Influence of Freeze–Thaw Cycles on the Mechanical Properties of Highly Rubberised Asphalt Mixtures Made with Warm and Cold Asphalt Binders

Abstract

:1. Introduction and Objective

2. Materials and Methods

2.1. Raw Materials

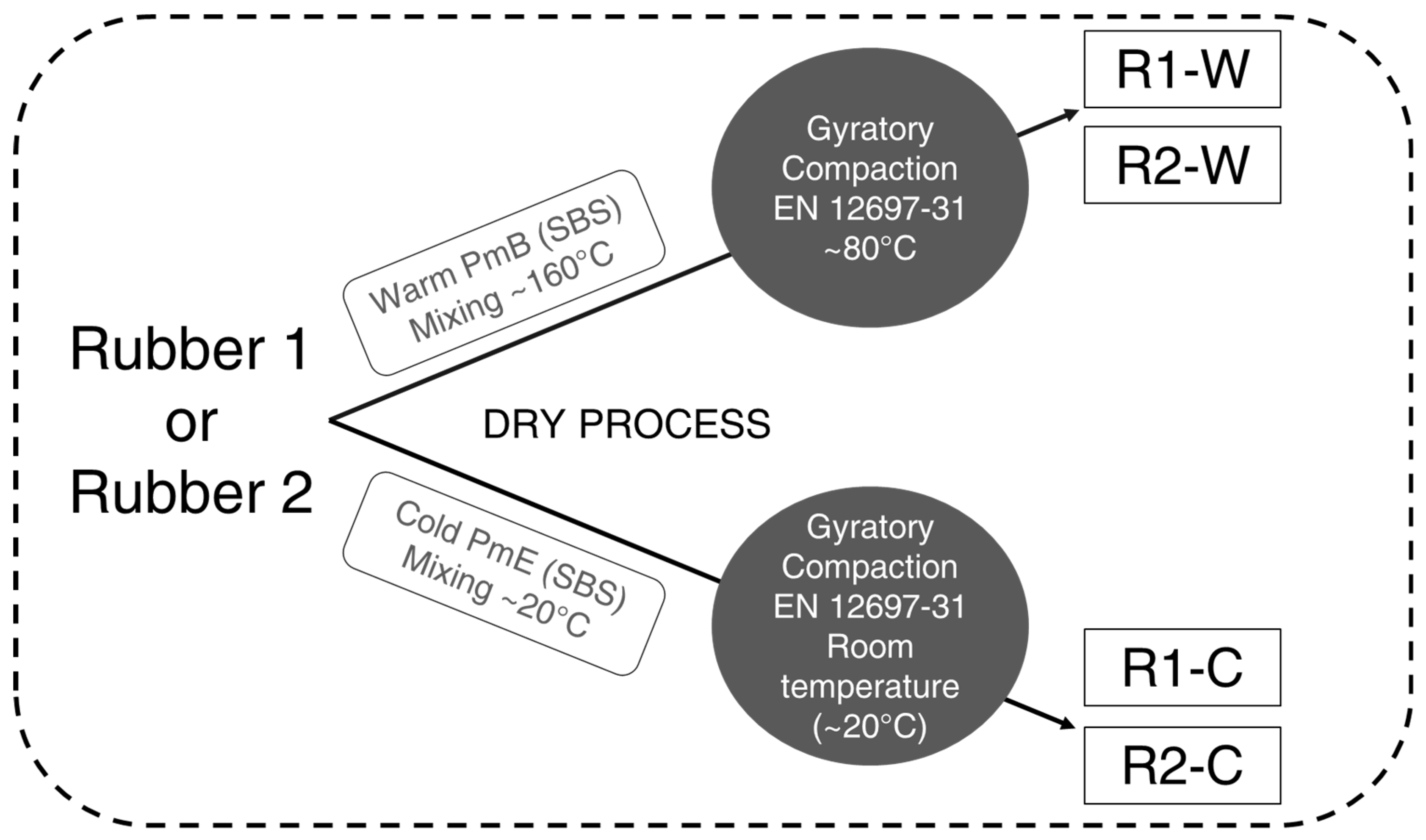

2.2. Highly-Rubberised Asphalt Concrete Samples’ Production

2.3. Freeze and Thaw Conditioning Procedure

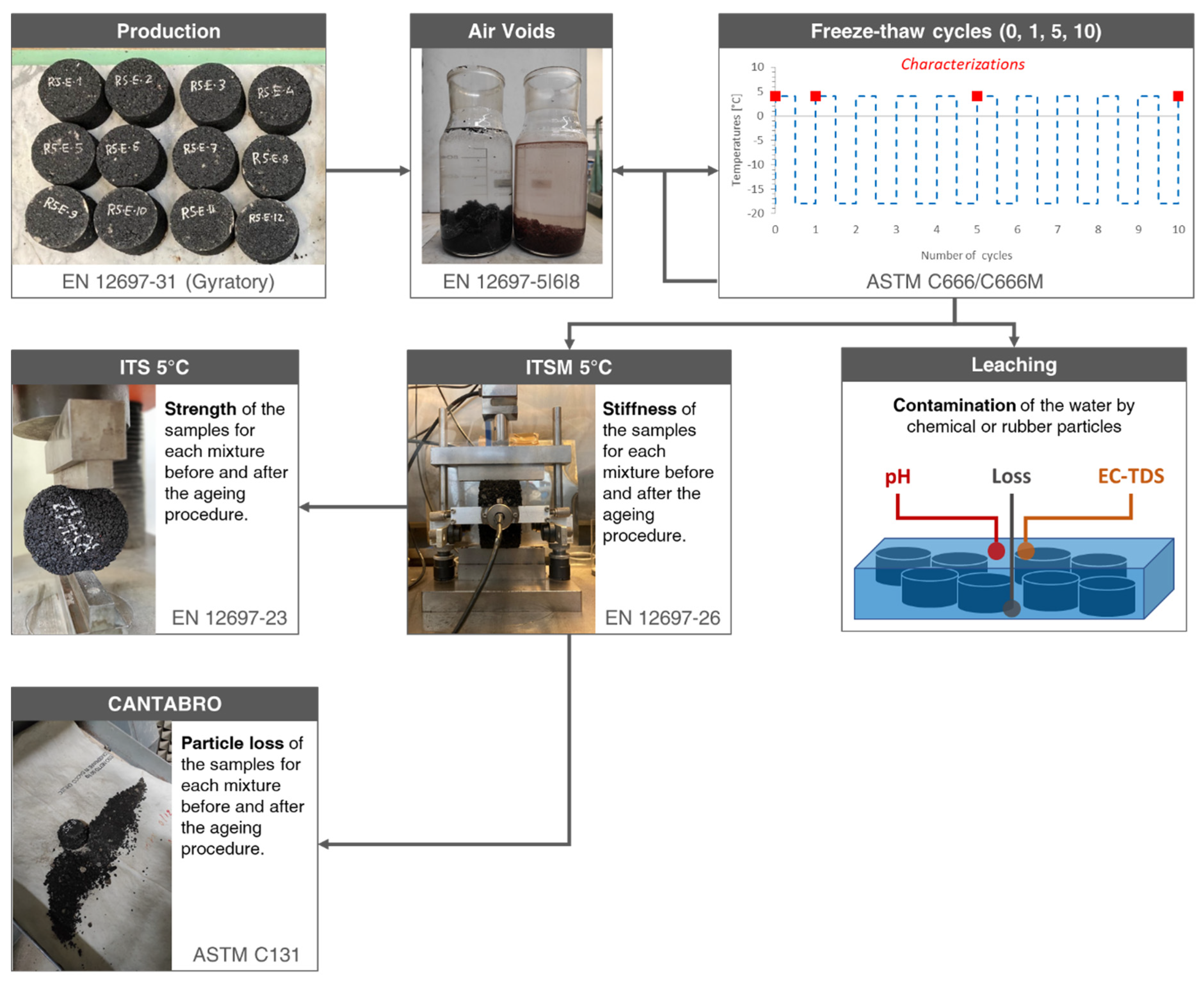

2.4. Characterisation

2.4.1. Densities and Air Voids’ Content

2.4.2. Indirect Tensile Stiffness Modulus

