End-of-Life Management of Biodegradable Plastic Dog Poop Bags through Composting of Green Waste

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Prototypes of Biodegradable Non-Fossil Derived Plastic Bags for Collecting Dog Poop

2.1.2. Commercially Available Biodegradable Plastic Bags for Collecting Dog Poop

2.1.3. Characteristics of the Investigated Biodegradable Plastic Dog Poop Bags

2.2. Methods

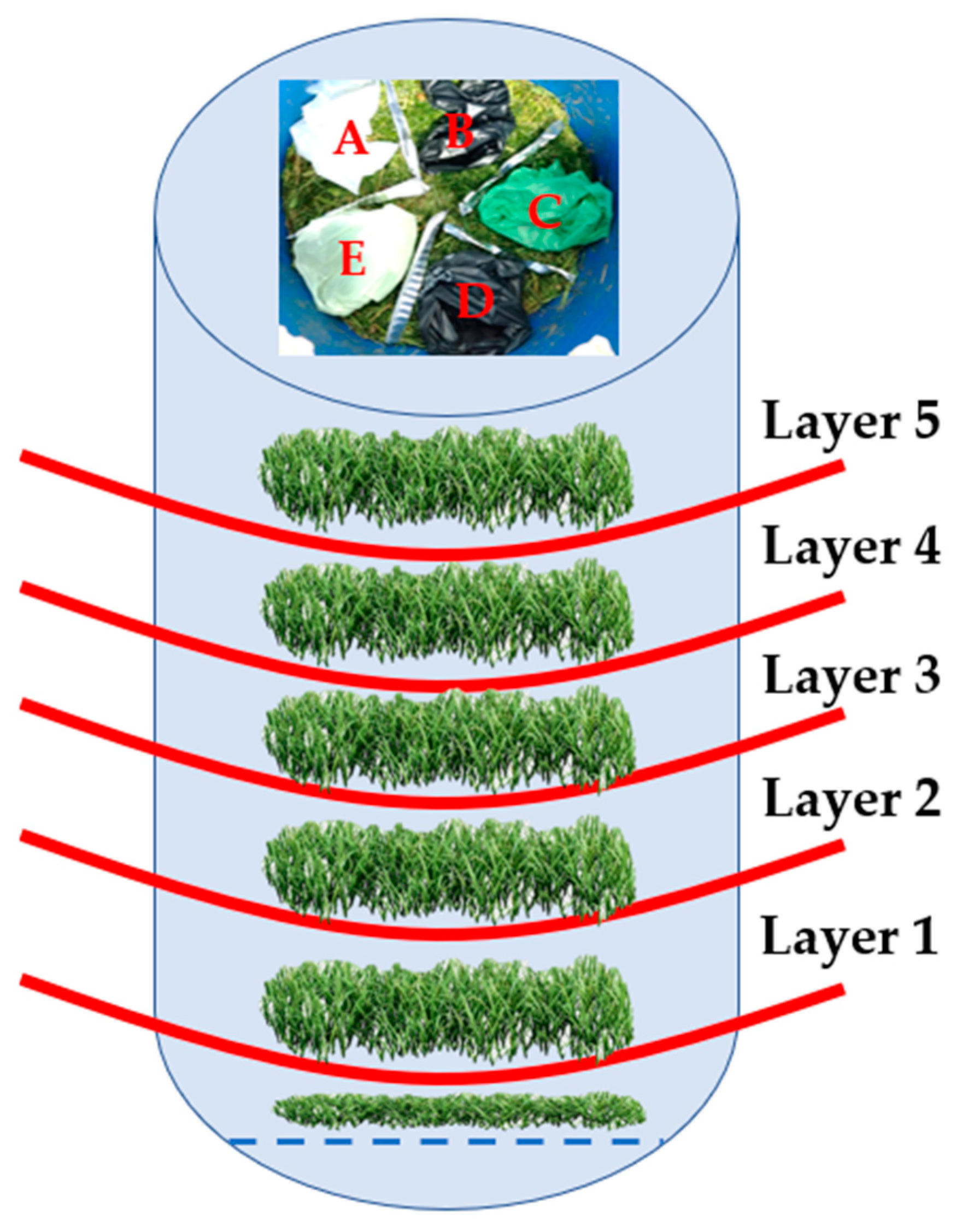

2.2.1. Laboratory Composting Set-Up

2.2.2. Laboratory Composting

2.2.3. Physical, Chemical and Microbiological Analysis of the Composted Mixtures

2.2.4. Determination of Mass Loss and Structural Changes of DPBs after Composting

