Numerical Simulation of Layered Bimetallic ZChSnSb8Cu4/Steel TIG-MIG Hybrid Welding Based on Simufact

Abstract

:1. Introduction

2. Materials and Methods

2.1. Analysis Process

2.2. Material Physical Property Parameters

2.3. Mesh Structure

2.4. Welding Heat Source Model

2.5. Welding Thermal Cycle

3. Results and Discussion

3.1. Comparison of TIG-MIG Hybrid Welding and Conventional MIG Welding Simulation

3.1.1. Comparison of Two-Dimensional Graphs of Welding Simulation Temperature

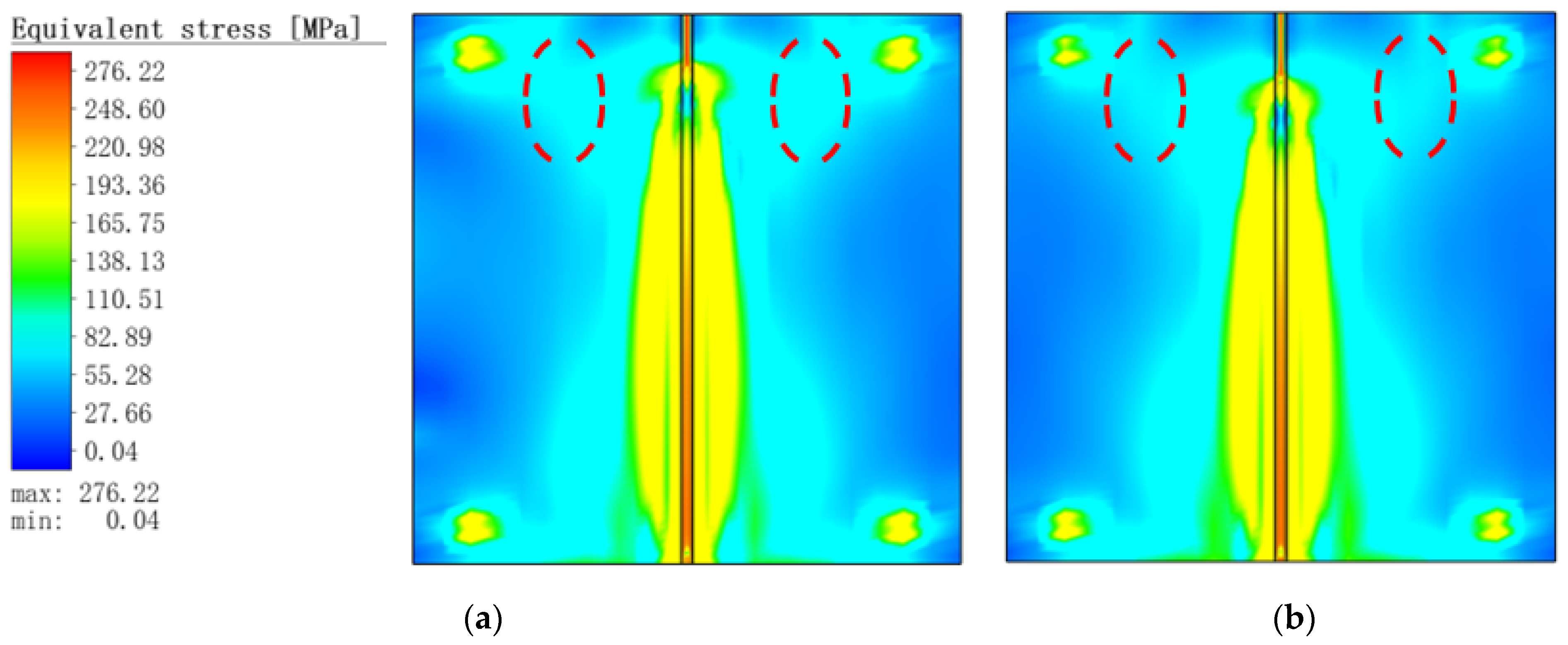

3.1.2. Comparison of von Mises Equivalent Stress

3.2. Distance between Electrodes for TIG-MIG Hybrid Welding

3.3. TIG-MIG Hybrid Welding Preheat Heat Source Current

3.3.1. Analysis the Total Deformation of Weldments

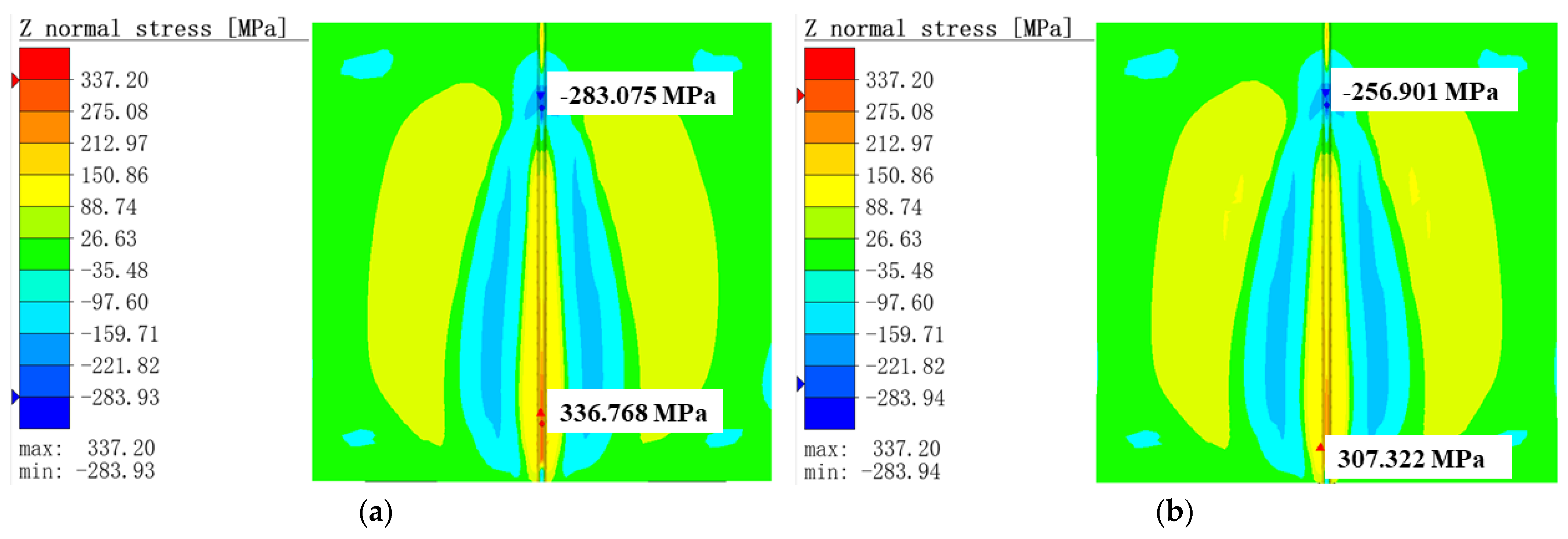

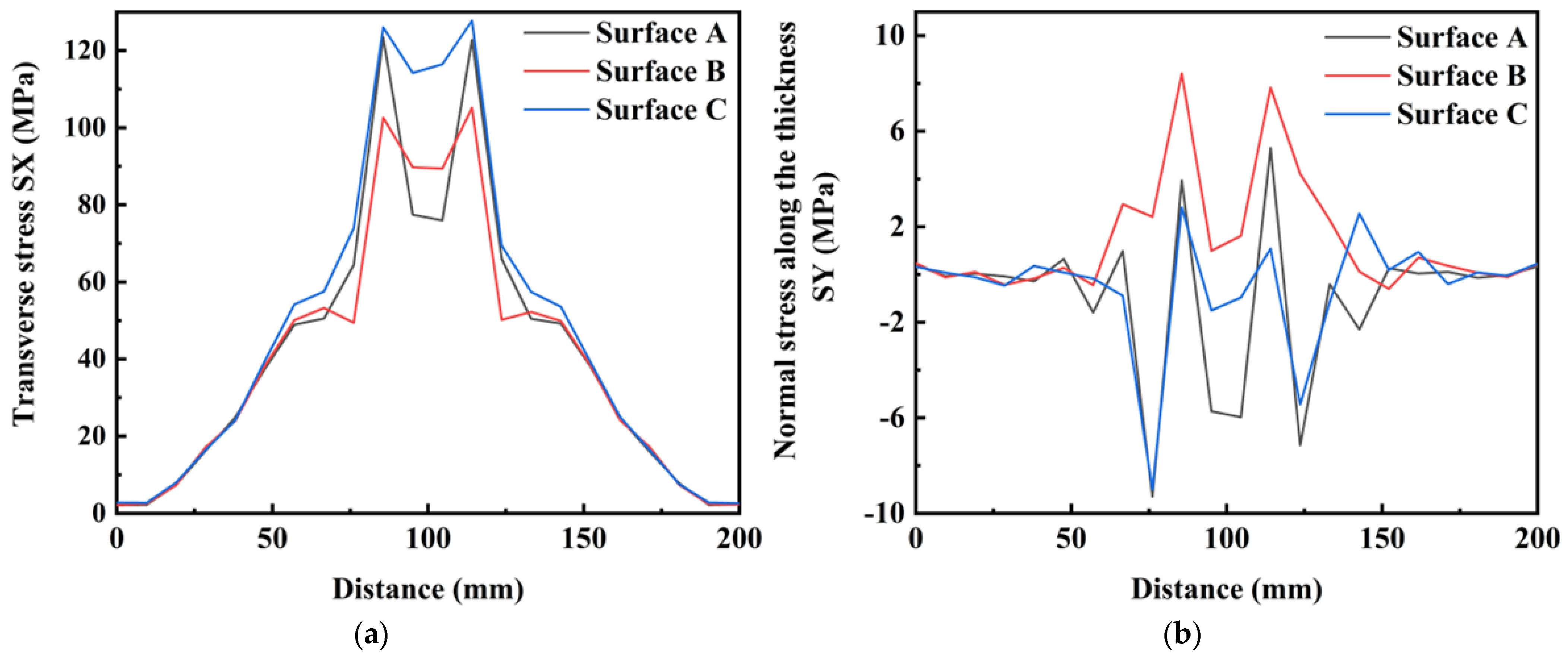

3.3.2. Analysis Residual Stress

4. Conclusions

- Based on the simulation results, TIG-MIG hybrid welding showed superiority in heat loss and stress concentration. At the connection of the heat-affected zone and the clamped area, the von Mises equivalent stress values of the MIG welding were higher than those of the hybrid welding by 20~30 MPa.

