Effect of Mechanically Treated Recycled Aggregates on the Long Term Mechanical Properties and Durability of Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Mechanical Treatment of Aggregates

2.2. Concrete Properties Investigated

2.3. Mixtures and Mixture Proportions

- “R” denoting recycled concrete aggregate

- “F” denoting the fine aggregates replacement (i.e., the second letter in nomenclature of each formulation)

- “C” denoting the coarse aggregates replacement

- “F” denoting the aggregate to be field, non-treated (i.e., the third letter in nomenclature of each formulation)

- “T” when aggregate is treated.

- “100”, “50” or “25” represent the replacement percentage of natural aggregates

- It should be noted that throughout the paper, the w/c ratio is suffixed at the end of each code name.

2.4. Casting and Curing

3. Results and Discussion

4. Conclusions

- The incorporation of 3-h mechanically treated RCA at 25%, 50% and 100% replacement levels offered a sharper increase in long-term compressive strengths than any other combination or reference mixture investigated in the study. The uprises in strength from 28 to 90 to 365 days reached a range of approximately 25%. Such differences were more drastic than those in porosities of the same combinations.

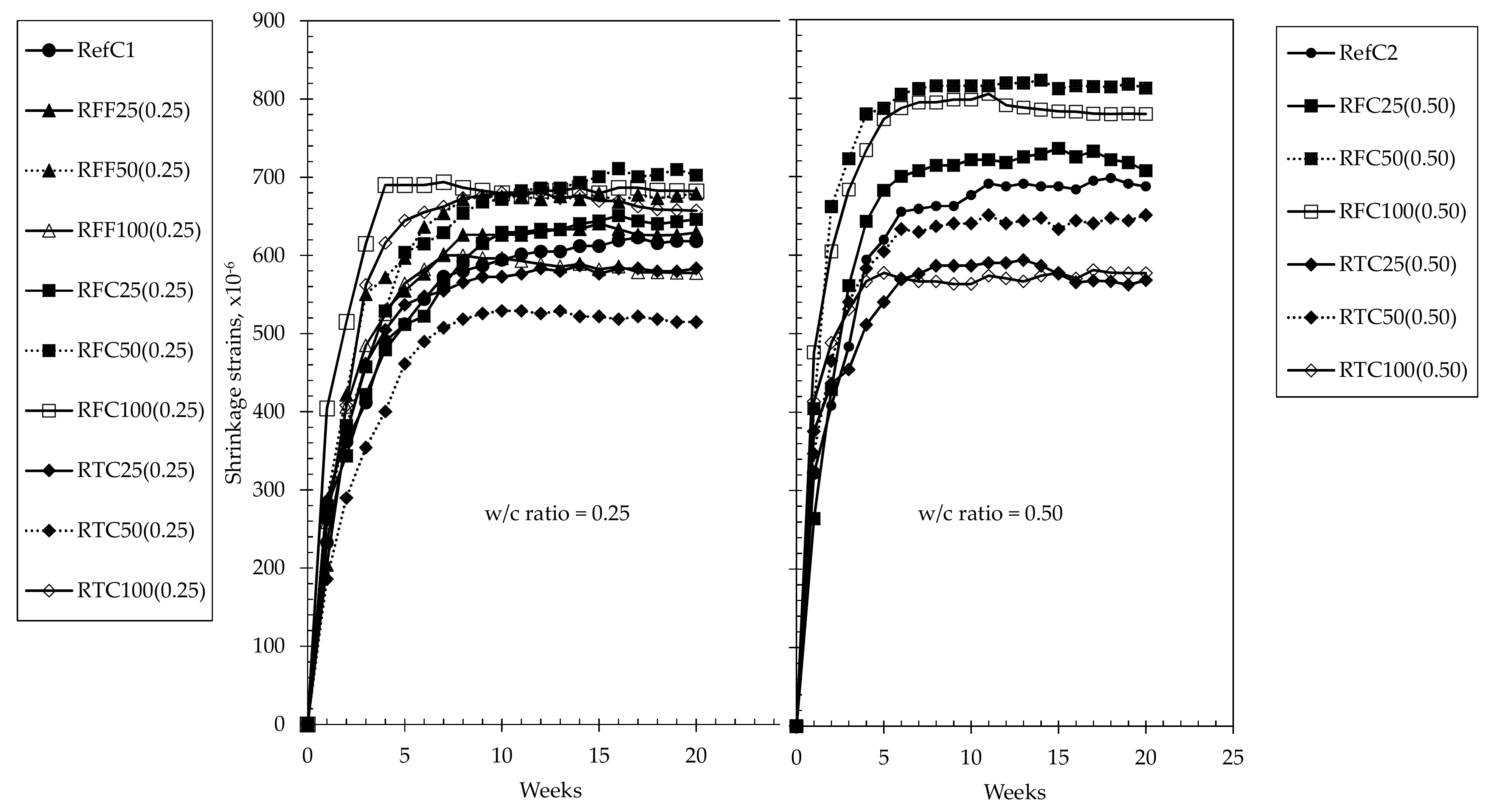

- An optimal mechanical treatment process appeared to offer a ‘shrinkage-controlling’ effect in treated RACs, where shrinkage strains of up to 20 weeks were reduced by almost 15% compared to reference concrete, and this was also reflected in the mass loss measurements.

- Optimal treatment of RCA in concrete initially appeared to have, to a lesser extent, affected the early-age compressive strengths and porosities of the investigated mixtures; then, it appeared to be benefitting only the strengths of high w/c ratio mixtures; and finally, it enhanced the long-term mechanical properties of both w/c ratios.

- The carbonation resistance and sulfate resistance of RAC appeared to be comparable to those of reference mixtures. As these two aspects are predominantly defined by the hydration products available within the cement paste and to a lesser extent by the aggregate quality, it follows that the incorporation of either treated or untreated RCA in concrete did not appear to expose RACs to any durability concerns.