2.2.5. Statistical Analysis

3. Results and Discussion

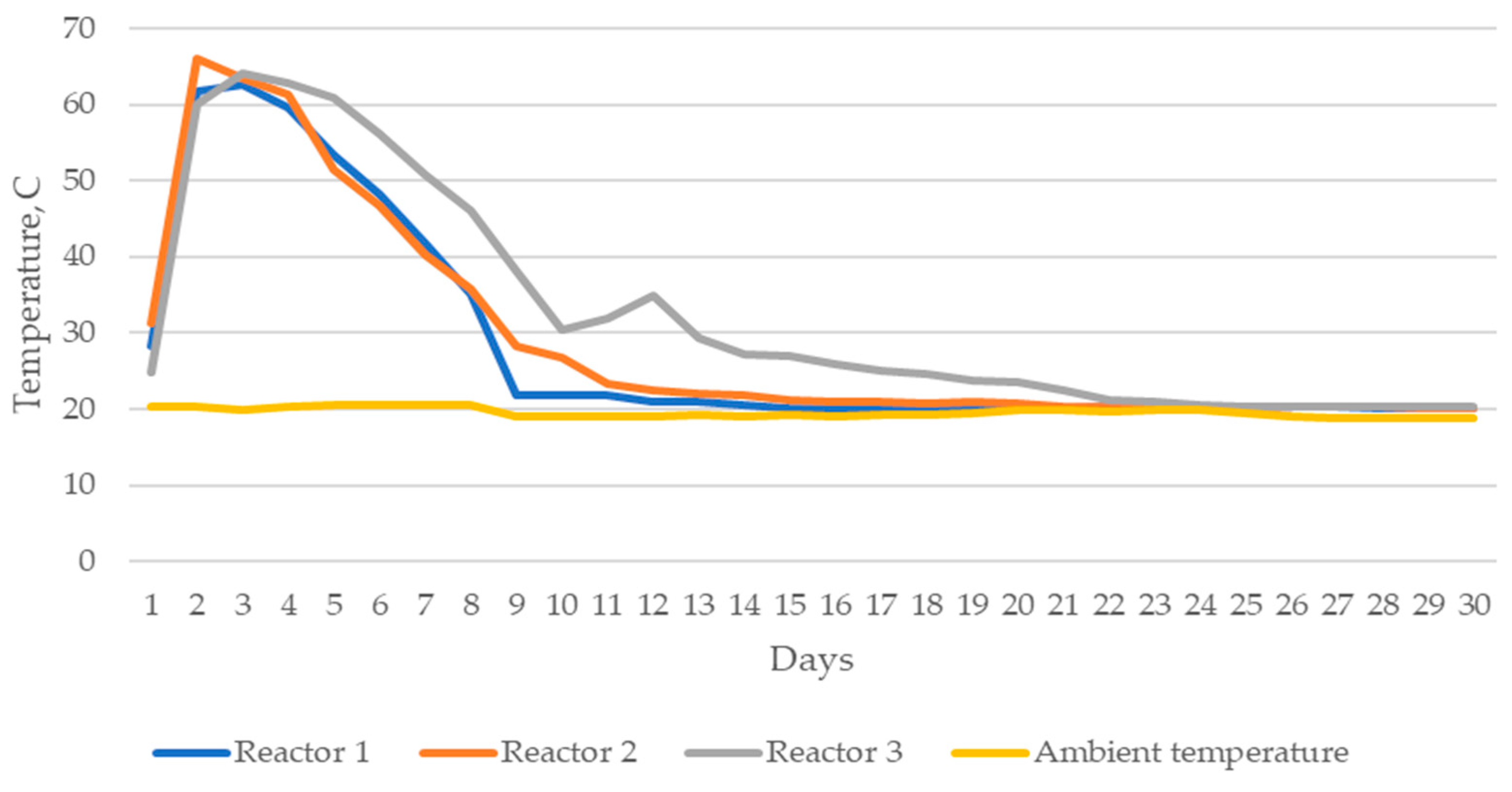

3.1. Laboratory Composting

3.1.1. Composting Dynamics

3.1.2. Physical, Chemical and Microbiological Properties of the Composted Mixtures and Fresh Compost

3.2. Characteristics of the Investigated Dog Poop Bags after Composting

