Numerical Modeling of Mechanical Behavior of Functionally Graded Polylactic Acid–Acrylonitrile Benzidine Styrene Produced via Fused Deposition Modeling: Experimental Observations

Abstract

1. Introduction

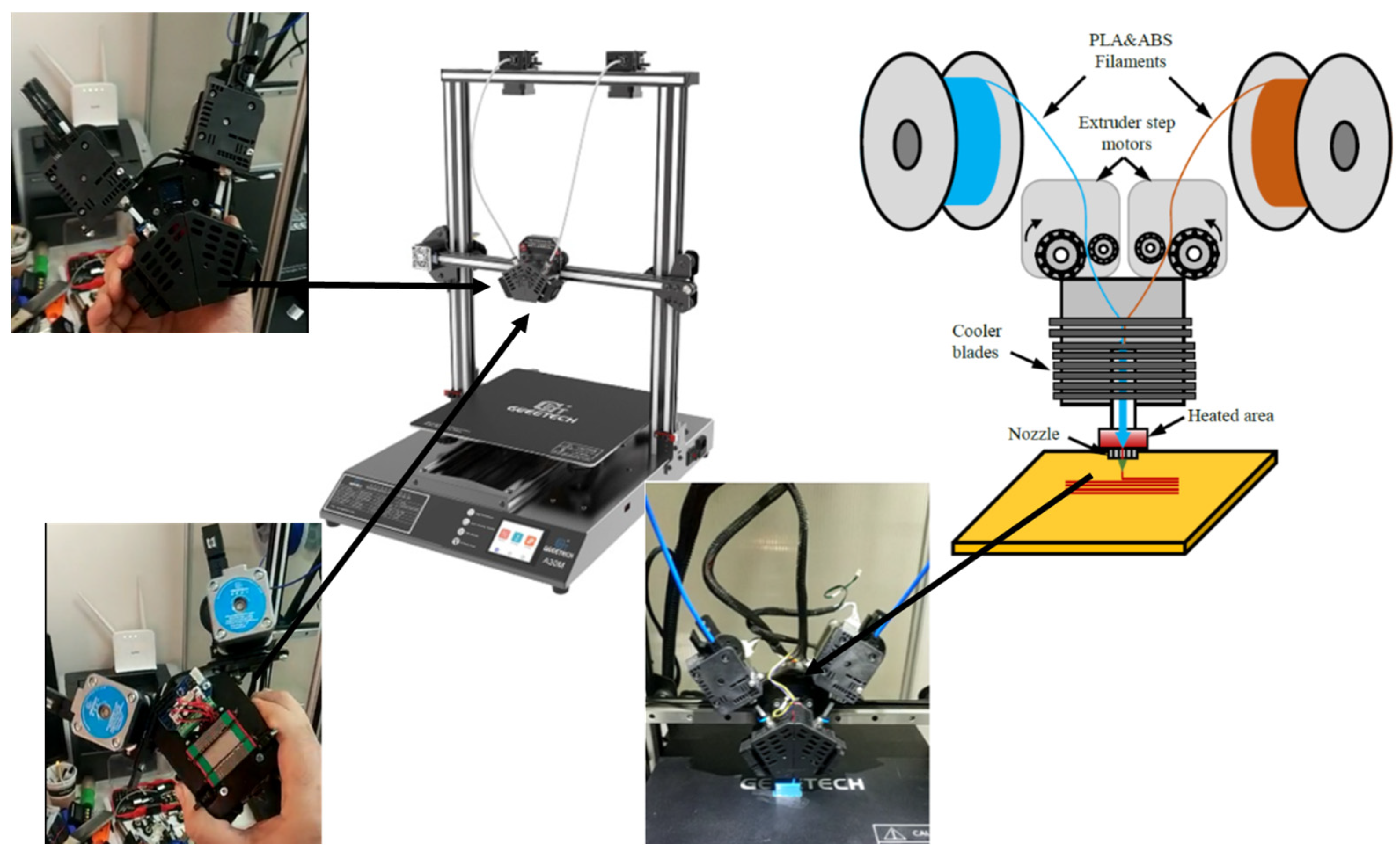

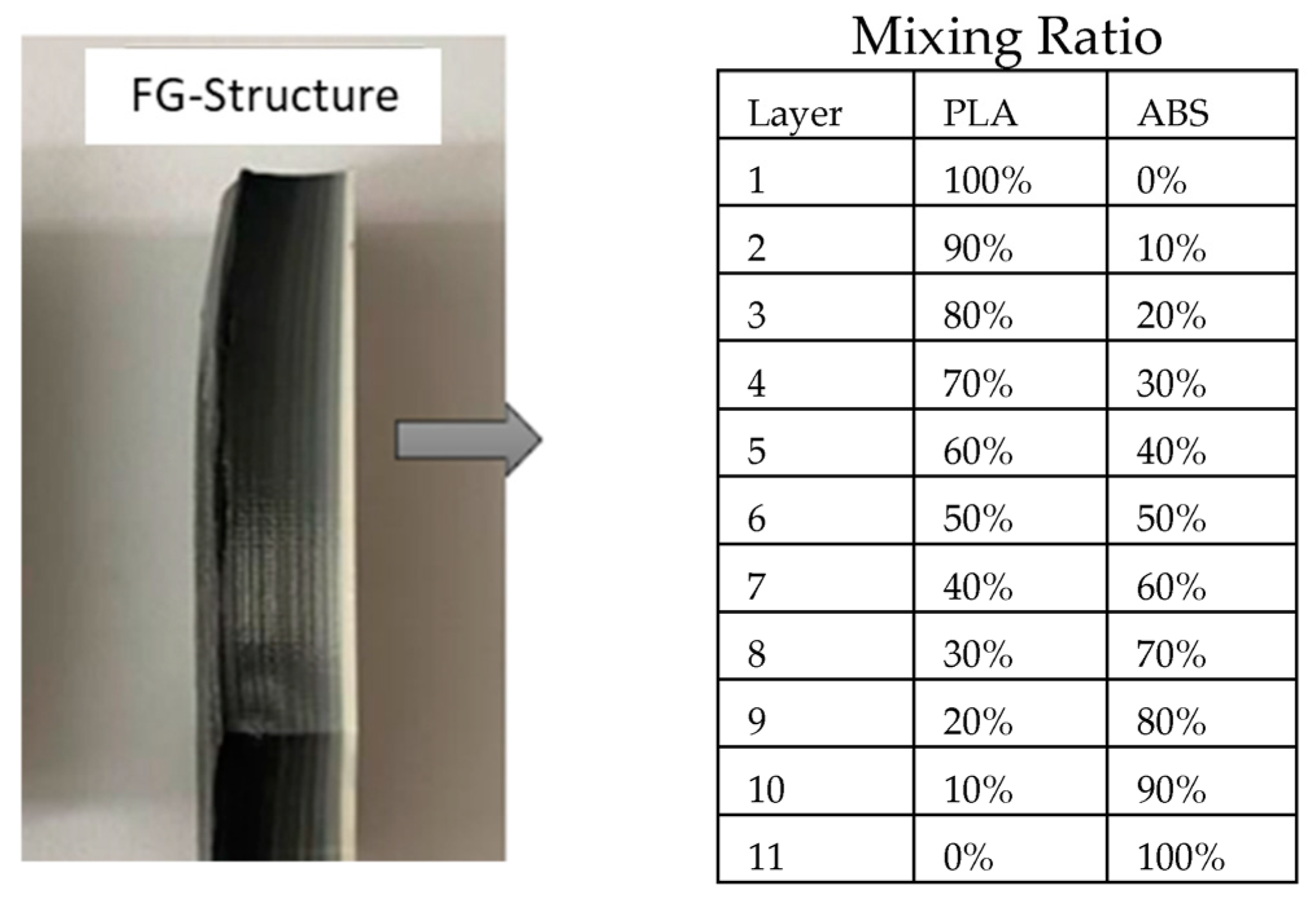

