Abstract

Predicting the punching shear strength (PSS) of fiber-reinforced polymer reinforced concrete (FRP-RC) beams is a critical task in the design and assessment of reinforced concrete structures. This study utilized three meta-heuristic optimization algorithms, namely ant lion optimizer (ALO), moth flame optimizer (MFO), and salp swarm algorithm (SSA), to select the optimal hyperparameters of the random forest (RF) model for predicting the punching shear strength (PSS) of FRP-RC beams. Seven features of FRP-RC beams were considered as inputs parameters, including types of column section (TCS), cross-sectional area of the column (CAC), slab’s effective depth (SED), span–depth ratio (SDR), compressive strength of concrete (CSC), yield strength of reinforcement (YSR), and reinforcement ratio (RR). The results indicate that the ALO-RF model with a population size of 100 has the best prediction performance among all models, with MAE of 25.0525, MAPE of 6.5696, R2 of 0.9820, and RMSE of 59.9677 in the training phase, and MAE of 52.5601, MAPE of 15.5083, R2 of 0.941, and RMSE of 101.6494 in the testing phase. The slab’s effective depth (SED) has the largest contribution to predicting the PSS, which means that adjusting SED can effectively control the PSS. Furthermore, the hybrid machine learning model optimized by metaheuristic algorithms outperforms traditional models in terms of prediction accuracy and error control.

1. Introduction

Fiber-reinforced polymers (FRPs) are increasingly used as a substitute for traditional steel reinforcement in civil engineering due to their lightweight, corrosion-resistant, and high-strength properties [1]. Composite structures of fiber-reinforced polymers (FRP) and concrete contribute to enhance the resistance and stiffness of structures while reducing the susceptibility of concrete to external corrosion [2]. Consequently, such structures are suitable for applications in retrofitting, rehabilitation, and repair projects [3,4,5]. As a critical structural element in the building construction, the performance assessment of FRP-reinforced concrete (RC) beams became a research hotspot and difficulty [6,7,8,9,10]. The composite structure of FRP-RC has the potential to improve the load-bearing capacity, durability, and sustainability of beams, making it an attractive option for a variety of construction applications. However, the shear strength of FRP-RC beams plays an important role in structural design, but it is difficult to calculate accurately.

The shear strength of FRP-RC beams can be calculated using experimental methods [8,11,12,13], numerical simulations [6,14,15,16], and artificial intelligence (AI) prediction methods [17,18,19]. Experimental analysis serves as an intuitive method for evaluating the performance of beams. However, using traditional mechanical methods to explain the shear behavior of FRP-RC beams is a challenging task [20]. This complexity significantly increases the costs associated with human resources, materials, and time. Numerical simulation methods demonstrated efficacy in analyzing the shear strength of FRP-RC beams. Nevertheless, the required loading conditions of the beams must be assumed for the practical applications, and obtaining valuable experimental data for modeling purposes is generally difficult. Furthermore, the mathematical structure of the models tends to be rather extensive, which complicates the model-building process [19]. Consequently, there is a need for a more efficient and accurate approach to predict the shear strength of FRP-RC beams.

With the continuous advancement of computer technology, artificial intelligence (AI) techniques represented by machine learning (ML) models are increasingly applied in the field of civil engineering, particularly in the prediction of the performance of RC beams [21,22,23,24,25,26,27,28,29,30]. Mansour et al. [31] utilized the artificial neural network (ANN) model to predict the shear performance of RC beams. The prediction results show that the ANN model can significantly improve the prediction accuracy compared to the empirical formula method. However, the development of the ANN model requires the determination and definition of its structure and parameters, which is time-consuming [32]. Abuodeh et al. [19] employed the resilient back-propagating neural network (RBPNN) model to explore the enhancement effects of FRP on the shear stress of RC beams. They analyzed the impact of various factors on the shear capacity of FRP-RC beams. Kaloop et al. [33] obtained promising results in predicting the shear strength of RC deep beams using the support vector regression (SVR) optimized by the African vultures optimization algorithm (AVOA), achieving a maximum error of ±3.39%. However, the performance of the BPNN model is heavily reliant on the quality and quantity of input data, and insufficient or unsuitable data potentially will lead to overfitting [34]. The SVR model is sensitive to the selection of the kernel function and hyperparameter values [35], and the prediction of the shear strength of FRP-RC beams is a complex nonlinear problem, which makes it difficult to select an appropriate kernel function.

Random forest (RF) is a type of ensemble ML model proposed by Breiman [36], which combines multiple decision trees to improve robustness and prevent overfitting. The feature importance scores provided by the RF model further improve the interpretability of the model. Owing to its exceptional performance, RF was extensively employed in predicting the mechanical properties of reinforced concrete (RC) in construction engineering [37,38,39,40,41]. Mohammed et al. [42] compared the performance of support vector machines (SVM) and RF models for predicting the shear strength of RC beams and found that the RF model has a better prediction accuracy than the SVM model. Zhang et al. [32] compared the prediction performance of the BPNN and RF models for estimating the shear strength of RC beams with and without stirrups. The results show that the RF model significantly outperformed the BPNN model. Feng et al. [20] conducted a comparison of various ML models and discovered that the RF model has strong performance for predicting the lateral strength of reinforced concrete (RC) walls, effectively estimating the shear strength of RC materials. In light of the aforementioned literature, it can be concluded that the RF model exhibits outstanding performance for predicting the shear strength of FRP-RC beams. Metaheuristic optimization algorithms represent a category of optimization techniques inspired by natural processes, frequently employed to determine the optimal combination of hyperparameters for improving the performance of ML models [43], and their efficiency in searching complex search spaces was applied in civil engineering [44]. Moayedi et al. [45] used the ant lion optimizer (ALO) to predict the soil shear strength, significantly improving the prediction accuracy of the ANN model. Huang et al. [46] used the moth–flame optimization (MFO) to improve the prediction accuracy of damage in concrete beams. Khajehzadeh et al. [47] used the salp swarm algorithm (SSA) to optimize the design of steel-reinforced concrete cantilever retaining walls and shallow foundation engineering structures. It is evident that the application of these metaheuristic algorithms can effectively enhance the predictive performance of the ML method in the field of structural engineering.

This paper aims to predict the punching shear strength (PSS) of FRP-RC beams using the RF model optimized by three metaheuristic algorithms (ALO, MFO, and SSA). The predictive performance of these hybrid models was compared and the best one was selected to predict the PSS of FRP-RC beams. The paper is organized as follows: Section 2 presents the three metaheuristic algorithms coupled with the RF model. Then, the preparation of the punching shear strength database for FRP-RC beams, the data processing, and the model evaluation metrics and interpretation methods are described in Section 3. Section 4 presents the predictive performance of the models and compares their performance. In this Section, feature importance analysis is adopted for the interpretation of model prediction performance. Finally, Section 5 summarizes the findings of the study and provides recommendations for future research.

2. Methodologies

2.1. Random Forest

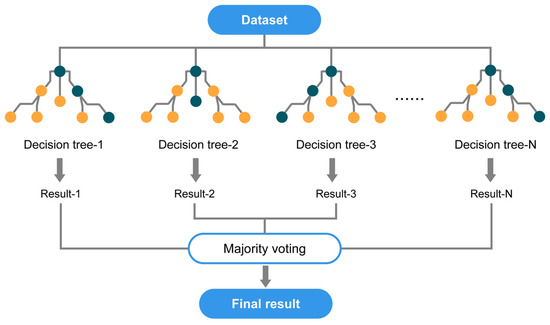

The random forest algorithm is a versatile and widely used ensemble learning technique in the field of machine learning and data science. It was first introduced by Leo Breiman in 2001 [36], combining the strengths of multiple decision tree models to improve overall accuracy and robustness [48], as shown in Figure 1. The key principle behind the random forest algorithm is the creation of numerous decision trees during the training phase, which then vote collectively to make a final prediction:

Figure 1.

Algorithm flow of random forest.

- (a)

- Bagging: The algorithm employs a technique known as bootstrap aggregating, or “bagging.” This process involves constructing multiple decision trees by randomly sampling the training data with replacement, which results in a diverse set of trees;

- (b)

- Feature randomness: At each node of the decision tree, the algorithm selects a random subset of features rather than using all features to make a split. This approach introduces additional randomness and further diversifies the individual trees, making the final model more robust;

- (c)

- Voting mechanism: During the prediction phase, each tree in the random forest contributes its independent decision, and the final prediction is determined by a majority vote among the trees. This ensemble approach reduces the risk of overfitting and improves the generalization capabilities of the model.