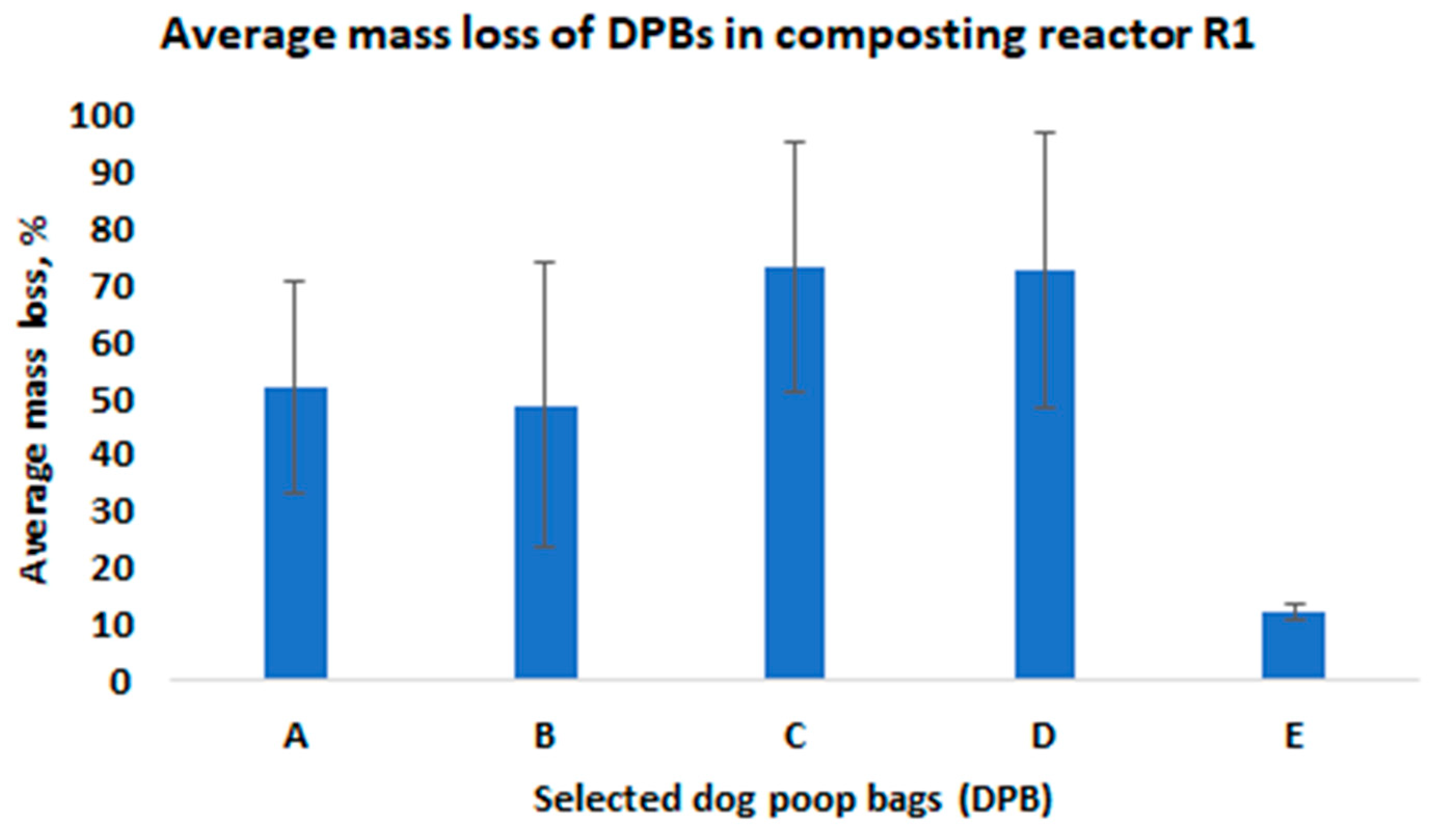

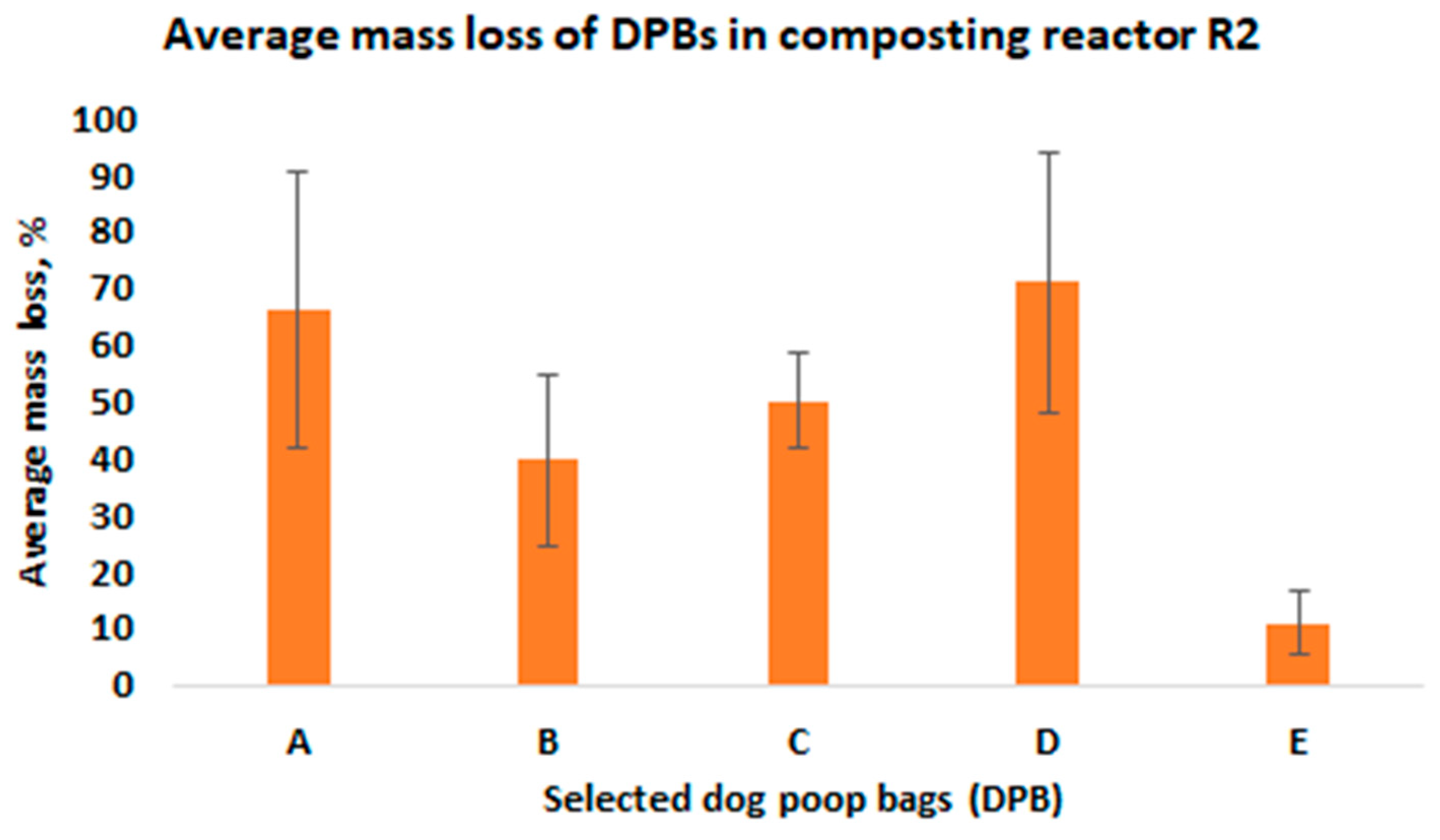

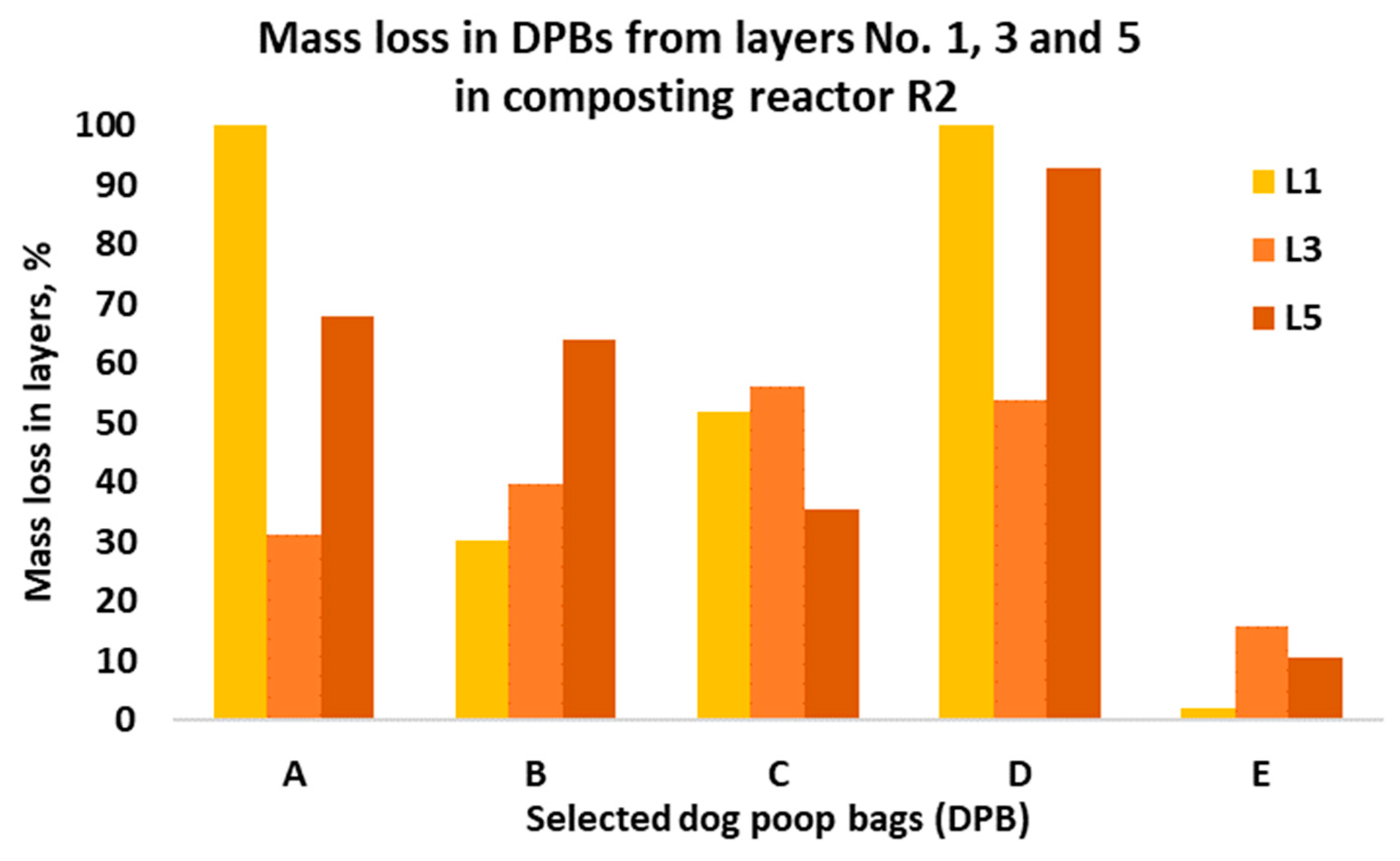

Mass Loss after the 4-Week Laboratory Composting

4. Summary and Conclusions

- After 4 weeks of laboratory composting, the average mass losses for DPBs A, B, C, D and E from R1 and R2 were as follows: 52%, 49%, 73%, 73%, 12% and 66%, 40%, 50%, 71%, and 11%, respectively.

- Although the investigated DPBs A–E after 4 weeks of laboratory composting demonstrated differences in decomposition (i.e., quantitative as well qualitative changes), all of them decomposed 100% after 90 days of laboratory composting.

