Microstructure of TiAl Capsules Processed by Electron Beam Powder Bed Fusion Followed by Post-Hot Isostatic Pressing

Abstract

:1. Introduction

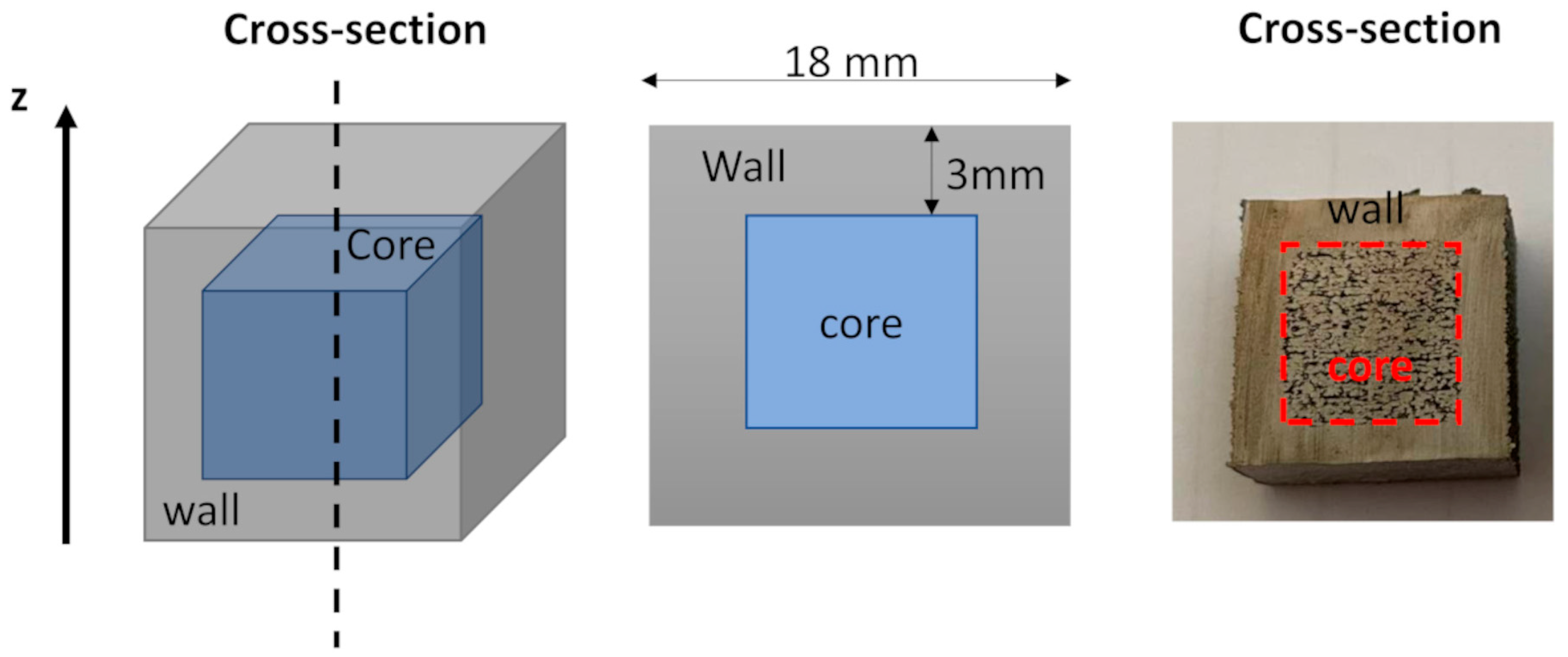

2. Materials and Methods

3. Results and Discussion

3.1. Porosity and Distortion Evaluation

3.2. Microstructure Evolution

3.3. Al-Loss Evaluation

3.4. XRD Analysis on the Powder

4. Conclusions

- Proper process parameters combined with the HIP treatment can produce dense samples with a relative density close to 100% both for the capsule with only the inner pre-heating step and the capsule with the inner melting step from 3000 mm/s to 5000 mm/s.

- The HIPed capsules showed a distortion due to the consolidation of the powder. The distortion can be limited by melting the inner part of the capsule with high beam speed (low energetic parameters). Using the current approach, area shrinkage of around 6.6% can be obtained in the case of capsule-3000.

- The application of high beam speeds to melt the internal part of the capsules limited the formation of large PPBs. In fact, the application of low energetic melting parameters partially melts the surface of the particles, reducing the risk of PPBs formation. The capsules-3000 showed an α2 concentration of 3.5% and an average size of 13 µm against the capsules-pre-heating with an α2 around 5.7% and an average size of around 23 µm.