2.4.3. Indirect Tensile Strength

2.4.4. Cantabro Loss

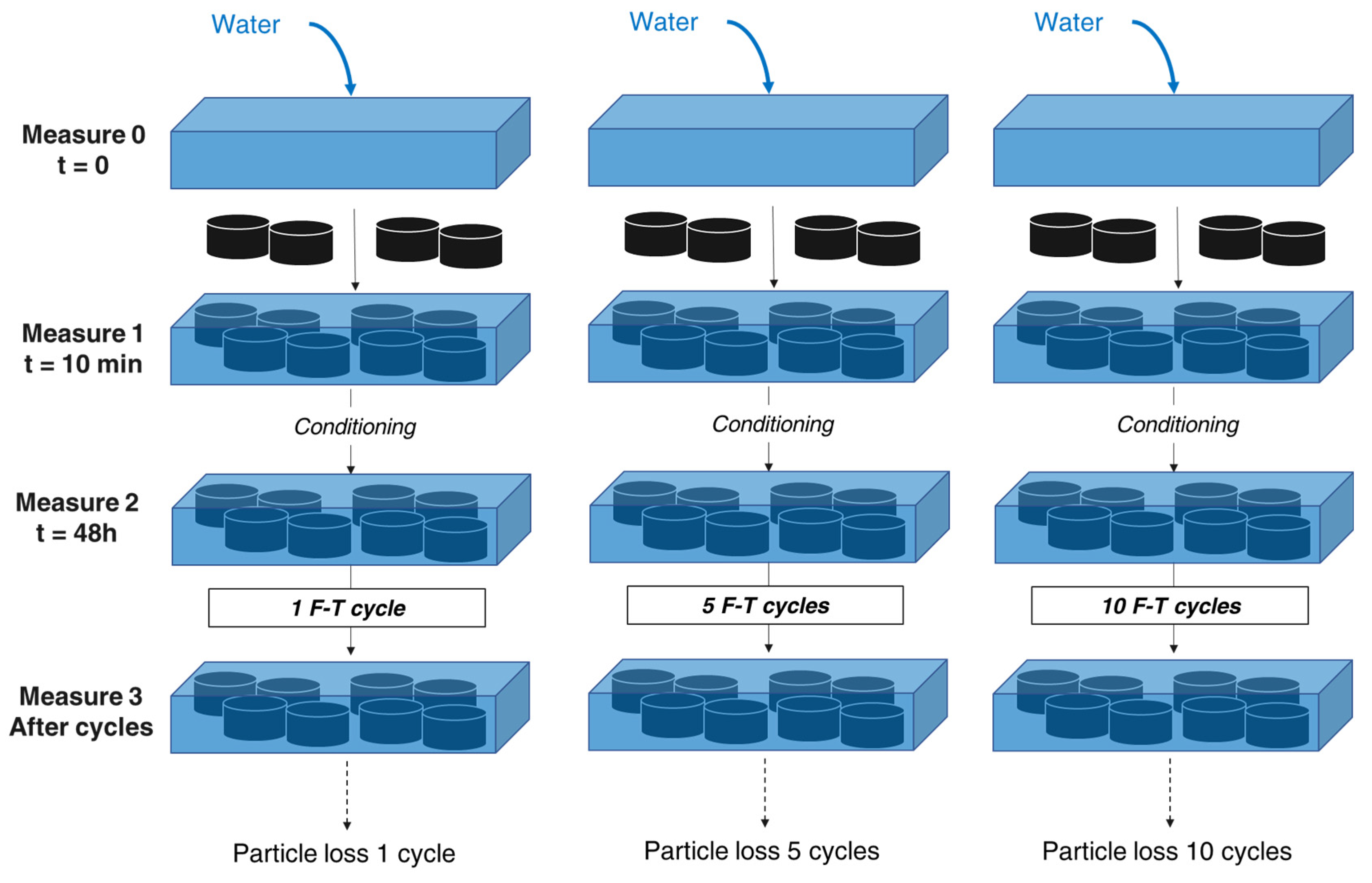

2.4.5. Measures of Particle Loss, pH, and Electric Conductivity-Total Dissolved Solid

3. Results and Discussion

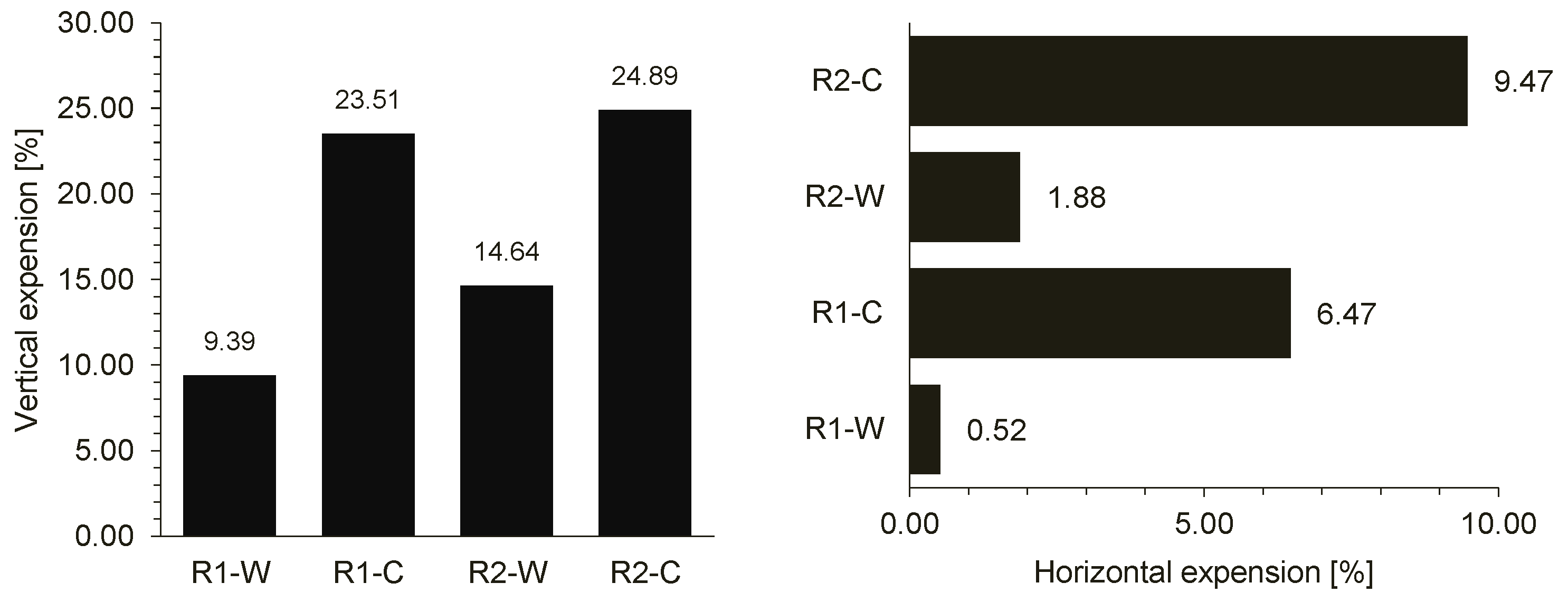

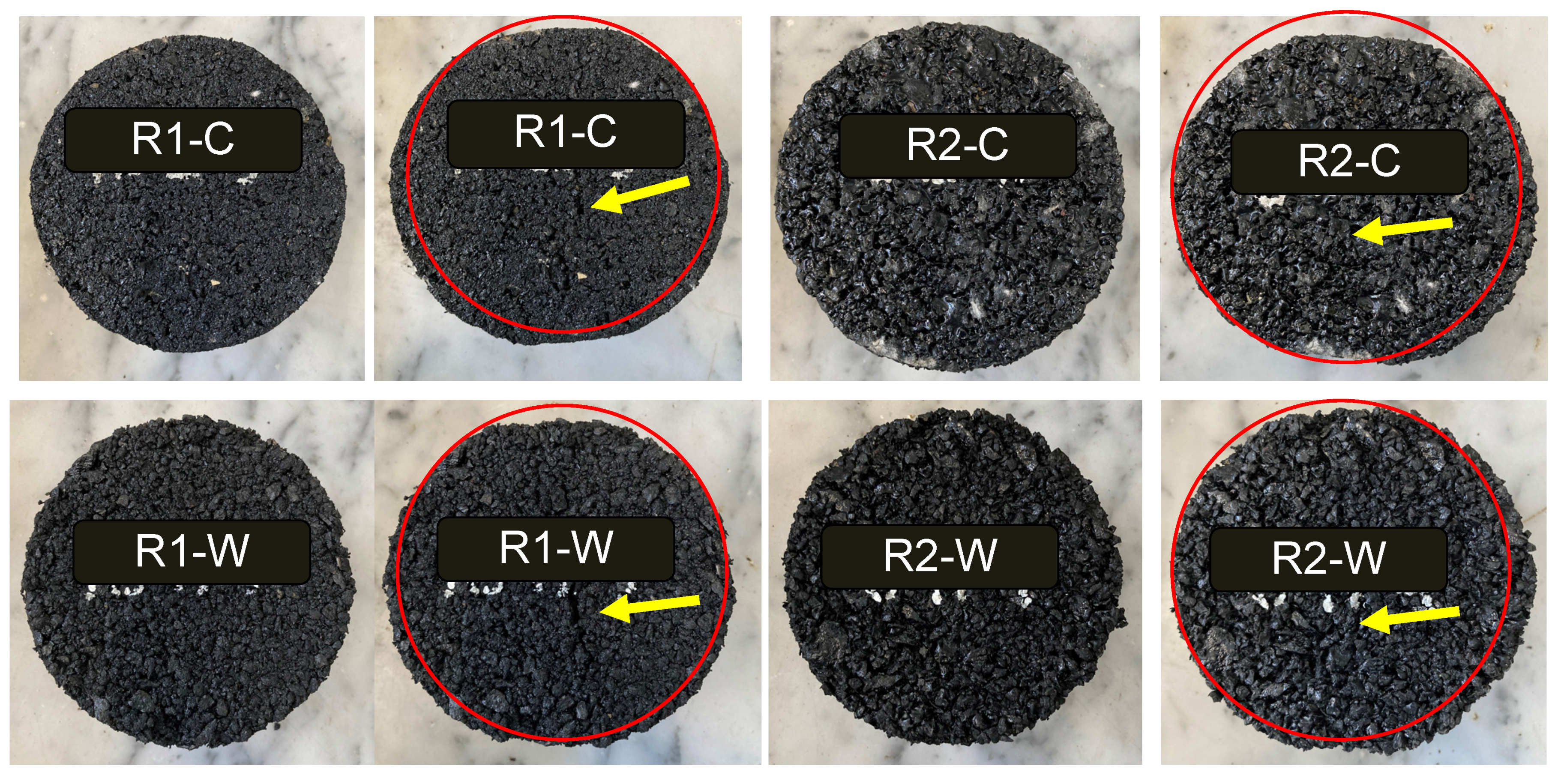

3.1. Volumetric, Geometrical Properties of the Mixtures and Relevant Observations

3.2. Mechanical Performances

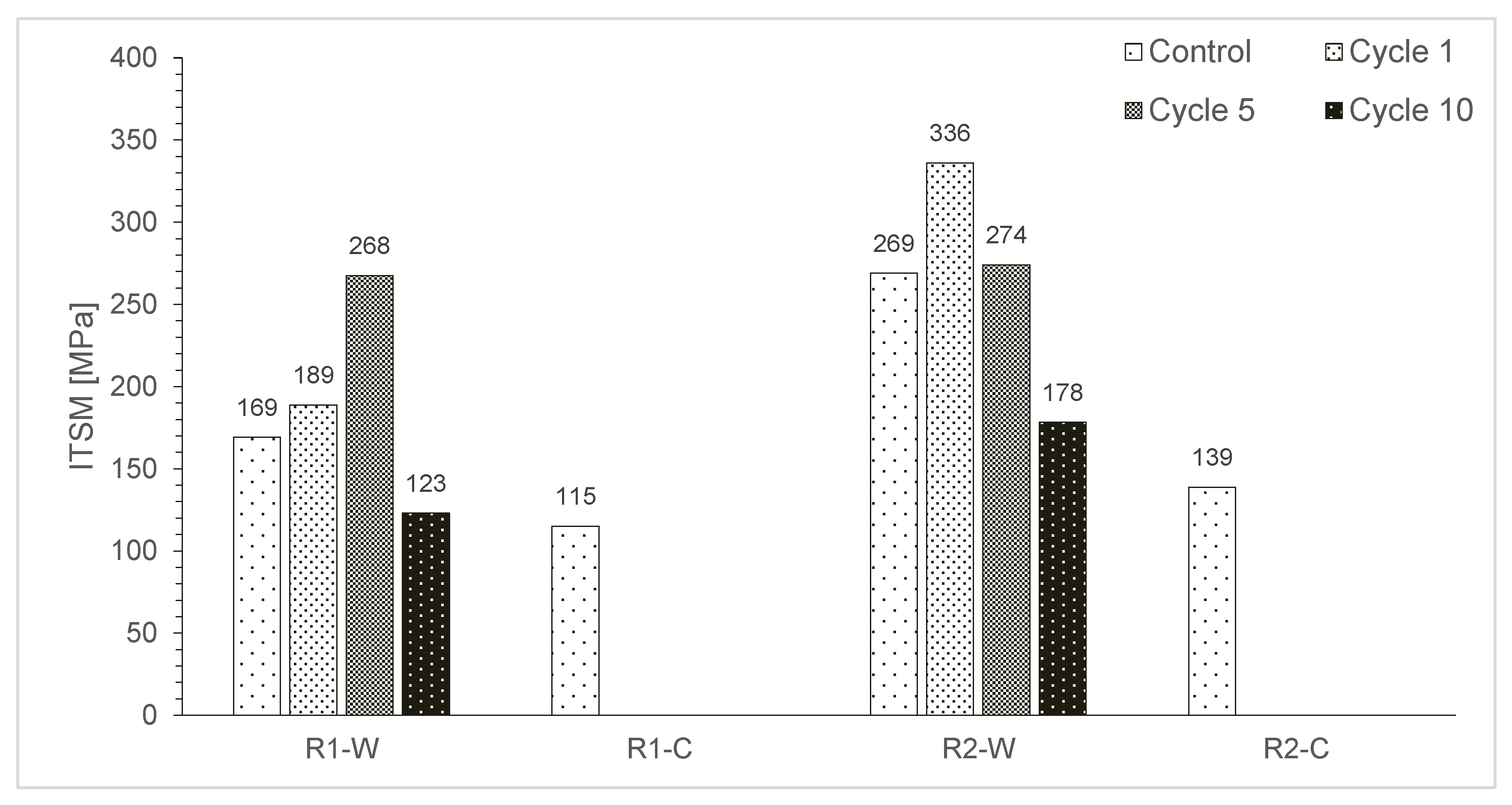

3.2.1. ITSM at 5 °C

3.2.2. ITS at 5 °C

3.3. Particle Loss

