide | Air | 6.40 | 6.71 × 10−3 | × | −6.57 × 10−2 |

| DALY | 7.330 | 0.340 | 0.036 | −0.143 |

| Substance | Influence Area | Production | Use | Landfill | Recycling |

|---|---|---|---|---|---|

| Carbon-14 | Air | 1.75 × 10−3 | 8.13 × 10−5 | 1.02 × 10−4 | × |

| Iodine-129 | Air | 2.55 x 10−5 | 4.53 × 10−7 | 3.41 × 10−7 | × |

| Krypton-85 | Air | 6.35 × 10−5 | 3.10 × 10−7 | 9.68 × 10−12 | × |

| Polon-210 | Air | × | 2.63 × 10−7 | × | × |

| Radon-222 | Air | 1.62 × 10−2 | 2.30 × 10−4 | 1.95 × 10−4 | × |

| Uranium-238 | Air | × | 1.74 × 10−7 | × | × |

| Cesium-134 | Water | 8.71 × 10−5 | 4.36 × 10−7 | 9.90 × 10−9 | × |

| Cesium-137 | Water | 9.74 × 10−4 | 4.81 × 10−6 | 2.53 × 10−7 | × |

| Cobalt-60 | Water | 1.19 × 10−4 | 6.08 × 10−7 | 1.49 × 10−7 | × |

| Rad-226 | Water | 2.94 × 10−5 | 2.32 × 10−7 | 9.64 × 10−8 | × |

| DALY | 0.0193 | 0.0003 | 0.0003 | × |

| Substance | Influence Area | Production | Use | Landfill | Recycling |

|---|---|---|---|---|---|

| 1,2-dichloro-1,1,2,2-tetrafluoroethane, CFC-114 | Air | 9.00 × 10−5 | 5.68 × 10−7 | 1.90 × 10−7 | × |

| Bromochloro-difluoromethane, Halon 1211 | Air | 1.43 × 10−6 | 2.59 × 10−6 | 1.48 × 10−7 | × |

| Bromotrifluoro | Air | 1.05 × 10−3 | 1.18 × 10−5 | 5.31 × 10−6 | −8.72 × 10−5 |

| methane, Halon 1301 | Air | × | 1.74 × 10−7 | × | × |

| Chlorodifluoro | Air | 1.21 × 10−5 | 5.63 × 10−7 | 3.28 × 10−10 | × |

| methane, HCFC-22 | Air | 2.89 × 10−6 | 1.17 × 10−8 | 2.95 × 10−14 | × |

| Dichlorodifluoro | Air | 1.16 × 10−5 | 1.97 × 10−7 | 2.63 × 10−7 | × |

| methane, CFC-12 | Air | 4.00 × 10−6 | 1.94 × 10−8 | 1.20 × 10−12 | × |

| DALY | 0.0012 | 0.0002 | 0.0001 | −0.0001 |

| Substance | Influence Area | Production | Use | Landfill | Recycling |

|---|---|---|---|---|---|

| Use of class II-III land | Raw Materials | 2.58 × 104 | 1.30 × 102 | × | × |

| Use of class II-IV land | Raw Materials | 3.25 × 103 | 22.7 | × | × |

| The use of class III-IV land | Raw Materials | 3.19 × 103 | 16.6 | × | × |

| The use of class IV land | Raw Materials | 3.75 × 102 | × | × | |

| Occupation of agricultural land by non-irrigated areas | Raw Materials | × | 44.1 | × | × |

| Occupation by a construction area | Raw Materials | 10 | 3.52 × 102 | × | |

| Seizure by a landfill | Raw Materials | 82.4 | 9.59 × 102 | 2.12 × 103 | × |

| The occupation of an area of a commercial or normal forest | Raw Materials | 3.78 × 102 | 1.33 × 103 | 15.4 | × |

| Occupation by an industrial area | Raw Materials | 55.1 | 4.74 × 102 | 15.8 | × |

| Occupation of built-up areas by an industrial area | Raw Materials | 42.4 | 17.6 | 18.0 | × |

| Occupation of an area with vegetation by an industrial area | Raw Materials | 1.01 × 102 | 15.2 | 31.9 | × |

| Occupation by the area of extraction of mineral resources | Raw Materials | 2.70 × 103 | 2.50 × 102 | 6.67 × 102 | × |

| Occupation of the area with sclerophyllous shrubs | Raw Materials | × | × | 46.0 | × |

| Occupation by communication areas, railway embankments | Raw Materials | × | 31.4 | × | × |

| Occupation by communication areas, rail network | Raw Materials | × | 34.7 | × | × |

| Occupation by communication areas, road embankments | Raw Materials | 32.6 | 100 | 90.7 | × |

