Dielectric Property and Breakdown Strength Performance of Long-Chain Branched Polypropylene for Metallized Film Capacitors

Abstract

:1. Introduction

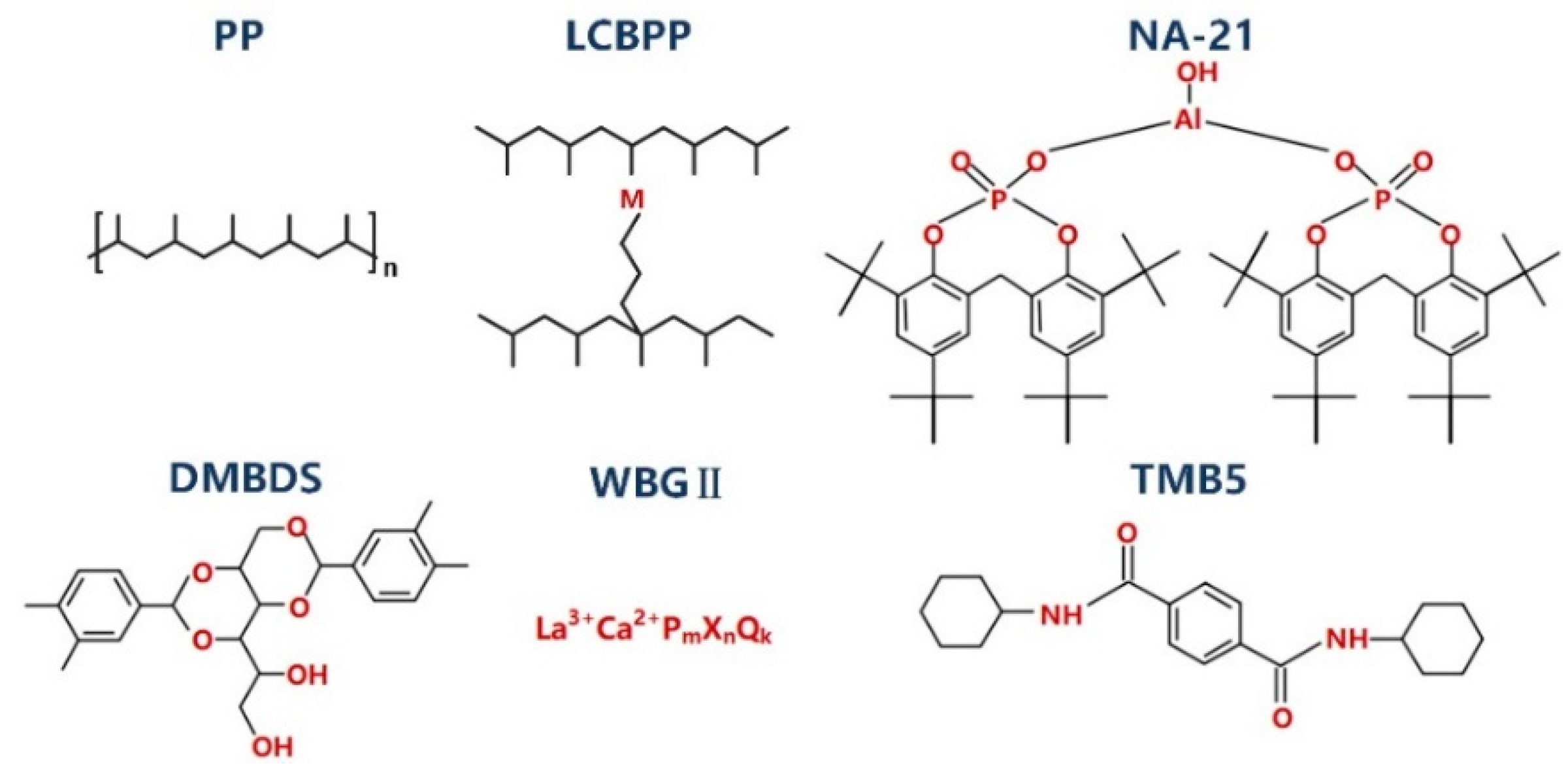

2. Materials and Methods

- (1)

- The LCBPP was rapidly mixed with the nucleating agent in a two-roll machine at 190 °C for 10 min. The added amount of nucleating agent was 0.03 wt% and 0.05 wt%, respectively.

- (2)

- The mixture was hot-pressed at 190 °C and 20 MPa for 3 min to form a film with a thickness of 25 μm. The film was cooled to 120 °C at a pressure of 20 MPa. The naming of the samples is shown in Table 1.