- When the distance between the electrodes of TIG-MIG hybrid welding was 6 mm, heat loss was minimized and the weld seam was completely fused. Increasing the distance between the electrodes led to an increase of the low temperature region, and the welding thermal efficiency gradually decreased to 0.639.

- As the current of the TIG torch increased, the total deformation in the weld area became more significant due to the increased extrusion of the substrate on the weld, caused by the temperature change. The increase in current of the TIG torch also caused significant changes of stress values in the weld and clamping areas of the weldment. When the TIG current was 100 A, the equivalent stress in the weld area increased by about 50 MPa.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, L.; Zhu, H.; Zhu, J.; Deng, Y. Effects of oil film thickness and viscosity on the performance of misaligned journal bearings with couple stress lubricants. Tribol. Int. 2020, 146, 106229. [Google Scholar] [CrossRef]

- Chatterton, S.; Pennacchi, P.; Vania, A.; De Luca, A.; Dang, P.V. Tribo-design of lubricants for power loss reduction in the oil-film bearings of a process industry machine: Modelling and experimental tests. Tribol. Int. 2019, 130, 133–145. [Google Scholar] [CrossRef]

- Martyushev, N.V.; Bublik, D.A.; Kukartsev, V.V.; Tynchenko, V.S.; Klyuev, R.V.; Tynchenko, Y.A.; Karlina, Y.I. Provision of Rational Parameters for the Turning Mode of Small-Sized Parts Made of the 29 NK Alloy and Beryllium Bronze for Subsequent Thermal Pulse Deburring. Materials 2023, 16, 3490. [Google Scholar] [CrossRef]

- Gao, Y.; Wang, J.; Liu, Y. Interfacial fracture toughness measurement of welded Babbitt alloy SnSb11Cu6/20Steel. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 1837–1849. [Google Scholar] [CrossRef]

- Ji, X.; Chen, Y. Tribological behavior of Babbitt alloy rubbing against Si3N4 and steel under dry friction condition. J. Mater. Eng. Perform. 2016, 25, 750–755. [Google Scholar] [CrossRef]