| Occupation by traffic areas, road network | Raw Materials | 78.5 | 96.1 | 2.65 × 103 | × |

| Convert non-irrigated land to arable land | Raw Materials | −1.83 × 102 | −2.44 × 102 | −68.0 | × |

| Transformation of environmentally neutral waste landfills | Raw Materials | × | −30.6 | × | × |

| Conversion of landfills for other waste | Raw Materials | × | −35.3 | × | × |

| Conversion of sanitary waste landfills | Raw Materials | × | × | −2.10 × 103 | × |

| Conversion into a forest area | Raw Materials | −56.2 | −80.6 | −23.6 | × |

| Transformation into an extensive forest area | Raw Materials | −9.02 | −2.73 × 102 | −3.78 | × |

| Transformation of the mining area of mineral resources | Raw Materials | −24.2 | −2.39 × 102 | −5.88 × 102 | × |

| Transformation into an area of pastures and meadows | Raw Materials | −38.2 | −86.0 | −3.09 × 103 | × |

| Transformation into the area of seas and oceans | Raw Materials | −1.25 × 102 | −2.00 × 102 | −44.4 | × |

| Transformation into an area with sclerophyllous shrubs | Raw Materials | × | −5.99 | −2.76 × 102 | × |

| Transformation of other, undefined areas | Raw Materials | −1.12 × 104 | −1.15 × 103 | −2.87 × 103 | × |

| Conversion of arable land | Raw Materials | 5.95 × 101 | 3.12 × 102 | 3.1 | × |

| Conversion of irrigated arable land | Raw Materials | 1.84 × 102 | 2.44 × 102 | 68.0 | × |

| Transformation into landfills | Raw Materials | 18,5 | 2.29 × 102 | 4.22 | × |

| Transformation into landfills affecting benthos | Raw Materials | 1.25 × 102 | 2.00 × 102 | 44.3 | × |

| Transformation into environmentally neutral waste landfills | Raw Materials | × | 3.16 | × | × |

| Conversion into a landfill for other waste | Raw Materials | × | 35.3 | × | × |

| Transformation into sanitary waste landfills | Raw Materials | × | × | 2.10 × 103 | × |

| Transformation of the forest area | Raw Materials | 3.13 × 102 | 7.90 | 3.53 × 102 | × |

| Converting an area of a commercial or normal forest | Raw Materials | 89.6 | 2.71 × 102 | 3.61 | × |

| Conversion into a heterogeneous agricultural area | Raw Materials | 27.6 | 39.7 | 14.2 | × |

| Conversion into an industrial area | Raw Materials | 26.2 | 3.45 × 102 | 2.91 | × |

| Converting built-up areas into an industrial area | Raw Materials | 26.4 | 12.0 | 15.1 | × |

| Converting an area with vegetation into an industrial area | Raw Materials | 61.2 | 11.1 | 21.9 | × |

| Transformation into the area of extraction of mineral resources | Raw Materials | 8.35 × 103 | 8.98 × 102 | 2.20 × 103 | × |

| Transformation of the area with sclerophyllous shrubs | Raw Materials | × | 5.16 | 2.76 × 102 | × |

| Transformation into communication areas, railway embankments | Raw Materials | × | 2.29 | × | × |

| Transformation into communication areas, railway network | Raw Materials | × | 2.5 | × | × |

| Transformation into communication areas, road embankments | Raw Materials | × | 20.3 | × | × |

| Transformation into communication areas, road network | Raw Materials | 36.0 | 39.4 | 4.31 × 102 | × |

| Transformation into other, undefined areas | Raw Materials | 47.5 | × | 1.44 | × |

| Transformation into artificial water reservoirs | Raw Materials | 1.97 × 103 | 68.2 | 5.09 × 102 | × |

| Transformation into artificial watercourses | Raw Materials | 19.4 | 25.3 | 7.14 | × |

| Substance | Influence Area | Production | Use | Landfill | Recycling |

|---|---|---|---|---|---|

| Aluminum, 24% Bauxite, 11% Raw Ore | Raw Materials | × | 3.47 × 101 | × | × |

| Boksite, fossil | Raw Materials | 8.08 × 104 | 1.87 × 102 | × | −6.91 × 103 |

| Chrome, fossil | Raw Materials | 4.95 × 104 | × | × | × |

| Copper, 0.99% sulfides, Cu 0.36% and Mo 8.2 x-3% crude ore | Raw Materials | × | 2.71 × 101 | × | × |

| Copper, 1.18% sulfides, Cu 0.39% and Mo 8.2 x-3% crude ore | Raw Materials | × | 1.49 × 102 | × | × |

