A Review on Roller Compaction Quality Control and Assurance Methods for Earthwork in Five Application Scenarios

Abstract

:1. Introduction

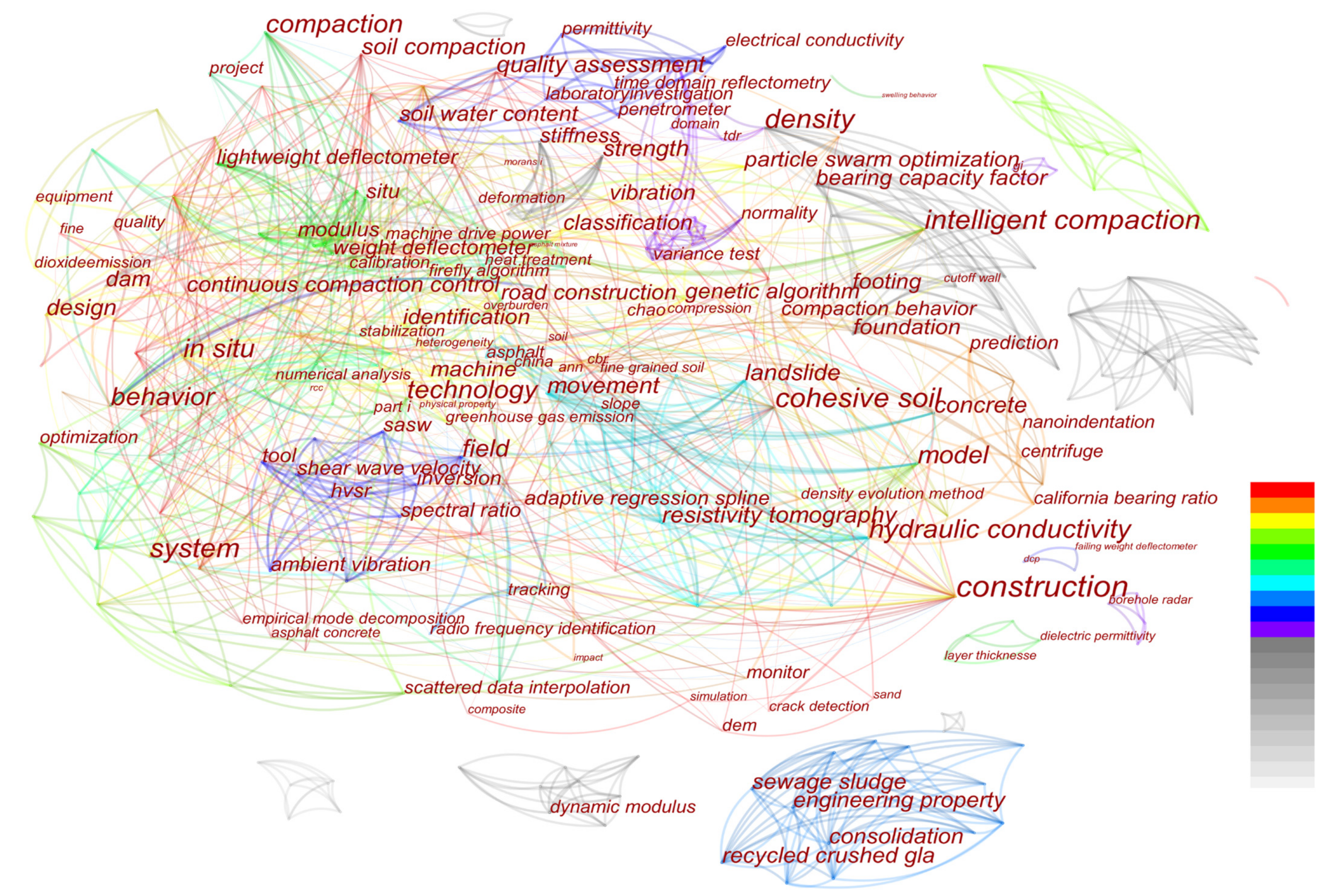

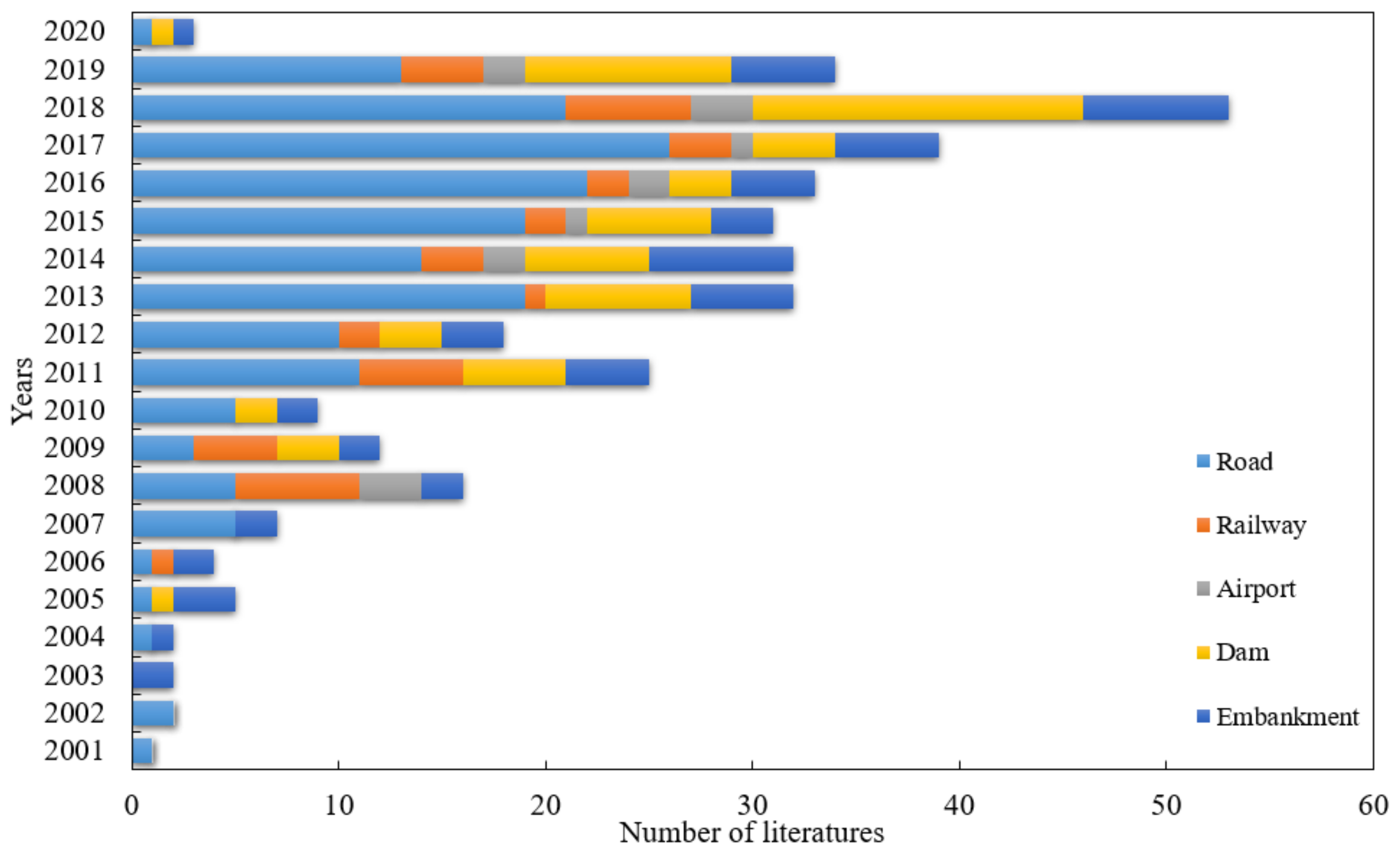

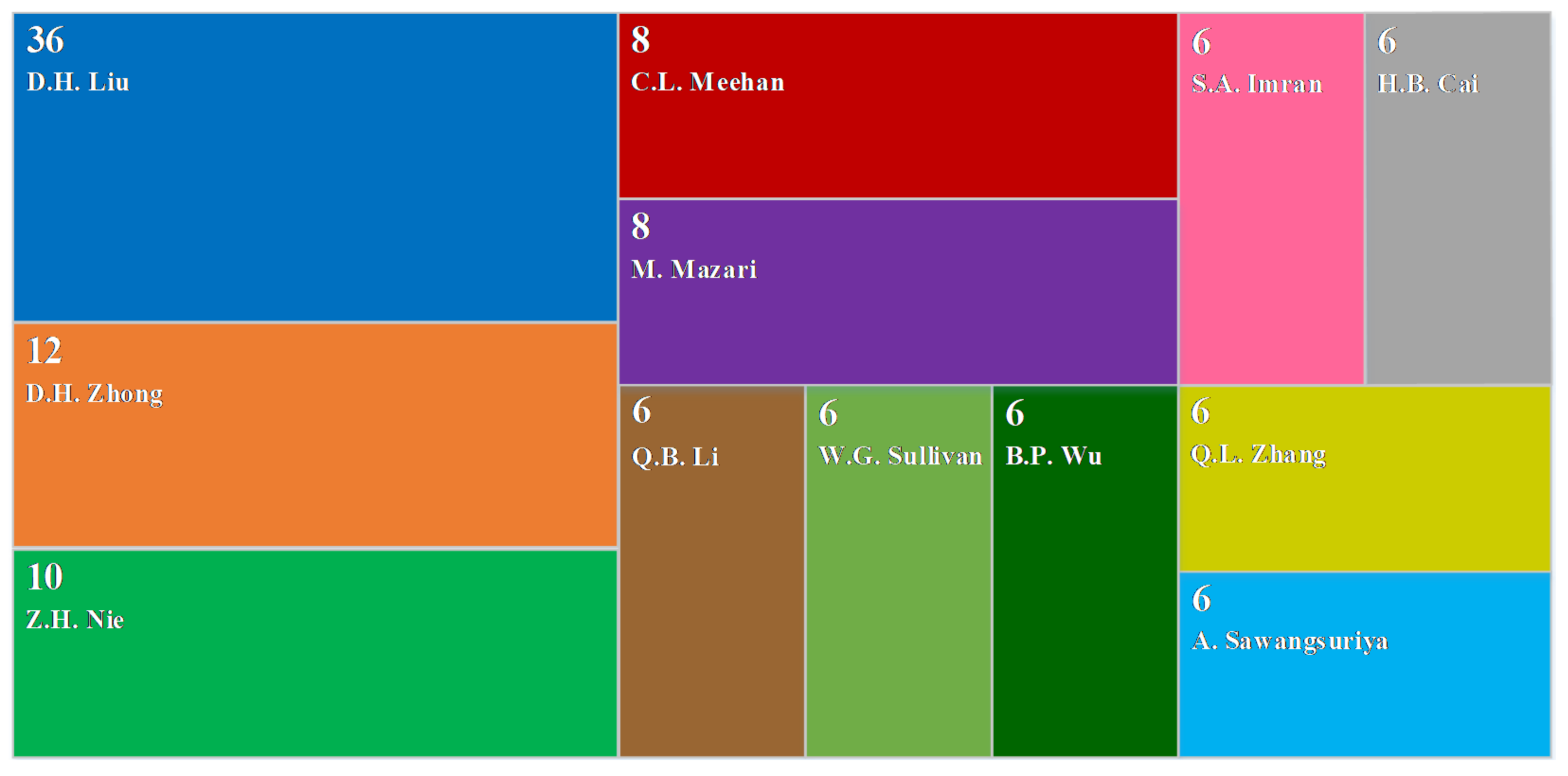

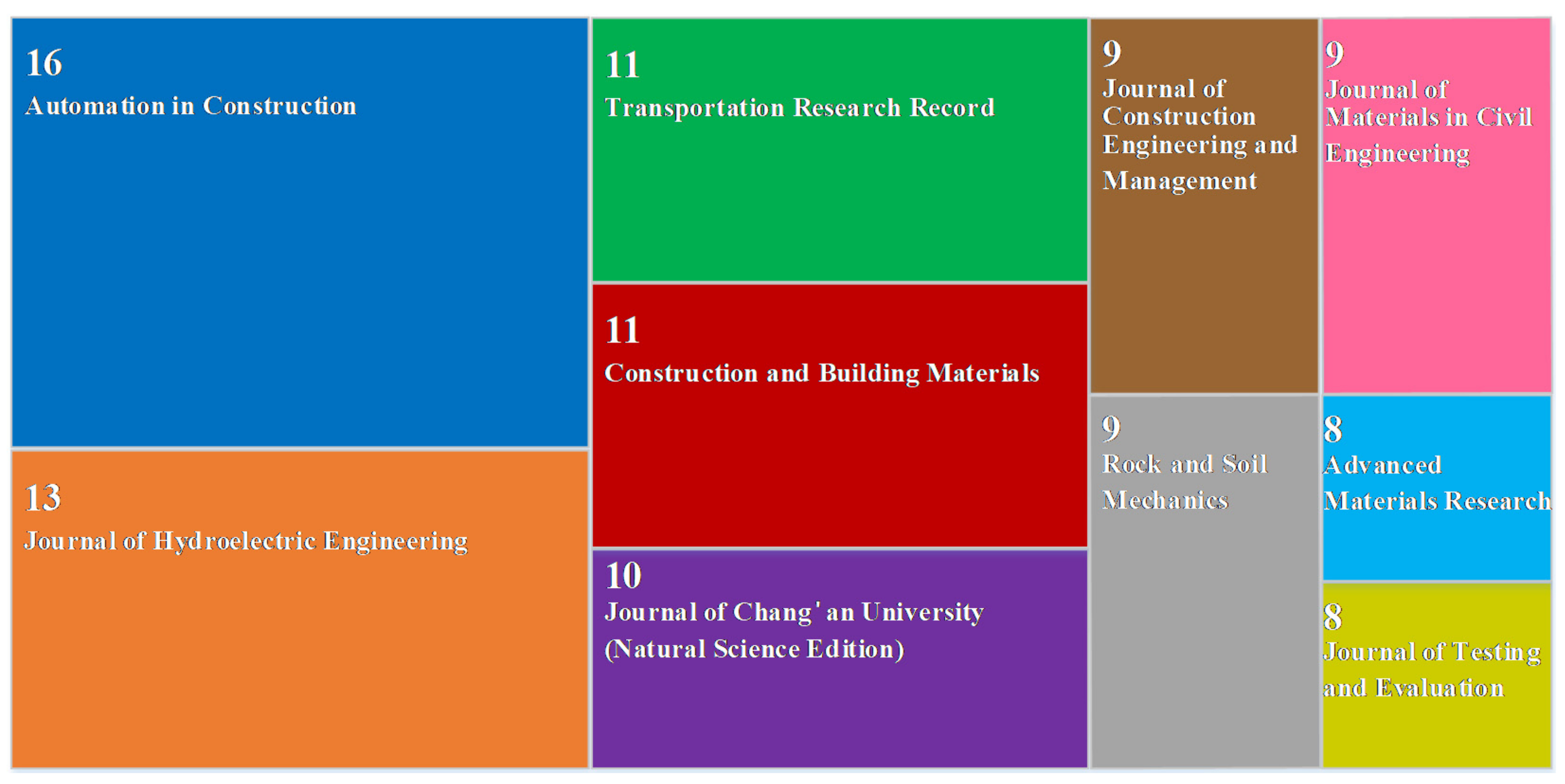

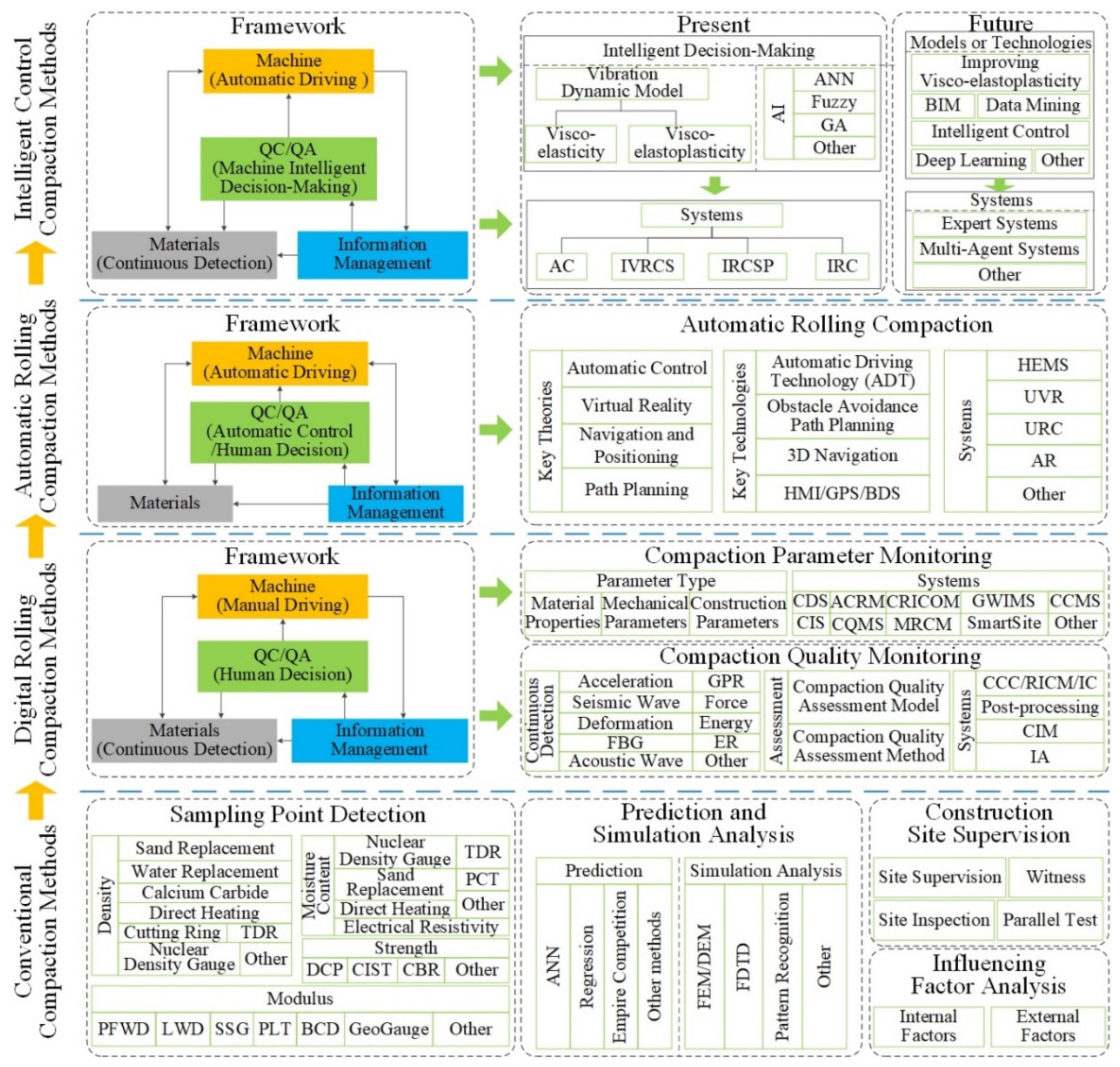

2. Methodology and Classification

2.1. Research Scope

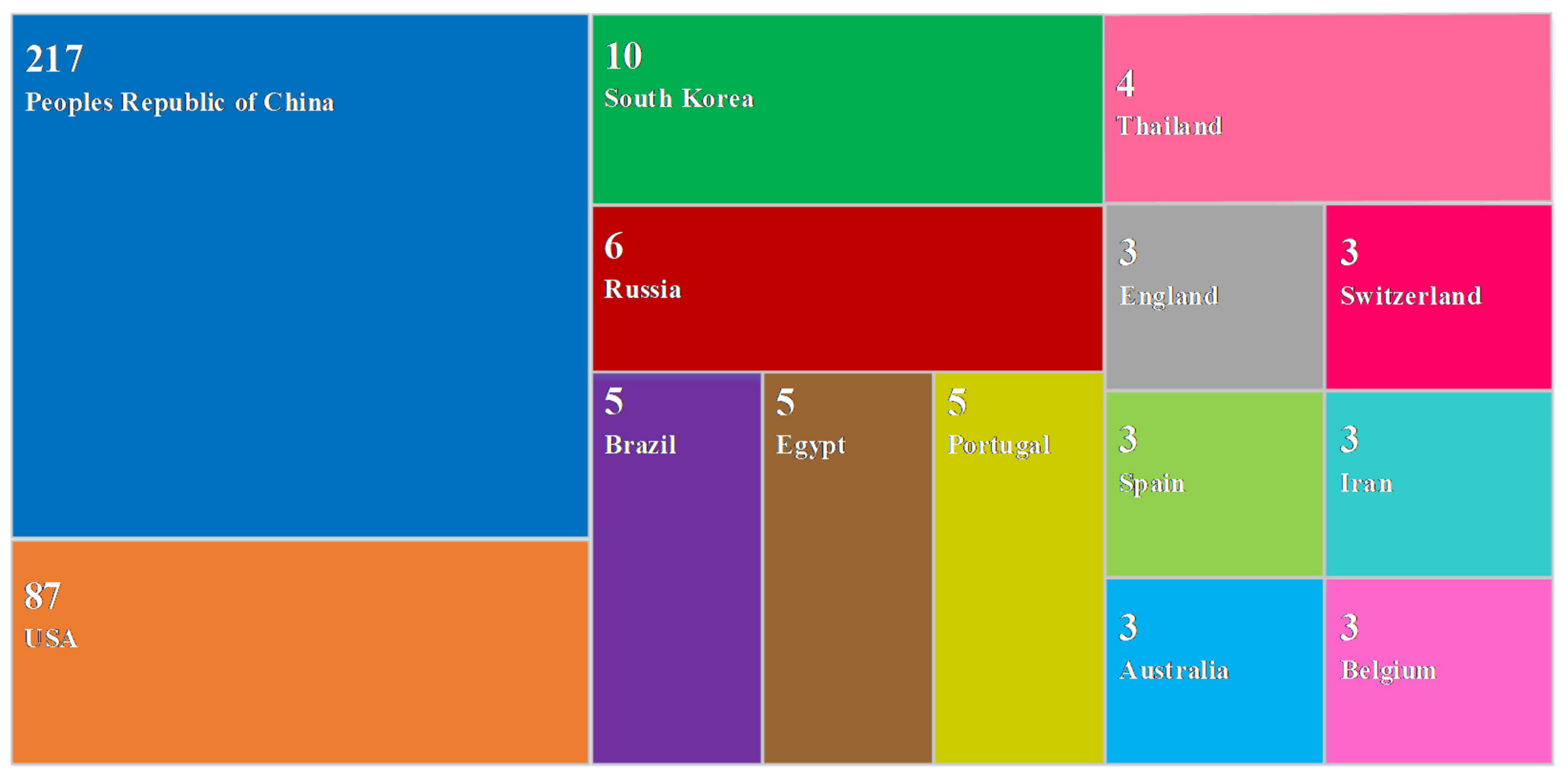

2.2. Literature Sources and Statistics

2.3. Classification of Compaction Quality Control and Assurance Methods for Earthwork

3. Conventional Compaction Method

3.1. Sampling Point Detection

3.2. Prediction and Simulation Analysis

3.3. Construction Site Supervision

3.4. Influencing Factor Analysis

4. Digital Rolling Compaction Method

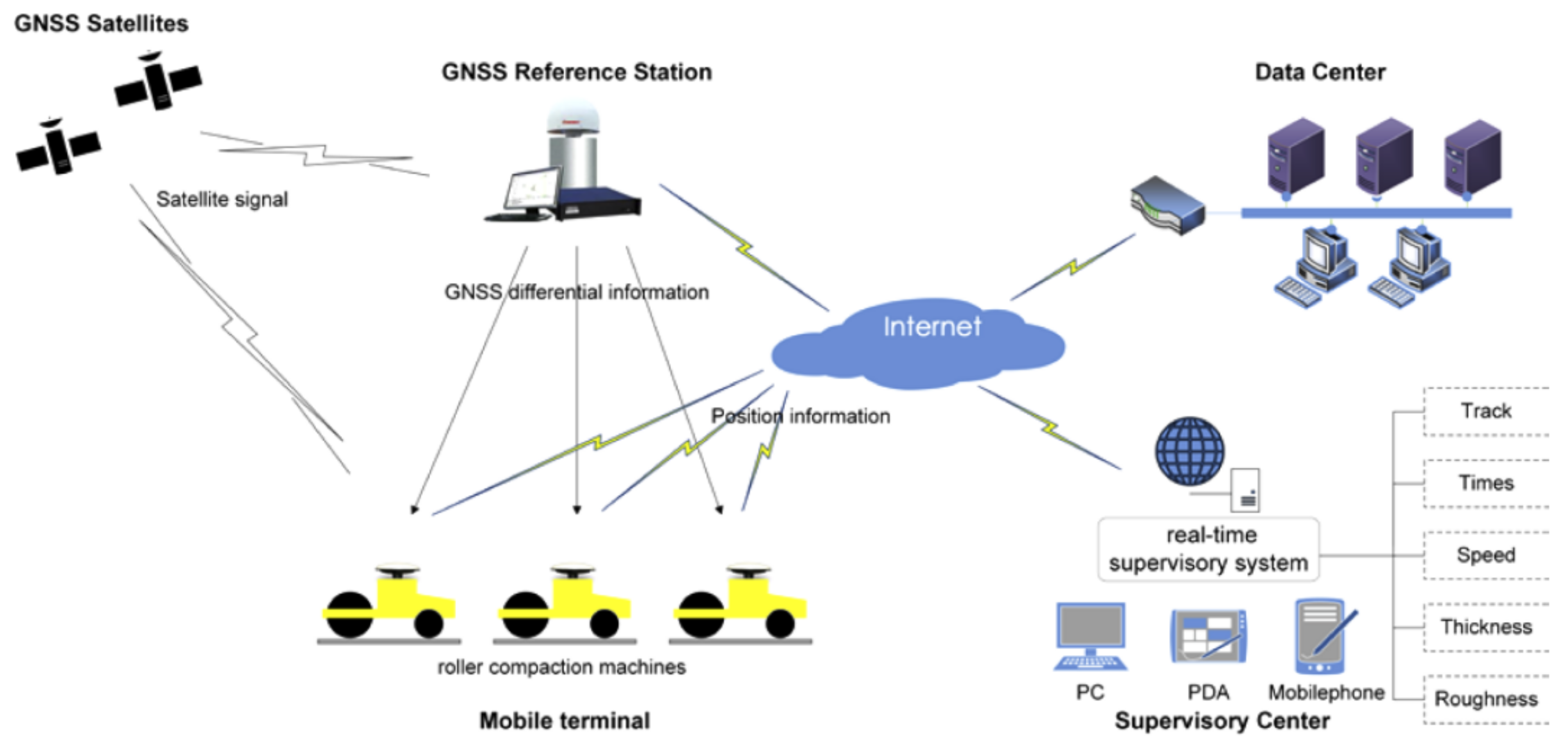

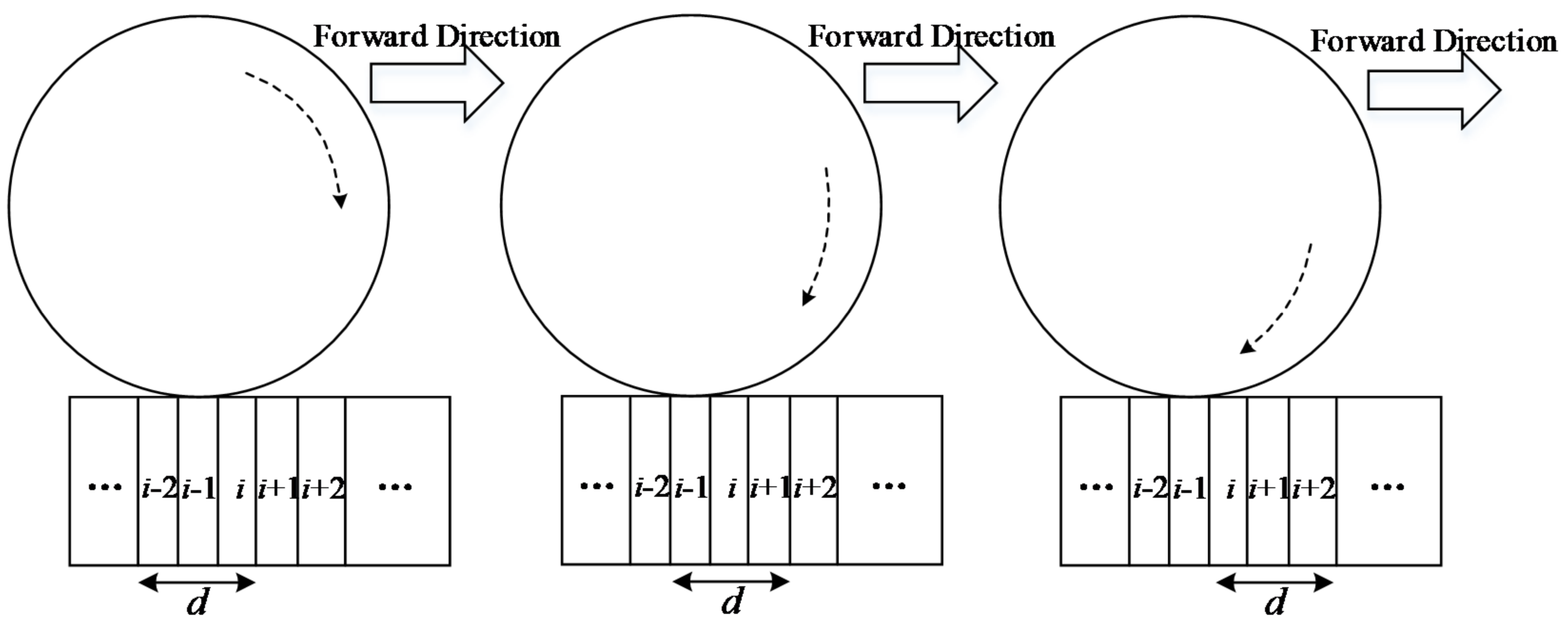

4.1. Compaction Parameter Monitoring

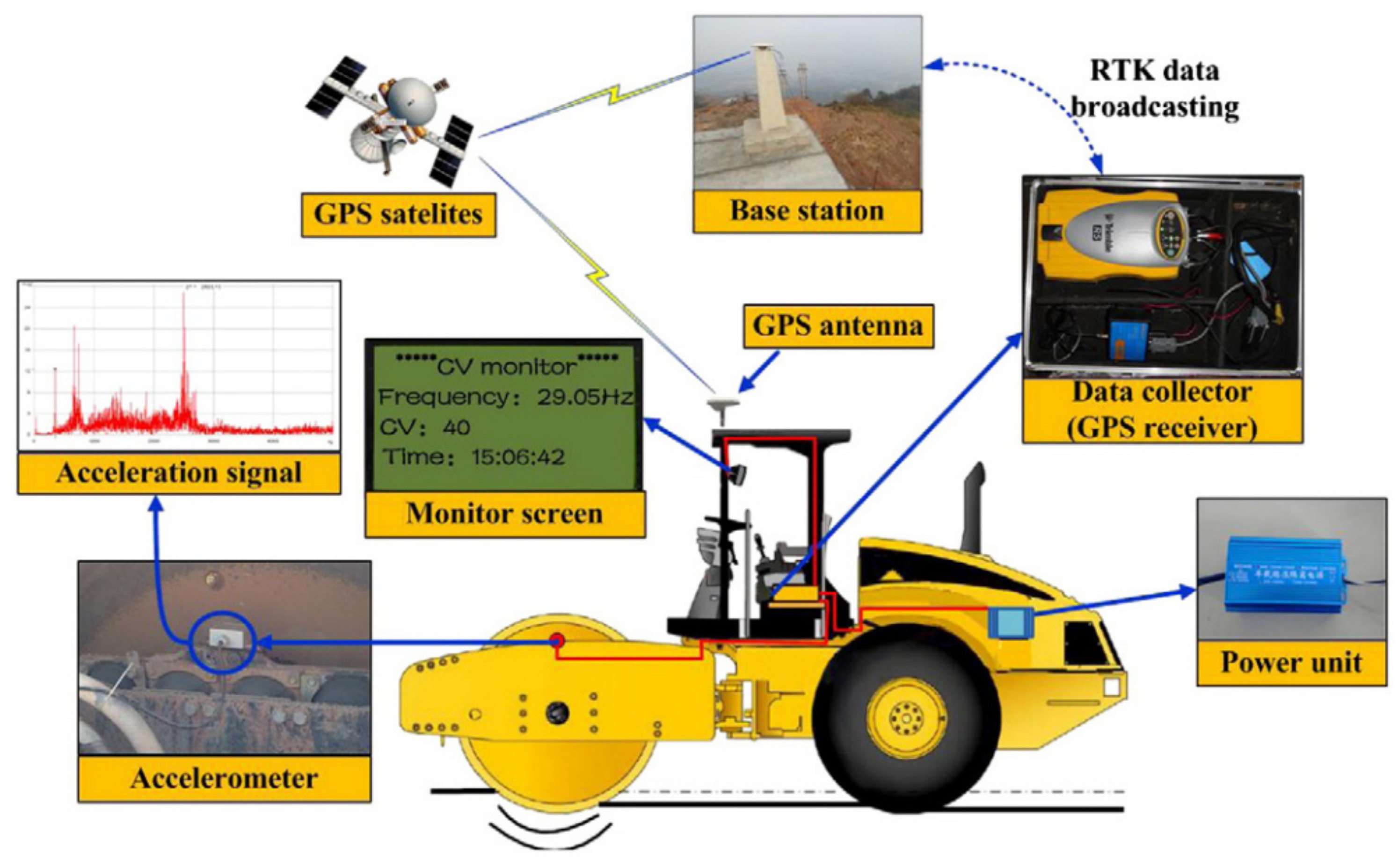

4.2. Compaction Quality Monitoring