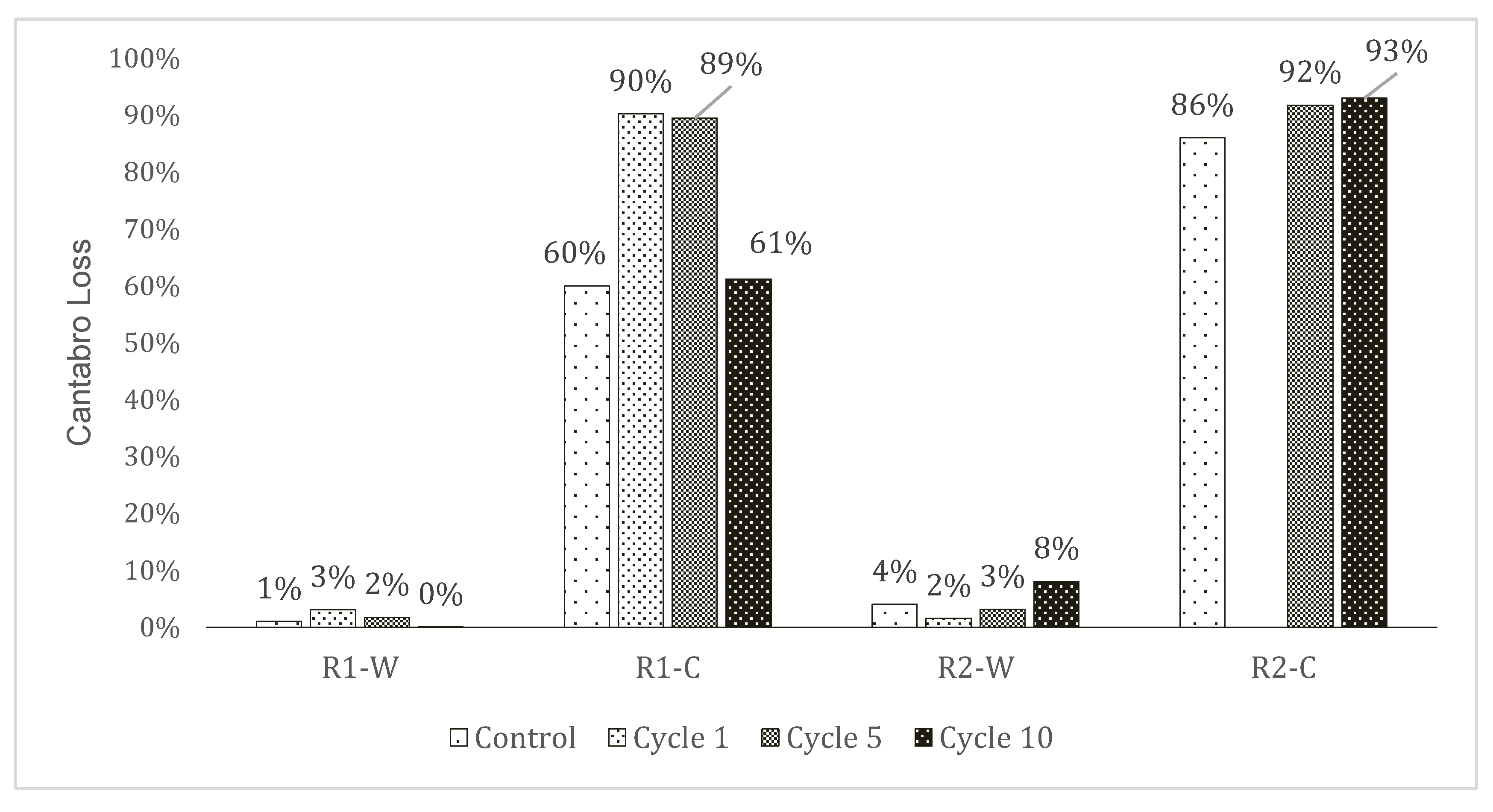

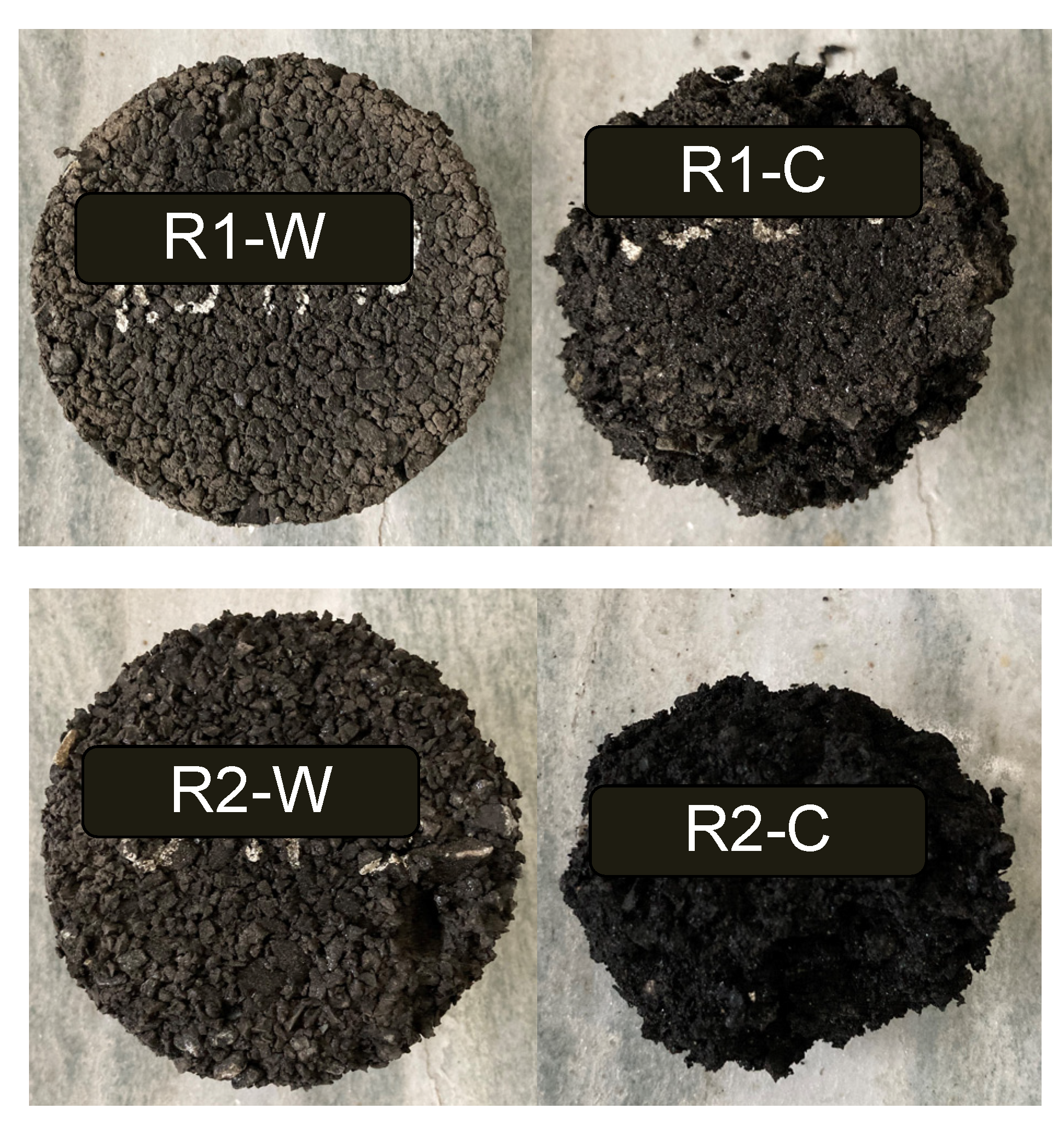

3.3.1. Cantabro Loss

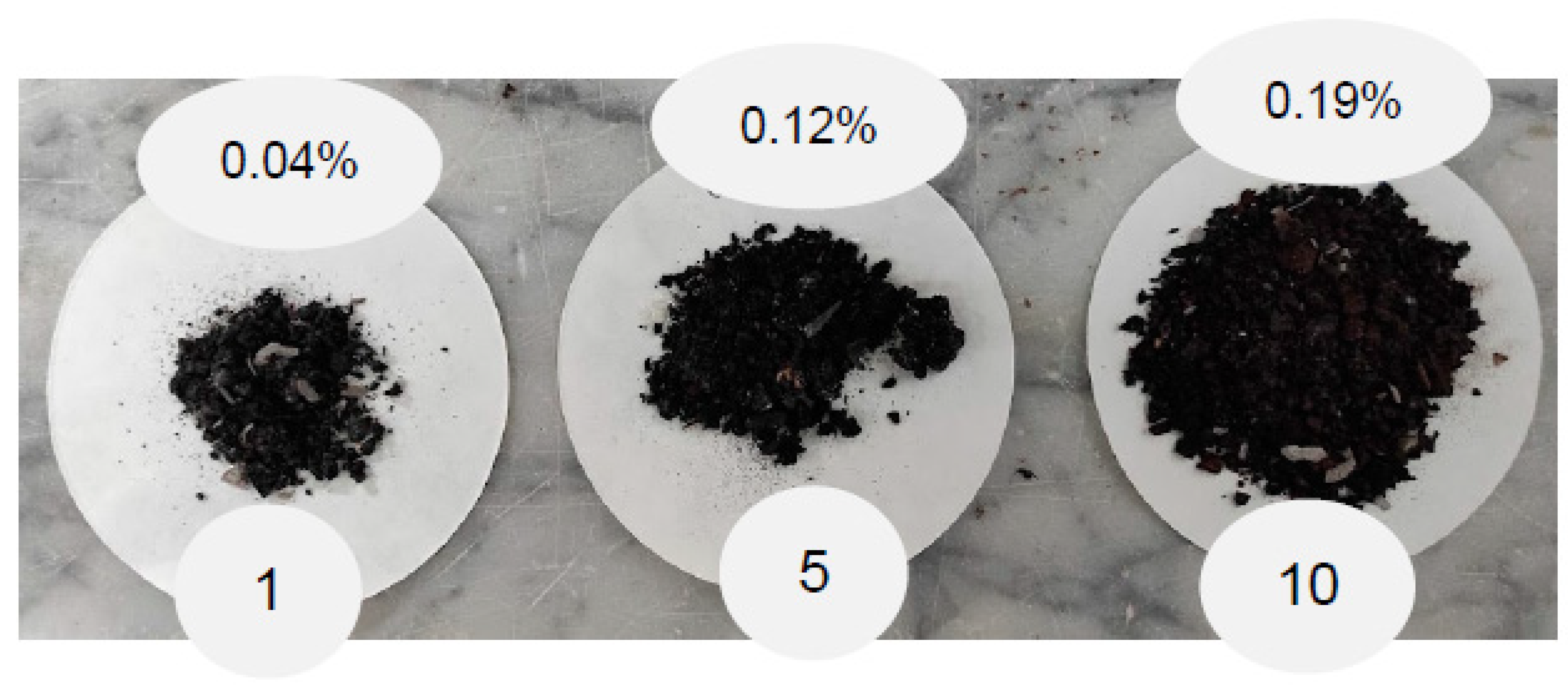

3.3.2. Particle Loss in the Thaw Water

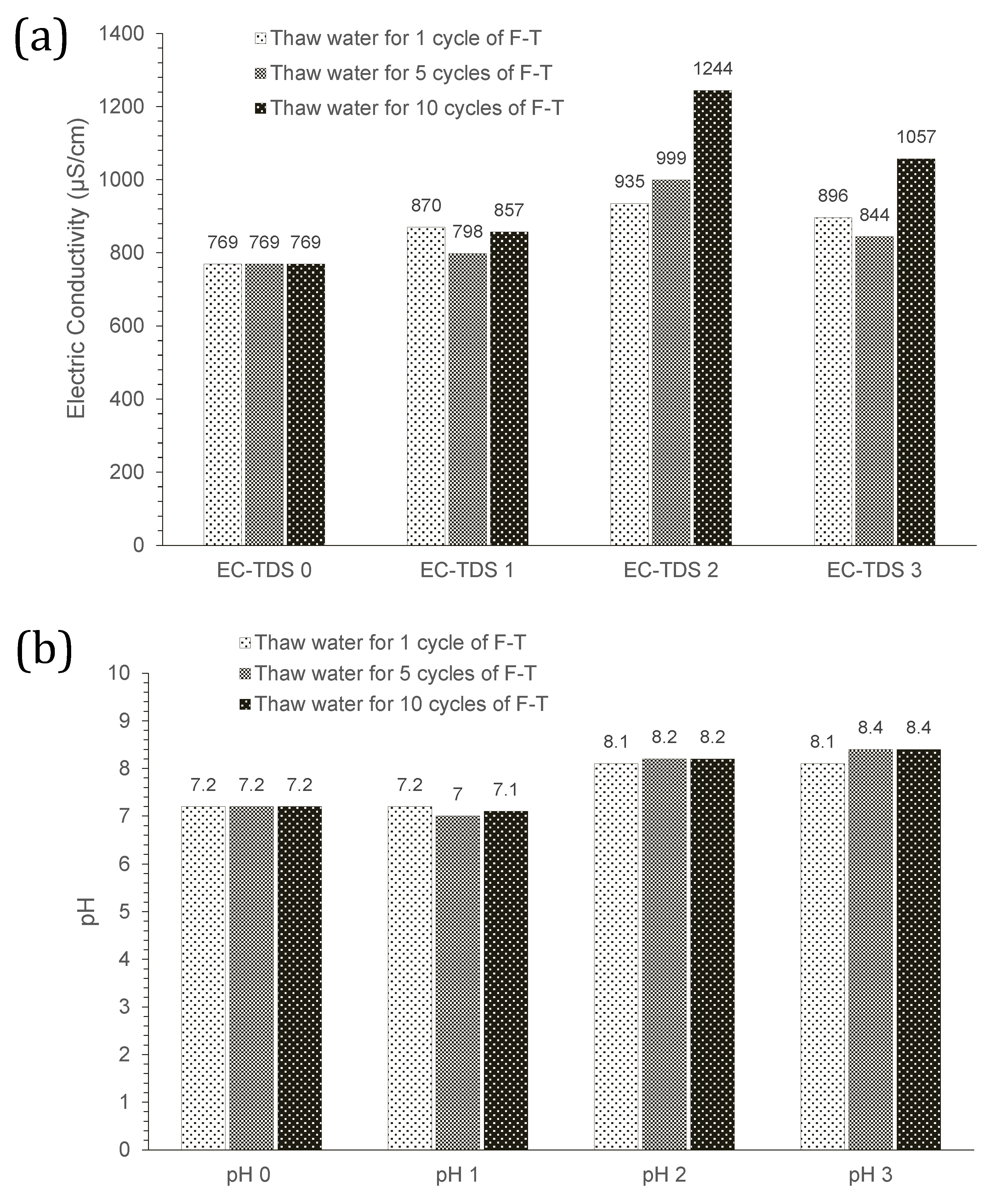

3.4. Leaching Analysis

4. Conclusions

- The visual, geometrical, and volumetric assessments have shown that the specimens made with the cold binder are softer, expand more and contain more air voids than other samples.

- The ITSM test outcomes show that R2-W is stiffer than R1-W, and that specimens made