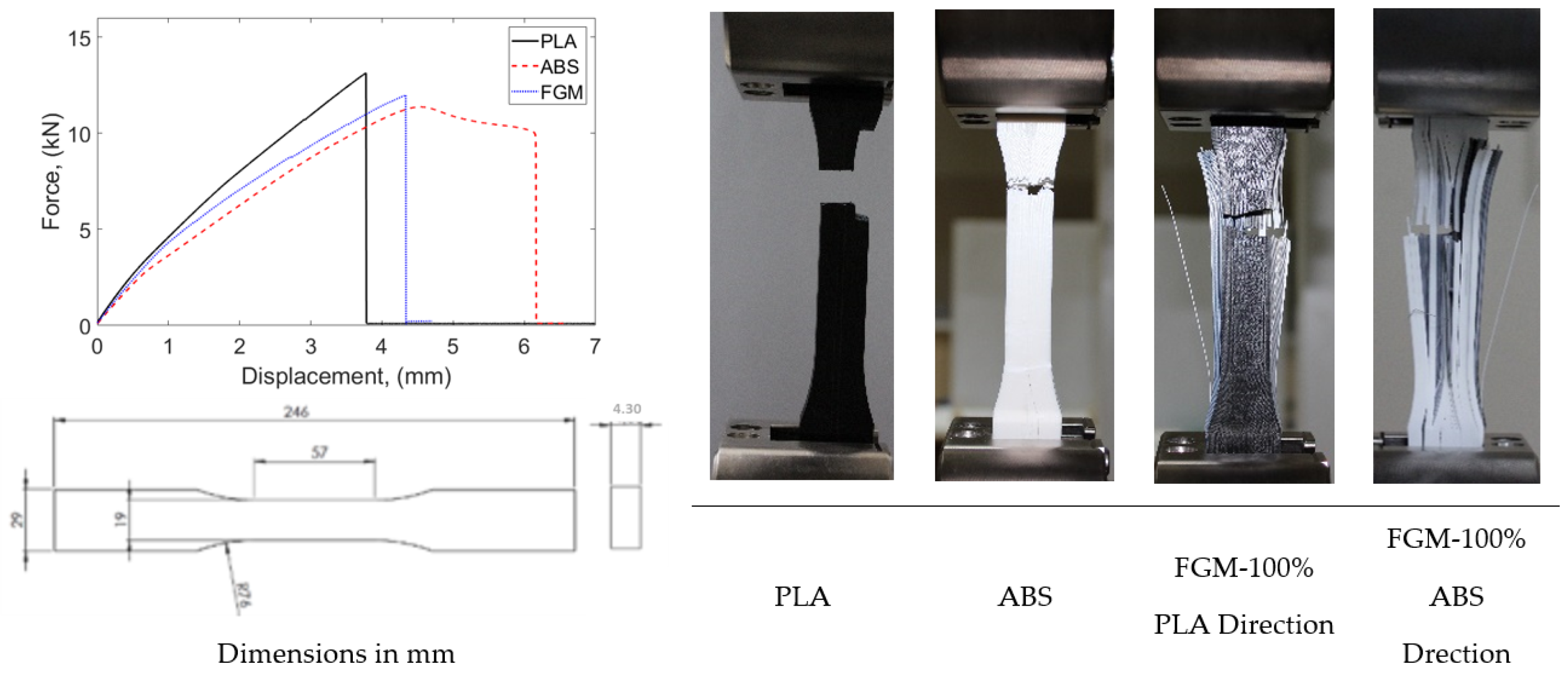

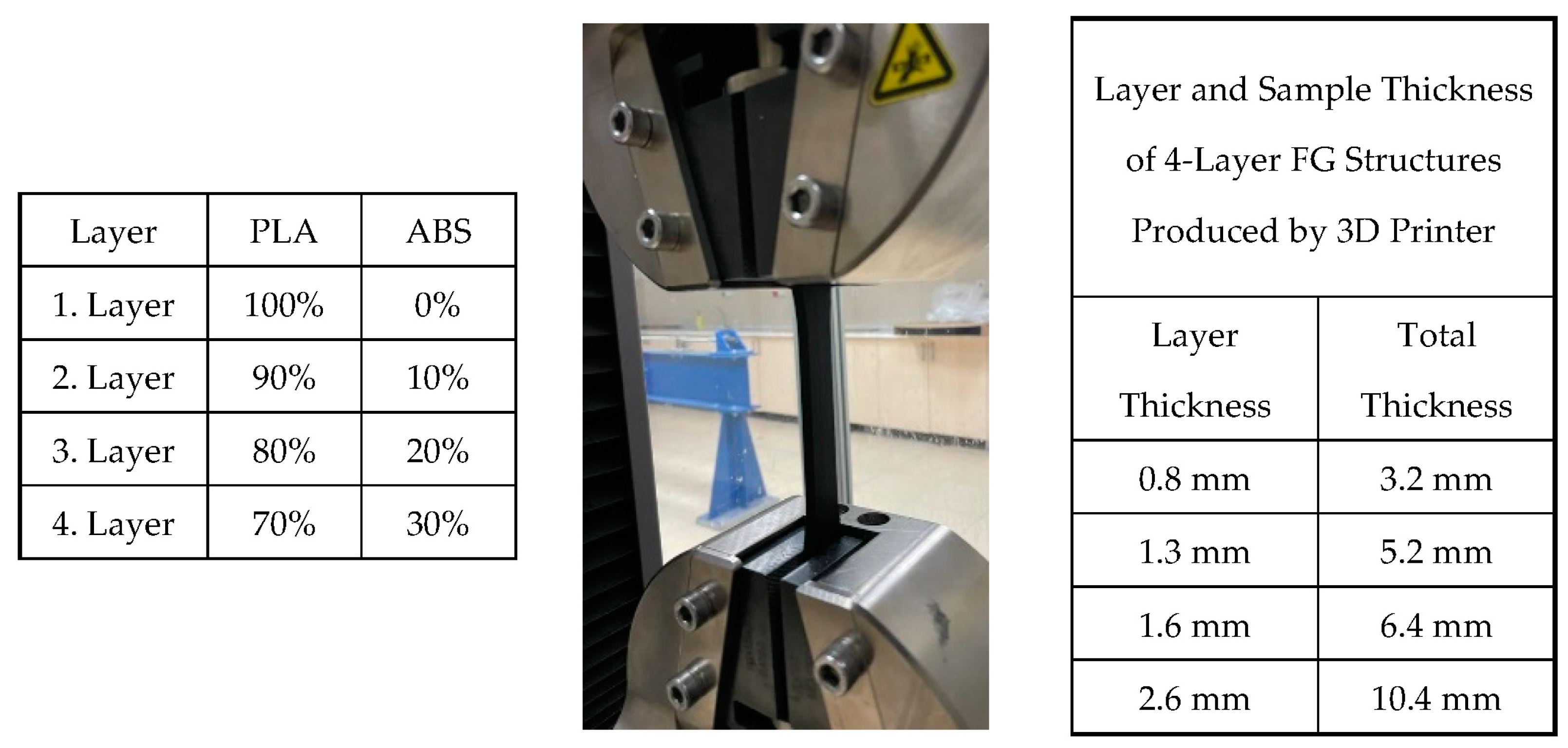

2. Material and Methods

