Investigation on Mechanical and Microstructure Properties of Silt Improved by Titanium Gypsum-Based Stabilizer

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

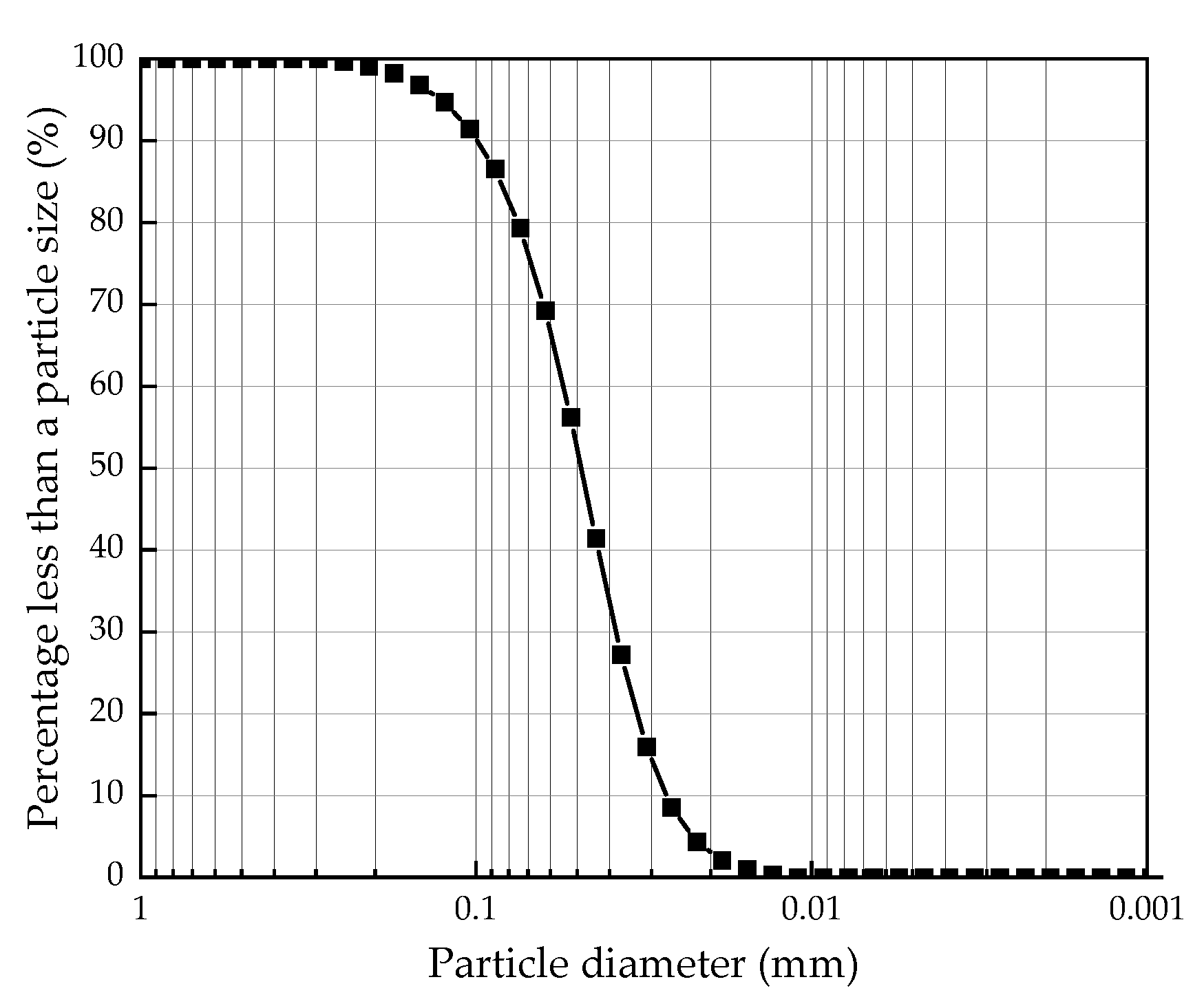

2.1.1. Soil

