Study on the Constitutive Relationship between Ordinary Concrete and Nano-Titanium Dioxide-Modified Concrete at High Temperature

Abstract

1. Introduction

2. Experimental Materials and Equipment

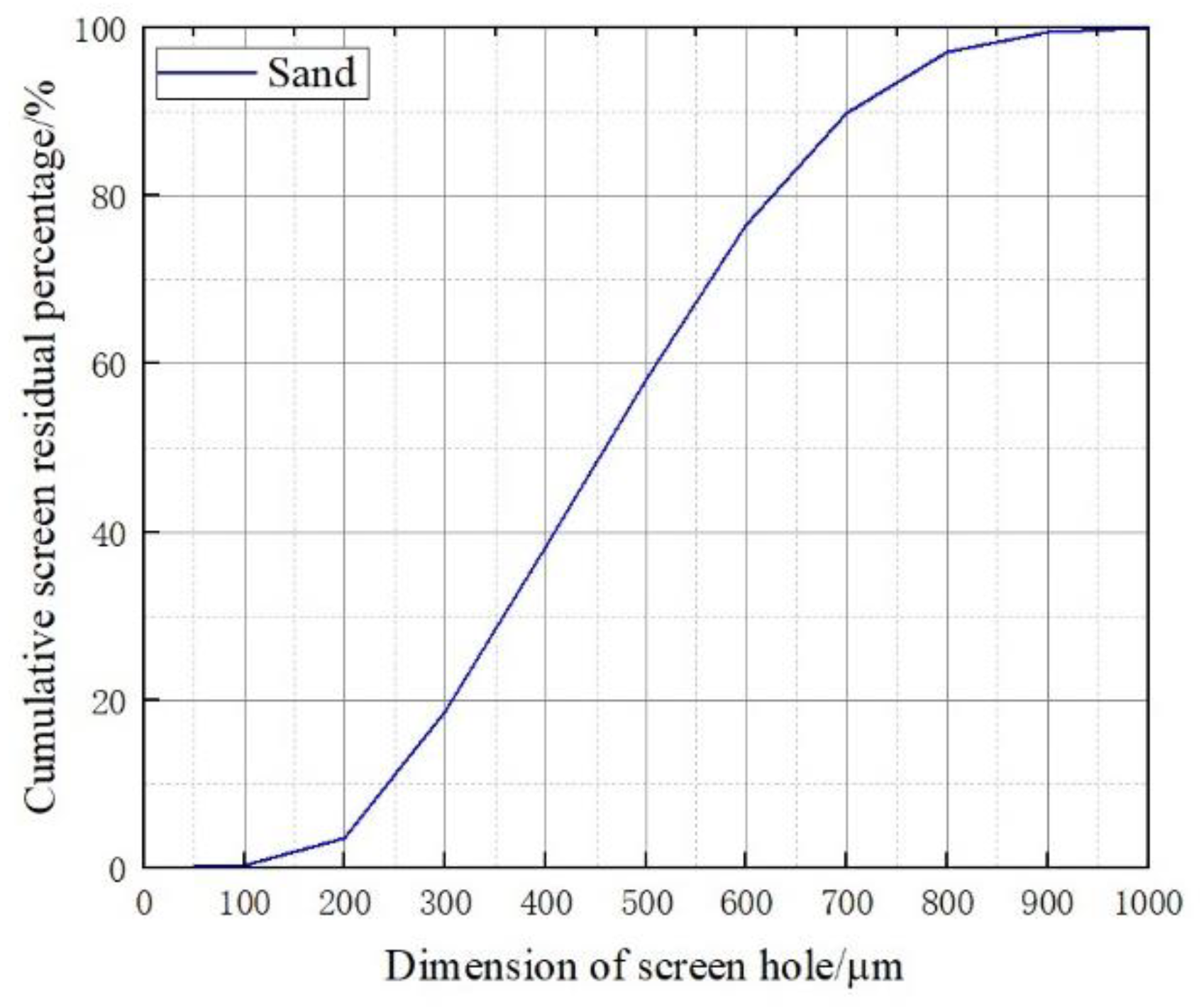

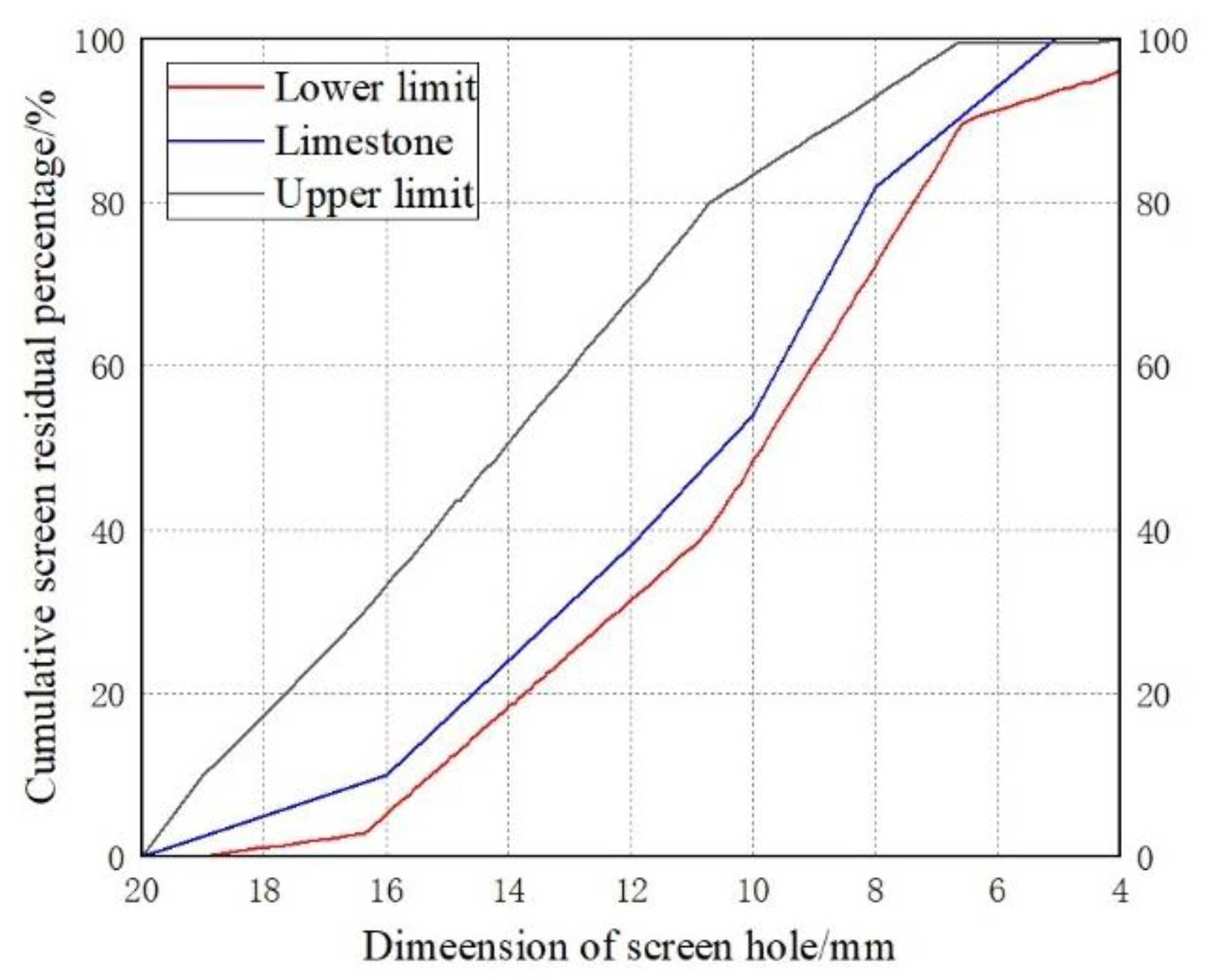

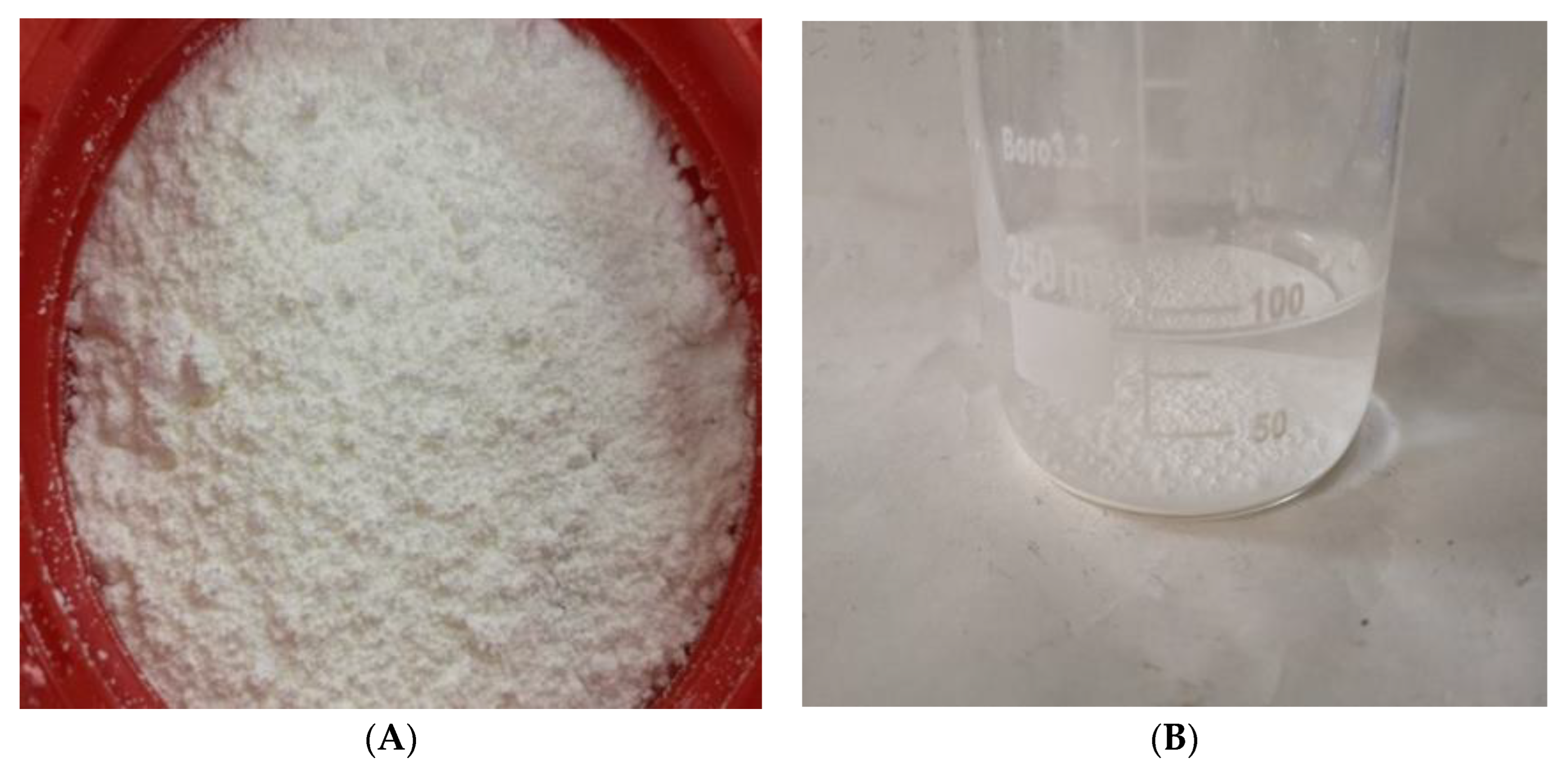

2.1. Materials

2.2. Sample Preparation

2.3. Test Equipment

- (1)

- Fifteen ordinary concrete and fifteen NTC3 specimens were carefully chosen and subsequently partitioned into five distinct groups.

- (2)

- After 28 days of natural conservation, it was subjected to high-temperature heat treatment of 200 °C, 400 °C, 600 °C, and 800 °C, respectively. The heating rate in the high-temperature furnace is 5 °C/min. The temperature is constant for 6 h after reaching the target temperature, and then naturally cooled in the furnace for 24 h.

