Effects of Small Deviations in Fiber Orientation on Compressive Characteristics of Plain Concrete Cylinders Confined with FRP Laminates

Abstract

1. Introduction

Research Significance

2. Finite Element Modeling

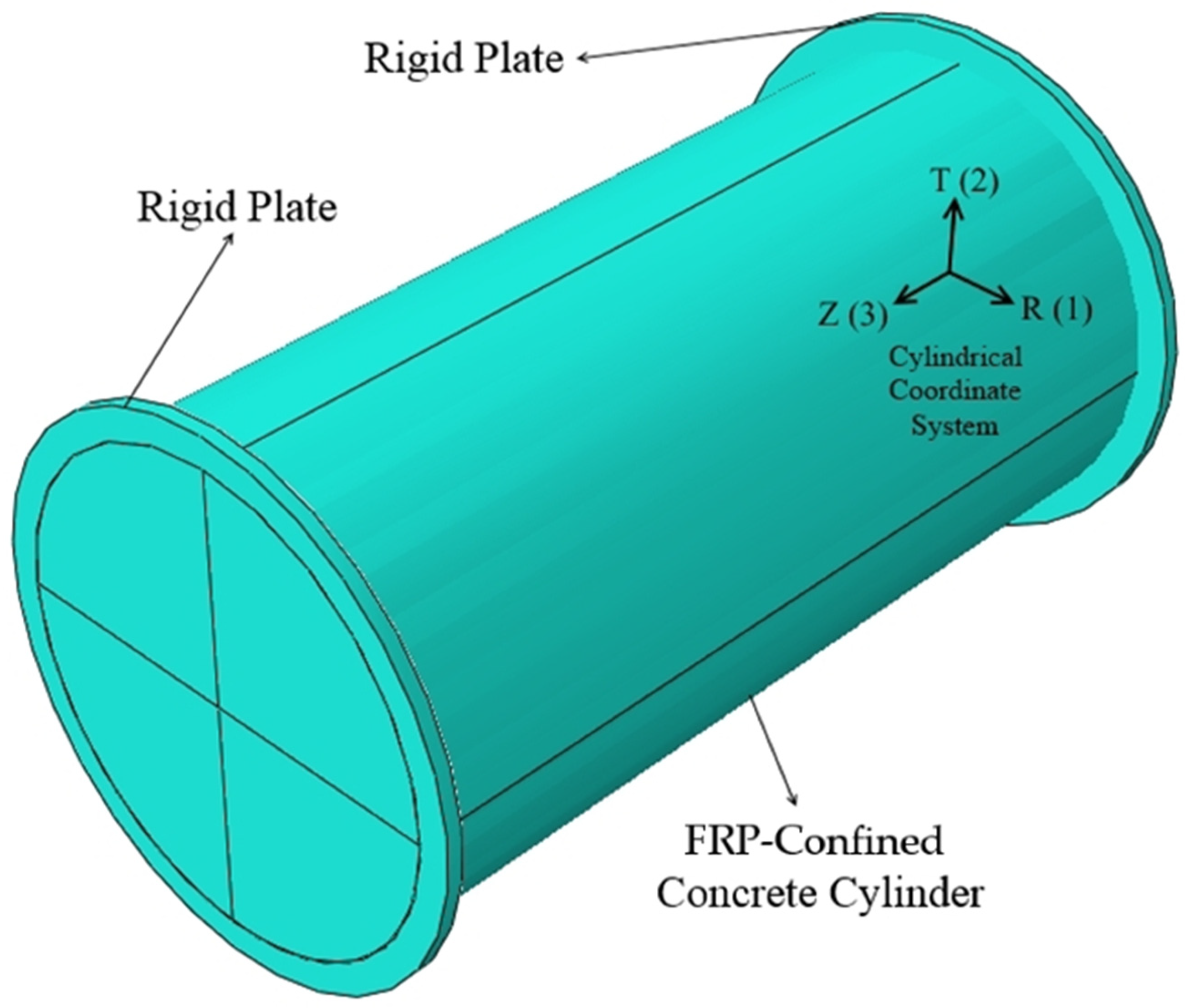

2.1. Geometry, Boundary Conditions, Loading and Failure Criterion

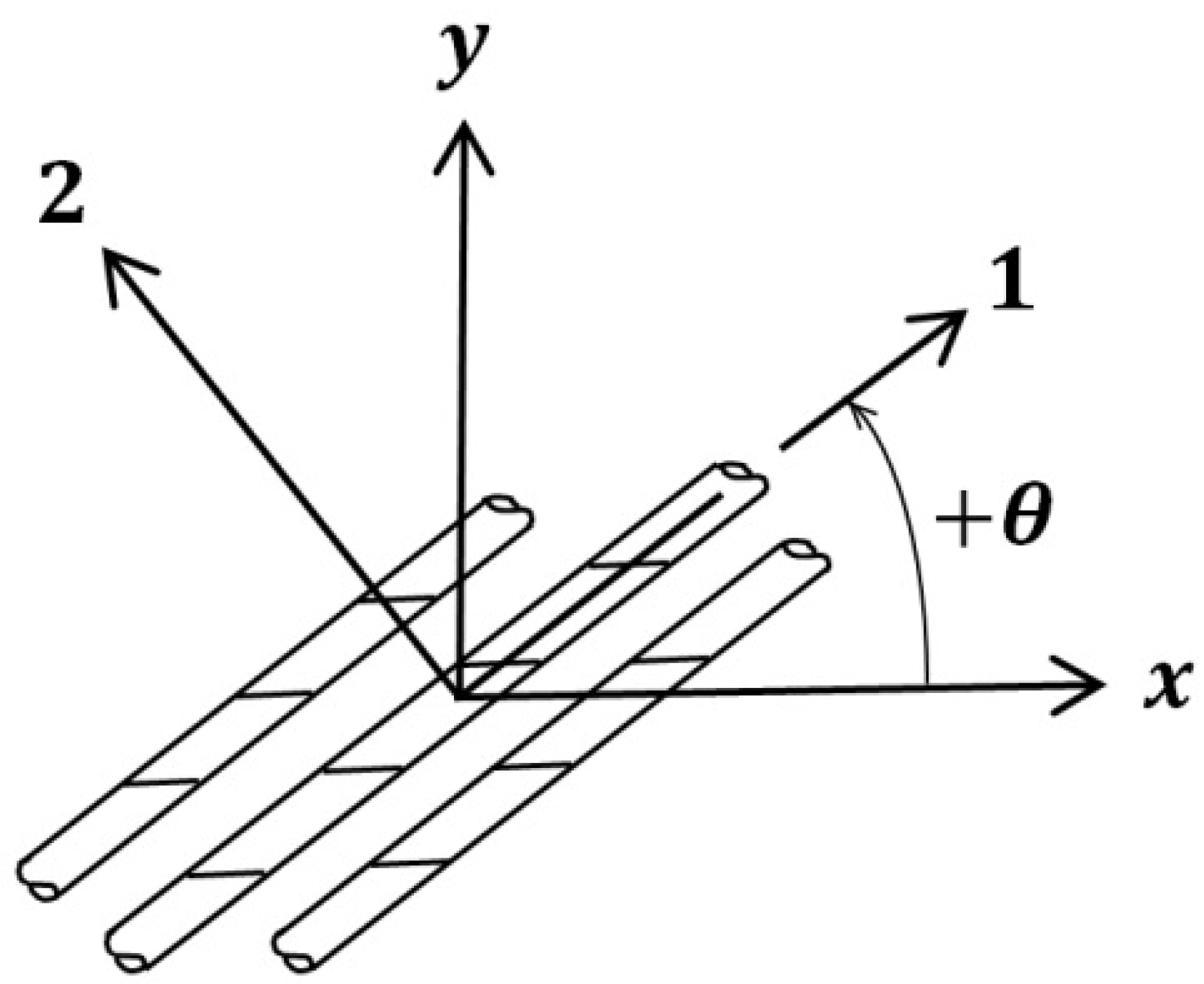

2.2. Modeling of FRP Wrap

2.3. Modeling of FRP-Confined Concrete

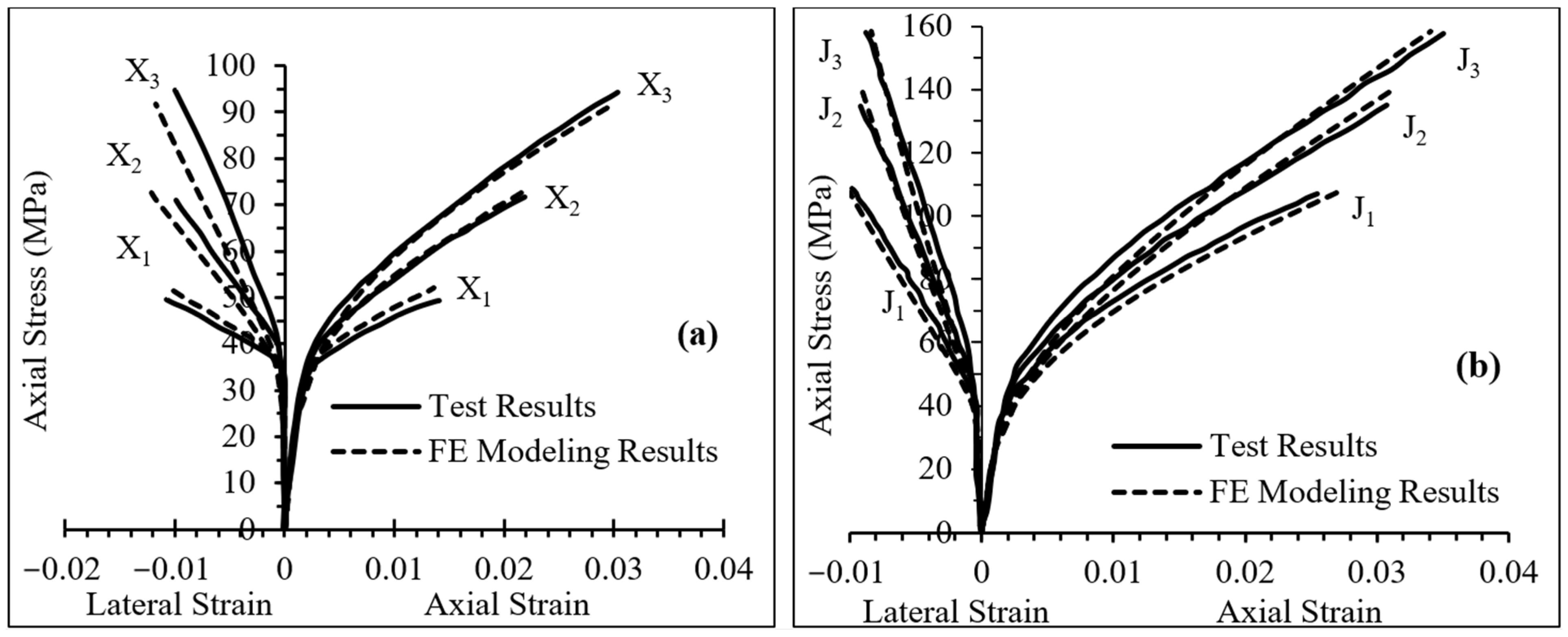

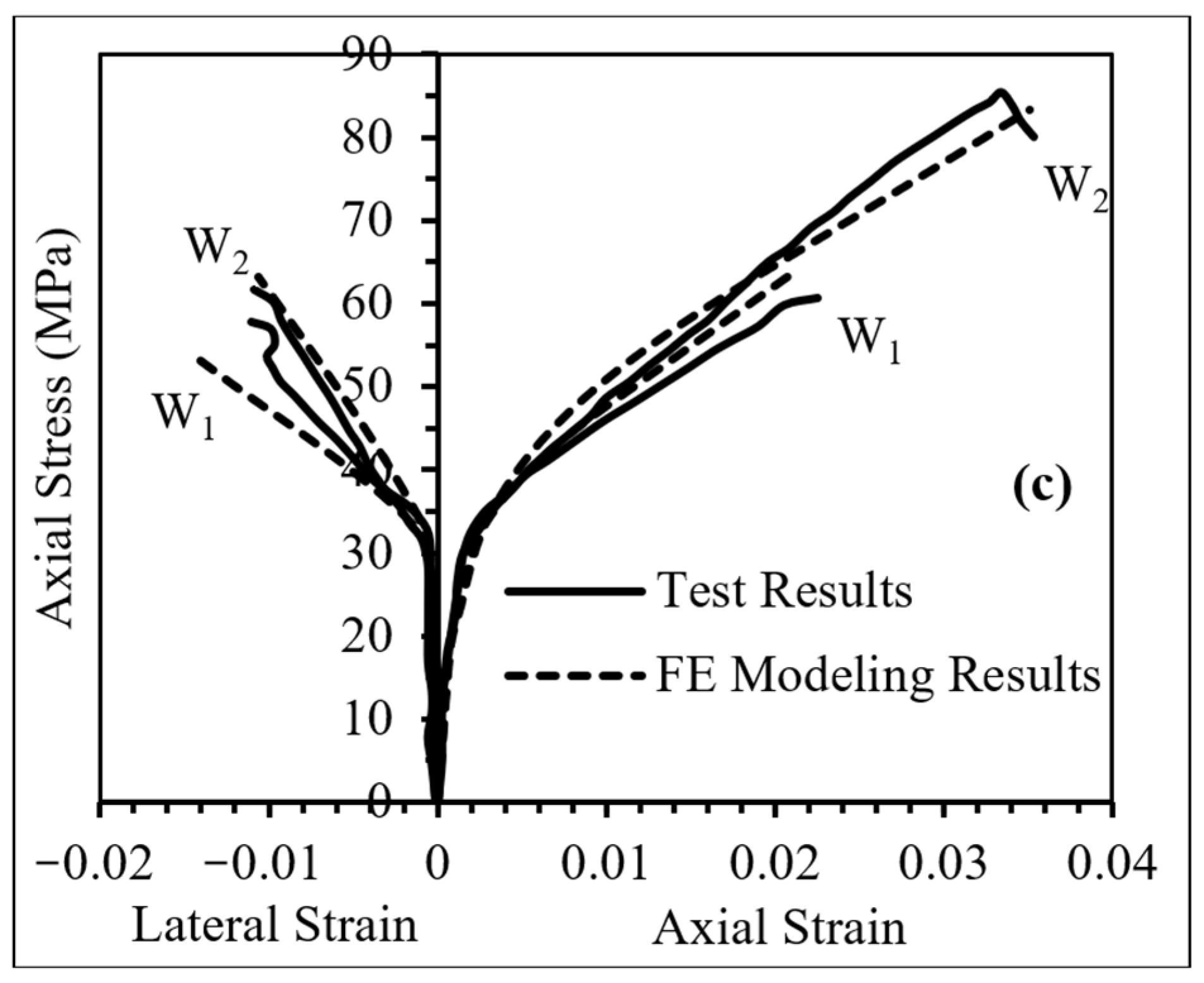

3. Validation of the FEM

4. Parametric Study

4.1. Investigated Parameters

4.2. Modeling Procedure of Concrete Confined using FRP with Inclined Fibers

4.3. Confined Concrete with Fibers in Hoop Direction

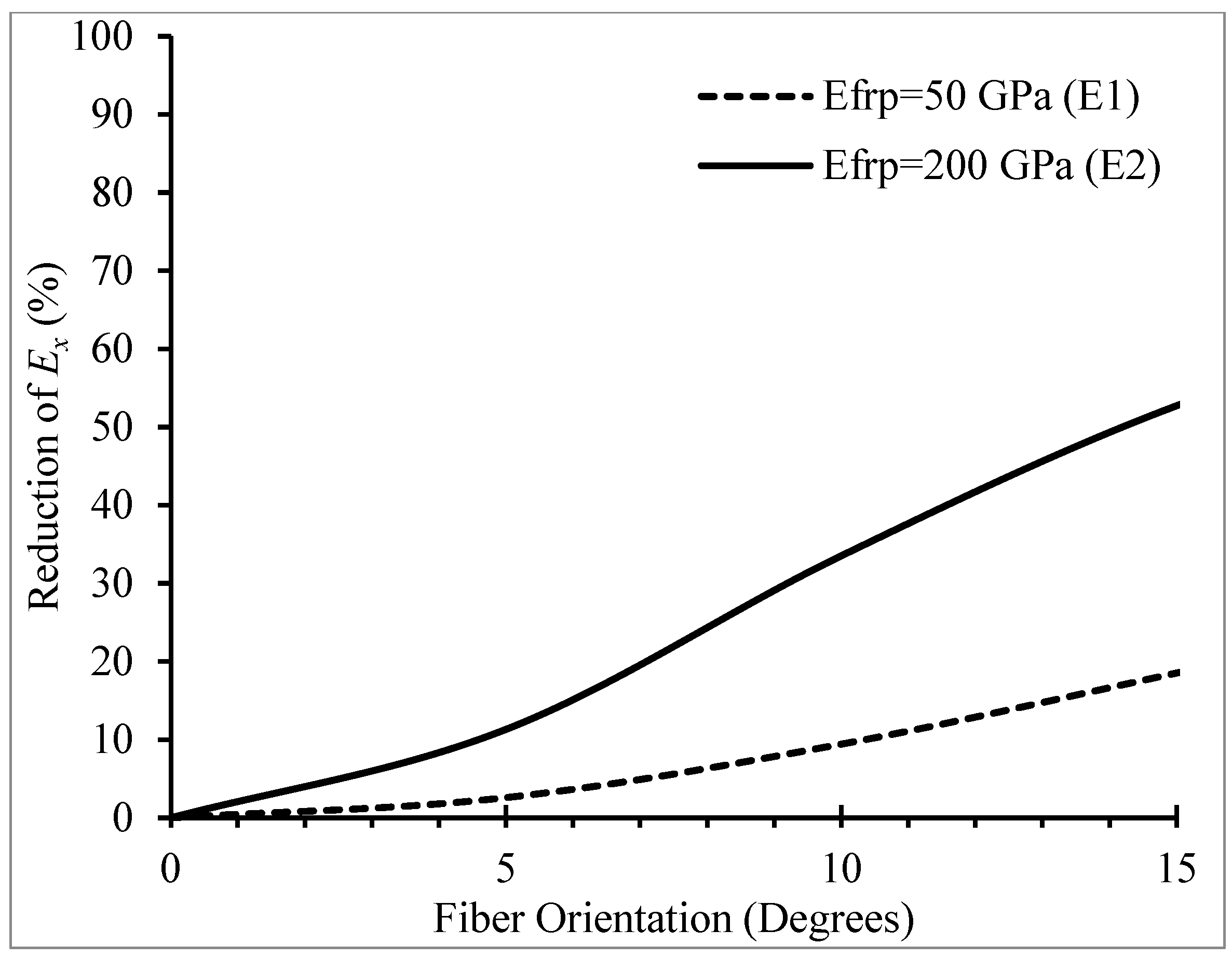

4.4. Effect of Fiber Orientation on FRP Modulus of Elasticity in Hoop Direction ()

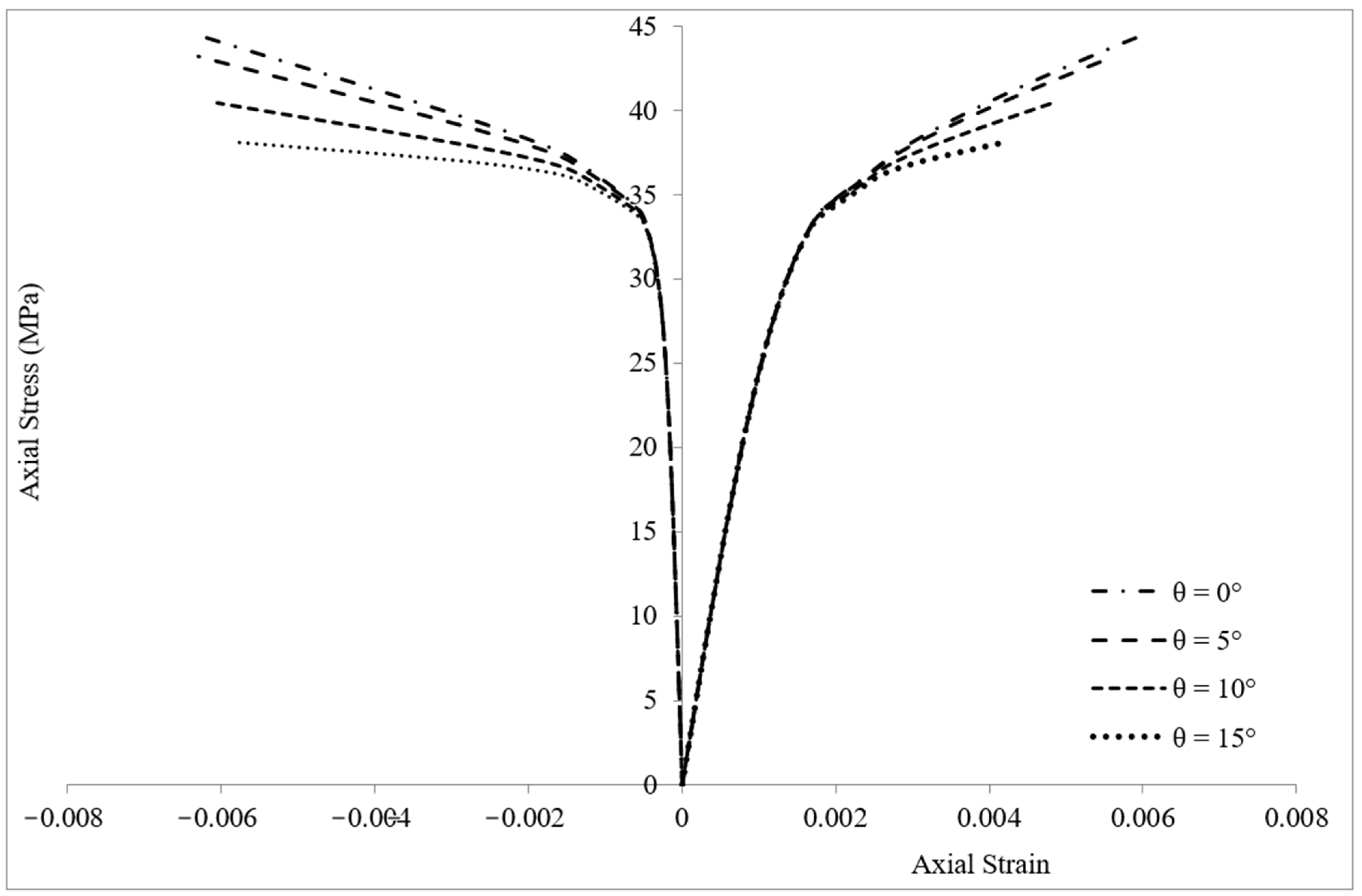

4.5. Effect of Fiber Orientation on Axial Stress–Axial and Lateral Strain Responses

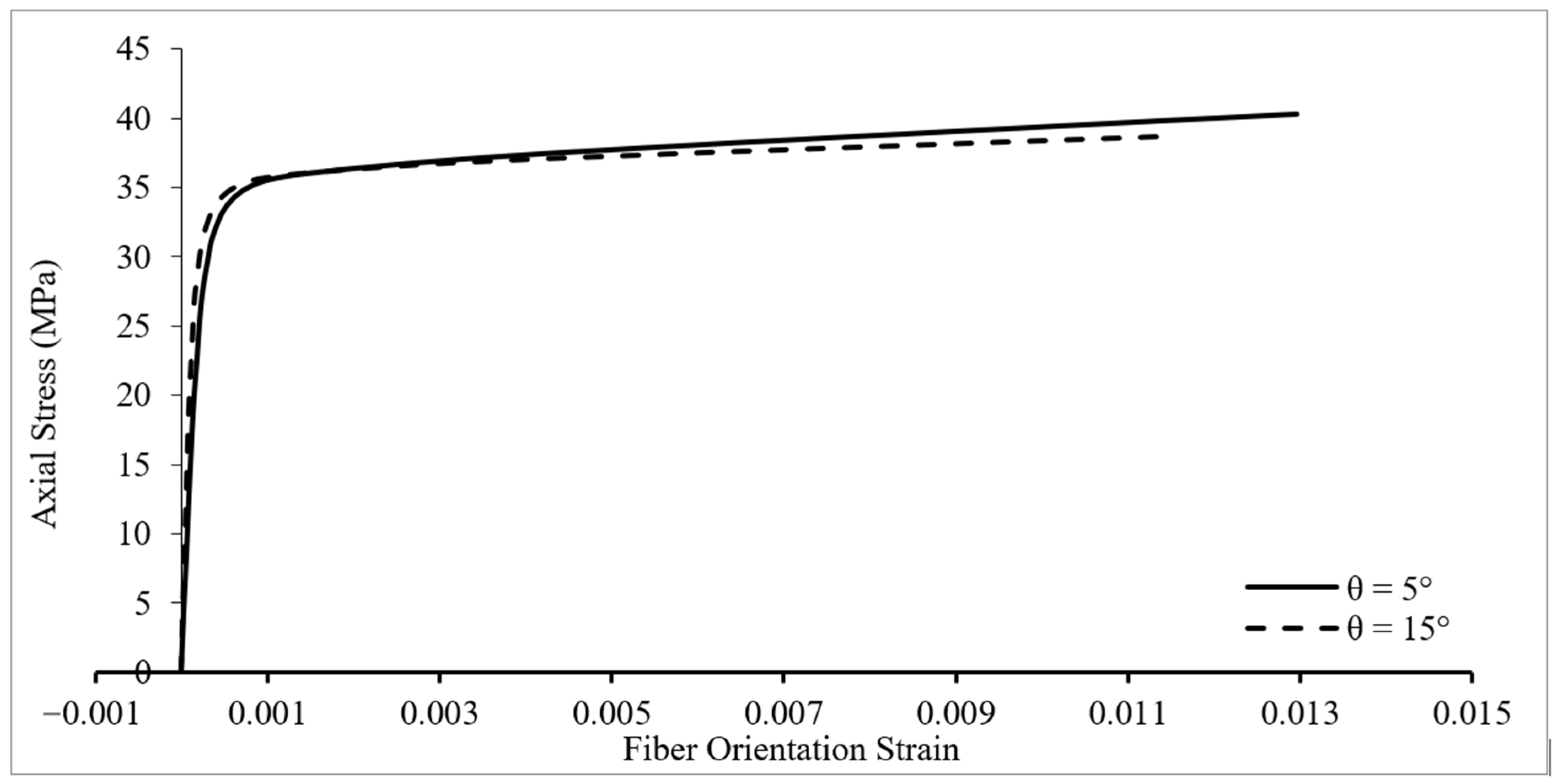

4.6. Variation of Concrete Axial Stress versus FRP Strain in Fiber Direction

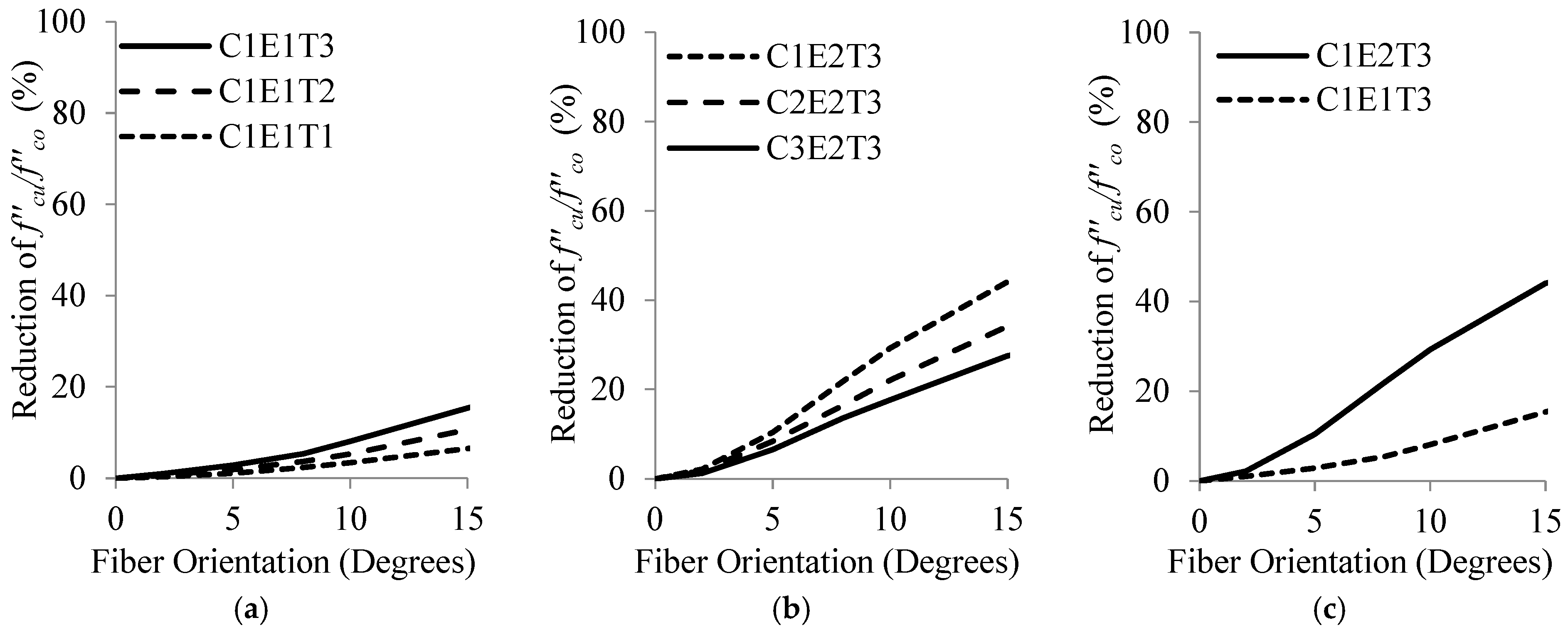

4.7. Effect of Fiber Orientation on Strength Improvement Ratio

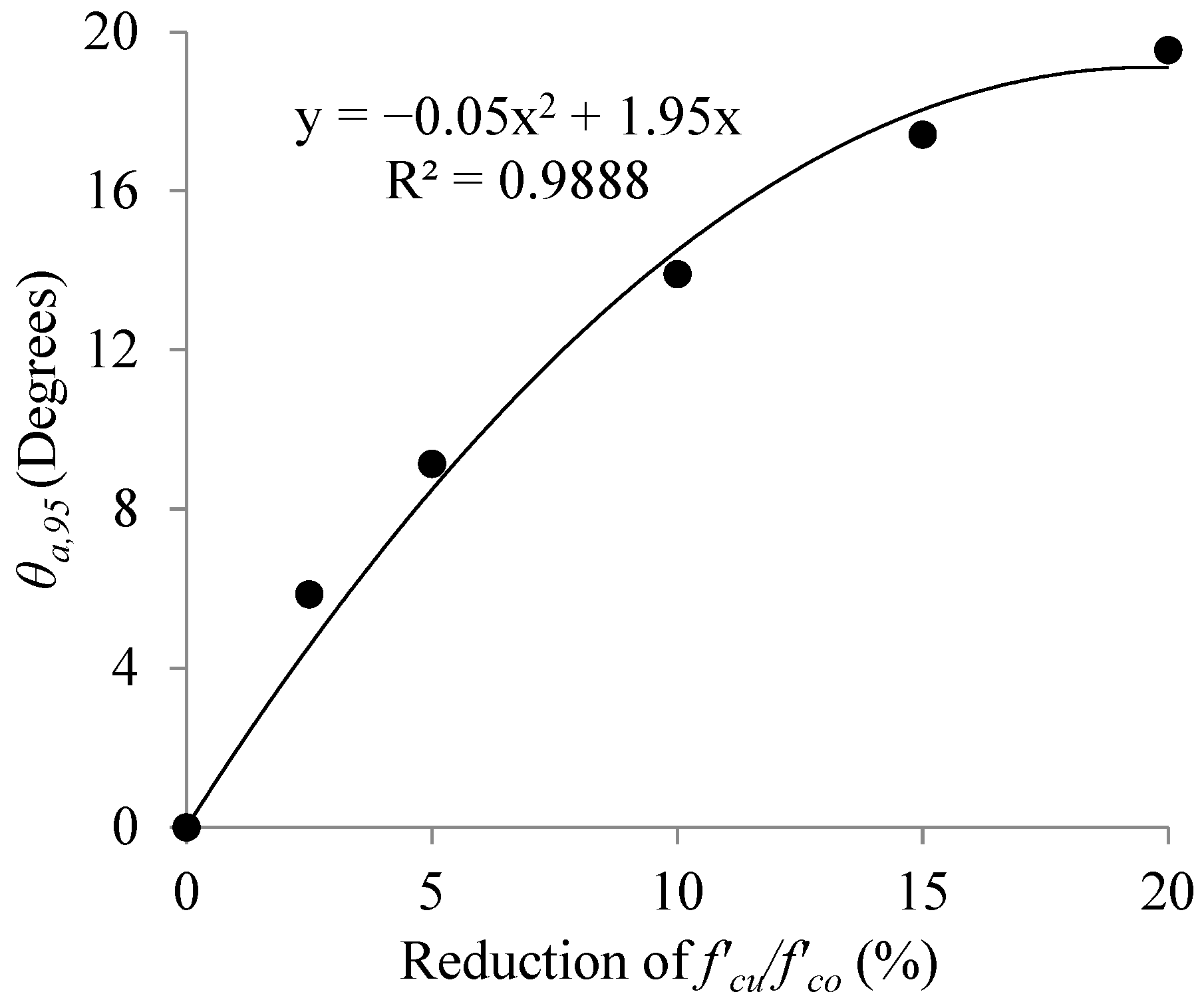

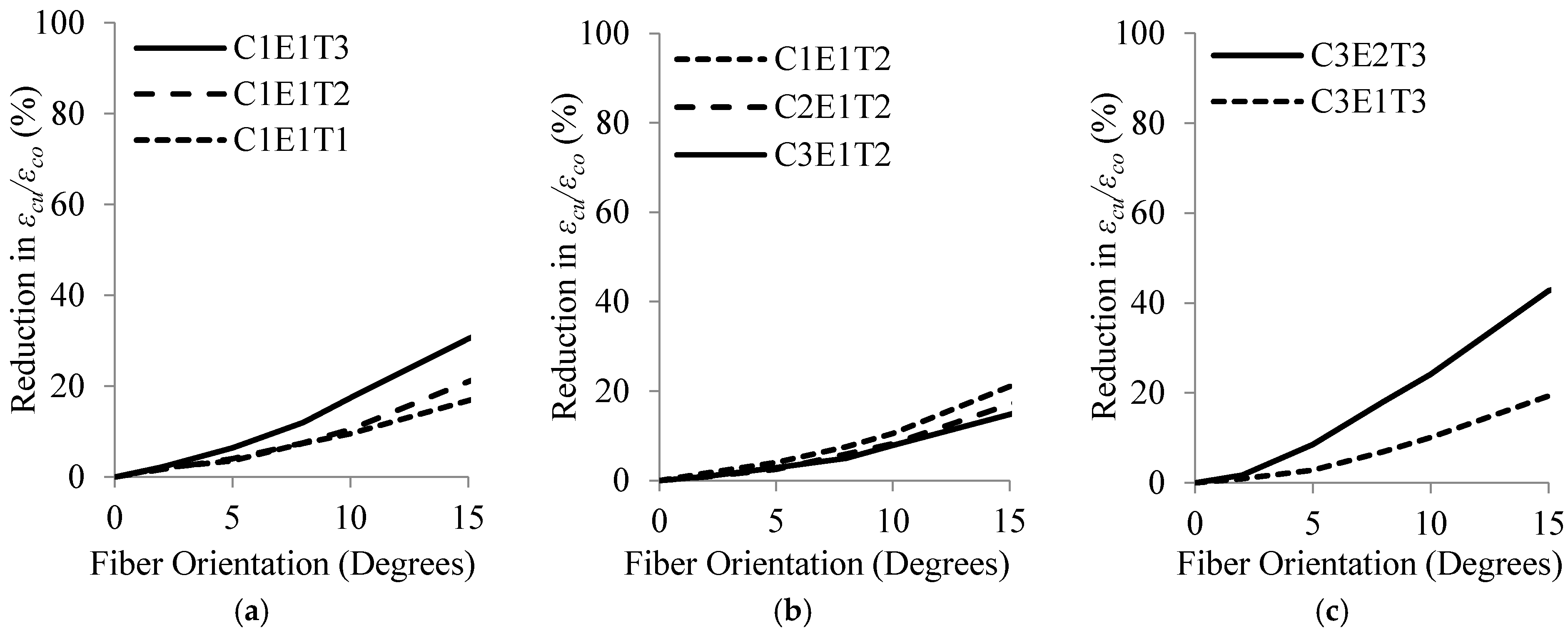