3. Results

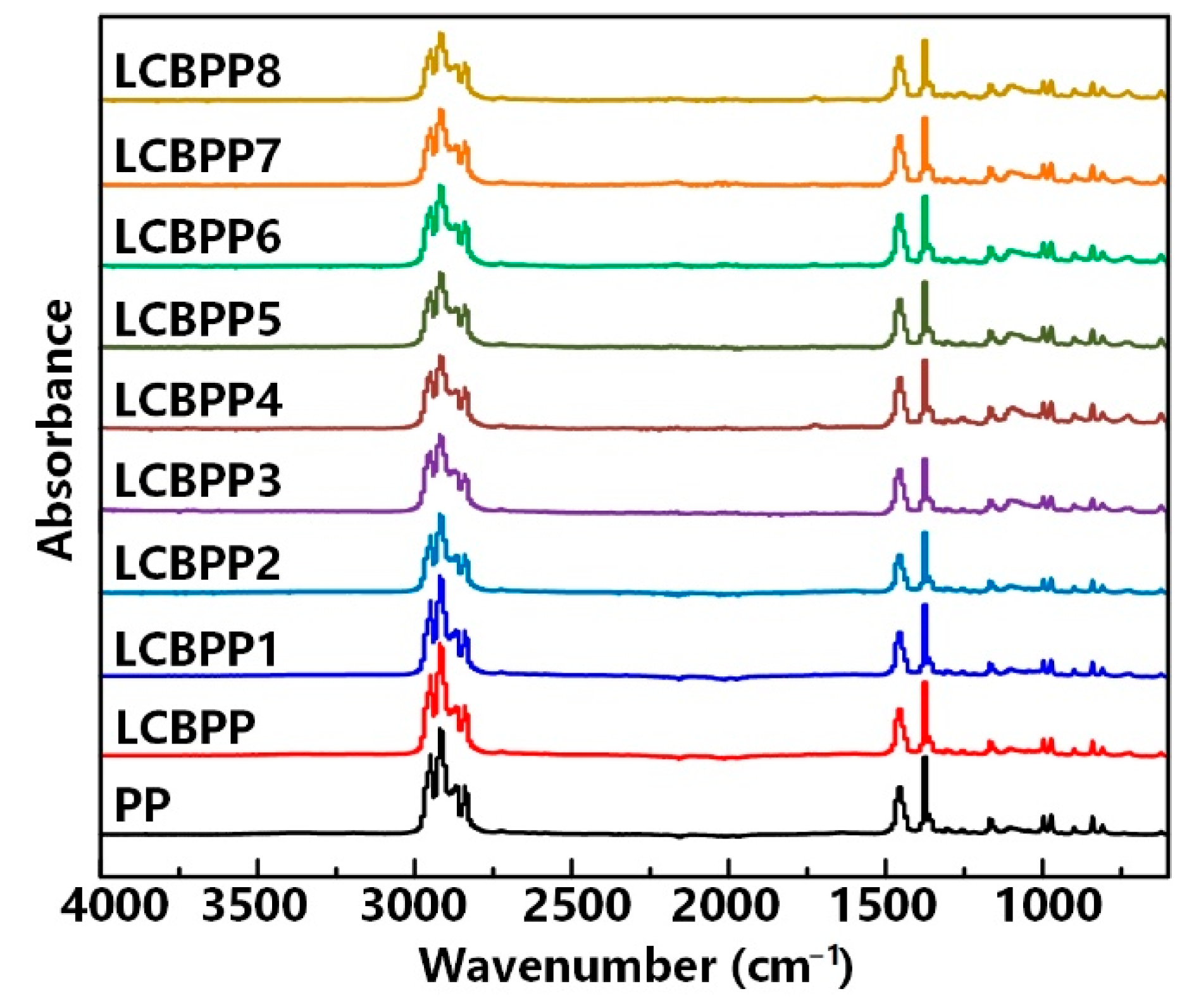

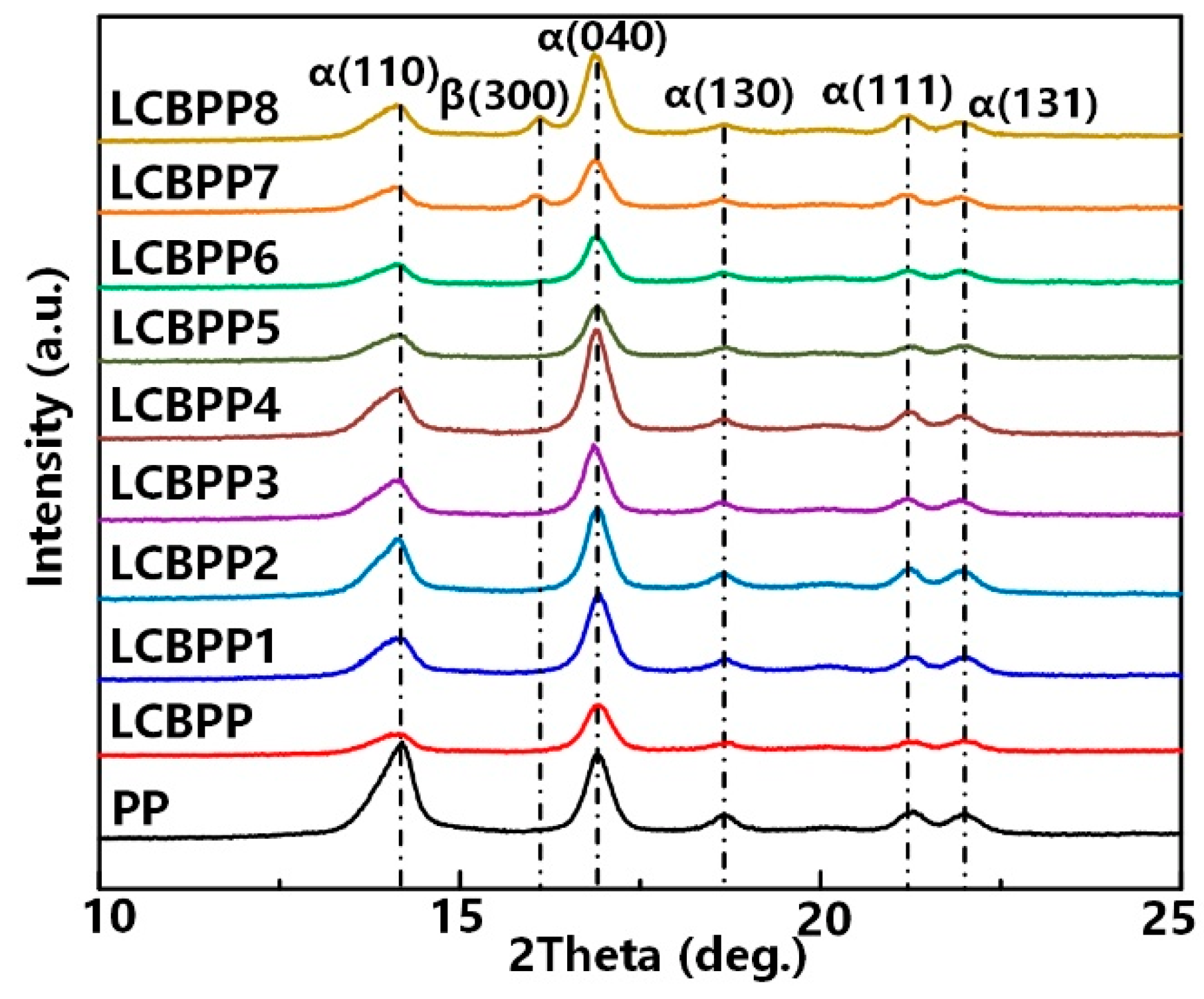

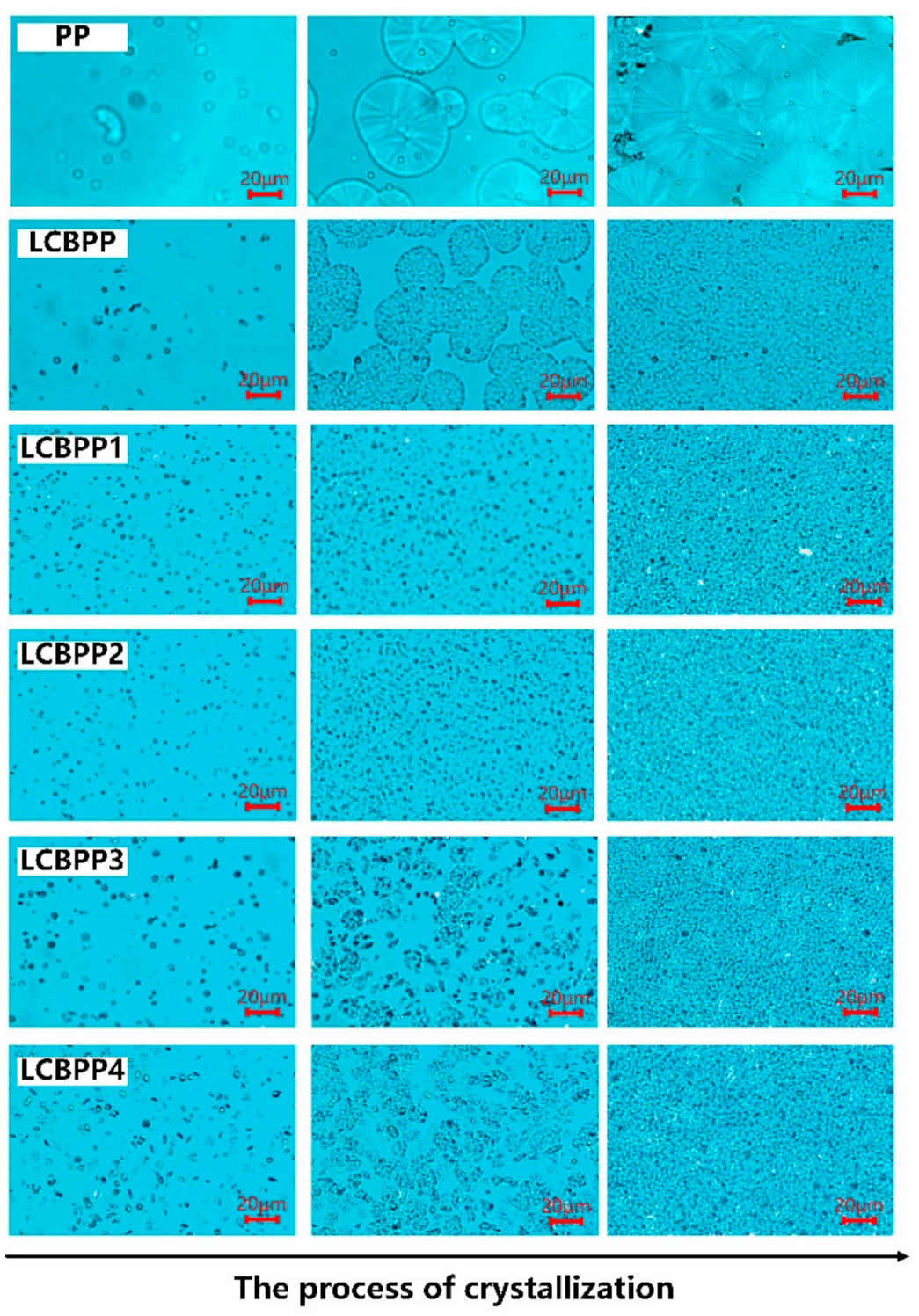

3.1. Microstructure Characteristics

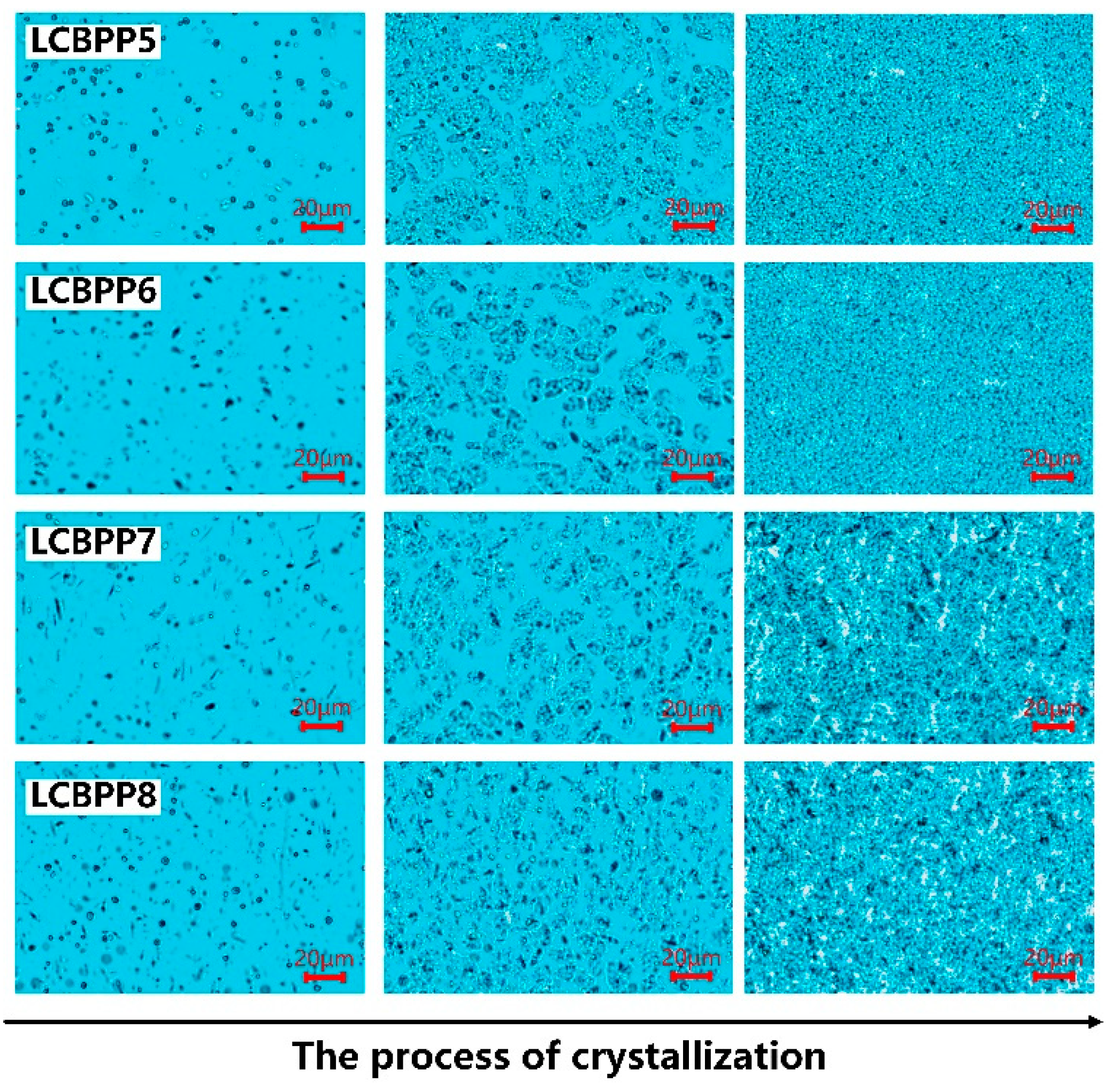

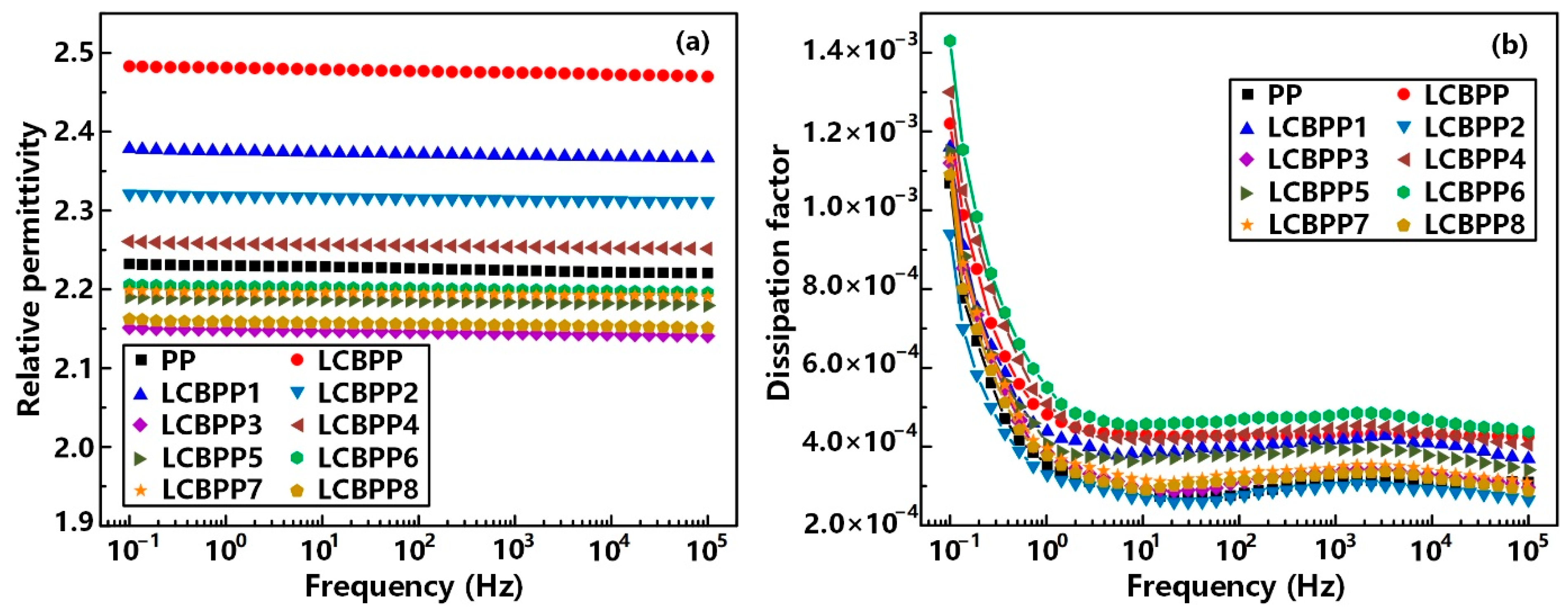

3.2. Relative Permittivity and Conductivity

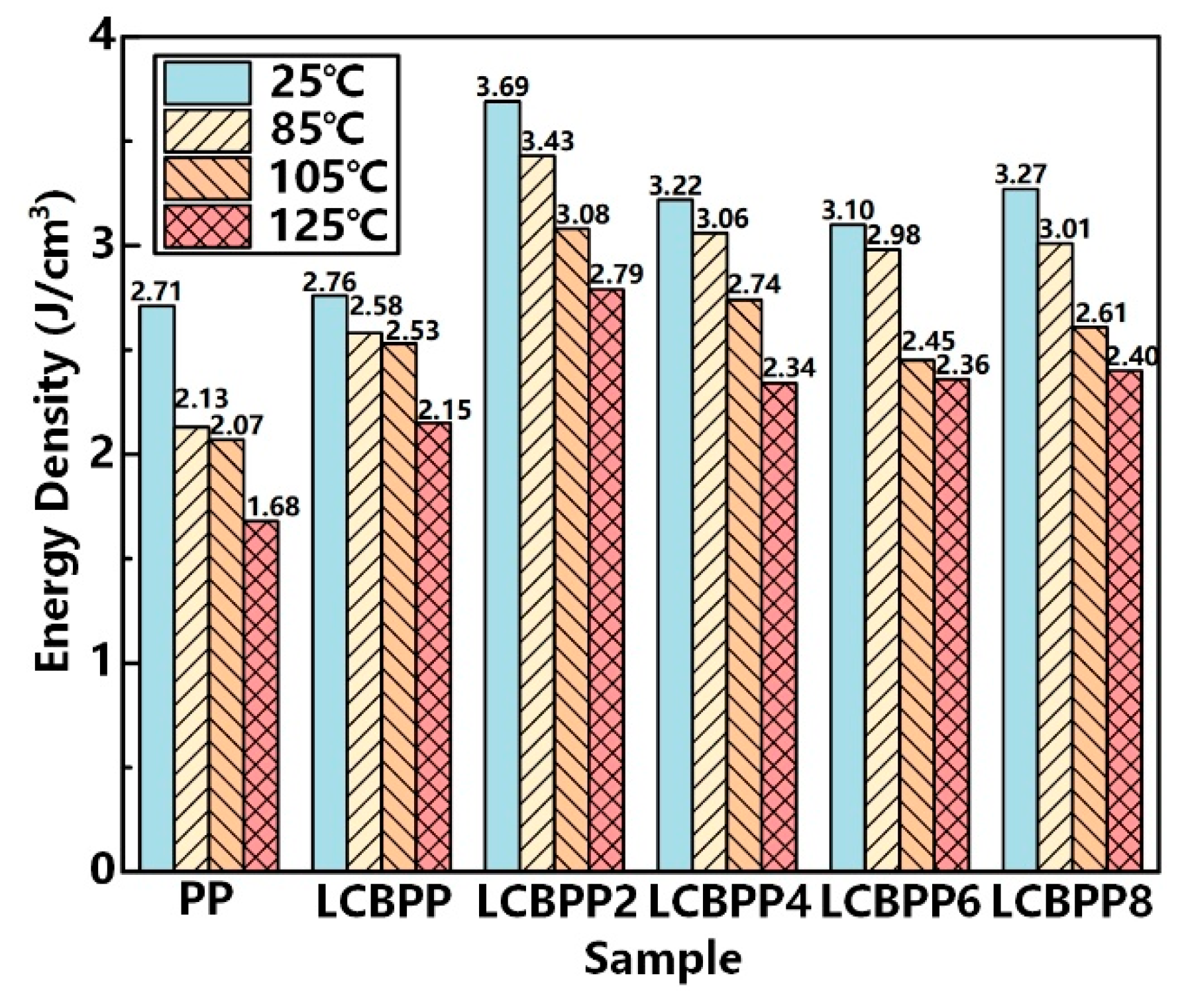

3.3. Breakdown Strength and Energy Density

4. Discussion

5. Conclusions

- (1)

- The spherulite density of LCBPP increases due to the flexibility of long-chain branches. The addition of different nucleating agents promoted the crystallization of LCBPP. Among them, the unit cell size of the NA-21 matrix and LCBPP melt can be well-matched, so the initial nucleation density of the modified film is higher. TMB-5 has a good effect of inducing the formation of β crystals by promoting epigenetic crystallization.

- (2)

- Due to the decrease in crystallinity, the dielectric constant and loss of LCBPP are relatively larger. The nucleating agent induces crystallization, and the dielectric constant of the modified films decreases. By introducing long-chain branches and adding nucleating agents, the conductivity loss of the modified films is reduced and the breakdown strength and energy storage density are improved. At 125 °C, the breakdown strength of the modified films added with NA-21 is increased by 108.6 kV/mm, and the energy storage density was increased by 66.1%.

- (3)

