A Highly Effective, UV-Curable, Intumescent, Flame-Retardant Coating Containing Phosphorus, Nitrogen, and Sulfur, Based on Thiol-Ene Click Reaction

Abstract

:1. Introduction

2. Experiment

2.1. Materials

2.2. Preparation of Samples

2.3. Characterization

2.3.1. Fourier Transform Infrared Spectroscopy (FTIR)

2.3.2. Limiting Oxygen Index (LOI)

2.3.3. Horizontal Burning Rate (HBR)

2.3.4. Thermo-Gravimetric Analysis (TG)

2.3.5. Cone Calorimetry Test (CCT)

2.3.6. Mechanical Properties

2.3.7. Adhesion Test

2.3.8. Optical Transparency

2.3.9. Morphology Observation

3. Results and Discussion

3.1. Curing Kinetics and Double Bond Conversion

3.2. Flame Retardancy of Fiber Composites

3.3. Combustion Behavior

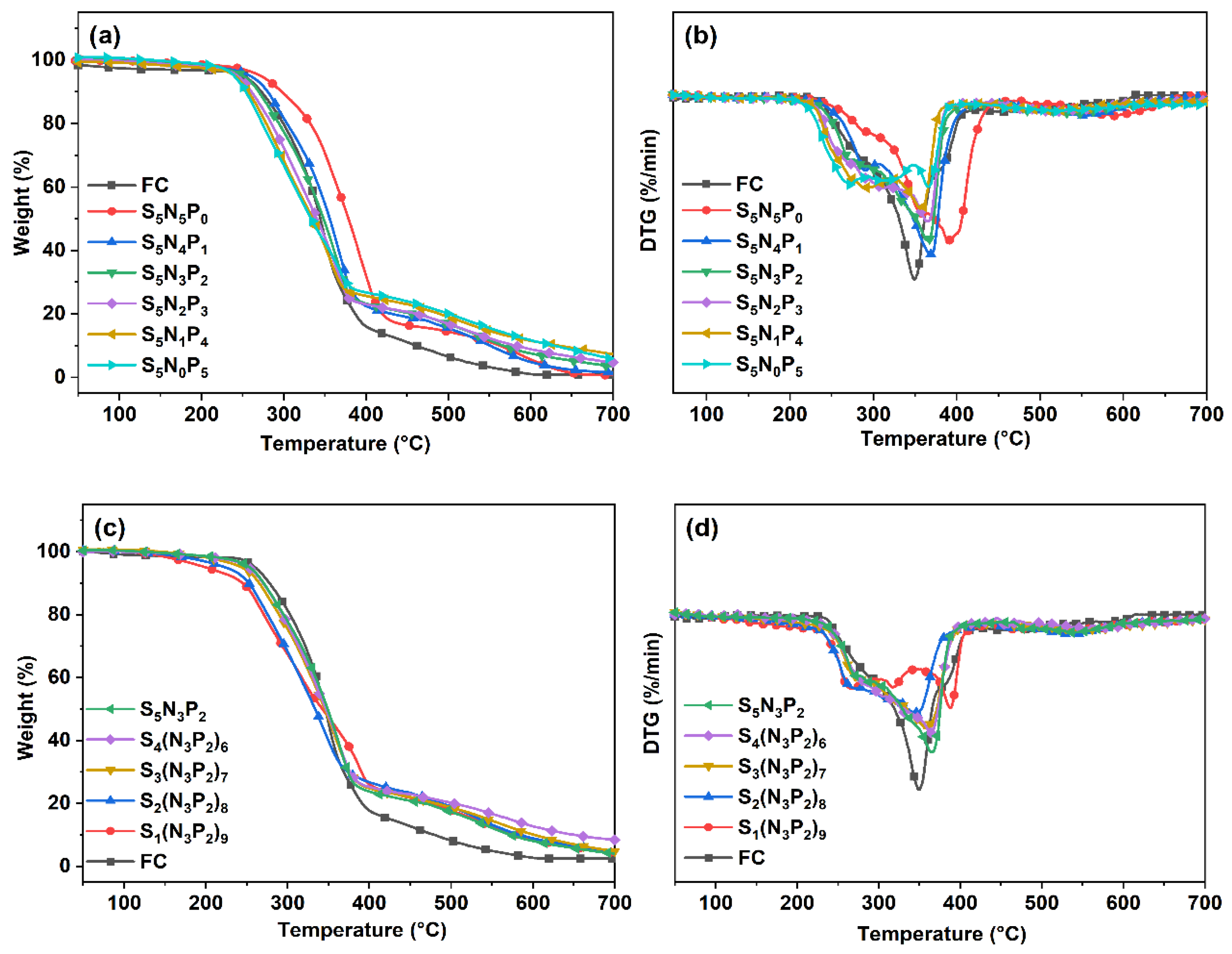

3.4. Thermogravimetric Analysis

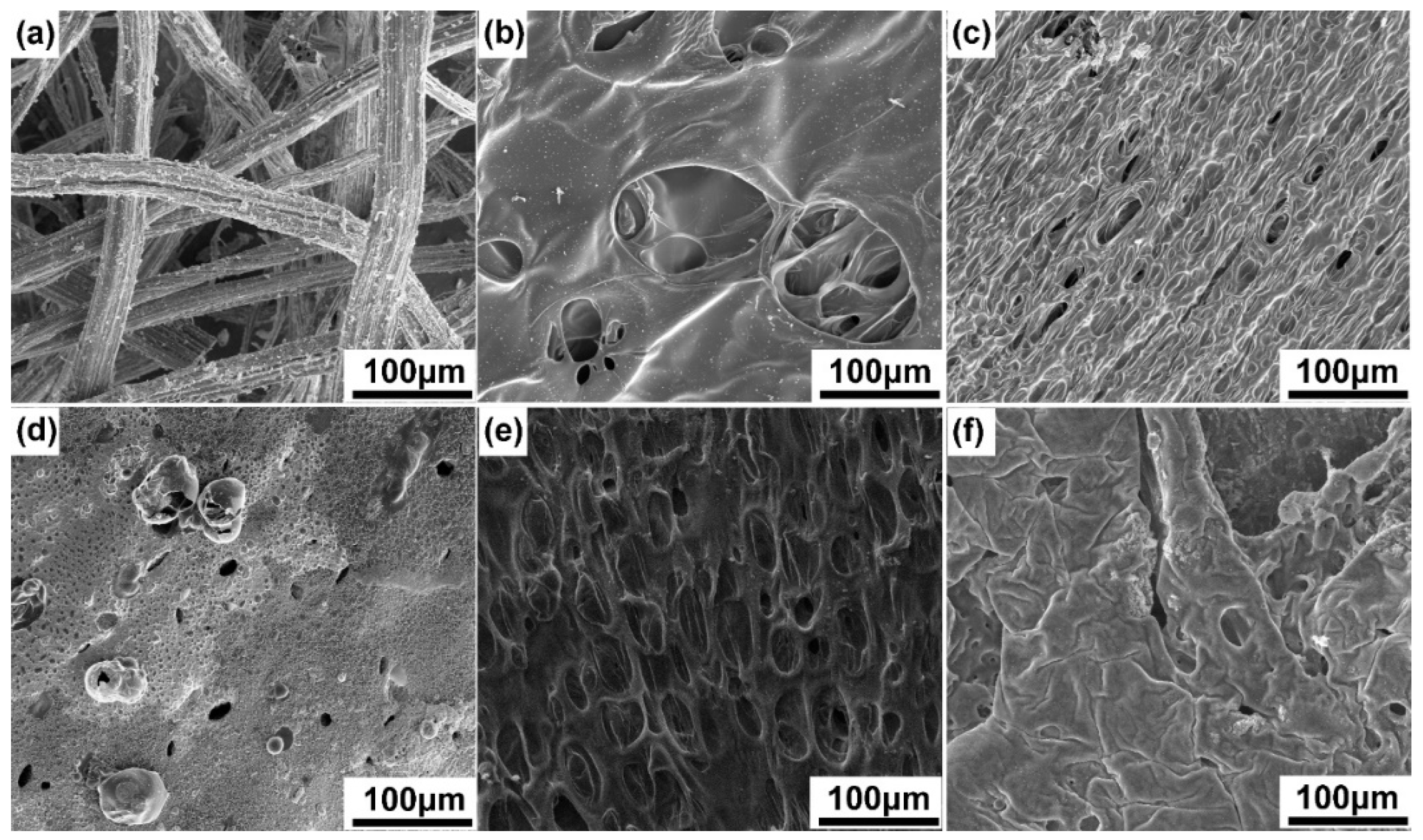

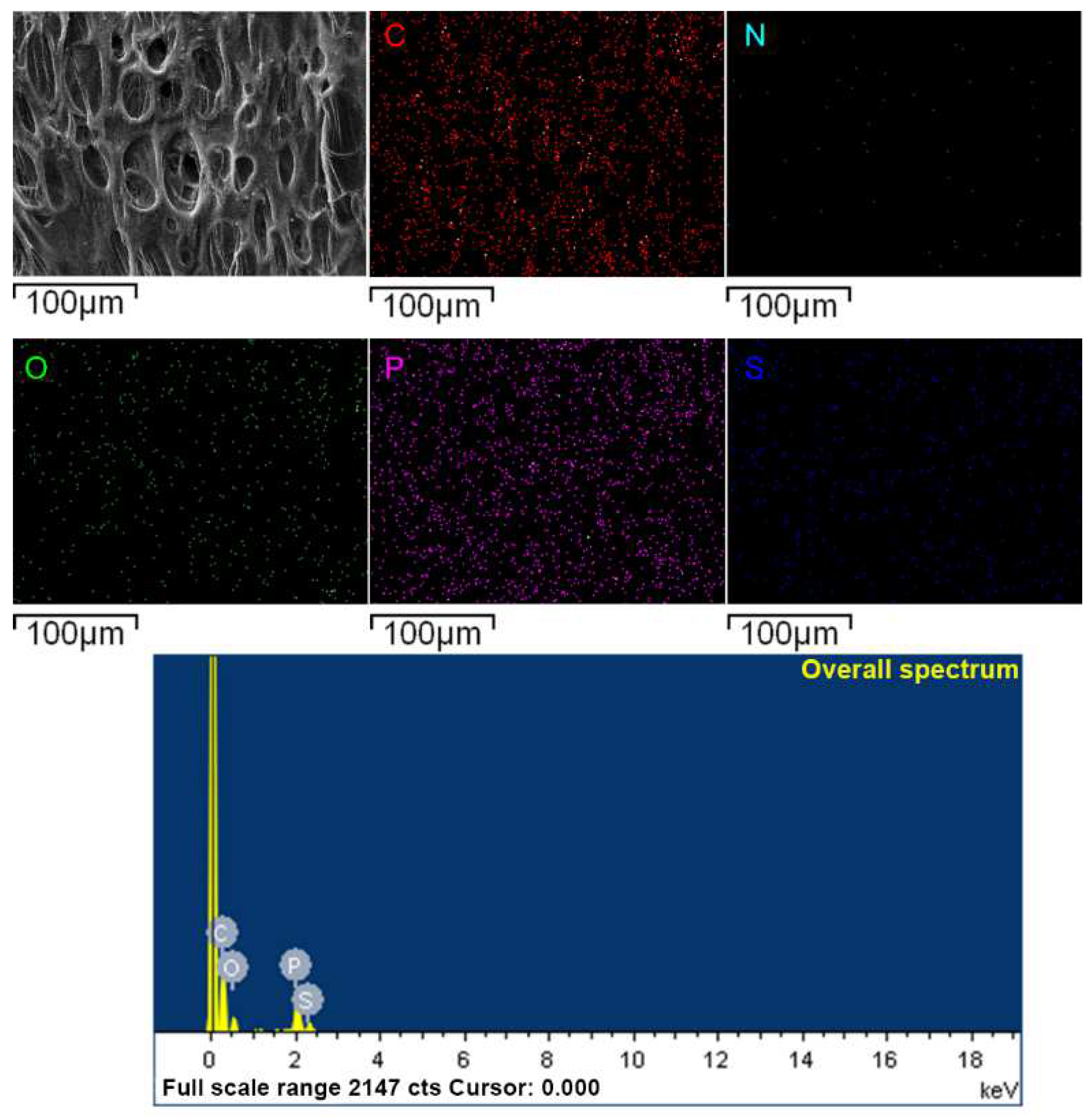

3.5. Char Residues Surface Morphologies Analysis and Elements Analysis

3.6. Adhesion and Mechanical Testing

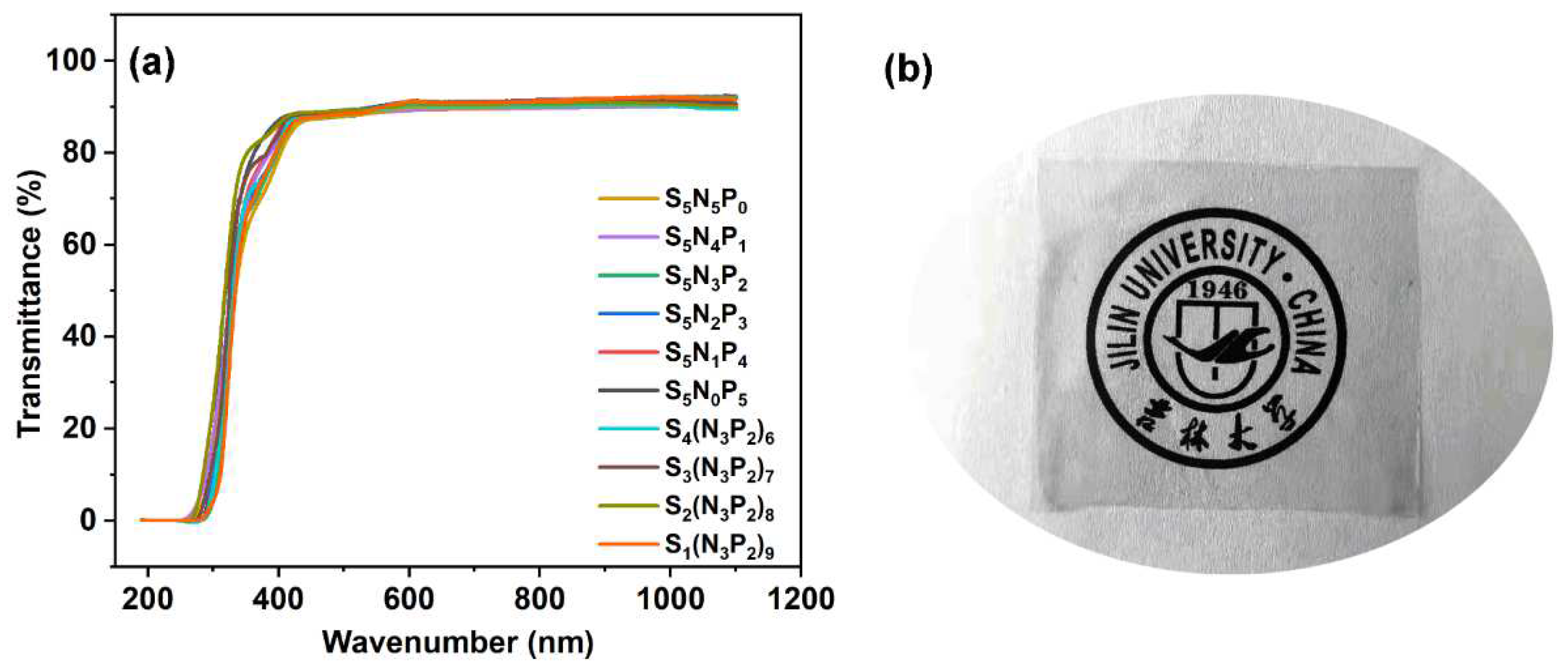

3.7. Optical Property

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, T.; Liu, T.; Ma, T.; Li, L.; Wang, Q.; Guo, C. Study on degradation of