3. Test Results and Discussion

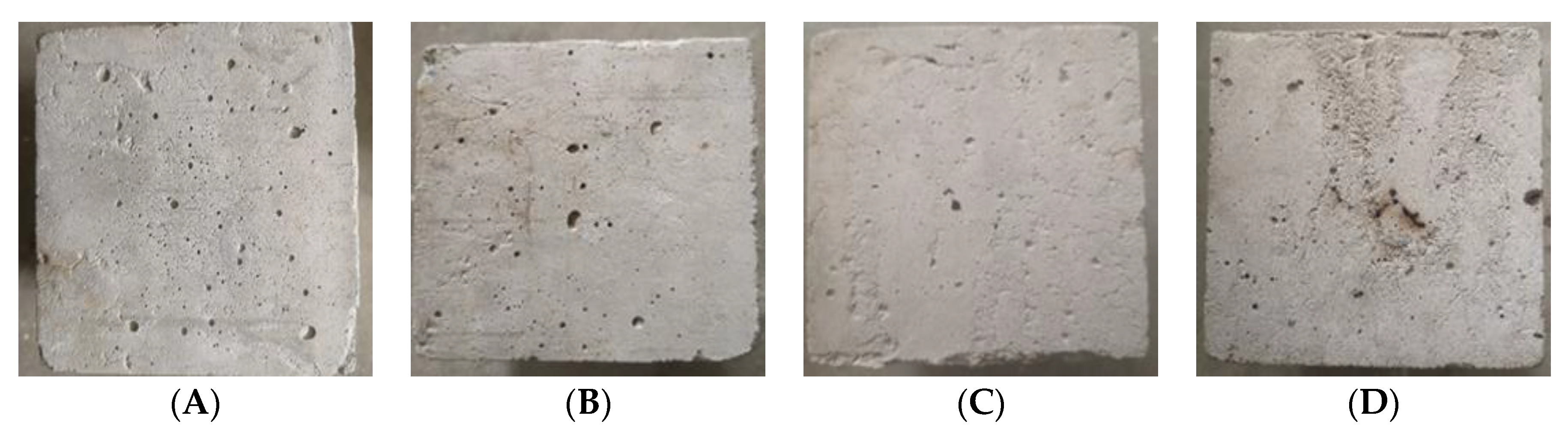

3.1. Surface Characteristics of Specimens after High Temperature

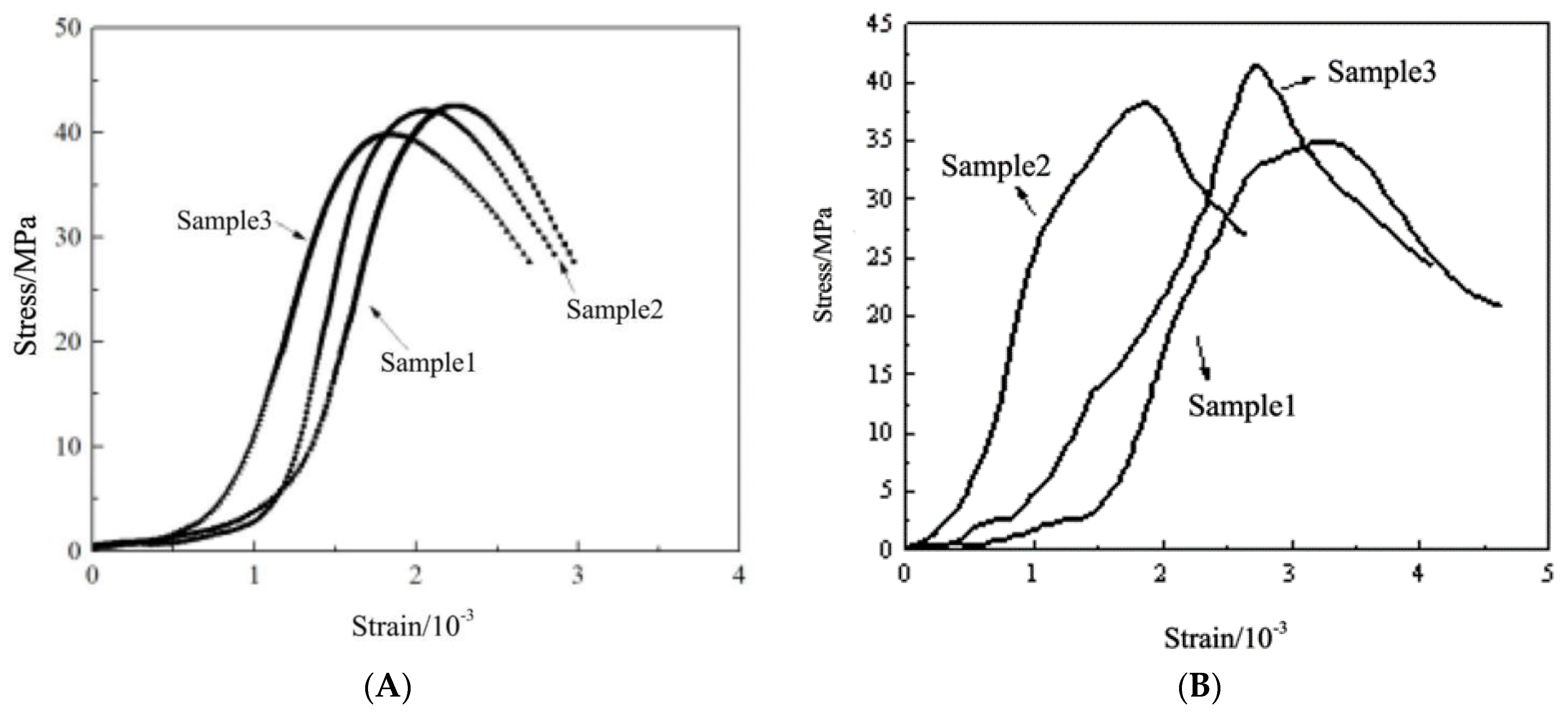

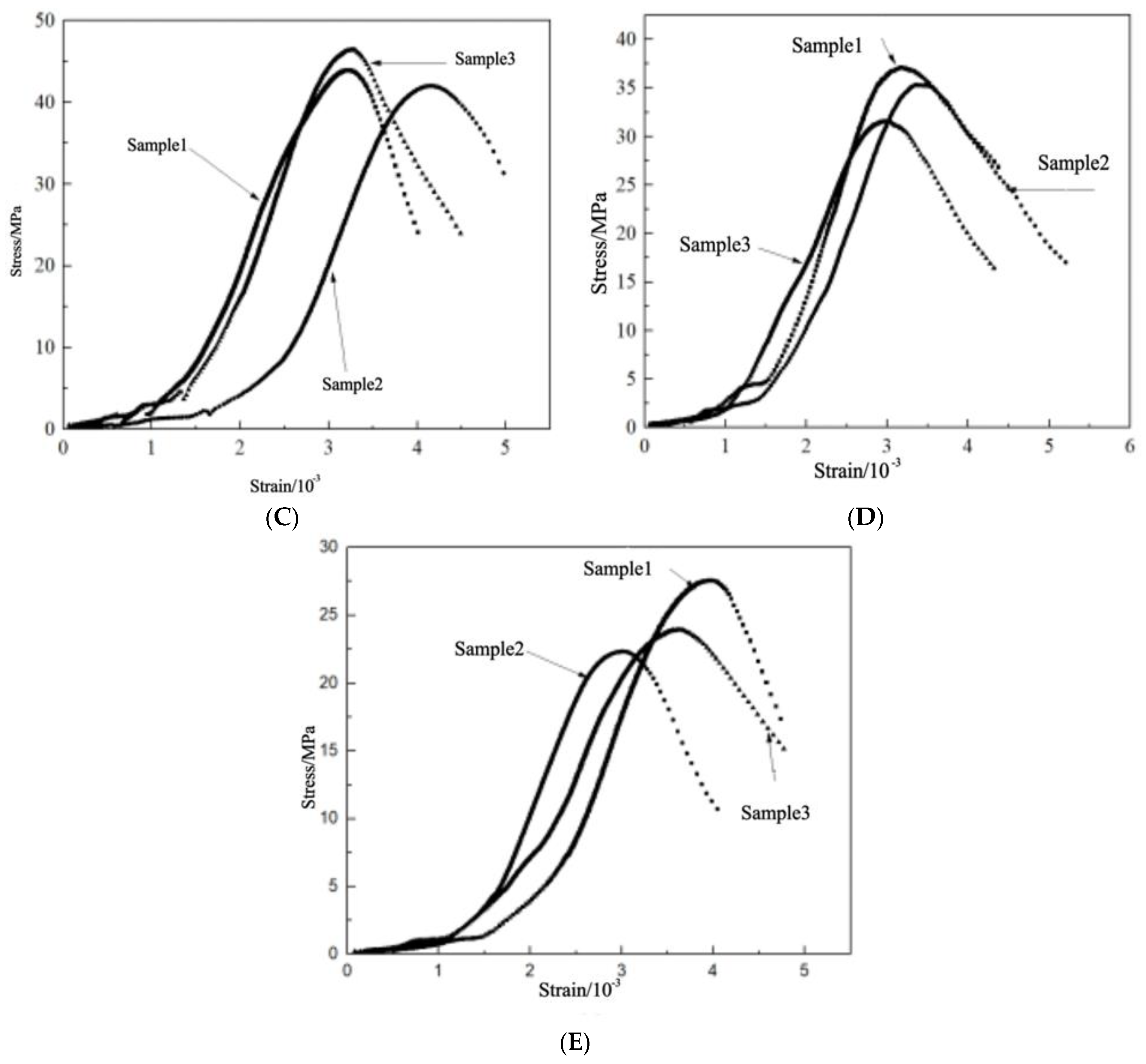

3.2. Mechanical Properties of Concrete after High Temperature

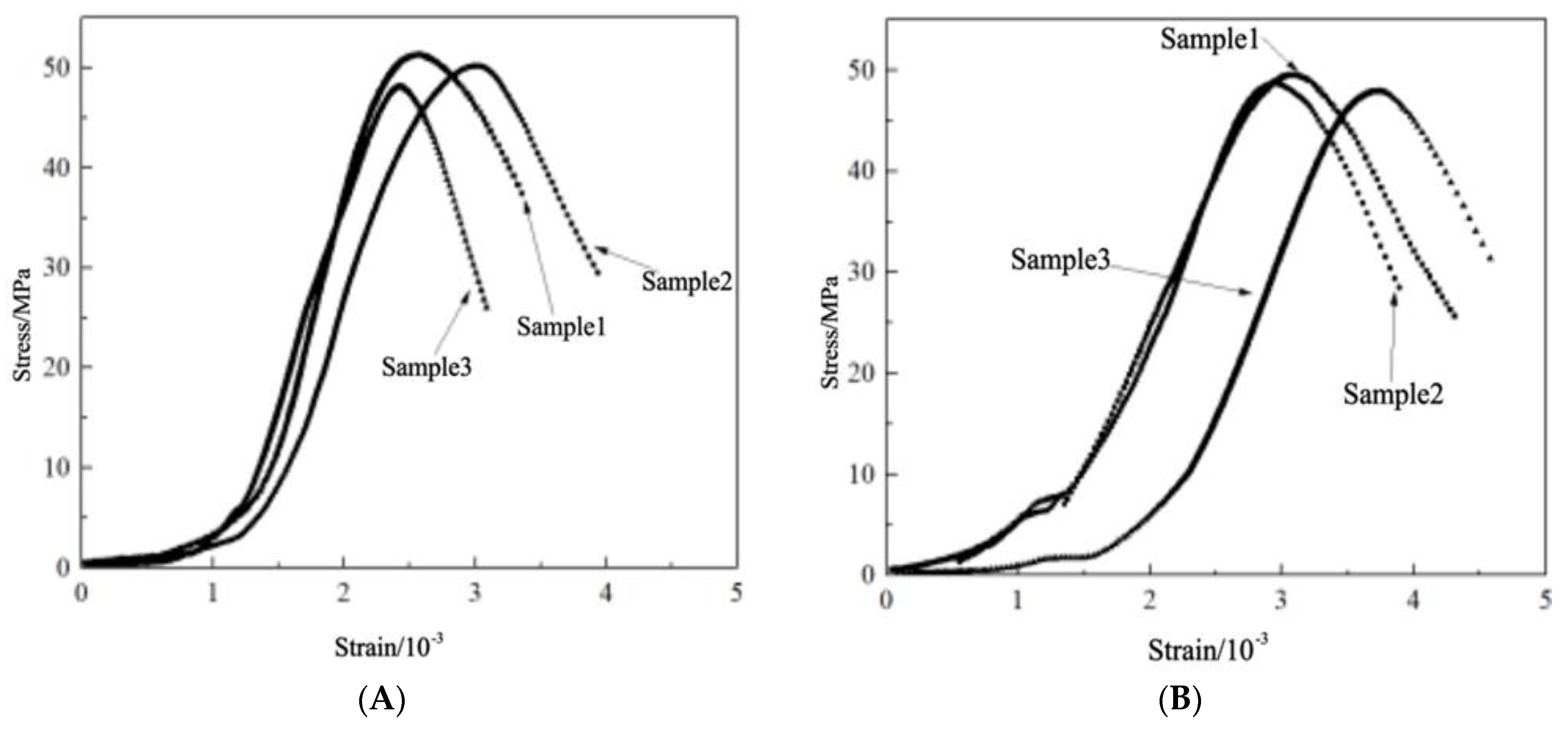

3.3. Mechanical Properties of NTC3 after High Temperature

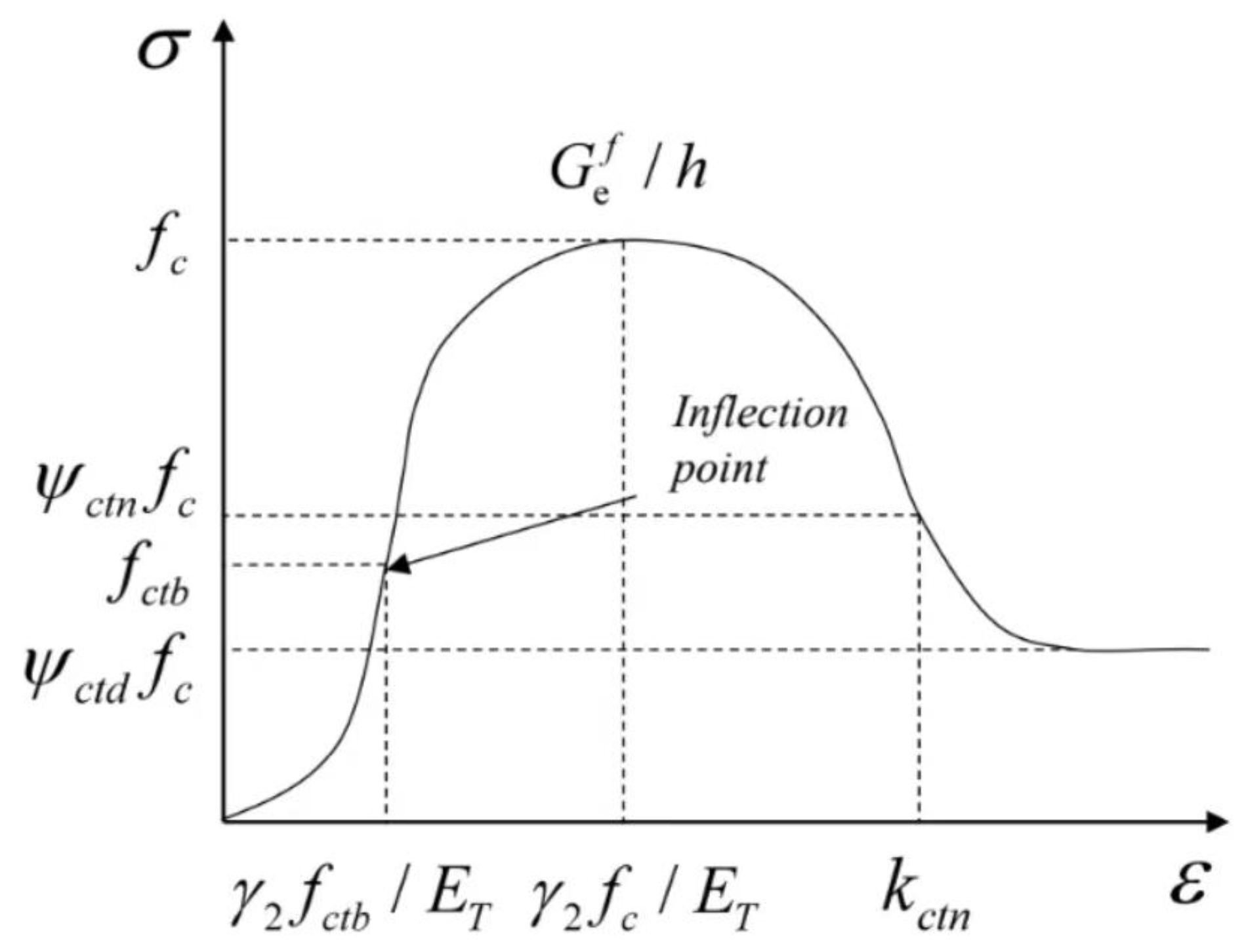

4. Establishment and Verification of Concrete Damage Constitutive Model

4.1. Derivation of the Damage Constitutive Equation

- where

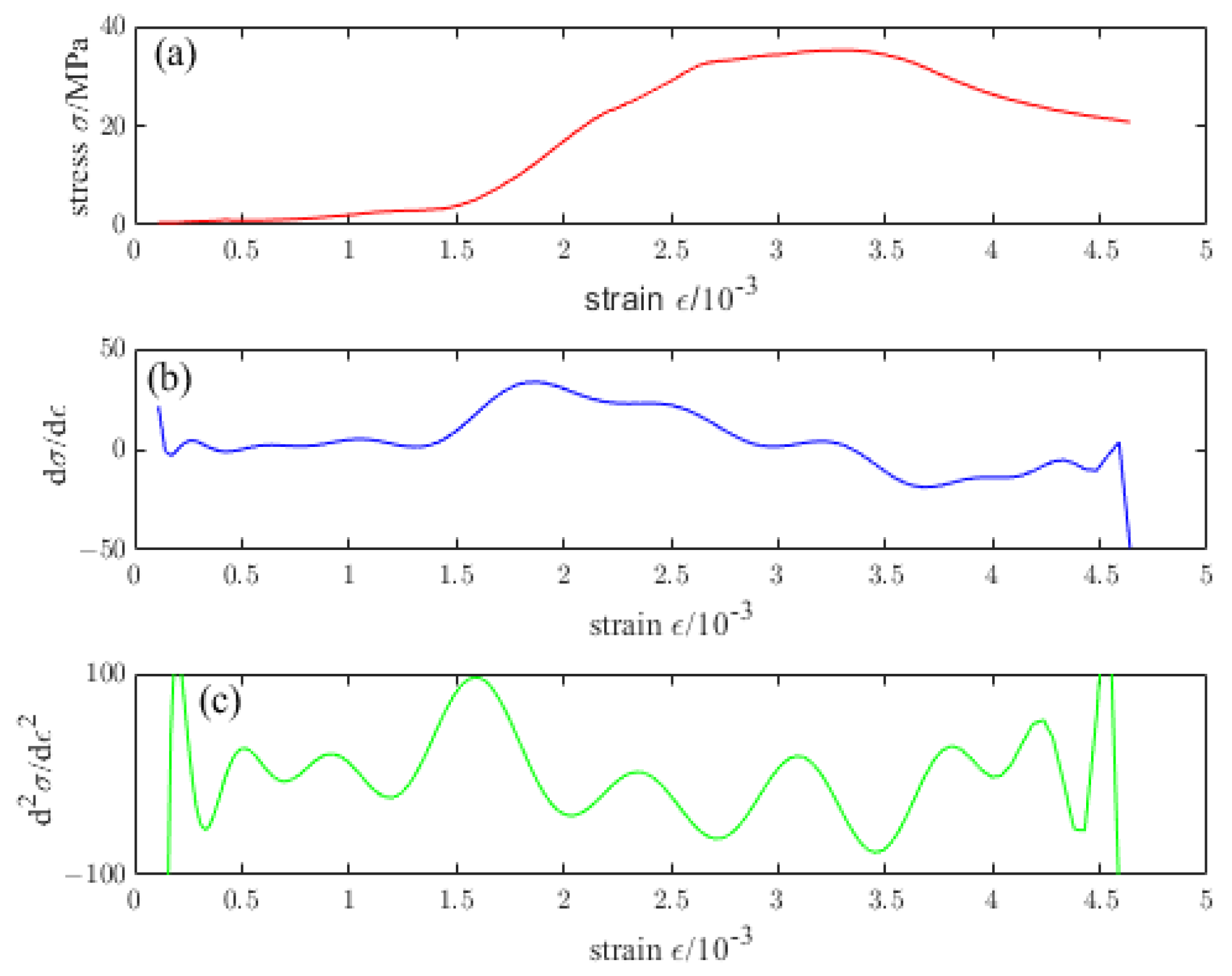

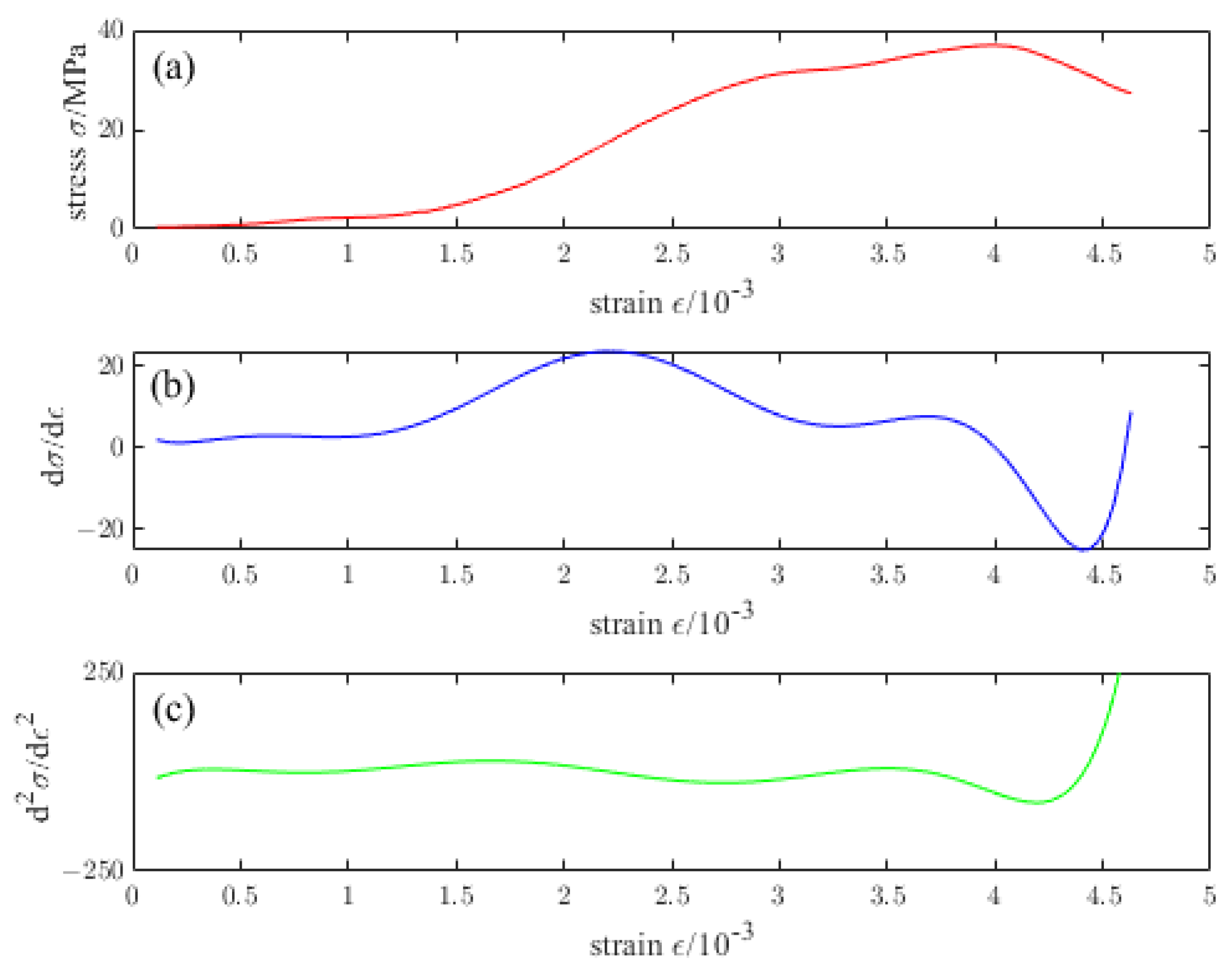

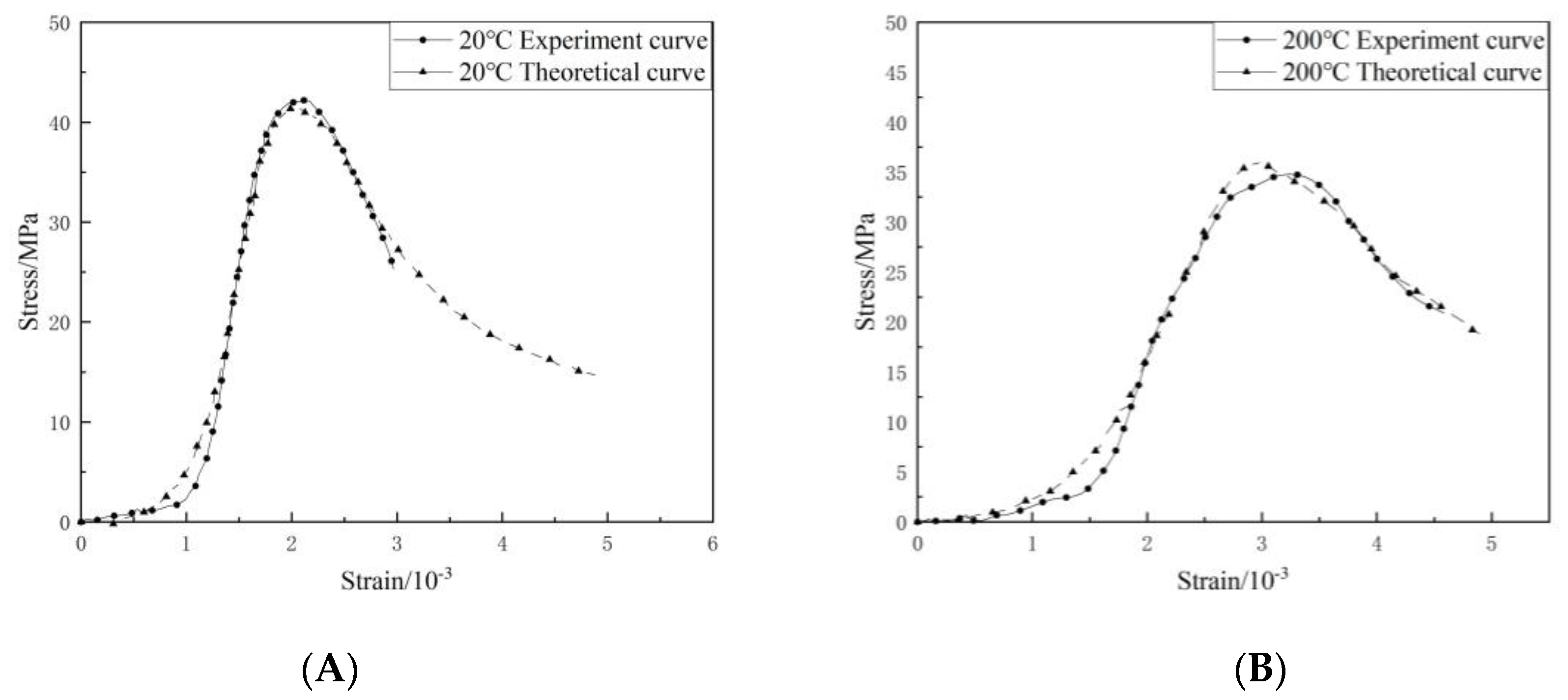

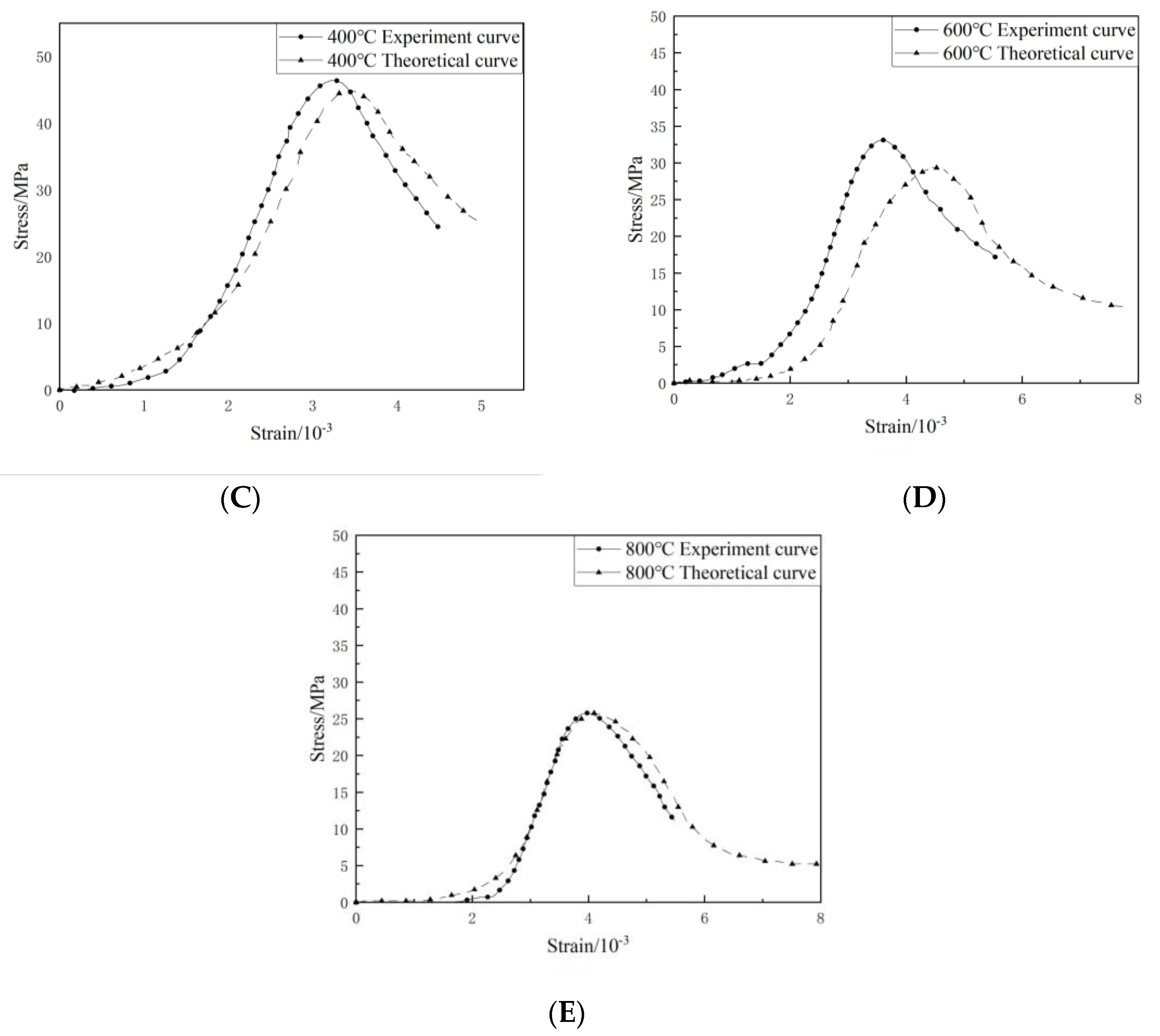

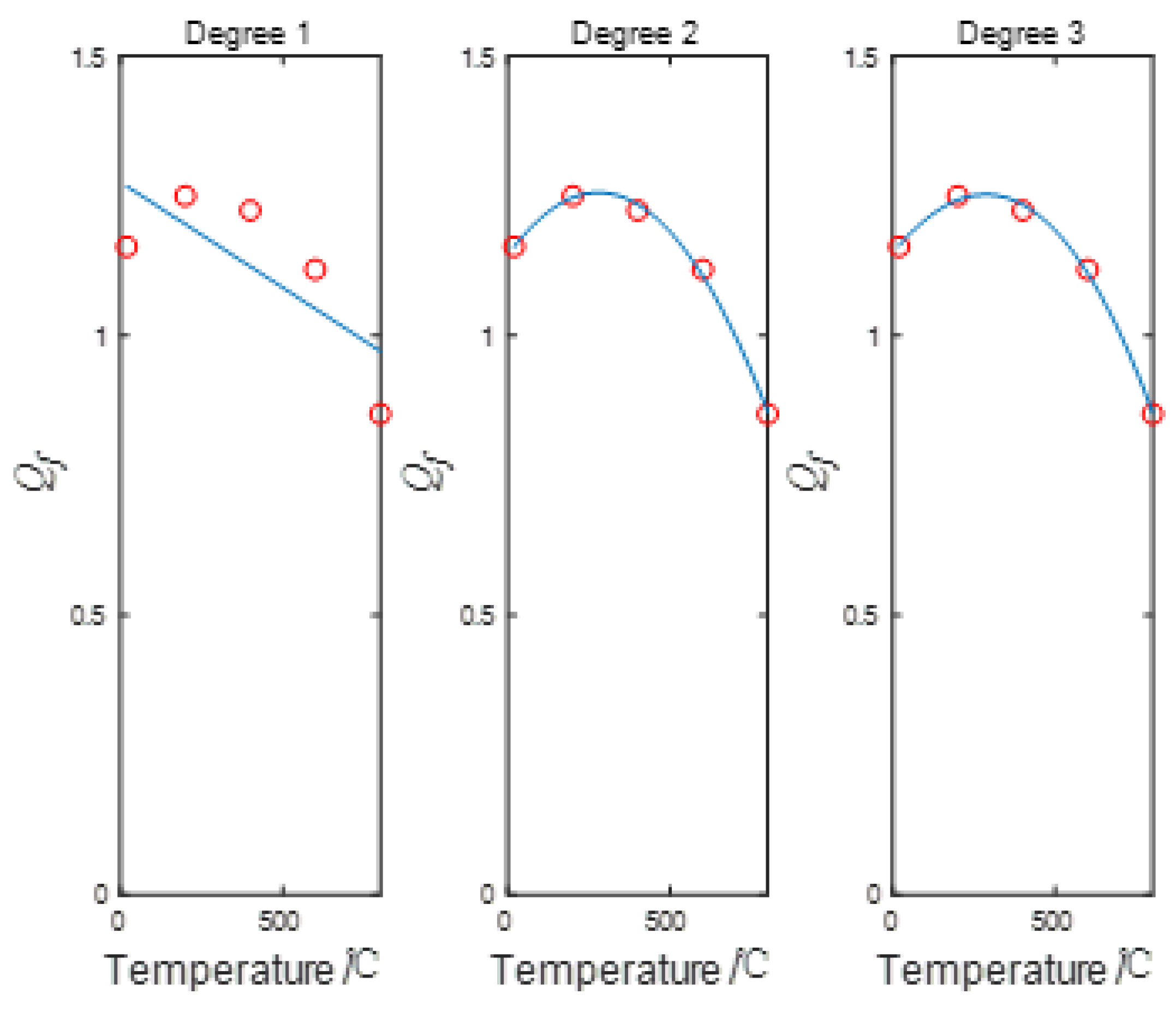

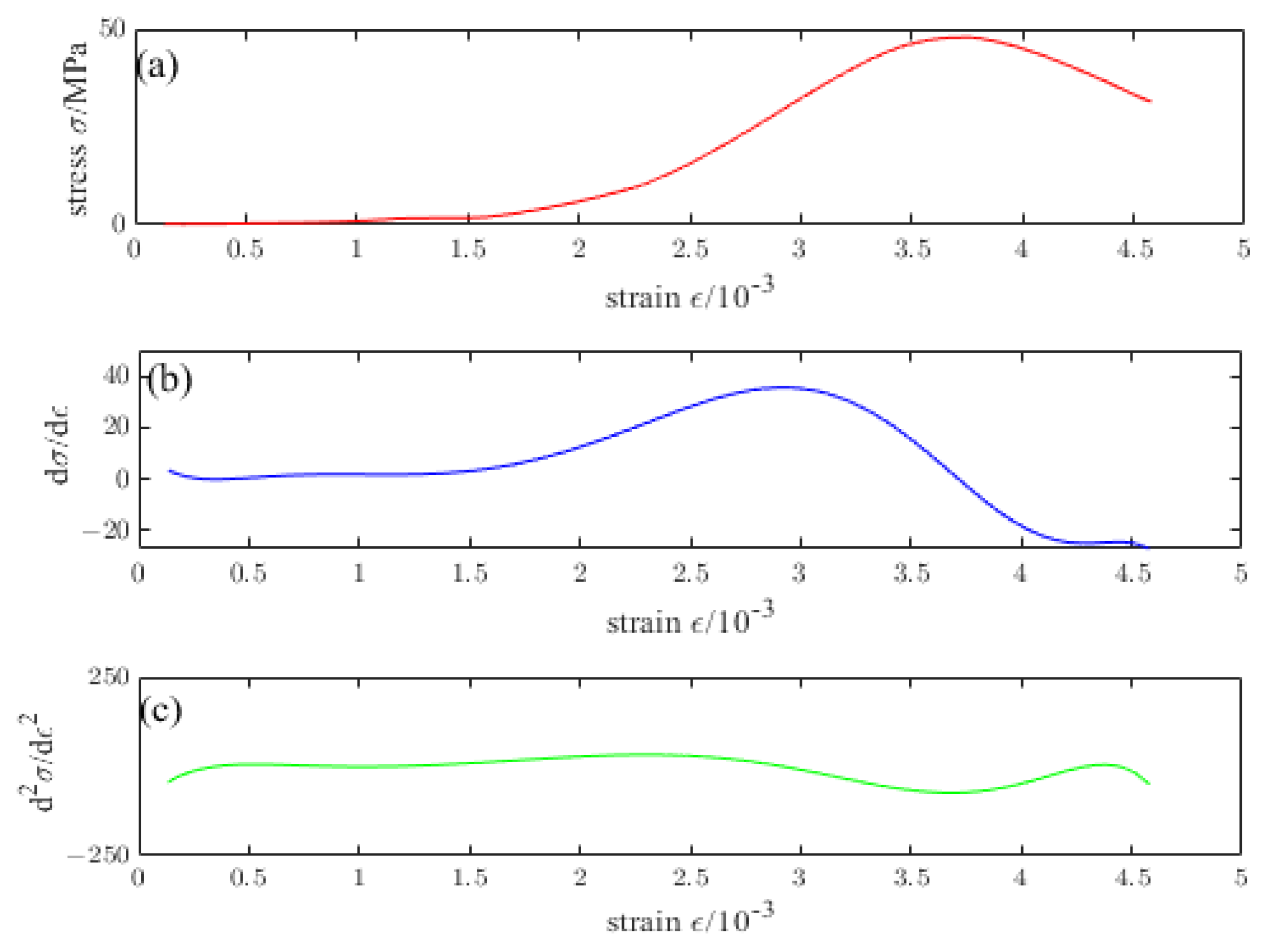

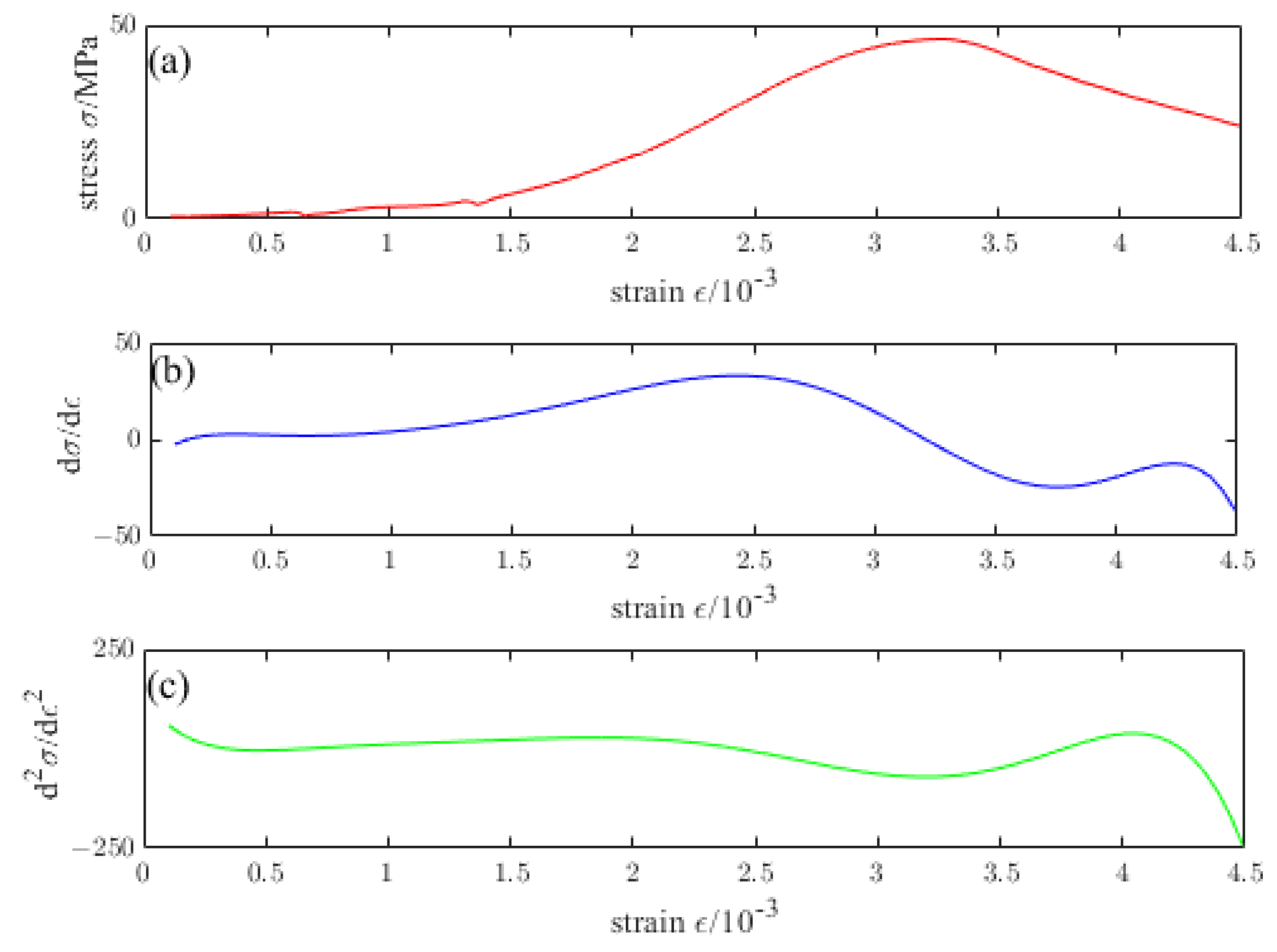

4.2. Damage Constitutive Model of Ordinary Concrete after High Temperature

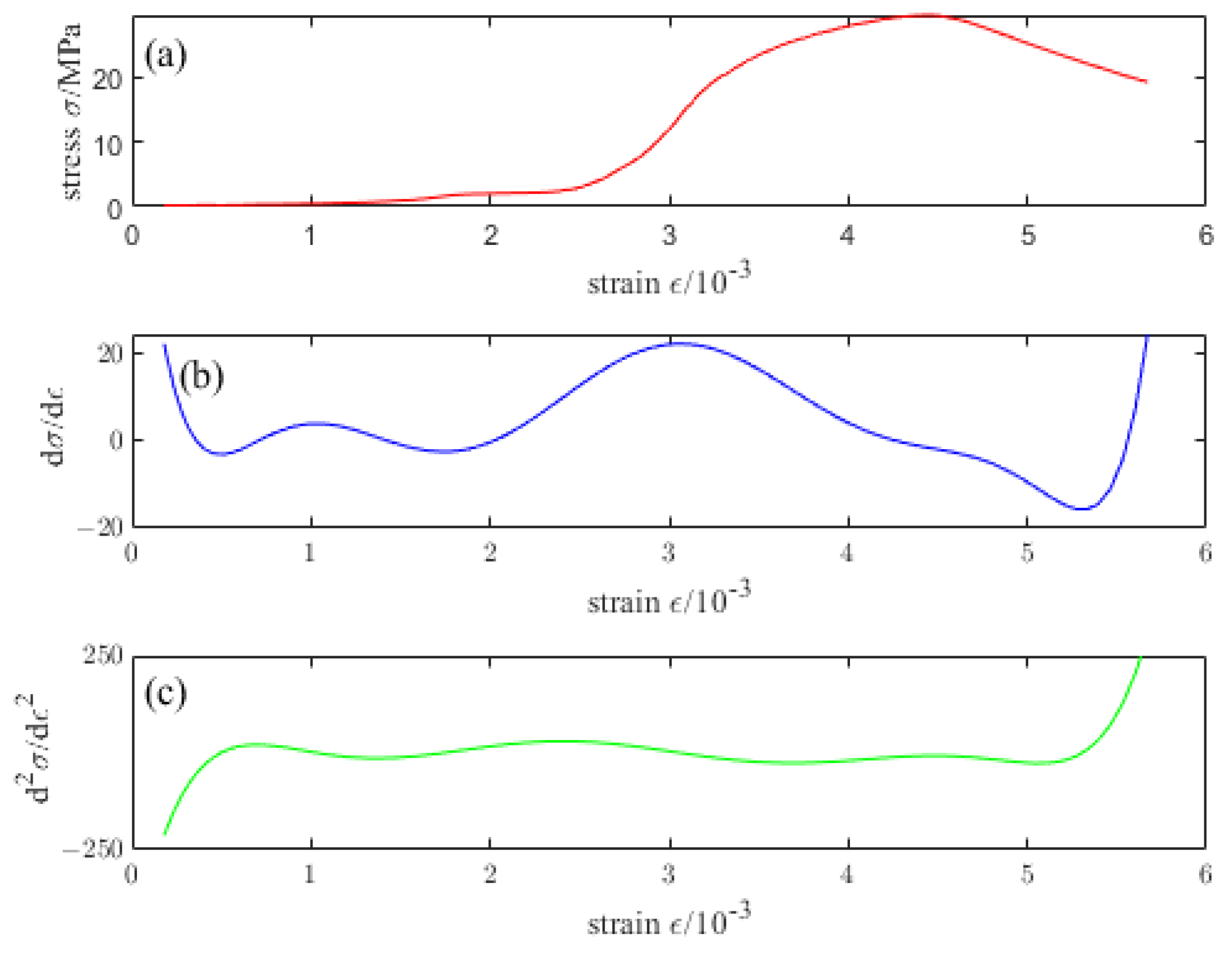

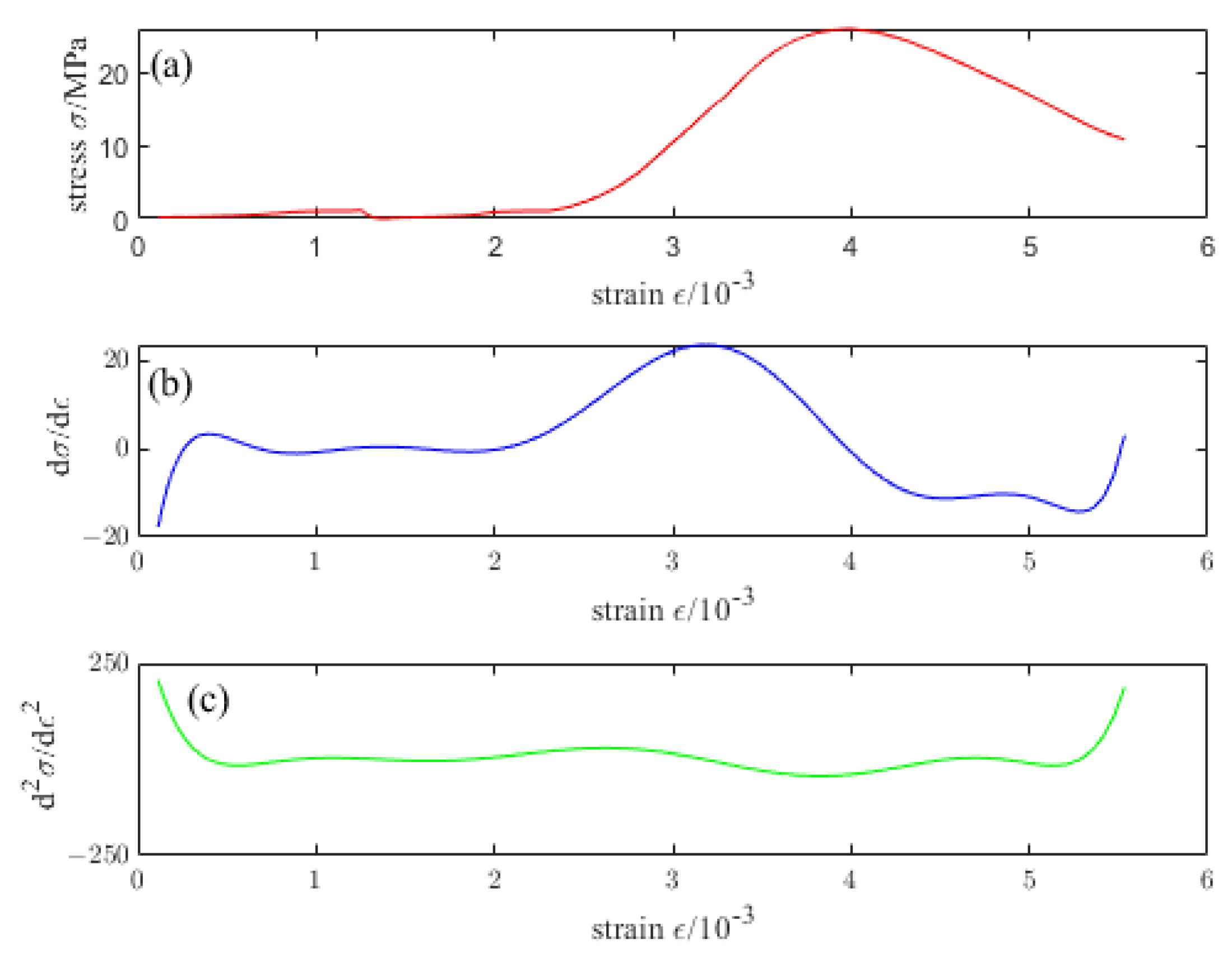

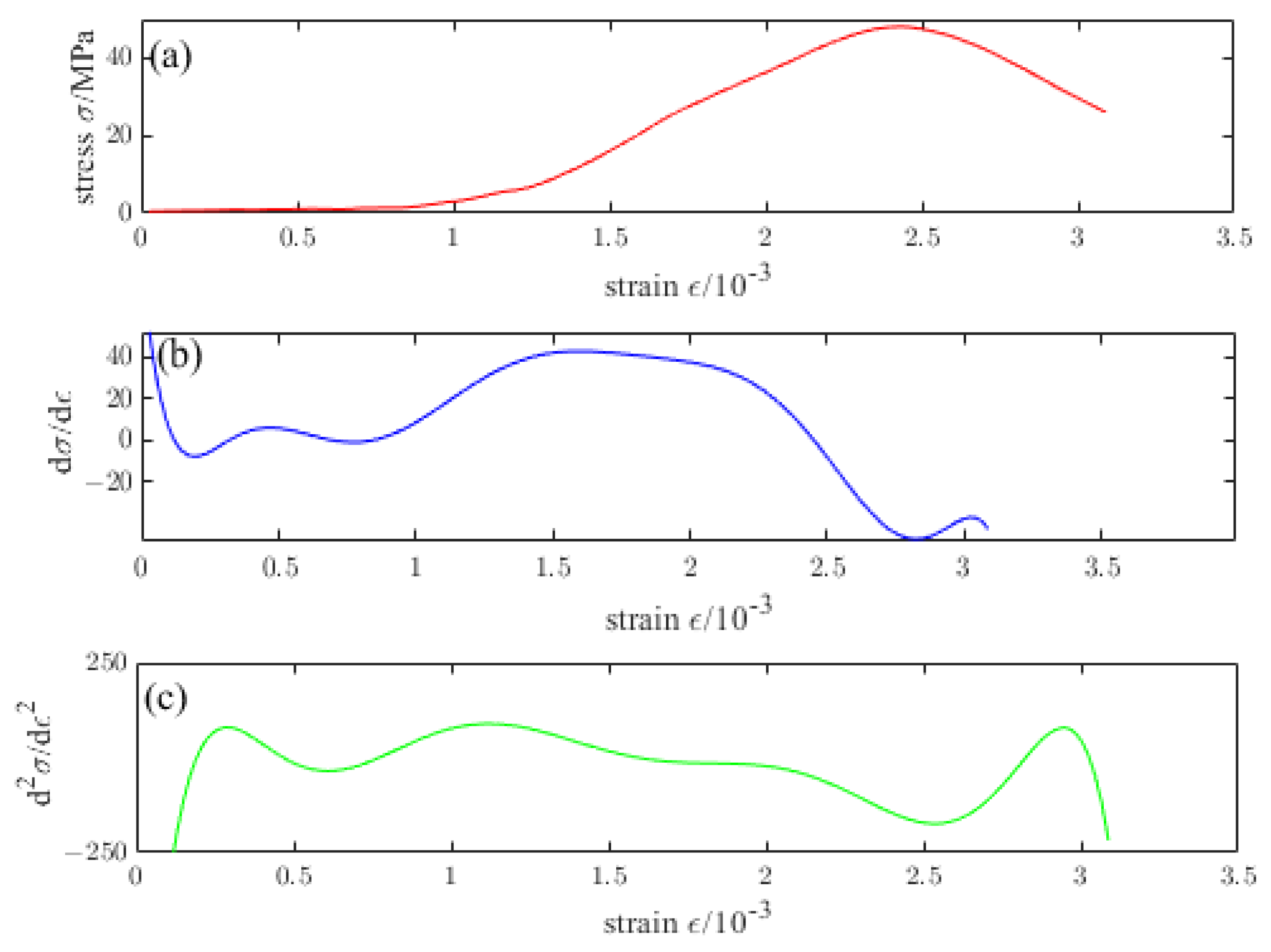

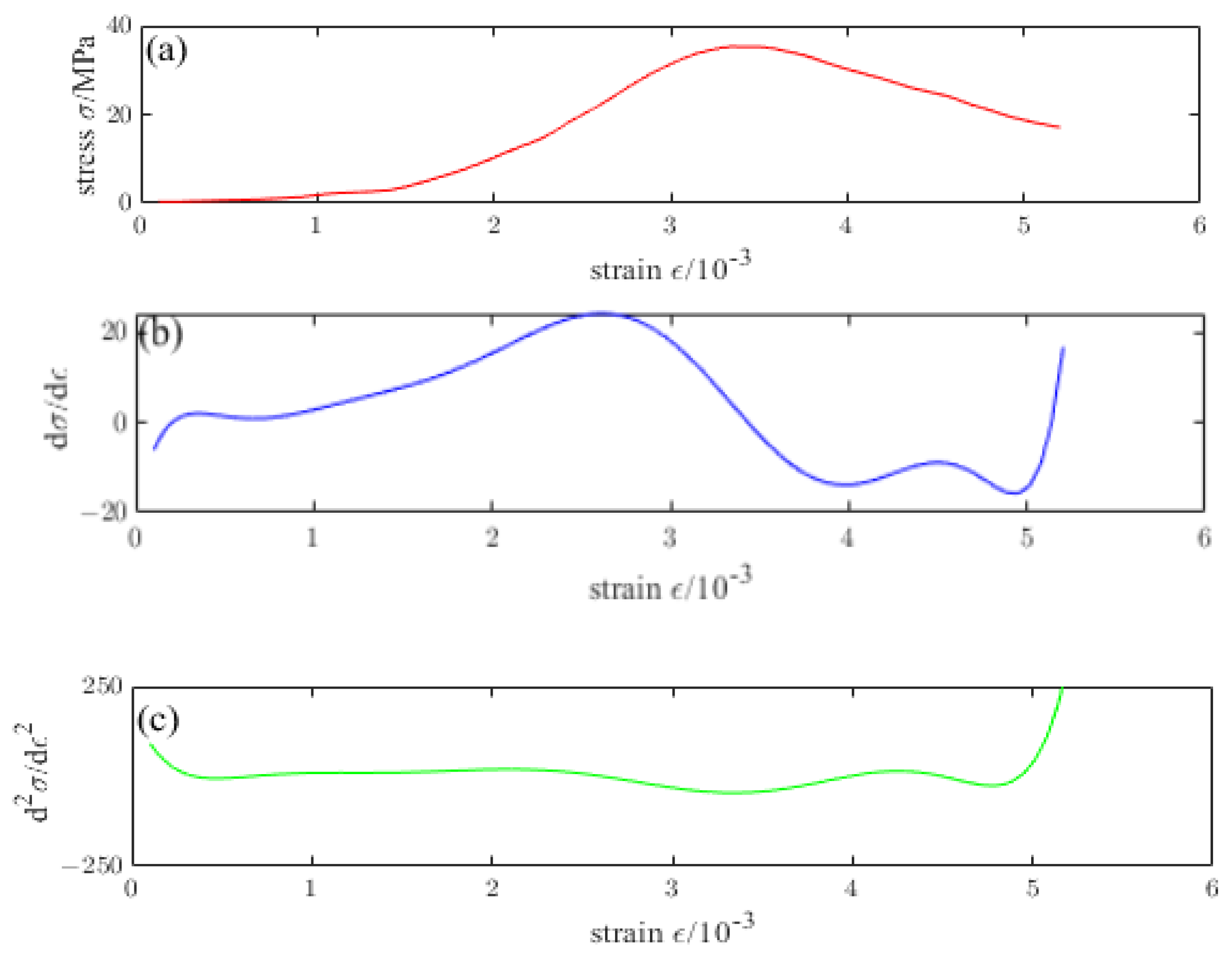

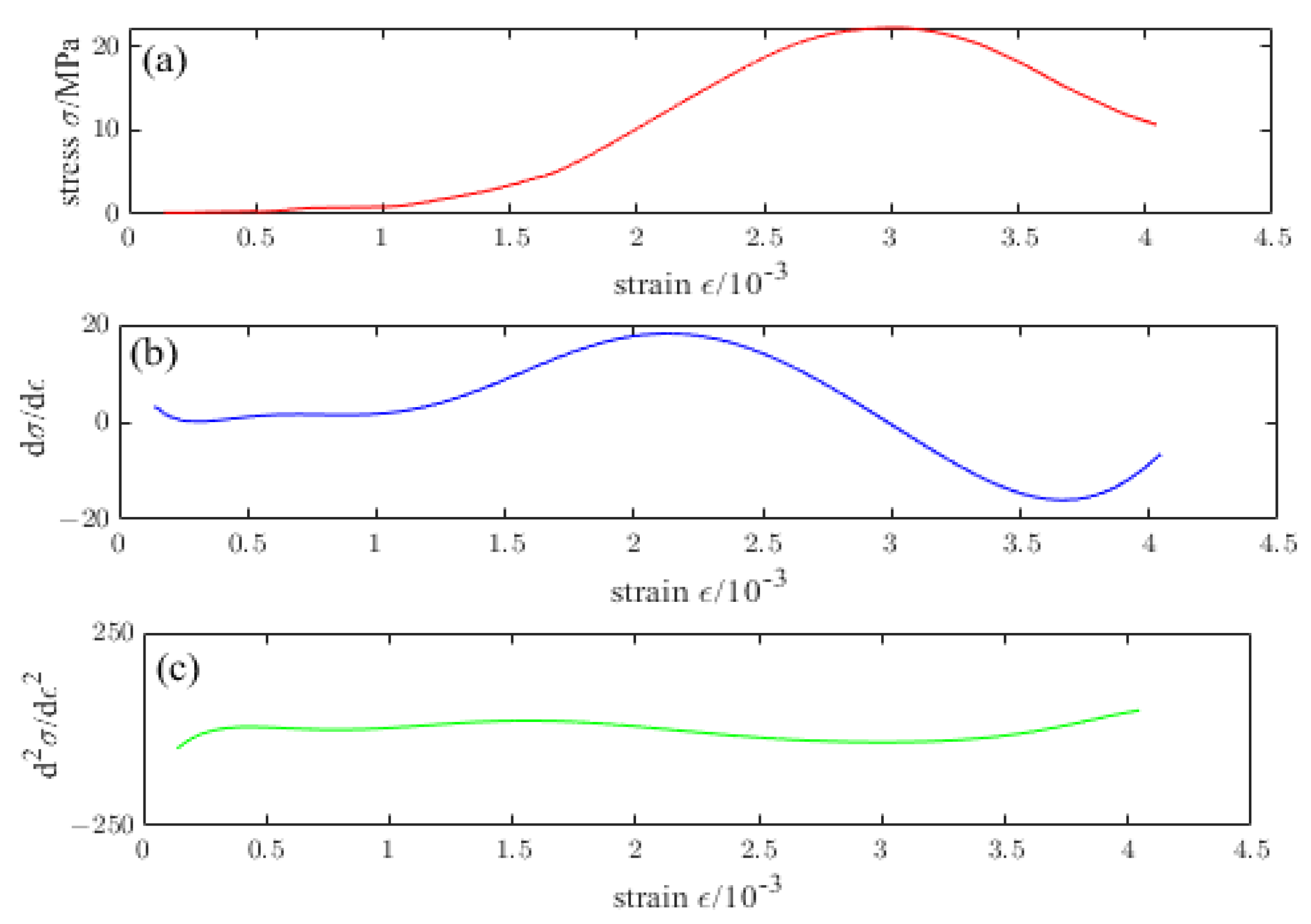