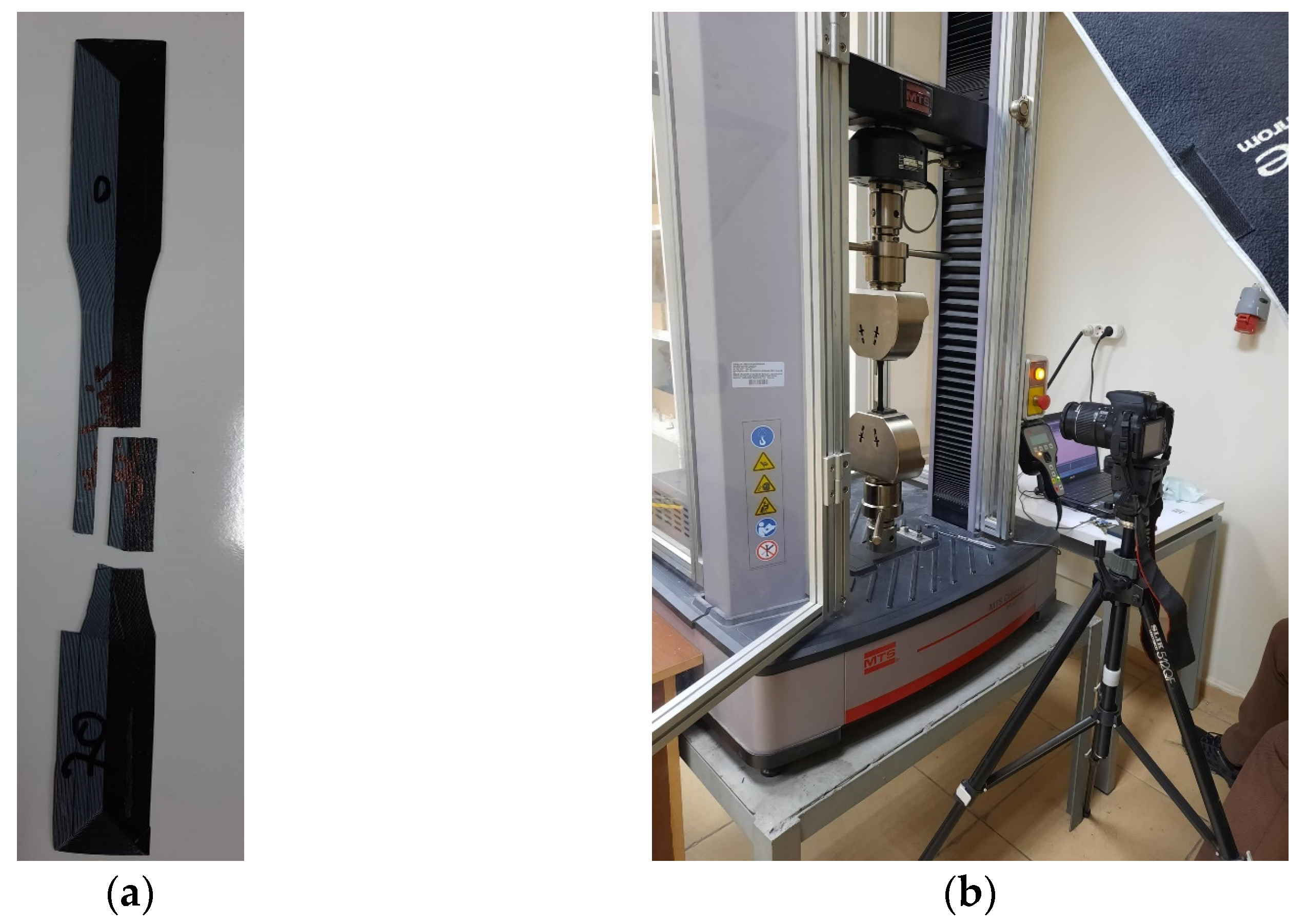

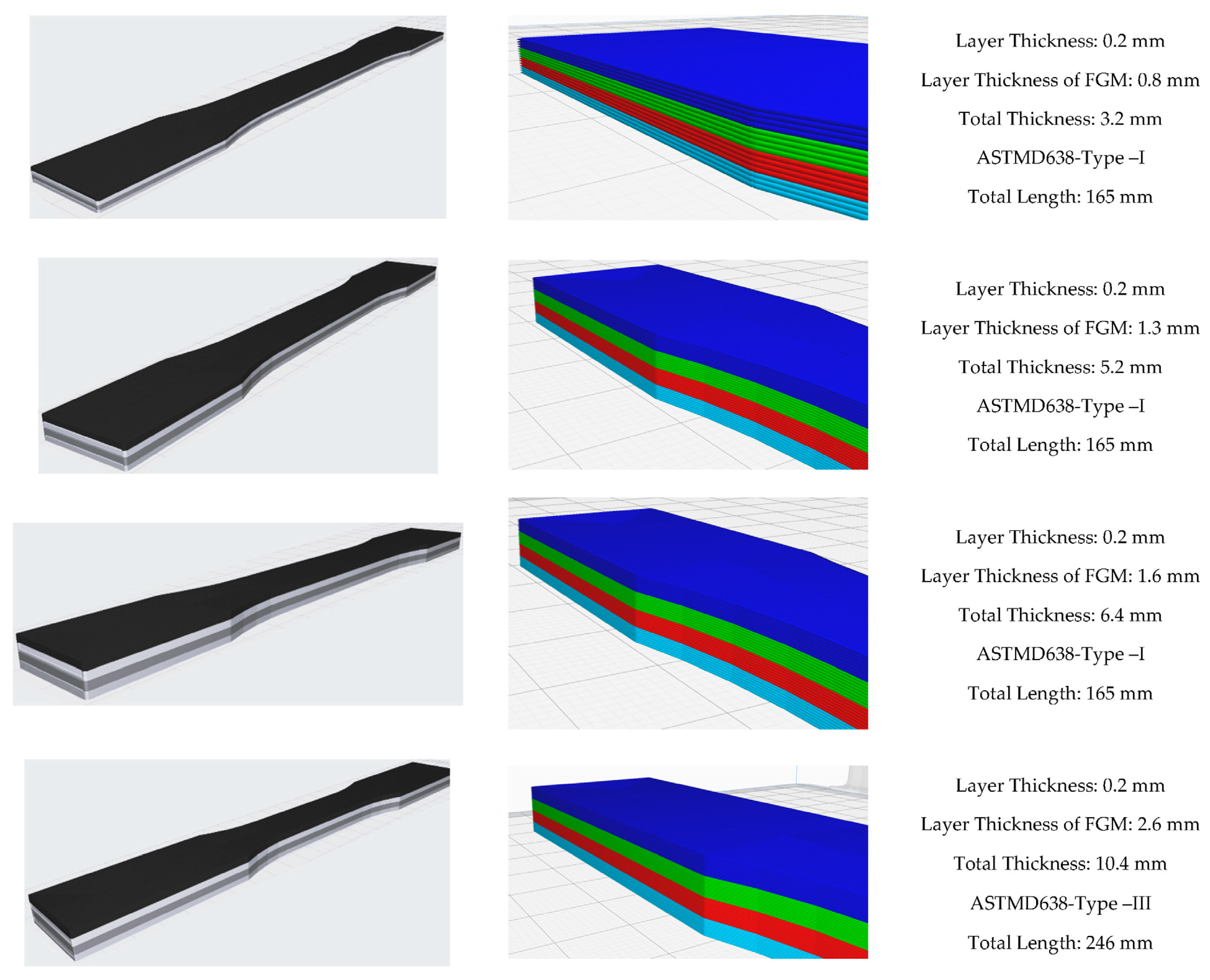

2.1. Experimental Process

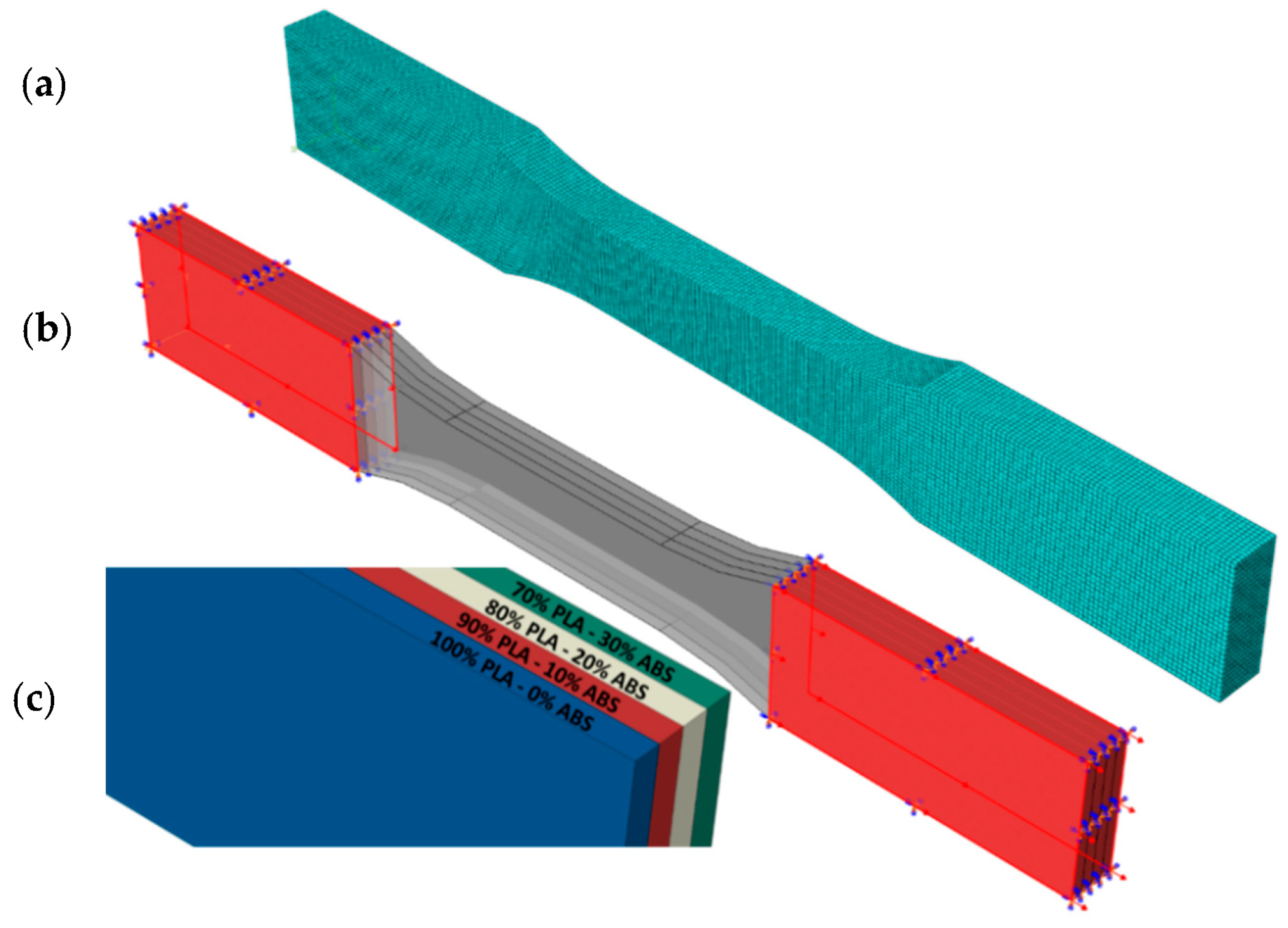