with PmE are softer than those made with PmB. The cold mixtures were too soft even at 5 °C and could not be tested with the ITSM procedure. In this case, a uniaxial compressive analysis should be preferred.

- The ITS of specimens made with PmE are lower than those made with PmB. The samples made with Rubber 1 have slightly higher ITS than those made with Rubber 2. Regarding the PmE samples, a modification in the mechanical structure is less evident, certainly because the control values start low and no main fluctuation is observed, while the PmB-made samples show a clear decrease in the ITS value with the F–T cycles.

- Concerning the Cantabro loss method, the variation of particles lost along the F–T cycles is very low for the cold specimens. The mixtures made with Rubber 1 record lower loss values after the Cantabro test and R1-W have similar Cantabro loss than a standard asphalt concrete (without rubber) at 0 cycles.

- The values of EC and pH are comparable to those observed in a parallel study on highly rubberised asphalt leaching The leaching is mainly observed in the first hours. The early leaching observed could be handled with several solutions such as rubber pre-treatment or water washing before their incorporation into the mix to limit and prevent their leaching into the pavement and consequently into the environment.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Rubbers

| Rubber | Granulates | Particle Size [mm] ISO 13322-2 | Bulk Density [kg/m3] EN 1097-3 | Specific Density [kg/m3] | PAHs 8 REACH [mg/kg] (Specification ≤ 20) |