The final prediction of the RF model is obtained by averaging the predictions of all the trees as follows:

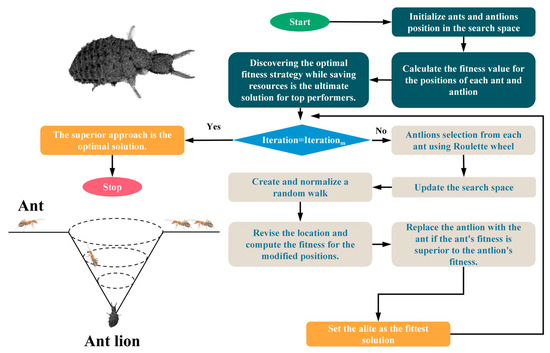

2.2. The Ant Lion Optimizer

The ant lion optimizer (ALO) is a meta-heuristic optimization algorithm proposed by Mirjalili [49] and inspired by the hunting behavior of ant lions. The ALO algorithm showed good performance in solving the complex optimization problems with high efficiency and accuracy. The algorithm involves the creation of an ant lion-inspired search space that consists of a central pit and surrounding terrain. In the ALO algorithm, the movement of the ant represents the exploration of the search space, while the lion represents the exploitation of the search space. The algorithm also includes a step of updating the pheromone trail, which enhances the convergence rate of the algorithm.

The free movement taken by ants in space while searching for food in nature can be expressed by the following equation:

where X denotes the position of the current ant individual, cs denotes the calculated cumulative sum, i denotes the number of iterations, n denotes the maximum number of iterations, and rand denotes a random number of [0, 1].

To simulate the hunting ability of ant lions, a roulette strategy was used to make it easier for the well-adapted ant lions to capture ants. When an ant approaches the trap of an ant lion, the random movement range of the ants is limited to a particular trap (the ants move randomly in a hypersphere layer). When an ant falls within the trap, the ant lion will spray sand at the ant, causing the ant to move closer and closer to the ant lion in the trap. Eventually, the ant lion captures the ants that fall into the trap and updates its position to the latest position of the captured ants in order to be able to capture them better, and this behavior is expressed in the mathematical model as follows:

where represents the position of the j-th ant lion at the s-th iteration and represents the position of the k-th ant at the s-th iteration.

In each iteration, the information of the best one is retained and affects the walking range of the ants in each future iteration, and this elite strategy maintains the best solution obtained at any stage of the optimization process. The flow of the ALO algorithm described above is shown in Figure 2:

Figure 2.

Flow chart of ant lion optimization algorithm.

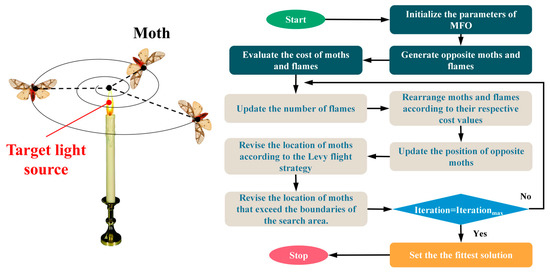

2.3. The Moth–Flame Optimization

The moth–flame optimization (MFO) algorithm is a novel intelligent optimization algorithm proposed by Seyedali Mirjalili and his colleagues in 2015 [50]. The algorithm is inspired by the unique navigation mechanism of moths during nocturnal flights, in which they use a lateral positioning mechanism to maintain a fixed angle relative to the moon, enabling straight flight using approximate parallel light from the distant moon. The MFO algorithm uses a mathematical model that incorporates concepts such as logarithmic spirals and a distance-based sorting mechanism to guide the moths towards the global optimum.

In the MFO algorithm, moths update their positions in space only with respect to a unique flame that corresponds to them, thus avoiding the algorithm being trapped in local optima. Moths continually move and search within the search space, with the position of the flame being the target position for the corresponding moth. The behavior of moths flying towards the flame can be expressed mathematically as follows:

where Mj represents the j-th moth and Fk represents the k-th flame; R is the spiral function.

Moths fly around specific flames in the MFO algorithm. When the fitness of any moth is higher than that of any flame, the position of the flame is updated accordingly. The flames also adaptively decrease during the iterative process, maintaining a balance between the global search capability and the local exploitation capability of the algorithm. The relevant mathematical formulae are presented as follows:

where Nf denotes the maximum number of flames, t denotes the current number of iterations, and T denotes the maximum number of iterations. The algorithmic flow of MFO described above can be represented in Figure 3:

Figure 3.

Flow chart of the moth–flame optimization.

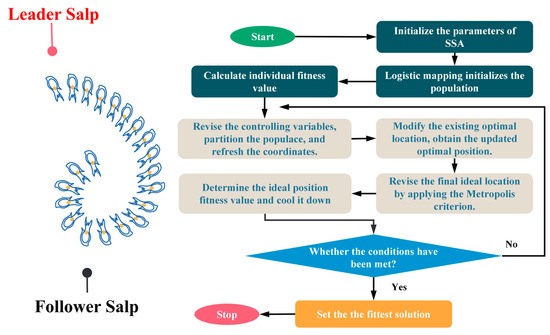

2.4. The Salp Swarm Algorithm

The salp swarm algorithm (SSA) is a bio-inspired optimization algorithm proposed by Mirjalili et al. [51] in 2014. SSA is inspired by the swimming behavior of salps, which are barrel-shaped planktonic tunicates that move by contracting and expanding their bodies.

During the foraging and movement in the ocean, salps often follow each other in a chain-like manner, with individuals connected head-to-tail. In such a “chain” group, there are leaders and followers, with the leaders responsible for tracking food and each follower only influenced by the salp in front of it. The position change of the leader during the foraging process of the salp population can be expressed by using the following equation:

where S1 represents the location of the first salp leader in the search space, G denotes the location where the food is located, ub and lb denote the upper and lower bounds of the search space, respectively, h1 represents the convergence factor in the optimization algorithm, and h2 and h3 represent the random number of [0, 1].

The follower moves with the change in position of the previous salp, so that the position of the follower changes as shown below:

where Sj and Sj−1 denote the two adjacent salp positions before the update and Sj′ denotes the updated salp position. The above SSA algorithm flow can be expressed in Figure 4:

Figure 4.

Flow chart of the salp swarm algorithm.

3. Data Manipulation and Performance Evaluation

3.1. Punching Shear Strength of FRP-RC Beams

The PSS is a crucial mechanical characteristic of FRP-RC beams [52,53,54,55,56], which refers to the ability of the beam to resist the shear force at the point of contact with a concentrated load, such as a column or a pedestal. The punching shear failure mode can result in catastrophic failure of the beam and poses a significant challenge for the design and construction of FRP-RC structures [57].

The PSS of FRP-RC (fiber-reinforced polymer-reinforced concrete) beams is typically influenced by numerous factors. Different column section types can affect the force distribution and overall stability of the structure, while the size of the column’s cross-sectional area also has an impact on the distribution of loads. The effective depth of the slab, usually defined as the distance from the extreme compression fiber to the centroid of the tensile reinforcement, plays a significant role in punching shear strength; a larger effective depth generally results in a higher moment of inertia, thereby leading to increased shear strength. On the other hand, a lower span–depth ratio typically corresponds to greater punching shear strength. In terms of material properties, the compressive strength of concrete, the yield strength of reinforcement, and the reinforcement ratio all contribute to the punching shear strength of FRP-RC beams. Understanding the interplay between these factors is essential for optimizing the design and overall performance of such structures.

ML models emerged as promising tools for predicting the PSS of FRP-RC beams [58,59]. By training an ML model with a large dataset of experimental results, the model can learn to identify the underlying patterns and relationships between the input parameters and the punching shear strength. The ML model can provide a more accurate and efficient prediction compared to traditional analytical methods that rely on empirical equations or simplifying assumptions.

3.2. Construct Database

This study aimed to create a comprehensive database of punching shear strength (PSS) for FRP-RC columns by compiling data from 26 published works [60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80,81,82,83,84,85]. The database contains information on several parameters, which can be categorized as follows: (1) geometric parameters, including the type of column section (TCS) represented by 1, 2, and 3 for circular, rectangular, and square columns, respectively, cross-sectional area of the column (CAC), slab’s effective depth (SED), and span–depth ratio (SDR); (2) concrete strength information, including the compressive strength of concrete (CSC); and (3) steel reinforcement information, including the yield strength of reinforcement (YSR) and reinforcement ratio (RR). The output parameter is the PSS of the beams. The values are presented in Table 1, which includes the units and statistical information. Some of the data from the FRP-RC PSS database are presented in Table 2.