2.2. Numerical Modeling

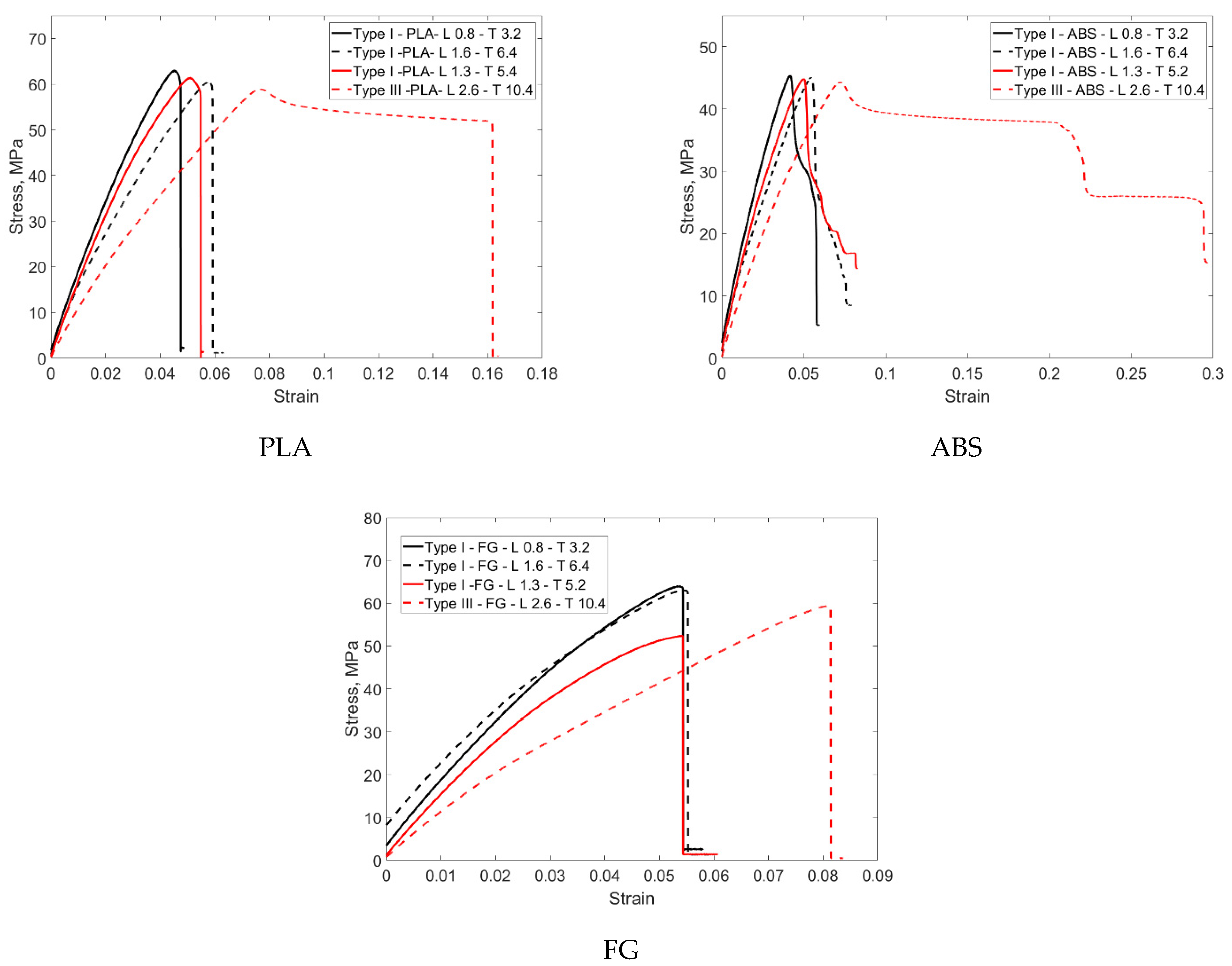

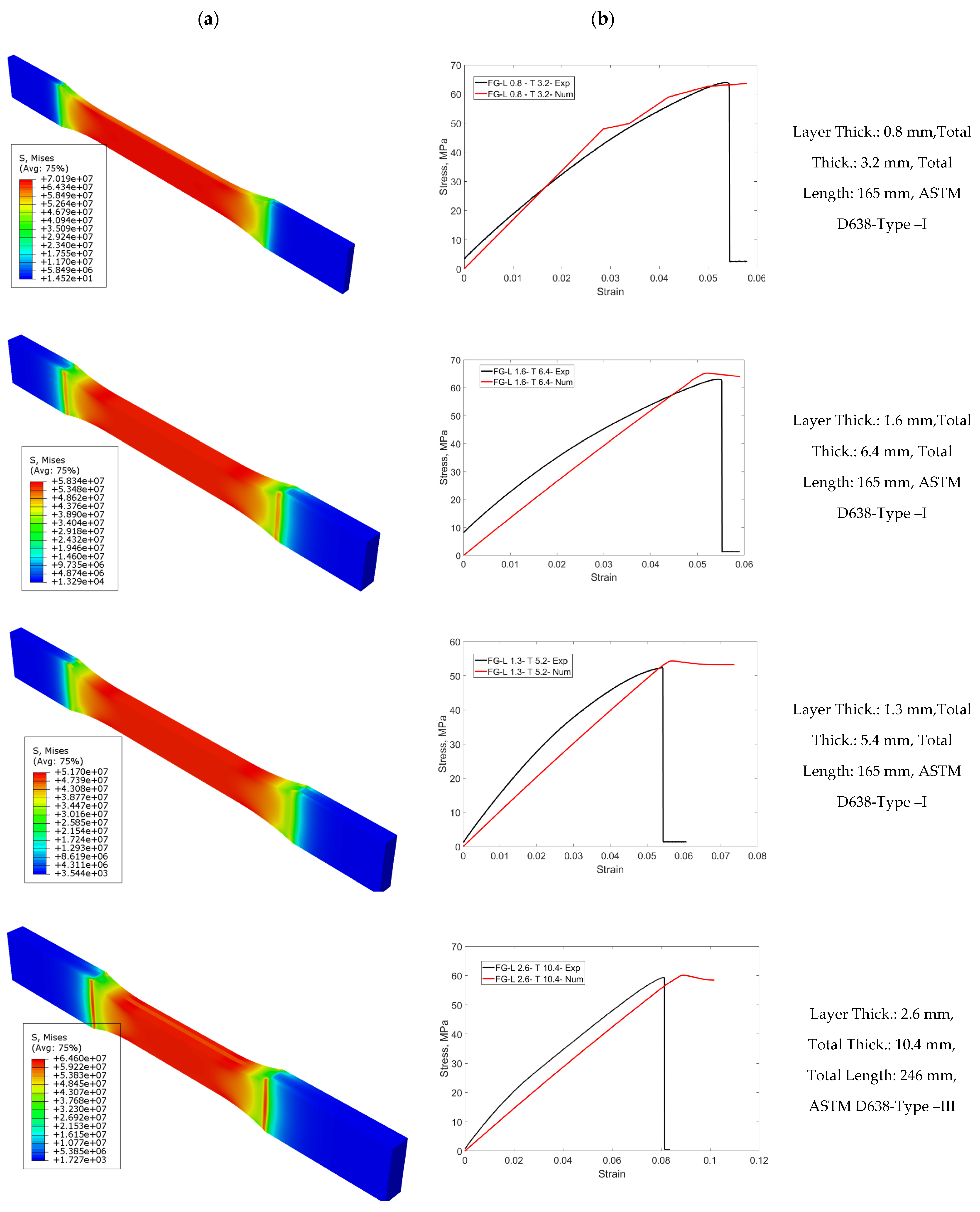

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Koizumi, M.; Niino, M. Overview of FGM research in Japan. MRS Bull. 1995, 20, 19–21. [Google Scholar] [CrossRef]