4.3. Damage Constitutive Model of NTC3 after High Temperature

5. Conclusions

- (1)

- Ordinary concrete and NTC3 specimens were subjected to various temperatures ranging from 20 °C to 800 °C. Notably, the volume expansion of both materials was not apparent within the temperature range of 200 °C to 600 °C. Additionally, the surface color of the specimens transitioned from gray to brown. At a temperature of 800 °C, the specimen exhibits the formation of black spots on its surface and undergoes volumetric expansion.

- (2)

- With the increase of temperature, ordinary concrete’s average peak compressive resistance is further reduced. At 800 °C, the average peak compressive strength of ordinary concrete was 23.120 MPa, which decreased by 44.32% compared with the initial time, and the approximate secant modulus decreased to 13.072 GPa. Similar to ordinary concrete, after high-temperature treatment from 400 °C to 800 °C, the compressive strength of NTC3 decreased, and the average peak compressive strength of NTC3 was 24.610 MPa at 800 °C, a decrease of 50.69% compared with the initial time. It can be seen that the incorporation of nano titanium dioxide at lower than 600 °C can help the high-temperature resistance of concrete, and when it is higher than 600 °C, the mechanical properties of ordinary concrete and NTC3 compression are basically no different.

- (3)

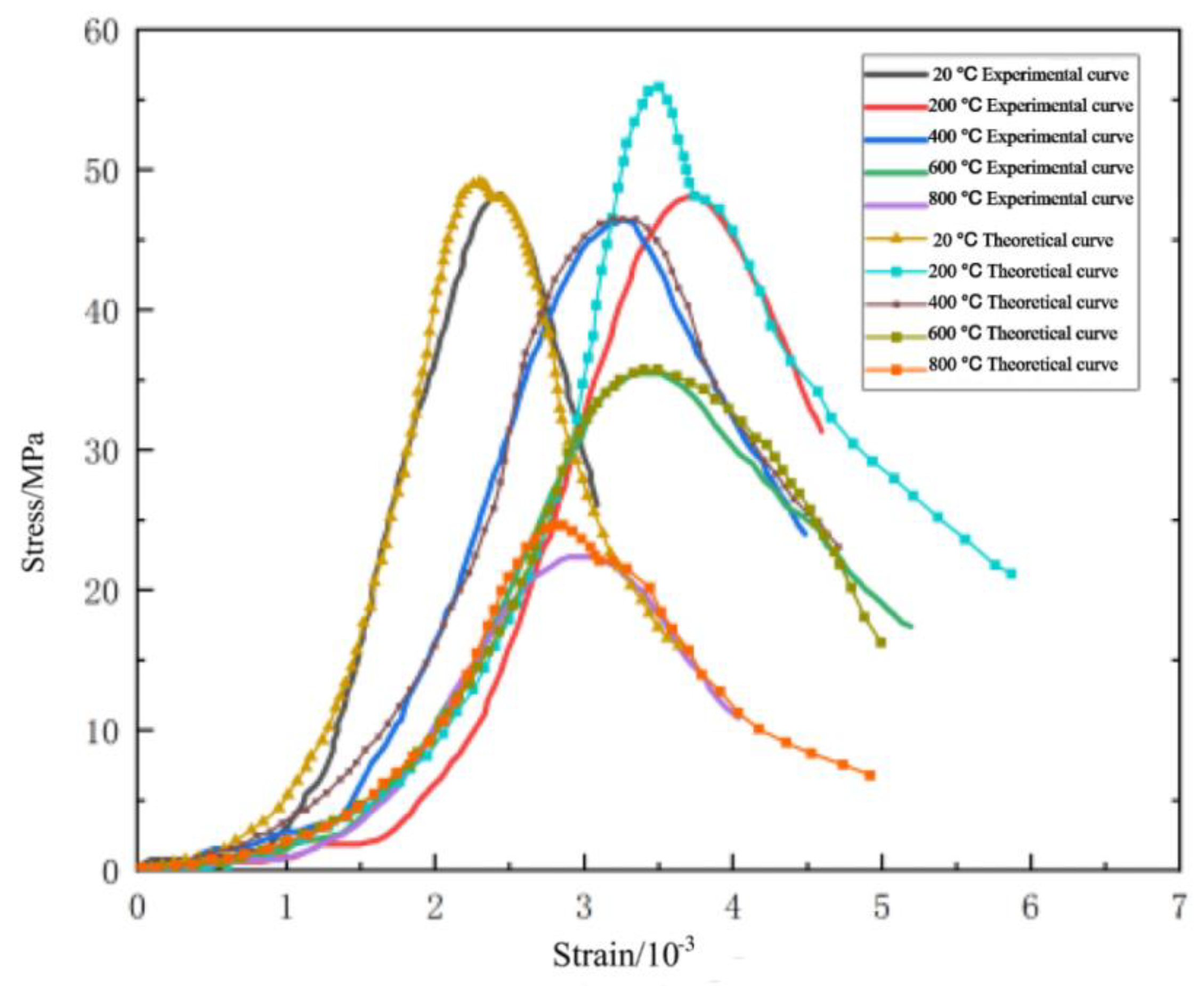

- The stress–strain curves exhibited by ordinary concrete specimens subjected to uniaxial compression and titanium nanoconcrete specimens prior to and subsequent to high-temperature exposure exhibit similar shapes and characteristics. A constitutive relationship formula was established for the stress–strain curve of ordinary concrete specimens and NTC3 under uniaxial compression. A constitutive relationship for the uniaxial compressive stress–strain behavior of concrete was established, taking into account the variable of high-temperature damage. The constitutive relationship of concrete under high temperatures has been enhanced in accordance with the law of continuous change.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Akca, A.H.; Zihnioğlu, N.Ö. High performance concrete under elevated temperatures. Constr. Build. Mater. 2013, 44, 317–328. [Google Scholar] [CrossRef]

