In Envelope Additive/Subtractive Manufacturing and Thermal Post-Processing of Inconel 718

Abstract

1. Introduction

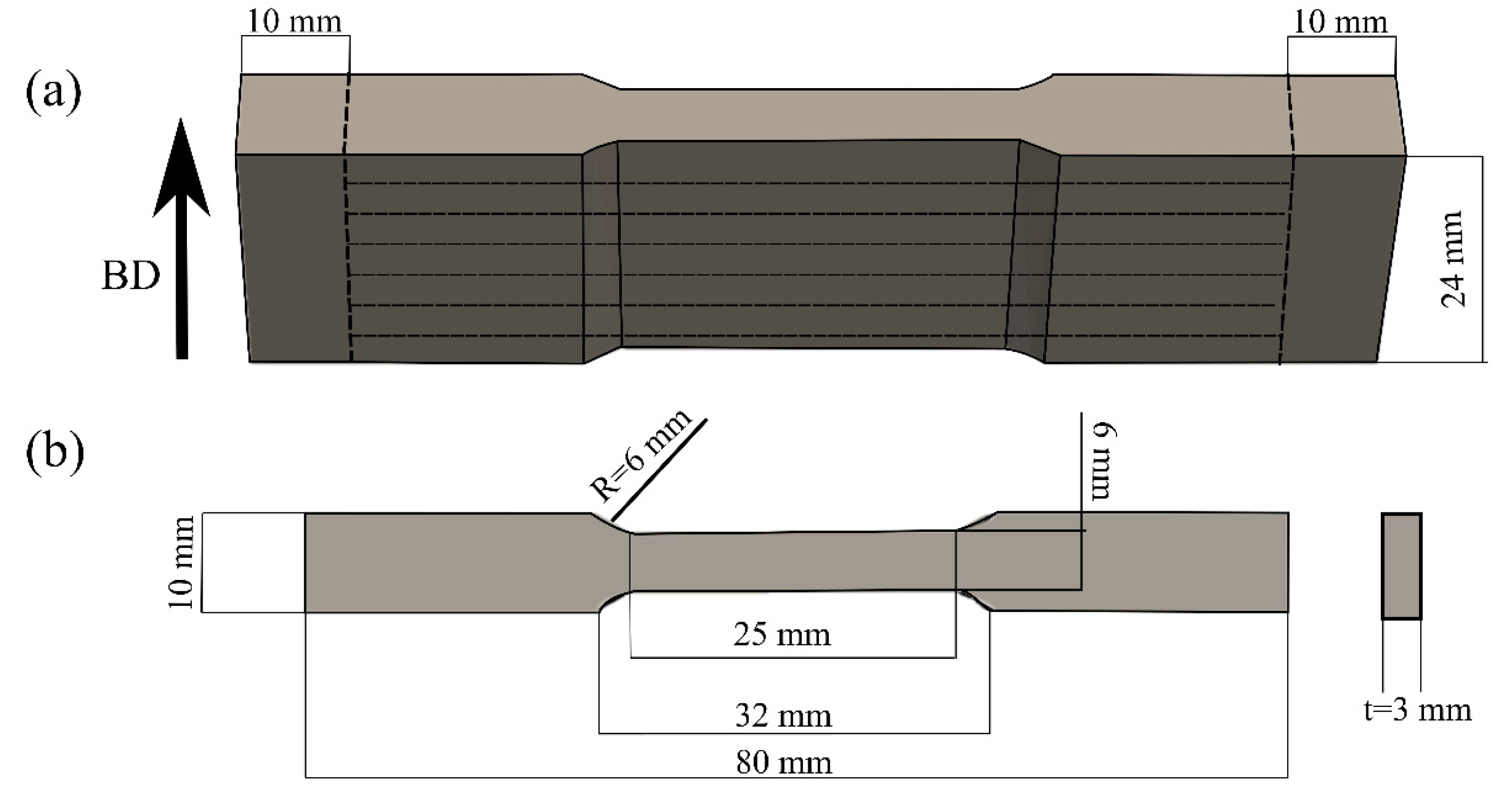

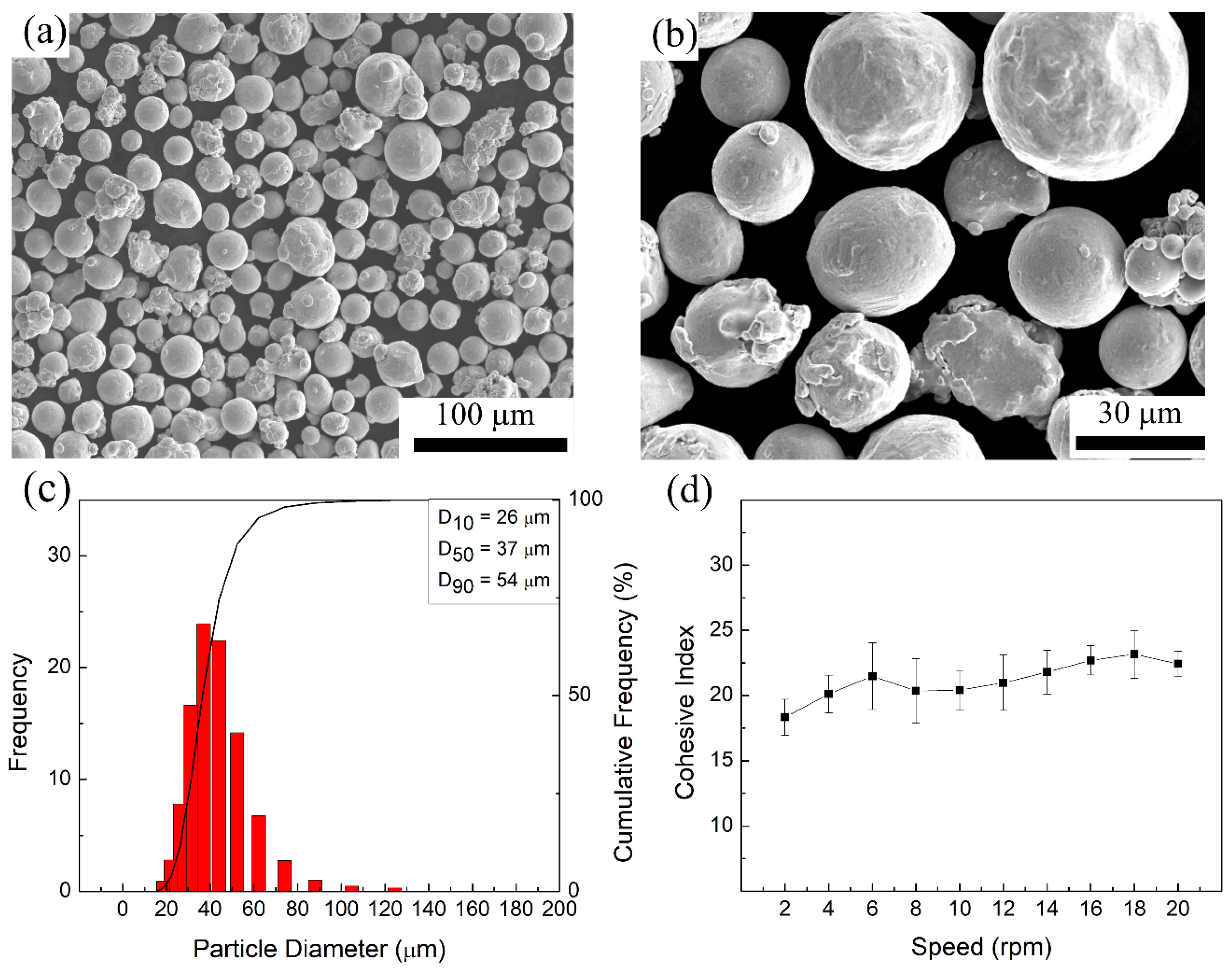

2. Materials and Methods

3. Results and Discussion

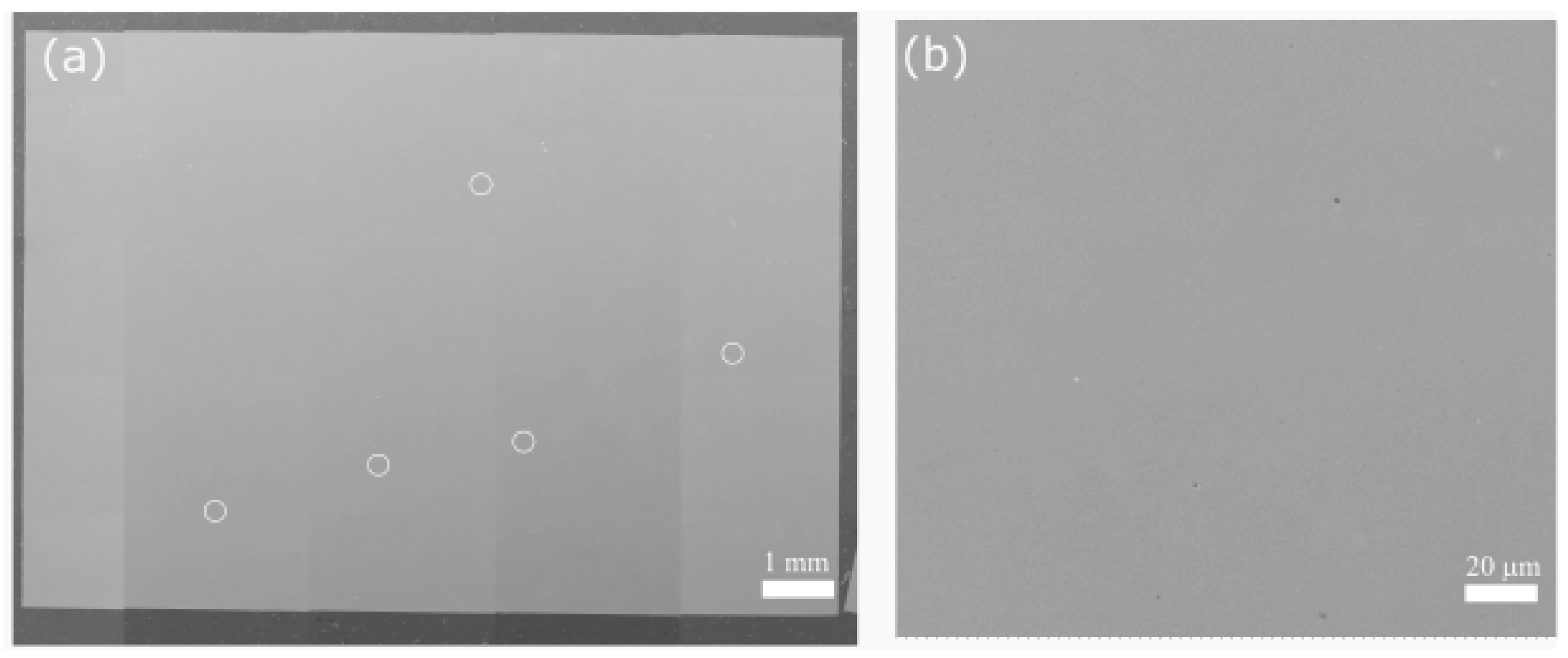

3.1. Surface Roughness

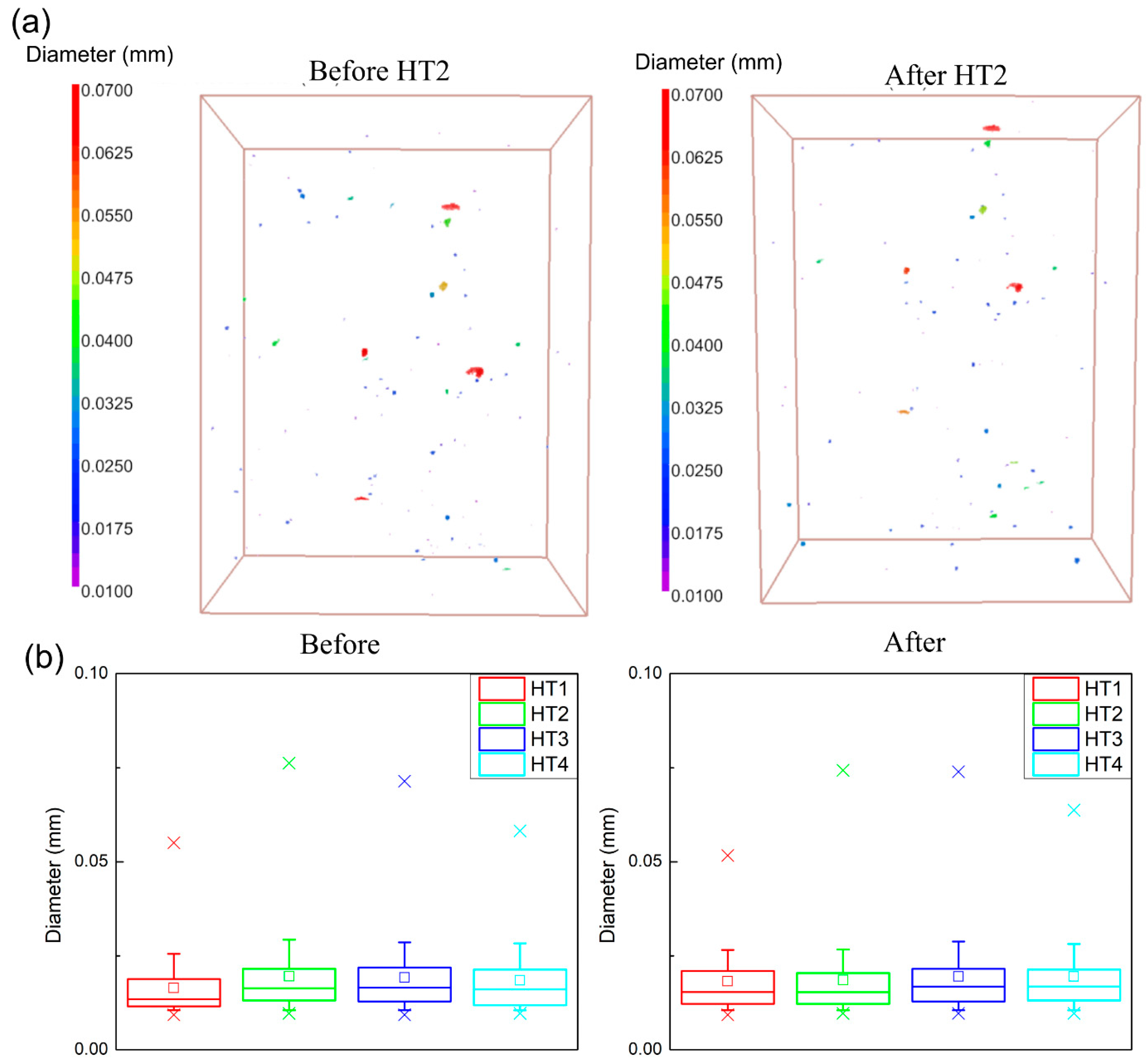