- Ramadan, M.; Alghamdi, A.S.; Subhani, T.; Halim, K.A. Fabrication and characterization of Sn-based Babbitt alloy nanocomposite reinforced with Al2O3 nanoparticles/carbon steel bimetallic material. Materials 2020, 13, 2759. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, L.; Liu, Y.; Ren, Y.; Shi, T.; Zhang, J. Improved microstructure and bonding strength via MIG arc brazing in Sn-based Babbitt layer for bearing fabrication. Mater. Res. Express 2019, 6, 116558. [Google Scholar] [CrossRef]

- Tao, X.; Ba, X.; Xu, G.; Liu, L. Effect of laser power on pulsed laser-induced MAG hybrid overhead welding of 4-mm-X70 pipeline steel. Opt. Laser Technol. 2023, 164, 109460. [Google Scholar] [CrossRef]

- Qi, X.; Huan, P.; Chen, X.; Wang, X.; Liu, Z.; Shen, X.; Di, H. Corrosion resistance and mechanism of X100 pipeline steel laser-metal active gas hybrid welds with Cr containing welding wire in NS4 solution. Corros. Sci. 2023, 221, 111329. [Google Scholar] [CrossRef]

- Wei, M.; Sun, K.; Zhang, X.; Zhang, C.; Chen, Z.; Zhou, J.; Xue, F. Microstructure and bonding strength of tin-based Babbitt alloy on ASTM 1045 steel by MIG arc brazing. J. Adhes. Sci. Technol. 2018, 32, 2150–2161. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, Q.; Shi, M.; Guo, J.; Li, H. The effect of TIG arc brazing current on interfacial structure and bonding strength of tin-based Babbit. J. Adhes. Sci. Technol. 2017, 31, 2312–2322. [Google Scholar] [CrossRef]

- Kanemaru, S.; Sasaki, T.; Sato, T.; Era, T.; Tanaka, M. Study for the mechanism of TIG-MIG hybrid welding process. Weld. World 2015, 59, 261–268. [Google Scholar] [CrossRef]

- Zong, R.; Chen, J.; Wu, C. A comparison of TIG-MIG hybrid welding with conventional MIG welding in the behaviors of arc, droplet and weld pool. J. Mater. Process. Technol. 2019, 270, 345–355. [Google Scholar] [CrossRef]

- Chen, J.; Wu, C.S.; Chen, M.A. Improvement of welding heat source models for TIG-MIG hybrid welding process. J. Manuf. Process. 2014, 16, 485–493. [Google Scholar] [CrossRef]

- Wu, X.; Zhao, X.; Chen, J.; Zhang, Z.; Wu, C. Simulation of the influence of welding parameters on weld pool behavior during a TIG-MIG hybrid welding process. J. Manuf. Process. 2022, 79, 460–475. [Google Scholar] [CrossRef]

- Kanemaru, S.; Sasaki, T.; Sato, T.; Mishima, H.; Tashiro, S.; Tanaka, M. Study for TIG–MIG hybrid welding process. Weld. World 2014, 58, 11–18. [Google Scholar] [CrossRef]

- Ding, M.; Liu, S.S.; Zheng, Y.; Wang, Y.C.; Li, H.; Xing, W.Q.; Yu, X.Y.; Dong, P. TIG-MIG hybrid welding of ferritic stainless steels and magnesium alloys with Cu interlayer of different thickness. Mater. Des. 2015, 88, 375–383. [Google Scholar] [CrossRef]

- Marques, E.S.; Silva, F.J.; Pereira, A.B. Comparison of finite element methods in fusion welding processes—A review. Metals 2020, 10, 75. [Google Scholar] [CrossRef] [Green Version]

- Behúlová, M.; Babalová, E. Numerical Simulation of Temperature Fields during Laser Welding–Brazing of Al/Ti Plates. Materials 2023, 16, 2258. [Google Scholar] [CrossRef]

- Xu, W.; Yang, S.; Tao, W.; Zhang, G.; Luo, H.; Li, S. Effects of laser beam oscillation welding parameters on Al-Si coated 22MnB5 weld joint properties. Opt. Laser Technol. 2022, 149, 107898. [Google Scholar] [CrossRef]

- Lu, Y.; Zhu, S.; Zhao, Z.; Chen, T.; Zeng, J. Numerical simulation of residual stresses in aluminum alloy welded joints. J. Manuf. Process. 2020, 50, 380–393. [Google Scholar] [CrossRef]

- Gong, H.; Liu, M.; Zhang, T.; He, Y.; Wu, Y.; Yu, Z. Study on Residual Stress and Optimization of Welding Parameters in Linear Friction Welding of TC17 Titanium Alloy. Materials 2022, 15, 8963. [Google Scholar] [CrossRef]