Table 1.

Statistical information of parameters included in the FRP-RC beams database.

Table 2.

Punching shear strength database for FRP-RC beams (partial data only).

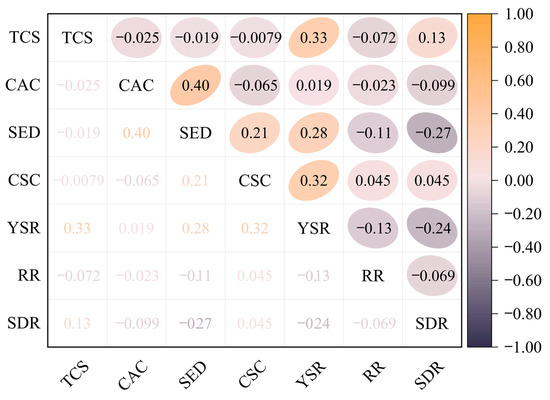

3.3. Parameter Correlation Analysis

Performing correlation analysis on parameters before establishing a ML model helps to identify the strength and direction of the relationships between the input variables [86]. The Pearson correlation coefficient is a statistical measure that evaluates the linear relationship between two continuous variables. It measures the degree to which the variables are associated and ranges from −1 to +1, with −1 indicating a perfectly negative linear relationship, 0 indicating no linear relationship, and +1 indicating a perfectly positive linear relationship [87]. The Pearson correlation coefficient analysis is commonly used in ML models to analyze the correlation between input parameters [88,89,90,91,92,93]. If the correlation coefficient between input parameters is high (generally above 0.8), it is necessary to consider selecting or discarding certain parameters to avoid data redundancy [94]. In this study, Pearson correlation coefficient analysis was performed on the characteristic parameters of seven parameters of FRP-RC beams, and the results are shown in Figure 5. It can be observed that the correlation coefficients between SDR, RR, YSR, SED, CAC, TCS, and CSC are all at a low level, indicating that there is no strong correlation between these parameters of the FRP-RC beams. Therefore, they can all be used as input parameters for generating the ML model without redundancy or increasing the amount of ineffective calculations.

Figure 5.

Pearson correlation coefficient analysis of the characteristic parameters of FRP-RC beams.

3.4. Evaluation Indicators

In the construction of various machine learning (ML) models [95,96], the selection of appropriate evaluation metrics plays a critical role in assessing the reliability and accuracy of the models. For solving the regression problems, the mean absolute error (MAE), the mean absolute percentage error (MAPE), the coefficient of determination (R2), and the root mean square error (RMSE) are widely used as evaluation metrics for regression models [93,97,98,99,100]. The MAE measures the average absolute difference between the predicted values and the measured values, which provides a measure of the accuracy of the model in predicting the target variable; the MAPE measures the average percentage difference between the predicted values and the measured values; and the R2 is a statistical measure that represents the proportion of the variance in the target variable that can be explained by the independent variables in the model. It ranges from 0 to 1, with higher values indicating a better fit between the model and the data; the RMSE measures the root mean squared difference between the predicted values and the measured values. In this study, MAE, MAPE, R2, and RMSE are selected as evaluation metrics for the ML model. Their definitions and calculation formulas are presented in Table 3.

Table 3.

Definition and calculation of evaluation indicators.

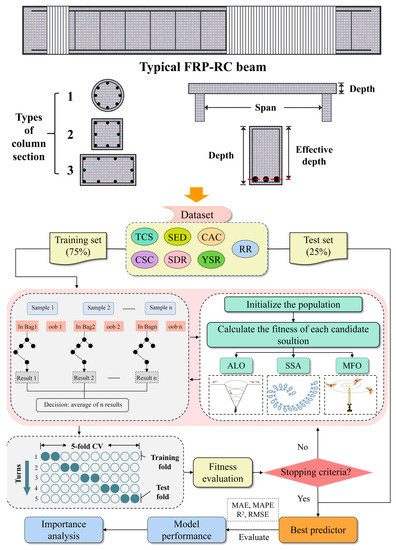

3.5. Hybrid Models

The database used in this study consists of 607 sets of data for FRP-RC beams. As shown in Figure 6, 75% of 607 sets of data were used as the training set, and the remaining 25% were used as the test set. In addition, all data were normalized to the range of −1 to 1. Cross-validation (CV) is a common technique used in machine learning to evaluate the performance of a model for estimating the performance of a model on new data and can help prevent the model from overfitting to the training data [101]. In this study, a five-fold CV is used in the training set where the dataset is divided into five equally sized subsets, and the process is repeated five times, with each subset used once as a validation set. In addition, the average RMSE value generated from five-fold CV was used as the fitness value [102].

Figure 6.

General flow chart of the algorithm.

In the RF model, the hyperparameters that need to be optimized are usually the number of trees and the maximum depth of trees [103]. Population size in machine learning refers to the number of individuals or data points within a population or dataset that are used for training and optimization purposes. In evolutionary algorithms and genetic programming, population size determines the diversity and exploration–exploitation trade-off during the search process [43]. Therefore, the population size in this study was set at 10, 50, 100, and 200, and the other parameter settings are presented in Table 4. Then, this study employed three types of meta-heuristic optimization algorithms, namely ALO, MFO, and SSA, to optimize the hyperparameters of the RF model. Subsequently, four evaluation indicators were used to assess the PSS prediction performance of the three hybrid models (ALO-RF, MFO-RF, and SSA-RF). Finally, the importance of each input parameter was analyzed to further enhance the interpretability of the model. The computational flowchart of the above models is shown in Figure 6.

Table 4.

Parameter setting of the hybrid models.

4. Results and Discussion

4.1. Model Validity Judgment

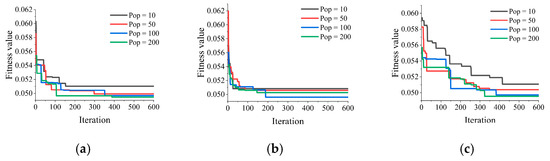

The RMSE is a widely used evaluation metric in machine learning because it provides a measure of the overall difference between the predicted values and the actual values, taking into account both the magnitude and direction of the errors. The aforementioned parameters render the PSS an appropriate selection for use as the fitness or objective function in optimization algorithms, which aim to identify the optimal set of model parameters that minimize the discrepancy between the predicted and actual values [104]. In this study, three different optimization algorithms, namely ALO, MFO, and SSA, were employed to optimize the hyperparameter combinations in the RF model for predicting the punching shear strength based on characteristic parameters of FRP-RC beams. The RMSE is used as the fitness value for searching the optimal combination of two hyperparameters of the RF model in the optimizer. The goal is to minimize the fitness value continuously to determine the optimal hyperparameter combination. Figure 7 shows the changes in fitness value curves for the three types of optimization algorithms. Changes have been made to the diagram.

Figure 7.

Variation curve of fitness value of hybrid model. (a) ALO-RF, (b) MFO-RF, and (c) SSA-RF.

Based on the results in Figure 7, it can be observed that the convergence speed is fastest when the population size is 200 among all ALO-RF models, and the final convergence results of the model are not significantly different when the population size is 50, 100, or 200. For the MFO-RF models, a population size of 100 yields relatively better convergence results. Two SSA-RF models with a population size of 100 or 200 achieved lower final convergence fitness values than other models that showed similar excellent results. Comparing the three hybrid models (ALO-RF, MFO-RF, and SSA-RF), it is found that ALO-RF and MFO-RF have faster convergence speeds than SSA-RF, indicating that ALO and MFO have more sensitive search abilities for the optimal hyperparameters in RF that are suitable for predicting punching shear strength. However, the final convergence fitness values of the three hybrid models are not significantly different, and further analysis is needed to evaluate their performance in predicting the punching shear strength of FRP-RC beams.