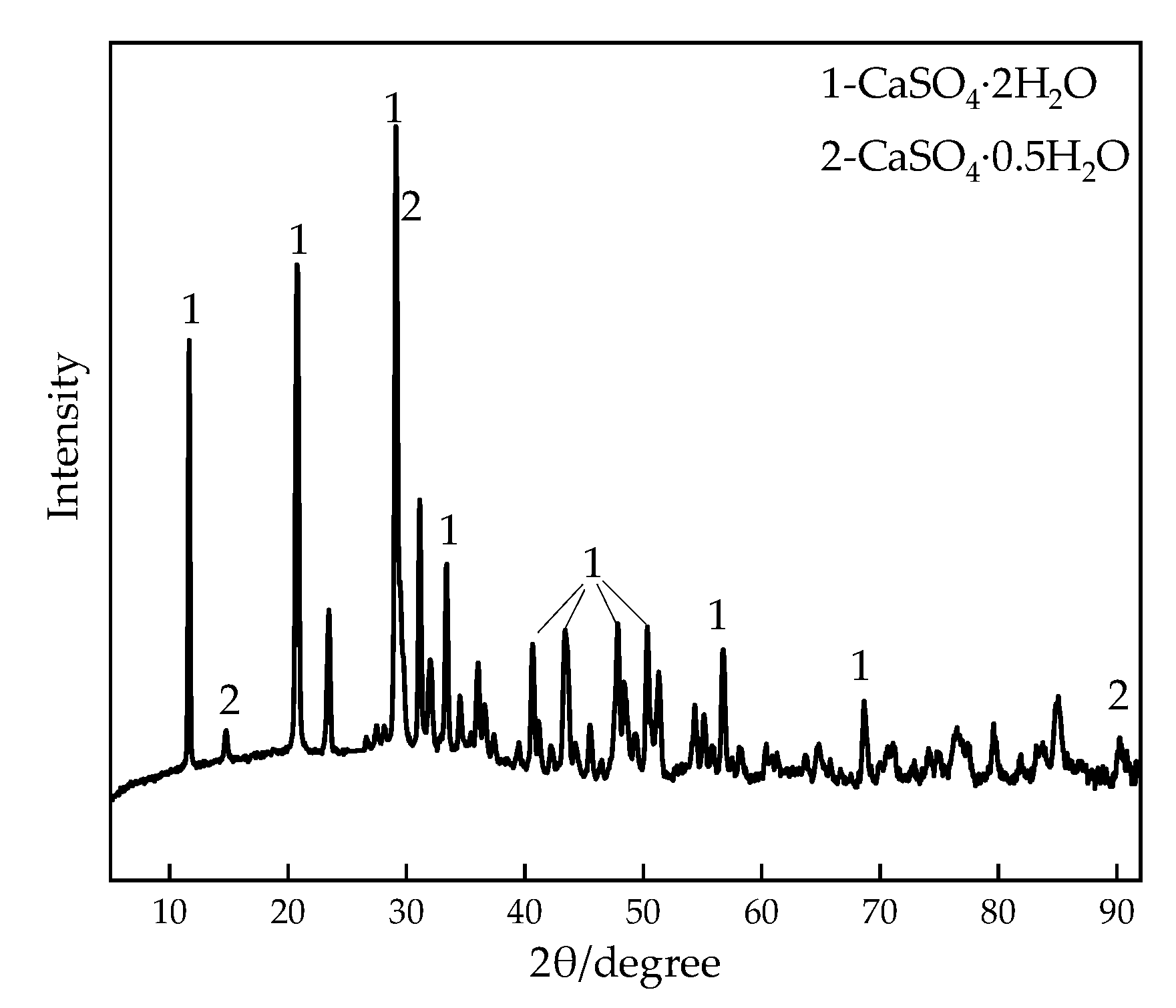

2.1.2. Binder

2.2. Test Methods

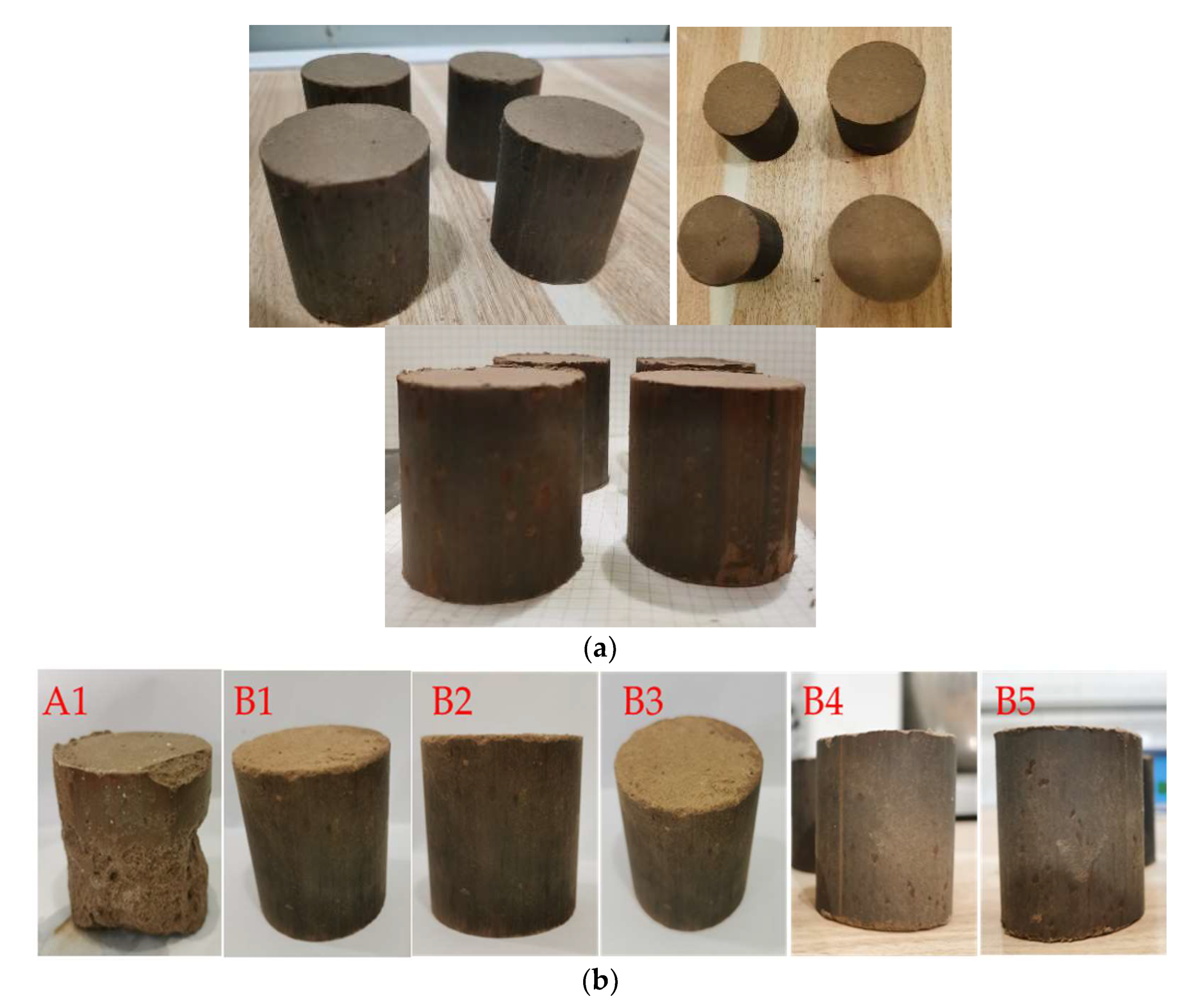

2.2.1. Sample Preparation and Curing

2.2.2. Unconfined Compressive Test (UCT)

2.2.3. Microscopic Test

- (1)

- SEM

- (2)

- MIP

- (3)

