The Effect of Preconditioning Temperature on Gas Permeability of Alkali-Activated Concretes †

Abstract

1. Introduction

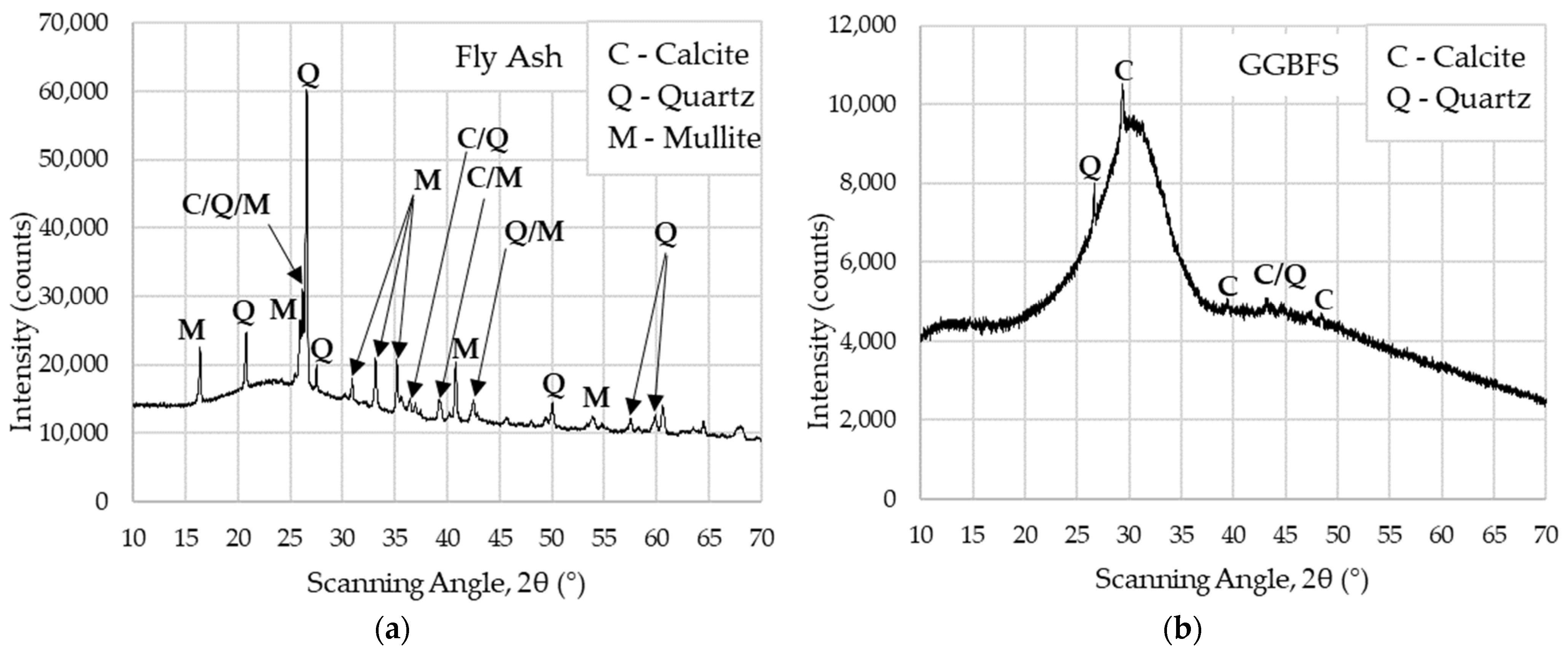

2. Materials

3. Methods

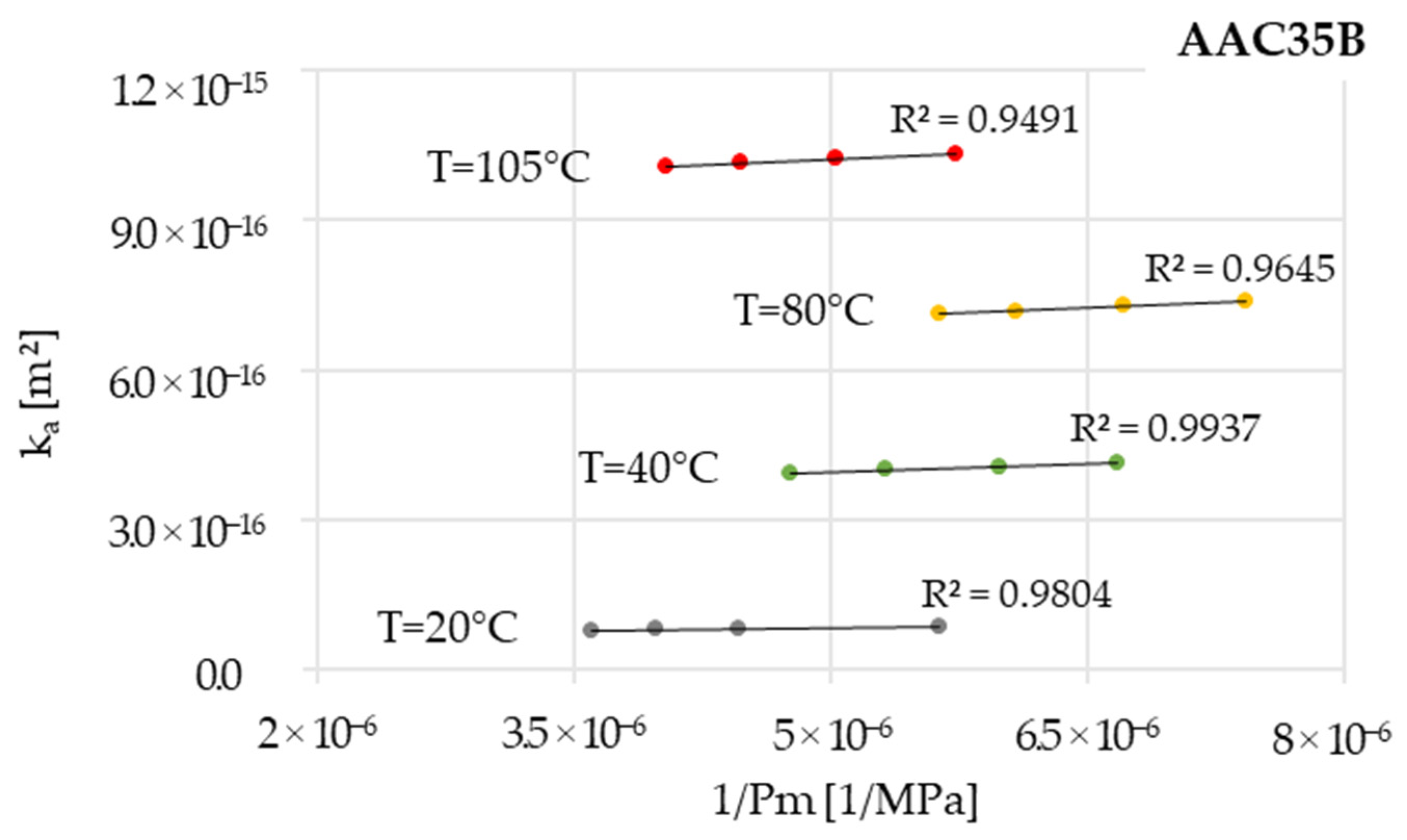

- kA—apparent permeability, m2;

- µ—viscosity of the gas at 20 ± 2 °C, Pa × s;

- L—thickness of the specimen, m;

- P1—inlet pressure, Pa;

- P2—outlet (atmospheric) pressure, Pa;

- Q—flow rate, m3/s;

- A—cross-sectional area of the specimen, m2.