3.2. Density

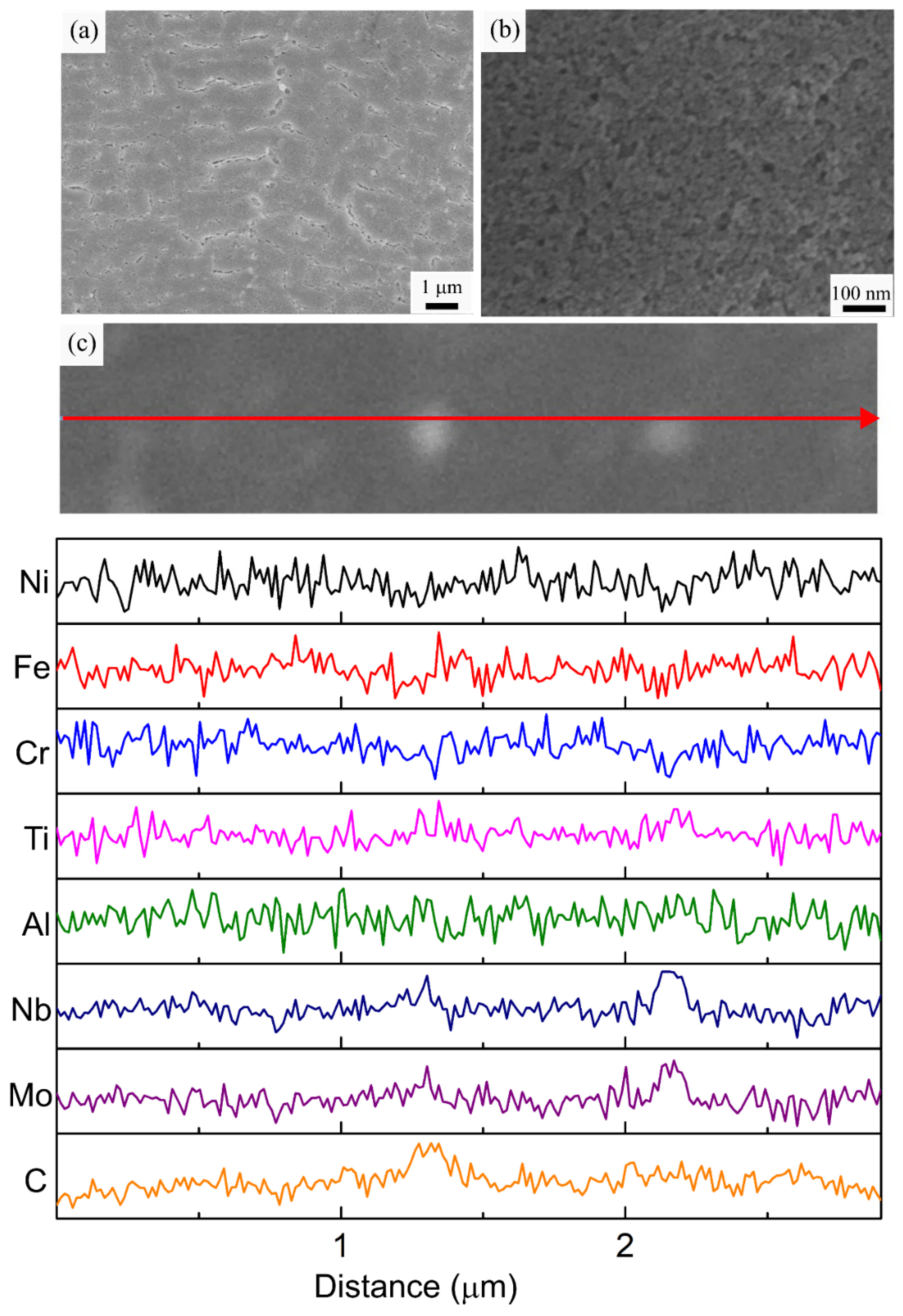

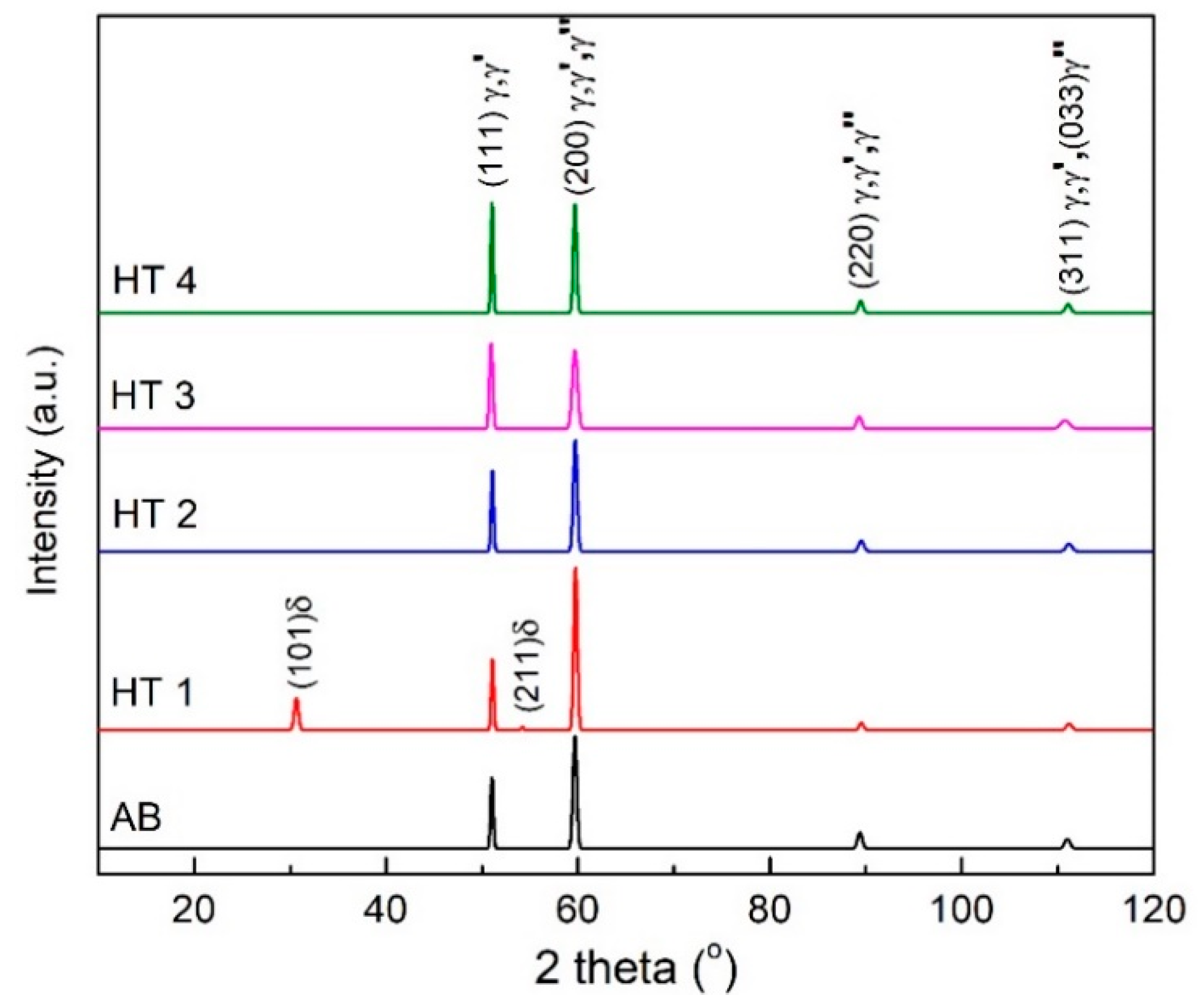

3.3. Microstructural Characterization

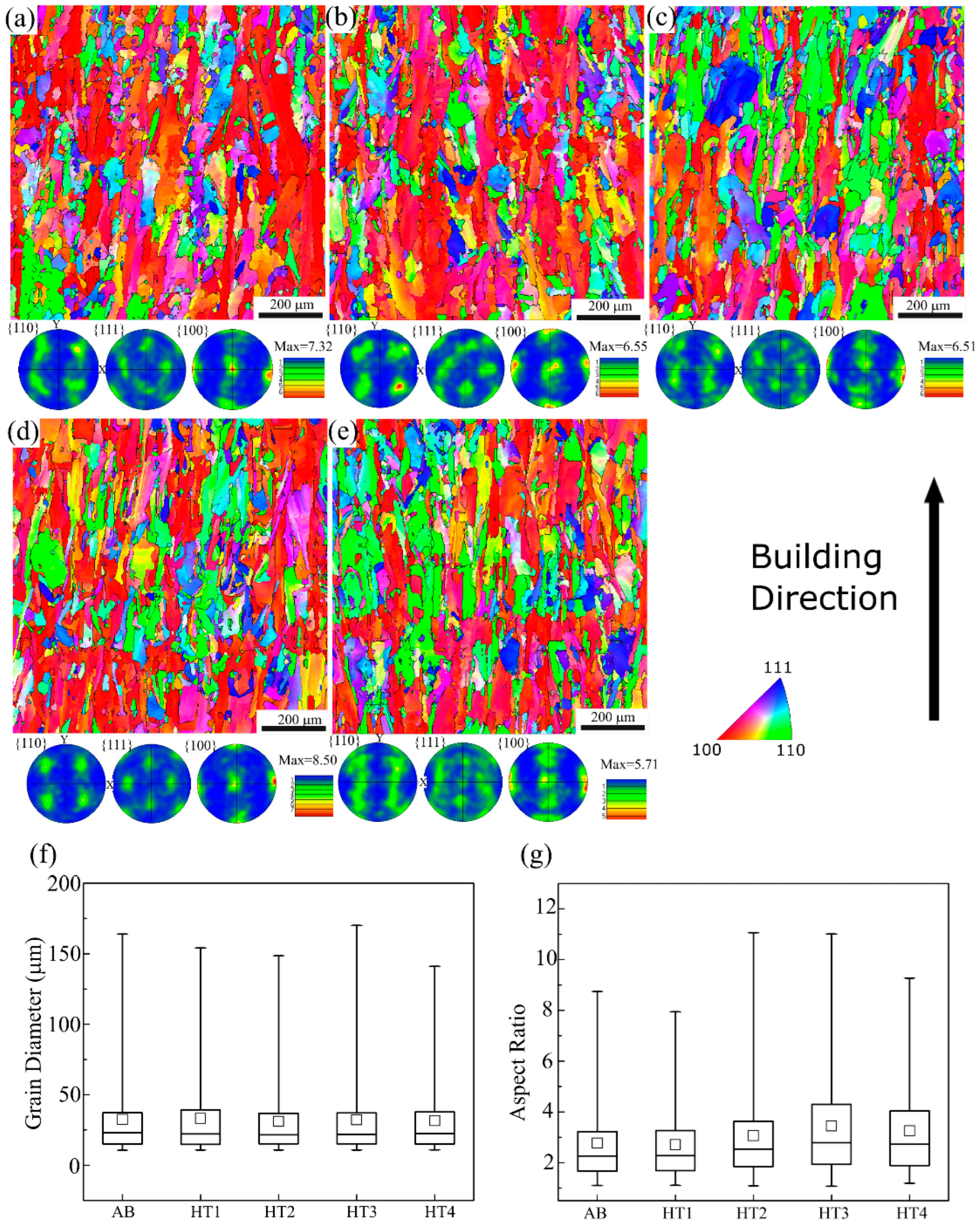

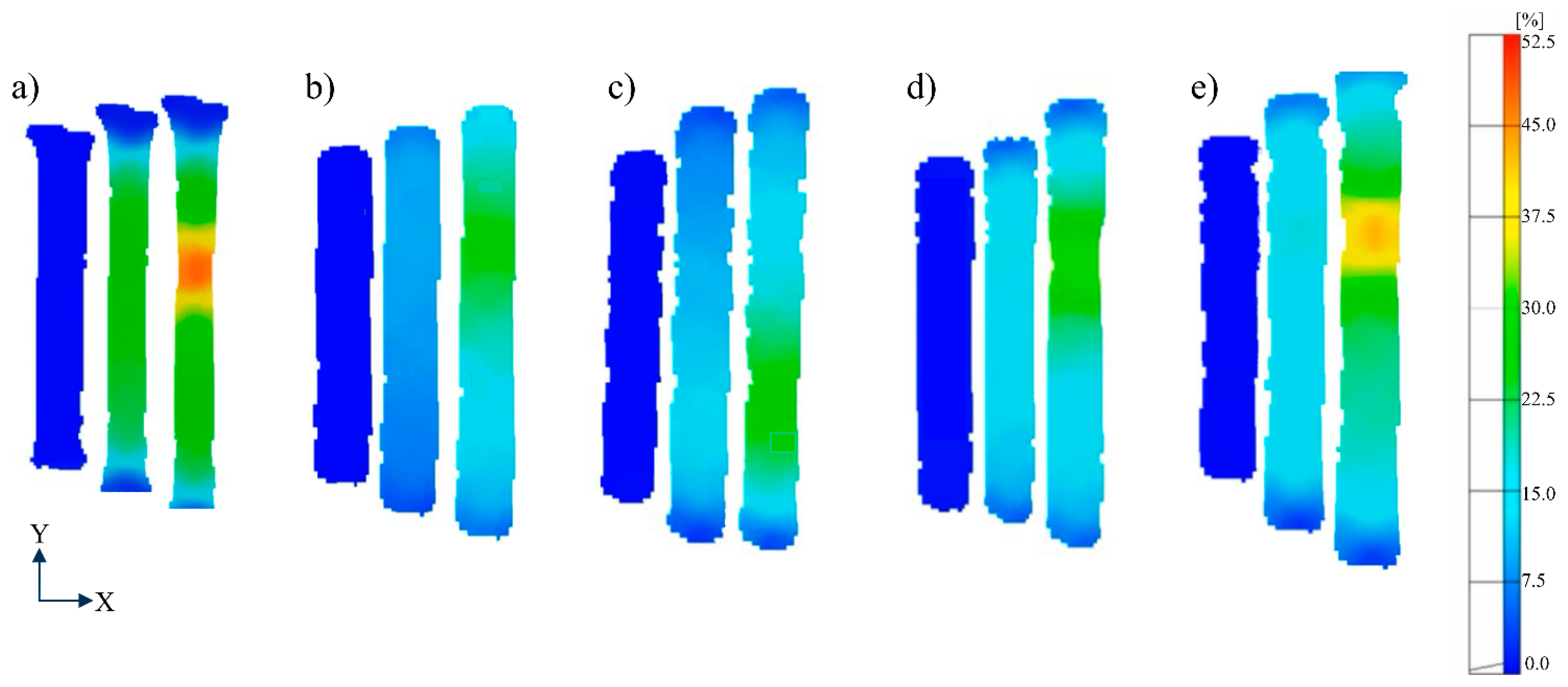

3.3.1. Grain Morphology and Texture

3.3.2. Phase Identification

3.4. Mechanical Characterization

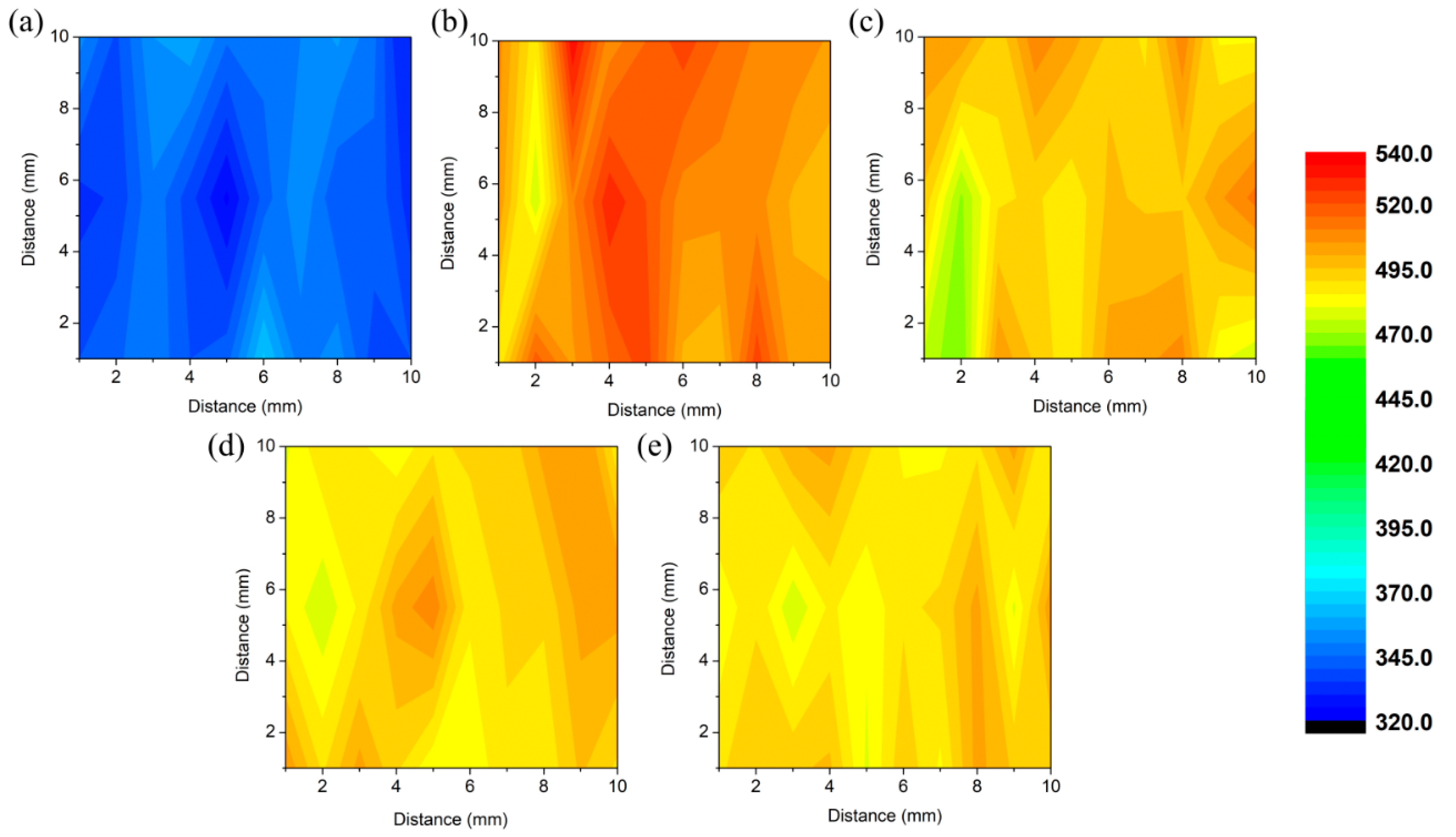