- The reductions in both porosity and RCP values were well correlated with the reduction in w/c ratio. In mixtures containing 100% replacement with either treated coarse RCA or untreated fine RCA, the reduction in the RCP at 28 and 90 days was significant, ranging between 40–50%, although as the samples matured (365 days), reductions were less (i.e., 33–38%). The same behaviour was observed in mixtures of high w/c ratio although improvements in chloride resistance were not as significant.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eurostat. Waste Statistics—Total Waste Generation. 2021. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics#Total_waste_generation (accessed on 17 December 2021).

- Directive 2018/851 amending Directive 2008/98/EC on waste Framework. Off. J. Eur. Union 2018, L-150, 109–140.

- Eurostat. Waste Statistics—Waste Treatment by Type of Recovery and Disposal, 2018 (% of Total Treatment). 2021. Available online: https://ec.europa.eu/eurostat/statistics-explained//index.php?title=File:Waste_treatment_by_type_of_recovery_and_disposal,_2018_(%25_of_total_treatment) (accessed on 17 December 2021).

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Augarde, C.E. Soil Mechanics and Earthen Construction: Strength and Mechanical Behaviour; Hall, M.R., Lindsay, R., Krayenhoff, M., Eds.; Woodhead Publishing Series in Energy, Modern Earth Buildings; Woodhead Publishing: Sawston, UK, 2012; pp. 204–221. ISBN 9780857090263. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Petrou, M.F.; Ioannou, I. Durability performance of self-compacting concrete. Constr. Build. Mater. 2012, 37, 320–325. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Savva, P.; Petrou, M.F.; Ioannou, I.; Pantazopoulou, S. Assessing the quality of concrete—Reinforcement interface in Self Compacting Concrete. Constr. Build. Mater. 2020, 240, 117933. [Google Scholar] [CrossRef]

- Berredjem, L.; Arabi, N.; Molez, L. Mechanical and durability properties of concrete based on recycled coarse and fine aggregates produced from demolished concrete. Constr. Build. Mater. 2020, 246, 118421. [Google Scholar] [CrossRef]

- Xiao, J.; Li, J.; Zhang, C. Mechanical properties of recycled aggregate concrete under unaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Lotfy, A.; Al-Fayez, M. Performance evaluation of structural concrete using controlled quality coarse and fine recycled concrete aggregate. Cem. Concr. Compos. 2015, 61, 36–43. [Google Scholar] [CrossRef]