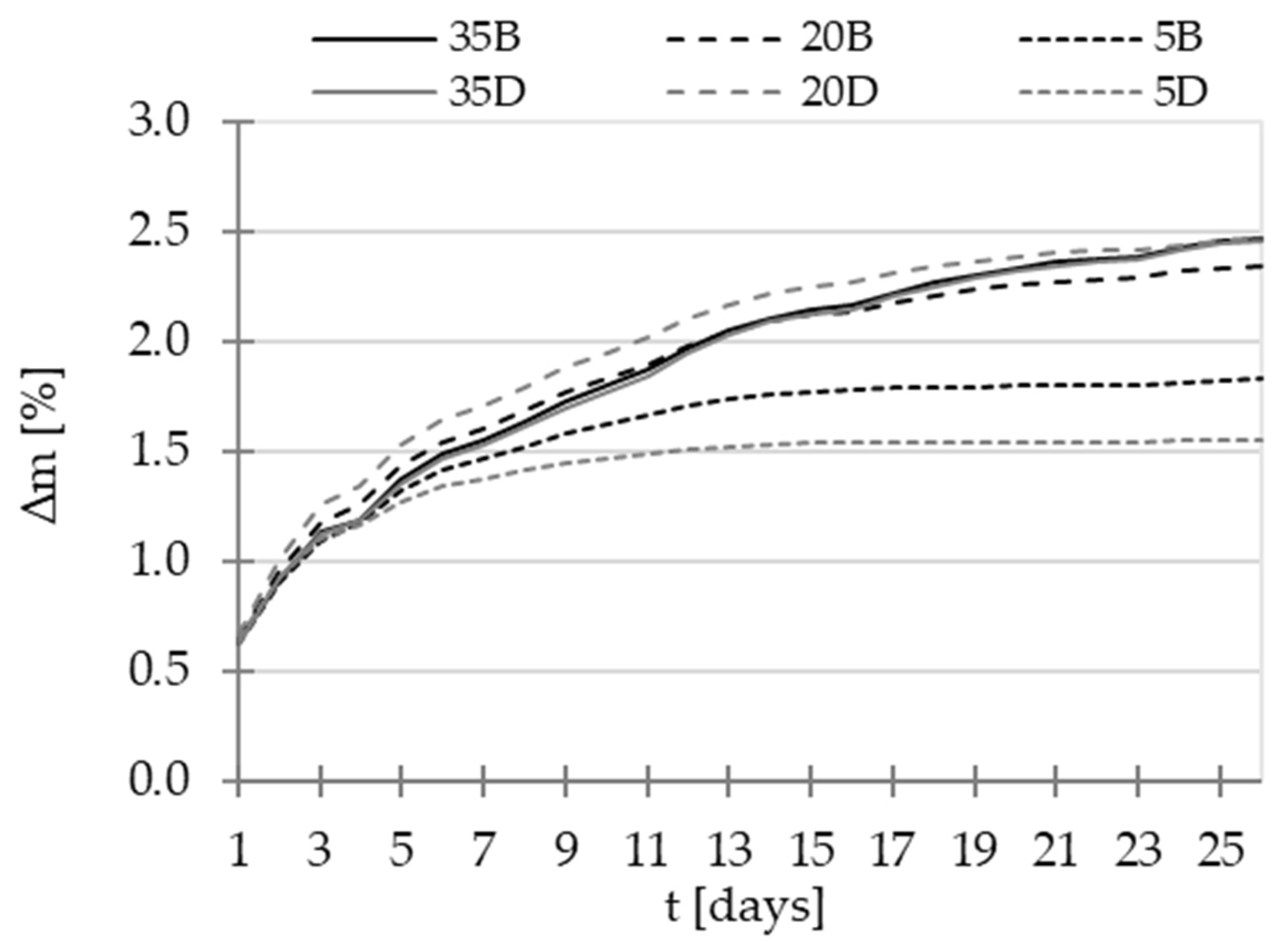

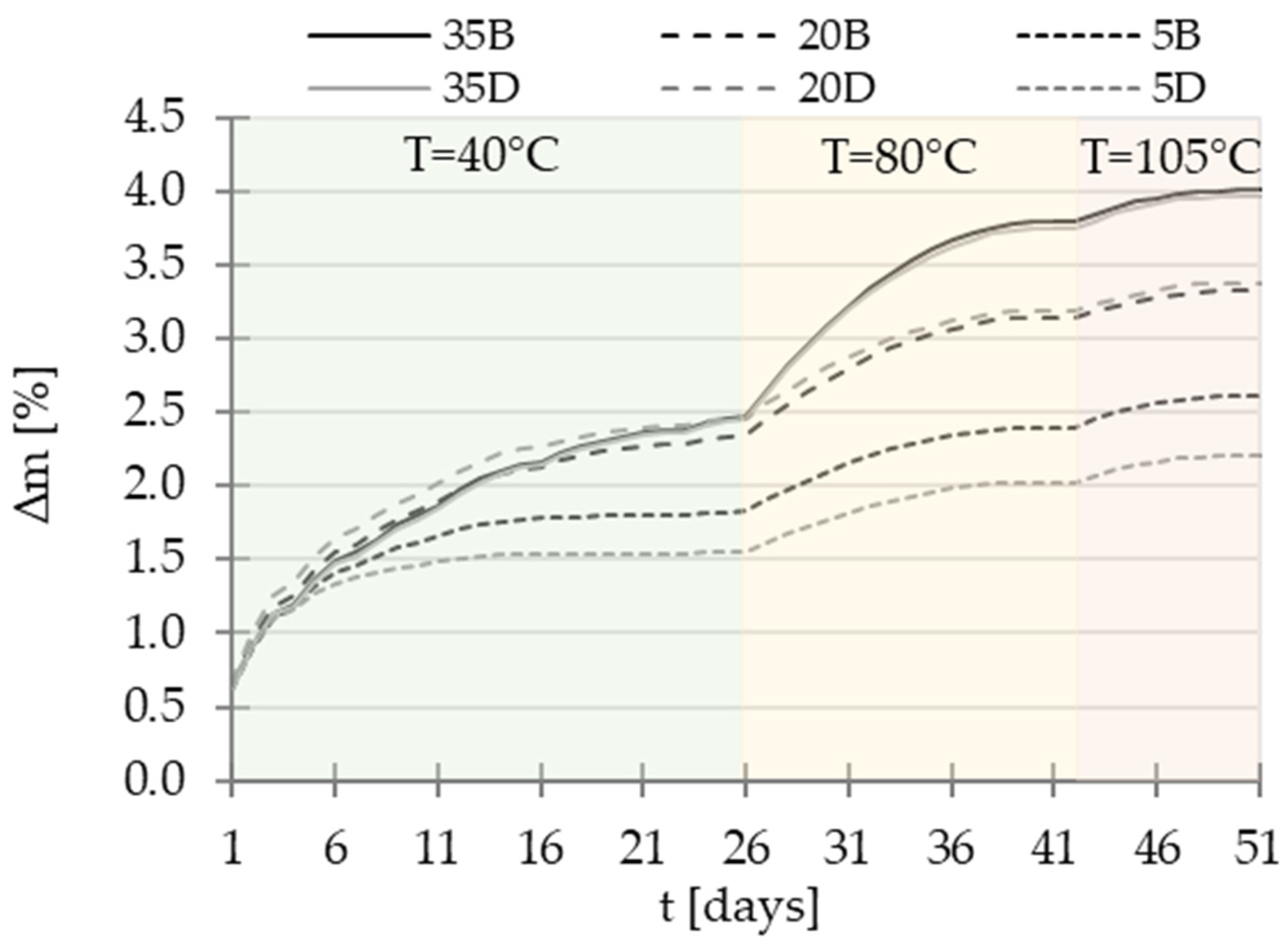

4. Results and Discussion

5. Conclusions

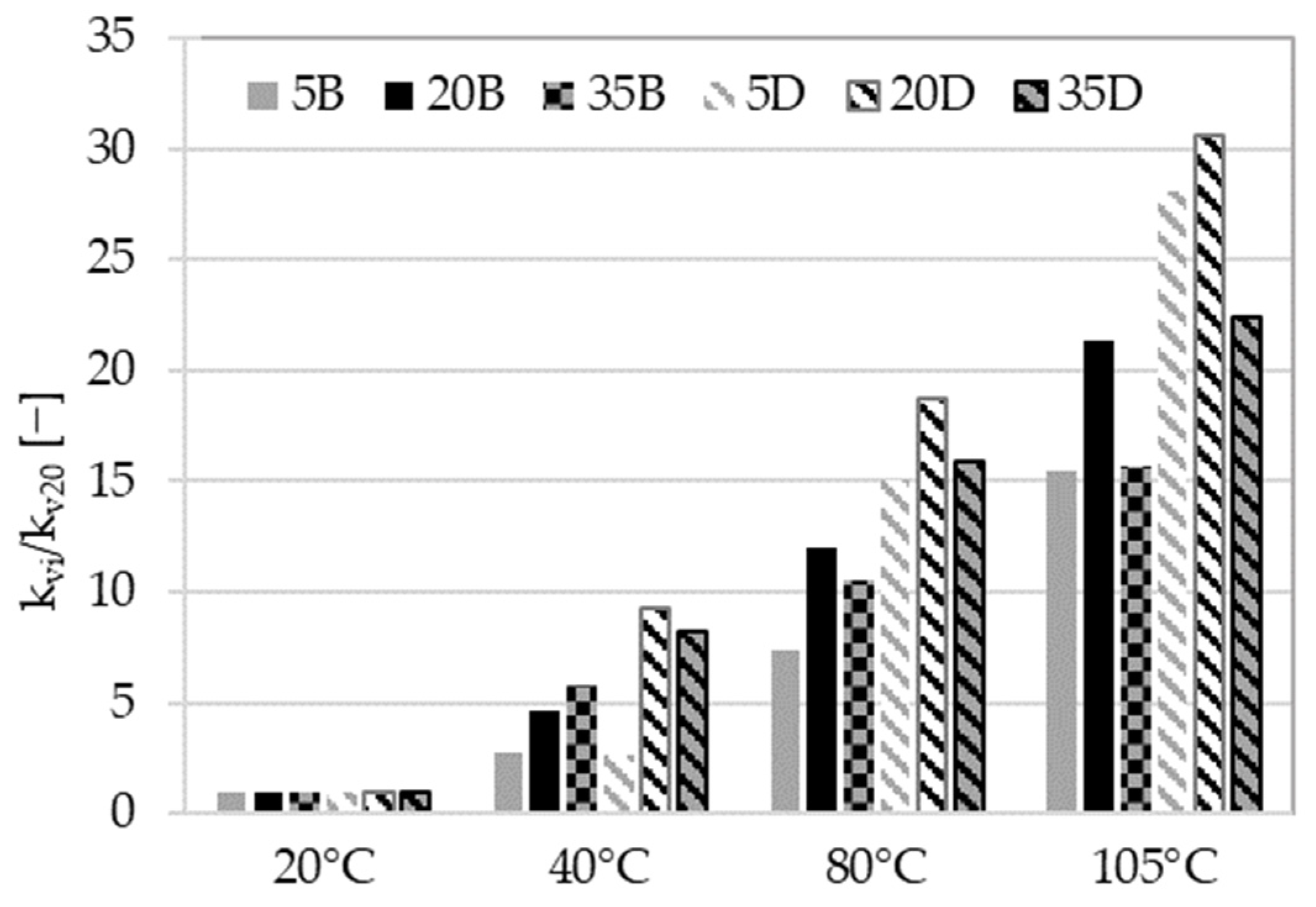

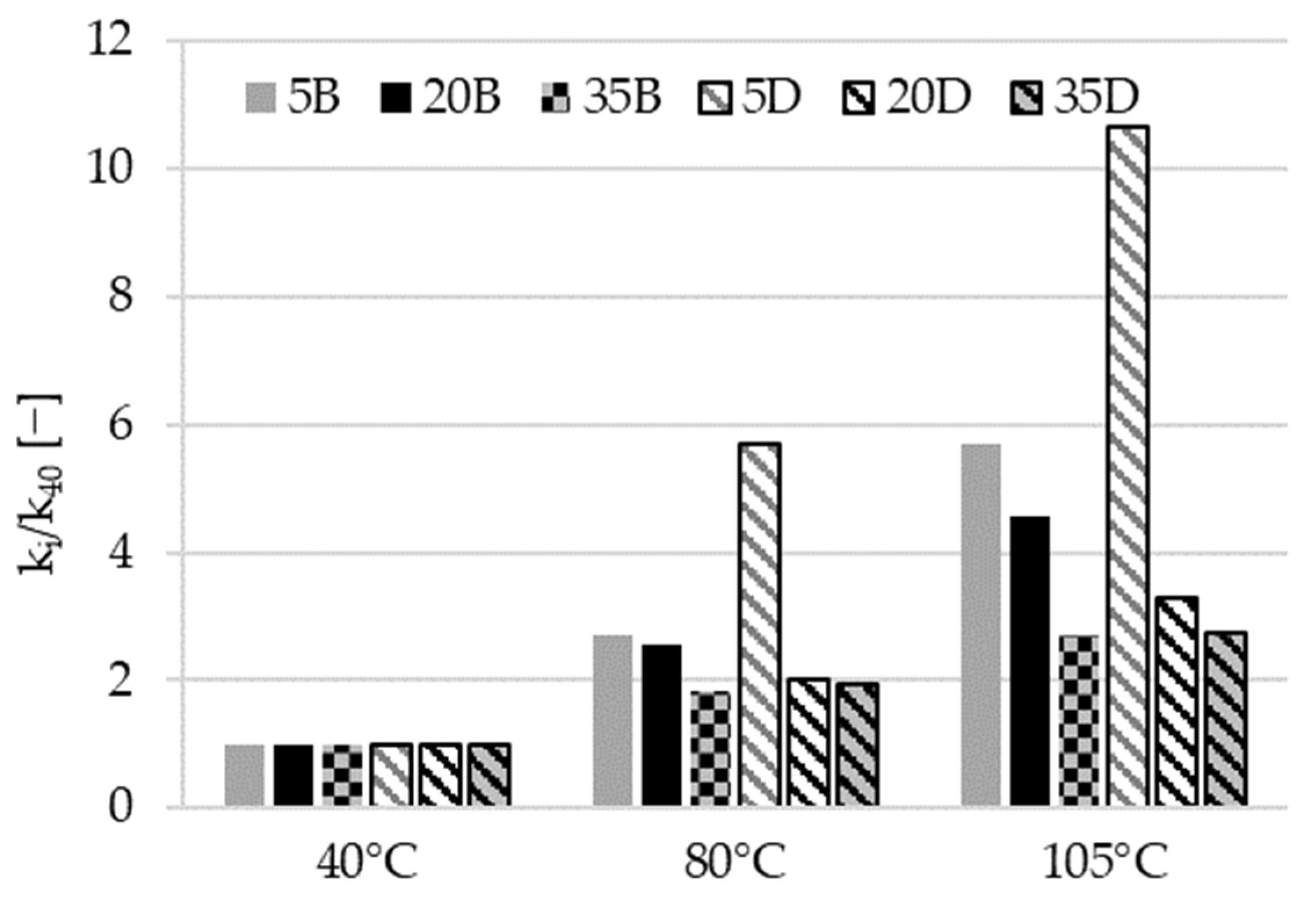

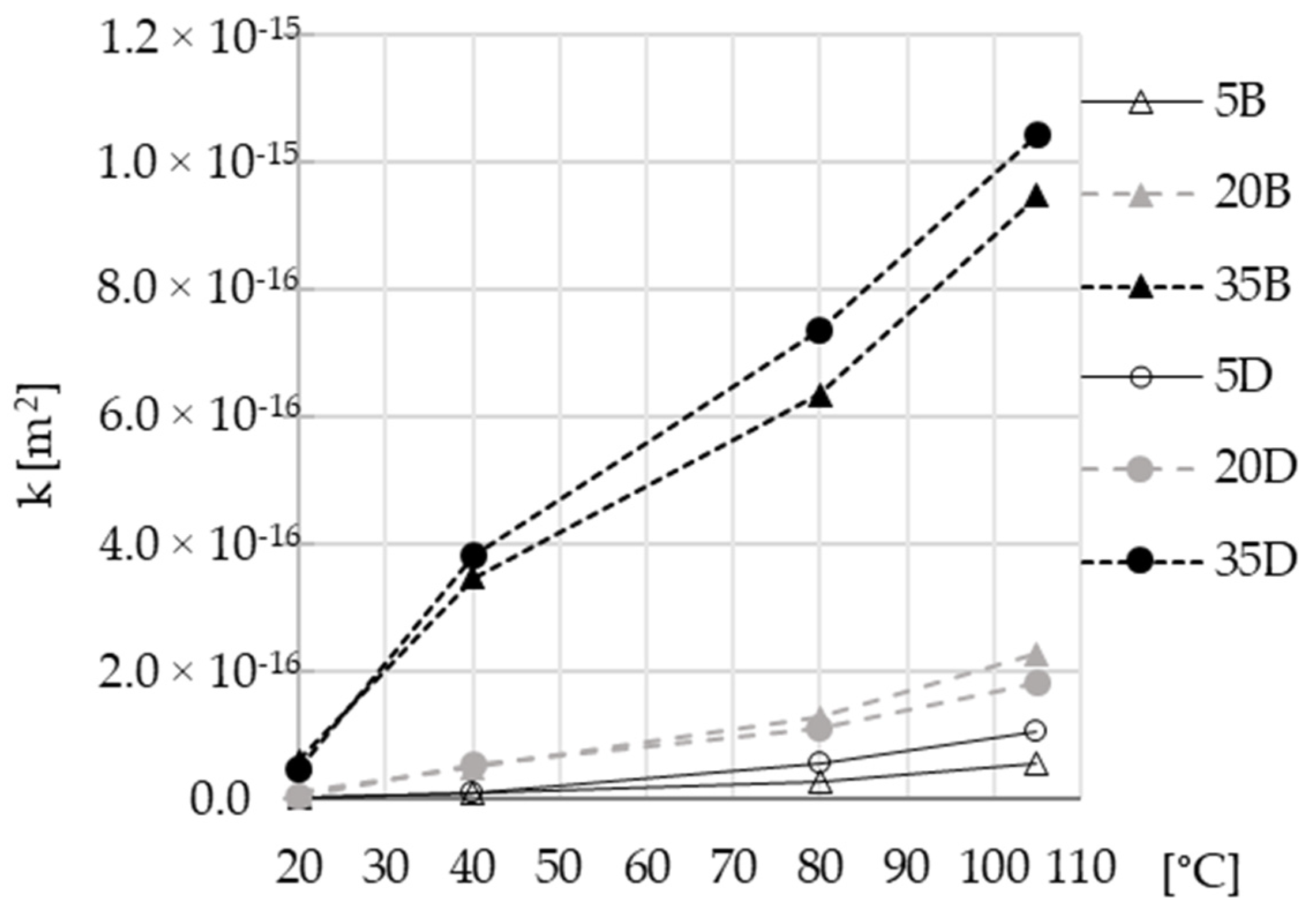

- The obtained permeability values are significantly affected by the drying temperature of the samples: the permeability may attain over a thirty-fold increase of its initial value after pretreatment at 105 °C;

- The effect of temperature on AAC permeability is strongly related to the precursor used and the nature of the aggregate. In general, the materials with low slag content (AAC5) have the lowest values of permeability for all the types of aggregate used. However, the permeability