3.4.1. Hardness

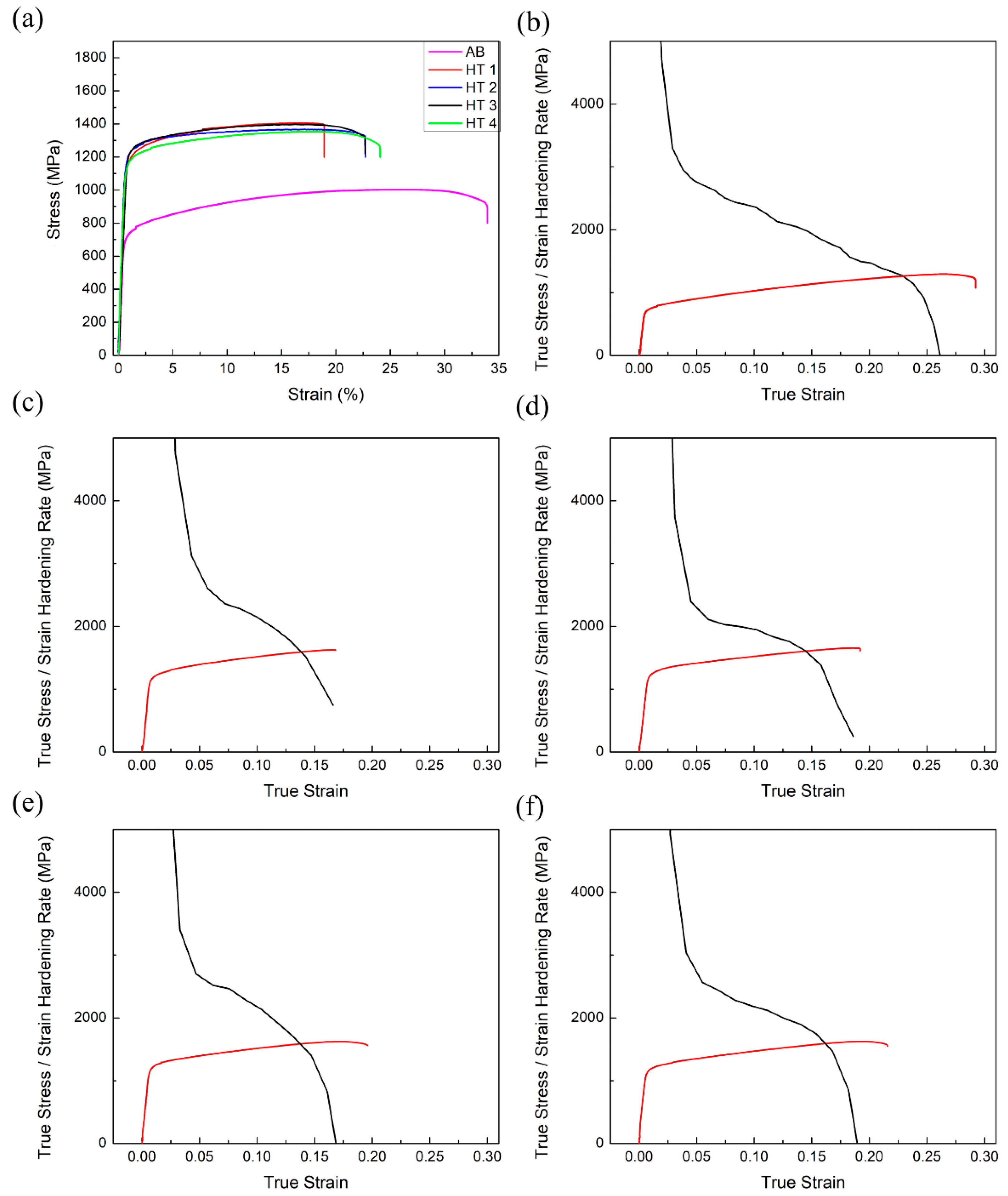

3.4.2. Tensile Properties

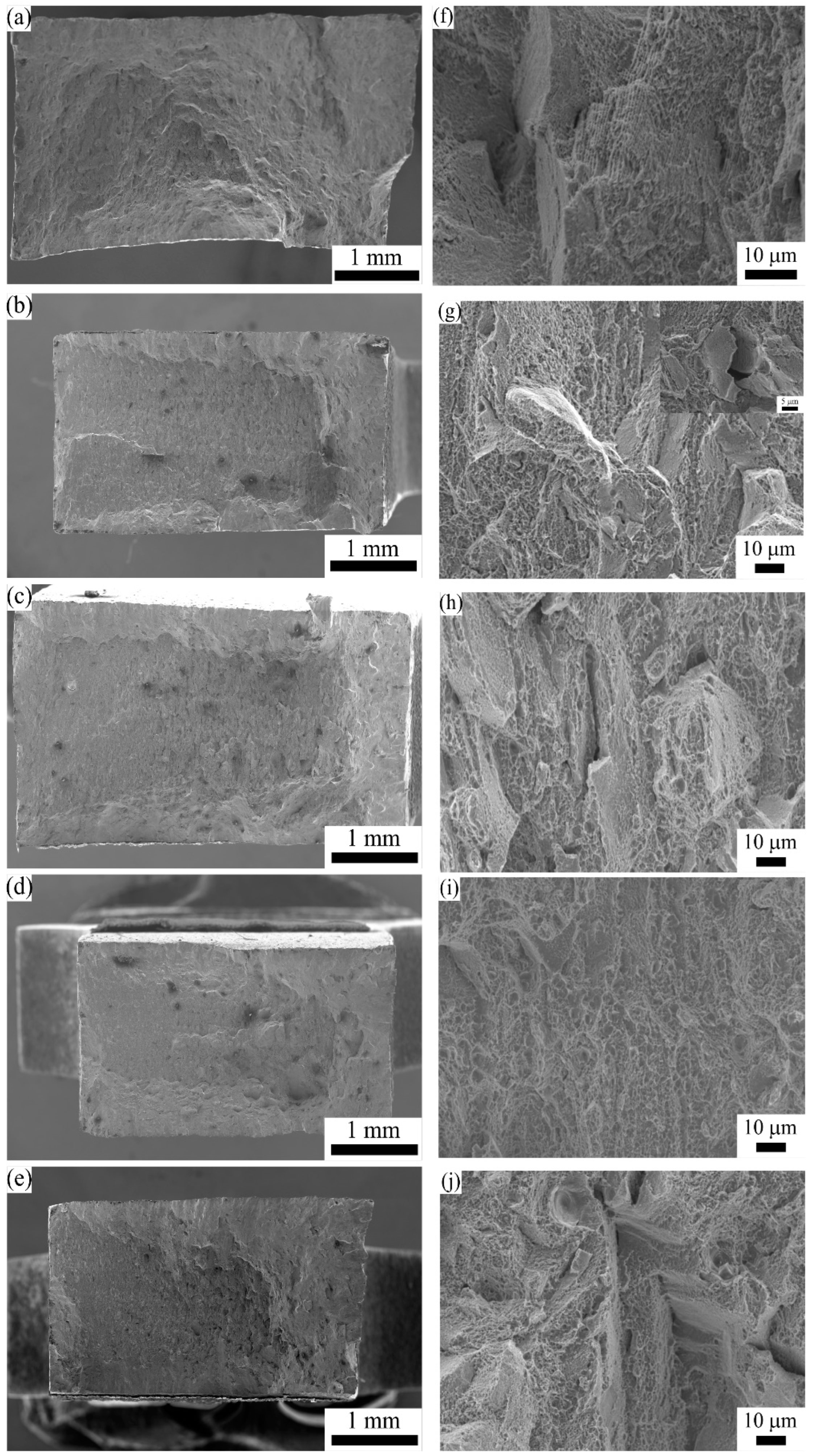

3.5. Fractography

4. Conclusions

- Additive/subtractive manufacturing results in a surface finish with lower roughness compared to the AB surface, allowing the use of a more flexible window for LPBF processing without consideration of the additive surface finish.

- Parts without any defects having 99.6–99.9% relative density were obtained with the processing parameters optimized for high-efficiency fabrication. µCT analysis showed that the majority of the pores were spherical and smaller than 30 µm. The density and pore size distribution of the specimens was maintained following all the applied heat treatments.

- The AB microstructure consisted of columnar grains parallel to the building direction, mainly aligned along the <100> direction. The texture, size, and aspect ratio of the grains were maintained after each of the applied heat treatments, showing that the grain morphology was stable at elevated temperatures.