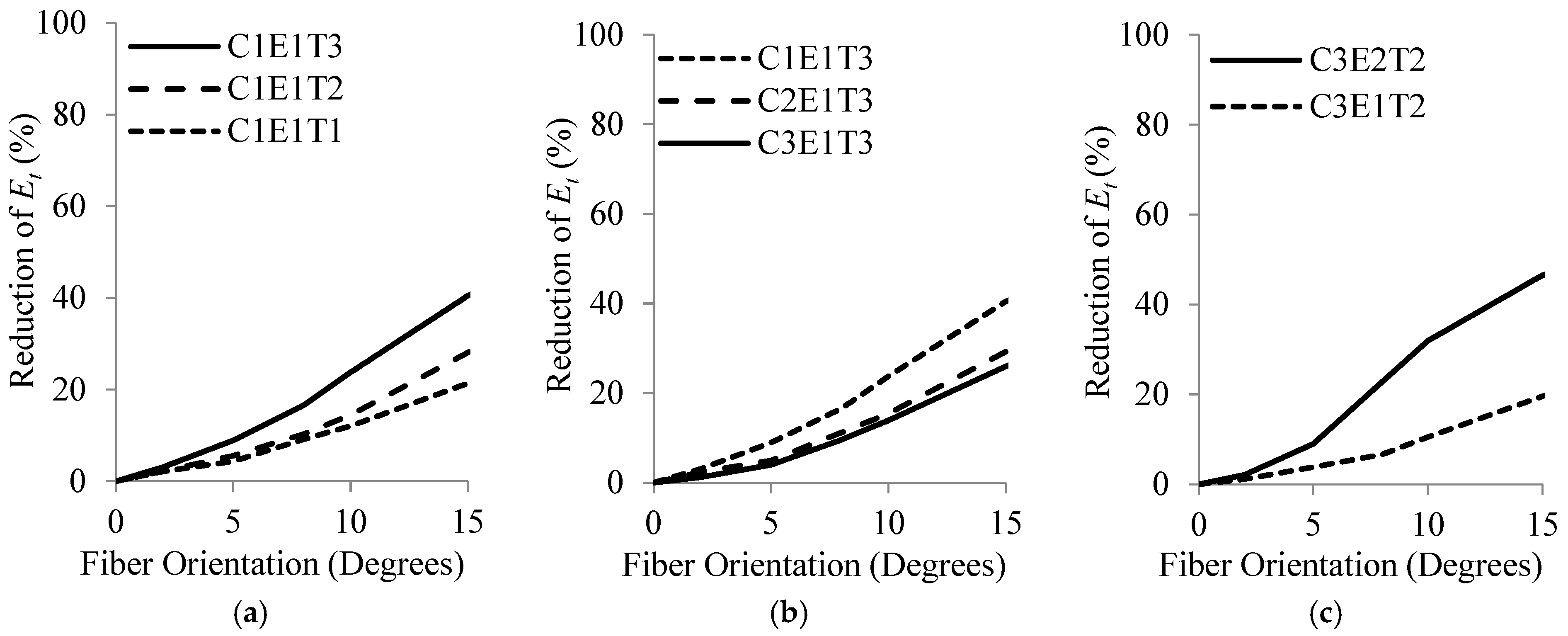

4.8. Effect of Fiber Orientation on Strain Improvement Ratio and Total Dissipated Energy

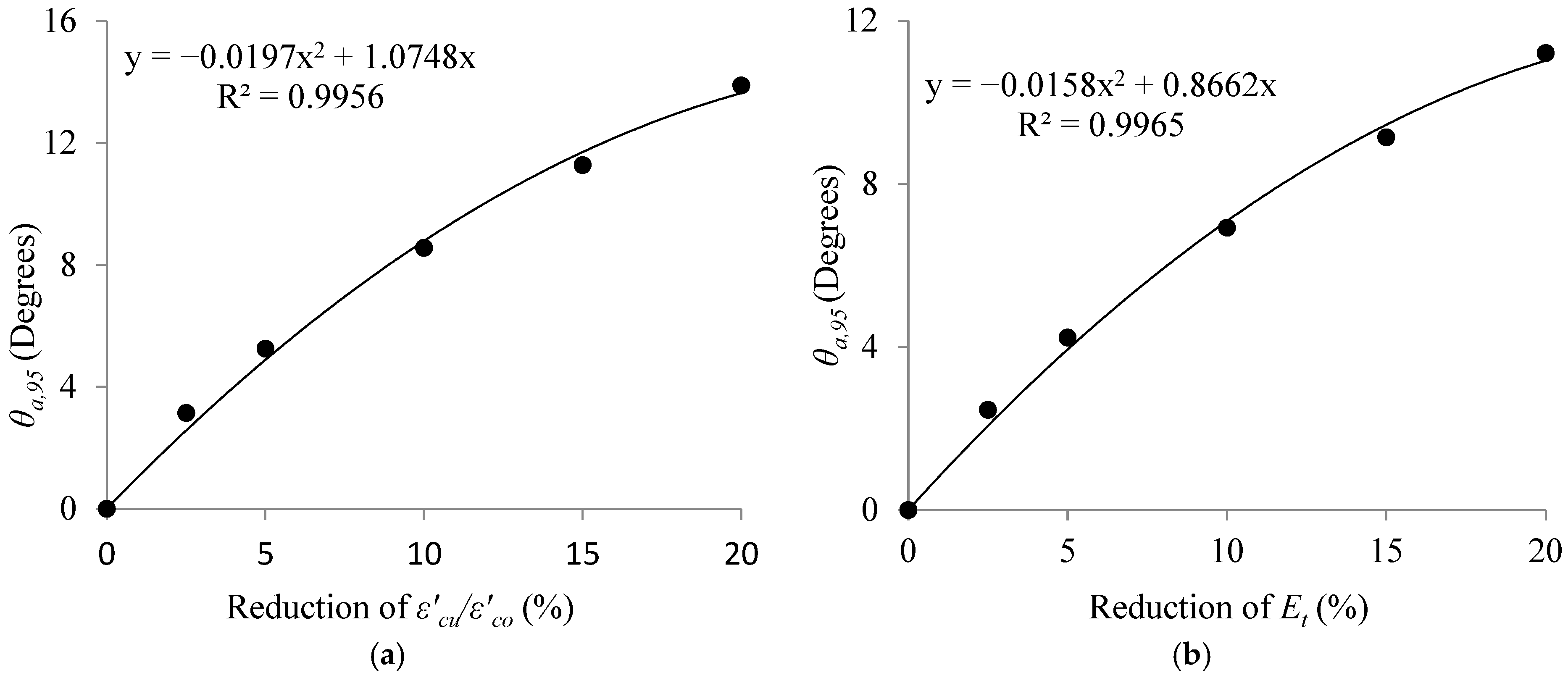

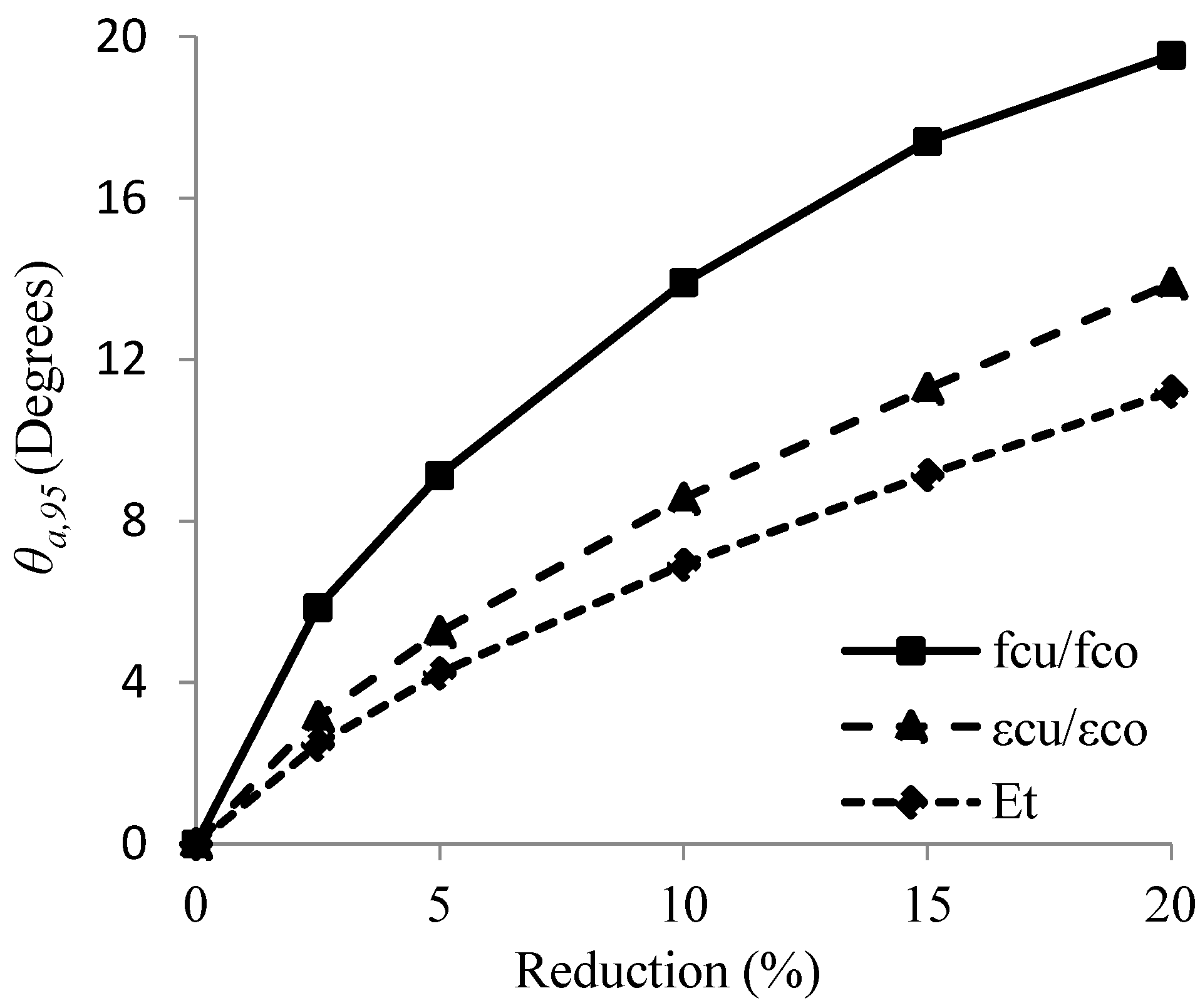

4.9. Comparison between Variations of Strength Improvement Ratio, Strain Improvement Ratio and Total Dissipated Energy with Deviation in Fiber Orientation

4.10. Potential Application of the Results

5. Conclusions

- For 5° deviation in fiber orientation, the average reduction in strength improvement ratio, strain improvement ratio and total dissipated energy was 2.4%, 2.8% and 4.5%, respectively. These numbers confirm the acceptable deviation from the intended direction of fiber alignment (5°) given by the current ACI 440.2 Design Guidelines.

- The calculated allowable limit of deviation in fiber orientation for a 2.5% reduction in strength improvement ratio, strain improvement ratio, and total dissipated energy was 6°, 3° and 2°, respectively, with a 95% confidence. In other words, with 6° deviations in fiber orientation, the strength improvement ratio would reduce by 2.5%, with a 95% confidence. Or, to limit the reduction in total dissipated energy to 2.5%, the deviation in fiber orientation should be less than 2°, with a 95% confidence.