- The investigated DPBs were arranged in layers at different depths inside the composting reactors, and thus could be exposed to different composting conditions related to oxygen concentration, moisture content, heat and air exchange, etc. This could have an effect on the degradation of these bags, which was evidenced by the reported mass losses after 4 weeks of composting.

- The fresh compost obtained after 90 days of laboratory composting of mowed grass mixed with bags containing dog poop showed insufficient quality, mostly in terms of microbial stability. However, after maturation, the obtained compost could be used for, e.g., soil reclamation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Report on Use of Plastics in Agriculture. 2019. Available online: https://saiplatform.org/wp-content/uploads/2019/06/190528-report_use-of-plastics-in-agriculture.pdf (accessed on 28 May 2019).

- Allison, A.L.; Lorencatto, F.; Michie, S.; Miodownik, M. Barriers and enables to buying biodegradable and compostable plastic packaging. Sustainability 2021, 13, 1463. [Google Scholar] [CrossRef]

- Plastics—The Facts 2019, An Analysis of European Plastics Production, Demand and Waste Data. Available online: https://plasticseurope.org/wp-content/uploads/2021/10/2019-Plastics-the-facts.pdf (accessed on 14 October 2019).

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A review of bioplastics and their adoption in the circular economy. Polymers 2021, 13, 1229. [Google Scholar] [CrossRef] [PubMed]

- Mai, L.; Zeng, E.; Zeng, E.Y. Dog poop bags: A non-negligible source of plastic pollution. Environ. Pollut. 2022, 292, 118355. [Google Scholar] [CrossRef] [PubMed]

- What Do You Do with Dog Waste? Available online: https://www.turningtogreen.com/post/what-do-you-do-with-dog-waste (accessed on 4 April 2020).

- How to Dispose of Dog Poop the “Green” Way: The Ultimate Guide to Eco-Friendly Pet Waste Management (Part 2). Available online: https://www.thezerowastepet.com/how-to-dispose-of-dog-poop/ (accessed on 31 January 2019).

- Rubel, D.; Carbajo, A. Dogs in public spaces of Buenos Aires, Argentina: Exploring patterns of the abundance of dogs, the canine faecal contamination, the behavior of people with dogs, and its relationships with demographic/economic variables. Prev. Vet. Med. 2019, 170, 104713. [Google Scholar] [CrossRef] [PubMed]

- Moshood, T.D.; Nawair, G.; Mahmud, F.; Mohamad, F.; Ahmad, M.H.; Ghani, A.A. Sustainability of biodegradable plastics: New problem or solution to solve the global pollution? Curr. Res. Green Sustain. Chem. 2022, 5, 100273. [Google Scholar] [CrossRef]

- Giola, C.; Giacobazzi, G.; Vannini, M.; Totaro, G.; Sisti, L.; Colonna, M.; Marchese, P.; Celli, A. End of Life of Biodegradable Plastics: Composting versus Re/Upcycling. ChemSusChem 2021, 14, 4167–4175. [Google Scholar] [CrossRef]

- Biodegradability of Plastics in the Open Environment. Available online: https://ec.europa.eu/info/research-and-innovation/strategy/support-policy-making/scientific-support-eu-policies/group-chief-scientific-advisors/biodegradability-plastics-open-environment_en (accessed on 27 November 2019).

- Rosenboom, J.-G.; Langer, R.; Traveso, G. Bioplastics for a circular economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Markowicz, F.; Szymańska-Pulikowska, A. Analysis of the possibility of environmental pollution by composted biodegradable and oxo-biodegradable plastics. Geoscience 2019, 9, 460. [Google Scholar] [CrossRef] [Green Version]

- Körner, I.; Redemann, K.; Stegmann, R. Behaviour of biodegradable plastics in composting facilities. Waste Manag. 2005, 25, 409–415. [Google Scholar] [CrossRef] [PubMed]

- Czekała, W.; Malińska, K.; Caceres, R.; Janczak, D.; Dach, J.; Lewicki, A. Co-composting of poultry manure mixtures amended with biochar—The effect of biochar on temperature and C-CO2 emission. Biores. Technol. 2016, 200, 921–927. [Google Scholar] [CrossRef] [PubMed]