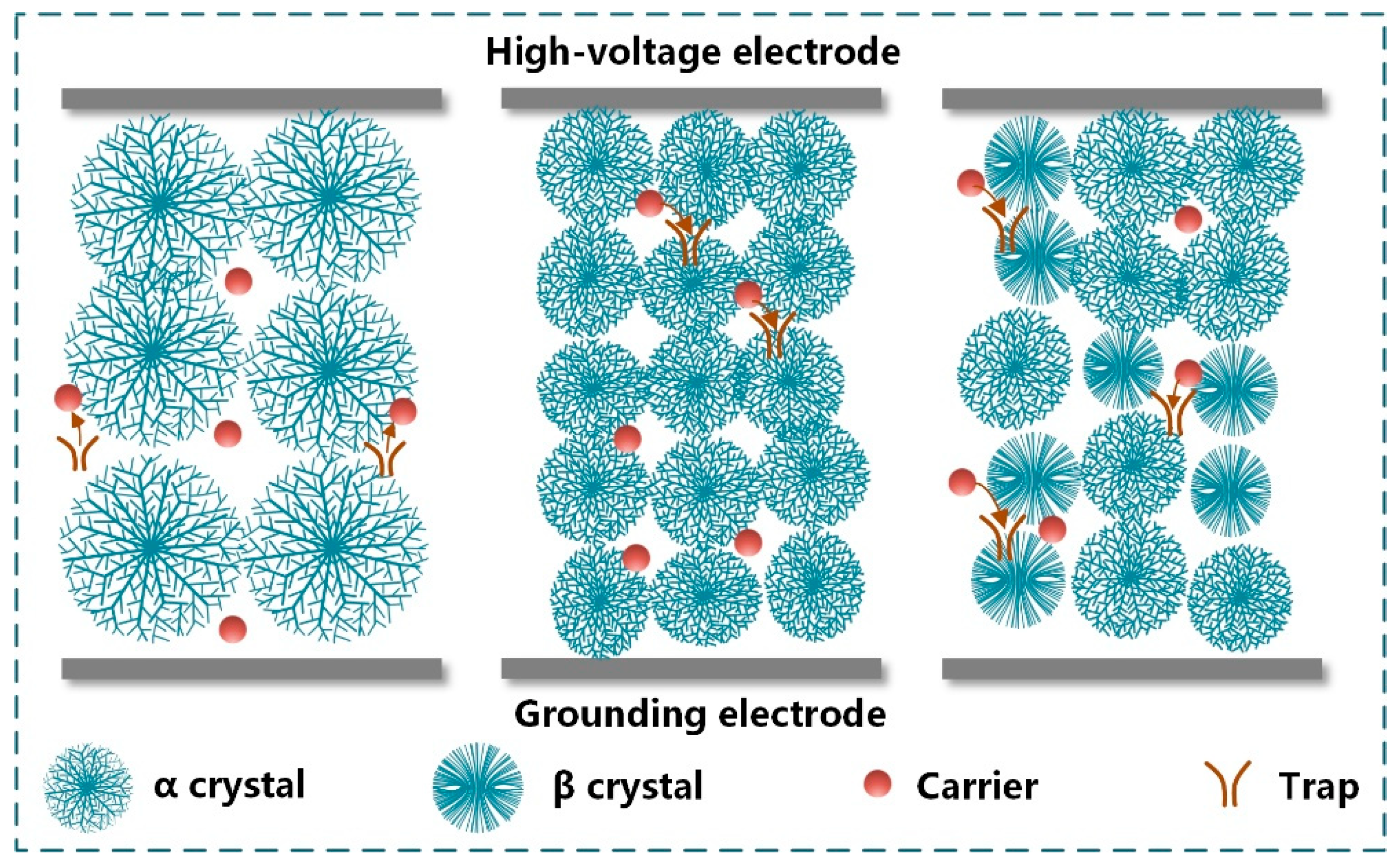

- Long-chain branches hinder the thermal motion of chains and promote heterogeneous nucleation, thereby improving the dielectric properties at high temperatures. The addition of nucleating agents increases the nucleation density of the films and shortens the mean free path of carriers. In addition, a large number of spherulite interfaces in the modified films introduced deep traps, which affected the carrier transport.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tan, D.Q. Review of polymer-based nanodielectric exploration and film scale-up for Advanced Capacitors. Adv. Funct. Mater. 2020, 30, 1808567. [Google Scholar] [CrossRef]

- Li, L.; Ai, D.; Ren, L.; Yao, B.; Han, Z.; Shen, Z.; Wang, J.; Chen, L.; Wang, Q. Scalable polymer nanocomposites with record high-temperature capacitive performance enabled by rationally designed nanostructured inorganic fillers. Adv. Mater. 2019, 31, 1900875. [Google Scholar] [CrossRef] [PubMed]

- Ho, J.S.; Greenbaum, S.G. Polymer capacitor dielectrics for high temperature applications. ACS Appl. Mater. Interfaces 2018, 10, 29189–29218. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Yuan, C.; Wang, S.; Zhu, Y.; Cheng, S.; Yang, X.; Yang, Y.; Hu, J.; He, J.; Li, Q. Interface-modulated nanocomposites based on polypropylene for high-temperature energy storage. Energy Storage Mater. 2020, 28, 255–263. [Google Scholar] [CrossRef]

- Li, Z.; Chen, X.; Zhang, C.; Baer, E.; Langhe, D.; Ponting, M.; Hosking, T.; Li, R.; Fukuto, M.; Zhu, F.; et al. High dielectric constant polycarbonate/nylon multilayer films capacitors with self-healing capability. ACS Appl. Polym. Mater. 2019, 1, 867–875. [Google Scholar] [CrossRef]

- Rabuffi, M.; Picci, G. Status Quo and future prospects for metallized polypropylene energy storage capacitors. IEEE Trans. Plasma Sci. 2002, 30, 1939–1942. [Google Scholar] [CrossRef]

- Chu, B.; Zhou, X.; Ren, K.; Neese, B.; Lin, M.; Wang, Q.; Bauer, F.; Zhang, Q. A dielectric polymer with high electric energy density and fast discharge speed. Science 2006, 313, 334–336. [Google Scholar] [CrossRef]

- Schneuwly, A.; Groning, P.; Schlapbach, L.; Irrgang, C.; Vogt, J. Breakdown behaviors of oil-impregnated polypropylene as dielectric in film capacitors. IEEE Trans. Dielectr. Electr. Insul. 1998, 6, 862–868. [Google Scholar] [CrossRef]

- Notingher, P. Study of space charge accumulation in polyolefins submitted to ac stress. IEEE Trans. Dielectr. Electr. Insul. 2001, 8, 972–984. [Google Scholar] [CrossRef]

- Langston, J.A.; Colby, R.H.; Chung, T.C. Synthesis and characterization of long chain branched isotactic polypropylene via metallocene catalyst and T-reagent. Macromolecules 2007, 40, 2712–2720. [Google Scholar] [CrossRef]

- Wang, L.; Wan, D.; Qiu, J.; Tang, T. Effects of long chain branches on the crystallization and foaming behaviors of polypropylene-g-poly(ethylene-co-1-butene) graft copolymers with well-defined molecular structures. Polymer 2012, 53, 4737–4757. [Google Scholar] [CrossRef]

- Ran, Z.; Du, B.; Xiao, M.; Liu, H.; Xing, J. Effect of crystallization regulation on the breakdown strength of metallized polypropylene film capacitors. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 175–182. [Google Scholar] [CrossRef]

- Yamaguchi, M.; Abe, S. LLDPE/LDPE blends. I. rheological, thermal, and mechanical properties. J. Appl. Polym. Sci. 1999, 74, 3153–3159. [Google Scholar] [CrossRef]

- Xu, R.; Du, B.; Xiao, M.; Li, J.; Xing, J. Dielectric properties dependent on crystalline morphology of PP film for HVDC capacitors application. Polymer 2021, 213, 123204. [Google Scholar] [CrossRef]