phosphorus and nitrogen composite UV-cured flame retardant coating on wood surface. Prog. Org. Coat. 2018, 124, 240–248. [Google Scholar] [CrossRef]

- Wang, T.S.; Li, L.P.; Wang, Q.W.; Xie, G.J.; Guo, C.G. Castor oil based UV-cured coatings using thiol-ene click reaction for thermal degradation with flame retardance. Ind. Crops Prod. 2019, 141, 111798. [Google Scholar] [CrossRef]

- Wang, T.; Li, L.; Cao, Y.; Wang, Q.; Guo, C. Preparation and flame retardancy of castor oil based UV-cured flame retardant coating containing P/Si/S on wood surface. Ind. Crops Prod. 2019, 130, 562–570. [Google Scholar] [CrossRef]

- Huang, Y.B.; Jiang, S.H.; Liang, R.C.; Liao, Z.W.; You, G.X. A green highly-effective surface flame-retardant strategy for rigid polyurethane foam: Transforming UV-cured coating into intumescent self-extinguishing layer. Compos. Part A-Appl. Sci. Manuf. 2019, 125, 125. [Google Scholar] [CrossRef]

- Xiao, Z.F.; Liu, S.L.; Zhang, Z.J.; Mai, C.; Xie, Y.J.; Wang, Q.W. Fire retardancy of an aqueous, intumescent, and translucent wood varnish based on guanylurea phosphate and melamine-urea-formaldehyde resin. Prog. Org. Coat. 2018, 121, 64–72. [Google Scholar] [CrossRef]