- Li, Z.; Liu, J.; Tian, Q. Method for controlling the absorbed water content of recycled fine aggregates by centrifugation. Constr. Build. Mater. 2018, 160, 316–325. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Etxeberria, M. Influence of recycled aggregates on long term mechanical properties and pore size distribution of concrete. Cem. Concr. Compos. 2011, 33, 286–291. [Google Scholar] [CrossRef]

- Bairagi, N.K.; Ravande, K.; Pareek, V.K. Behaviour of concrete with different proportions of natural and recycled aggregates. Resour. Conserv. Recycl. 1993, 9, 109–126. [Google Scholar] [CrossRef]

- Muduli, R.; Mukharjee, B.B. Performance assessment of concrete incorporating recycled coarse aggregates and metakaolin: A systematic approach. Constr. Build. Mater. 2020, 233, 117223. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F. Durability properties evaluation of self-compacting concrete prepared with waste fine and coarse recycled concrete aggregates. Constr. Build. Mater. 2020, 236, 117540. [Google Scholar] [CrossRef]

- Manzi, S.; Mazzotti, C.; Bignozzi, M.C. Short and long-term behavior of structural concrete with recycled concrete aggregate. Cem. Concr. Compos. 2013, 37, 312–318. [Google Scholar] [CrossRef]

- Fathifazl, G.; Ghani Razaqpur, A.; Burkan Isgor, O.; Abbas, A.; Fournier, B.; Foo, S. Creep and drying shrinkage characteristics of concrete produced with coarse recycled concrete aggregate. Cem. Concr. Compos. 2011, 33, 1026–1037. [Google Scholar] [CrossRef]

- Gonzalez-Corominas, A.; Etxeberria, M. Effects of using recycled concrete aggregates on the shrinkage of high performance concrete. Constr. Build. Mater. 2016, 115, 32–41. [Google Scholar] [CrossRef]

- Corinaldesi, V. Mechanical and elastic behaviour of concretes made of recycled-concrete coarse aggregates. Constr. Build. Mater. 2010, 24, 1616–1620. [Google Scholar] [CrossRef]

- Yang, S.; Lim, Y. Mechanical strength and drying shrinkage properties of RCA concretes produced from old railway concrete sleepers using by a modified EMV method. Constr. Build. Mater. 2018, 185, 499–507. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Prediction of the shrinkage behavior of recycled aggregate concrete: A review. Constr. Build. Mater. 2015, 77, 327–339. [Google Scholar] [CrossRef]

- Bulatović, V.; Melešev, M.; Radeka, M.; Radonjanin, V.; Lukić, I. Evaluation of sulfate resistance of concrete with recycled and natural aggregates. Constr. Build. Mater. 2017, 152, 614–631. [Google Scholar] [CrossRef]

- Berndt, M.L. Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 2606–2613. [Google Scholar] [CrossRef]

- Corral-Higuera, R.; Arredondo-Rea, S.P.; Neri-Flores, M.A.; Gómez-Soberón, J.M.; Almeraya Calderón, F.; Castorena-González, J.H.; Almaral-Sánchez, J.L. Sulfate attack and reinforcement corrosion in concrete with recycled concrete aggregates and supplementary cementing materials. Int. J. Electrochem. Sci. 2011, 6, 613–621. [Google Scholar]

- Sáez del Bosque, I.F.; Van den Heede, P.; De Belie, N.; Sánchez de Rojas, M.I.; Medina, C. Carbonation of concrete with construction and demolition waste based recycled aggregates and cement with recycled content. Constr. Build. Mater. 2020, 234, 117336. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Structural concrete with simultaneous incorporation of fine and coarse recycled concrete aggregates: Mechanical, durability and long-term properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Abbas, A.; Fathifazl, G.; Isgor, O.B.; Razaqpur, A.G.; Fournier, B.; Foo, S. Durability of recycled aggregate concrete designed with equivalent mortar volume method. Cem. Concr. Compos. 2009, 31, 555–563. [Google Scholar] [CrossRef]

- Dimitriou, G.; Savva, P.; Petrou, M.F. Enhancing mechanical and durability properties of recycled aggregate concrete. Constr. Build. Mater. 2018, 158, 228–235. [Google Scholar] [CrossRef]

- Pandurangan, K. Influence of treatment methods on the bond strength of recycled aggregate concrete. Constr. Build. Mater. 2016, 120, 212–221. [Google Scholar] [CrossRef]