- The total dissipated energy reduced the most with deviation in fiber orientation, followed by the strain improvement ratio and strength improvement ratio.

- The adverse effects of deviation in fiber orientation were positively associated with and , and negatively associated with . In other words, the effectiveness of FRP confinement reduced the most in specimens with higher FRP modulus of elasticity and wrap thickness, and lower concrete compressive strength.

- For the numerical specimens analyzed, the CFRP wrap was more sensitive than GFRP to deviation in fiber orientation, considering the strength improvement ratio.

- The reduction in the strength improvement ratio, strain improvement ratio, and total dissipated energy followed a similar trend to that of the FRP hoop modulus of elasticity () with deviation in fiber orientation.

- The reduction in the strength improvement ratio, strain improvement ratio and total dissipated energy with deviation in fiber orientation was more sensitive to the FRP modulus of elasticity than the FRP wrap thickness or concrete compressive strength.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Notation

| Deviation in fiber orientation from the hoop direction | |

| Ultimate compressive strength of the FRP-confined concrete | |

| Ultimate axial strain of the FRP-confined concrete | |

| Total dissipated energy of the FRP-confined concrete | |

| FRP modulus of elasticity in the fiber direction | |

| FRP modulus of elasticity in the transverse direction | |

| FRP Poisson’s ratio in the plane | |

| FRP shear modulus in the plane | |

| Concrete modulus of elasticity | |

| Concrete Poisson’s ratio | |

| Unconfined concrete compressive strength | |

| Strength improvement ratio | |

| Axial strain at the peak stress of unconfined concrete | |

| Strain improvement ratio | |

| Angle of friction in the DP plasticity model | |

| K | Flow stress ratio in the DP plasticity model |

| Dilation angle in the DP plasticity model | |

| Axial plastic strain | |

| Lateral stiffness ratio | |

| FRP modulus of elasticity in hoop direction | |

| FRP modulus of elasticity | |

| FRP wrap thickness | |

| D | Diameter of concrete cylinder |

| Initial slope of | |

| A constant equal to 157,000 | |

| Lateral stress | |

| Lateral strain of the FRP wrap | |

| Concrete axial strain | |

| Concrete axial stress | |

| Ultimate tensile hoop strain of the FRP wrap | |

| Lateral stiffness of FRP wrap | |

| Allowable limit of deviation in | |

| Allowable limit of deviation in with 95% confidence | |

| Allowable limit of deviation in with 99% confidence |