| Copper, 1.42% sulfides, Cu 0.81% and Mo 8.2 x-3% crude ore | Raw Materials | × | 3.96 × 101 | × | × |

| Copper, 2.19% sulfides, 1.83% Cu, and 8.2 x-3% Mo crude ore | Raw Materials | × | 1.97 × 102 | × | × |

| Copper, fossil | Raw Materials | 8.31 × 104 | 2.76 × 104 | × | × |

| Iron ores, fossil | Raw Materials | 9.18 × 10−4 | × | × | −2.44 × 104 |

| Iron, 46% ore, 25% raw ore | Raw Materials | × | 4.50 × 101 | × | × |

| Iron, fossil | Raw Materials | 2.24 × 104 | 1.79 × 102 | × | × |

| Molybdenum, 0.022% sulfides, Mo 8.2 x-3% and Cu 0.36% crude ore | Raw Materials | × | 3.26 × 101 | × | × |

| Molybdenum, 0.11% sulfides, Mo 4.1 x-2% and Cu 0.36% crude ore | Raw Materials | × | 6.57 × 101 | × | × |

| Nickel, 1.98% Silicates, 1.04% Crude Ore | Raw Materials | 7.54 × 102 | 5.95 × 102 | 5.86 × 102 | × |

| Fossil nickel | Raw Materials | 1.04 × 106 | × | × | × |

| PDF·m2/r | 1.279.121 | 29.134 | 1.043 | −31.277 |

| Substance | Influence Area | Production | Use | Landfill | Recycling |

|---|---|---|---|---|---|

| Coal, 18 MJ/kg, fossil | Raw Materials | 1.15 × 105 | 6.48 × 102 | × | −5.35 × 104 |

| Fossil coal, unspecified, fossil | Raw Materials | 5.04 × 103 | 3.20 × 104 | 2.07 × 102 | × |

| Gas production processes linked to coal extraction/kg | Raw Materials | 3.75 × 104 | 2.20 × 102 | × | × |

| Gas extraction processes associated with coal extraction/m3 | Raw Materials | 1.25 × 103 | 1.02 × 104 | 6.49 × 101 | × |

| Natural gas, 35 MJ/m3, fossil | Raw Materials | 6.11 × 105 | 2.72 × 103 | × | 8.59 × 103 |

| Natural gas, 36.6 MJ/m3, fossil fuel | Raw Materials | 3.07 × 103 | 4.12 × 102 | × | −3.98 × 104 |

| Natural gas, raw material, 35 MJ/m3, fossil fuel | Raw Materials | × | × | × | −5.95 × 104 |

| Natural gas, fossil gas | Raw Materials | 1.94 × 105 | 4.37 × 104 | 8.21 × 103 | |

| Crude oil, 42.6 MJ/kg, fossil | Raw Materials | 1.30 × 106 | 5.45 × 103 | × | −1.73 × 105 |

| Crude oil, raw material, 41 MJ/kg, fossil | Raw Materials | × | × | × | −5.61 × 104 |

| Petroleum, fossil | Raw Materials | 2.00 × 105 | 1.14 × 105 | 5.80 × 104 | × |

| PDF·m2/r | 2.469.917 | 209.483 | 66.463 | −373.783 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobaszek, Ł.; Piasecka, I.; Flizikowski, J.; Tomporowski, A.; Sokolovskij, E.; Bałdowska-Witos, P. Environmentally Oriented Analysis of Benefits and Expenditures in the Life Cycle of a Wind Power Plant. Materials 2023, 16, 538. https://doi.org/10.3390/ma16020538

Sobaszek Ł, Piasecka I, Flizikowski J, Tomporowski A, Sokolovskij E, Bałdowska-Witos P. Environmentally Oriented Analysis of Benefits and Expenditures in the Life Cycle of a Wind Power Plant. Materials. 2023; 16(2):538. https://doi.org/10.3390/ma16020538

Chicago/Turabian StyleSobaszek, Łukasz, Izabela Piasecka, Józef Flizikowski, Andrzej Tomporowski, Edgar Sokolovskij, and Patrycja Bałdowska-Witos. 2023. "Environmentally Oriented Analysis of Benefits and Expenditures in the Life Cycle of a Wind Power Plant" Materials 16, no. 2: 538. https://doi.org/10.3390/ma16020538

APA StyleSobaszek, Ł., Piasecka, I., Flizikowski, J., Tomporowski, A., Sokolovskij, E., & Bałdowska-Witos, P. (2023). Environmentally Oriented Analysis of Benefits and Expenditures in the Life Cycle of a Wind Power Plant. Materials, 16(2), 538. https://doi.org/10.3390/ma16020538