- From the analysis, it seems that the particles with small sizes formed more α2 phases with respect to the bigger particles, thus generating more PPBs during the HIP treatment. Therefore, this aspect should be taken into account for considering the recycling of the powder. Significantly, the presence of small particles should be carefully checked.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Biamino, S.; Penna, A.; Ackelid, U.; Sabbadini, S.; Tassa, O.; Fino, P.; Pavese, M.; Gennaro, P.; Badini, C. Electron beam melting of Ti–48Al–2Cr–2Nb alloy: Microstructure and mechanical properties investigation. Intermetallics 2011, 19, 776–781. [Google Scholar] [CrossRef]

- Wimler, D.; Lindemann, J.; Kremmer, T.; Clemens, H.; Mayer, S. Microstructure and mechanical properties of novel TiAl alloys tailored via phase and precipitate morphology. Intermetallics 2021, 138, 107316. [Google Scholar] [CrossRef]

- Appel, F.; Oehring, M.; Wagner, R. Novel design concepts for gamma-base titanium aluminide alloys. Intermetallics 2000, 8, 1283–1312. [Google Scholar] [CrossRef]

- Appel, F.; Clemens, H.; Fischer, F. Modeling concepts for intermetallic titanium aluminides. Prog. Mater. Sci. 2016, 81, 55–124. [Google Scholar] [CrossRef]

- Todai, M.; Nakano, T.; Liu, T.; Yasuda, H.Y.; Hagihara, K.; Cho, K.; Ueda, M.; Takeyama, M. Effect of building direction on the microstructure and tensile properties of Ti-48Al-2Cr-2Nb alloy additively manufactured by electron beam melting. Addit. Manuf. 2017, 13, 61–70. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.-W.; Dimiduk, D.M. Progress in the understanding of gamma titanium aluminides. JOM 1911, 43, 40–47. [Google Scholar] [CrossRef]

- Wu, X. Review of alloy and process development of TiAl alloys. Intermetallics 2006, 14, 1114–1122. [Google Scholar] [CrossRef]

- Fu, Z.; Körner, C. Actual state-of-the-art of electron beam powder bed fusion. Eur. J. Mater. 2022, 2, 54–116. [Google Scholar] [CrossRef]

- Ladani, L.; Sadeghilaridjani, M. Review of Powder Bed Fusion Additive Manufacturing for Metals. Metals 2021, 11, 1391. [Google Scholar] [CrossRef]

- Schwerdtfeger, J.; Körner, C. Selective electron beam melting of Ti–48Al–2Nb–2Cr: Microstructure and aluminium loss. Intermetallics 2014, 49, 29–35. [Google Scholar] [CrossRef]

- Cho, K.; Morita, N.; Matsuoka, H.; Yasuda, H.Y.; Todai, M.; Ueda, M.; Takeyama, M.; Nakano, T. Influence of Input Energy Density on Morphology of Unique Layered Microstructure of γ-TiAl Alloys Fabricated by Electron Beam Powder Bed Fusion. Mater. Trans. 2023, 64, 44–49. [Google Scholar] [CrossRef]

- Wartbichler, R.; Clemens, H.; Mayer, S.; Ghibaudo, C.; Rizza, G.; Galati, M.; Iuliano, L.; Biamino, S.; Ugues, D. On the Formation Mechanism of Banded Microstructures in Electron Beam Melted Ti–48Al–2Cr–2Nb and the Design of Heat Treatments as Remedial Action. Adv. Eng. Mater. 2021, 23, 2101199. [Google Scholar] [CrossRef]

- Knörlein, J.; Franke, M.M.; Schloffer, M.; Körner, C. In-situ aluminum control for titanium aluminide via electron beam powder bed fusion to realize a dual microstructure. Addit. Manuf. 2022, 59, 103132. [Google Scholar] [CrossRef]

- Mohammad, A.; Al-Ahmari, A.M.; AlFaify, A.; Mohammed, M.K. Effect of melt parameters on density and surface roughness in electron beam melting of gamma titanium aluminide alloy. Rapid Prototyp. J. 2017, 23, 474–485. [Google Scholar] [CrossRef]

- Bieske, J.; Franke, M.; Schloffer, M.; Körner, C. Microstructure and properties of TiAl processed via an electron beam powder bed fusion capsule technology. Intermetallics 2020, 126, 106929. [Google Scholar] [CrossRef]

- Gao, R.; Peng, H.; Guo, H.; Chen, B. A Combined Powder Metallurgical Approach to Process Gamma-TiAl with Composite Structure. Met. Mater. Trans. A 2022, 53, 2351–2368. [Google Scholar] [CrossRef]

- Güther, V.; Allen, M.; Klose, J.; Clemens, H. Metallurgical processing of titanium aluminides on industrial scale. Intermetallics 2018, 103, 12–22. [Google Scholar] [CrossRef]

- Aguilar, J.; Schievenbusch, A.; Kättlitz, O. Investment casting technology for production of TiAl low pressure turbine blades—Process engineering and parameter analysis. Intermetallics 2011, 19, 757–761. [Google Scholar] [CrossRef]