- Kodur, V. Properties of Concrete at Elevated Temperatures. Int. Sch. Res. Not. 2014, 2014, 468510. [Google Scholar] [CrossRef]

- Xiao, J.; König, G. Study on concrete at high temperature in China—An overview. Fire Saf. J. 2004, 39, 89–103. [Google Scholar] [CrossRef]

- Kakae, N.; Miyamoto, K.; Momma, T.; Sawada, S.; Kumagai, H.; Ohga, Y.; Hirai, H.; Abiru, T. Physical and Thermal Properties of Concrete Subjected to High Temperature. J. Adv. Concr. Technol. 2017, 15, 190–212. [Google Scholar] [CrossRef]

- Maruyama, I.; Sasano, H.; Nishioka, Y.; Igarashi, G. Strength and Young’s modulus change in concrete due to long-term drying and heating up to 90 °C. Cem. Concr. Res. 2014, 66, 48–63. [Google Scholar] [CrossRef]

- Li, P.; Liu, J.; Duan, S.; Huang, R. Variation Pattern of the Compressive Strength of Concrete under Combined Heat and Moisture Conditions. Materials 2023, 16, 1548. [Google Scholar] [CrossRef]

- Liu, C.; Chen, J. High Temperature Degradation Mechanism of Concrete with Plastering Layer. Materials 2022, 15, 398. [Google Scholar] [CrossRef]