Appendix A. Comprehensive Numerical Results

| Reduction in | Reduction in (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 50 | 0.2 | 1.34 | 0.31 | 4.16 | 1.96 | 0.98 | 2.09 | |

| 50 | 0.5 | 1.84 | 0.66 | 7.50 | 1.68 | 2.29 | 2.21 | |

| 50 | 1 | 2.69 | 0.98 | 14.93 | 2.19 | 6.35 | 3.04 | |

| 200 | 0.2 | 1.53 | 0.84 | 3.94 | 2.25 | 1.00 | 3.02 | |

| 200 | 0.5 | 2.28 | 1.40 | 7.10 | 1.88 | 2.52 | 3.01 | |

| 200 | 1 | 3.88 | 2.16 | 11.64 | 2.15 | 6.33 | 3.90 | |

| 50 | 0.2 | 1.16 | 0.33 | 2.87 | 2.37 | 1.20 | 2.81 | |

| 50 | 0.5 | 1.48 | 0.25 | 4.57 | 0.81 | 2.32 | 1.00 | |

| 50 | 1 | 1.96 | 0.75 | 7.45 | 1.70 | 4.76 | 2.34 | |

| 200 | 0.2 | 1.32 | 1.22 | 2.61 | 4.03 | 1.13 | 5.34 | |

| 200 | 0.5 | 1.72 | 3.45 | 4.61 | 8.71 | 2.58 | 11.82 | |

| 200 | 1 | 2.50 | 1.82 | 7.06 | 2.45 | 5.35 | 3.95 | |

| 50 | 0.2 | 1.07 | 0.08 | 2.34 | 0.02 | 1.41 | 0.05 | |

| 50 | 0.5 | 1.33 | 0.24 | 3.52 | 0.94 | 2.52 | 1.16 | |

| 50 | 1 | 1.68 | 0.35 | 5.44 | 0.91 | 4.74 | 1.20 | |

| 200 | 0.2 | 1.23 | 1.29 | 2.14 | 4.36 | 1.33 | 5.91 | |

| 200 | 0.5 | 1.52 | 0.66 | 3.43 | 1.51 | 2.63 | 2.13 | |

| 200 | 1 | 2.03 | 1.23 | 5.37 | 1.71 | 5.31 | 2.74 |

| Reduction in | (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 50 | 0.2 | 1.33 | 1.06 | 4.10 | 3.55 | 0.96 | 4.32 | |