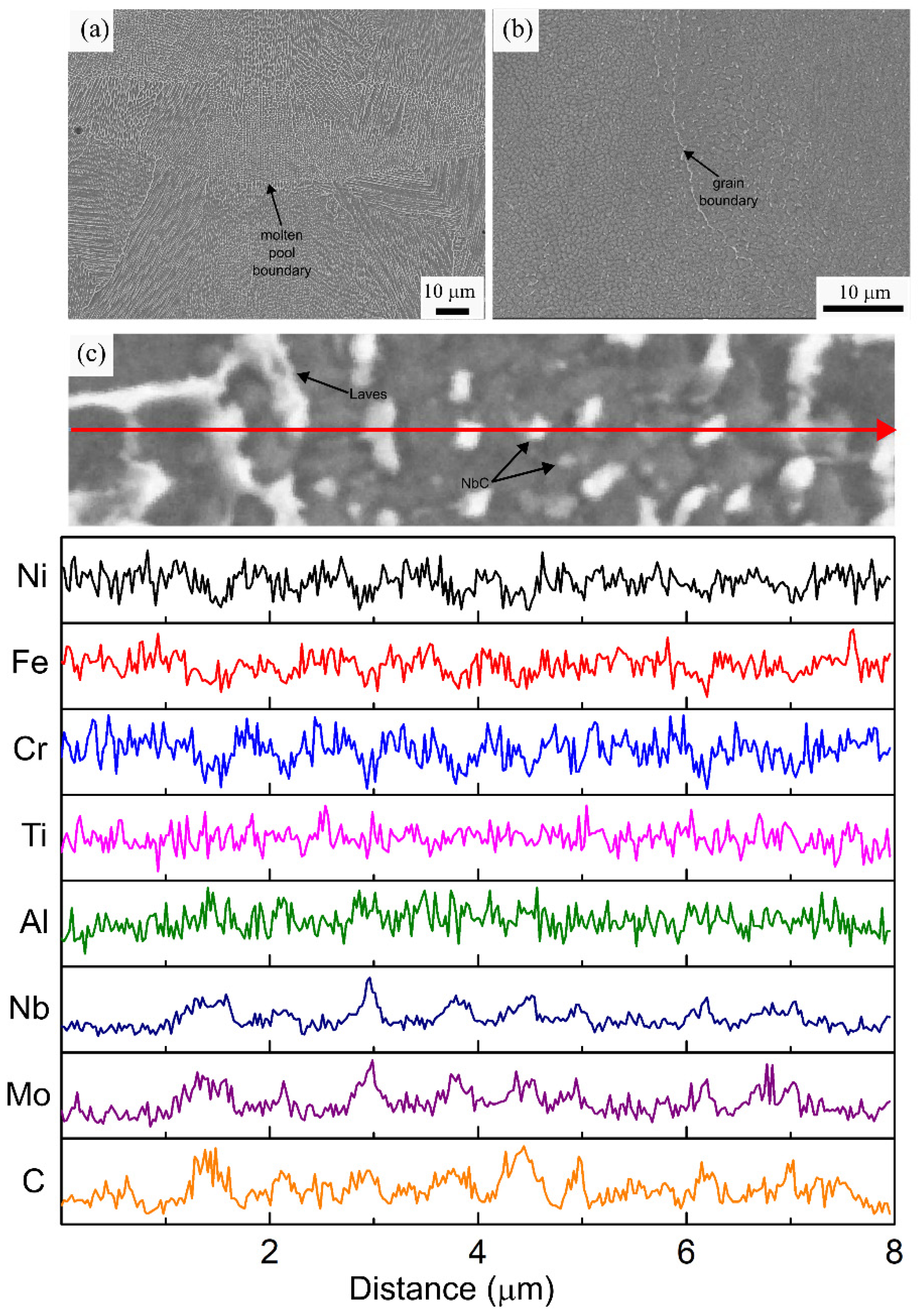

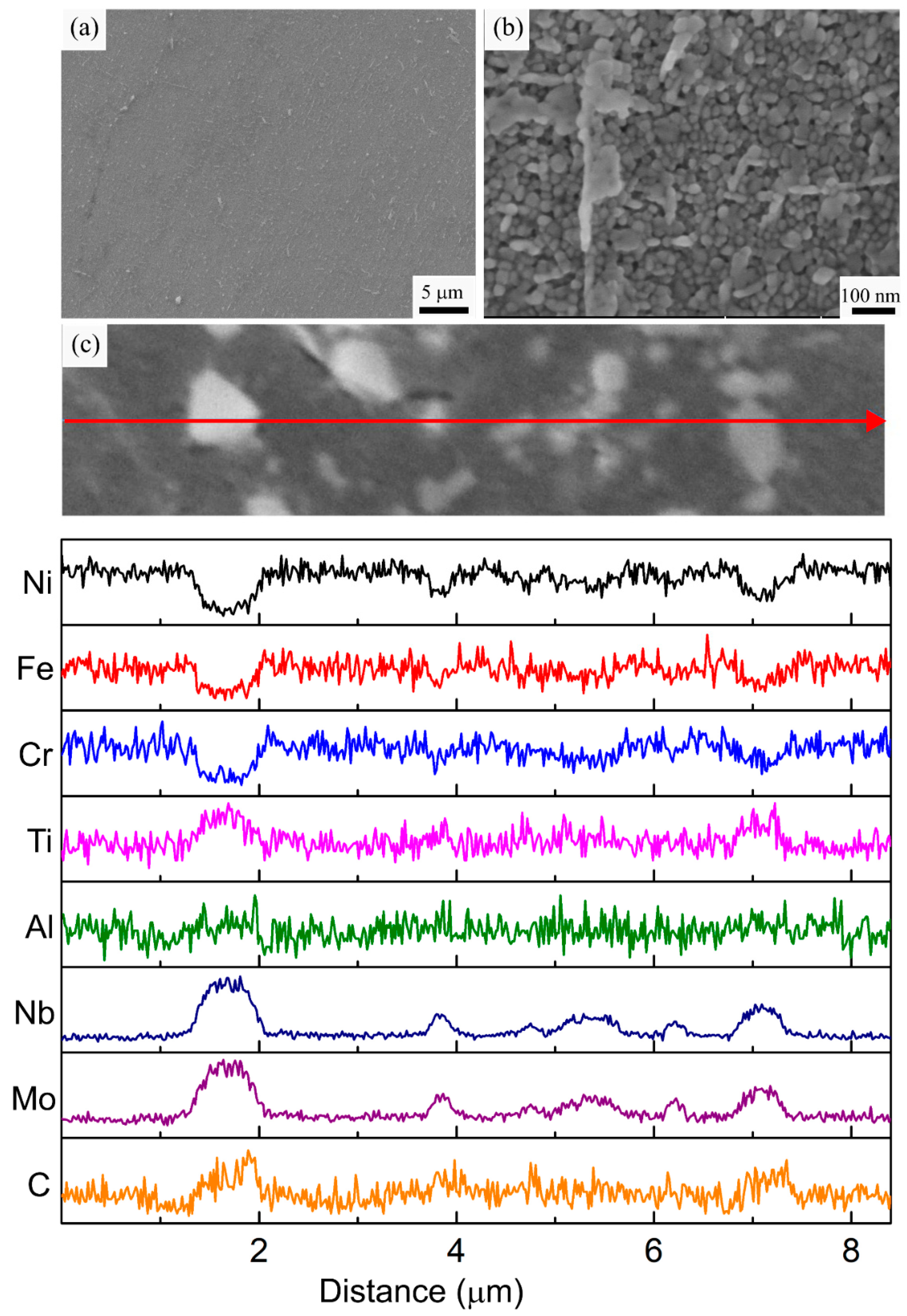

- The AB specimen exhibited a cellular dendritic sub-grain structure having fine discrete carbide particles and Laves phase on the boundaries without the presence of γ′/γ″ precipitates. This cellular sub-grain structure dissolved after the three standard heat treatments and was preserved only after HT4, a non-standard heat treatment adapted for additively processed IN718.

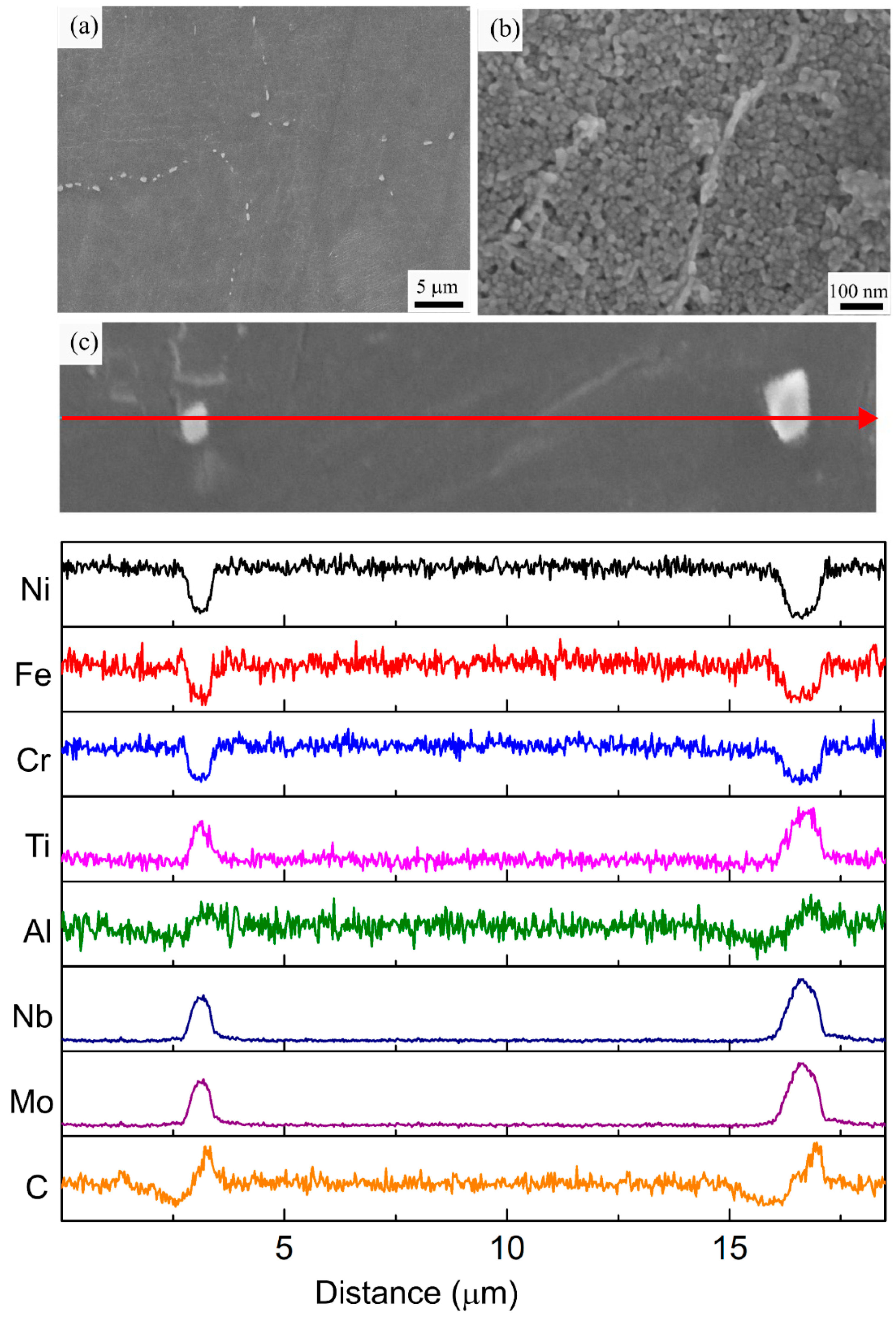

- After the specimens were subjected to the HT1, the formation of the δ phase along with the γ′/γ″ precipitates was observed.

- HT2 and HT3 each resulted in the formation of spherical carbide particles and γ′/γ″ precipitates. Hence, the extra solutionizing step in the HT2 did not affect the phases formed in the final microstructure. The main difference between the microstructure of these two specimen conditions was the size of the precipitates and carbide particles. The carbide particles were smaller in the HT3 condition due to the limited coarsening at lower homogenization temperature, whereas the size distribution of the strengthening precipitates was larger due to the higher aging temperature of this specimen.

- The non-standard heat treatment with a short solutionizing step and one-step aging (HT4) was effective for Laves phase dissolution, while preserving the carbide particles. The HT4 condition also had the finest γ′/γ″ size distribution.