4.2.1. Continuous Detection Method

4.2.2. Compaction Quality Assessment

4.2.3. Compaction Quality Monitoring Systems

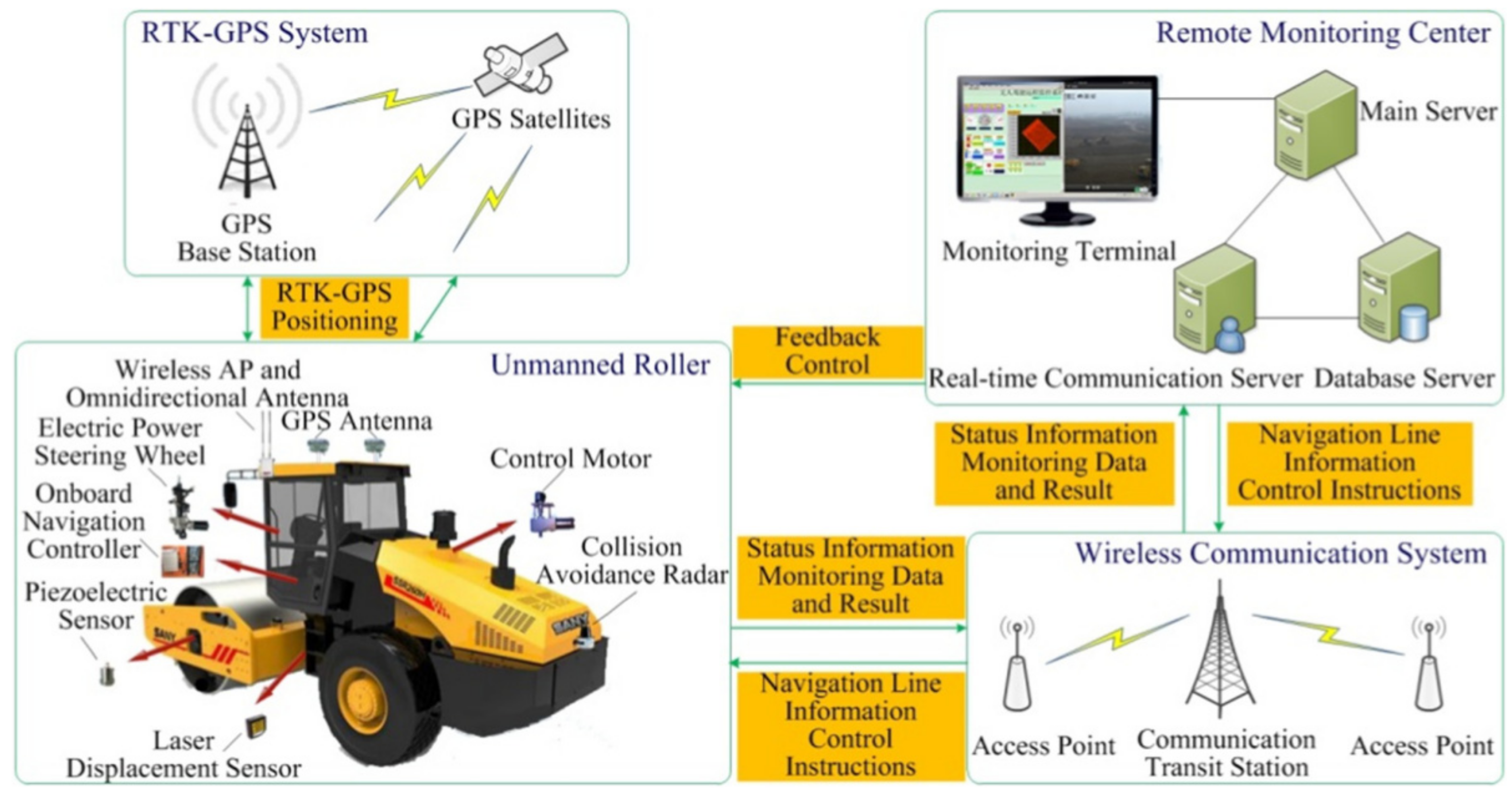

5. Automatic Rolling Compaction Method

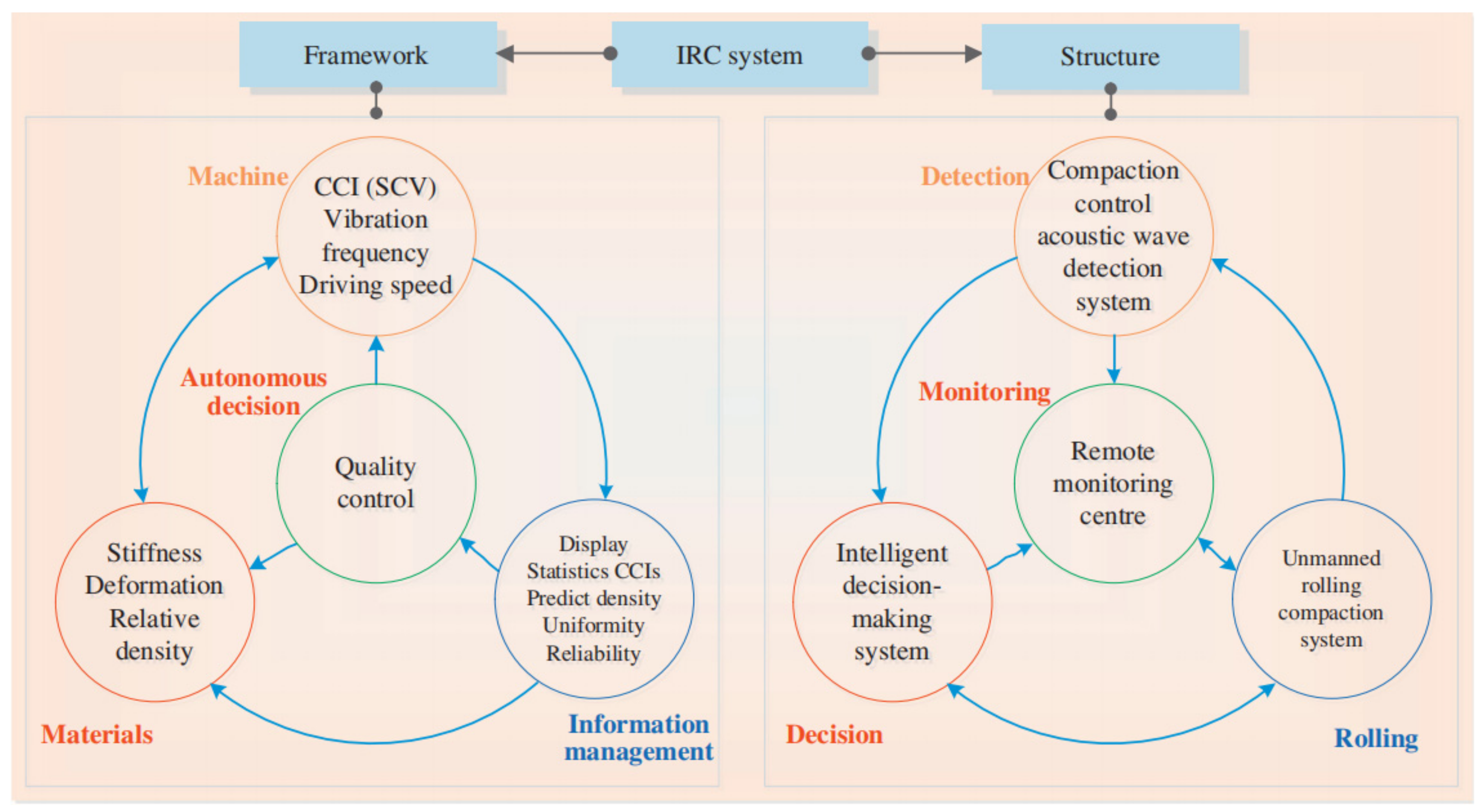

6. Intelligent Control Compaction Method

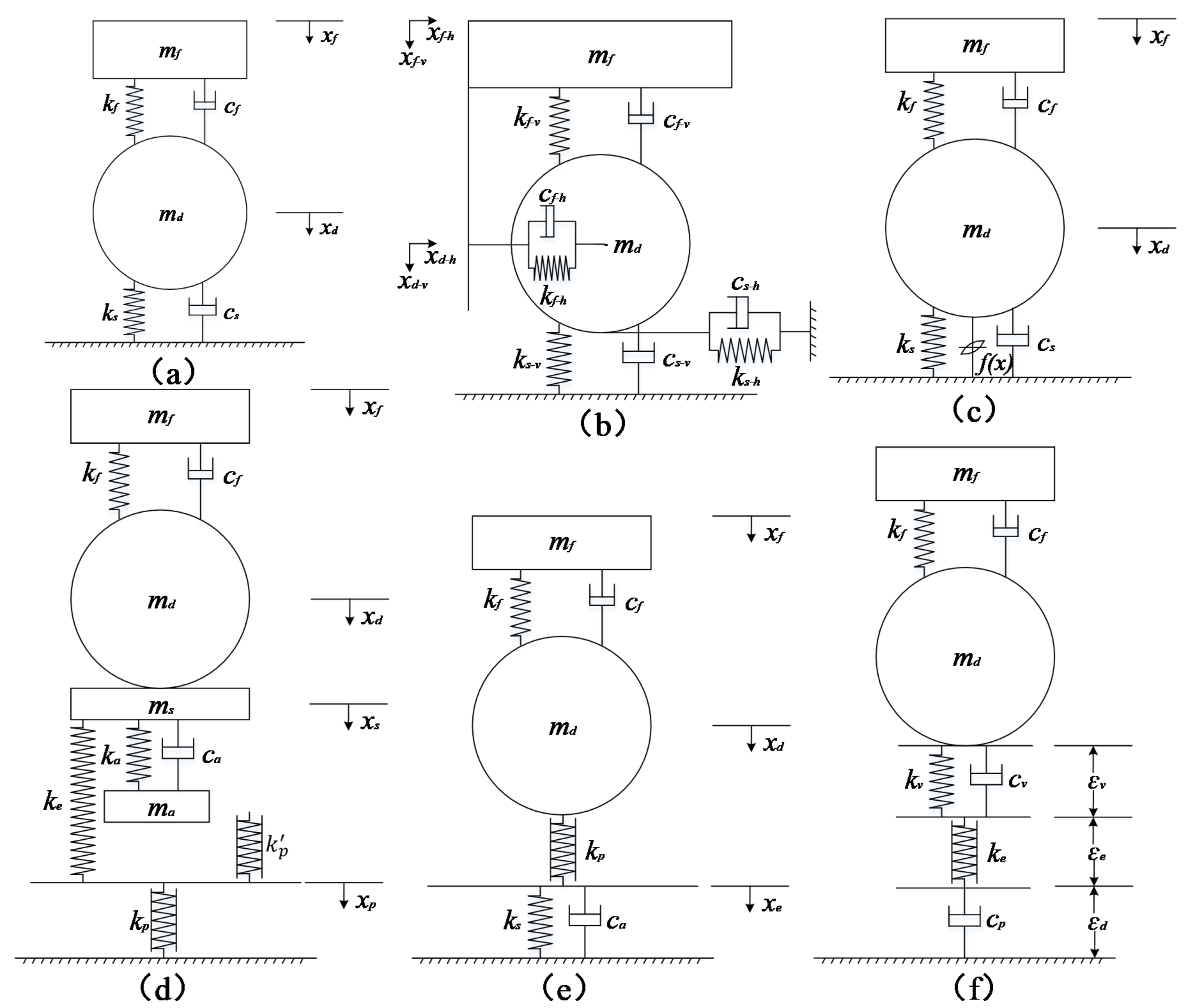

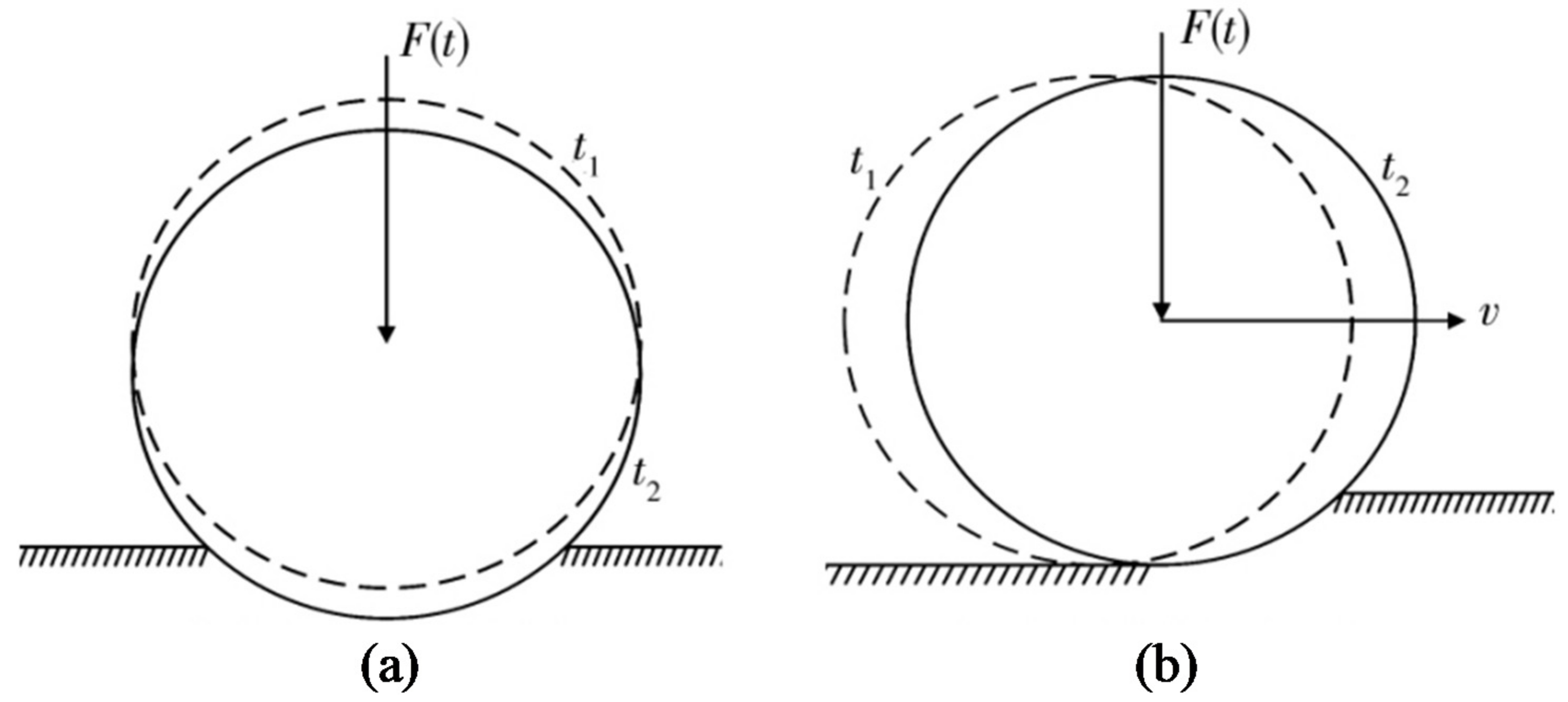

6.1. Vibration Compaction Model

6.1.1. Viscoelastic Model

6.1.2. Viscoelastic Plastic Model

6.2. Prediction Model Based on AI

6.3. Compound Model

6.4. Intelligent Control Compaction Systems

7. Conclusions and Future Directions

- In terms of digital rolling compaction methods, a comprehensive CCI measurement system considering the uncertainty is needed for single-layer analysis; a simple and realistic mathematical representation of the complex compaction dynamics is also required; real-time calculation and analysis of multi-source heterogeneous data is also an important research direction; standardized