| 50 | 0.5 | 1.81 | 1.90 | 7.32 | 4.03 | 2.21 | 5.55 | |

| 50 | 1 | 2.64 | 2.83 | 14.28 | 6.41 | 5.96 | 8.90 | |

| 200 | 0.2 | 1.48 | 3.91 | 3.66 | 9.19 | 0.91 | 12.48 | |

| 200 | 0.5 | 2.14 | 7.39 | 6.55 | 9.40 | 2.22 | 14.90 | |

| 200 | 1 | 3.55 | 10.40 | 10.76 | 9.53 | 5.45 | 17.27 | |

| 50 | 0.2 | 1.15 | 1.03 | 2.80 | 4.82 | 1.16 | 5.91 | |

| 50 | 0.5 | 1.47 | 1.02 | 4.49 | 2.51 | 2.27 | 3.30 | |

| 50 | 1 | 1.94 | 1.81 | 7.32 | 3.48 | 4.63 | 4.96 | |

| 200 | 0.2 | 1.29 | 2.97 | 2.50 | 7.85 | 1.07 | 10.61 | |

| 200 | 0.5 | 1.67 | 6.38 | 4.33 | 14.24 | 2.36 | 19.54 | |

| 200 | 1 | 2.33 | 8.38 | 6.50 | 10.20 | 4.66 | 16.50 | |

| 50 | 0.2 | 1.06 | 0.61 | 2.31 | 1.25 | 1.39 | 1.73 | |

| 50 | 0.5 | 1.32 | 1.04 | 3.45 | 2.89 | 2.45 | 3.81 | |

| 50 | 1 | 1.67 | 1.36 | 5.33 | 2.83 | 4.60 | 3.94 | |

| 200 | 0.2 | 1.21 | 2.70 | 2.08 | 7.15 | 1.28 | 9.85 | |

| 200 | 0.5 | 1.48 | 3.15 | 3.26 | 6.23 | 2.44 | 8.98 | |

| 200 | 1 | 1.92 | 6.53 | 5.00 | 8.50 | 4.72 | 13.52 |

| Reduction in | Reduction in (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 50 | 0.2 | 1.31 | 2.36 | 3.93 | 7.41 | 0.91 | 9.12 | |

| 50 | 0.5 | 1.78 | 3.66 | 7.05 | 7.52 | 2.10 | 10.25 | |

| 50 | 1 | 2.57 | 5.36 | 13.42 | 12.03 | 5.46 | 16.56 | |

| 200 | 0.2 | 1.42 | 8.09 | 3.29 | 18.51 | 0.78 | 24.71 | |

| 200 | 0.5 | 1.97 | 14.85 | 5.88 | 18.69 | 1.86 | 28.60 | |

| 200 | 1 | 3.10 | 21.83 | 9.36 | 21.29 | 4.24 | 35.57 | |

| 50 | 0.2 | 1.14 | 1.90 | 2.74 | 6.77 | 1.13 | 8.46 | |

| 50 | 0.5 | 1.45 | 2.49 | 4.34 | 5.88 | 2.16 | 7.86 | |

| 50 | 1 | 1.89 | 4.12 | 6.98 | 7.97 | 4.33 | 11.17 | |

| 200 | 0.2 | 1.26 | 5.85 | 2.32 | 14.51 | 0.96 | 19.50 | |

| 200 | 0.5 | 1.58 | 11.44 | 3.83 | 24.23 | 1.97 | 32.69 | |

| 200 | 1 | 2.13 | 16.45 | 5.82 | 19.66 | 3.86 | 30.71 | |

| 50 | 0.2 | 1.05 | 1.42 | 2.28 | 2.89 | 1.36 | 3.93 | |

| 50 | 0.5 | 1.31 | 2.03 | 3.37 | 4.96 | 2.38 | 6.64 | |

| 50 | 1 | 1.63 | 3.29 | 5.11 | 6.93 | 4.34 | 9.55 | |

| 200 | 0.2 | 1.18 | 5.05 | 1.97 | 12.37 | 1.18 | 16.97 | |

| 200 | 0.5 | 1.41 | 7.80 | 2.91 | 16.45 | 2.07 | 22.77 | |

| 200 | 1 | 1.78 | 13.62 | 4.48 | 18.05 | 3.96 | 27.49 |

| Reduction in | Reduction in (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 50 | 0.2 | 1.30 | 3.38 | 3.84 | 9.54 | 0.88 | 12.02 | |

| 50 | 0.5 | 1.75 | 5.30 | 6.83 | 10.50 | 2.00 | 14.43 | |

| 50 | 1 | 2.49 | 8.08 | 12.60 | 17.40 | 4.99 | 23.76 | |

| 200 | 0.2 | 1.38 | 10.54 | 3.09 | 23.32 | 0.71 | 30.89 | |

| 200 | 0.5 | 1.85 | 20.05 | 5.39 | 25.48 | 1.62 | 37.83 | |

| 200 | 1 | 2.80 | 29.24 | 8.40 | 29.41 | 3.51 | 46.69 | |

| 50 | 0.2 | 1.13 | 2.68 | 2.70 | 8.24 | 1.10 | 10.45 | |

| 50 | 0.5 | 1.43 | 3.62 | 4.23 | 8.23 | 2.09 | 11.02 | |

| 50 | 1 | 1.86 | 5.85 | 6.75 | 10.99 | 4.12 | 15.39 | |

| 200 | 0.2 | 1.23 | 7.73 | 2.22 | 18.34 | 0.90 | 24.56 | |

| 200 | 0.5 | 1.51 | 15.02 | 3.49 | 30.94 | 1.73 | 41.05 | |

| 200 | 1 | 1.98 | 22.09 | 5.31 | 26.69 | 3.33 | 40.32 | |

| 50 | 0.2 | 1.04 | 2.12 | 2.25 | 4.01 | 1.33 | 5.48 | |

| 50 | 0.5 | 1.29 | 3.22 | 3.27 | 7.87 | 2.28 | 10.51 | |

| 50 | 1 | 1.61 | 4.89 | 4.93 | 10.10 | 4.13 | 13.88 | |

| 200 | 0.2 | 1.16 | 6.64 | 1.90 | 15.47 | 1.12 | 21.16 | |

| 200 | 0.5 | 1.36 | 11.10 | 2.66 | 23.55 | 1.83 | 31.91 | |

| 200 | 1 | 1.69 | 17.66 | 4.15 | 24.14 | 3.52 | 35.60 |

| Reduction in | Reduction in (%) | |||||||

|---|---|---|---|---|---|---|---|---|

| 50 | 0.2 | 1.26 | 6.48 | 3.53 | 16.84 | 0.79 | 21.34 | |

| 50 | 0.5 | 1.65 | 10.61 | 6.02 | 21.02 | 1.68 | 28.04 | |

| 50 | 1 | 2.30 | 15.37 | 10.61 | 30.46 | 3.90 | 40.43 | |

| 200 | 0.2 | 1.27 | 17.45 | 2.50 | 38.10 | 0.53 | 48.40 | |

| 200 | 0.5 | 1.60 | 30.88 | 4.08 | 43.62 | 1.08 | 58.66 | |

| 200 | 1 | 2.22 | 44.07 | 6.27 | 47.29 | 2.16 | 67.16 | |

| 50 | 0.2 | 1.11 | 5.09 | 2.54 | 13.76 | 1.02 | 17.56 | |

| 50 | 0.5 | 1.38 | 7.48 | 3.83 | 16.99 | 1.82 | 22.40 | |

| 50 | 1 | 1.75 | 11.52 | 5.95 | 21.52 | 3.45 | 29.25 | |

| 200 | 0.2 | 1.16 | 12.70 | 1.93 | 28.98 | 0.74 | 37.92 | |

| 200 | 0.5 | 1.37 | 22.97 | 2.77 | 45.23 | 1.24 | 57.52 | |

| 200 | 1 | 1.68 | 34.12 | 4.14 | 42.82 | 2.25 | 59.55 | |

| 50 | 0.2 | 1.02 | 4.23 | 2.13 | 9.19 | 1.24 | 12.18 | |

| 50 | 0.5 | 1.25 | 6.30 | 3.03 | 14.76 | 2.05 | 19.56 | |

| 50 | 1 | 1.53 | 9.45 | 4.43 | 19.31 | 3.55 | 25.94 | |

| 200 | 0.2 | 1.11 | 11.01 | 1.69 | 24.73 | 0.95 | 33.11 | |

| 200 | 0.5 | 1.27 | 17.25 | 2.25 | 35.44 | 1.44 | 46.50 | |

| 200 | 1 | 1.49 | 27.51 | 3.13 | 42.73 | 2.34 | 57.20 |

References

- Hussain, Z.; Pu, Z.; Hussain, A.; Ahmed, S.; Shah, A.U.; Ali, A.; Ali, A. Effect of fiber dosage on water permeability using a newly designed apparatus and crack monitoring of steel fiber–reinforced concrete under direct tensile loading. Struct. Health Monit. 2021, 21, 2083–2096. [Google Scholar] [CrossRef]

- Umar, T.; Yousaf, M.; Akbar, M.; Abbas, N.; Hussain, Z.; Ansari, W.S. An Experimental Study on Non-Destructive Evaluation of the Mechanical Characteristics of a Sustainable Concrete Incorporating Industrial Waste. Materials 2022, 15, 7346. [Google Scholar] [CrossRef] [PubMed]

- Banaeipour, A.; Al Sarfin, M.A.; Thomas, R.J.; Maguire, M.; Sorensen, A.D. Laboratory and Field Evaluation of Commercially Available Rapid-Repair Materials for Concrete Bridge Deck Repair. J. Perform. Constr. Facil. 2022, 36, 04022031. [Google Scholar] [CrossRef]

- Majed, M.M.; Tavakkolizadeh, M.; Allawi, A.A. Finite element analysis of rectangular RC beams strengthened with FRP laminates under pure torsion. Struct. Concr. 2021, 22, 1946–1961. [Google Scholar] [CrossRef]

- Triantafillou, T.; Matthys, S. Fibre-reinforced polymer reinforcement enters fib Model Code 2010. Struct. Concr. 2013, 14, 335–341. [Google Scholar] [CrossRef]

- Fanaradelli, T.; Rousakis, T. Assessment of analytical stress and strain at peak and at ultimate conditions for fiber-reinforcement polymer-confined reinforced concrete columns of rectangular sections under axial cyclic loading. Struct. Concr. 2021, 22, 95–108. [Google Scholar] [CrossRef]

- Ziaadiny, H.; Abbasnia, R. Unified cyclic stress-strain model for FRP-confined concrete circular, square and rectangular prisms. Struct. Concr. 2016, 17, 220–234. [Google Scholar] [CrossRef]

- Vincent, T.; Ozbakkaloglu, T. Influence of fiber orientation and specimen end condition on axial compressive behavior of FRP-confined concrete. Constr. Build. Mater. 2013, 47, 814–826. [Google Scholar] [CrossRef]

