Isobaric Thermal Expansivity and Isothermal Compressibility of Liquid Metals

Abstract

1. Introduction

2. Method

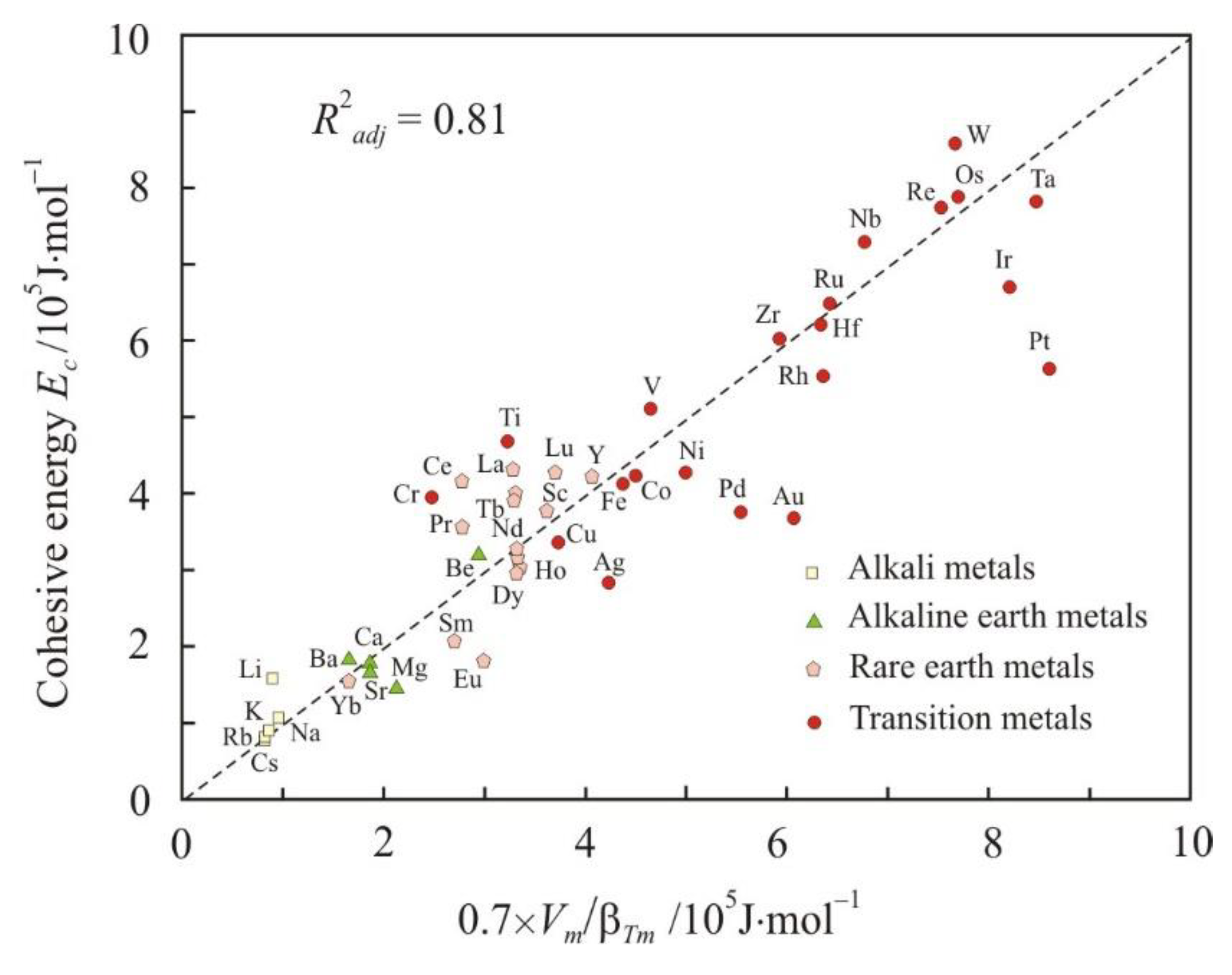

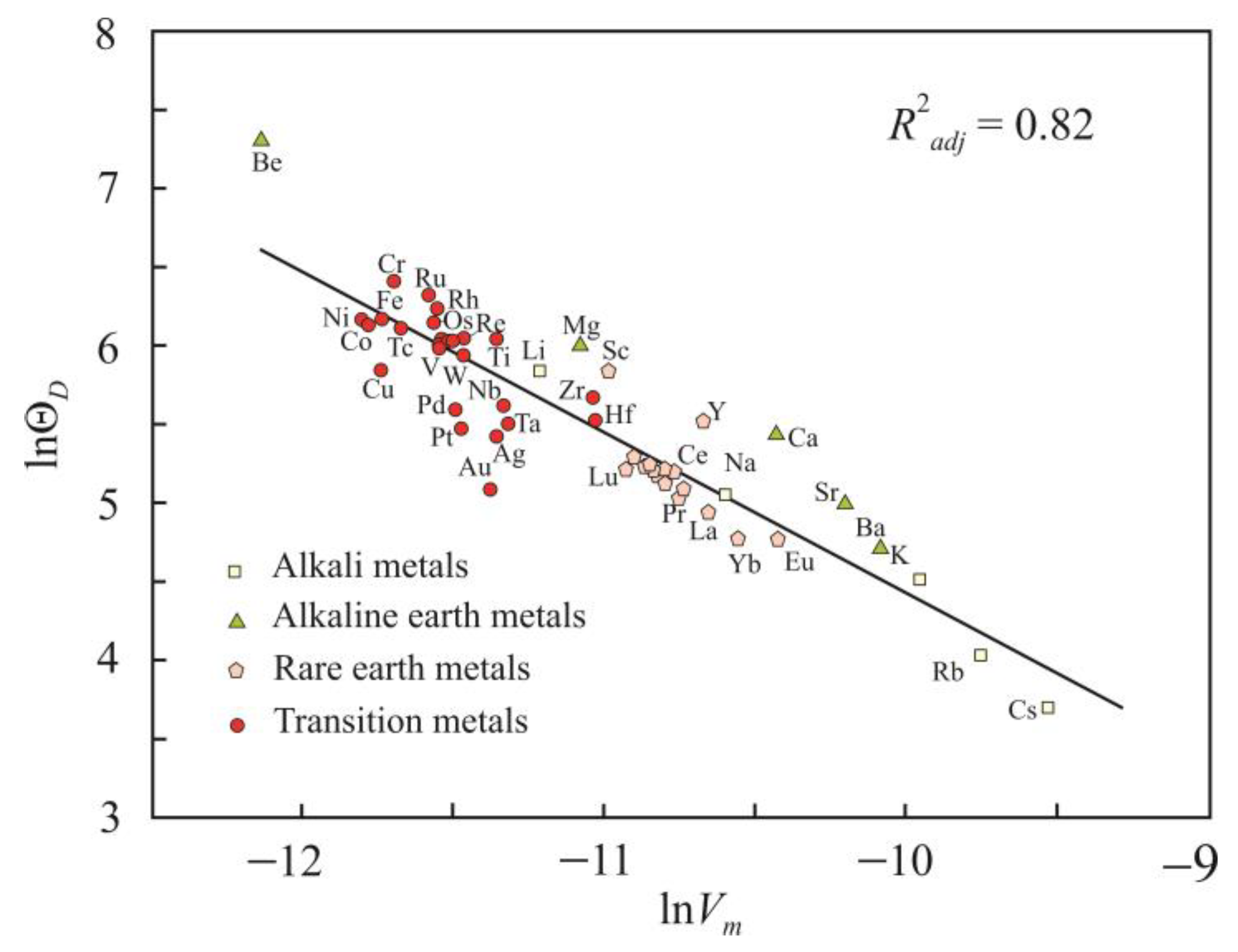

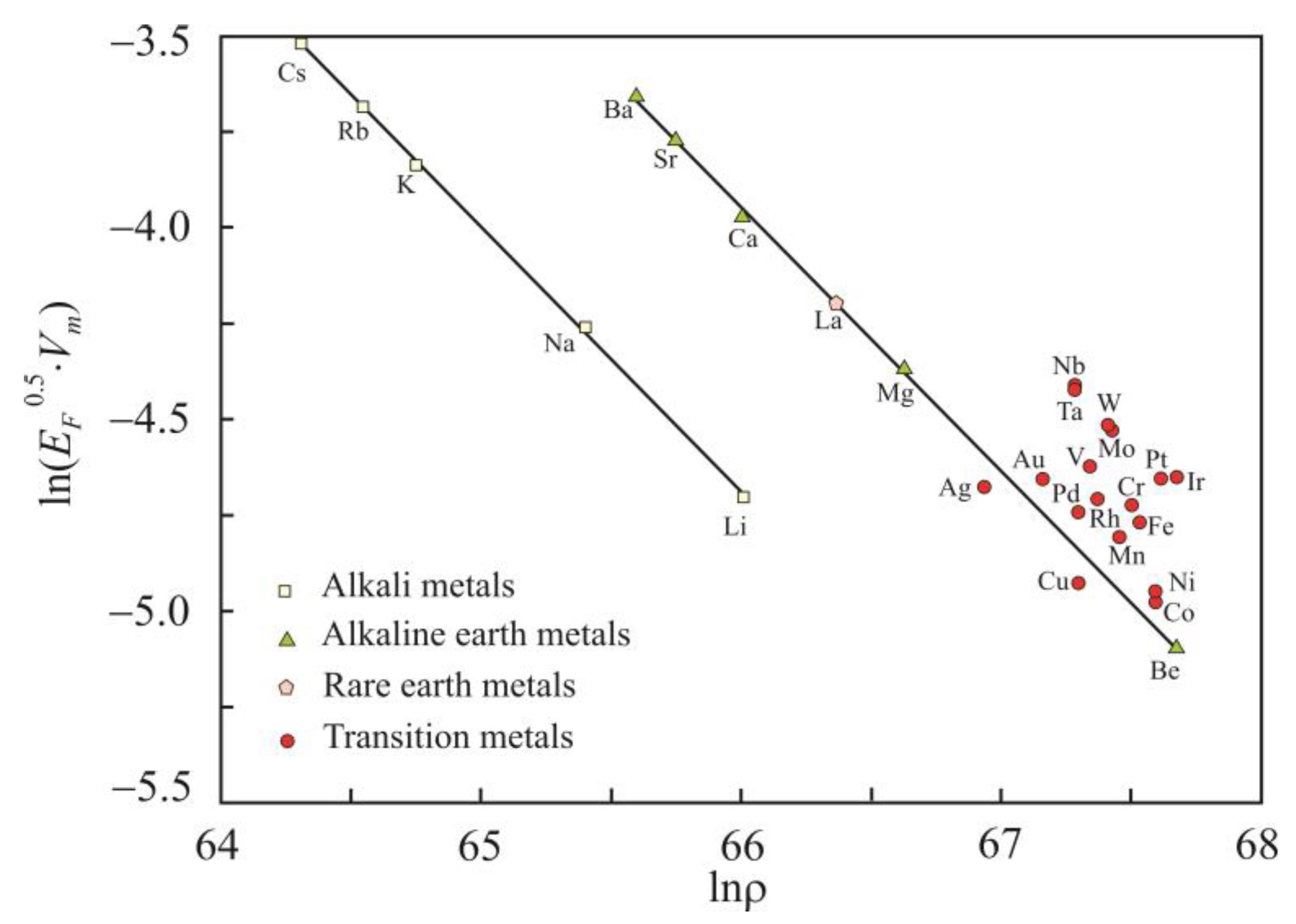

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Temperly, H.N.V.; Rowlinson, J.S.; Rushbrooke, G.S. (Eds.) Physics of Simple Liquids; North-Holland Publishing Company: Amsterdam, The Netherlands, 1968; 713p. [Google Scholar]

- Barrat, J.-L.; Hansen, J.-P. Basic Concepts of Simple and Complex Liquids; The University Press: Cambridge, UK, 2003; pp. 7–35. [Google Scholar]

- De With, G. Liquid-State Physical Chemistry: Fundamentals, Modeling, and Applications; Wiley-VCH: Weinheim, Germany, 2013; pp. 155–220. [Google Scholar]

- Glasstone, S.; Laidler, K.J.; Eyring, H. The Theory of Rate Processes: The Kinetics of Chemical Reactions, Viscosity, Diffusion and Electrochemical Phenomena; McGraw–Hill Book Co.: New York, NY, USA, 1941; pp. 477–551. [Google Scholar]