- Hammad, A.; Churiaque, C.; Sánchez-Amaya, J.M.; Abdel-Nasser, Y. Experimental and numerical investigation of hybrid laser arc welding process and the influence of welding sequence on the manufacture of stiffened flat panels. J. Manuf. Process. 2021, 61, 527–538. [Google Scholar] [CrossRef]

- Li, L.; Du, Z.; Sheng, X.; Zhao, M.; Song, L.; Han, B.; Li, X. Comparative analysis of GTAW+ SMAW and GTAW welded joints of duplex stainless steel 2205 pipe. Int. J. Press. Vessel. Pip. 2022, 199, 104748. [Google Scholar] [CrossRef]

- Sajek, A.; Nowacki, J. Comparative evaluation of various experimental and numerical simulation methods for determination of t8/5 cooling times in HPAW process weldments. Arch. Civ. Mech. Eng. 2018, 18, 583–591. [Google Scholar] [CrossRef]

- Dornelas, P.H.G.; Da Cruz Payão Filho, J.; Farias, F.W.C.; Oliveira, V.H.P.M.E.; de Oliveira Moraes, D.; Júnior, P.Z. FEM-thermodynamic simulation methodology to predict the influence of t8/5 on the coarse grain heat-affected zone of a Cr-Mo low-alloy steel pipe. J. Manuf. Process. 2020, 60, 520–529. [Google Scholar] [CrossRef]

- Hälsig, A.; Pehle, S.; Kusch, M.; Mayr, P. Reducing potential errors in the calculation of cooling rates for typical arc welding processes. Weld. World 2017, 61, 745–754. [Google Scholar] [CrossRef]

- Chen, J.; Zong, R.; Wu, C.; Padhy, G.K.; Hu, Q. Influence of low current auxiliary TIG arc on high speed TIG-MIG hybrid welding. J. Mater. Process. Technol. 2017, 243, 131–142. [Google Scholar] [CrossRef]

- Lou, X.F.; Chen, M.A.; Wu, C.S.; Ye, K.L. Humping and undercutting suppression mechanism for high speed TIG-MIG hybrid welding. Trans. China Weld. Inst. 2014, 35, 87–90. [Google Scholar]

| Property | Value | Unit |

|---|---|---|

| Environment temperature | 20 | °C |

| Thermal conductivity coefficient | 0.05 | 103 W·m−1·°C−1 |

| Heat transfer coefficient | 1.0 | 102 W·m−2·°C−1 |

| Density | 7.8 | 103 kg·m−3 |

| Specific heat | 460 | J·g−1·°C−1 |

| Sb | Cu | Pb | As | Sn |

|---|---|---|---|---|

| 8.0 | 4.0 | 0.35 | 0.1 | balance |

| C | Si | Mn | P | S | Fe |

|---|---|---|---|---|---|

| 0.16 | 0.15 | 0.37 | 0.014 | 0.010 | balance |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, H.; Fan, C.; Yang, S.; Wang, J.; Pei, W.; Chu, Z. Numerical Simulation of Layered Bimetallic ZChSnSb8Cu4/Steel TIG-MIG Hybrid Welding Based on Simufact. Materials 2023, 16, 5346. https://doi.org/10.3390/ma16155346

Guo H, Fan C, Yang S, Wang J, Pei W, Chu Z. Numerical Simulation of Layered Bimetallic ZChSnSb8Cu4/Steel TIG-MIG Hybrid Welding Based on Simufact. Materials. 2023; 16(15):5346. https://doi.org/10.3390/ma16155346

Chicago/Turabian StyleGuo, Hao, Chenkang Fan, Shufeng Yang, Jianmei Wang, Wenle Pei, and Zhibing Chu. 2023. "Numerical Simulation of Layered Bimetallic ZChSnSb8Cu4/Steel TIG-MIG Hybrid Welding Based on Simufact" Materials 16, no. 15: 5346. https://doi.org/10.3390/ma16155346

APA StyleGuo, H., Fan, C., Yang, S., Wang, J., Pei, W., & Chu, Z. (2023). Numerical Simulation of Layered Bimetallic ZChSnSb8Cu4/Steel TIG-MIG Hybrid Welding Based on Simufact. Materials, 16(15), 5346. https://doi.org/10.3390/ma16155346