- Micelli, F.; Modarelli, R. Experimental and analytical study on properties affecting the behaviour of FRP-confined concrete. Compos. Part B Eng. 2013, 45, 1420–1431. [Google Scholar] [CrossRef]

- Moretti Marina, L. Effectiveness of different confining configurations of FRP jackets for concrete columns. Struct. Eng. Mech. 2019, 72, 155–168. [Google Scholar]

- Alanazi, A.; Upton, G.; Adegoke, M.; Shokouhian, M.; Head, M. Experimental Investigation of Residual Compressive Strength of Partially Confined Concrete Column Retrofitted Using CFRP Wrap. In Structures Congress 2019: Buildings and Natural Disasters-Selected Papers from the Structures Congress; American Society of Civil Engineers: Reston, VA, USA, 2019; pp. 218–229. [Google Scholar]

- Li, G.; Maricherla, D.; Singh, K.; Pang, S.S.; John, M. Effect of fiber orientation on the structural behavior of FRP wrapped concrete cylinders. Compos. Struct. 2006, 74, 475–483. [Google Scholar] [CrossRef]

- Li, G. Experimental study of FRP confined concrete cylinders. Eng. Struct. 2006, 28, 1001–1008. [Google Scholar] [CrossRef]

- Veerapandian, V.; Pandulu, G.; Jayaseelan, R.; Sathish Kumar, V.; Murali, G.; Vatin, N.I. Numerical Modelling of Geopolymer Concrete In-Filled Fibre-Reinforced Polymer Composite Columns Subjected to Axial Compression Loading. Materials 2022, 15, 3390. [Google Scholar] [CrossRef] [PubMed]

- Burgoyne, C.; Gerritse, A.; Hole, A.; Pilakoutas, K.; Taerwe, L.; Triantafillou, T.; Pascale, G.; Di Tommaso, A. Bulletin 14. In Externally Bonded FRP Reinforcement for RC Structures: Technical Report on the Design and Use of Externally Bonded Fibre Reinforced Polymer (FRP) Reinforcement for Reinforced Concrete (RC) Structures; International Federation for Structural Concrete: Lausanne, Switzerland, 2001. [Google Scholar]

- Hyer, M.W.; White, S.R. Stress Analysis of Fiber-Reinforced Composite Materials; WCB McGraw-Hill: Boston, MA, USA, 1998; Volume xvii, 627p. [Google Scholar]

- American Concrete Institute. 2R-17 Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2017. [Google Scholar]

- Mirmiran, A.; Shahawy, M. Behavior of concrete columns confined by fiber composites. J. Struct. Eng. 1997, 123, 583–590. [Google Scholar] [CrossRef]

- Karbhari, V.M.; Gao, Y. Composite jacketed concrete under uniaxial compression—Verification of simple design equations. J. Mater. Civ. Eng. 1997, 9, 185–193. [Google Scholar] [CrossRef]

- Rochette, P.; Labossiere, P. Axial testing of rectangular column models confined with composites. J. Compos. Constr. 2000, 4, 129–136. [Google Scholar] [CrossRef]

- Pessiki, S.; Harries, K.A.; Kestner, J.T.; Sause, R.; Ricles, J.M. Axial behavior of reinforced concrete columns confined with FRP jackets. J. Compos. Constr. 2001, 5, 237–245. [Google Scholar] [CrossRef]

- Fam, A.Z.; Rizkalla, S.H. Behavior of axially loaded concrete-filled circular fiber-reinforced polymer tubes. Struct. J. 2001, 98, 280–289. [Google Scholar]

- Fam, A.; Flisak, B.; Rizkalla, S. Experimental and analytical modeling of concrete-filled FRP tubes subjected to combined bending and axial loads. ACI Struct. J. 2003, 100, 499–509. [Google Scholar]

- Fam, A.; Pando, M.; Filz, G.; Rizkalla, S. Precast piles for Route 40 bridge in Virginia using concrete filled FRP tubes. PCI J. 2003, 48, 32–45. [Google Scholar] [CrossRef]

- Mohamed, H.M.; Masmoudi, R. Axial load capacity of concrete-filled FRP tube columns: Experimental versus theoretical predictions. J. Compos. Constr. 2010, 14, 231–243. [Google Scholar] [CrossRef]

- Karouche, A.; Hebbache, K.; Belebchouche, C.; Lahbari, N.; Kessal, O.; Czarnecki, S. External Confined Concrete Cylinders Behavior under Axial Compression Using CFRP Wrapping. Materials 2022, 15, 8232. [Google Scholar] [CrossRef] [PubMed]

- El-Zefzafy, H.; Mohamed, H.M.; Masmoudi, R. Freeze-thaw effects on the behaviour of concrete-filled FRP tube columns. Proc. Annu. Conf.-Can. Soc. Civ. Eng. 2011, 2, 1563–1572. [Google Scholar]

- Mohamed, H.; El Zefzafy, H.; Masmoudi, R. Review of ACI 440.2R design method for strength and axial load capacity of concrete filled-FRP tubes columns. Proc. Annu. Conf.-Can. Soc. Civ. Eng. 2010, 1, 814–823. [Google Scholar]

- Mohamed, H.; Masmoudi, R. Assessment of confinement models for concrete confined with FRP tubes. In Proceedings of the 24th Annual Technical Conference of the American Society for Composites 2009 and 1st Joint Canadian-American Technical Conference on Composites, Newark, NJ, USA, 15–17 September 2009; Volume 2, pp. 1233–1251. [Google Scholar]

- Mohamed, H.; Masmoudi, R. Experimental study for the slenderness ratio of the axially loaded CFFT columns. In Proceedings of the 4th International Conference on FRP Composites in Civil Engineering, CICE, Zurich, Switzerland, 22–24 July 2008. [Google Scholar]

- Mohamed, H.; Masmoudi, R.; Chaallal, O. Compressive behavior of filament winded GFRP tube-encased concrete columns. In Proceedings of the 4th International Conference on FRP Composites in Civil Engineering, CICE, Zurich, Switzerland, 22–24 July 2008. [Google Scholar]

- Au, C.; Buyukozturk, O. Effect of fiber orientation and ply mix on fiber reinforced polymer-confined concrete. J. Compos. Constr. 2005, 9, 397–407. [Google Scholar] [CrossRef]

- Abdelkarim, O.I.; ElGawady, M.A. Behavior of hollow FRP-concrete-steel columns under static cyclic axial compressive loadingp. Eng. Struct. 2016, 123, 77–88. [Google Scholar] [CrossRef]

- Elsanadedy, H.M.; Al-Salloum, Y.A.; Alsayed, S.H.; Iqbal, R.A. Experimental and numerical investigation of size effects in FRP-wrapped concrete columns. Constr. Build. Mater. 2012, 29, 56–72. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; Hadi, M.N. Predicting strength and strain enhancement ratios of circular fiber-reinforced polymer tube confined concrete under axial compression using artificial neural networks. Adv. Struct. Eng. 2019, 22, 1426–1443. [Google Scholar] [CrossRef]

- AL-Shalif, S.A.; Akın, A.; Aksoylu, C.; Arslan, M.H. Strengthening of shear-critical reinforced concrete T-beams with anchored and non-anchored GFRP fabrics applications. Structures 2022, 44, 809–827. [Google Scholar] [CrossRef]

- Arslana, M.H.; Yazman, Ş.; Hamad, A.A.; Aksoylu, C.; Özkılıç, Y.O.; Gemi, L. Shear strengthening of reinforced concrete T-beams with anchored and non-anchored CFRP fabrics. Structures 2022, 39, 527–542. [Google Scholar] [CrossRef]

- Seffo, M.; Hamcho, M. Strength of concrete cylinder confined by composite materials (CFRP). Energy Procedia 2012, 19, 276–285. [Google Scholar] [CrossRef]

- Sulaimana, A.; Almansour, H.; Aoude, H. Effect of fiber orientation on the behavior of cfrp confined concrete cylinders. Proc. Annu. Conf.-Can. Soc. Civ. Eng. 2016, 2, 1251–1263. [Google Scholar]

- Abbas, N.; Yousaf, M.; Akbar, M.; Saeed, M.A.; Huali, P.; Hussain, Z. An Experimental Investigation and Computer Modeling of Direct Tension Pullout Test of Reinforced Concrete Cylinder. Inventions 2022, 7, 77. [Google Scholar] [CrossRef]

- Rabbat, B.; Russell, H. Friction coefficient of steel on concrete or grout. J. Struct. Eng. 1985, 111, 505–515. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H. Compressive behavior of concrete confined by carbon fiber composite jackets. J. Mater. Civ. Eng. 2000, 12, 139–146. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-oriented stress–strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J. Ultimate condition of fiber reinforced polymer-confined concrete. J. Compos. Constr. 2004, 8, 539–548. [Google Scholar] [CrossRef]

- Teng, J.; Huang, Y.L.; Lam, L.; Ye, L.P. Theoretical model for fiber-reinforced polymer-confined concrete. J. Compos. Constr. 2007, 11, 201–210. [Google Scholar] [CrossRef]

- Jiang, T.; Teng, J. Analysis-oriented stress–strain models for FRP–confined concrete. Eng. Struct. 2007, 29, 2968–2986. [Google Scholar] [CrossRef]

- ACI Committee 318. In Building Code Requirements for Structural Concrete (ACI 318-05) and Commentary (ACI 318R-05); American Concrete Institute: Farmington Hills, MI, USA, 2005; 430p.