- Wang, Y.-S.; Wu, J.-Y. An energy-based elastoplastic damage model for concrete at high temperatures. Int. J. Damage Mech. 2022. ahead of online. [Google Scholar] [CrossRef]

- Majorana, C.E.; Salomoni, V.; Schrefler, B.A. Hygrothermal and mechanical model of concrete at high temperature. Mat. Struct. 1998, 31, 378–386. [Google Scholar] [CrossRef]

- Yao, Y.; Guo, H.; Tan, K. An elastoplastic damage constitutive model of concrete considering the effects of dehydration and pore pressure at high temperatures. Mater. Struct. 2020, 53, 19. [Google Scholar] [CrossRef]

- Gernay, T.; Millard, A.; Franssen, J.-M. A multiaxial constitutive model for concrete in the fire situation: Theoretical formulation. Int. J. Solids Struct. 2013, 50, 3659–3673. [Google Scholar] [CrossRef]

- Davie, C.T.; Pearce, C.J.; Bićanić, N. Aspects of Permeability in Modelling of Concrete Exposed to High Temperatures. Trans. Porous. Med. 2012, 95, 627–646. [Google Scholar] [CrossRef]

- Hacıefendioğlu, K.; Akbulut, Y.; Nayır, S.; Başağa, H.B.; Altunışık, A.C. Automated Estimation of Exposed Temperature and Strength Changing Ratio for Fire-Damaged Concrete Using Deep Learning Method. Exp. Technol. 2022, 46, 793–810. [Google Scholar] [CrossRef]

- Danying, G.; Liangping, Z.; Gang, C. Compressive stress-strain relationship of fiber and nanosized material reinforced concrete in high temperature. China Civ. Eng. J. 2017, 50, 46–58. (In Chinese) [Google Scholar]

- Fu, Y. Study on High Temperature Resistance of Nano-Cementitious Materials; Zhejiang University: Hangzhou, China, 2014. (In Chinese) [Google Scholar]

- Elkady, H.M.; Yasien, A.M.; Elfeky, M.S.; Serag, M.E. Assessment of mechanical strength of nano silica concrete (NSC) subjected to elevated temperatures. J. Struct. Fire Eng. 2019, 10, 90–109. [Google Scholar] [CrossRef]

- Nachtane, M.; Tarfaoui, M.; Sassi, S.; El Moumen, A.; Saifaoui, D. An investigation of hygrothermal aging effects on high strain rate behaviour of adhesively bonded composite joints. Compos. Part B Eng. 2019, 172, 111–120. [Google Scholar] [CrossRef]

- Rawat, G.; Gandhi, S.; Murthy, Y.I. A critical assessment on the effect of nano-titanium dioxide on the properties of concrete. Gradevinar 2022, 74, 7. [Google Scholar] [CrossRef]