- Martinez-Echevarria, M.J.; Lopez-Alonso, M.; Garach, L.; Alegre, J.; Poon, C.S.; Agrela, F.; Cabrera, M. Crushing treatment on recycled aggregates to improve their mechanical behaviour for use in unbound road layers. Constr. Build. Mater. 2020, 263, 120517. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T.; Foo, T.W.J. Microwave-assisted beneficiation of recycled concrete aggregates. Constr. Build. Mater. 2011, 25, 3469–3479. [Google Scholar] [CrossRef]

- Kazmi, S.M.S.; Munir, M.J.; Wu, Y.F.; Patnaikuni, I.; Zhou, Y.; Xing, F. Influence of different treatment methods on the mechanical behavior of recycled aggregate concrete: A comparative study. Cem. Concr. Compos. 2019, 104, 103398. [Google Scholar] [CrossRef]

- Xuan, D.; Zhan, B.; Poon, C.S. Assessment of mechanical properties of concrete incorporating carbonated recycled concrete aggregates. Cem. Concr. Compos. 2016, 65, 67–74. [Google Scholar] [CrossRef]

- Alqarni, A.S.; Abbas, H.; Al-Shwikh, K.M.; Al-Salloum, Y.A. Treatment of recycled concrete aggregate to enhance concrete performance. Constr. Build. Mater. 2021, 307, 124960. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the Improvement of Recycled Aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Ismail, S.; Ramli, M. Mechanical strength and drying shrinkage properties of concrete containing treated coarse recycled concrete aggregates. Constr. Build. Mater. 2014, 68, 726–739. [Google Scholar] [CrossRef]

- Ismail, S.; Ramli, M. Engineering properties of treated recycled concrete aggregate (RCA) for structural applications. Constr. Build. Mater. 2013, 44, 464–476. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Le, K.N. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef] [Green Version]

- Kim, Y.; Hanif, A.; Kazmi, S.M.S.; Munir, M.J.; Park, C. Properties enhancement of recycled aggregate concrete through pretreatment of coarse aggregates—Comparative assessment of assorted techniques. J. Clean. Prod. 2018, 191, 339–349. [Google Scholar] [CrossRef]

- Katkhuda, H.; Shatarat, N. Improving the mechanical properties of recycled concrete aggregate using chopped basalt fibers and acid treatment. Constr. Build. Mater. 2017, 140, 328–335. [Google Scholar] [CrossRef]

- Al-Bayati, H.K.A.; Das, P.K.; Tighe, S.L.; Baaj, H. Evaluation of various treatment methods for enhancing the physical and morphological properties of coarse recycled concrete aggregate. Constr. Build. Mater. 2016, 112, 284–298. [Google Scholar] [CrossRef]

- Kanellopoulos, A.; Nicolaides, D.; Petrou, M. Mechanical and durability properties of concretes containing recycled lime powder and recycled aggregates. Constr. Build. Mater. 2014, 53, 253–259. [Google Scholar] [CrossRef]

- Savva, P.; Ioannou, S.; Oikonomopoulou, K.; Nicolaides, D.; Petrou, M.F. A mechanical treatment method for recycled aggregates and its effect on recycled aggregate-based concrete. Materials 2021, 14, 2186. [Google Scholar] [CrossRef] [PubMed]

- Pepe, M.; Toledo Filho, R.D.; Koenders, E.A.B.; Martinelli, E. Alternative processing procedures for recycled aggregates in structural concrete. Constr. Build. Mater. 2014, 69, 124–132. [Google Scholar] [CrossRef]

- ASTM C131/C131M-14; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2014; pp. 1–5.

- CYS EN 1097-6:2013; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. CEN (European Committee for Standardization): Brussels, Belgium, 2013.

- ASTM C88/C88M—18; Standard Test Method for Soundness of Aggregates by Use of Sodium Sulfate or Magnesium Sulfate. ASTM International: West Conshohocken, PA, USA, 2018; pp. 1–6. [CrossRef]

- CYS EN 933-3; Tests for Geometrical Properties of Aggregates Part 3: Determination of Particle Shape–Flakiness Index. CEN: Brussels, Belgium, 2012.

- CYS EN 933-4; Tests for Geometrical Properties of Aggregates Part 4: Determination of Particle Shape—Shape Index. CEN: Brussels, Belgium, 2008.