values for AAC with dolomite aggregate increase more significantly than for those with basalt aggregate for almost all of the tested temperatures;

- The main causes of permeability increases with temperature preconditioning are microstructure changes linked particularly with pore size increases, while the total porosity impact seems to be negligible;

- The interplay between preconditioning temperature and pore structure in concretes is a complex phenomenon that is contingent upon the composition of the precursor and the coarse aggregate used. These two factors independently modulate the gas permeability of concrete under varying temperature conditions;

- Permeability test reports need to include sample preconditioning conditions to enable the correct interpretation of results;

- The gas permeability of materials with the same binder could be compared under the same standardized conditions, taking into consideration the influence of aggregate type and the quality of the zone between the paste and the aggregate.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bernal, S.A.; Bílek, V.; Criado, M.; Fernández-Jiménez, A.; Kavalerova, E.; Krivenko, P.V.; Palacios, M.; Palomo, A.; Provis, J.L.; Puertas, F.; et al. Durability and testing—Degradation via mass transport. In RILEM State-of-the-Art Reports: Alkali Activated Materials; Provis, J.L., van Deventer, J.S.J., Eds.; Springer: Dordrecht, The Netherlands; Heidelberg, Germany; New York, NY, USA; London, UK, 2014; Volume 13, pp. 223–276. [Google Scholar]

- Meyer, C. The greening of the concrete industry. Cem. Concr. Compos. 2009, 31, 601–605. [Google Scholar] [CrossRef]

- Decky, M.; Papanova, Z.; Juhas, M.; Kudelcikova, M. Evaluation of the Effect of Average Annual Temperatures in Slovakia between 1971 and 2020 on Stresses in Rigid Pavements. Land 2022, 11, 764. [Google Scholar] [CrossRef]

- Li, K.F. Durability Design of Concrete Structure: Phenomena, Modeling and Application; Wily & Sons: London, UK, 2016. [Google Scholar]

- Beushausen, H.; Luco, L.F. Performance-Based Specifications and Control of Concrete Durability, RILEM State-of-the-Art Reports RILEM TC 230-PSC; Springer: Dordrecht, The Netherlands, 2016. [Google Scholar]