- The AB specimen had the lowest strength and hardness and the highest elongation. The strength and hardness were improved, while the elongation decreased after each of the applied heat treatments due to the precipitation of the strengthening phases. The strength and elongation of all heat-treated specimens were above the minimum requirement for wrought IN718 in the heat-treated condition. Despite the differences observed in their microstructures, all heat-treated specimens showed similar strength values. HT1 resulted in the lowest elongation and the highest rate of softening due to the presence of the δ phase. The cellular sub-grain structure observed in the HT4 specimen resulted in the highest elongation at break, without the strength-ductility trade-off.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reed, R.C. The Superalloys Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2006; 372p, ISBN 9780511541285. [Google Scholar] [CrossRef]

- Ramakrishna, M.; Koppoju, S.; Telasang, G.; Korla, R.; Padmanabham, G. Effect of solutionizing temperature on the microstructural evolution during double aging of powder bed fusion-additive manufactured IN718 alloy. Mater. Charact. 2021, 172, 110868. [Google Scholar] [CrossRef]

- Chlebus, E.; Gruber, K.; Kuźnicka, B.; Kurzac, J.; Kurzynowski, T. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater. Sci. Eng. A 2015, 639, 647–655. [Google Scholar] [CrossRef]

- Li, J.; Zhao, Z.; Bai, P.; Qu, H.; Liu, B.; Li, L.; Wu, L.; Guan, R.; Liu, H.; Guo, Z. Microstructural evolution and mechanical properties of IN718 alloy fabricated by selective laser melting following different heat treatments. J. Alloys Compd. 2019, 772, 861–870. [Google Scholar] [CrossRef]

- Lippold, J.C.; Kiser, S.D.; DuPont, J.N. Welding Metallurgy and Weldability of Nickel-Base Alloys. J. Chem. Inf. Model. 2009, 53, 456. [Google Scholar] [CrossRef]

- Blackwell, P.L. The mechanical and microstructural characteristics of laser-deposited IN718. J. Mater. Process. Technol. 2005, 170, 240–246. [Google Scholar] [CrossRef]

- Yong, C.K.; Gibbons, G.J.; Wong, C.C.; West, G. A Critical Review of the Material Characteristics of Additive Manufactured IN718 for High-Temperature Application. Metals 2020, 10, 1576. [Google Scholar] [CrossRef]

- Gruber, K.; Stopyra, W.; Kobiela, K.; Madejski, B.; Malicki, M.; Kurzynowski, T. Mechanical properties of Inconel 718 additively manufactured by laser powder bed fusion after industrial high-temperature heat treatment. J. Manuf. Process. 2022, 73, 642–659. [Google Scholar] [CrossRef]

- Froes, F.; Boyer, R. Additive Manufacturing for the Aerospace Industry. 2019. Available online: https://search.ebscohost.com/login.aspx?direct=true&scope=site&db=nlebk&db=nlabk&AN=1805939 (accessed on 14 December 2022).

- Li, K.; Ma, R.; Zhang, M.; Chen, W.; Li, X.; Zhang, D.Z.; Tang, Q.; Murr, L.E.; Li, J.; Cao, H. Hybrid post-processing effects of magnetic abrasive finishing and heat treatment on surface integrity and mechanical properties of additively manufactured Inconel 718 superalloys. J. Mater. Sci. Technol. 2022, 128, 10–21. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Paccou, E.; Mokhtari, M.; Keller, C.; Nguejio, J.; Lefebvre, W.; Sauvage, X.; Boileau, S.; Babillot, P.; Bernard, P.; Bauster, E. Investigations of powder reusing on microstructure and mechanical properties of Inconel 718 obtained by additive manufacturing. Mater. Sci. Eng. A. 2021, 828, 142113. [Google Scholar] [CrossRef]

- Sarafan, S.; Wanjara, P.; Gholipour, J.; Bernier, F.; Osman, M.; Sikan, F.; Soost, J.; Amos, R.; Patnaik, P.; Brochu, M. Benchmarking of 316L Stainless Steel Manufactured by a Hybrid Additive/Subtractive Technology. J. Manuf. Mater. Process. 2022, 6, 30. [Google Scholar] [CrossRef]

- Sarafan, S.; Wanjara, P.; Gholipour, J.; Bernier, F.; Osman, M.; Sikan, F.; Molavi-Zarandi, M.; Soost, J.; Brochu, M.; Wang, H.; et al. Manufacturing and Materials Processing Evaluation of Maraging Steel Produced Using Hybrid Additive/Subtractive Manufacturing. J. Manuf. Mater. Process. 2021, 5, 107. [Google Scholar] [CrossRef]

- Muñiz-Lerma, J.A.; Tian, Y.; Wang, X.; Gauvin, R.; Brochu, M. Microstructure evolution of Inconel 738 fabricated by pulsed laser powder bed fusion. Prog. Addit. Manuf. 2018, 4, 97–107. [Google Scholar] [CrossRef]

- Wills, V.A.; McCartney, D.G. A comparative study of solidification features in nickel-base superalloys: Microstructural evolution and microsegregation. Mater. Sci. Eng. A 1991, 145, 223–232. [Google Scholar] [CrossRef]

- Harrison, N.J.; Todd, I.; Mumtaz, K. Reduction of micro-cracking in nickel superalloys processed by Selective Laser Melting: A fundamental alloy design approach. Acta Mater. 2015, 94, 59–68. [Google Scholar] [CrossRef]

- Marchese, G.; Basile, G.; Bassini, E.; Aversa, A.; Lombardi, M.; Ugues, D.; Fino, P.; Biamino, S. Study of the microstructure and cracking mechanisms of hastelloy X produced by laser powder bed fusion. Materials 2018, 11, 106. [Google Scholar] [CrossRef]

- Rielli, V.V.; Piglione, A.; Pham, M.-S.; Primig, S. On the detailed morphological and chemical evolution of phases during laser powder bed fusion and common post-processing heat treatments of IN718. Addit. Manuf. 2022, 50, 102540. [Google Scholar] [CrossRef]

- Huang, W.; Yang, J.; Yang, H.; Jing, G.; Wang, Z.; Zeng, X. Heat treatment of Inconel 718 produced by selective laser melting: Microstructure and mechanical properties. Mater. Sci. Eng. A 2019, 750, 98–107. [Google Scholar] [CrossRef]

- ASTM B213-20; Standard Test Methods for Flow Rate of Metal Powders Using the Hall Funnel. ASTM International: West Conshohocken, PA, USA, 2020. [CrossRef]

- ASTM B964-16; Standard Test Methods for Flow Rate of Metal Powders Using the Carney Funnel. ASTM International: West Conshohocken, PA, USA, 2016. [CrossRef]

- van Humbeeck, J.; Lumay, G.; Schrooten, J.; Yablokova, G.; Boschini, F.; Cloots, R.; Luyten, J.; Speirs, M.; Kruth, J.-P. Rheological behavior of β-Ti and NiTi powders produced by atomization for SLM production of open porous orthopedic implants. Powder Technol. 2015, 283, 199–209. [Google Scholar] [CrossRef]

- Spierings, A.B.; Voegtlin, M.; Bauer, T.; Wegener, K. Powder flowability characterisation methodology for powder-bed-based metal additive manufacturing. Prog. Addit. Manuf. 2016, 1, 9–20. [Google Scholar] [CrossRef]

- ISO 25178-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- ASTM E8/E8M-22; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2022; pp. 1–27. [CrossRef]

- ASM, Special Metals INCONEL® Alloy 718. Available online: https://asm.matweb.com/search/SpecificMaterial.asp?bassnum=NINC34 (accessed on 14 December 2022).

- AMS F Corrosion Heat Resistant Alloys Committee. Alloy Bars, Forgings, and Rings, Corrosion and Heat Resistant. Nickel Base-19Cr-3.1Mo-5.1(Cb + Ta)-0.90Ti-0.50Al Solution and Precipitation Heat Treated Consumable Electrode or Vacuum Induction Melted AMS5663; SAE Int.: Warrendale, PA, USA, 1965. [Google Scholar]

- AMS F Corrosion Heat Resistant Alloys Committee. Corrosion and Heat-Resistant, Investment Castings, 52.5 Ni-19Cr-3.0 Mo-5.1 Cb (Nb)-0.90 Ti-0.60 Al-18Fe, Vacuum Melted Homogenization and Solution Heat Treated AMS5383; SAE Int.: Warrendale, PA, USA, 1966. [Google Scholar]

- AMS F Corrosion Heat Resistant Alloys Committee. Alloy Bars, Forgings, and Rings, Corrosion and Heat Resistant Nickel Base-19Cr-3.1Mo-5.1(Cb + Ta)-0.90Ti-0.50Al Consumable Electrode Melted, Solution Treated at 1950 F (1065.6 C) AMS5664; SAE Int.: Warrendale, PA, USA, 1965. [Google Scholar]

- Gallmeyer, T.G.; Moorthy, S.; Kappes, B.B.; Mills, M.J.; Amin-Ahmadi, B.; Stebner, A.P. Knowledge of process-structure-property relationships to engineer better heat treatments for laser powder bed fusion additive manufactured Inconel 718. Addit. Manuf. 2020, 31, 100977. [Google Scholar] [CrossRef]

- Atabay, S.E.; Sanchez-Mata, O.; Muñiz-Lerma, J.A.; Brochu, M. Microstructure and mechanical properties of difficult to weld Rene 77 superalloy produced by laser powder bed fusion. Mater. Sci. Eng. A 2021, 827, 142053. [Google Scholar] [CrossRef]

- Sarafan, S.; Wanjara, P.; Lévesque, J.-B.; Gholipour, J.; Champliaud, H.; Mathieu, L. Through-thickness residual stresses, microstructure, and mechanical properties of electron beam-welded CA6NM martensitic stainless steel after postweld heat treatment. Adv. Mater. Sci. Eng. 2020, 2020, 7194214–7194216. [Google Scholar] [CrossRef]

- Wanjara, P.; Dalgaard, E.; Gholipour, J.; Cao, X.; Cuddy, J.; Jonas, J.J. Effect of pre-and post-weld heat treatments on linear friction welded Ti-5553. Metall. Mater. Trans. A 2014, 45, 5138–5157. [Google Scholar] [CrossRef]