- XRD

3. Results

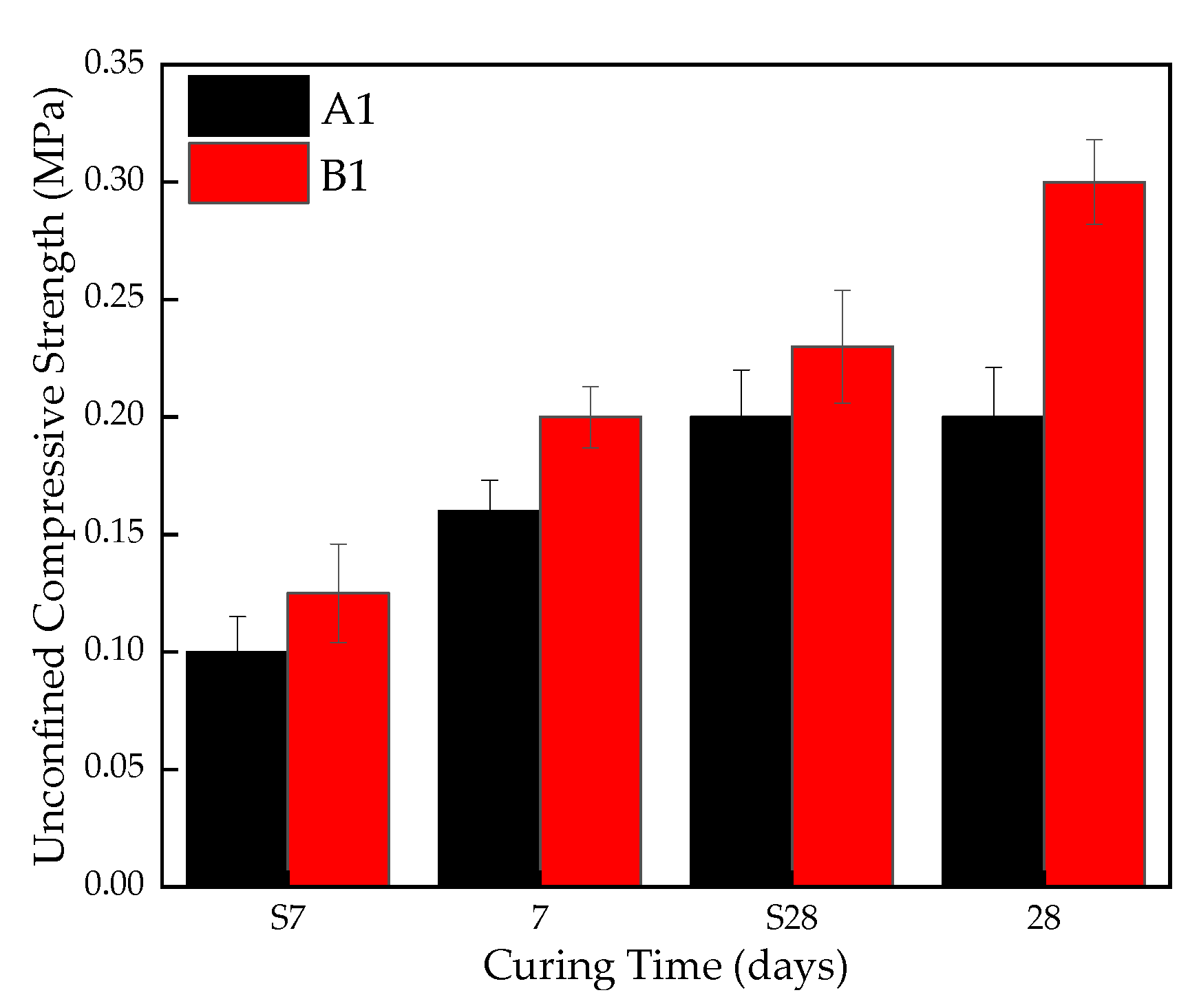

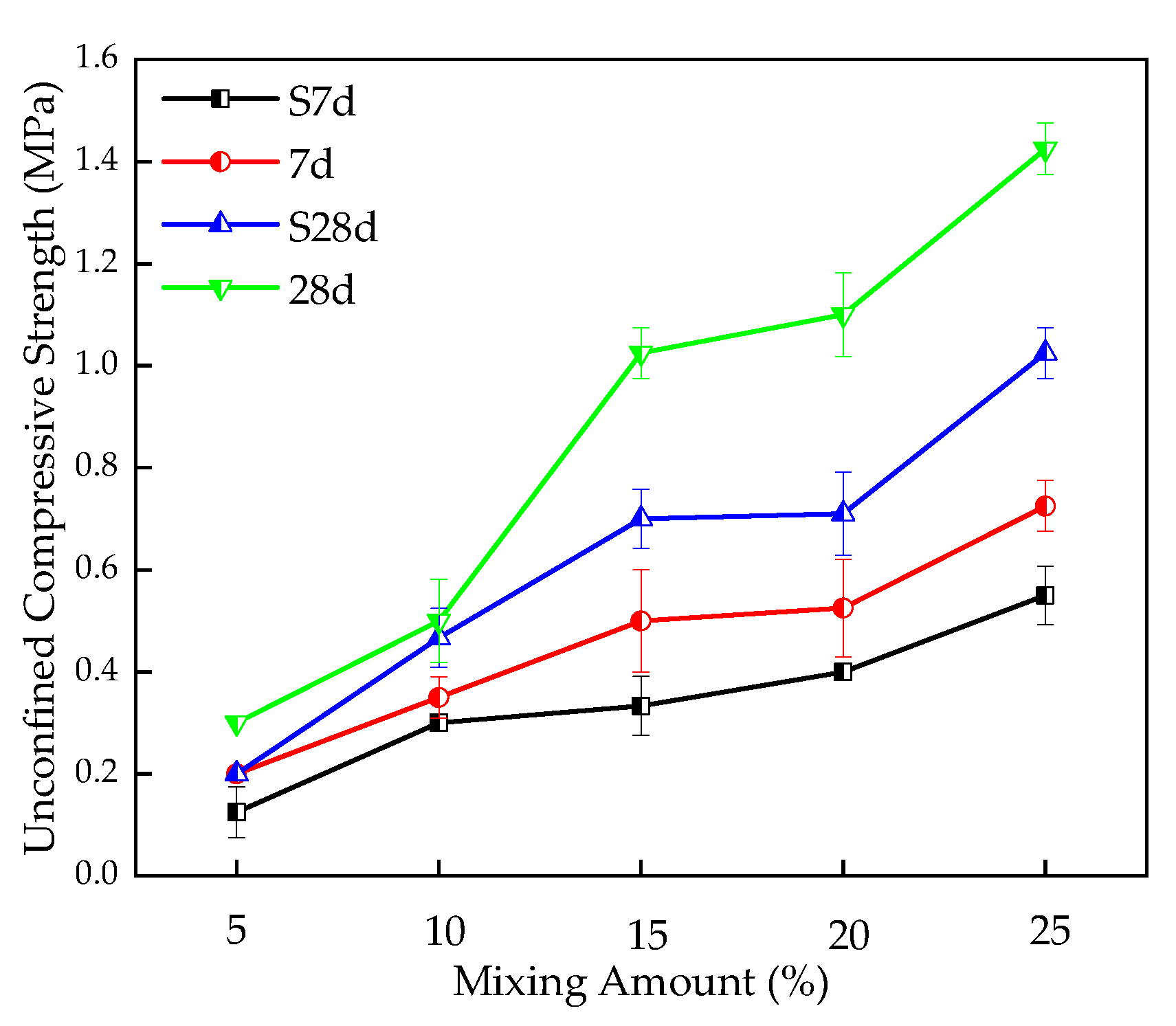

3.1. Effect of TS on UCS of Stabilized Silt

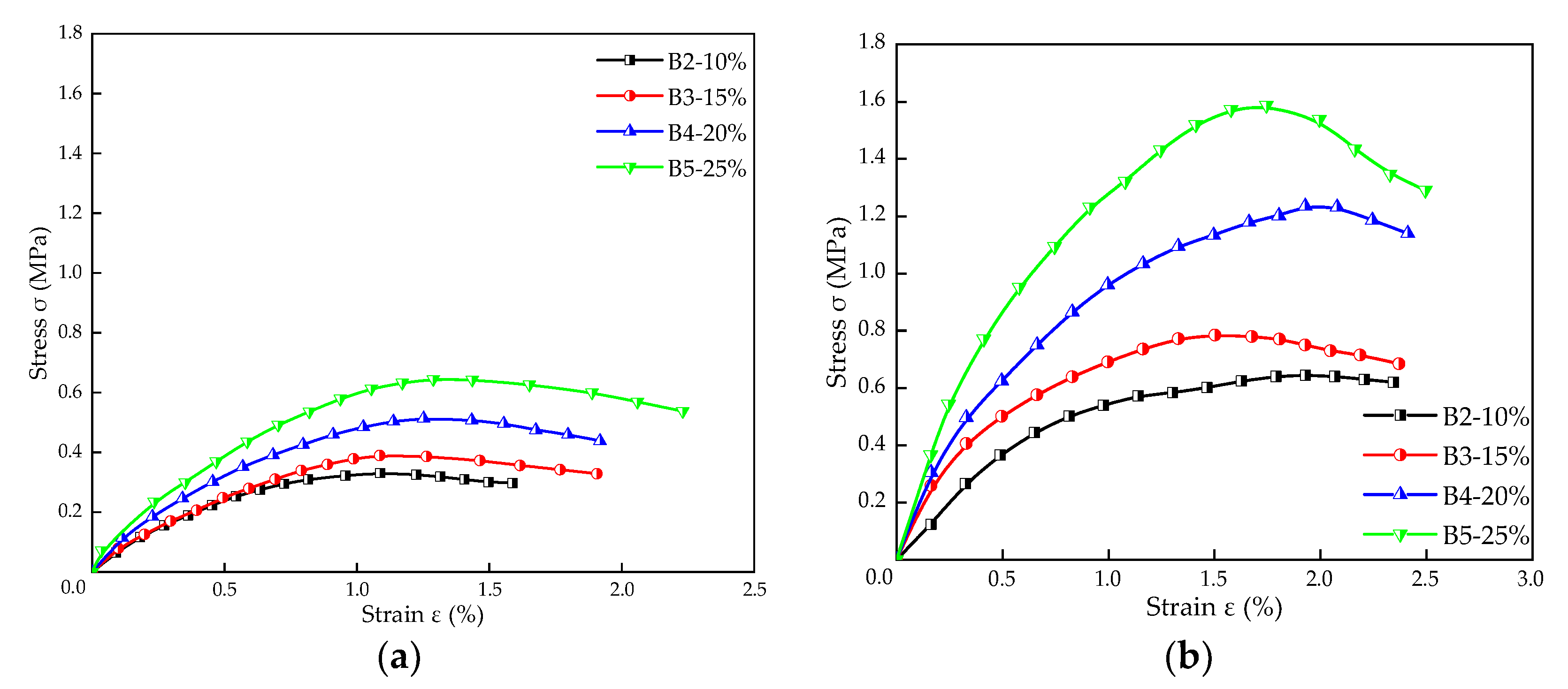

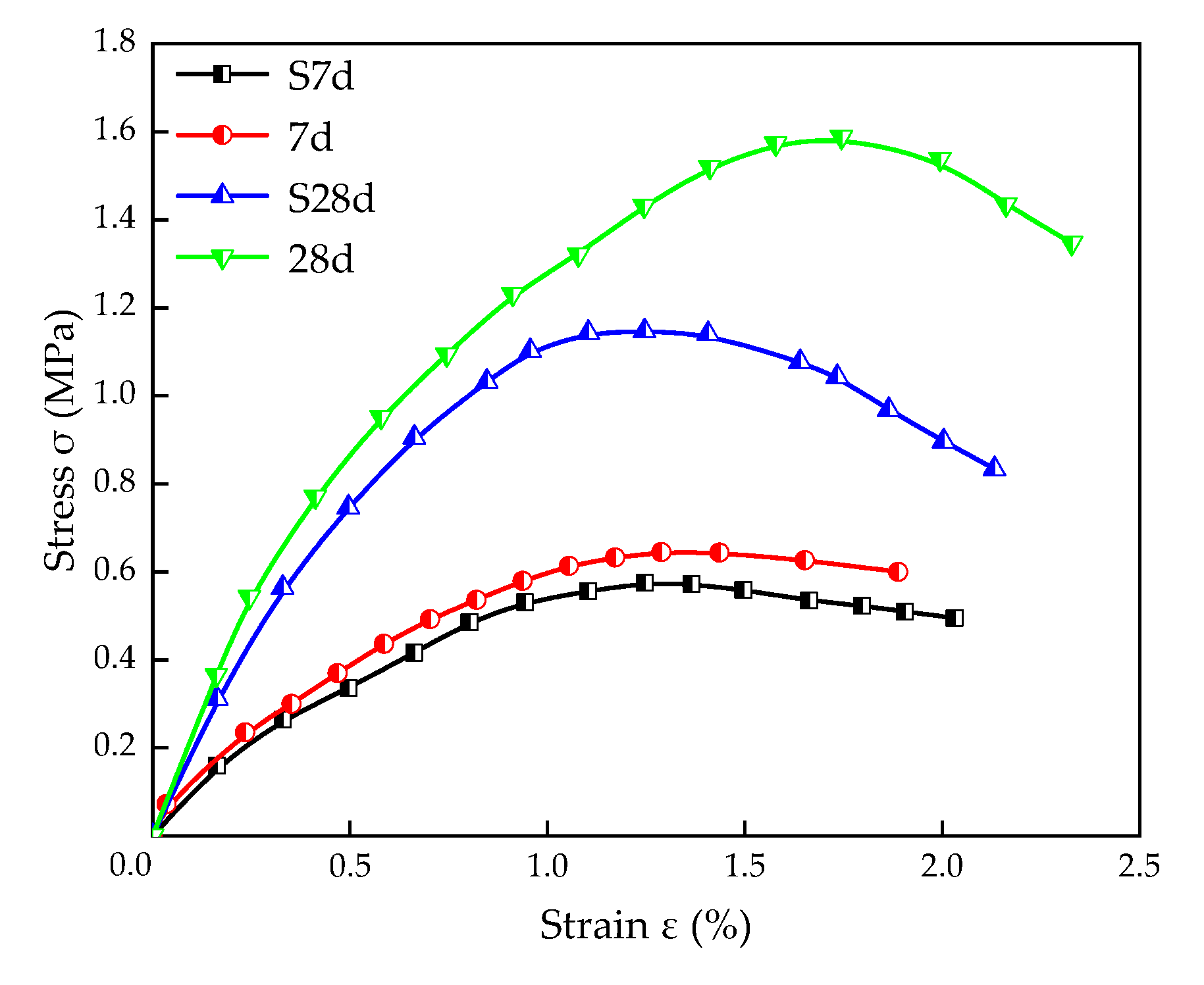

3.1.1. Stress–Strain Characteristics

3.1.2. Unconfined Compressive Strength (UCS)

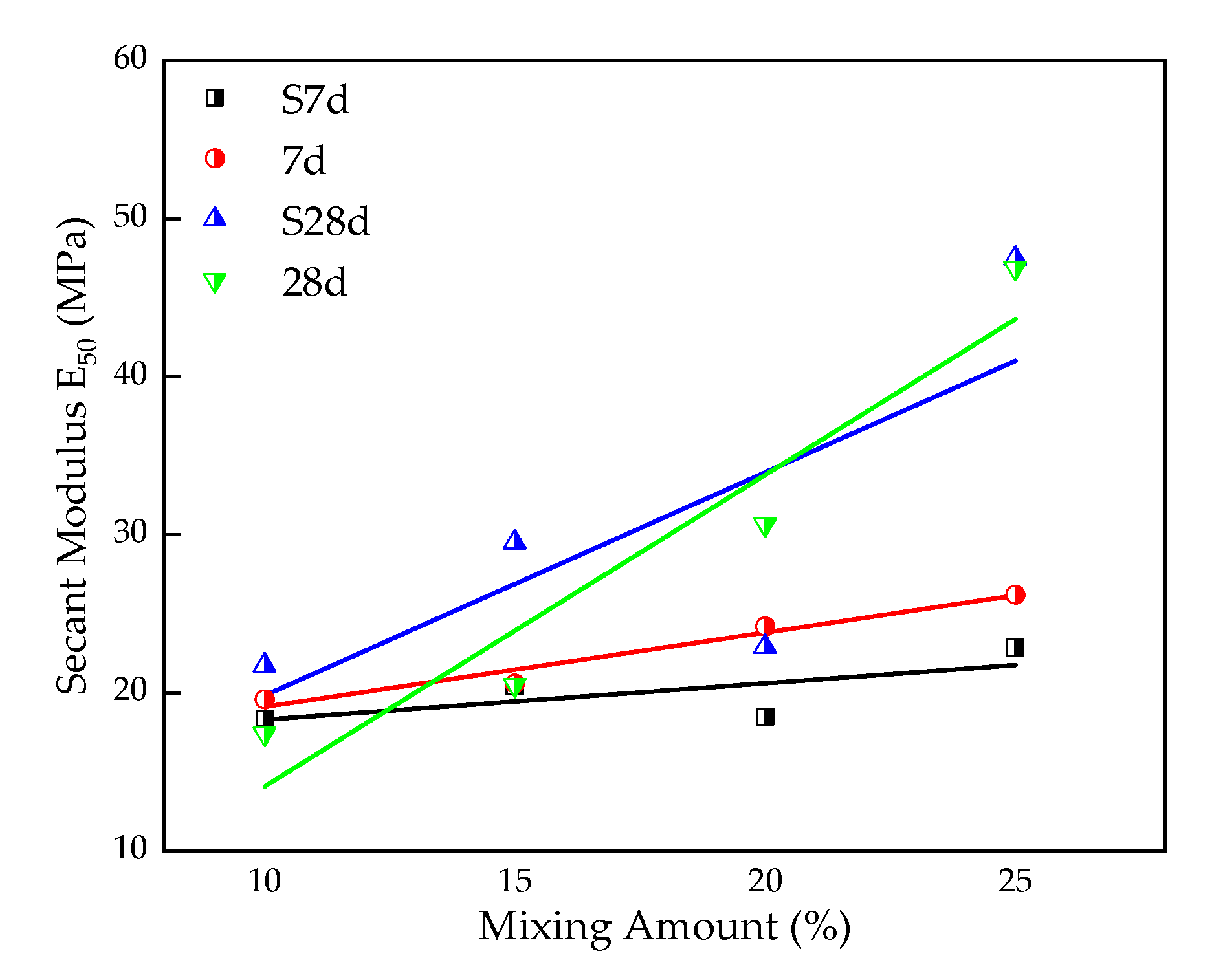

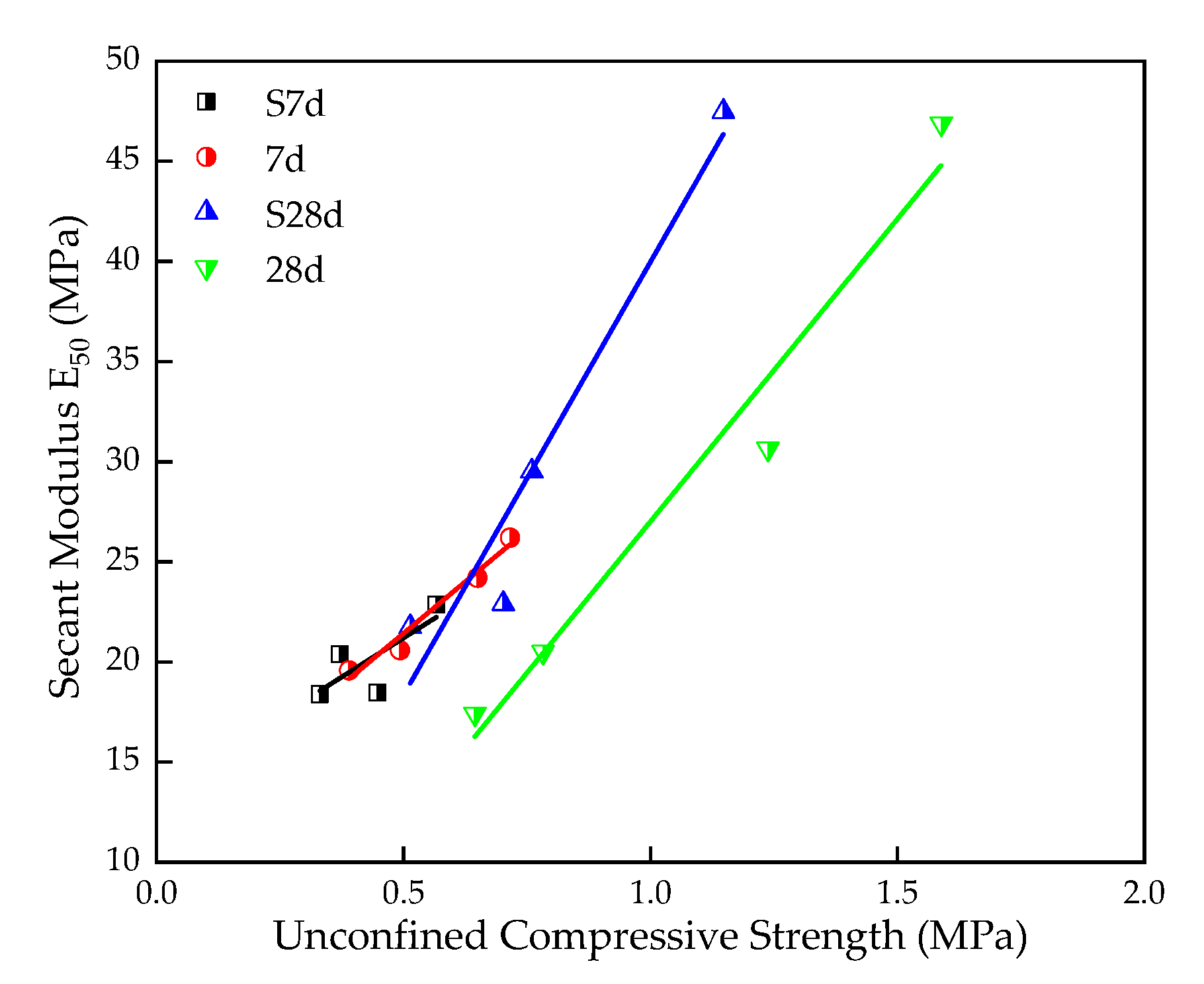

3.1.3. Secant Modulus E50

3.2. Effect of TS on Water Stability of Stabilized Silt