- Luo, F.; Xu, C.; Wang, K.; Deng, H.; Chen, F.; Fu, Q. Exploring temperature dependence of the toughening behavior of beta-nucleated impact polypropylene copolymer. Polymer 2012, 53, 1783–1790. [Google Scholar] [CrossRef]

- Zhang, Y.; He, B.; Hou, H.; Guo, L. Isothermal crystallization of isotactic polypropylene nucleated with a novel aromatic heterocyclic phosphate nucleating agent. J. Macromol. Sci. Part B Phys. 2017, 56, 811–820. [Google Scholar] [CrossRef]

- Shepard, T.A.; Delsorbo, C.R.; Louth, R.M.; Walborn, J.L.; Norman, D.A.; Harvey, N.G.; Spontak, R.J. Self-organization and polyolefin nucleation efficacy of 1,3:2,4-di-p-methylbenzylidene sorbitol. J. Polym. Sci. Part B Polym. Phys. 1997, 35, 2617–2628. [Google Scholar] [CrossRef]

- Wang, W.; Hu, H.; Feng, J.; Chen, Y. Rare-earth-containing Crystalline Phase Modifier for PP. Plastics 2004, 33, 29–34. [Google Scholar]

- Varga, J.; Karger-Kocsis, J. Rules of supermolecular structure formation in sheared isotactic polypropylene melts. J. Polym. Sci. Part B Polym. Phys. 1996, 34, 657–670. [Google Scholar] [CrossRef]

- Asandulesa, M.; Musteata, V.E.; Bele, A.; Dascalu, M.; Bronnikov, S.; Racles, C. Molecular dynamics of polysiloxane polar-nonpolar co-networks and blends studied by dielectric relaxation spectroscopy. Polymer 2018, 149, 73–84. [Google Scholar] [CrossRef]

- Larsson, O.; Said, E.; Berggren, M.; Crispin, X. Insulator polarization mechanisms in polyelectrolyte-gated organic field-effect transistors. Adv. Funct. Mater. 2009, 19, 3334–3341. [Google Scholar] [CrossRef]

- Asandulesa, M.; Kostromin, S.; Podshivalov, A.; Tameev, A.; Bronnikov, S. Relaxation processes in a polymer composite for bulk heterojunction: A dielectric spectroscopy study. Polymer 2020, 203, 122785. [Google Scholar] [CrossRef]

- Umran, H.M.; Wang, F.P.; He, Y.S. Ageing: Causes and effects on the reliability of polypropylene film used for HVDC capacitor. IEEE Access 2020, 8, 40413–40430. [Google Scholar] [CrossRef]

- Xu, R.; Xing, J.; Du, B.; Xiao, M.; Li, J. Improved breakdown strength of polypropylene film by polycyclic compounds addition for power capacitors. Materials 2021, 14, 1185. [Google Scholar] [CrossRef]

- Smith, R.; Liang, C.; Landry, M.; Nelson, J.; Schadler, L. The mechanisms leading to the useful electrical properties of polymer nanodielectrics. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 187–196. [Google Scholar] [CrossRef]

- Seven, K.M.; Cogen, J.M.; Person, T.; Reffner, J.R.; Gilchrist, J.F. The effect of inorganic and organic nucleating agents on the electrical breakdown strength of polyethylene. J. Appl. Polym. Sci. 2018, 135, 46325. [Google Scholar] [CrossRef]

| Sample | PP | LCBPP | LCBPP1 | LCBPP2 | LCBPP3 | LCBPP4 | LCBPP5 | LCBPP6 | LCBPP7 | LCBPP8 |

|---|---|---|---|---|---|---|---|---|---|---|

| Nucleating agent | - | - | NA-21 | NA-21 | DMDBS | DMDBS | WBG-II | WBG-II | TMB5 | TMB5 |

| Content (wt%) | 0 | 0 | 0.03 | 0.05 | 0.03 | 0.05 | 0.03 | 0.05 | 0.03 | 0.05 |