application process and cost-benefit assessment in the context of the full life cycle are necessary to be established; improving the utilization level of data in the construction stage and integrating the type of method into the on-site project management architecture more reasonably is also a topic worth studying.

- As far as automatic rolling compaction methods are concerned, the biggest challenges causing slow adoption of methods have been identified as: lack of targeted specifications, unstandardized construction procedures, multi-machine collaborative rolling, adaptive path planning issues, scheduling, and management issues are the research priorities that need to be focused on the next step.

- For intelligent control compaction methods, specifications and construction procedures remain to be gradually formulated and standardized; the effective improvement of computing power and data management level is also an inevitable development trend; the real-time data transmission awaits further optimization. In addition, other directions are gradually attracting the attention of relevant researchers, such as improving visco-elastoplasticity, convergent use of new technologies (BIM, data mining, intelligent control, deep learning, et al.), design and development of expert systems, multi-agent systems and other intelligent control compaction systems, fusion application of pluralistic control thought, and intelligent control theory.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CMV | Compaction Meter Value |

| RMV | Resonant Meter Value |

| CCV | Compaction Control Value |

| CV | Compaction Value |

| CF | Crest Factor Value |

| Acceleration Peak Value | |

| OMV | Oscillometer Value |

| AA | Acceleration Amplitude |

| Turbulence Factor | |

| THD | Total Harmonic Distortion |

| P-wave Velocity | |

| S-wave Velocity | |

| VCV | Vibratory Compaction Value |

| Improved Index of Ground Reaction Force Index | |

| Material Stiffness | |