3.3. Mineralogical and Microstructural Analysis

3.3.1. X-ray Diffraction

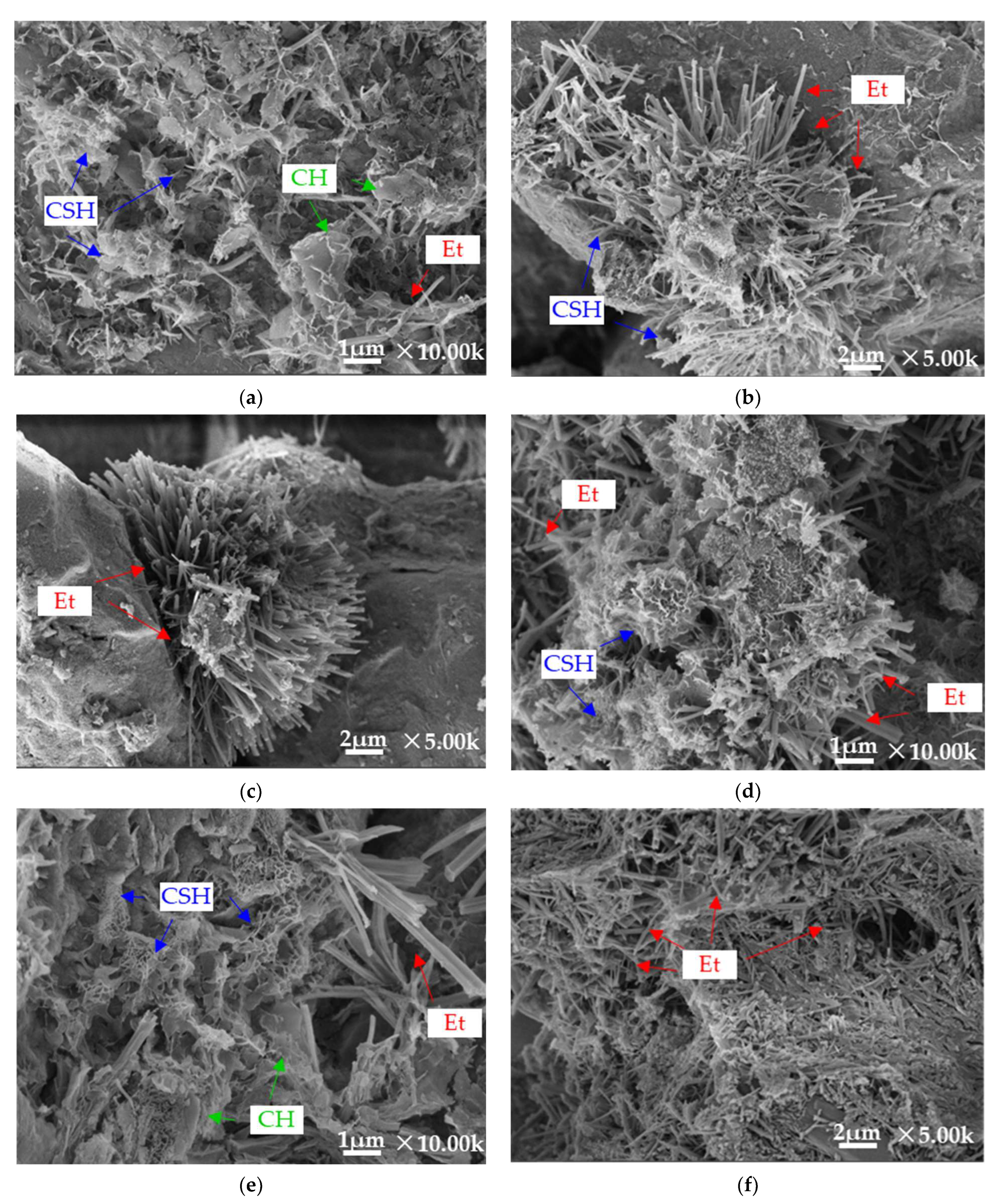

3.3.2. Scanning Electron Microscope (SEM) Observation

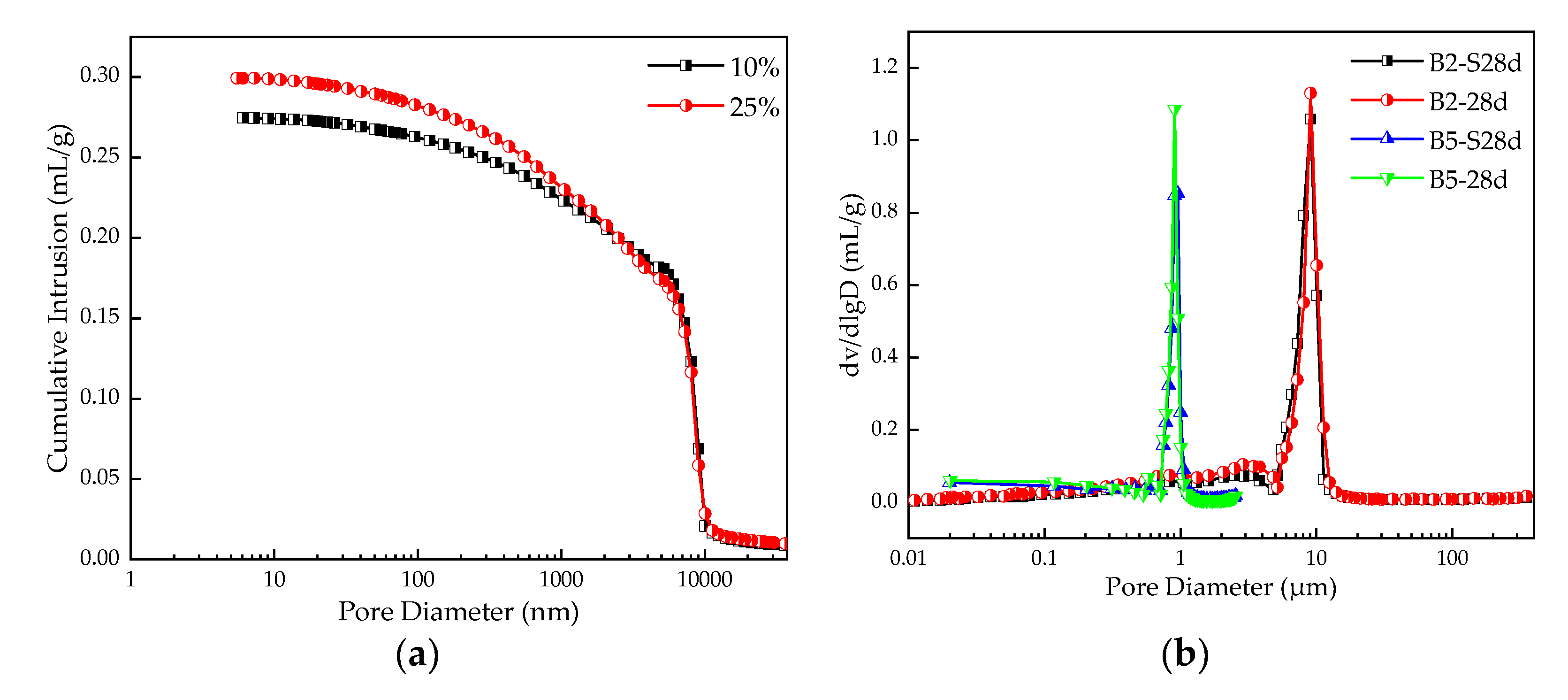

3.3.3. Mercury Intrusion Porosimetry (MIP) Analysis

4. Discussion

5. Conclusions

- The addition of TS improves the performance of silt. TS significantly improved the mechanical properties of silt, which was represented by the increase of unconfined compression strength crossing;

- The content and curing age of TS have an obvious influence on the strength characteristics of stabilized silt. With the increase of TS content, the unconfined compressive strength of stable silt increases. The strength of stabilized silt after curing for 28 days is around 1.4~2 times compared with that after curing for 7 days. Because ettringite absorbs water and expands, the strength of the specimen under water immersion curing is lower than that under standard curing;

- The fitting relationship between E50 obtained from the stress–strain curve and UCS was linear. E50 increased with the increase of UCS, and the growth rate was different under different curing conditions;

- The water stability coefficient has an obvious relationship with TS content. When TS is added to the silt, the water resistance coefficient of the stabilized soil is up to 94%, which is better than that of the silt without TS, while the water resistance is optimum when the content of TS is 10%;