- Lokhande, G.; Chambhare, S.; Jagtap, R. Synthesis and properties of phosphate-based diacrylate reactive diluent applied to UV-curable flame-retardant wood coating. J. Coat. Technol. Res. 2017, 14, 255–266. [Google Scholar] [CrossRef]

- Banerjee, I.; Pangule, R.C.; Kane, R.S. Antifouling Coatings: Recent Developments in the Design of Surfaces That Prevent Fouling by Proteins, Bacteria, and Marine Organisms. Adv. Mater. 2011, 23, 690–718. [Google Scholar] [CrossRef]

- Wei, D.D.; Liao, B.; Huang, J.H.; Zhang, M.; Pang, H. Fabrication of castor oil-based hyperbranched urethane acrylate UV-curable coatings via thiol-ene click reactions. Prog. Org. Coat. 2019, 135, 114–122. [Google Scholar] [CrossRef]

- Contreras, P.P.; Agarwal, S. Photo-polymerizable, low shrinking modular construction kit with high efficiency based on vinylcyclopropanes. Polym. Chem. 2016, 7, 3100–3106. [Google Scholar] [CrossRef] [Green Version]

- Alvankarian, J.; Majlis, B.Y. Exploiting the Oxygen Inhibitory Effect on UV Curing in Microfabrication: A Modified Lithography Technique. PLoS ONE 2015, 10, e0119658. [Google Scholar] [CrossRef] [Green Version]

- Corcione, C.E.; Striani, R.; Frigione, M. UV-cured methacrylic-silica hybrids: Effect of oxygen inhibition on photo-curing kinetics. Thermochim. Acta. 2014, 576, 47–55. [Google Scholar] [CrossRef]

- Husar, B.; Ligon, S.C.; Wutzel, H.; Hoffmann, H.; Liska, R. The formulator’s guide to anti-oxygen inhibition additives. Prog. Org. Coat. 2014, 77, 1789–1798. [Google Scholar] [CrossRef]

- Chen, W.B.; Wang, L.; Liu, X.Y.; Chen, B.; Zhao, G.F. Synthesis and preliminary photopolymerization evaluation of novel photoinitiators containing phototrigger to overcome oxygen inhibition in the UV-curing system. J. Photochem. Photobiol. A Chem. 2020, 388, 112187. [Google Scholar] [CrossRef]

- Wei, J.; Liu, F. Novel Highly Efficient Macrophotoinitiator Comprising Benzophenone, Coinitiator Amine, and Thio Moieties for Photopolymerization. Macromolecules 2009, 42, 5486–5491. [Google Scholar] [CrossRef]

- Roper, T.; Kwee, T.; Lee, T.; Guymon, C.A.; Hoyle, C.E. Photopolymerization of pigmented thiol ene systems. Polymer 2004, 45, 2921–2929. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, G.X.; Cui, Y.Y.; Tian, J.F.; He, M.H.; Yang, J.W. Castor Oil Based Biothiol as a Highly Stable and Self-Initiated Oligomer for Photoinitiator-Free UV Coatings. ACS Sustain. Chem. Eng. 2017, 5, 376–381. [Google Scholar] [CrossRef]

- Liu, C.H.; Li, T.C.; Zhang, J.H.; Chen, S.F.; Xu, Z.C.; Zhang, A.Q.; Zhang, D.H. Preparation and properties of phosphorous-nitrogen containing UV-curable polymeric coatings based on thiol-ene click reaction. Prog. Org. Coat. 2016, 90, 21–27. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Liang, H.B.; Yang, H.T.; Xiong, L.; Zhou, J.P.; Huang, S.M.; Zhao, C.H.; Zhong, J.; Fan, X.F. UV-curable self-healing polyurethane coating based on thiol-ene and Diels-Alder double click reactions. Prog. Org. Coatings 2019, 137, 105282. [Google Scholar] [CrossRef]

- Liang, B.; Li, R.P.; Zhang, C.Q.; Yang, Z.H.; Yuan, T. Synthesis and characterization of a novel tri-functional bio-based methacrylate prepolymer from castor oil and its application in UV-curable coatings. Ind. Crops Prod. 2019, 135, 170–178. [Google Scholar] [CrossRef]