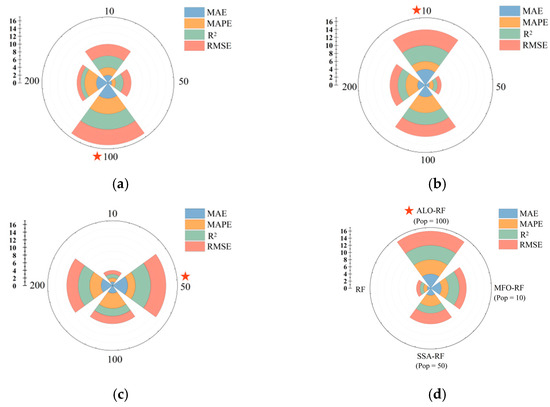

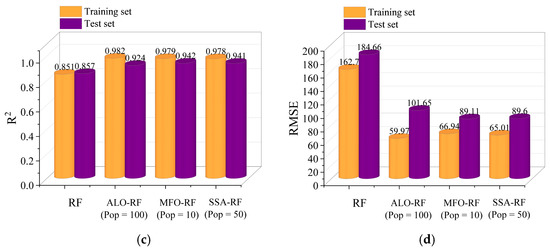

4.2. Hybrid Models Performance Evaluation

To comprehensively evaluate the predictive performance of ALO-RF, MFO-RF, and SSA-RF for PSS, this study calculated four evaluation metrics (MAE, MAPE, R2, and RMSE) for each model and scored them based on their ranking in each metric (four points for the best ranking, and one point for the worst ranking), selecting the model with the highest overall score as the current optimal model. The score rankings of each model are shown in Figure 8, with larger fan-shaped areas indicating higher scores and better predictive performance for PSS. As shown in Figure 8a, the evaluation metrics of ALO-RF (Pop = 100) are significantly better than those under other population sizes, indicating that 100 is the optimal population size for ALO-RF to predict PSS in FRP-RC beams. From Figure 8b, it can be seen that MFO-RF (Pop = 10) has a slightly inferior performance in MAPE compared to the models with population sizes of 100 and 200, but its evaluation metrics in MAE, R2, and RMSE are superior to other models, and its overall performance is the best among all population sizes. Similarly, Figure 8c shows that SSA-RF (Pop = 50) exhibits the best predictive performance for PSS.

Figure 8.

Quantitative comparison of the prediction performance of each model (Red pentagrams indicate optimal models). (a) ALO-RF, (b) MFO-RF, (c) SSA-RF, and (d) hybrid models.

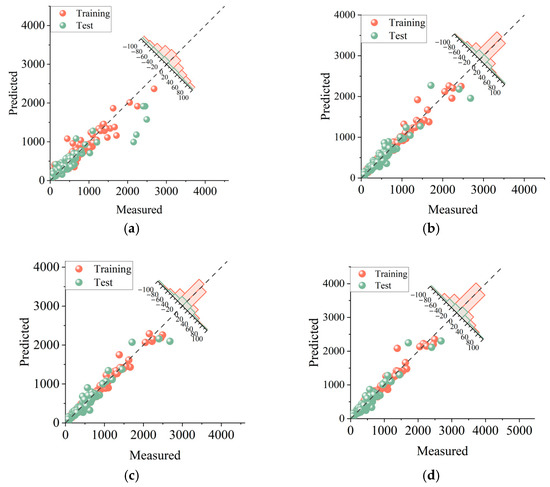

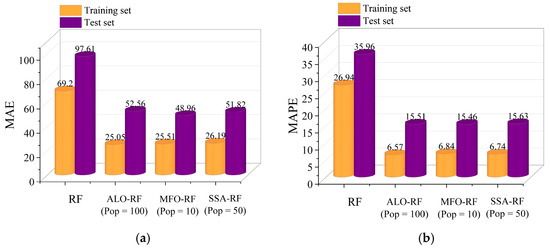

To further compare the PSS prediction performance of ALO-RF (Pop = 100), MFO-RF (Pop = 10), and SSA-RF (Pop = 50), and validate the effectiveness of the three metaheuristic optimization algorithms, this study introduced an unoptimized RF model that was trained and tested on the same dataset with parameters set as shown in Table 5. The comparison between predicted and measured PSS values for FRP-RC beams is visually presented in Figure 9 and Figure 10. In the figure, the red and green dots represent the distribution of predicted and measured values in the training and testing sets, respectively. The closer these points are to the diagonal dashed line, the better the prediction performance of the model. The difference distribution plot in the upper right corner shows the distribution of differences between predicted and measured values. It can be seen from Figure 9 that the error distribution range of ALO-RF (Pop = 100), MFO-RF (Pop = 10), and SSA-RF (Pop = 50) is smaller and more concentrated compared to the unoptimized RF model, indicating that the three metaheuristic optimization algorithms effectively reduce the prediction error. Furthermore, the error distribution of ALO-RF (Pop = 100) is mainly concentrated in the range of [−20, 20], while that of MFO-RF (Pop = 10) is mainly concentrated in the range of [−40, 40], and that of SSA-RF (Pop = 50) is mainly concentrated in the range of [−60, 60], indicating that ALO-RF (Pop = 100) has a smaller error range in predicting the PSS for FRP-RC beams.

Table 5.

Parameter setting of RF model.

Figure 9.

Distribution of results for ALO-RF (Pop = 100), MFO-RF (Pop = 10), SSA-RF (Pop = 50), and unoptimized RF models. (a) RF, (b) ALO-RF (Pop = 100), (c) MFO-RF (Pop = 10), and (d) SSA-RF (Pop = 50).

Figure 10.

The results for ALO-RF (Pop = 100), MFO-RF (Pop = 10), SSA-RF (Pop = 50), and unoptimized RF models. (a) MAE, (b) MAPE, (c) R2, and (d) RMSE.

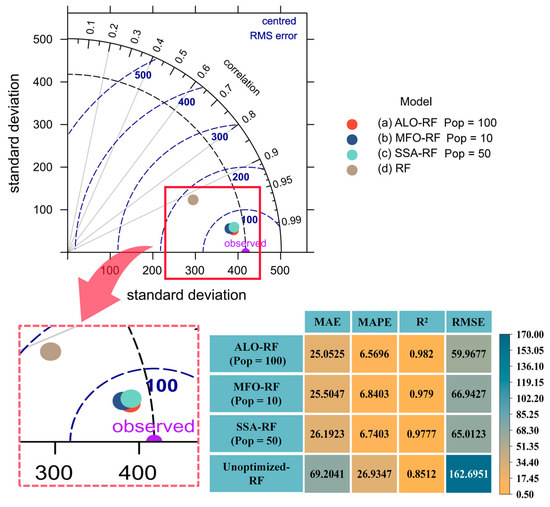

The Taylor diagram is a graphical tool used to compare multiple models or observations in terms of their correlation, variance, and overall pattern [106]. In Figure 11, Taylor diagrams are used to analyze the performance of ALO-RF (Pop = 100), MFO-RF (Pop = 10), SSA-RF (Pop = 50), and unoptimized RF in predicting the PSS of FRP-RC beams. As shown in Figure 10a, the data points of ALO-RF (Pop = 100), MFO-RF (Pop = 10), and SSA-RF (Pop = 50) in the training set are closer to the observation points than RF, indicating smaller RMSE values. ALO-RF (Pop = 100) also has a smaller azimuth angle, indicating a higher correlation coefficient. These findings suggest that ALO, MFO, and SSA optimization algorithms can efficiently capture the inherent relationship between various characteristic parameters of FRP-RC beams and PSS, and search for suitable hyperparameter combinations to improve the predictive performance of the RF model.

Figure 11.

Taylor diagram analysis of the hybrid model (training set).

Based on the comprehensive analysis, and combined with Figure 8d, ALO-RF (Pop = 100) demonstrated the best predictive performance, with MAE of 25.0525, MAPE of 6.5696, R2 of 0.9820, and RMSE of 59.9677 in the training set, and MAE of 52.5601, MAPE of 15.5083, R2 of 0.941, and RMSE of 101.6494 in the testing set. These results indicate that the ALO algorithm with a population size of 100 can effectively capture the optimal hyperparameter combination and further improve the ability of the RF model to capture the intrinsic relationship between the input parameters and PSS of FRP-RC beam.

Feng et al. [20] developed various ML algorithms and compared their predictive performance for assessing the PSS of FRP-RC beams. However, these models were confined to traditional, independent ML techniques. In contrast, the present research employs a RF model with an enhanced ability to prevent overfitting. Additionally, three metaheuristic optimization algorithms were introduced to tune the hyperparameter of the RF model, enabling better identification of the intrinsic relationship between input parameters of FRP-RC beams and the PSS, thereby improving prediction accuracy.