- The microscopic test results show that the hydration reaction, pozzolanic reaction, and ion exchange occur in the TS stabilized silt, and the reaction products mainly include C-S-H, CH, and Et. When the mixing amount of TS is high, the gels, needle-like crystals, and rod-needle crystals are rich, and the pore structure is denser. At the same time, the remaining gypsum crystals from the TS internal reaction filled the inside of the stable silt, densifying the soil pore structure;

- TS can effectively stabilize silt with excellent mechanical properties. TS stabilized silt can solve the problem of lack of subgrade fill, effectively reduce engineering costs, promote the comprehensive utilization of solid waste, and contribute to the sustainable development of the road industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, Q.; Duan, W.; Liu, X.; Fang, P.; Chen, R.; Wang, T.; Hao, Z. Engineering Performance Evaluation of Recycled Red Mud Stabilized Loessial Silt as a Sustainable Subgrade Material. Materials 2022, 15, 3391. [Google Scholar] [CrossRef] [PubMed]

- Cai, G.; Zhang, T.; Liu, S.; Li, J.; Jie, D. Stabilization Mechanism and Effect Evaluation of Stabilized Silt with Lignin Based on Laboratory Data. Mar. Georesour.Geotechnol. 2014, 34, 331–340. [Google Scholar] [CrossRef]

- Azadi, H.; Sidek, N.; Noor, M. Effect of pozzolanic process on the strength of stabilized lime clay. Electron. J. Geotech. Eng. 2008, 13, 1–19. [Google Scholar]

- Pakbaz, M.; Alipour, R. Influence of cement addition on the geotechnical properties of an Iranian clay. Appl. Clay Sci. 2012, 67–68, 1–4. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Rachan, R.; Chinkulkijniwat, A.; Raksachon, Y.; Suddeepong, A. Analysis of strength development in cement-stabilized silty clay from microstructural considerations. Constr. Build. Mater. 2010, 24, 2011–2021. [Google Scholar] [CrossRef]

- Kang, G.; Tsuchida, T.; Kim, Y. Strength and stiffness of cement-treated marine dredged clay at various curing stages. Constr. Build. Mater. 2017, 132, 71–84. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Horpibulsuk, S.; Chanprasert, P.; Sukmak, P.; Arulrajah, A. Compressive strength development in fly ash geopolymer masonry units manufactured from water treatment sludge. Constr. Build. Mater. 2015, 82, 20–30. [Google Scholar] [CrossRef]

- Consoli, N.; Prietto, P.; da Silva Lopes, L.; Winter, D. Control factors for the long term compressive strength of lime treated sandy clay soil. Transp. Geotech. 2014, 1, 129–136. [Google Scholar] [CrossRef]

- Sharma, L.; Sirdesai, N.; Sharma, K.; Singh, T. Experimental study to examine the independent roles of lime and cement on the stabilization of a mountain soil: A comparative study. Appl. Clay Sci. 2018, 152, 183–195. [Google Scholar] [CrossRef]

- Dhar, S.; Hussain, M. The strength and microstructural behavior of lime stabilized subgrade soil in road construction. Int. J. Geotech. Eng. 2019, 15, 471–483. [Google Scholar] [CrossRef]

- Chang, J.; Jiang, J.-Q.; Lei, M.; Luo, S.-L.; He, G.-F.; Lin, J.-Y. Road performance and microscopic action mechanism of low liquid limit silt solidified by AT curing agent. Arab. J. Geosci. 2022, 15, 664. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, G.; Liu, S.; Puppala, A. Engineering properties and microstructural characteristics of foundation silt stabilized by lignin-based industrial by-product. KSCE J. Civ. Eng. 2016, 20, 2725–2736. [Google Scholar] [CrossRef]

- Yanmei, Z.; Jincheng, L.; Xiaofeng, Z.; Feifei, C. Study on unsaturated mechanical properties of lignin-lime improved silt. Jpn. Geotech. Soc. Spec. Publ. 2019, 7, 125–132. [Google Scholar] [CrossRef]

- Kong, X.; Song, S.; Wang, M.; Zhao, Q. Experimental Research of Low Liquid Limit Silt Stabilized by Lignin in the Flooding Area of Yellow River. Geotech. Geol. Eng. 2019, 37, 5211–5217. [Google Scholar] [CrossRef]

- Cui, K.; Fan, S. Indoor direct shear and uniaxial compression testing of polymer-modified silt. Clust. Comput. 2017, 22 (Suppl. 3), 5447–5455. [Google Scholar] [CrossRef]

- Yuan, H.; Ren, G.; Liu, K.; Zheng, W.; Zhao, Z. Experimental Study of EICP Combined with Organic Materials for Silt Improvement in the Yellow River Flood Area. Appl. Sci. 2020, 10, 7678. [Google Scholar] [CrossRef]

- Lo, S.; Wardani, S. Strength and dilatancy of a silt stabilized by a cement and fly ash mixture. Can. Geotech. J. 2002, 39, 77–89. [Google Scholar] [CrossRef]

- Dungca, J. Fly-Ash-Based Geopolymer as Stabilizer for Silty Sand Embankment Materials. Int. J. GEOMATE 2018, 14, 143–149. [Google Scholar] [CrossRef]

- Zhu, Z.; Pu, S.; Zhang, J.; Wan, Y.; Song, W.; Wang, H. Water resistance and compressibility of silt solidified with lime and fly-ash mixtures. Environ. Earth Sci. 2021, 80, 103. [Google Scholar] [CrossRef]

- Du, Y.-J.; Jiang, N.-J.; Liu, S.-Y.; Horpibulsuk, S.; Arulrajah, A. Field evaluation of soft highway subgrade soil stabilized with calcium carbide residue. Soils Found. 2016, 56, 301–314. [Google Scholar] [CrossRef]

- Aldaood, A.; Bouasker, M.; Al-Mukhtar, M. Geotechnical properties of lime-treated gypseous soils. Appl. Clay Sci. 2014, 88–89, 39–48. [Google Scholar] [CrossRef]

- Wu, J.; Liu, L.; Deng, Y.; Zhang, G.; Zhou, A.; Xiao, H. Use of recycled gypsum in the cement-based stabilization of very soft clays and its micro-mechanism. J. Rock Mech. Geotech. Eng. 2022, 14, 909–921. [Google Scholar] [CrossRef]

- Suárez, S.; Roca, X.; Gasso, S. Product-specific life cycle assessment of recycled gypsum as a replacement for natural gypsum in ordinary Portland cement: Application to the Spanish context. J. Clean. Prod. 2016, 117, 150–159. [Google Scholar] [CrossRef]

- Khadka, S.; Jayawickrama, P.; Senadheera, S.; Segvic, B. Stabilization of highly expansive soils containing sulfate using metakaolin and fly ash based geopolymer modified with lime and gypsum. Transp. Geotech. 2020, 23, 100327. [Google Scholar] [CrossRef]

- Andavan, S.; Pagadala, V. Experimental study on addition of lime and fly ash for the soil stabilization. Mater. Today Proc. 2020, 22, 1065–1069. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, J.; Li, S.; Gao, Y.; Liu, C.; Qi, Y. Effect of different gypsums on the workability and mechanical properties of red mud-slag based grouting materials. J. Clean. Prod. 2020, 245, 118759. [Google Scholar] [CrossRef]