|---|---|---|---|---|---|

| Rubber 1 | Fine | 0–1.2 | 0.440 | 1.028 (EN 1097-6) * | 6.5 |

| Medium | 1.0–2.8 | 0.440 | 1.028 (EN 1097-6) * | 6.5 | |

| Coarse | 2.5–4.0 | 0.440 | 1.028 (EN 1097-6) * | 6.5 | |

| Rubber 2 | Powder | 0.2–0.8 | 0.345 | 1.160 (ASTM D1817-05) | <15 |

| Fine | 0.8–3.0 | 0.420 | 1.160 (ASTM D1817-05) | <15 | |

| Coarse | 2.0–4.0 | 0.455 | 1.160 (ASTM D1817-05) | <15 |

| Percent Retained per Sieve [%] | ||||||

|---|---|---|---|---|---|---|

| Rubber 1 | Rubber 2 | |||||

| Sieve (mm) | Fine | Medium | Large | Powder | Fine Mix | Coarse |

| 4 | 0.00 | 0.00 | 0.15 | 0.00 | 0.00 | 0.00 |

| 2 | 0.00 | 34.18 | 97.90 | 0.00 | 22.00 | 95.79 |

| 1 | 0.09 | 58.68 | 1.88 | 0.00 | 73.88 | 4.18 |

| 0.5 | 65.96 | 6.94 | 0.00 | 85.30 | 4.01 | 0.04 |

| 0.25 | 23.91 | 0.02 | 0.01 | 14.50 | 0.03 | 0.00 |

| 0.125 | 8.22 | 0.05 | 0.03 | 0.20 | 0.01 | 0.00 |

| 0.063 | 1.71 | 0.10 | 0.03 | 0.00 | 0.05 | 0.00 |

| <0.063 | 0.11 | 0.03 | 0.00 | 0.00 | 0.02 | 0.00 |

| Total | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

Appendix A.2. Aggregates

| Virgin Aggregates | Particle Size [mm] EN 933-1 | Specific Density EN 1097-6 |

|---|---|---|

| Limestone 1 | 8–14 | 2.661 |

| Limestone 2 | 4–8 | 2.669 |

| Limestone filler | ≤0.063 | 2.667 |

| Percent Retained per Sieve [%] | ||

|---|---|---|

| Sieve (mm) | 4–8 | 8–14 |

| 14 | 0 | 1.87 |

| 12.5 | 0 | 5.64 |

| 10 | 0 | 26.65 |

| 8 | 0.71 | 29.75 |

| 6.3 | 34.24 | 30.79 |

| 4 | 56.15 | 4.85 |

| 2 | 8.83 | 0.29 |

| 1 | 0.04 | 0.07 |

| 0.5 | 0.02 | 0.03 |

| 0.25 | 0.01 | 0.02 |

| 0.125 | 0.01 | 0.01 |

| 0.063 | 0.00 | 0.01 |

| <0.063 | 0.01 | 0.04 |

| Total | 100.00 | 100.00 |

Appendix A.3. Bitumen

| Code | Modifier | Penetration (25 °C) | Softening Point | Resistance to Hardening RTFOT (EN 12607-1) | Flash Point COC | Dynamic Viscosity | ||

|---|---|---|---|---|---|---|---|---|

| Change in Mass (Absolute Value) | Retained Penetration (25 °C) | Increase in Softening Point (Severity 1) | ||||||

| EN 1426 | EN 1427 | - | EN 1426 | EN 1427 | EN ISO 2592 | EN 13702 | ||

| dmm | °C | % | % | °C | °C | mPa.s | ||

| W | SBS | 25–55 | ≥70 | ≤0.5 | ≥65 | ≤8 | ≥250 | 295 (135 °C) |

Appendix A.4. Emulsion

| Code | Modifier | Binder Content | Breaking Index | Viscosity at 40 °C (Cup Discharge Time 4 mm) | Adhesiveness | Penetration (25 °C) | Softening Point |

|---|---|---|---|---|---|---|---|

| EN 1428 | EN 13075-1 | EN 12846 | EN 13614 | EN 1426 | EN 1427 | ||

| % | - | sec | % | dmm | °C | ||

| C | SBS | 67–69 | 70–155 | 5–70 | ≥90 | 45–80 | ≥60 |

References

- Jiang, W.; Huang, Y.; Sha, A. A Review of Eco-Friendly Functional Road Materials. Constr. Build. Mater. 2018, 191, 1082–1092. [Google Scholar] [CrossRef]

- El-Hakim, M.; Tighe, S. Impact of Freeze-Thaw Cycles on Mechanical Properties of Asphalt Mixes. Transp. Res. Rec. J. Transp. Res. Board 2014, 2444, 20–27. [Google Scholar] [CrossRef]

- Ud Din, I.M.; Mir, M.S.; Farooq, M.A. Effect of Freeze-Thaw Cycles on the Properties of Asphalt Pavements in Cold Regions: A Review. Transp. Res. Procedia 2020, 48, 3634–3641. [Google Scholar] [CrossRef]

- Xu, H.; Shi, H.; Zhang, H.; Li, H.; Leng, Z.; Tan, Y. Evolution of Dynamic Flow Behavior in Asphalt Mixtures Exposed to Freeze-Thaw Cycles. Constr. Build. Mater. 2020, 255, 119320. [Google Scholar] [CrossRef]

- Fan, Z.; Xu, H.; Xiao, J.; Tan, Y. Effects of Freeze-Thaw Cycles on Fatigue Performance of Asphalt Mixture and Development of Fatigue-Freeze-Thaw (FFT) Uniform Equation. Constr. Build. Mater. 2020, 242, 118043. [Google Scholar] [CrossRef]

- Fakhri, M.; Ali Siyadati, S.; Aliha, M.R.M. Impact of Freeze–Thaw Cycles on Low Temperature Mixed Mode I/II Cracking Properties of Water Saturated Hot Mix Asphalt: An Experimental Study. Constr. Build. Mater. 2020, 261, 119939. [Google Scholar] [CrossRef]

- Meng, A.; Xu, H.; Feng, X.; Tan, Y. Feasibility of Freeze-Thaw Damage Analysis for Asphalt Mixtures through Dynamic Nondestructive Testing. Constr. Build. Mater. 2020, 233, 117220. [Google Scholar] [CrossRef]

- Kavussi, A.; Karimi, M.M.; Ahmadi Dehaghi, E. Effect of Moisture and Freeze-Thaw Damage on Microwave Healing of Asphalt Mixes. Constr. Build. Mater. 2020, 254, 119268. [Google Scholar] [CrossRef]

- Ishaq, M.A.; Giustozzi, F. Rejuvenator Effectiveness in Reducing Moisture and Freeze/Thaw Damage on Long-Term Performance of 20% RAP Asphalt Mixes: An Australian Case Study. Case Stud. Constr. Mater. 2020, 13, e00454. [Google Scholar] [CrossRef]

- Teltayev, B.B.; Rossi, C.O.; Izmailova, G.G.; Amirbayev, E.D. Effect of Freeze-Thaw Cycles on Mechanical Characteristics of Bitumens and Stone Mastic Asphalts. Appl. Sci. 2019, 9, 458. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Fan, T.; Ping, K. Influence of Freeze–Thaw Cycles on Thermal Conductivity, Water Permeability and Mechanical Properties of Asphalt Mixtures. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 45, 953–962. [Google Scholar] [CrossRef]

- Feng, D.; Yi, J.; Wang, D.; Chen, L. Impact of Salt and Freeze–Thaw Cycles on Performance of Asphalt Mixtures in Coastal Frozen Region of China. Cold Reg. Sci. Technol. 2010, 62, 34–41. [Google Scholar] [CrossRef]

- Guo, Q.; Li, G.; Gao, Y.; Wang, K.; Dong, Z.; Liu, F.; Zhu, H. Experimental Investigation on Bonding Property of Asphalt-Aggregate Interface under the Actions of Salt Immersion and Freeze-Thaw Cycles. Constr. Build. Mater. 2019, 206, 590–599. [Google Scholar] [CrossRef]

- Karimi, M.M.; Dehaghi, E.A.; Behnood, A. A Fracture-Based Approach to Characterise Long-Term Performance of Asphalt Mixes under Moisture and Freeze-Thaw Conditions. Eng. Fract. Mech. 2021, 241, 107418. [Google Scholar] [CrossRef]