- Alobaidi, Y.M.; Hilal, N.N.; Faraj, R.H. An experimental investigation on the nano-fly ash preparation and its effects on the performance of self-compacting concrete at normal and elevated temperatures. Nanotechnol. Environ. Eng. 2021, 6, 2. [Google Scholar] [CrossRef]

- Zhang, Z. Influence of nano—SiO2 on mechanical properties of basalt fiber/concrete after heating at high temperatures. Compos. Sci. Eng. 2022, 4, 62–67. (In Chinese) [Google Scholar]

- Nikbin, I.M.; Mehdipour, S.; Dezhampanah, S.; Mohammadi, R.; Mohebbi, R.; Moghadam, H.H.; Sadrmomtazi, A. Effect of high temperature on mechanical and gamma ray shielding properties of concrete containing nano-TiO2. Radiat. Phys. Chem. 2020, 174, 108967. [Google Scholar] [CrossRef]

- Bastami, M.; Baghbadrani, M.; Aslani, F. Performance of nano-Silica modified high strength concrete at elevated temperatures. Constr. Build. Mater. 2014, 68, 402–408. [Google Scholar] [CrossRef]

- Xu, C.; Liao, H.-H.; Chen, Y.-L.; Du, X.; Peng, B.; Fernandez-Steeger, T.M. Corrosion Performance of Nano-TiO2-Modified Concrete under a Dry–Wet Sulfate Environment. Materials 2021, 14, 5900. [Google Scholar] [CrossRef] [PubMed]

- Xu, C.; Chen, Y.; Wang, S.; Javadi, A.; Du, X.; Azzam, R. Mechanical Properties of Tonalite Subjected to Combined Effects of Chemical Corrosion and Freeze-Thaw Cycles. Appl. Sci. 2019, 9, 3890. [Google Scholar] [CrossRef]

- GB 50081-2002; Standard for Test Method of Mechanical Properties on Ordinary Concrete [Standard]. China Architecture & Building Press: Beijing, China.

- Lemaitre, J. Coupled elasto-plasticity and damage constitutive equations. Comput. Methods Appl. Mech. Eng. 1985, 51, 31–49. [Google Scholar] [CrossRef]

- Chen, Q.; Chen, Y.; Xiao, P.; Du, X.; Pan, Y.; Azzam, R. Mechanical properties and damage constitutive model of sandstone after acid corrosion and high temperature treatments. Int. J. Min. Sci. Technol. 2023; in press. [Google Scholar] [CrossRef]

| Element | SiO2 | Al2O3 | CaO | Fe2O3 | MgO | SO3 |

|---|---|---|---|---|---|---|

| Cement | 22.02 | 5.2 | 64.42 | 5.23 | 1.02 | 2.1 |

| Element | Density/ g/cm3 | Melting Point °C | Boiling Point °C | Particle Size nm |

|---|---|---|---|---|

| nano-titanium dioxide | 4.260 | 1855 | 2900 | 25 |

| Group | Cement (kg/m3) | Limestone (kg/m3) | Sand (kg/m3) | Water (kg/m3) | Nano-Titanium Dioxide (kg/m3) |

|---|---|---|---|---|---|

| OC | 415 | 1224 | 583 | 177 | 0 |

| NTC3 | 402.550 | 1224 | 583 | 177 | 12.450 |

| Temperature/°C | No. | Peak Stress/MPa | Peak Strain/10−3 | 0.1 Times the Peak Stress/MPa | 0.1 Times the Peak Strain/10−3 | Approximate Secant Modulus/GPa |

|---|---|---|---|---|---|---|

| 20 | 1 | 42.630 | 2.234 | 4.263 | 1.035 | 31.999 |

| 2 | 42.130 | 2.057 | 4.213 | 1.087 | 39.090 | |

| 3 | 39.820 | 1.835 | 3.982 | 0.744 | 32.849 | |

| average value | 41.527 | 2.042 | 4.152 | 0.955 | 34.646 | |

| standard deviation | 1.224 | 0.163 | 0.122 | 1.151 | 3.161 | |

| 200 | 1 | 35.190 | 3.304 | 3.519 | 1.448 | 17.064 |

| 2 | 38.140 | 1.845 | 3.814 | 0.356 | 23.053 | |

| 3 | 41.690 | 2.739 | 4.169 | 0.920 | 20.627 | |

| average value | 37.943 | 3.558 | 3.794 | 1.448 | 16.700 | |

| standard deviation | 2.344 | 0.433 | 0.234 | 0.233 | 3.348 | |

| 400 | 1 | 41.170 | 2.961 | 4.117 | 1.199 | 21.029 |

| 2 | 35.670 | 3.741 | 3.567 | 1.759 | 16.197 | |

| 3 | 36.990 | 3.972 | 3.699 | 1.386 | 12.874 | |

| average value | 37.943 | 3.558 | 3.794 | 1.448 | 16.700 | |

| standard deviation | 2.344 | 0.433 | 0.234 | 0.233 | 3.348 | |

| 600 | 1 | 32.140 | 3.139 | 3.214 | 1.400 | 16.634 |

| 2 | 29.450 | 4.442 | 2.945 | 2.514 | 13.747 | |

| 3 | 33.170 | 3.616 | 3.317 | 1.626 | 15.002 | |

| standard deviation | 1.569 | 0.538 | 0.157 | 0.481 | 1.182 | |

| average value | 31.587 | 3.732 | 3.159 | 1.847 | 15.128 | |

| 800 | 1 | 25.960 | 4.007 | 2.596 | 2.534 | 15.862 |

| 2 | 20.880 | 3.430 | 2.088 | 1.881 | 12.132 | |

| 3 | 22.520 | 4.535 | 2.252 | 2.729 | 11.223 | |

| average value | 23.120 | 3.991 | 2.312 | 2.381 | 13.072 | |

| standard deviation | 2.117 | 0.451 | 0.212 | 0.363 | 2.007 |

| Temperature/°C | No. | Peak Stress/MPa | Peak Strain/10−3 | 0.1 Times the Peak Stress/MPa | 0.1 Times the Peak Strain/10−3 | Approximate Secant Modulus/GPa |

|---|---|---|---|---|---|---|

| 20 | 1 | 51.370 | 2.568 | 5.137 | 1.192 | 33.600 |

| 2 | 50.220 | 3.019 | 5.022 | 1.332 | 26.792 | |

| 3 | 48.130 | 2.427 | 4.813 | 1.126 | 33.295 | |

| average value | 49.907 | 2.671 | 4.991 | 1.217 | 31.229 | |

| standard deviation | 1.341 | 0.252 | 0.134 | 0.859 | 3.140 | |

| 200 | 1 | 49.60 | 3.068 | 4.960 | 1.460 | 20.977 |

| 2 | 48.680 | 2.940 | 4.868 | 0.975 | 22.296 | |

| 3 | 47.910 | 3.738 | 4.791 | 1.883 | 23.245 | |

| average value | 48.730 | 3.249 | 4.873 | 1.439 | 22.173 | |

| standard deviation | 0.691 | 0.350 | 0.070 | 0.371 | 0.930 | |

| 400 | 1 | 43.950 | 3.220 | 4.395 | 1.179 | 19.380 |

| 2 | 42.010 | 4.163 | 4.201 | 2.014 | 17.594 | |

| 3 | 46.430 | 3.284 | 4.643 | 1.332 | 21.407 | |

| average value | 44.130 | 3.556 | 4.413 | 1.508 | 19.46 | |

| standard deviation | 1.809 | 0.430 | 0.181 | 0.363 | 1.558 | |

| 600 | 1 | 37.150 | 3.170 | 3.715 | 1.146 | 16.519 |

| 2 | 35.320 | 3.361 | 3.532 | 1.499 | 17.072 | |

| 3 | 31.520 | 2.984 | 3.152 | 1.120 | 15.219 | |

| average value | 34.663 | 3.172 | 3.466 | 1.255 | 16.270 | |

| standard deviation | 2.345 | 0.154 | 0.234 | 0.173 | 0.777 | |

| 800 | 1 | 27.580 | 3.961 | 2.758 | 1.775 | 11.355 |

| 2 | 22.320 | 3.012 | 2.232 | 1.330 | 11.943 | |

| 3 | 23.920 | 3.619 | 2.392 | 1.330 | 9.405 | |

| average value | 24.607 | 3.531 | 2.461 | 1.4780 | 10.901 | |

| standard deviation | 2.202 | 0.392 | 0.220 | 0.210 | 1.085 |

| 20 | 70.8039 | 21.307 | 4.759893 | 0.300931 | 1.4324 |

| 200 | 31.4246 | 16.137 | 3.876739 | 0.513524 | 1.9908 |

| 400 | 22.2528 | 18.239 | 2.721436 | 0.819641 | 2.2306 |

| 600 | 30.2136 | 14.205 | 6.508785 | 0.470149 | 3.0601 |

| 800 | 26.7927 | 14.784 | 5.805952 | 0.551796 | 3.2037 |

| 20 | 41.53 | 3.4 | 0.586550 | 1.349064 | 2.6664 |

| 200 | 35.19 | 2.8 | 1.119823 | 3.355044 | 3.8865 |

| 400 | 36.96 | 2.4 | 1.660915 | 3.986195 | 4.5632 |

| 600 | 29.45 | 4.6 | 0.974780 | 4.483986 | 5.3598 |

| 800 | 25.96 | 4.1 | 0.968854 | 3.993900 | 5.5234 |

| 20 | 48.13 | 41.53 | 1.159 |

| 200 | 47.91 | 38.34 | 1.250 |

| 400 | 46.43 | 37.94 | 1.224 |

| 600 | 35.32 | 31.59 | 1.118 |

| 800 | 22.32 | 25.96 | 0.860 |

| 20 | 46.08 | 20.410 | 3.6 | 0.443 | 1.596 |

| 200 | 33.50 | 29.483 | 3.3 | 0.880 | 2.920 |

| 400 | 31.83 | 29.170 | 2.7 | 0.916 | 2.429 |

| 600 | 23.95 | 22.703 | 2.8 | 0.948 | 2.615 |

| 800 | 17.47 | 12.514 | 3.0 | 0.716 | 2.129 |

| 20 | 48.13 | 2.3 | 1.044 | 2.427 | 2.824 |

| 200 | 47.91 | 2.6 | 1.430 | 3.738 | 4.292 |

| 400 | 46.43 | 2.3 | 1.459 | 3.284 | 3.758 |

| 600 | 35.32 | 2.3 | 1.475 | 3.361 | 4.931 |

| 800 | 22.32 | 2.4 | 1.278 | 3.012 | 3.665 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, D.; Wang, Z.; Pan, Y.; Huang, J.; Fernández-Steeger, T.M.; Xu, C.; Tang, X.; Long, Z.; Tang, Y. Study on the Constitutive Relationship between Ordinary Concrete and Nano-Titanium Dioxide-Modified Concrete at High Temperature. Materials 2023, 16, 4910. https://doi.org/10.3390/ma16144910

Wu D, Wang Z, Pan Y, Huang J, Fernández-Steeger TM, Xu C, Tang X, Long Z, Tang Y. Study on the Constitutive Relationship between Ordinary Concrete and Nano-Titanium Dioxide-Modified Concrete at High Temperature. Materials. 2023; 16(14):4910. https://doi.org/10.3390/ma16144910

Chicago/Turabian StyleWu, Dongpeng, Zhicheng Wang, Yungui Pan, Jian Huang, Tomás Manuel Fernández-Steeger, Chao Xu, Xinlong Tang, Zhiyu Long, and Yufei Tang. 2023. "Study on the Constitutive Relationship between Ordinary Concrete and Nano-Titanium Dioxide-Modified Concrete at High Temperature" Materials 16, no. 14: 4910. https://doi.org/10.3390/ma16144910

APA StyleWu, D., Wang, Z., Pan, Y., Huang, J., Fernández-Steeger, T. M., Xu, C., Tang, X., Long, Z., & Tang, Y. (2023). Study on the Constitutive Relationship between Ordinary Concrete and Nano-Titanium Dioxide-Modified Concrete at High Temperature. Materials, 16(14), 4910. https://doi.org/10.3390/ma16144910