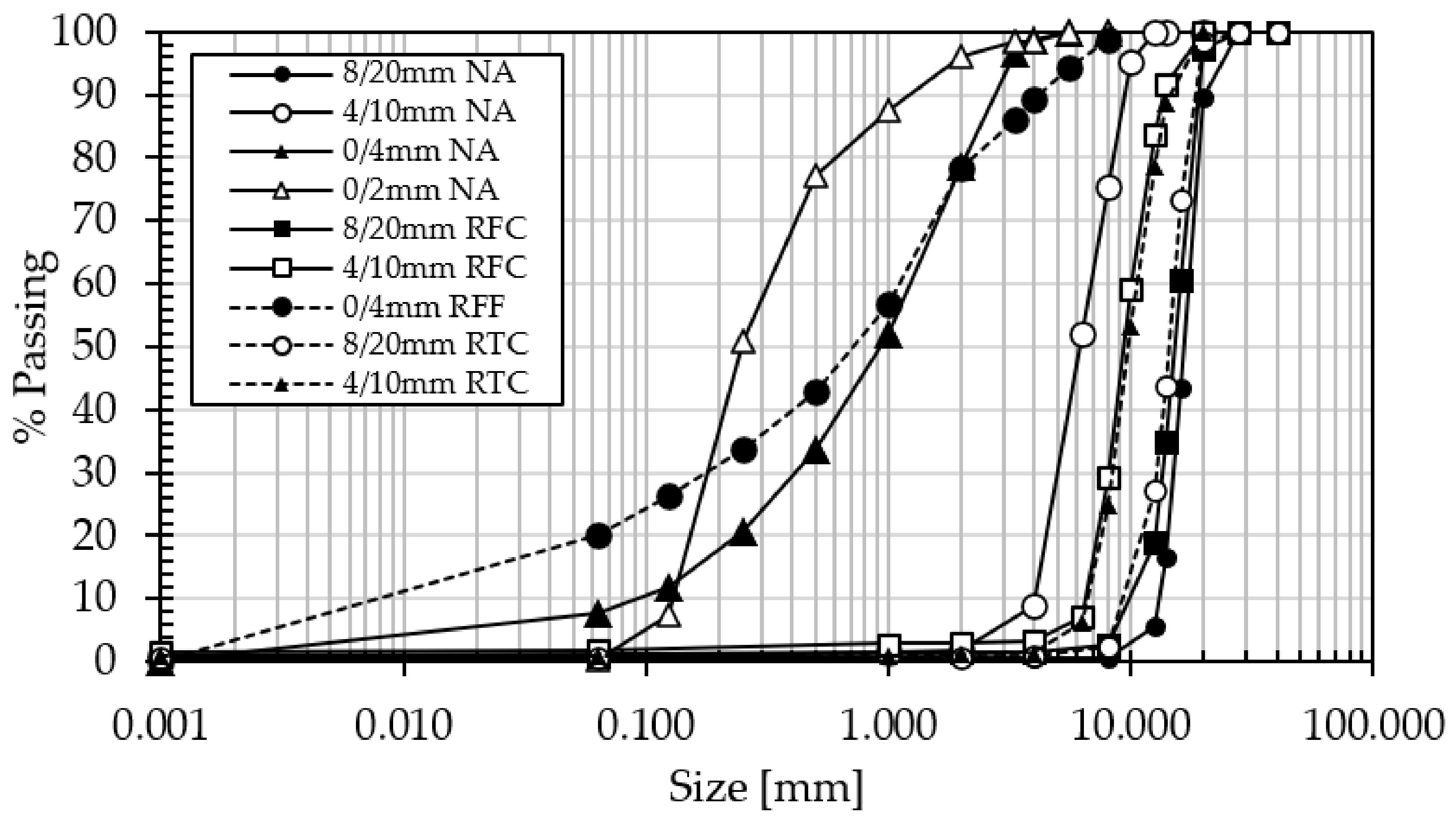

- CYS EN 933-1:2012; Test for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. CEN (European Committee for Standardization): Brussels, Belgium, 2012.

- CYS EN 12390-3:2009; Testing Hardened Concrete-Part 3: Compressive Strength of Test Specimens. CEN (European Committee for Standardization): Brussels, Belgium, 2009.