To validate the effectiveness and superiority of the proposed predictive model, the best prediction performance of the ALO-RF model was compared with other models developed using the same database. The performance comparison results of the three models are listed in Table 6. The results show that the proposed ALO-RF model has higher prediction performance than previously published models by means of the higher R2 values. This suggests that the ALO-RF model provides a better explanation of the relationship between input parameters and the PSS of FRP-RC beams. The methodology can be adapted and fine-tuned to address specific challenges or research questions in different areas, leading to more accurate and reliable predictions [107,108]. The methodology can be adapted and fine-tuned to address specific challenges or research questions in different areas, leading to more accurate and reliable predictions.

Table 6.

Performance comparison between previous works and the proposed model.

4.3. Importance Evaluation of Feature Parameters

The feature importance analysis is an essential step in understanding the underlying relationships between the input features and the target variable, which can be used to improve the performance and interpretability of the model. RF can provide important insights into the relative importance of different features in predicting the target variable. This approach involves a quantitative assessment of the contribution of each feature to the predictive performance of the model, enabling researchers to identify the most significant features for the task at hand [109,110,111,112,113,114,115,116,117,118,119]. These importance scores can be calculated by the Gini index:

where Gini(Xa) represents the Gini index, P(Xa = Yb) represents probability, and Xa = Yb represents an estimated value.

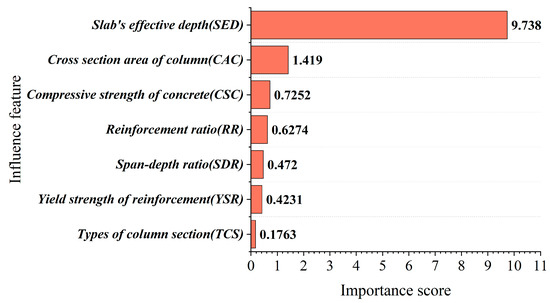

Figure 12 displays the importance scores of each input variable in the RF model, and according to the data in the figure, it can be seen that slab’s effective depth (SED) has the highest importance score among all the feature parameters of FRP-RC beams. The result highlights the close relationship between SED and PSS, which plays a prominent role in predicting the PSS based on the ALO-RF model. Although the importance scores of CAC, CSC, RR, SDR, YSR, and TCS are lower compared to SED, they still have a significant underlying relationship with PSS. Overall, slab’s effective depth (SED) has the highest contribution to predicting the PSS among all the parameters, indicating a strong internal relationship between SED and PSS, and adjusting SED can effectively control the variation in PSS.

Figure 12.

Importance analysis of input parameters of FRP-RC beams.

5. Conclusions

This study investigates the efficacy of three metaheuristic optimization algorithms (ALO, MFO, and SSA) in fine-tuning the hyperparameters of a random forest (RF) model for predicting the PSS of FRP-RC beams. The results demonstrate that the ALO-RF model exhibits a faster convergence rate compared to both MFO-RF and SSA-RF, indicating that ALO and MFO exhibit heightened sensitivity in searching for optimal hyperparameters when predicting the PSS of FRP-RC beams using the RF model. Notably, the ALO-RF model, employing a population size of 100, yields the most accurate predictive performance, characterized by a narrower distribution range of errors and a higher correlation coefficient. Furthermore, the study identifies the significant energy dissipation (SED) as the input parameter exerting the most significant influence on PSS prediction, emphasizing that adjusting the SED can effectively regulate PSS variations.

However, the scarcity of experimental data presents a significant challenge to accurately predicting the performance of FRP-RC beams, which in turn hampers the development and validation of predictive models. Furthermore, the intricate material behavior between the FRP reinforcement and the concrete matrix adds to the complexity of prediction efforts. Although advanced machine learning and optimization algorithms can provide accurate predictions, they often involve high computational requirements, which can result in prolonged training and prediction times. In future research, increasing the amount of experimental data on FRP-RC beams may improve the quality and generalizability of predictive models. Additionally, enhancing our understanding of the material behavior between the FRP reinforcement and the concrete matrix can aid in the development of more precise and dependable prediction models.

Author Contributions

Conceptualization, J.Z.; investigation, P.Y., C.L. and Y.Q.; methodology, P.Y. and J.Z.; software, P.Y. and C.L.; supervision, J.Z.; visualization, P.Y., S.H. and Y.Q.; writing—original draft, P.Y.; writing—review and editing, J.Z., S.H., C.L. and Y.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research is supported by the the Distinguished Youth Science Foundation of Hunan Province of China (2022JJ10073).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The authors do not have permission to share data.

Acknowledgments

The authors want to thank all the members who give us lots of help and cooperation.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhou, Y.-W.; Wu, Y.-F. General model for constitutive relationships of concrete and its composite structures. Compos. Struct. 2012, 94, 580–592. [Google Scholar] [CrossRef]

- Zhou, Y.; Zheng, Y.; Pan, J.; Sui, L.; Xing, F.; Sun, H.; Li, P. Experimental investigations on corrosion resistance of innovative steel-FRP composite bars using X-ray microcomputed tomography. Compos. Part B Eng. 2018, 161, 272–284. [Google Scholar] [CrossRef]

- Zhou, Y.; Guo, M.; Sui, L.; Xing, F.; Hu, B.; Huang, Z.; Yun, Y. Shear strength components of adjustable hybrid bonded CFRP shear-strengthened RC beams. Compos. Part B Eng. 2018, 163, 36–51. [Google Scholar] [CrossRef]

- Huang, X.; Sui, L.; Xing, F.; Zhou, Y.; Wu, Y. Reliability assessment for flexural FRP-Strengthened reinforced concrete beams based on Importance Sampling. Compos. Part B Eng. 2018, 156, 378–398. [Google Scholar] [CrossRef]

- Li, P.; Sui, L.; Xing, F.; Zhou, Y. Static and cyclic response of low-strength recycled aggregate concrete strengthened using fiber-reinforced polymer. Compos. Part B Eng. 2018, 160, 37–49. [Google Scholar] [CrossRef]

- Chen, G.M.; Teng, J.G.; Chen, J.F. Shear Strength Model for FRP-Strengthened RC Beams with Adverse FRP-Steel Interaction. J. Compos. Constr. 2013, 17, 50–66. [Google Scholar] [CrossRef]

- Nasrollahzadeh, K.; Basiri, M.M. Prediction of shear strength of FRP reinforced concrete beams using fuzzy inference system. Expert Syst. Appl. 2014, 41, 1006–1020. [Google Scholar] [CrossRef]

- El-Sayed, A.K.; El-Salakawy, E.F.; Benmokrane, B. Shear strength of FRP-reinforced concrete beams without transverse reinforcement. ACI Mater. J. 2006, 103, 235. [Google Scholar]

- Nakamura, H.; Higai, T. Evaluation of shear strength of concrete beams reinforced with FRP. Doboku Gakkai Ronbunshu 1995, 1995, 89–100. [Google Scholar] [CrossRef]

- Alam, M.S.; Hussein, A. Size Effect on Shear Strength of FRP Reinforced Concrete Beams without Stirrups. J. Compos. Constr. 2013, 17, 507–516. [Google Scholar] [CrossRef]

- Ashour, A.F.; Kara, I.F. Size effect on shear strength of FRP reinforced concrete beams. Compos. Part B Eng. 2014, 60, 612–620. [Google Scholar] [CrossRef]

- Oller, E.; Pujol, M.; Marí, A. Contribution of externally bonded FRP shear reinforcement to the shear strength of RC beams. Compos. Part B Eng. 2018, 164, 235–248. [Google Scholar] [CrossRef]

- Kueres, S.; Will, N.; Hegger, J. Shear strength of prestressed FRP reinforced concrete beams with shear reinforcement. Eng. Struct. 2020, 206, 110088. [Google Scholar] [CrossRef]

- Gao, D.; Zhang, C. Shear Strength Prediction Model of FRP Bar-Reinforced Concrete Beams without Stirrups. Math. Probl. Eng. 2020, 2020, 7516502. [Google Scholar] [CrossRef]

- Jumaa, G.B.; Yousif, A.R. Numerical modeling of size effect in shear strength of FRP-reinforced concrete beams. In Structures; Elsevier: Amsterdam, The Netherlands, 2019; Volume 20, pp. 237–254. [Google Scholar]

- Chen, G.; Chen, J.; Teng, J. On the finite element modelling of RC beams shear-strengthened with FRP. Constr. Build. Mater. 2012, 32, 13–26. [Google Scholar] [CrossRef]

- Ebid, A.M.; Deifalla, A. Prediction of shear strength of FRP reinforced beams with and without stirrups using (GP) technique. Ain Shams Eng. J. 2021, 12, 2493–2510. [Google Scholar] [CrossRef]