- Evans, A.G.; Hutchinson, J.W. The mechanics of coating delamination in thermal gradients. Surf. Coat. Technol. 2007, 201, 7905–7916. [Google Scholar] [CrossRef]

- Miyamoto, Y.; Kaysser, W.A.; Rabin, B.H.; Kawasaki, A.; Ford, R.G. (Eds.) Functionally Graded Materials: Design, Processing and Applications; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2013; Volume 5. [Google Scholar]

- Tan, S.C. Stress Concentrations in Laminated Composites; Routledge: Oxfordshire, UK, 2017. [Google Scholar]

- Zhou, Y.C.; Hashida, T. Thermal fatigue failure induced by delamination in thermal barrier coating. Int. J. Fatigue 2002, 24, 407–417. [Google Scholar] [CrossRef]

- Saleh, B.; Jiang, J.; Fathi, R.; Al-hababi, T.; Xu, Q.; Wang, L.; Song, D.; Ma, A. 30 Years of functionally graded materials: An overview of manufacturing methods, Applications and Future Challenges. Compos. Part B Eng. 2020, 201, 108376. [Google Scholar] [CrossRef]

- Ituarte, I.F.; Boddeti, N.; Hassani, V.; Dunn, M.L.; Rosen, D.W. Design and additive manufacture of functionally graded structures based on digital materials. Addit. Manuf. 2019, 30, 100839. [Google Scholar] [CrossRef]

- Hirai, T.; Sasaki, M. Vapor-deposited functionally gradient materials. JSME Int. J. Ser. 1 Solid Mech. Strength Mater. 1991, 34, 123–129. [Google Scholar] [CrossRef]

- Abdulrahman, K.O.; Abed, A.M.; Bayode, A.; Bhowmick, S.; Dey, S.; Hien, T.D.; Karsh, P.K.; Gaba, V.K.; Singh, A.K.; Singh, O.K.; et al. Hierarchical Composite Materials: Materials, Manufacturing, Engineering; Walter de Gruyter GmbH & Co. KG: Berlin, Germany, 2018; Volume 8. [Google Scholar]

- Nagarajan, N.; Nicholson, P.S. Nickel–alumina functionally graded materials by electrophoretic deposition. J. Am. Ceram. Soc. 2004, 87, 2053–2057. [Google Scholar] [CrossRef]

- Malinina, M.; Sammi, T.; Gasik, M.M. Corrosion resistance of homogeneous and FGM coatings. In Materials Science Forum; Trans Tech Publications Ltd.: Berlin, Germany, 2005; Volume 492, pp. 305–310. [Google Scholar]

- Watanabe, Y.; Inaguma, Y.; Sato, H.; Miura-Fujiwara, E. A novel fabrication method for functionally graded materials under centrifugal force: The centrifugal mixed-powder method. Materials 2009, 2, 2510–2525. [Google Scholar] [CrossRef]

- Ozieblo, A.; Wejrzanowski, T.; Konopka, K.; Szafran, M.; Kurzydlowski, K.J. Microstructure of Al2O3-Fe FGM obtained by modified slip-casting method. Mater. Sci. Forum 2005, 492, 665–672. [Google Scholar] [CrossRef]

- Jamian, S.; Watanabe, Y.; Sato, H. Formation of compositional gradient in Al/SiC FGMs fabricated under huge centrifugal forces using solid-particle and mixed-powder methods. Ceram. Int. 2019, 45, 9444–9453. [Google Scholar] [CrossRef]

- Choy, S.Y.; Sun, C.N.; Leong, K.F.; Wei, J. Compressive properties of functionally graded lattice structures manufactured by selective laser melting. Mater. Des. 2017, 131, 112–120. [Google Scholar] [CrossRef]

- Gautam, R.; Idapalapati, S. Compressive properties of additively manufactured functionally graded Kagome lattice structure. Metals 2019, 9, 517. [Google Scholar] [CrossRef]

- Chen, F.; Jia, M.; She, Y.; Wu, Y.; Shen, Q.; Zhang, L. Mechanical behavior of AlN/Mo functionally graded materials with various compositional structures. J. Alloys Compd. 2020, 816, 152512. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Li, X.; Tan, Y.H.; Willy, H.J.; Wang, P.; Lu, W.; Cagirici, M.; Ong, C.Y.A.; Herng, T.S.; Wei, J.; Ding, J. Heterogeneously tempered martensitic high strength steel by selective laser melting and its micro-lattice: Processing, microstructure, superior performance and mechanisms. Mater. Des. 2019, 178, 107881. [Google Scholar] [CrossRef]

- Singh, N.; Singh, R.; Ahuja, I.P.S. On development of functionally graded material through fused deposition modelling assisted investment casting from Al2O3/SiC reinforced waste low density polyethylene. Trans. Indian Inst. Met. 2018, 71, 2479–2485. [Google Scholar] [CrossRef]

- Liu, T.; Guessasma, S.; Zhu, J.; Zhang, W.; Belhabib, S. Functionally graded materials from topology optimisation and stereolithography. Eur. Polym. J. 2018, 108, 199–211. [Google Scholar] [CrossRef]

- Leoni, F.; Dal Fabbro, P.; Rosso, S.; Grigolato, L.; Meneghello, R.; Concheri, G.; Savio, G. Functionally Graded AM: Bridging the Gap between Design and Material Extrusion. Appl. Sci. 2023, 13, 1467. [Google Scholar] [CrossRef]

- Baca, D.; Ahmad, R. The impact on the mechanical properties of multi-material polymers fabricated with a single mixing nozzle and multi-nozzle systems via fused deposition modeling. Int. J. Adv. Manuf. Technol. 2020, 106, 4509–4520. [Google Scholar] [CrossRef]