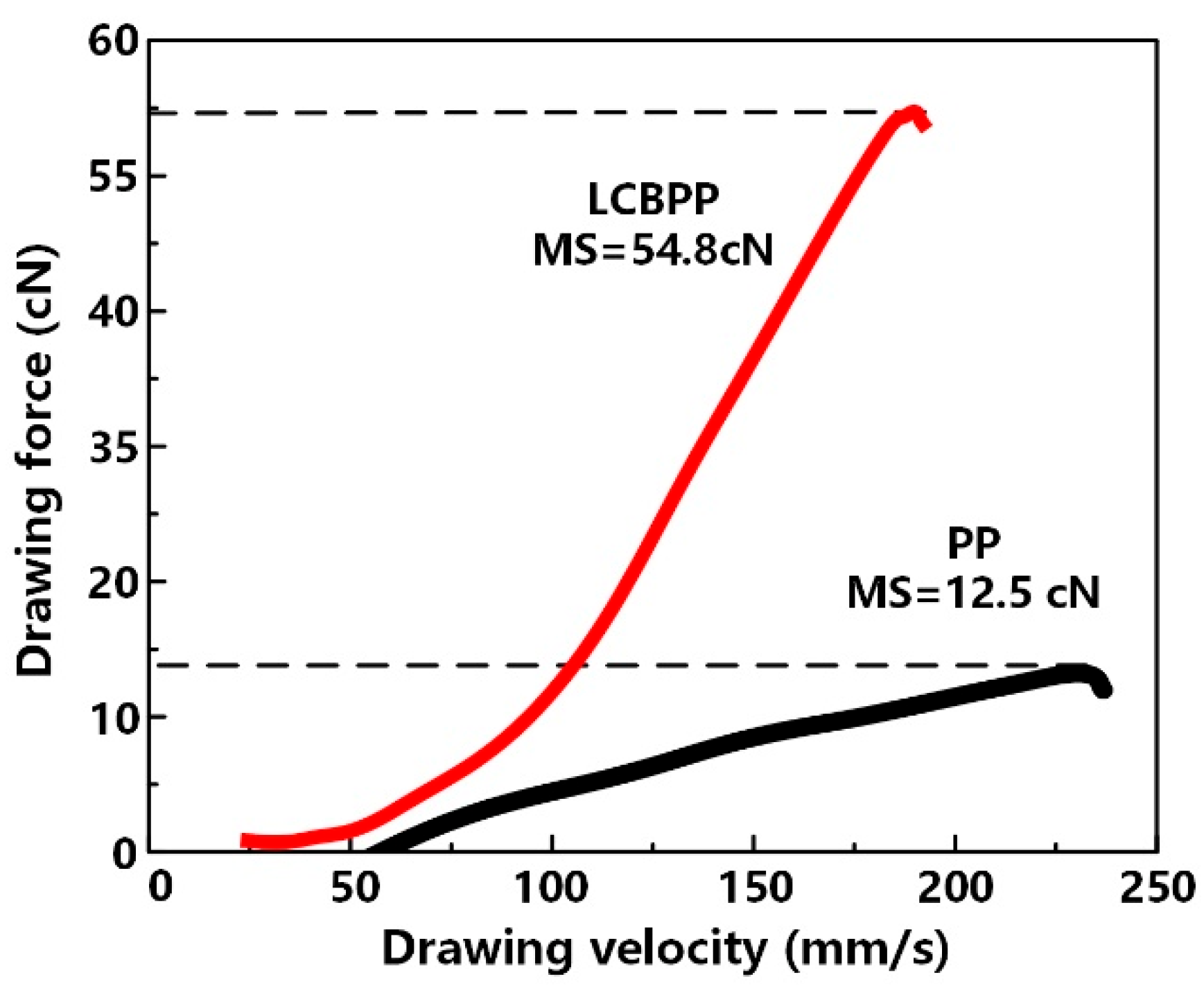

| Parameter | Mw (104 g/mol) | Mn (104 g/mol) | PDI | MS (cN) | MFR (g/10 min) | |

|---|---|---|---|---|---|---|

| Sample | ||||||

| PP | 33.1 | 7.7 | 4.3 | 12.5 | 3.00 | |

| LCBPP | 37.0 | 7.5 | 4.9 | 54.8 | 2.00 | |

| Sample | PP | LCBPP | LCBPP1 | LCBPP2 | LCBPP3 | LCBPP4 | LCBPP5 | LCBPP6 | LCBPP7 | LCBPP8 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Parameter | |||||||||||

| Tc (°C) | 114.8 | 120.4 | 122.8 | 124.2 | 122.0 | 122.1 | 121.1 | 122.0 | 121.9 | 121.9 | |

| Tm (°C) | 162.9 | 166.9 | 167.4 | 168.4 | 167.9 | 167.9 | 167.9 | 167.9 | 165.9 | 165.9 | |

| 152.0 | 152.9 | 153.9 | |||||||||

| Hm (J/g) | 92.6 | 71.2 | 78.8 | 80.9 | 78.7 | 86.5 | 77.0 | 80.8 | 76.1 | 77.3 | |

| Xc (%) | 44.3 | 34.1 | 37.7 | 38.7 | 37.7 | 41.4 | 36.8 | 38.6 | 36.4 | 37.0 | |

| Sample | PP | LCBPP | LCBPP1 | LCBPP2 | LCBPP3 | LCBPP4 | LCBPP5 | LCBPP6 | LCBPP7 | LCBPP8 | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Parameter | |||||||||||

| 25 °C | Eb (kV/mm) | 524.4 | 500.8 | 589.1 | 599.4 | 548.7 | 567.4 | 549.1 | 563.3 | 559.1 | 584.6 |

| β | 9.63 | 10.89 | 17.58 | 13.46 | 22.14 | 18.69 | 11.93 | 13.37 | 12.25 | 17.15 | |

| 85 °C | Eb (kV/mm) | 464.3 | 482.3 | 570.7 | 577.8 | 524.6 | 552.5 | 547.0 | 552.4 | 550.0 | 560.6 |

| β | 9.21 | 10.53 | 15.67 | 13.18 | 18.84 | 11.45 | 11.40 | 12.10 | 10.43 | 12.76 | |

| 105 °C | Eb (kV/mm) | 457.5 | 479.9 | 530.5 | 547.8 | 509.4 | 523.0 | 493.8 | 501.1 | 513.6 | 522.5 |

| β | 8.97 | 9.68 | 13.13 | 10.76 | 13.01 | 11.55 | 11.72 | 11.82 | 10.62 | 11.95 | |

| 125 °C | Eb (kV/mm) | 412.9 | 442.3 | 507.6 | 521.5 | 471.5 | 483.5 | 461.5 | 492.0 | 462.3 | 501.2 |

| β | 8.36 | 9.28 | 12.87 | 10.52 | 12.13 | 11.83 | 10.84 | 9.33 | 10.96 | 11.51 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, M.; Zhang, M.; Liu, H.; Du, B.; Qin, Y. Dielectric Property and Breakdown Strength Performance of Long-Chain Branched Polypropylene for Metallized Film Capacitors. Materials 2022, 15, 3071. https://doi.org/10.3390/ma15093071

Xiao M, Zhang M, Liu H, Du B, Qin Y. Dielectric Property and Breakdown Strength Performance of Long-Chain Branched Polypropylene for Metallized Film Capacitors. Materials. 2022; 15(9):3071. https://doi.org/10.3390/ma15093071

Chicago/Turabian StyleXiao, Meng, Mengdie Zhang, Haoliang Liu, Boxue Du, and Yawei Qin. 2022. "Dielectric Property and Breakdown Strength Performance of Long-Chain Branched Polypropylene for Metallized Film Capacitors" Materials 15, no. 9: 3071. https://doi.org/10.3390/ma15093071

APA StyleXiao, M., Zhang, M., Liu, H., Du, B., & Qin, Y. (2022). Dielectric Property and Breakdown Strength Performance of Long-Chain Branched Polypropylene for Metallized Film Capacitors. Materials, 15(9), 3071. https://doi.org/10.3390/ma15093071