- Dróżdż, D.; Malińska, K.; Kacprzak, M.; Mrowiec, M.; Szczypiór, A.; Postawa, P.; Stachowiak, T. Potential of Fish Pond Sediments Composts as Organic Fertilizers. Waste Biomass Valor. 2020, 11, 5151–5163. [Google Scholar] [CrossRef] [Green Version]

- Dróżdż, D.; Wystalska, K.; Malińska, K.; Grosser, A.; Grobelak, A.; Kacprzak, M. Management of poultry manure in Poland-Current state and future perspectives. J. Environ. Manag. 2020, 264, 110327. [Google Scholar] [CrossRef] [PubMed]

- Breitenbeck, G.A.; Schellinger, D. Calculating the Reduction in Material Mass And Volume during Composting. Compost. Sci. Util. 2004, 12, 365–371. [Google Scholar] [CrossRef]

- Khan, E.; Khaodhir, S.; Ruangrote, D. Effects of moisture content and initial pH in composting process on heavy metal removal characteristics of grass clipping compost used for stormwater filtration. Bioresour. Technol. 2009, 100, 4454–4461. [Google Scholar] [CrossRef] [PubMed]

- Liang, C.; Das, K.C.; McClendon, R.W. The influence of temperature and moisture contents regimes on the aerobic microbial activity of a biosolids composting blend. Bioresour. Technol. 2003, 8, 131–137. [Google Scholar] [CrossRef]

- Frederick, M.C.; Adinarayana, R.C.; Forney, L.J. Yard Waste Composting: Studies Using Different Mixes of Leaves and Grass in a Laboratory Scale System. Compost. Sci. Util. 1993, 1, 85–96. [Google Scholar] [CrossRef]

- Rozporzadzenia Komisji (UE) nr 142/2011. Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/HTML/?uri=CELEX:32011R0142&from=PL (accessed on 25 February 2011).

- Kukier, E.; Kozieł, N.; Goldsztejn, M.; Kwiatek, K. Aktualne wymagania sanitarno-weterynaryjne dla nawozów organicznych i polepszaczy gleby w Polsce. Życie Weter. 2016, 91, 125–127. [Google Scholar]

- Shepherd, M.W.; Liang, P.; Jiang, X.; Doyle, M.P.; Erickson, M.C. Microbiological analysis of composts produced on South Carolina poultry farms. J. Appl. Microbiol. 2010, 108, 2067–2076. [Google Scholar] [CrossRef] [PubMed]

- Folino, A.; Karageorgiou, A.; Calabro, P.S.; Komilis, D. Biodegradation of wasted bioplastics in natural and industrial environments; a review. Sustainability 2020, 12, 6030. [Google Scholar] [CrossRef]

| Type of DPB | DPB-A | DPB-B |

|---|---|---|

| Thickness | 25 microns | 40 microns |

| Material | Bioplast 400D | Bioplast 400D |

| Bioplast 400 ELIT | Bioplast 400 ELIT | |

| Filler used in the inner layer | 20% of CaCO3 bio-based from seashells no pigment | 5% of black bio-based pigment |

| Color | semi-transparent | black |

| DPBs | Visualization | Properties | Composition |

|---|---|---|---|

| A |  | Width: 150 mm Height: 210 mm Thickness: 0.025 mm Color: White, milky Non-commercial product Average weight: 2.65 g | Biodegradable with calcium carbonate as a filler. Origin: Non-fossil derived. |

| B |  | Width: 170 mm Height: 245 mm Thickness: 0.04 mm Color: Black, glossy Non-commercial product Average weight: 3.74 g | Biodegradable with organic pigment. Origin: Non-fossil derived. |

| C |  | Width: 145 mm Height: 295 mm Thickness: 0.017 mm Color: Green, matte Commercially available product Average weight: 2.69 g | A dog poop bag made of biodegradable plastics *. Origin: No data on the origin. |

| D |  | Width: 140 mm Height: 310 mm Thickness: 0.02 mm Color: Graphite, matte Commercially available product Average weight: 2.86 g | A dog poop bag produced from corn starch *. Origin: Bio-based. |

| E |  | Width: 140 mm Height: 310 mm Thickness: 0.02 mm Color: Light yellow, matte Commercially available product Average weight: 2.608 g | A dog poop bag produced from corn starch *. Origin: Bio-based. |