- Azari, A.; Nikzad, S. The evolution of rapid prototyping in dentistry: A review. Rapid Prototyp. J. 2009, 15, 216–225. [Google Scholar] [CrossRef]

- Elkaseer, A.; Schneider, S.; Scholz, S.G. Experiment-based process modeling and optimization for high-quality and resource-efficient FFF 3D printing. Appl. Sci. 2020, 10, 2899. [Google Scholar] [CrossRef]

- Su, Z.; Inaba, K.; Karmakar, A.; Das, A. Characterization of Mechanical Property of PLA-ABS Functionally Graded Material Fabricated by Fused Deposition Modeling. Gas Turbine India Conf. Am. Soc. Mech. Eng. 2021, 85536, V001T01A003. [Google Scholar]

- Wang, P.; Zou, B.; Ding, S.; Zhuang, Y.; Liu, J.; Li, L. Functionally graded polyetheretherketone-based composites additively manufactured by material extrusion using a transition interface design method. Compos. Part A Appl. Sci. Manuf. 2022, 158, 106977. [Google Scholar] [CrossRef]

- Salem, T.; Jiao, P.; Zaabar, I.; Li, X.; Zhu, R.; Lajnef, N. Functionally graded materials beams subjected to bilateral constraints: Structural instability and material topology. Int. J. Mech. Sci. 2021, 194, 106218. [Google Scholar] [CrossRef]

- Subramaniyan, M.K.; Veeman, D.; Gurusamy John Kennedy, S.; Panda, B.; Yang, C. Mechanical performance and microscopic characterization of additively manufactured functionally graded material (WPC/Ceramic-PLA) via fused deposition modelling. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023. [Google Scholar] [CrossRef]

- Xavior, M.A.; Nishanth, D.; Kumar, N.N.; Jeyapandiarajan, P. Synthesis and Testing of FGM made of ABS Plastic Material. Mater. Today Proc. 2020, 22, 1838–1844. [Google Scholar] [CrossRef]

- Hasanov, S.; Gupta, A.; Nasirov, A.; Fidan, I. Mechanical characterization of functionally graded materials produced by the fused filament fabrication process. J. Manuf. Process. 2020, 58, 923–935. [Google Scholar] [CrossRef]

- Hong, J.; Wang, S.; Qiu, X.; Zhang, G. Bending and Wave Propagation Analysis of Magneto-Electro-Elastic Functionally Graded Porous Microbeams. Crystals 2022, 12, 732. [Google Scholar] [CrossRef]

- Jędrysiak, J. Theoretical Tolerance Modelling of Dynamics and Stability for Axially Functionally Graded (AFG) Beams. Materials 2023, 16, 2096. [Google Scholar] [CrossRef]

- Hasanov, S.; Gupta, A.; Alifui-Segbaya, F.; Fidan, I. Hierarchical homogenization and experimental evaluation of functionally graded materials manufactured by the fused filament fabrication process. Compos. Struct. 2021, 275, 114488. [Google Scholar] [CrossRef]

- Riiz Machinery Ltd., Co., FILAMEON. Available online: https://www.filameon.com (accessed on 12 December 2022).

- Ultimaker CURA. Available online: https://ultimaker.com/software/ultimaker-cura (accessed on 5 June 2021).

- ASTM, D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- Abaqus/Standart (Version 6.14), User’s Manual, Finite Element Software. Available online: http://www.simulia.com (accessed on 1 May 2014).

| Layer thickness | 0.2 mm |

| Filler fiber thickness | 0.4 mm |

| Wall thickness | 0.4 mm |

| Print speed | 30 mm/s |

| Filling pattern | line (0°) |

| Properties | PLA | ABS |

|---|---|---|

| Filament diameter (mm) | 1.75 | 1.75 |

| Density (gr/cm3) | 1.24 | 1.04 |

| Bed temperature (°C) | 60 | 80–100 |

| Nozzle temperature (°C) | 205 | 220 |

| Melt Flow Index (210 °C/2.16 kg) | 6 | 80–120 |

| Tensile strength (MPa) | 53 | 45 |

| Elongation (%) | 6 | 10 |

| Bending strength (MPa) | 83 | 73 |

| Rackwell hardness | 108 | 108 |

| Max service temperature (°C) | 55 | 85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sevim, C.; Caliskan, U.; Demirbas, M.D.; Ekrikaya, S.; Apalak, M.K. Numerical Modeling of Mechanical Behavior of Functionally Graded Polylactic Acid–Acrylonitrile Benzidine Styrene Produced via Fused Deposition Modeling: Experimental Observations. Materials 2023, 16, 5177. https://doi.org/10.3390/ma16145177

Sevim C, Caliskan U, Demirbas MD, Ekrikaya S, Apalak MK. Numerical Modeling of Mechanical Behavior of Functionally Graded Polylactic Acid–Acrylonitrile Benzidine Styrene Produced via Fused Deposition Modeling: Experimental Observations. Materials. 2023; 16(14):5177. https://doi.org/10.3390/ma16145177

Chicago/Turabian StyleSevim, Caglar, Umut Caliskan, Munise Didem Demirbas, Safa Ekrikaya, and Mustafa Kemal Apalak. 2023. "Numerical Modeling of Mechanical Behavior of Functionally Graded Polylactic Acid–Acrylonitrile Benzidine Styrene Produced via Fused Deposition Modeling: Experimental Observations" Materials 16, no. 14: 5177. https://doi.org/10.3390/ma16145177

APA StyleSevim, C., Caliskan, U., Demirbas, M. D., Ekrikaya, S., & Apalak, M. K. (2023). Numerical Modeling of Mechanical Behavior of Functionally Graded Polylactic Acid–Acrylonitrile Benzidine Styrene Produced via Fused Deposition Modeling: Experimental Observations. Materials, 16(14), 5177. https://doi.org/10.3390/ma16145177