- Maurya, A.K.; Kumar, A. Effect of building orientation & heat-treatment on microhardness & surface roughness of additive manufactured IN718 alloy. Mater. Today Proc. 2021, 59, 628–635. [Google Scholar] [CrossRef]

- Balbaa, M.; Mekhiel, S.; Elbestawi, M.; McIsaac, J. On selective laser melting of Inconel 718: Densification, surface roughness, and residual stresses. Mater. Des. 2020, 193, 108818. [Google Scholar] [CrossRef]

- Kladovasilakis, N.; Charalampous, P.; Tsongas, K.; Kostavelis, I.; Tzovaras, D.; Tzetzis, D. Influence of Selective Laser Melting Additive Manufacturing Parameters in Inconel 718 Superalloy. Materials 2022, 15, 1362. [Google Scholar] [CrossRef]

- Atabay, S.E.; Sanchez-Mata, O.; Muñiz-Lerma, J.A.; Gauvin, R.; Brochu, M. Microstructure and mechanical properties of rene 41 alloy manufactured by laser powder bed fusion. Mater. Sci. Eng. A 2020, 773, 138849. [Google Scholar] [CrossRef]

- Moussaoui, K.; Rubio, W.; Mousseigne, M.; Sultan, T.; Rezai, F. Effects of Selective Laser Melting additive manufacturing parameters of Inconel 718 on porosity, microstructure and mechanical properties. Mater. Sci. Eng. A 2018, 735, 182–190. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, Q.; Ma, Z.; Yu, L. Comparative study on the microstructure evolution of selective laser melted and wrought IN718 superalloy during subsequent heat treatment process and its effect on mechanical properties. Mater. Sci. Eng. A 2020, 791, 139735. [Google Scholar] [CrossRef]

- Liu, P.; Hu, J.; Sun, S.; Feng, K.; Zhang, Y.; Cao, M. Microstructural evolution and phase transformation of Inconel 718 alloys fabricated by selective laser melting under different heat treatment. J. Manuf. Process. 2019, 39, 226–232. [Google Scholar] [CrossRef]

- Wei, H.L.; Mazumder, J.; DebRoy, T. Evolution of solidification texture during additive manufacturing. Sci. Rep. 2015, 5, 16446. [Google Scholar] [CrossRef]

- Li, H.; Zhang, C.; Liu, H.B.; Li, M.Q. Bonding interface characteristic and shear strength of diffusion bonded Ti-17 titanium alloy. Trans. Nonferrous Met. Soc. China 2015, 25, 80–87. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.; Shi, Y.; Zhu, Z.; Zhang, D. Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Cao, Y.; Bai, P.; Liu, F.; Hou, X. Investigation on the precipitates of IN718 alloy fabricated by selective laser melting. Metals 2019, 9, 1128. [Google Scholar] [CrossRef]

- Zhang, D.; Niu, W.; Cao, X.; Liu, Z. Effect of standard heat treatment on the microstructure and mechanical properties of selective laser melting manufactured Inconel 718 superalloy. Mater. Sci. Eng. A 2015, 644, 32–40. [Google Scholar] [CrossRef]

- Gruber, K.; Dziedzic, R.; Kuźnicka, B.; Madejski, B.; Malicki, M. Impact of high temperature stress relieving on final properties of Inconel 718 processed by laser powder bed fusion. Mater. Sci. Eng. A 2021, 813, 141111. [Google Scholar] [CrossRef]

- Cao, G.H.; Sun, T.Y.; Wang, C.H.; Li, X.; Liu, M.; Zhang, Z.X.; Hu, P.F.; Russell, A.M.; Schneider, R.; Gerthsen, D.; et al. Investigations of γ′ γ″ and δ precipitates in heat-treated Inconel 718 alloy fabricated by selective laser melting. Mater. Charact. 2018, 136, 398–406. [Google Scholar] [CrossRef]

- Hosseini, E.; Popovich, V.A. A review of mechanical properties of additively manufactured Inconel 718. Addit. Manuf. 2019, 30, 100877. [Google Scholar] [CrossRef]

- Yasnikov, I.S.; Vinogradov, A.; Estrin, Y. Revisiting the Considère criterion from the viewpoint of dislocation theory fundamentals. Scr. Mater. 2014, 76, 37–40. [Google Scholar] [CrossRef]

- Xu, J.; Gruber, H.; Boyd, R.; Jiang, S.; Peng, R.L.; Moverare, J.J. On the strengthening and embrittlement mechanisms of an additively manufactured Nickel-base superalloy. Materialia 2020, 10, 100657. [Google Scholar] [CrossRef]

- Pröbstle, M.; Neumeier, S.; Feldner, P.; Rettig, R.; Helmer, H.E.; Singer, R.F.; Göken, M. Improved creep strength of nickel-base superalloys by optimized γ/γ′ partitioning behavior of solid solution strengthening elements. Mater. Sci. Eng. A 2016, 676, 411–420. [Google Scholar] [CrossRef]

| Element | Cr | Mo | Nb | Al | Ti | C | Si | Mn | Ni | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Wt.% | 19.19 | 3.07 | 5.25 | 0.64 | 0.93 | 0.04 | 0.15 | 0.14 | 52.37 | 18.22 |

| Designation | Standard | Treatment | Temperature (°C) | Time (h) | Cooling |

|---|---|---|---|---|---|

| AB | - | - | - | - | - |

| HT1 | AMS 5663 [30] | Solution | 980 | 1 | AC |

| Age | 720 | 8 | FC to 620 °C (55 °C/h) | ||

| 620 | 8 | AC | |||

| HT2 | AMS 5383 [31] | Homogenize | 1080 | 1.5 | AC |

| Solution | 980 | 1 | AC | ||

| Age | 720 | 8 | FC to 620 °C | ||

| 620 | 8 | AC | |||

| HT3 | AMS 5664 [32] | Homogenize | 1065 | 1 | AC |

| Age | 750 | 10 | FC to 620 °C | ||

| 650 | 8 | AC | |||

| HT4 | Non-standard [33] | Solution | 1020 | 0.25 | WQ |

| Age | 720 | 24 | AC |

| Condition | Linear Roughness (µm) | Areal Roughness (µm) | ||

|---|---|---|---|---|

| Ra | Rz | Sa | Sz | |

| As-built | 5.24 ± 0.37 | 30.94 ± 1.70 | 9.17 | 66.52 |

| Machined | 0.66 ± 0.06 | 4.05 ± 0.53 | 1.43 | 13.90 |

| Condition | Archimedean Density (g/cm3) | Total Pore Volume (%) | Pore Density (#/mm3) |

|---|---|---|---|

| AB | 8.16 ± 0.01 | 0.006 | 32 |

| HT1 | 8.18 ± 0.02 | 0.003 | 24 |

| HT2 | 8.18 ± 0.01 | 0.005 | 29 |

| HT3 | 8.18 ± 0.03 | 0.008 | 37 |

| HT4 | 8.18 ± 0.02 | 0.007 | 32 |

| CONDITION | YS (MPA) | UTS (MPA) | ELONGATION (%) |

|---|---|---|---|

| AB | 790.8 ± 6.5 | 1007.7 ± 5.8 | 34.0 ± 2.5 |

| HT1 | 1133.9 ± 31.6 | 1387.2 ± 18.5 | 18.3 ± 0.7 |

| HT2 | 1204.6 ± 7.0 | 1381.6 ± 11.8 | 21.4 ± 1.3 |

| HT3 | 1189.5 ± 12.3 | 1387.1 ± 10.2 | 21.0 ± 2.1 |

| HT4 | 1102.7 ± 28.9 | 1346.7 ± 22.6 | 24.0 ± 0.1 |

| Wrought [29] | 1034 | 1241 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the National Research Council Canada. Submitted for possible open access publication under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atabay, S.E.; Wanjara, P.; Bernier, F.; Sarafan, S.; Gholipour, J.; Soost, J.; Amos, R.; Patnaik, P.; Brochu, M. In Envelope Additive/Subtractive Manufacturing and Thermal Post-Processing of Inconel 718. Materials 2023, 16, 1. https://doi.org/10.3390/ma16010001

Atabay SE, Wanjara P, Bernier F, Sarafan S, Gholipour J, Soost J, Amos R, Patnaik P, Brochu M. In Envelope Additive/Subtractive Manufacturing and Thermal Post-Processing of Inconel 718. Materials. 2023; 16(1):1. https://doi.org/10.3390/ma16010001

Chicago/Turabian StyleAtabay, Sila Ece, Priti Wanjara, Fabrice Bernier, Sheida Sarafan, Javad Gholipour, Josh Soost, Robert Amos, Prakash Patnaik, and Mathieu Brochu. 2023. "In Envelope Additive/Subtractive Manufacturing and Thermal Post-Processing of Inconel 718" Materials 16, no. 1: 1. https://doi.org/10.3390/ma16010001

APA StyleAtabay, S. E., Wanjara, P., Bernier, F., Sarafan, S., Gholipour, J., Soost, J., Amos, R., Patnaik, P., & Brochu, M. (2023). In Envelope Additive/Subtractive Manufacturing and Thermal Post-Processing of Inconel 718. Materials, 16(1), 1. https://doi.org/10.3390/ma16010001