- Miao, J.T.; Yuan, L.; Guan, Q.B.; Liang, G.Z.; Gu, A.J. Water-Phase Synthesis of a Biobased Allyl Compound for Building UV-Curable Flexible Thiol Ene Polymer Networks with High Mechanical Strength and Transparency. Acs Sustain. Chem. Eng. 2018, 6, 7902–7909. [Google Scholar] [CrossRef]

- Wu, C.D.; Wu, J.L.; Ma, K.K.; Zhang, D.L.; Xiong, S.Y.; Zhang, J.; Luo, G.Q.; Chen, F.; Shen, Q.; Zhang, L.M.; et al. Synthesis of AA7075-AA7075/B4C bilayer composite with enhanced mechanical strength via plasma activated sintering. J. Alloys Compd. 2017, 701, 416–424. [Google Scholar] [CrossRef]

- Huang, Y.B.; Jiang, S.H.; Liang, R.C.; Sun, P.; Hai, Y.; Zhang, L. Thermal-triggered insulating fireproof layers: A novel fire-extinguishing MXene composites coating. Chem. Eng. J. 2020, 391, 123621. [Google Scholar] [CrossRef]

- Wang, X.; Song, L.; Xing, W.Y.; Lu, H.D.; Hu, Y.A. A effective flame retardant for epoxy resins based on poly(DOPO substituted dihydroxyl phenyl pentaerythritol diphosphonate). Mater. Chem. Phys. 2011, 125, 536–541. [Google Scholar] [CrossRef]

- Phalak, G.; Patil, D.; Patil, A.; Mhaske, S. Synthesis of acrylated cardanol diphenyl phosphate for UV curable flame-retardant coating application. Eur. Polym. J. 2019, 121, 109320. [Google Scholar] [CrossRef]

- Xing, W.Y.; Hu, Y.; Song, L.; Chen, X.L.; Zhang, P.; Ni, J.X. Thermal degradation and combustion of a novel UV curable coating containing phosphorus. Polym. Degrad. Stab. 2009, 94, 1176–1182. [Google Scholar] [CrossRef]

- Liu, R.; Zhu, G.G.; Li, Z.Q.; Liu, X.Y.; Chen, Z.G.; Ariyasivam, S. Cardanol-based oligomers with “hard core, flexible shell” structures: From synthesis to UV curing applications. Green Chem. 2015, 17, 3319–3325. [Google Scholar] [CrossRef]

- Qu, L. Research on Properties of Phosphours/Nitrogen/Silicon/Graphene-Containing Synergic Flame-Retardant Epoxy resin. Ph.D. Thesis, Jilin University, Changchun, China, 2020. [Google Scholar]

- Ma, T.T.; Guo, C.G. Synergistic effect between melamine cyanurate and a novel flame retardant curing agent containing a caged bicyclic phosphate on flame retardancy and thermal behavior of epoxy resins. J. Anal. Appl. Pyrolysis 2017, 124, 239–246. [Google Scholar] [CrossRef]

- Bai, Z.M.; Song, L.; Hu, Y.; Yuen, R.K.K. Preparation, Flame Retardancy, and Thermal Degradation of Unsaturated Polyester Resin Modified with a Novel Phosphorus Containing Acrylate. Ind. Eng. Chem. Res. 2013, 52, 12855–12864. [Google Scholar] [CrossRef]

- Sun, J.; Wang, X.D.; Wu, D.Z. Novel Spirocyclic Phosphazene-Based Epoxy Resin for Halogen-Free Fire Resistance: Synthesis, Curing Behaviors, and Flammability Characteristics. Acs Appl. Mater. Interfaces 2012, 4, 4047–4061. [Google Scholar] [CrossRef]

- Carioscia, J.A.; Lu, H.; Stanbury, J.W.; Bowman, C.N. Thiol-ene oligomers as dental restorative materials. Dent. Mater. 2005, 21, 1137–1143. [Google Scholar] [CrossRef]

- Cramer, N.B.; Scott, J.P.; Bowman, C.N. Photopolymerizations of thiol-ene polymers without photoinitiators. Macromolecules 2002, 35, 5361–5365. [Google Scholar] [CrossRef]

- Duan, W.; Li, M.; Sun, H.; Cheng, J.; Zhang, J. Preparation and charactrization of hybrid thiol-ene/epoxy UV-thermal dual-curing systems. Adhesion 2017, 38, 16–22. [Google Scholar]