- Lindemann, F.A. Über die Berechnung molekularer Eigenfrequenzen. Phys. Z. 1910, 11, 609–612. [Google Scholar]

- Andrade, E.D.C. A theory of the viscosity of liquids—Part 1. Phil. Mag. 1934, 17, 497–511. [Google Scholar] [CrossRef]

- Kittel, C. Introduction to Solid State Physics; John Wiley & Sons: Hoboken, NJ, USA, 2005; 680p. [Google Scholar]

- Gopal, E.S.R. Specific Heats at Low Temperatures; Plenum Press: New York, NY, USA, 1966; pp. 25–27. [Google Scholar]

- Grimvall, G.; Sjödin, S. Correlation of properties of materials to Debye and melting temperature. Phys. Scr. 1974, 10, 340–352. [Google Scholar] [CrossRef]

- Iida, T.; Guthrie, R.I.L. The Thermophysical Properties of Metallic Liquids; University Press: Oxford, UK, 2015; pp. 497–543. [Google Scholar]

- Ziman, J.M. Principles of the Theory of Solids; The University Press: Cambridge, UK, 1972; pp. 66–67. [Google Scholar]

- Drebushchak, V.A. Thermal expansion of solids: Review on theories. J. Therm. Anal. Calorim. 2020, 142, 1097–1113. [Google Scholar] [CrossRef]

- Blumm, J.; Henderson, J.B. Measurement of the volumetric expansion and bulk density at metals in solid and molten regions. High Temp.-High Press. 2000, 32, 109–113. [Google Scholar] [CrossRef]

- Tsagareyshvili, D.S. Methods for Calculating Thermal and Elastic Properties of Crystalline Inorganic Substances; Metsniereba: Tbilisi, Georgia, 1977; pp. 22–26. [Google Scholar]

- Kaptay, G. A unified model for the cohesive enthalpy, critical temperature, surface tension and volume thermal expansion coefficient of liquid metals of bcc, fcc and hcp crystals. Mater. Sci. Eng. A 2008, 495, 19–26. [Google Scholar] [CrossRef]

- Tsuru, Y.; Shinzato, Y.; Saito, Y.; Shimazu, M.; Shiono, M.; Mirinaga, M. Estimation of linear thermal expansion coefficient from cohesive energy obtained by ab-initio calculation of metals and ceramics. J. Ceram. Soc. Jpn. 2010, 118, 241–245. [Google Scholar] [CrossRef]

- Gangopadhyay, A.K.; Bendert, J.C.; Mauro, N.A.; Kelton, K.F. Inverse correlation between cohesive energy and thermal expansion coefficient in liquid transition metal alloys. J. Phys. Condens. Matter 2012, 24, 375102. [Google Scholar] [CrossRef] [PubMed]

- Aqra, F. The cohesive energy density and the isothermal compressibility: Their relationships with the surface tension. Phys. B 2014, 446, 28–31. [Google Scholar] [CrossRef]

- Marcus, Y. The internal pressure and cohesive energy density of liquid metallic elements. J. Chem. Thermodyn. 2016, 109, 11–15. [Google Scholar] [CrossRef]

- Markus, Y. Relationship between the internal pressure, the cohesive energy, and the surface tension of liquidus. Phys. Chem. Liq. 2016, 55, 522–531. [Google Scholar] [CrossRef]

- Granato, A.V.; Joncich, D.M.; Khonik, V.A. Melting, thermal expansion, and the Lindemann rule for elemental substances. Appl. Phys. Lett. 2010, 97, 171911. [Google Scholar] [CrossRef]

- Longo, S.G. Principles and Applications of Dimensional Analysis and Similarity; Springer Nature Switzerland: Cham, Switzerland, 2021; 428p. [Google Scholar]

- Sedov, L.I. Similarity and Dimensional Methods in Mechanics; CRC Press: Boca Raton, FL, USA, 1993; 479p. [Google Scholar]

- Starodubtsev, Y.N.; Tsepelev, V.S. Analysis of the kinematic viscosity and self-diffusion of liquid metals at the melting temperature. High Temp. 2021, 59, 192–197. [Google Scholar] [CrossRef]