- Stanish, K.D.; Hooton, R.D.; Thomas, M.D. Testing the Chloride Penetration Resistance of Concrete: A Literature Review; FHWA: Washington, DC, USA, 1997. [Google Scholar]

- Katz, A.J.; Thompson, A.H. Quantitative prediction of permeability. Phys. Rev. B 1986, 34, 8179–8181. [Google Scholar] [CrossRef] [PubMed]

- Kropp, J. Permeability of Concrete as a Criterion of its Durability. Mater. Struct./Matériaux Constr. 1999, 32, 5. [Google Scholar]

- Cather, R.; Figg, J.W.; Marsden, A.F.; O’Brien, T.P. Improvements to the figg method for determining the air permeability of concrete. Mag. Concr. Res. 2015, 36, 241–245. [Google Scholar] [CrossRef]

- Kropp, J.; Hilsdorf, H.K. Performance Criteria for Concrete Durability, State-of-the-Art Report of RILEM TC116-PCD; E&FN Spon: London, UK, 1995. [Google Scholar]

- Yang, K.; Basheer, P.A.M.; Bai, Y.; Magee, B.J.; Long, A.E. Development of a new in situ test method to measure the air permeability of high performance concretes. NDT Int. 2014, 64, 30–40. [Google Scholar] [CrossRef]

- Romer, M. Effect of moisture and concrete composition on the Torrent permeability measurement. Mater. Struct. 2005, 38, 541–547. [Google Scholar] [CrossRef]

- Zhang, D.; Li, K. Concrete gas permeability from different methods: Correlation analysis. Cem. Concr. Compos. 2019, 104, 103379. [Google Scholar] [CrossRef]

- Alexander, M.G. Service life design and modelling of concrete structures—Background, developments, and implementation. Rev. ALCONPAT 2018, 8, 224–245. [Google Scholar] [CrossRef]

- XP P18-463; French Standards, Concretes—Gas Permeability Test on Hardened Concrete. Available online: https://www.boutique.afnor.org/en-gb/standard/xp-p18463/concrete-testing-gas-permeability-on-hardened-concrete/fa175662/38414 (accessed on 29 May 2023).

- Provis, J.; Ismail, I.; Myers, R.; Rose, V.; Van Deventer, J. Characterising the Structure and Permeability of Alkali-Activated Binders. In Proceedings of the International RILEM Conference on Advances in Construction Materials Through Science and Engineering, Hong Kong, China, 5–7 September 2011. [Google Scholar]

- Sogbossi, H.; Verdier, J.; Multon, S. Permeability and damage of partially saturated concrete exposed to elevated temperature. Cem. Concr. Compos. 2020, 109, 103563. [Google Scholar] [CrossRef]

- Sitarz, M.; Hager, I.; Kochanek, J. Effect of High Temperature on Mechanical Properties of Geopolymer Mortar. MATEC Web Conf. 2018, 163, 06004. [Google Scholar] [CrossRef]

- Criado, M.; Palomo, A.; Fernández-Jiménez, A. Alkali activation of fly ashes. Part 1: Effect of curing conditions on the carbonation of the reaction products. Fuel 2005, 84, 2048–2054. [Google Scholar] [CrossRef]

- Dudek, M.; Sitarz, M. Analysis of changes in the microstructure of geopolymer mortar after exposure to high temperatures. Materials 2020, 13, 4263. [Google Scholar] [CrossRef] [PubMed]

- Poornima, N.; Katyal, D.; Revathi, T.; Sivasakthi, M.; Jeyalakshmi, R. Effect of curing on mechanical strength and microstructure of fly ash blend GGBS geopolymer, Portland cement mortar and its behavior at elevated temperature. Mater. Today Proc. 2021, 47, 863–870. [Google Scholar] [CrossRef]

- Runci, A.; Serdar, M. Effect of curing time on the chloride diffusion of alkali-activated slag. Case Stud. Constr. Mater. 2022, 16, e00927. [Google Scholar] [CrossRef]

- Noushini, A.; Castel, A. The effect of heat-curing on transport properties of low-calcium fly ash-based geopolymer concrete. Constr. Build. Mater. 2016, 112, 464–477. [Google Scholar] [CrossRef]

- Chi, M. Effects of dosage of alkali-activated solution and curing conditions on the properties and durability of alkali-activated slag concrete. Constr. Build. Mater. 2012, 35, 240–245. [Google Scholar] [CrossRef]

- Swanepoel, J.C.; Strydom, C.A. Utilisation of fly ash in a geo- polymeric material. Appl. Geochem. 2002, 17, 1143–1148. [Google Scholar] [CrossRef]

- Fernandez-Jimenez, A.; Palomo, A. Alkali-activated fly ashes: Properties and characteristics. In Proceedings of the 11th International Congress on the Chemistry of Cement, Durban, South Africa, 11–16 May 2003; pp. 1332–1340. [Google Scholar]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-activated fly ashes, a cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Jiang, W.; Roy, D. Hydrothermal processing of new fly ash cement. Ceram. Bull. 1990, 71, 642–647. [Google Scholar]

- Bakharev, T. Geopolymeric materials prepared using Class F fly ash and elevated temperature curing. Cem. Concr. Res. 2005, 35, 1224–1232. [Google Scholar] [CrossRef]

- Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete; ASTM International: West Conshohocken, PA, USA, 2019.