- Chiang, T.H.; Hsieh, T.E. A study of monomer’s effect on adhesion strength of UV-curable resins. Int. J. Adhes. Adhes. 2006, 26, 520–531. [Google Scholar] [CrossRef]

| Coating | PETMP (mol) | TAC (mol) | PM-2 (mol) | [SH]: [C=C] (mol) | N:P (mol) |

|---|---|---|---|---|---|

| S5N5P0 | 3 | 4 | 0 | 5:5 | 5:0 |

| S5N4P1 | 3 | 3.2 | 2.4 | 5:5 | 4:1 |

| S5N3P2 | 3 | 2.4 | 4.8 | 5:5 | 3:2 |

| S5N2P3 | 3 | 1.6 | 7.2 | 5:5 | 2:3 |

| S5N1P4 | 3 | 0.8 | 9.6 | 5:5 | 1:4 |

| S5N0P5 | 3 | 0 | 12 | 5:5 | 0:5 |

| S4(N3P2)6 | 1.5 | 1.8 | 3.6 | 4:6 | 3:2 |

| S3(N3P2)7 | 1.5 | 2.8 | 5.6 | 3:7 | 3:2 |

| S2(N3P2)8 | 1.5 | 4.8 | 9.6 | 2:8 | 3:2 |

| S1(N3P2)9 | 1.5 | 10.8 | 21.6 | 1:9 | 3:2 |

| Coating | LOI (%) | HBR (mm/min) or Self-Extinguishing Time (s) | C=C Conversion (%) | -SH Conversion (%) |