- CYS EN 12390-6:2009; Testing Hardened Concrete-Part 3: Splitting Tensile Strength of Test Specimens. CEN (European Committee for Standardization): Brussels, Belgium, 2009.

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2012; pp. 1–8. [CrossRef]

- Dhir, R.; McCarthy, M.; Zhou, S.; Tittle, P. Role of cement content in specifications for concrete durability: Cement type influences. Proc. Inst. Civ. Eng. Build. 2004, 157, 113–127. [Google Scholar] [CrossRef]

- BS EN 12390-12:2020; Testing Hardened Concrete Part 12: Determination of the Carbonation Resistance of Concrete—Accelerated Carbonation Method. CEN (European Commitee for Standardization): Brussels, Belgium, 2020.

- BS EN 1367-4; Tests for Thermal and Weathering Properties of Aggregates: Determination of Drying Shrinkagr. CEN (European Commitee for Standardization): Brussels, Belgium, 2008.

- EN 206-1; Concrete—Specification, Performance, Production and Conformity. CEN (European Committee for Standardization): Brussels, Belgium, 2016.

- BS 1881-125: 1986; Testing Concrete. The British Standards Institution: London, UK, 1986; pp. 1–14.

- Al-Baghdadi, H. Experimental Study on Sulfate Resistance of Concrete with Recycled Aggregate Modified with Polyvinyl Alcohol (PVA). Case Stud. Constr. Mater. 2021, 14, e00527. [Google Scholar] [CrossRef]

- Lee, S.; Moon, H.Y.; Swamy, R.N.; Kim, S.S.; Kim, J.P. Sulfate attack of mortars containing recycled fine aggregates. ACI Mater. J. 2005, 102, 224–230. [Google Scholar]

| Properties | Relevant Standard | 0/2 mm NA | 4/10 mm NA 1 | 4/10 mm RTC 2 | 4/10 mm RFC 3 | 0/4 mm NA | 0/4 mm RFF 4 | 8/20 mm NA | 8/20 mm RFC | 8/20 mm RTC |

|---|---|---|---|---|---|---|---|---|---|---|

| Los Angeles Coefficient (LA) (%) | ASTM C131 [47] | - | 29 | 15 | 32 | - | - | 29 * | 32 * | 15 * |

| Particle Density (Kg/m3) | EN 1097-6 [48] | 2530 | 2473 | 2430 | 2517 | 2267 | 2299 | 2500 | 2430 | 2400 |

| Particle Density, SSD (Kg/m3) | EN 1097-6 [48] | 2580 | 2567 | 2539 | 2681 | 2378 | 2413 | 2600 | 2530 | 2490 |

| Water Absorption (%) (WA) (%) | EN 1097-6 [48] | 1.80 | 3.79 | 4.48 | 6.52 | 4.89 | 4.95 | 4.10 | 4.40 | 4.00 |

| Soundness (%) | ASTM C88 [49] | - | 30 | 14 | 41 | - | - | 30 * | 41 * | 14 * |

| Flakiness Index | EN 933-3 [50] | - | 16 | 4 | 5 | - | - | 7 | 5 | 6 |

| Shape Index | EN 933-4 [51] | - | 9 | 5 | 7 | - | - | 9 | 16 | 15 |

| Test | Standard | Age of Testing (Days) | Specimens | ||

|---|---|---|---|---|---|

| Hardened Concrete properties | Mechanical | Compressive Strength | EN 12390-3 [53] | 28, 90, 365 | 100 mm cubes |

| Tensile Splitting Strength | EN 12390-6 [54] | 28, 90 | 100Φ200 mm cylinders | ||

| Durability | Carbonation Resistance | EN 12390-12 [57] | Weekly up to 5 weeks | 300 × 75 × 75 mm prism | |

| Open Porosity | [7] | 28, 90, 365 | 100 mm cubes | ||

| Drying Shrinkage | EN 1367 [58] | Weekly up to 20 weeks | 300 × 75 × 75 mm prism | ||

| Sulfate Resistance | Reference [56] | Weekly up to 40 weeks | 300 × 75 × 75 mm prism | ||

| Chloride Ion Resistivity | ASTM C-1202 [55] | 28, 56, 90, 365 | 100Φ200 mm cylinders | ||