- Aughenbaugh, K.L.; Stutzman, P.; Juenger, M.C.G. Identifying glass compositions in fly ash. Front. Mater. 2016, 3, 1. [Google Scholar] [CrossRef]

- Kalombe, R.M.; Ojumu, V.T.; Eze, C.P.; Nyale, S.M.; Kevern, J.; Petrik, L.F. Fly ash-based geopolymer building materials for green and sustainable development. Materials 2020, 13, 5699. [Google Scholar] [CrossRef] [PubMed]

- Hager, I.; Sitarz, M.; Mróz, K. Fly-ash based geopolymer mortar for high-temperature application—Effect of slag addition. J. Clean. Prod. 2021, 316, 128168. [Google Scholar] [CrossRef]

- Kollek, J.J. The determination of the permeability of concrete to oxygen by the Cembureau method—A recommendation. Mater. Struct. 1989, 22, 225–230. [Google Scholar] [CrossRef]

- Lide, D.R.; Frederikse, H.P.R. CRC Handbook of Chemistry and Physics, 84th ed.; CRC Press LLC: New York, NY, USA, 2003; p. 1004. [Google Scholar]

- Zhang, J.; Jin, T.; He, Y.; Wang, Y.; Gao, Y.; Zhang, Y. The slippage effect of concrete gas permeability and the influence of its microstructure. Constr. Build. Mater. 2022, 333, 127384. [Google Scholar] [CrossRef]

- Pei, Y.; Agostini, F.; Skoczylas, F. The effects of high temperature heating on the gas permeability and porosity of a cementitious material. Cem. Concr. Res. 2017, 95, 141–151. [Google Scholar] [CrossRef]

- Choinska, M. Effets de la Température, du Chargement Mécanique et de Leurs Interactions sur la Perméabilité du Béton de Structure; Ecole Centrale de Nantes (ECN), University of Nantes: Nantes, France, 2006. [Google Scholar]

| wt.% | SiO2 | Al2O3 | FexOy | CaO | MgO | SO3 | K2O | Na2O | P2O5 | TiO2 | Mn3O4 | Cl− |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| FA | 52.30 | 28.05 | 6.32 | 3.05 | 1.71 | 0.28 | 2.51 | 0.76 | 0.69 | 1.35 | 0.07 | - |

| GGBFS | 39.31 | 7.61 | 1.49 | 43.90 | 4.15 | 0.51 | 0.36 | 0.47 | - | - | - | 0.04 |

| Characteristic | Unit | Woellner Geosil® 34417 |

|---|---|---|

| Na2O content | wt.% | 16.74 |

| SiO2 content | wt.% | 27.5 |

| Density | g/cm3 | 1.552 |

| Viscosity | mPa × s | 470 |

| Weight ratio (WR = wt.% SiO2/wt. Na2O) | - | 1.64 |

| Molar ratio (MR = mol SiO2/mol Na2O) | - | 1.70 |

| AAC5B | AAC20B | AAC35B | AAC5D | AAC20D | AAC35D | |

|---|---|---|---|---|---|---|

| Porosity 20 °C (%) | 14.87 | 11.77 | 7.30 | 14.51 | 13.27 | 10.91 |

| Porosity 105 °C (%) | 17.96 | 13.14 | 10.44 | 15.42 | 13.57 | 9.94 |

| AAC5B | AAC20B | AAC35B | AAC5D | AAC20D | AAC35D | |

|---|---|---|---|---|---|---|

| k20 (m2) | 3.53 × 10−18 | 1.08 × 10−17 | 6.07 × 10−17 | 3.81 × 10−18 | 6 × 10−18 | 4.65 × 10−17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duży, P.; Colombel, M.C.; Hager, I.; Amiri, O. The Effect of Preconditioning Temperature on Gas Permeability of Alkali-Activated Concretes. Materials 2023, 16, 4143. https://doi.org/10.3390/ma16114143

Duży P, Colombel MC, Hager I, Amiri O. The Effect of Preconditioning Temperature on Gas Permeability of Alkali-Activated Concretes. Materials. 2023; 16(11):4143. https://doi.org/10.3390/ma16114143

Chicago/Turabian StyleDuży, Patrycja, Marta Choinska Colombel, Izabela Hager, and Ouali Amiri. 2023. "The Effect of Preconditioning Temperature on Gas Permeability of Alkali-Activated Concretes" Materials 16, no. 11: 4143. https://doi.org/10.3390/ma16114143

APA StyleDuży, P., Colombel, M. C., Hager, I., & Amiri, O. (2023). The Effect of Preconditioning Temperature on Gas Permeability of Alkali-Activated Concretes. Materials, 16(11), 4143. https://doi.org/10.3390/ma16114143