|---|---|---|---|---|

| FC | 22.8 | 14.3 mm/min | - | - |

| S5N5P0 | 25.6 | 5.8 mm/min | 98.6 | 81.1 |

| S5N4P1 | 26.7 | 125 s | 99.7 | 79.0 |

| S5N3P2 | 27.2 | 79 s | 98.8 | 70.9 |

| S5N2P3 | 26.9 | 94 s | 98.2 | 65.4 |

| S5N1P4 | 26.5 | 94 s | 99.7 | 65.2 |

| S5N0P5 | 26.3 | 91 s | 99.3 | 62.0 |

| S4(N3P2)6 | 28.6 | 85 s | 100 | 92.0 |

| S3(N3P2)7 | 27.0 | 140 s | 100 | 96.2 |

| S2(N3P2)8 | 25.9 | 214 s | 97.1 | 87.6 |

| S1(N3P2)9 | 25.5 | 220 s | 92.8 | 81.8 |

| Samples | TTI | PHRR | Mean EHC | THR | TSR | TSP |

|---|---|---|---|---|---|---|

| S5N5P0 | 20 | 384.42 | 21.33 | 52.44 | 243.55 | 2.36 |

| S5N3P2 | 11 | 294.55 | 21.37 | 47.57 | 254.18 | 2.32 |

| S5N0P5 | 10 | 296.37 | 19.84 | 50.89 | 434.56 | 3.96 |

| S4(N3P2)6 | 18 | 279.25 | 23.73 | 47.80 | 217.03 | 2.18 |

| S1(N3P2)9 | 7 | 362.53 | 20.26 | 46.41 | 321.83 | 2.93 |

| Samples | T5% (°C) | Tmax1 (°C) | Tmax2 (°C) | Yc (wt%) | ||||

|---|---|---|---|---|---|---|---|---|

| N2 | Air | N2 | Air | N2 | Air | N2 | Air | |

| FC | 296 | 251 | 355 | - | 435 | 349 | 6.55 | 0.79 |

| S5N5P0 | 291 | 271 | 378 | 285 | 450 | 390 | 9.59 | 0.69 |

| S5N4P1 | 265 | 259 | 376 | 291 | 458 | 368 | 11.14 | 1.51 |

| S5N3P2 | 252 | 251 | 350 | 271 | 456 | 366 | 14.49 | 3.50 |

| S5N2P3 | 251 | 243 | 291 | 290 | 464 | 365 | 16.53 | 4.64 |

| S5N1P4 | 244 | 240 | 277 | 291 | 449 | 357 | 18.41 | 6.68 |

| S5N0P5 | 237 | 239 | 276 | 269 | 422 | 366 | 20.78 | 5.82 |

| S4(N3P2)6 | 258 | 252 | 342 | 280 | 465 | 365 | 13.76 | 8.46 |

| S3(N3P2)7 | 238 | 244 | 285 | 271 | 459 | 357 | 14.10 | 4.88 |

| S2(N3P2)8 | 219 | 224 | 272 | 264 | 463 | 345 | 14.94 | 4.63 |

| S1(N3P2)9 | 225 | 200 | 271 | 264 | 456 | 388 | 14.49 | 4.37 |

| Coating | C | O | N | P | S |

|---|---|---|---|---|---|

| S5N5P0 | 83.73 | 11.89 | 0 | 0.5 | 3.88 |

| S5N3P2 | 77.37 | 14.91 | 0 | 4.97 | 2.75 |

| S5N0P5 | 59.63 | 26.25 | 0 | 12.72 | 1.41 |

| S4(N3P2)6 | 69.53 | 22.51 | 0 | 6.55 | 1.42 |

| S1(N3P2)9 | 68.79 | 20.71 | 0 | 10.5 | 0 |

| Coating | C-Content (wt%) | O-Content (wt%) | N-Content (wt%) | P-Content (wt%) | S-Content (wt%) |

|---|---|---|---|---|---|

| S5N5P0 | 48.23 | 23.39 | 6.82 | 0 | 15.59 |

| S5N3P2 | 42.41 | 31.27 | 3.28 | 4.85 | 12.51 |

| S5N0P5 | 37.05 | 38.55 | 0 | 9.34 | 9.64 |

| S4(N3P2)6 | 42.58 | 32.23 | 3.90 | 5.76 | 9.92 |

| S1(N3P2)9 | 42.93 | 34.99 | 5.70 | 8.42 | 2.41 |

| Samples | Tensile Strength (MPa) | Flexural Strength (MPa) | Adhesion (Grade) | |

|---|---|---|---|---|

| Coating Loss Rate (%) | Adhesion Grade | |||

| FC | 26.05 ± 0.85 | 34.27 ± 2.50 | - | - |

| S5N5P0 | 24.85 ± 2.55 | 44.65 ± 1.45 | 0 | 0 |

| S5N4P1 | 25.87 ± 3.57 | 44.39 ± 2.62 | 0 | 0 |

| S5N3P2 | 25.76 ± 3.82 | 42.52 ± 2.56 | 0 | 0 |

| S5N2P3 | 24.38 ± 2.60 | 39.96 ± 3.35 | 0 | 0 |

| S5N1P4 | 25.24 ± 2.54 | 45.15 ± 2.81 | 0 | 0 |

| S5N0P5 | 24.15 ± 2.61 | 40.90 ± 2.36 | 0 | 0 |

| S4(N3P2)6 | 26.11 ± 1.83 | 42.02 ± 2.74 | 3 | 1 |

| S3(N3P2)7 | 28.34 ± 2.52 | 48.11 ± 1.64 | 5 | 1 |

| S2(N3P2)8 | 28.95 ± 0.53 | 50.29 ± 2.29 | 14 | 2 |

| S1(N3P2)9 | 30.67 ± 2.63 | 52.31 ± 1.98 | 48 | 4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Dou, Y.; Li, X.; Fang, S.; Li, J.; Li, Q. A Highly Effective, UV-Curable, Intumescent, Flame-Retardant Coating Containing Phosphorus, Nitrogen, and Sulfur, Based on Thiol-Ene Click Reaction. Materials 2022, 15, 3358. https://doi.org/10.3390/ma15093358

Li W, Dou Y, Li X, Fang S, Li J, Li Q. A Highly Effective, UV-Curable, Intumescent, Flame-Retardant Coating Containing Phosphorus, Nitrogen, and Sulfur, Based on Thiol-Ene Click Reaction. Materials. 2022; 15(9):3358. https://doi.org/10.3390/ma15093358

Chicago/Turabian StyleLi, Wenqian, Yanli Dou, Xuefei Li, Shengbo Fang, Jian Li, and Quanming Li. 2022. "A Highly Effective, UV-Curable, Intumescent, Flame-Retardant Coating Containing Phosphorus, Nitrogen, and Sulfur, Based on Thiol-Ene Click Reaction" Materials 15, no. 9: 3358. https://doi.org/10.3390/ma15093358

APA StyleLi, W., Dou, Y., Li, X., Fang, S., Li, J., & Li, Q. (2022). A Highly Effective, UV-Curable, Intumescent, Flame-Retardant Coating Containing Phosphorus, Nitrogen, and Sulfur, Based on Thiol-Ene Click Reaction. Materials, 15(9), 3358. https://doi.org/10.3390/ma15093358