- Kara, I.F. Prediction of shear strength of FRP-reinforced concrete beams without stirrups based on genetic programming. Adv. Eng. Softw. 2011, 42, 295–304. [Google Scholar] [CrossRef]

- Abuodeh, O.R.; Abdalla, J.A.; Hawileh, R.A. Prediction of shear strength and behavior of RC beams strengthened with externally bonded FRP sheets using machine learning techniques. Compos. Struct. 2019, 234, 111698. [Google Scholar] [CrossRef]

- Feng, D.-C.; Wang, W.-J.; Mangalathu, S.; Hu, G.; Wu, T. Implementing ensemble learning methods to predict the shear strength of RC deep beams with/without web reinforcements. Eng. Struct. 2021, 235, 111979. [Google Scholar] [CrossRef]

- Deifalla, A.; Salem, N.M. A Machine Learning Model for Torsion Strength of Externally Bonded FRP-Reinforced Concrete Beams. Polymers 2022, 14, 1824. [Google Scholar] [CrossRef]

- Shen, Y.; Sun, J.; Liang, S. Interpretable Machine Learning Models for Punching Shear Strength Estimation of FRP Reinforced Concrete Slabs. Crystals 2022, 12, 259. [Google Scholar] [CrossRef]

- Chou, J.-S.; Pham, T.-P.; Nguyen, T.-K.; Pham, A.-D.; Ngo, N.-T. Shear strength prediction of reinforced concrete beams by baseline, ensemble, and hybrid machine learning models. Soft Comput. 2019, 24, 3393–3411. [Google Scholar] [CrossRef]

- Liang, S.; Shen, Y.; Gao, X.; Cai, Y.; Fei, Z. Symbolic machine learning improved MCFT model for punching shear resistance of FRP-reinforced concrete slabs. J. Build. Eng. 2023, 69, 106257. [Google Scholar] [CrossRef]

- Nikoo, M.; Aminnejad, B.; Lork, A. Predicting Shear Strength in FRP-Reinforced Concrete Beams Using Bat Algorithm-Based Artificial Neural Network. Adv. Mater. Sci. Eng. 2021, 2021, 5899356. [Google Scholar] [CrossRef]

- Alrouh, N.; Maalej, M.; Barakat, S. Modeling the Shear Strength of FRP-Strengthened Rc Beams Using Artificial Neural Networks. Mater. Sci. Forum 2021, 1047, 207–213. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Abbas, H.; Al-Salloum, Y.A.; Almusallam, T.H. Prediction of Intermediate Crack Debonding Strain of Externally Bonded FRP Laminates in RC Beams and One-Way Slabs. J. Compos. Constr. 2014, 18, 04014008. [Google Scholar] [CrossRef]

- Pham, T.M.; Hadi, M.N.S. Predicting Stress and Strain of FRP-Confined Square/Rectangular Columns Using Artificial Neural Networks. J. Compos. Constr. 2014, 18, 04014019. [Google Scholar] [CrossRef]

- Gopinath, S.; Kumar, A. Artificial Neural Network–Based Numerical Model to Predict Flexural Capacity of Masonry Panels Strengthened with Textile Reinforced Mortar. J. Compos. Constr. 2021, 25, 06020004. [Google Scholar] [CrossRef]

- Karim, M.R.; Islam, K.; Billah, A.H.M.M.; Alam, M.S. Shear Strength Prediction of Slender Concrete Beams Reinforced with FRP Rebar Using Data-Driven Machine Learning Algorithms. J. Compos. Constr. 2023, 27, 04023003. [Google Scholar] [CrossRef]

- Mansour, M.; Dicleli, M.; Lee, J.; Zhang, J. Predicting the shear strength of reinforced concrete beams using artificial neural networks. Eng. Struct. 2004, 26, 781–799. [Google Scholar] [CrossRef]

- Zhang, J.; Sun, Y.; Li, G.; Wang, Y.; Sun, J.; Li, J. Machine-learning-assisted shear strength prediction of reinforced concrete beams with and without stirrups. Eng. Comput. 2020, 38, 1293–1307. [Google Scholar] [CrossRef]

- Kaloop, M.R.; Roy, B.; Chaurasia, K.; Kim, S.-M.; Jang, H.-M.; Hu, J.-W.; Abdelwahed, B.S. Shear Strength Estimation of Reinforced Concrete Deep Beams Using a Novel Hybrid Metaheuristic Optimized SVR Models. Sustainability 2022, 14, 5238. [Google Scholar] [CrossRef]

- Li, J.; Cheng, J.H.; Shi, J.Y.; Huang, F. Brief introduction of back propagation (BP) neural network algorithm and its improvement. In Advances in Computer Science and Information Engineering; Springer: Berlin/Heidelberg, Germany, 2012; Volume 2, pp. 553–558. [Google Scholar]

- Awad, M.; Khanna, R.; Awad, M.; Khanna, R. Support Vector Regression. Efficient Learning Machines: Theories, Concepts, and Applications for Engineers and System Designers; Springer Nature: Berlin, Germany, 2015; pp. 67–80. [Google Scholar]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Khan, K.; Iqbal, M.; Salami, B.A.; Amin, M.N.; Ahamd, I.; Alabdullah, A.A.; Abu Arab, A.M.; Jalal, F.E. Estimating Flexural Strength of FRP Reinforced Beam Using Artificial Neural Network and Random Forest Prediction Models. Polymers 2022, 14, 2270. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Lin, J.; Lei, X.; Wei, T. Compressive strength prediction of basalt fiber reinforced concrete via random forest algorithm. Mater. Today Commun. 2022, 30, 103117. [Google Scholar] [CrossRef]

- Mei, X.; Cui, Z.; Sheng, Q.; Zhou, J.; Li, C. Application of the improved POA-RF model in predicting the strength and energy absorption property of a novel aseismic rubber-concrete material. Materials 2023, 16, 1286. [Google Scholar] [CrossRef]

- Mangalathu, S.; Jeon, J.-S. Classification of failure mode and prediction of shear strength for reinforced concrete beam-column joints using machine learning techniques. Eng. Struct. 2018, 160, 85–94. [Google Scholar] [CrossRef]

- Sun, Y.; Li, G.; Zhang, J.; Qian, D. Prediction of the Strength of Rubberized Concrete by an Evolved Random Forest Model. Adv. Civ. Eng. 2019, 2019, 5198583. [Google Scholar] [CrossRef]

- Mohammed, H.R.M.; Ismail, S. Random Forest versus Support Vector Machine Models’ Applicability for Predicting Beam Shear Strength. Complexity 2021, 2021, 9978409. [Google Scholar] [CrossRef]

- Halim, A.H.; Ismail, I.; Das, S. Performance assessment of the metaheuristic optimization algorithms: An exhaustive review. Artif. Intell. Rev. 2020, 54, 2323–2409. [Google Scholar] [CrossRef]

- Kaveh, A. Applications of Metaheuristic Optimization Algorithms in Civil Engineering; Springer International Publishing: Basel, Switzerland, 2017. [Google Scholar] [CrossRef]

- Moayedi, H.; Bui, D.T.; Anastasios, D.; Kalantar, B. Spotted Hyena Optimizer and Ant Lion Optimization in Predicting the Shear Strength of Soil. Appl. Sci. 2019, 9, 4738. [Google Scholar] [CrossRef]

- Huang, M.; Lei, Y. Bearing Damage Detection of a Reinforced Concrete Plate Based on Sensitivity Analysis and Chaotic Moth-Flame-Invasive Weed Optimization. Sensors 2020, 20, 5488. [Google Scholar] [CrossRef]

- Khajehzadeh, M.; Iraji, A.; Majdi, A.; Keawsawasvong, S.; Nehdi, M.L. Adaptive Salp Swarm Algorithm for Optimization of Geotechnical Structures. Appl. Sci. 2022, 12, 6749. [Google Scholar] [CrossRef]

- Biau, G. Analysis of a random forests model. J. Mach. Learn. Res. 2012, 13, 1063–1095. [Google Scholar]

- Mirjalili, S. The ant lion optimizer. Adv. Eng. Softw. 2015, 83, 80–98. [Google Scholar] [CrossRef]

- Mirjalili, S. Moth-flame optimization algorithm: A novel nature-inspired heuristic paradigm. Knowl. Based Syst. 2015, 89, 228–249. [Google Scholar] [CrossRef]

- Mirjalili, S.; Gandomi, A.H.; Mirjalili, S.Z.; Saremi, S.; Faris, H.; Mirjalili, S.M. Salp Swarm Algorithm: A bio-inspired optimizer for engineering design problems. Adv. Eng. Softw. 2017, 114, 163–191. [Google Scholar] [CrossRef]