| Geomaterial Dynamic Modulus | |

| Intelligent Compaction Analyzer Modulus | |

| MDP | Machine Drive Power |

| Omega | Energy Transmitted to the Soil |

| E | Compaction Power Per Unit Volume |

| DMV | Dissipation Measured Value |

| CEV | Compaction Energy Value |

| SCV | Sound Compaction Value |

| CSD | Contact Stress Distribution |

| NCI | Normalized Compaction Indicator |

References

- Cai, H.; Kuczek, T.; Dunston, P.S.; Li, S. Correlating Intelligent Compaction Data to In Situ Soil Compaction Quality Measurements. J. Constr. Eng. Manag. 2017, 143, 04017038. [Google Scholar] [CrossRef]

- Xu, Q.W.; Chang, G.K. Adaptive quality control and acceptance of pavement material density for intelligent road construction. Autom. Constr. 2016, 62, 78–88. [Google Scholar] [CrossRef]

- White, D.J.; Vennapusa, P.K.R.; Gieselman, H.H. Field assessment and specification review for roller-integrated compaction monitoring technologies. Adv. Civ. Eng. 2011, 2011, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Fernandes, F.M.; Pereira, M.; Correia, A.G.; Lourenco, P.B.; Caldeira, L. Assessment of layer thickness and uniformity in railway embankments with ground penetrating radar. In Proceedings of the 1st International Conference on Transportation Geotechnics, Nottingham, UK, 25–27 August 2008; pp. 571–575. [Google Scholar]

- Nie, Z.-H.; Wang, X.; Jiao, T. Anomalous Data Detection for Roller-Integrated Compaction Measurement. Int. J. Géoméch. 2016, 16, B4015004. [Google Scholar] [CrossRef]

- Zagyapan, M.; Fairfield, C. Continuous surface wave and impact methods of measuring the stiffness and density of railway ballast. NDT E Int. 2002, 35, 75–81. [Google Scholar] [CrossRef]

- Yao, Y.-P.; Ruan, Y.-Z.; Chen, J.; Geng, Y.; Zhang, X.; Liu, B.-Y.; Zong, X.-P.; Yu, G.-Z. Research on a Real-Time Monitoring Platform for Compaction of High Embankment in Airport Engineering. J. Constr. Eng. Manag. 2018, 144, 04017096. [Google Scholar] [CrossRef]