- Popovics, S. A numerical approach to the complete stress-strain curve of concrete. Cem. Concr. Res. 1973, 3, 583–599. [Google Scholar] [CrossRef]

- Karabinis, A.I.; Rousakis, T. Concrete confined by FRP material: A plasticity approach. Eng. Struct. 2002, 24, 923–932. [Google Scholar] [CrossRef]

- Yu, T.; Teng, J.G.; Wong, Y.L.; Dong, S.L. Finite element modeling of confined concrete-I: Drucker–Prager type plasticity model. Eng. Struct. 2010, 32, 665–679. [Google Scholar] [CrossRef]

- Wang, L.-M.; Wu, Y.-F. Effect of corner radius on the performance of CFRP-confined square concrete columns: Test. Eng. Struct. 2008, 30, 493–505. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, Y.; Zhao, X. Application of Drucker-Prager plasticity model for stress-strain modeling of FRP confined concrete columns. Procedia Eng. 2011, 14, 687–694. [Google Scholar] [CrossRef]

| ID | Source | Error (%) | Error (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| X1 | Xiao and Wu [42] | 34 | 105 | 0.38 | 1.41 | 1.36 | 3.6 | 49.3 | 52.1 | 5.7 |

| X2 | Xiao and Wu [42] | 34 | 105 | 0.76 | 2.18 | 2.21 | 1.4 | 71.8 | 73.5 | 2.4 |

| X3 | Xiao and Wu [42] | 34 | 105 | 1.14 | 3.04 | 2.99 | 1.6 | 94.2 | 91.6 | 2.8 |

| J1 | Jiang and Teng [46] | 38 | 240.7 | 0.68 | 2.53 | 2.69 | 6.3 | 106.9 | 107.3 | 0.4 |

| J2 | Jiang and Teng [46] | 38 | 240.7 | 1.02 | 3.08 | 3.12 | 1.3 | 135.1 | 139.1 | 2.9 |

| J3 | Jiang and Teng [46] | 38 | 240.7 | 1.36 | 3.42 | 3.51 | 2.6 | 158.4 | 157.8 | 0.4 |

| W1 | Wang and Wu [51] | 31 | 230.5 | 0.33 | 2.25 | 2.12 | 5.8 | 60.7 | 63.9 | 5.3 |

| W2 | Wang and Wu [51] | 31 | 230.5 | 0.66 | 3.53 | 3.48 | 1.4 | 80.1 | 83.3 | 4.0 |

| Notation | Notation | Notation | |||

|---|---|---|---|---|---|

| 20 | C1 | 50 | E1 | 0.2 | T1 |

| 35 | C2 | 200 | E2 | 0.5 | T2 |

| 50 | C3 | 1.0 | T3 |

| 50 | 16.67 | 0.25 | 8.33 | 8.33 | 3.21 | 0.025 |

| 200 | 13.00 | 0.30 | 10.30 | 10.30 | 9.00 | 0.01 |

| 50 | 0.2 | 132 | 1.3 | 4.2 | 1.0 | 1.2 | 2.9 | 1.2 | 1.1 | 2.3 | 1.4 |

| 50 | 0.5 | 329 | 1.8 | 7.6 | 2.3 | 1.5 | 4.6 | 2.4 | 1.3 | 3.6 | 2.6 |

| 50 | 1.0 | 658 | 2.7 | 15.3 | 6.6 | 1.9 | 7.6 | 4.9 | 1.7 | 5.5 | 4.8 |

| 200 | 0.2 | 526 | 1.5 | 4.0 | 1.0 | 1.3 | 2.7 | 1.2 | 1.2 | 2.2 | 1.4 |

| 200 | 0.5 | 1316 | 2.3 | 7.2 | 2.6 | 1.8 | 5.0 | 2.9 | 1.5 | 3.5 | 2.7 |

| 200 | 1.0 | 2632 | 3.9 | 11.9 | 6.6 | 2.5 | 7.2 | 5.6 | 2.1 | 5.5 | 5.5 |

| Parameter | from 0° to 15° | |||

|---|---|---|---|---|

| Min | Max | Avg | SD | |

| (T1) | 0.1 | 17.5 | 4.4 | 4.1 |

| (T2) | 0.2 | 30.9 | 7.5 | 7.5 |

| (T3) | 0.4 | 44.1 | 11.1 | 11.0 |

| (E1) | 0.1 | 15.4 | 3.5 | 3.4 |

| (E2) | 0.7 | 44.1 | 11.8 | 10.0 |

| (C1) | 0.3 | 50.2 | 13.5 | 13.6 |

| (C2) | 0.3 | 38.5 | 10.1 | 10.2 |

| (C3) | 0.1 | 32.4 | 8.4 | 8.5 |

| Deviation in Fiber Orientation (Degrees) | ||||||

|---|---|---|---|---|---|---|

| Min | Max | Avg | SD | 95% CI | 99% CI | |

| 2 | 0.1 | 3.5 | 1.0 | 0.8 | 1.2 | 1.2 |

| 5 | 0.6 | 10.4 | 2.4 | 2.9 | 2.9 | 3.1 |

| 8 | 1.4 | 21.8 | 7.3 | 5.8 | 8.4 | 8.8 |

| 10 | 2.1 | 29.2 | 10.0 | 7.6 | 11.4 | 11.9 |

| 15 | 4.2 | 44.1 | 16.4 | 11.0 | 18.4 | 19.2 |

| Deviation in Fiber Orientation (Degrees) | ||||||

|---|---|---|---|---|---|---|

| Min | Max | Avg | SD | |||

| 2 | 11 | 5 | 3 | 6 | 6 | |

| 3 | 17 | 8 | 4 | 9 | 9 | |

| 5 | 26 | 13 | 6 | 14 | 14 | |

| 6 | 29 | 16 | 7 | 17 | 18 | |

| 8 | 30 | 18 | 7 | 20 | 20 | |

| Fiber Orientation (Degrees) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Avg | Min | Max | Avg | |||||

| 2.5 | 5 | 11 | 8 | 8 | 9 | 2 | 5 | 3 | 4 | 4 |

| 5 | 8 | 17 | 12 | 13 | 13 | 3 | 8 | 5 | 6 | 6 |

| 10 | 11 | 26 | 18 | 20 | 20 | 5 | 14 | 8 | 9 | 10 |

| 15 | 15 | 29 | 23 | 25 | 26 | 6 | 24 | 12 | 14 | 15 |

| 20 | 19 | 27 | 24 | 26 | 27 | 8 | 29 | 15 | 17 | 19 |

| Fiber Orientation (Degrees) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Avg | Min | Max | Avg | Min | Max | Avg | |||||||

| 2.5 | 4 | 11 | 7 | 8 | 9 | 2 | 9 | 5 | 7 | 7 | 2 | 7 | 4 | 5 | 5 |

| 5 | 6 | 17 | 11 | 13 | 14 | 4 | 13 | 8 | 10 | 11 | 3 | 10 | 6 | 8 | 8 |

| 10 | 6 | 23 | 13 | 16 | 17 | 5 | 21 | 10 | 12 | 13 | 3 | 16 | 8 | 9 | 10 |

| 15 | 9 | 24 | 14 | 17 | 18 | 6 | 29 | 14 | 17 | 18 | 4 | 21 | 10 | 13 | 13 |

| 20 | 13 | 29 | 20 | 25 | 27 | 8 | 25 | 14 | 18 | 19 | 5 | 27 | 13 | 16 | 17 |

| Fiber Orientation (Degrees) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min | Max | Avg | Min | Max | Avg | Min | Max | Avg | |||||||

| 2.5 | 1 | 8 | 4 | 5 | 6 | 2 | 10 | 5 | 6 | 7 | 2 | 11 | 5 | 7 | 7 |

| 5 | 2 | 13 | 6 | 8 | 9 | 3 | 15 | 7 | 9 | 10 | 3 | 17 | 8 | 11 | 12 |

| 10 | 3 | 21 | 9 | 13 | 14 | 4 | 26 | 12 | 16 | 17 | 5 | 27 | 13 | 17 | 18 |

| 15 | 4 | 29 | 12 | 15 | 16 | 6 | 29 | 14 | 17 | 18 | 6 | 29 | 16 | 19 | 20 |

| 20 | 5 | 25 | 13 | 16 | 17 | 8 | 25 | 14 | 18 | 19 | 8 | 27 | 16 | 20 | 22 |

| Parameter | Deviation in Fiber Orientation from 0° to 15° | |||

|---|---|---|---|---|

| Avg | SD | Avg | SD | |

| (T1) | 10.7 | 9.0 | 14.1 | 11.7 |

| (T2) | 13.9 | 12.3 | 18.9 | 16.3 |

| (T3) | 15.4 | 13.0 | 22.3 | 18.3 |

| (E1) | 7.9 | 6.7 | 10.6 | 8.9 |

| (E2) | 18.7 | 13.1 | 26.2 | 17.7 |

| (C1) | 20.4 | 16.7 | 27.9 | 21.9 |

| (C2) | 18.1 | 16.1 | 24.1 | 20.3 |

| (C3) | 15.3 | 14.4 | 20.6 | 18.5 |

| Fiber Orientation (Degrees) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Avg | SD | 95% CI | 99% CI | Avg | SD | 95% CI | 99% CI | |

| 2 | 2.3 | 1.9 | 2.7 | 2.8 | 3.2 | 2.5 | 3.7 | 3.9 |

| 5 | 2.8 | 3.3 | 3.4 | 3.7 | 4.5 | 5.3 | 5.5 | 5.9 |

| 8 | 12.6 | 6.3 | 13.7 | 14.2 | 17.9 | 9.8 | 19.7 | 20.5 |

| 10 | 16.9 | 8.3 | 18.4 | 19.1 | 23.7 | 12.5 | 26.0 | 27.0 |

| 15 | 28.4 | 12.2 | 30.7 | 31.6 | 37.9 | 16.6 | 41.0 | 42.2 |

| Reduction (%) | Deviation in Fiber Orientation (Degrees) | |||||||

|---|---|---|---|---|---|---|---|---|

| Avg | SD | Avg | SD | |||||

| 3 | 2 | 3 | 3 | 2 | 1 | 2 | 2 | |

| 5 | 2 | 5 | 5 | 4 | 2 | 4 | 4 | |

| 8 | 3 | 9 | 9 | 6 | 3 | 7 | 7 | |

| 11 | 4 | 11 | 12 | 9 | 4 | 9 | 9 | |

| 13 | 5 | 14 | 14 | 10 | 4 | 11 | 12 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Banaeipour, A.; Tavakkolizadeh, M.; Akbar, M.; Hussain, Z.; Ostrowski, K.A.; Bahadori, A.; Spyrka, M. Effects of Small Deviations in Fiber Orientation on Compressive Characteristics of Plain Concrete Cylinders Confined with FRP Laminates. Materials 2023, 16, 261. https://doi.org/10.3390/ma16010261

Banaeipour A, Tavakkolizadeh M, Akbar M, Hussain Z, Ostrowski KA, Bahadori A, Spyrka M. Effects of Small Deviations in Fiber Orientation on Compressive Characteristics of Plain Concrete Cylinders Confined with FRP Laminates. Materials. 2023; 16(1):261. https://doi.org/10.3390/ma16010261

Chicago/Turabian StyleBanaeipour, Ali, Mohammadreza Tavakkolizadeh, Muhammad Akbar, Zahoor Hussain, Krzysztof Adam Ostrowski, Alireza Bahadori, and Mariusz Spyrka. 2023. "Effects of Small Deviations in Fiber Orientation on Compressive Characteristics of Plain Concrete Cylinders Confined with FRP Laminates" Materials 16, no. 1: 261. https://doi.org/10.3390/ma16010261

APA StyleBanaeipour, A., Tavakkolizadeh, M., Akbar, M., Hussain, Z., Ostrowski, K. A., Bahadori, A., & Spyrka, M. (2023). Effects of Small Deviations in Fiber Orientation on Compressive Characteristics of Plain Concrete Cylinders Confined with FRP Laminates. Materials, 16(1), 261. https://doi.org/10.3390/ma16010261