| DPB | Reactor R1 | Reactor R2 | Reactor R3 |

|---|---|---|---|

| (5 Layers) | (5 Layers) | (3 Layers) | |

| A | 1 bag per each layer | 1 bag per each layer | 1 bag with 20 g of dog poop per each layer |

| B | 1 bag per each layer | 1 bag per each layer | 1 bag with 20 g of dog poop per each layer |

| C | 1 bag per each layer | 1 bag per each layer | 1 bag with 20 g of dog poop per each layer |

| D | 1 bag per each layer | 1 bag per each layer | 1 bag with 20 g of dog poop per each layer |

| E | 1 bag per each layer | 1 bag per each layer | 1 bag with 20 g of dog poop per each layer |

| Composted Mixtures | MC | OM | pH | EC | Total N | P2O5 | TOC | Ratio C/N |

|---|---|---|---|---|---|---|---|---|

| % | % | - | mS | % | mg·g−1 | % | - | |

| Composted mixture (R1) | 85.14 ± 1.31 | 72.69 ± 3.24 | 8.877 | 5.099 | 3.98 ± 0.08 | 10.76 ± 0.07 | 40.38 ± 0.02 | 10.14 |

| Composted mixture (R2) | 85.17 ± 1.50 | 71.45 ± 4.11 | 8.866 | 3.992 | 4.70 ± 0.08 | 10.62 ± 0.07 | 39.69 ± 0.05 | 8.44 |

| Fresh compost (R3) | 86.12 ± 1.32 | 70.39 ± 3.18 | 8.897 | 3.893 | 4.52 ± 0.07 | 10.49 ± 0.06 | 38.72 ± 0.03 | 8.56 |

| Replication Number | * CFU Enterococcus faecalis/g Material | Enterococcus faecalis Index | CFU | Coliform Index | Bacteria of the Genus Salmonella |

|---|---|---|---|---|---|

| Escherichia coli/g Material | |||||

| Sample 1 | 1.5 × 102 | 10−2 | 15 × 105 | 10−6 | Not isolated |

| Sample 2 | 2.4 × 102 | 10−2 | 24 × 105 | 10−7 | Not isolated |

| Sample 3 | 1.4 × 102 | 10−3 | 15 × 105 | 10−7 | Not isolated |

| Sample 4 | 46 × 102 | 10−2 | 46 × 105 | 10−7 | Not isolated |

| Sample 5 | 21 × 102 | 10−2 | 21 × 105 | 10−7 | Not isolated |

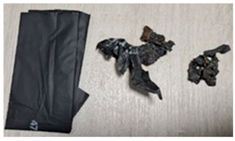

| DPB | Before and after Composting (Layer 1 and Layer 5) | Changes in DPBs Observed after Composting |

|---|---|---|

| A |  | Volume reduction. Color changes. Delicate, falling apart. |

| B |  | Moderate volume reduction. |

| C |  | Significant change in mass and volume. Change in hardness. |

| D |  | Volume reduction. Delicate, falling apart. |

| E |  | Volume reduction. Change in hardness. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dróżdż, D.; Malińska, K.; Postawa, P.; Stachowiak, T.; Nowak, D. End-of-Life Management of Biodegradable Plastic Dog Poop Bags through Composting of Green Waste. Materials 2022, 15, 2869. https://doi.org/10.3390/ma15082869

Dróżdż D, Malińska K, Postawa P, Stachowiak T, Nowak D. End-of-Life Management of Biodegradable Plastic Dog Poop Bags through Composting of Green Waste. Materials. 2022; 15(8):2869. https://doi.org/10.3390/ma15082869

Chicago/Turabian StyleDróżdż, Danuta, Krystyna Malińska, Przemysław Postawa, Tomasz Stachowiak, and Dorota Nowak. 2022. "End-of-Life Management of Biodegradable Plastic Dog Poop Bags through Composting of Green Waste" Materials 15, no. 8: 2869. https://doi.org/10.3390/ma15082869

APA StyleDróżdż, D., Malińska, K., Postawa, P., Stachowiak, T., & Nowak, D. (2022). End-of-Life Management of Biodegradable Plastic Dog Poop Bags through Composting of Green Waste. Materials, 15(8), 2869. https://doi.org/10.3390/ma15082869