- Wang, L. A research on applying digital monitoring technology in airport field engineering. J. Civ. Aviat. 2019, 3, 22–24. [Google Scholar]

- Liu, D.; Sun, J.; Zhong, D.; Song, L. Compaction Quality Control of Earth-Rock Dam Construction Using Real-Time Field Operation Data. J. Constr. Eng. Manag. 2012, 138, 1085–1094. [Google Scholar] [CrossRef]

- Zhang, Q.L.; Liu, T.Y.; Zhang, Z.S.; Huangfu, Z.H.; Li, Q.B.; An, Z.Z. Compaction quality assessment of rockfill materials using roller-integrated acoustic wave detection technique. Autom. Constr. 2019, 97, 110–121. [Google Scholar] [CrossRef]

- Dondi, G.; Sangiorgi, C.; Lantieri, C. Applying geostatistics to continuous compaction control of construction and demolition materials for road embankments. J. Geotech. Geoenviron. 2014, 140, 06013005. [Google Scholar] [CrossRef]

- He, Z.L.; Zhang, J.Y. Compaction quality inspection method of soil-rock filled embankment based on continuous compaction control technology. Adv. Civ. Eng. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Y.; Chen, J.; Zhang, Y. Intelligent compaction practice and development: A bibliometric analysis. Eng. Constr. Arch. Manag. 2019, 27, 1213–1232. [Google Scholar] [CrossRef]

- White, D.J.; Vennapusa, P.K.R. Report of the Workshop on Intelligent Construction for Earthworks; EERC Publication ER09–02; Sheraton West Des Moines Hotel: West Des Moines, IA, USA, 2009; pp. 1–156. [Google Scholar]

- White, D.J.; Vennapusa, P.K. A Review of Roller-Integrated Compaction Monitoring Technologies for Earthworks; Final Report ER10-04; Iowa State University: Ames, IA, USA, 2010; pp. 1–36. [Google Scholar]

- Liu, D.; Lin, M.; Li, S. Real-Time Quality Monitoring and Control of Highway Compaction. Autom. Constr. 2015, 62, 114–123. [Google Scholar] [CrossRef]

- Zhang, Q.; An, Z.; Liu, T.; Zhang, Z.; Huangfu, Z.; Li, Q.; Yang, Q.; Liu, J. Intelligent rolling compaction system for earth-rock dams. Autom. Constr. 2020, 116, 103246. [Google Scholar] [CrossRef]

- White, D.J.; Jaselskis, E.J.; Schaefer, V.R.; Cackler, E.T. Real-time compaction monitoring in cohesive soils from machine response. Transport. Res. Rec. 2005, 1936, 173–180. [Google Scholar] [CrossRef]

- Sandström, A.J.; Pettersson, J.C. Intelligent systems for QA/QC in soil compaction. In Proceedings of the Annual Transportation Research Board Meeting, Washington, DC, USA, 11–14 January 2004; Transportation Research Board: Washington, DC, USA, 2004; pp. 1–17. [Google Scholar]

- Kumar, S.A.; Aldouri, R.; Nazarian, S.; Si, J. Accelerated assessment of quality of compacted geomaterials with intelligent compaction technology. Constr. Build. Mater. 2016, 113, 824–834. [Google Scholar] [CrossRef]

- Adam, D. Continuous compaction control (CCC) with vibratory rollers. Environmental Geotechnics. In Proceedings of the 1st Australia-New Zealand Conference on Environmental Geotechnics-Geoenvironment 97, Melbourne, Victoria, Australia, 26–28 November 1997; A. A. Balkema: Rotterdam, The Netherlands, 1997; pp. 245–250. [Google Scholar]

- Pistrol, J.; Villwock, S.; Völkel, W.; Kopf, F.; Adam, D. Continuous Compaction Control (CCC) with Oscillating Rollers. Procedia Eng. 2016, 143, 514–521. [Google Scholar] [CrossRef] [Green Version]

- Meehan, C.L.; Cacciola, D.V.; Tehrani, F.S.; Baker, W.J., III. Assessing soil compaction using continuous compaction control and location-specific in situ tests. Autom. Constr. 2017, 73, 31–44. [Google Scholar] [CrossRef]

- Liu, D.H.; Li, Z.L.; Lian, Z.H. Compaction quality assessment of earth-rock dam materials using roller-integrated compaction monitoring technology. Autom. Constr. 2014, 44, 234–246. [Google Scholar] [CrossRef]

- White, D.J.; Thompson, M.J. Relationships between In Situ and Roller-Integrated Compaction Measurements for Granular Soils. J. Geotech. Geoenvironmental Eng. 2008, 134, 1763–1770. [Google Scholar] [CrossRef]

- Nie, Z.H.; Jiao, T.; Wang, X.; Qiu, T. Assessment of compaction quality based on two index parameters from roller-integrated compaction measurements. J. Test. Eval. 2018, 46, 428–433. [Google Scholar] [CrossRef]

- Vennapusa, P.K.R.; White, D.J.; Reddy, K.R.; Yesiller, N.; Zekkos, D.; Farid, A. Machine Drive Power Based Roller-Integrated Compaction Measurements for Cohesive Embankment Construction. Geo. Chic. 2016, 2016, 571–580. [Google Scholar] [CrossRef]

- FHWA. Intelligent Compaction Measurement Values (ICMV); U.S. Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2014; pp. 1–9.

- Briaud, J.; Seo, J. Intelligent Compaction: Overview and Research Needs; Texas A&M University: College Station, TX, USA, 2003; pp. 1–84. [Google Scholar]

- Anderegg, R.; Kaufmann, K. Intelligent compaction with vibratory rollers: Feedback control systems in automatic compaction and compaction control. Transport. Res. Rec. 2004, 1868, 124–134. [Google Scholar] [CrossRef]

- Xu, Q.; Chang, G.K.; Gallivan, V.L. Development of a systematic method for intelligent compaction data analysis and management. Constr. Build. Mater. 2012, 37, 470–480. [Google Scholar] [CrossRef]

- Rinehart, R.V.; Mooney, M.A.; Facas, N.F.; Musimbi, O.M. Examination of roller-integrated continuous compaction control on Colorado test site. Transport. Res. Rec. 2012, 2310, 3–9. [Google Scholar] [CrossRef]

- Kassem, E.; Liu, W.T.; Scullion, T.; Masad, E.; Chowdhury, A. Development of compaction monitoring system for asphalt pavements. Constr. Build. Mater. 2015, 96, 334–345. [Google Scholar] [CrossRef]

- Xu, G.H.; Gao, H.; Luo, Z.H.; Huang, J.; Wang, D.S. Application of continuous and intelligent compaction control technology in high-speed railway construction. Road Mach. Constr. Mech. 2017, 34, 30–34. [Google Scholar]

- Yao, Y.P.; Ruan, Y.Z.; Liu, B.Y.; Chen, J.; Jiang, H.X. Control technology of construction quality for high filled airport based on Beidou satellite navigation system. Chin. J. Geotech. Eng. 2015, 37, 6–10. [Google Scholar]

- Zhang, Q.; Liu, T.; Li, Q. Roller-Integrated Acoustic Wave Detection Technique for Rockfill Materials. Appl. Sci. 2017, 7, 1118. [Google Scholar] [CrossRef] [Green Version]

- An, Z.Z.; Liu, T.Y.; Huangfu, Z.H.; Zhang, Q.L.; Li, C.S.; Li, Q.B. Neural network model for evaluating compaction quality of rockfill materials by compaction meter value. J. Hydroelectr. Eng. 2020, 39, 110–120. [Google Scholar]

- Zhang, Q.; Liu, T.; Zhang, Z.; Huangfu, Z.; Li, Q.; An, Z. Unmanned rolling compaction system for rockfill materials. Autom. Constr. 2019, 100, 103–117. [Google Scholar] [CrossRef]

- Fang, X.; Bian, Y.; Yang, M.; Liu, G. Development of a path following control model for an unmanned vibratory roller in vibration compaction. Adv. Mech. Eng. 2018, 10, 1–16. [Google Scholar] [CrossRef] [Green Version]

- Yang, M.; Bian, Y.; Liu, G.; Zhang, H. Path Tracking Control of an Articulated Road Roller with Sideslip Compensation. IEEE Access 2020, 8, 127981–127992. [Google Scholar] [CrossRef]

- Chen, Z.Y.; Zhao, Y.F.; Zhou, B.; Jiang, L.; Zhao, H.M. Study and application of unmanned driving technology or filling and rolling construction of earth-rockfill dam. Water Resour. Hydropower Eng. 2019, 50, 1–7. [Google Scholar]

- Shi, M.N.; Cui, B.; Wang, J.J.; Guan, T.; Tong, D.W.; Ren, B.Y. Research on cooperative complete coverage path planning for unmanned roller group under complex construction conditions. J. Hydraul. Eng. 2020, 51, 1544–1557. [Google Scholar]