- Salama, A.E.; Hassan, M.; Benmokrane, B.; Ferrier, E. Modified strip model for punching-shear strength of FRP-reinforced concrete edge–column slab connections. Eng. Struct. 2020, 216, 110769. [Google Scholar] [CrossRef]

- Alrousan, R.Z.; Bara’a, R.A. Punching shear behavior of FRP reinforced concrete slabs under different opening configurations and loading conditions. Case Stud. Constr. Mater. 2022, 17, e01508. [Google Scholar] [CrossRef]

- Hassan, M.; Ahmed, E.A.; Benmokrane, B. Punching Shear Behavior of Two-Way Slabs Reinforced with FRP Shear Reinforcement. J. Compos. Constr. 2015, 19, 04014030. [Google Scholar] [CrossRef]

- Alkhatib, S.; Deifalla, A. Punching Shear Strength of FRP-Reinforced Concrete Slabs without Shear Reinforcements: A Reliability Assessment. Polymers 2022, 14, 1743. [Google Scholar] [CrossRef]

- Theodorakopoulos, D.D.; Swamy, N. Analytical Model to Predict Punching Shear Strength of FRP-Reinforced Concrete Flat SlabsSlabs. ACI Struct. J. 2007, 104, 257. [Google Scholar] [CrossRef]

- Guadagnini, M.; Pilakoutas, K.; Waldron, P. Shear Resistance of FRP RC Beams: Experimental Study. J. Compos. Constr. 2006, 10, 464–473. [Google Scholar] [CrossRef]

- Badra, N.; Haggag, S.A.; Deifalla, A.; Salem, N.M. Development of machine learning models for reliable prediction of the punching shear strength of FRP-reinforced concrete slabs without shear reinforcements. Measurement 2022, 201, 111723. [Google Scholar] [CrossRef]

- Wakjira, T.G.; Al-Hamrani, A.; Ebead, U.; Alnahhal, W. Shear capacity prediction of FRP-RC beams using single and ensenble ExPlainable Machine learning models. Compos. Struct. 2022, 287, 115381. [Google Scholar] [CrossRef]

- Elstner, R.C.; Hognestad, E. Shearing strength of reinforced concrete slabs. J. Proc. 1956, 53, 29–58. [Google Scholar]

- Rosenthal, I. Experimental investigation of flat plate floors. J. Proc. 1959, 56, 153–166. [Google Scholar]

- Kinnunen, S.; Nylander, H. Punching of Concrete Slabs without Shear Reinforcement; Elander: New York, NY, USA, 1960; Volume 158, p. 112. [Google Scholar]

- Moe, J. Shearing Strength of Reinforced Concrete Slabs and Footings under Concentrated Loads; Portland Cement Association, Research and Development Laboratories: Washington, DC, USA, 1961. [Google Scholar]

- Yitzhaki, D. Punching strength of reinforced concrete slabs. J. Proc. 1966, 63, 527–542. [Google Scholar]

- Mowrer, R.D.; Vanderbilt, M.D. Shear strength of lightweight aggregate reinforced concrete flat plates. J. Proc. 1967, 64, 722–729. [Google Scholar]

- Hawkins, N.M.; Mitchell, D.; Hanna, S.N. The Effects of Shear Reinforcement on the Reversed Cyclic Loading Behavior of Flat Plate Structures. Can. J. Civ. Eng. 1975, 2, 572–582. [Google Scholar] [CrossRef]

- Criswell, M.E. Static and dynamic response of reinforced concrete slab-column connections. Spec. Publ. 1974, 42, 721–746. [Google Scholar]

- Li, V.C.; Liang, E. Fracture Processes in Concrete and Fiber Reinforced Cementitious Composites. J. Eng. Mech. 1986, 112, 566–586. [Google Scholar] [CrossRef]

- Rankin, G.; Long, A. Predicting the punching strength of conventional slab-column specimens. Proc. Inst. Civ. Eng. 1987, 82, 327–346. [Google Scholar] [CrossRef]

- Tolf, P. Influence of the Slab Thickness on the Strength of Concrete Slabs at Punching (Tests with Circular Slabs); Royal Institute of Technology, Department of Structural Mechanics and Engineering: Stockholm, Sweden, 1988. [Google Scholar]

- Marzouk, H.; Emam, M.; Sameh Hilal, M. Effect of high-strength concrete slab on the behavior of slab-column connections. ACI Struct. J. 1998, 95, 227–237. [Google Scholar]

- Tomaszewicz, A. Punching Shear Capacity of Reinforced Concrete Slabs; SINTEF: Trondheim, Norway, 1993. [Google Scholar]

- Ramdane, K.E. Punching shear of high performance concrete slabs. In Proceedings of the 4th International Symposium on Utilization of High-Strength/High-Performance Concrete, Paris, France, 29–31 May 1996; pp. 1015–1026. [Google Scholar]

- Hallgren, M.; Kinnunen, S. Increase of punching shear capacity by using high strength concrete. In Proceedings of the 4th International Symposium on Utilization of High-Strength/High-Performance Concrete, Paris, France, 29–31 May 1996; pp. 1037–1046. [Google Scholar]

- Ghannoum, C.M. Effect of High-Strength Concrete on the Performance of Slab-Column Specimens; McGill University: Montréal, QC, Canada, 1998. [Google Scholar]

- Okamura, H.; Ozawa, K.; Ouchi, M. Self-compacting concrete. Struct. Concr. 2000, 1, 3–17. [Google Scholar] [CrossRef]

- Matthys, S.; Taerwe, L. Concrete Slabs Reinforced with FRP Grids. II: Punching Resistance. J. Compos. Constr. 2000, 4, 154–161. [Google Scholar] [CrossRef]

- Ospina, C.E.; Alexander, S.D.; Cheng, J.R. Punching of two-way concrete slabs with fiber-reinforced polymer reinforcing bars or grids. Struct. J. 2003, 100, 589–598. [Google Scholar]

- Guandalini, S. Punching of Reinforced Concrete Slabs. Ph.D. Thesis, EPFL, Lausanne, Switzerland, 2005. [Google Scholar]

- Ozden, S.; Ersoy, U.; Ozturan, T. Punching shear tests of normal- and high-strength concrete flat plates. Can. J. Civ. Eng. 2006, 33, 1389–1400. [Google Scholar] [CrossRef]

- Zhang, M.; Wu, H.; Li, Q.; Huang, F. Further investigation on the dynamic compressive strength enhancement of concrete-like materials based on split Hopkinson pressure bar tests. Part I: Experiments. Int. J. Impact Eng. 2009, 36, 1327–1334. [Google Scholar] [CrossRef]

- Rizk, E.; Marzouk, H.; Hussein, A. Punching Shear of Thick Plates with and without Shear Reinforcement. ACI Struct. J. 2011, 108, 581–591. [Google Scholar] [CrossRef]

- Lips, S.; Ruiz, M.F.; Muttoni, A. Experimental Investigation on Punching Strength and Deformation Capacity of Shear-Reinforced Slabs. ACI Struct. J. 2012, 109, 889–900. [Google Scholar] [CrossRef]

- Einpaul, J.; Ospina, C.E.; Ruiz, M.F.; Muttoni, A. Punching Shear Capacity of Continuous Slabs. ACI Struct. J. 2016, 113, 861–872. [Google Scholar] [CrossRef]

- Yi, W.-J.; Zhao, D.-B.; Kunnath, S.K. Simplified Approach for Assessing Shear Resistance of Reinforced Concrete Beams under Impact Loads. ACI Struct. J. 2016, 113, 747–756. [Google Scholar] [CrossRef]

- Benesty, J.; Chen, J.; Huang, Y. On the Importance of the Pearson Correlation Coefficient in Noise Reduction. IEEE Trans. Audio, Speech, Lang. Process. 2008, 16, 757–765. [Google Scholar] [CrossRef]

- Cohen, I.; Huang, Y.; Chen, J.; Benesty, J. Pearson Correlation Coefficient. In Noise Reduction in Speech Processing; Springer: Berlin/Heidelberg, Germany, 2009. [Google Scholar]

- Jebli, I.; Belouadha, F.-Z.; Kabbaj, M.I.; Tilioua, A. Prediction of solar energy guided by pearson correlation using machine learning. Energy 2021, 224, 120109. [Google Scholar] [CrossRef]