- Lövqvist, L.; Balieu, R.; Kringos, N. A Micromechanical Model of Freeze-Thaw Damage in Asphalt Mixtures. Int. J. Pavement Eng. 2019, 22, 1017–1029. [Google Scholar] [CrossRef] [Green Version]

- Tahami, S.A.; Mirhosseini, A.F.; Dessouky, S.; Mork, H.; Kavussi, A. The Use of High Content of Fine Crumb Rubber in Asphalt Mixes Using Dry Process. Constr. Build. Mater. 2019, 222, 643–653. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, L.; Feng, L.; Guo, Y. Research on Fatigue Performance of Composite Crumb Rubber Modified Asphalt Mixture under Freeze Thaw Cycles. Constr. Build. Mater. 2022, 323, 126603. [Google Scholar] [CrossRef]

- Li, D.; Leng, Z.; Wang, H.; Chen, R.; Wellner, F. Structural and Mechanical Evolution of the Multiphase Asphalt Rubber during Aging Based on Micromechanical Back-Calculation and Experimental Methods. Mater. Des. 2022, 215, 110421. [Google Scholar] [CrossRef]

- Xiao, R.; Polaczyk, P.; Huang, B. Measuring Moisture Damage of Asphalt Mixtures: The Development of a New Modified Boiling Test Based on Color Image Processing. Measurement 2022, 190, 110699. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Edmondson, V.; Dias, E. Crumb Rubber Used in Concrete to Provide Freeze–Thaw Protection (Optimal Particle Size). J. Clean. Prod. 2016, 112, 599–606. [Google Scholar] [CrossRef]

- You, L.; You, Z.; Dai, Q.; Xie, X.; Washko, S.; Gao, J. Investigation of Adhesion and Interface Bond Strength for Pavements Underlying Chip-Seal: Effect of Asphalt-Aggregate Combinations and Freeze-Thaw Cycles on Chip-Seal. Constr. Build. Mater. 2019, 203, 322–330. [Google Scholar] [CrossRef]

- ASTM C666/C666M; Test Method for Resistance of Concrete to Rapid Freezing and Thawing. Available online: http://www.astm.org/cgi-bin/resolver.cgi?C666C666M-15 (accessed on 27 January 2021).

- Makoundou, C.; Sangiorgi, C.; Johansson, K.; Wallqvist, V. Development of Functional Rubber-Based Impact-Absorbing Pavements for Cyclist and Pedestrian Injury Reduction. Sustainability 2021, 13, 11283. [Google Scholar] [CrossRef]

- EN 12697-55:2019; Bituminous Mixtures—Test Methods—Part 55: Organoleptic Assessment of Mixtures with Bitumen Emulsion. Available online: https://m.boutique.afnor.org/fr-fr/norme/bs-en-12697552019/melanges-bitumineux-methodes-dessai-pour-melange-hydrocarbone/eu161562/233434 (accessed on 19 December 2021).

- EN 12697-26:2018; Bituminous Mixtures—Test Methods—Part 26: Stiffness. Available online: https://www.sis.se/en/produkter/civil-engineering/road-engineering/road-construction-materials/ss-en-12697-262018/ (accessed on 25 August 2021).

- EN 12697-23:2017; Bituminous Mixtures—Test Methods—Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens. Available online: https://www.sis.se/en/produkter/civil-engineering/road-engineering/road-construction-materials/ss-en-12697-232017/ (accessed on 25 August 2021).

- ASTM C131/131M; Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. Available online: http://www.astm.org/cgi-bin/resolver.cgi?C131C131M-20 (accessed on 25 August 2021).

- EN 12697-6:2020; Bituminous Mixtures. Test Methods. Determination of Bulk Density of Bituminous Specimens. Available online: https://shop.bsigroup.com/products/bituminous-mixtures-test-methods-determination-of-the-bulk-density-of-bituminous-specimens (accessed on 19 December 2021).

- EN 12697-5:2018; Bituminous Mixtures. Test Methods. Determination of the Maximum Density. Available online: https://shop.bsigroup.com/products/bituminous-mixtures-test-methods-determination-of-the-maximum-density/tracked-changes (accessed on 19 December 2021).

- EN 12697-8:2018; Bituminous Mixtures. Test Methods. Determination of Void Characteristics of Bituminous Specimens. Available online: https://shop.bsigroup.com/products/bituminous-mixtures-test-methods-determination-of-void-characteristics-of-bituminous-specimens/tracked-changes (accessed on 19 December 2021).

- Building Materials, Soil and Dredging Spoil. Available online: https://business.gov.nl/regulation/building-materials-soil-dredging-spoil/ (accessed on 27 January 2022).

| (Volume of the Total Mix) | Warm PmB (SBS) | Cold PmE (SBS) | ||

|---|---|---|---|---|

| R1-W | R2-W | R1-C | R2-C | |

| Rubber amount [%] | 56 | 56 | ||

| Binder amount [%] | 15 | 18 | ||

| Aggregates and filler [%] | 29 | 26 | ||

| Mixes | EN12697-6 D Density [kg/m3] | EN12697-5 B Maximum Density [kg/m3] | EN12697-8 VA (%) | EN12697-8 VMA (%) |

|---|---|---|---|---|

| R1-W | 1.467 ± 0.058 | 1.396 | 4.7 ± 3.7 | 34.0 ± 4.8 |

| R2-W | 1.406 ± 0.030 | 1.458 | 3.5 ± 2.0 | 31.7 ± 1.4 |

| R1-C | 1.300 ± 0.036 | 1.544 | 16.6 ± 2.3 | 42.4 ± 1.3 |

| R2-C | 1.430 ± 0.026 | 1.605 | 11.1 ± 1.6 | 39.7 ± 1.1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Makoundou, C.; Sangiorgi, C. Influence of Freeze–Thaw Cycles on the Mechanical Properties of Highly Rubberised Asphalt Mixtures Made with Warm and Cold Asphalt Binders. Materials 2022, 15, 2701. https://doi.org/10.3390/ma15072701

Makoundou C, Sangiorgi C. Influence of Freeze–Thaw Cycles on the Mechanical Properties of Highly Rubberised Asphalt Mixtures Made with Warm and Cold Asphalt Binders. Materials. 2022; 15(7):2701. https://doi.org/10.3390/ma15072701

Chicago/Turabian StyleMakoundou, Christina, and Cesare Sangiorgi. 2022. "Influence of Freeze–Thaw Cycles on the Mechanical Properties of Highly Rubberised Asphalt Mixtures Made with Warm and Cold Asphalt Binders" Materials 15, no. 7: 2701. https://doi.org/10.3390/ma15072701

APA StyleMakoundou, C., & Sangiorgi, C. (2022). Influence of Freeze–Thaw Cycles on the Mechanical Properties of Highly Rubberised Asphalt Mixtures Made with Warm and Cold Asphalt Binders. Materials, 15(7), 2701. https://doi.org/10.3390/ma15072701