- Pace, M.; Telesca, A.; Marroccoli, M.; Valenti, G. Use of industrial byproducts as alumina sources for the synthesis of calcium sulfoaluminate cements. Environ. Sci. Technol. 2011, 45, 6124–6128. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Wang, F.; Huang, H.; Guo, Y.; Li, B.; Liu, Y.; Chu, P. Gypsum blocks produced from TiO2 production by-products. Environ. Technol. 2016, 37, 1094–1100. [Google Scholar] [CrossRef]

- Zhai, W.; Dai, Y.; Zhao, W.; Yuan, H.; Qiu, D.; Chen, J.; Gustave, W.; Maguffin, S.; Chen, Z.; Liu, X.; et al. Simultaneous immobilization of the cadmium, lead and arsenic in paddy soils amended with titanium gypsum. Environ. Pollut. 2020, 258, 113790. [Google Scholar] [CrossRef]

- Li, J.; Wang, W.; Xu, D.; Wang, X.; Mao, Y. Preparation of sulfoaluminate cementitious material using harmful titanium gypsum: Material properties and heavy metal immobilization characteristics. Waste Dispos. Sustain. Energy 2020, 2, 127–137. [Google Scholar] [CrossRef]

- Chen, S.; Yuan, H. Characterization and optimization of eco-friendly cementitious materials based on titanium gypsum, fly ash, and calcium carbide residue. Constr. Build. Mater. 2022, 349, 128635. [Google Scholar] [CrossRef]

- Zha, F.; Qiao, B.; Kang, B.; Xu, L.; Chu, C.; Yang, C. Engineering properties of expansive soil stabilized by physically amended titanium gypsum. Constr. Build. Mater. 2021, 303, 124456. [Google Scholar] [CrossRef]

- Ebailila, M.; Kinuthia, J.; Oti, J. Role of Gypsum Content on the Long-Term Performance of Lime-Stabilised Soil. Materials 2022, 15, 5099. [Google Scholar] [CrossRef] [PubMed]

- Du, Y.-J.; Jiang, N.-J.; Liu, S.-Y.; Jin, F.; Singh, D.; Puppala, A. Engineering properties and microstructural characteristics of cement-stabilized zinc-contaminated kaolin. Can. Geotech. J. 2014, 51, 289–302. [Google Scholar] [CrossRef]

- Lee, F.-H.; Lee, Y.; Chew, S.-H.; Yong, K.-Y. Strength and Modulus of Marine Clay-Cement Mixes. J. Geotech. Geoenviron. Eng. 2005, 131, 178–186. [Google Scholar] [CrossRef]

- Lemaire, K.; Deneele, D.; Bonnet, S.; Legret, M. Effects of lime and cement treatment on the physicochemical, microstructural and mechanical characteristics of a plastic silt. Eng. Geol. 2013, 166, 255–261. [Google Scholar] [CrossRef]

- Cho, B.; Choi, H. Physical and chemical properties of concrete using GGBFS-KR slag-gypsum binder. Constr. Build. Mater. 2016, 123, 436–443. [Google Scholar] [CrossRef]

- Abdila, S.; Abdullah, M.; Ahmad, R.; Rahim, S.; Rychta, M.; Wnuk, I.; Nabialek, M.; Muskalski, K.; Tahir, M.; Syafwandi; et al. Evaluation on the Mechanical Properties of Ground Granulated Blast Slag (GGBS) and Fly Ash Stabilized Soil via Geopolymer Process. Materials 2021, 14, 2833. [Google Scholar] [CrossRef]

- Jiang, N.; Wang, C.; Wang, Z.; Li, B.; Liu, Y. Strength Characteristics and Microstructure of Cement Stabilized Soft Soil Admixed with Silica Fume. Materials 2021, 14, 1929. [Google Scholar] [CrossRef]

- Adeleke, B.; Kinuthia, J.; Oti, J. Impacts of MgO waste:GGBS formulations on the performance of a stabilised natural high sulphate bearing soil. Constr. Build. Mater. 2022, 315, 125745. [Google Scholar] [CrossRef]

| Optimum Moisture Content (%) | Maximum Dry Density (g/cm3) | Liquid Limit (%) | Plastic Limit (%) | Plasticity Index | Specific Gravity |

|---|---|---|---|---|---|

| 14.4 | 1.6 | 29.8 | 20.1 | 9.7 | 2.7 |

| Particle Size (mm) | >0.25 | 0.25–0.075 | 0.075–0.05 | 0.05–0.005 | 0.005–0.002 | <0.002 |

| Content (%) | 0.3 | 20.3 | 23.2 | 56.2 | 0 | 0 |

| Oxides | SO3 | CaO | Fe2O3 | TiO2 | SiO2 | Al2O3 | MgO |

|---|---|---|---|---|---|---|---|

| Value (%) | 36.7 | 33.9 | 13.0 | 8.5 | 4.1 | 1.2 | 0.9 |

| Sample ID | C | L | TG | Mixing Amount | Curing Time (Days) | Test Items |

|---|---|---|---|---|---|---|

| A1 | 1 | 1 | - | 5% | 7d 1, S7d 1, 28d 1, S28d 1 | UCT, ERT, XRD, SEM, MIP |

| B1 | 1 | 1 | 8 | 5% | ||

| B2 | 1 | 1 | 8 | 10% | ||

| B3 | 1 | 1 | 8 | 15% | ||

| B4 | 1 | 1 | 8 | 20% | ||

| B5 | 1 | 1 | 8 | 25% |

| Sample ID | Mixing Amount | 7d | S28d | 28d |

|---|---|---|---|---|

| B2 | 10% | SEM | SEM, MIP | SEM, MIP |

| B5 | 25% | SEM | SEM, MIP | SEM, MIP, XRD |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lin, Q.; Zhen, X.; Rong, Y.; Li, Y.; Zhang, H.; Zhang, Q.; Yao, Z.; Yao, K. Investigation on Mechanical and Microstructure Properties of Silt Improved by Titanium Gypsum-Based Stabilizer. Materials 2023, 16, 271. https://doi.org/10.3390/ma16010271

Lin Q, Zhen X, Rong Y, Li Y, Zhang H, Zhang Q, Yao Z, Yao K. Investigation on Mechanical and Microstructure Properties of Silt Improved by Titanium Gypsum-Based Stabilizer. Materials. 2023; 16(1):271. https://doi.org/10.3390/ma16010271

Chicago/Turabian StyleLin, Qiqi, Xidong Zhen, Yu Rong, Yunlong Li, Haiyan Zhang, Qiping Zhang, Zhanyong Yao, and Kai Yao. 2023. "Investigation on Mechanical and Microstructure Properties of Silt Improved by Titanium Gypsum-Based Stabilizer" Materials 16, no. 1: 271. https://doi.org/10.3390/ma16010271

APA StyleLin, Q., Zhen, X., Rong, Y., Li, Y., Zhang, H., Zhang, Q., Yao, Z., & Yao, K. (2023). Investigation on Mechanical and Microstructure Properties of Silt Improved by Titanium Gypsum-Based Stabilizer. Materials, 16(1), 271. https://doi.org/10.3390/ma16010271