- Zhu, Z.Y.; Liu, Y.L.; Gou, G.Q.; Gao, W.; Chen, J. Effect of heat input on interfacial characterization of the butter joint of hot-rolling CP-Ti/Q235 bimetallic sheets by Laser + CMT. Sci. Rep. 2021, 11, 1–11. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, S.; Zhang, T.; Zhou, X.; Li, S. Effects of post-weld heat treatment on the microstructure and mechanical properties of laser-welded NiTi/304SS joint with Ni filler. Mater. Sci. Eng. A 2020, 771, 138545. [Google Scholar] [CrossRef]

- Wimler, D.; Lindemann, J.; Reith, M.; Kirchner, A.; Allen, M.; Vargas, W.G.; Franke, M.; Klöden, B.; Weißgärber, T.; Güther, V.; et al. Designing advanced intermetallic titanium aluminide alloys for additive manufacturing. Intermetallics 2021, 131, 107109. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S. Design, Processing, Microstructure, Properties, and Applications of Advanced Inter-metallic TiAl Alloys. Adv. Eng. Mater. 2013, 15, 191–215. [Google Scholar] [CrossRef]

- Baudana, G.; Biamino, S.; Ugues, D.; Lombardi, M.; Fino, P.; Pavese, M.; Badini, C. Titanium aluminides for aerospace and automotive applications processed by Electron Beam Melting: Contribution of Politecnico di Torino. Met. Powder Rep. 2016, 71, 193–199. [Google Scholar] [CrossRef]

- Ghibaudo, C.; Wartbichler, R.; Marchese, G.; Clemens, H.; Ugues, D.; Biamino, S. Influence of focus offset on the microstructure of an intermetallic γ-TiAl based alloy produced by electron beam powder bed fusion. J. Manuf. Process. 2023, 89, 132–141. [Google Scholar] [CrossRef]

- Liu, Y.; Li, Z.; Liu, N.; Zheng, L.; Xu, W. Effect of Oxygen Content of Powders on Previous Particle Boundaries in Hot Isostatic Pressed TiAl Alloy. In High Performance Structural Materials; Springer: Singapore, 2018; pp. 779–787. [Google Scholar] [CrossRef]

- Liu, Y.; Liang, X.; Liu, B.; He, W.; Li, J.; Gan, Z.; He, Y. Investigations on processing powder metallurgical high-Nb TiAl alloy sheets. Intermetallics 2014, 55, 80–89. [Google Scholar] [CrossRef]

- Niu, H.; Gao, T.; Sun, Q.; Zhang, H.; Zhang, D.; Liu, G. Prior particle boundaries and microstructural homogenization of a β-solidifying γ-TiAl alloy fabricated from prealloyed powder. Mater. Sci. Eng. A 2018, 737, 151–157. [Google Scholar] [CrossRef]

| Al | Cr | Nb | Fe | Ti |

|---|---|---|---|---|

| 48.73 | 1.92 | 2.00 | 0.03 | Bal. |

| Samples | Beam Speed (mm/s) | Beam Current (mA) | Line Offset (mm) | Area Energy (J/mm2) |

|---|---|---|---|---|

| Wall part * | 1600 | 10 | 0.2 | 1.875 |

| Capsule-3000 | 3000 | 6 | 0.3 | 0.400 |

| Capsule-4000 | 4000 | 6 | 0.3 | 0.300 |

| Capsule-5000 | 5000 | 6 | 0.3 | 0.240 |

| Capsule-preheating | - | - | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bakhshi Farkoush, H.; Marchese, G.; Bassini, E.; Aversa, A.; Biamino, S. Microstructure of TiAl Capsules Processed by Electron Beam Powder Bed Fusion Followed by Post-Hot Isostatic Pressing. Materials 2023, 16, 5510. https://doi.org/10.3390/ma16165510

Bakhshi Farkoush H, Marchese G, Bassini E, Aversa A, Biamino S. Microstructure of TiAl Capsules Processed by Electron Beam Powder Bed Fusion Followed by Post-Hot Isostatic Pressing. Materials. 2023; 16(16):5510. https://doi.org/10.3390/ma16165510

Chicago/Turabian StyleBakhshi Farkoush, Hanieh, Giulio Marchese, Emilio Bassini, Alberta Aversa, and Sara Biamino. 2023. "Microstructure of TiAl Capsules Processed by Electron Beam Powder Bed Fusion Followed by Post-Hot Isostatic Pressing" Materials 16, no. 16: 5510. https://doi.org/10.3390/ma16165510

APA StyleBakhshi Farkoush, H., Marchese, G., Bassini, E., Aversa, A., & Biamino, S. (2023). Microstructure of TiAl Capsules Processed by Electron Beam Powder Bed Fusion Followed by Post-Hot Isostatic Pressing. Materials, 16(16), 5510. https://doi.org/10.3390/ma16165510