- Starodubtsev, Y.N.; Tsepelev, V.S. Analysis of surface tension and viscosity of liquid metals. Metall. Mater. Trans. B 2021, 52, 1886–1890. [Google Scholar] [CrossRef]

- Starodubtsev, Y.N.; Tsepelev, V.S. Effect of atomic size on the isothermal bulk modulus and surface tension of liquid metals. Metall. Mater. Trans. B 2022, 53, 2547–2552. [Google Scholar] [CrossRef]

- Schenk, T.; Holland-Moritz, D.; Somonet, V.; Bellissent, R.; Herlach, D.M. Icosahedral short-range order in deeply undercooled metallic melts. Phys. Rev. Lett. 2002, 89, 075507. [Google Scholar] [CrossRef]

- Zhai, Q.; Luo, J.; Zhao, P. Effect of thermal cycle on liquid structure of pure iron at just above its melting point. ISIJ Int. 2004, 44, 1279–1282. [Google Scholar] [CrossRef]

- Stewart, G.R. Measurement of the low-temperature specific heat. Rev. Sci. Instrum. 1983, 54, 1–11. [Google Scholar] [CrossRef]

- Blairs, S. Review of data for velocity of sound in pure liquid metals and metalloids. Int. Mater. Rev. 2007, 52, 321–344. [Google Scholar] [CrossRef]

- Sigalas, M.; Papaconstantopoulos, D.A.; Bacalis, N.C. Total energy and structure of the 3d, 4d, and 5d metals. Phys. Rev. B 1992, 45, 5777–5783. [Google Scholar] [CrossRef] [PubMed]

- Halas, S.; Durakiewicz, T. Work functions of elements expressed in terms of the Fermi energy and the density of free electrons. J. Phys. Condens. Mater. 1998, 10, 10815–10826. [Google Scholar] [CrossRef]

- Marcus, Y. On the compressibility of liquid metals. J. Chem. Thermodyn. 2016, 109, 11–15. [Google Scholar] [CrossRef]

- Wacke, S.; Górecki, T.; Górecki, C.; Książek, K. Relations between the cohesive energy, atomic volume, bulk modulus and sound velocity in metals. J. Phys. Conf. Ser. 2011, 289, 012020. [Google Scholar] [CrossRef]

- Delogu, F. Homogeneous melting of metals with different crystalline structure. J. Phys. Condens. Matter 2006, 18, 5639–5653. [Google Scholar] [CrossRef]

- Anderson, O.L. The Grüneisen parameter for the last 30 years. Geophys. J. Int. 2000, 143, 279–294. [Google Scholar] [CrossRef]

- Boness, D.F.; Brown, J.M.; McMahan, A.K. The electronic thermodynamics of iron under Earth core conditions. Phys. Earth Planet. Inter. 1986, 42, 227–240. [Google Scholar] [CrossRef]

- Anderson, O.L. Equations of State of Solids for Geophysics and Ceramic Science; Oxford University Press: New York, NY, USA, 1995; pp. 29–30. [Google Scholar]

- Ashcroft, N.W.; Mermin, N.D. Solid State Physics; Harcout College: Fort Worth, TX, USA, 1976; p. 4. [Google Scholar]

- Swalin, R.A. Thermodynamics of Solids; John Wiley & Sons: New York, NY, USA, 1972; pp. 63–65. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Starodubtsev, Y.N.; Tsepelev, V.S. Isobaric Thermal Expansivity and Isothermal Compressibility of Liquid Metals. Materials 2023, 16, 3801. https://doi.org/10.3390/ma16103801

Starodubtsev YN, Tsepelev VS. Isobaric Thermal Expansivity and Isothermal Compressibility of Liquid Metals. Materials. 2023; 16(10):3801. https://doi.org/10.3390/ma16103801

Chicago/Turabian StyleStarodubtsev, Yuri N., and Vladimir S. Tsepelev. 2023. "Isobaric Thermal Expansivity and Isothermal Compressibility of Liquid Metals" Materials 16, no. 10: 3801. https://doi.org/10.3390/ma16103801

APA StyleStarodubtsev, Y. N., & Tsepelev, V. S. (2023). Isobaric Thermal Expansivity and Isothermal Compressibility of Liquid Metals. Materials, 16(10), 3801. https://doi.org/10.3390/ma16103801