| Water | Portland Cement | Sand 0/2 Mm | Sand 0/4 Mm | Aggregate 4/10 Mm | Aggregate 8/20 Mm | Recycled Sand 0/4 Mm | Recycled Aggregate 4/10 Mm | Recycled Aggregate 4/10 Mm | Recycled Aggregate 8/20 Mm | Recycled Aggregate 8/20 Mm | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Code | - | PC | - | - | NA 4/10 mm | NA 8/20 mm | RFF 0/4 mm | RFC 4/10 mm | RTC 4/10 mm | RFC 8/20 mm | RTC 8/20 mm | |

| w/c Ratio | Description | - | CEM I 52.5N to EN197-1 | Natural Fine Sand | Natural Diabase Sand | Natural Crushed Aggregate | Natural Crushed Aggregate | Field Sand (Untreated) | Field Aggregate (Untreated) | Mechanically Treated Aggregate | Field Aggregate (Untreated) | Mechanically Treated Aggregate |

| Constituent Contents in Mix Design (kg/m3) | ||||||||||||

| 0.25 | REFC1 | 216 | 864 | 184 | 335 | 730 | - | - | - | - | - | - |

| RFF25 | 216 | 864 | 183 | 251 | 730 | - | 84 | - | - | - | - | |

| RFF50 | 216 | 864 | 184 | 167 | 730 | - | 167 | - | - | - | - | |

| RFF100 | 216 | 864 | 183 | - | 730 | - | 334 | - | - | - | - | |

| RFC25 | 216 | 864 | 183 | 334 | 548 | - | - | 183 | - | - | - | |

| RFC50 | 216 | 864 | 184 | 334 | 365 | - | - | 365 | - | - | - | |

| RFC100 | 216 | 864 | 184 | 335 | - | - | - | 730 | - | - | - | |

| RTC25 | 216 | 864 | 184 | 335 | 547 | - | - | - | 182 | - | - | |

| RTC50 | 216 | 864 | 184 | 335 | 365 | - | - | - | 365 | - | - | |

| RTC100 | 216 | 864 | 184 | 334 | - | - | - | - | 730 | - | - | |

| 0.50 | REFC2 | 200 | 400 | 406 | 266 | 386 | 629 | - | - | - | - | - |

| RFC25 | 200 | 400 | 407 | 266 | 289 | 471 | - | 96 | - | 157 | - | |

| RFC50 | 200 | 400 | 407 | 266 | 192 | 314 | - | 192 | - | 314 | - | |

| RFC100 | 200 | 400 | 407 | 266 | - | - | - | 385 | - | 628 | - | |

| RTC25 | 200 | 400 | 406 | 266 | 289 | 471 | - | - | 96 | - | 157 | |

| RTC50 | 200 | 400 | 406 | 266 | 193 | 314 | - | - | 193 | - | 314 | |

| RTC100 | 200 | 400 | 406 | 266 | - | - | - | - | 385 | - | 629 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oikonomopoulou, K.; Ioannou, S.; Savva, P.; Spanou, M.; Nicolaides, D.; Petrou, M.F. Effect of Mechanically Treated Recycled Aggregates on the Long Term Mechanical Properties and Durability of Concrete. Materials 2022, 15, 2871. https://doi.org/10.3390/ma15082871

Oikonomopoulou K, Ioannou S, Savva P, Spanou M, Nicolaides D, Petrou MF. Effect of Mechanically Treated Recycled Aggregates on the Long Term Mechanical Properties and Durability of Concrete. Materials. 2022; 15(8):2871. https://doi.org/10.3390/ma15082871

Chicago/Turabian StyleOikonomopoulou, Konstantina, Sokrates Ioannou, Pericles Savva, Maria Spanou, Demetris Nicolaides, and Michael F. Petrou. 2022. "Effect of Mechanically Treated Recycled Aggregates on the Long Term Mechanical Properties and Durability of Concrete" Materials 15, no. 8: 2871. https://doi.org/10.3390/ma15082871

APA StyleOikonomopoulou, K., Ioannou, S., Savva, P., Spanou, M., Nicolaides, D., & Petrou, M. F. (2022). Effect of Mechanically Treated Recycled Aggregates on the Long Term Mechanical Properties and Durability of Concrete. Materials, 15(8), 2871. https://doi.org/10.3390/ma15082871