- Pilania, G.; Wang, C.; Jiang, X.; Rajasekaran, S.; Ramprasad, R. Accelerating materials property predictions using machine learning. Sci. Rep. 2013, 3, 2810. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, R.; Qiu, Y.; Khandelwal, M. A true triaxial strength criterion for rocks by gene expression programming. J. Rock Mech. Geotech. Eng. 2023, 1–13. [Google Scholar] [CrossRef]

- Elton, D.C.; Boukouvalas, Z.; Butrico, M.S.; Fuge, M.D.; Chung, P.W. Applying machine learning techniques to predict the properties of energetic materials. Sci. Rep. 2018, 8, 9059. [Google Scholar] [CrossRef]

- Chen, C.; Zhou, J. A new empirical chart for coal burst liability classification using Kriging method. J. Cent. South Univ. 2023, 30, 1205–1216. [Google Scholar] [CrossRef]

- Wu, Y.; Zhou, Y. Hybrid machine learning model and Shapley additive explanations for compressive strength of sustainable concrete. Constr. Build. Mater. 2022, 330, 127298. [Google Scholar] [CrossRef]

- Shrestha, N. Detecting multicollinearity in regression analysis. Am. J. Appl. Math. Stat. 2020, 8, 39–42. [Google Scholar] [CrossRef]

- Qiu, Y.; Zhou, J.; Khandelwal, M.; Yang, H.; Yang, P.; Li, C. Performance evaluation of hybrid WOA-XGBoost, GWO-XGBoost and BO-XGBoost models to predict blast-induced ground vibration. Eng. Comput. 2021, 38, 4145–4162. [Google Scholar] [CrossRef]

- Zhou, J.; Qiu, Y.; Zhu, S.; Armaghani, D.J.; Li, C.; Nguyen, H.; Yagiz, S. Optimization of support vector machine through the use of metaheuristic algorithms in forecasting TBM advance rate. Eng. Appl. Artif. Intell. 2020, 97, 104015. [Google Scholar] [CrossRef]

- Chou, J.-S.; Tsai, C.-F.; Pham, A.-D.; Lu, Y.-H. Machine learning in concrete strength simulations: Multi-nation data analytics. Constr. Build. Mater. 2014, 73, 771–780. [Google Scholar] [CrossRef]

- Chen, H.; Li, X.; Wu, Y.; Zuo, L.; Lu, M.; Zhou, Y. Compressive Strength Prediction of High-Strength Concrete Using Long Short-Term Memory and Machine Learning Algorithms. Buildings 2022, 12, 302. [Google Scholar] [CrossRef]

- DeRousseau, M.A.; Laftchiev, E.; Kasprzyk, J.R.; Rajagopalan, B.; Srubar, W.V., III. A comparison of machine learning methods for predicting the compressive strength of field-placed concrete. Constr. Build. Mater. 2019, 228, 116661. [Google Scholar] [CrossRef]

- Ahmad, A.; Ahmad, W.; Chaiyasarn, K.; Ostrowski, K.A.; Aslam, F.; Zajdel, P.; Joyklad, P. Prediction of Geopolymer Concrete Compressive Strength Using Novel Machine Learning Algorithms. Polymers 2021, 13, 3389. [Google Scholar] [CrossRef]

- Yoon, J. Forecasting of Real GDP Growth Using Machine Learning Models: Gradient Boosting and Random Forest Approach. Comput. Econ. 2020, 57, 247–265. [Google Scholar] [CrossRef]

- Yao, H.; Li, X.; Pang, H.; Sheng, L.; Wang, W. Application of random forest algorithm in hail forecasting over Shandong Peninsula. Atmospheric Res. 2020, 244, 105093. [Google Scholar] [CrossRef]

- Yang, P.; Yong, W.; Li, C.; Peng, K.; Wei, W.; Qiu, Y.; Zhou, J. Hybrid Random Forest-Based Models for Earth Pressure Balance Tunneling-Induced Ground Settlement Prediction. Appl. Sci. 2023, 13, 2574. [Google Scholar] [CrossRef]

- Chai, T.; Draxler, R.R. Root mean square error (RMSE) or mean absolute error (MAE)?—Arguments against avoiding RMSE in the literature. Geosci. Model Dev. 2014, 7, 1247–1250. [Google Scholar] [CrossRef]

- Probst, P.; Wright, M.N.; Boulesteix, A.L. Hyperparameters and tuning strategies for random forest. Wiley Interdiscipl. Rev. Data Min. Knowl. Discov. 2019, 9, e1301. [Google Scholar] [CrossRef]

- Taylor, K.E. Summarizing multiple aspects of model performance in a single diagram. J. Geophys. Res. Atmos. 2001, 106, 7183–7192. [Google Scholar] [CrossRef]

- Izadifar, M.; Ukrainczyk, N.; Uddin, K.M.S.; Middendorf, B.; Koenders, E. Dissolution of β-C2S Cement Clinker: Part 2 Atomistic Kinetic Monte Carlo (KMC) Upscaling Approach. Materials 2022, 15, 6716. [Google Scholar] [CrossRef]

- Izadifar, M.; Ukrainczyk, N.; Uddin, K.M.S.; Middendorf, B.; Koenders, E. Dissolution of Portlandite in Pure Water: Part 2 Atomistic Kinetic Monte Carlo (KMC) Approach. Materials 2022, 15, 1442. [Google Scholar] [CrossRef]

- Loh, W.Y. Classification and regression trees. Wiley Interdiscip. Rev. Data Min. Knowl. Discov. 2011, 1, 14–23. [Google Scholar] [CrossRef]

- Zhou, J.; Dai, Y.; Du, K.; Khandelwal, M.; Li, C.; Qiu, Y. COSMA-RF: New intelligent model based on chaos optimized slime mould algorithm and random forest for estimating the peak cutting force of conical picks. Transp. Geotech. 2022, 36, 100806. [Google Scholar] [CrossRef]

- Chen, Y.; Yong, W.; Li, C.; Zhou, J. Predicting the Thickness of an Excavation Damaged Zone around the Roadway Using the DA-RF Hybrid Model. Comput. Model. Eng. Sci. 2022, 136, 2507–2526. [Google Scholar] [CrossRef]

- Dai, Y.; Khandelwal, M.; Qiu, Y.; Zhou, J.; Monjezi, M.; Yang, P. A hybrid metaheuristic approach using random forest and particle swarm optimization to study and evaluate backbreak in open-pit blasting. Neural Comput. Appl. 2022, 34, 6273–6288. [Google Scholar] [CrossRef]

- Han, H.; Armaghani, D.J.; Tarinejad, R.; Zhou, J.; Tahir, M.M. Random Forest and Bayesian Network Techniques for Probabilistic Prediction of Flyrock Induced by Blasting in Quarry Sites. Nat. Resour. Res. 2020, 29, 655–667. [Google Scholar] [CrossRef]

- Yu, Z.; Shi, X.; Zhou, J.; Chen, X.; Qiu, X. Effective Assessment of Blast-Induced Ground Vibration Using an Optimized Random Forest Model Based on a Harris Hawks Optimization Algorithm. Appl. Sci. 2020, 10, 1403. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, J.; Armaghani, D.J.; Tahir, M.M.; Pham, B.T.; Van Huynh, V. A Combination of Feature Selection and Random Forest Techniques to Solve a Problem Related to Blast-Induced Ground Vibration. Appl. Sci. 2020, 10, 869. [Google Scholar] [CrossRef]

- Zhou, J.; Li, E.; Wei, H.; Li, C.; Qiao, Q.; Armaghani, D.J. Random Forests and Cubist Algorithms for Predicting Shear Strengths of Rockfill Materials. Appl. Sci. 2019, 9, 1621. [Google Scholar] [CrossRef]

- Zhou, J.; Asteris, P.G.; Armaghani, D.J.; Pham, B.T. Prediction of ground vibration induced by blasting operations through the use of the Bayesian Network and random forest models. Soil Dyn. Earthq. Eng. 2020, 139, 106390. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, Y.; Yong, W. Performance evaluation of hybrid YYPO-RF, BWOA-RF and SMA-RF models to predict plastic zones around underground powerhouse caverns. Géoméch. Geophys. Geo-Energy Geo-Resour. 2022, 8, 1–29. [Google Scholar] [CrossRef]

- Zhou, J.; Huang, S.; Qiu, Y. Optimization of random forest through the use of MVO, GWO and MFO in evaluating the stability of underground entry-type excavations. Tunn. Undergr. Space Technol. 2022, 124, 104494. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).