- Shi, G.S. Implementation and application of unmanned rolling dam construction technology for high arch dam. Build. Tech. Dev. 2020, 47, 31–33. [Google Scholar]

- Lin, S.M.; Wang, G.Y. An Intelligent Rolling Compaction System for Subgrade and Pavement. CN Patent CN109356003A, 2018. [Google Scholar]

- Li, Q.B.; Zhang, Q.L.; An, Z.Z.; Liu, T.Y. An Intelligent Rolling Compaction System for Earthwork. CN Patent CN201810720255.3, 2018. [Google Scholar]

- Botev, V.; Azidhak, A. Intelligent Compaction-Autonomous Compactor Concept Evaluation. Master’s Thesis, University of Gothenburg, Göteborg, Sweden, 2015; pp. 1–73. [Google Scholar]

- Luo, X.Q.; Bi, J.F. Unmanned Intelligent Vibratory Roller Compactor and System for Rolling Earthwork. CN Patent CN107761701A, 2018. [Google Scholar]

- China Electricity Council. D/T5129-2013-Specifications for Rolled Earth-Rockfill Dam Construction; China Electric Power Press: Beijing, China, 2013. [Google Scholar]

- Research Institute of Highway Ministry of Transport. JTG/T F20-2015-Technical Guidelines for Construction of Highway Roadbases; China Communications Press: Beijing, China, 2015. [Google Scholar]

- CCCC Third Highway Engineering Co. Ltd. JTG/T 3610-2019-Technical Specifications for Construction of Highway Subgrades; China Communications Press: Beijing, China, 2015. [Google Scholar]

- FHWA Generic Soils IC Specification. Intelligent Compaction Technology for Soil Application; Federal Highway Administration, US, Department of Transportation: Washington, DC, USA, 2014.

- Southwest Jiaotong University. Q/CR 9210-2015-Technical Specification for Continuous Compaction Control of Fill Engineering of Railway Earth Structure; China Railway Publishing House: Beijing, China, 2015. [Google Scholar]

- Barman, M.; Imran, S.A.; Nazari, M.; Commuri, S.; Zaman, M. Intelligent Compaction of Stabilized Subgrade of Flexible Pavement. IFCEE 2015, 2015, 2554–2566. [Google Scholar] [CrossRef]

- Patel, S.; Mani, I. Effect of multiple passes of tractor with varying normal load on subsoil compaction. J. Terramechanics 2011, 48, 277–284. [Google Scholar] [CrossRef]

- Chen, J.; Huang, B.; Shu, X.; Hu, C. DEM Simulation of Laboratory Compaction of Asphalt Mixtures Using an Open Source Code. J. Mater. Civ. Eng. 2015, 27, 04014130. [Google Scholar] [CrossRef]

- ASTM. D4914-2008; Standard Test Methods for Density and Unit Weight of Soil and Rock in Place by the Sand Replacement Method in a Test Pit. Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM. D7830/D7830M-14; Standard Test Methods for In-place Density (unit weight) and Water Content of Soil Using an Electromagnetic Soil Density Gauge. Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM. D4959-2007; Standard Test Methods for Determination of Water (Moisture) Content of Soil by Direct Heating. Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM. D6938-2017; Standard Test Methods for In-place Density and Water Content of Soil and Soil-Aggregate by Nuclear methods. Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2007.

- Power China, Chengdu Engineering Corporation Limited. DL/T5356-2006-Code for Coarse-Grained Soil Tests for Hydropower and Water Conservancy Engineering; China Electric Power Press: Beijing, China, 2006. [Google Scholar]

- De Resende, L.R.M.; Filho, W.L.D.O.; Nogueira, C.D.L. Use of the DCP test for compaction control of staged dikes in mining tailings dams. Rem. Rev. Esc. Minas 2013, 66, 493–498. [Google Scholar] [CrossRef] [Green Version]

- ASTM. D5874-02; Standard Test Methods for Determination of the Impact Value (IV) of a Soil. Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM. D2583-2007; Standard Test Methods for Measuring Deflections with a Lightweight Deflect Meter (LWD). Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM. D6758-18; Standard Test Methods for Measuring Stiffness and Apparent Modulus of Soil and Soil-Aggregate in-Place by an Electro-Mechanical Method. Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2018.

- Brandl, H.; Adam, D. Sophisticated Continuous Compaction Control of Soils and Granular Materials. In Proceedings of the 14th International Conference on Soil Mechanics and Foundation Engineering, Hamburg, Germany, 6–12 September 1997; pp. 1–6. [Google Scholar]

- McCook, D.; Shanklin, D.W. NRCS experience with field density test methods including the sand-cone, nuclear gage, rubber balloon, drive-cylinder, and clod test. In Constructing and Controlling Compaction of Earth Fills; Shanklin, D., Talbot, J., Rademacher, K., Eds.; ASTM International: West Conshohocken, PA, USA, 2000; pp. 92–2000. [Google Scholar]

- Arvidsson, J.; Keller, T. Sill stress as affected by wheel load and tyre inflation pressure. Soil. Till. Res. 2007, 96, 284–291. [Google Scholar] [CrossRef]

- Lamandé, M.; Schjønning, P.; Tøgersen, F.A. Mechanical behaviour of an undisturbed soil subjected to loadings: Effects of load and contact area. Soil Tillage Res. 2007, 97, 91–106. [Google Scholar] [CrossRef]

- Lamandé, M.; Schjønning, P. Transmission of vertical stress in a real soil profile. Part II: Effect of tyre size, inflation pressure and wheel load. Soil Tillage Res. 2011, 114, 71–77. [Google Scholar] [CrossRef]

- Ansorge, D.; Godwin, R. The effect of tyres and a rubber track at high axle loads on soil compaction, Part 1: Single axle-studies. Biosyst. Eng. 2007, 98, 115–126. [Google Scholar] [CrossRef] [Green Version]

- Ansorge, D.; Godwin, R. The effect of tyres and a rubber track at high axle loads on soil compaction—Part 2: Multi-axle machine studies. Biosyst. Eng. 2008, 99, 338–347. [Google Scholar] [CrossRef] [Green Version]

- Klos, M.; Waszczyszyn, Z. Prediction of Compaction Characteristics of Granular Soils by Neural Networks. Artificial Neural Networks-ICANN 2010, Lecture Notes in Computer Science; Springer: Berlin, Heidelberg, 2010; pp. 42–45. [Google Scholar]

- Raper, R.L.; Reeves, D.W. In-Row Subsoiling and Controlled Traffic Effects on Coastal Plain Soils. Trans. ASABE 2007, 50, 1109–1115. [Google Scholar] [CrossRef] [Green Version]

- Arman, K. Prediction of soil compaction under pneumatic tires a using fuzzy logic approach. J. Terramech. 2008, 45, 103–108. [Google Scholar] [CrossRef]

- Bayat, H.; Neyshabouri, M.R.; Hajabbasi, M.A.; Mahboubi, A.A.; Mosaddeghi, M.R. Comparing neural networks, linear and nonlinear regression techniques to model penetration resistance. Turk. J. Agric. For. 2008, 32, 425–433. [Google Scholar]

- Taghavifar, H.; Mardani, A.; Taghavifar, L. A hybridized artificial neural network and imperialist competitive algorithm optimization approach for prediction of soil compaction in soil bin facility. Measurement 2013, 46, 2288–2299. [Google Scholar] [CrossRef]

- Cosanti, B.; Presti, D.C.F.L.; Squeglia, N. An Innovative Method to Evaluate Degree of Compaction of River Embankments. Eng. Geol. Soc. Territ. 2015, 2, 853–856. [Google Scholar] [CrossRef]

- Li, H.; Schindler, C. Analysis of soil compaction and tire mobility with finite element method. Proc. Inst. Mech. Eng. Part K J. Multi. Body Dyn. 2013, 227, 275–291. [Google Scholar] [CrossRef]

- Zolotarevskaya, D.I. Mathematical simulation and calculation of the soil compaction under dynamic loads. Eurasian Soil Sci. 2011, 44, 407–416. [Google Scholar] [CrossRef]

- Shoaib, M.; Kari, L. Non-linear elasto-plastic shock wave simulation in high-velocity compaction by discrete element method. AIP Conf. Proc. 2012, 1474, 171–174. [Google Scholar] [CrossRef]

- Ghanbari, E.; Hamidi, A. Numerical modeling of rapid impact compaction in loose sands. Géoméch. Eng. 2014, 6, 487–502. [Google Scholar] [CrossRef]

- Xia, K. Numerical prediction of soil compaction in geotechnical engineering. Comptes Rendus Mécanique 2014, 342, 208–219. [Google Scholar] [CrossRef]

- Shangguan, P.; Al-Qadi, I.; Lahouar, S. Pattern recognition algorithms for density estimation of asphalt pavement during compaction: A simulation study. J. Appl. Geophys. 2014, 107, 8–15. [Google Scholar] [CrossRef]

- Du, G.; Chen, B.; Yang, H. Application of GPS rolling compaction monitoring system in the quality management of earth-rock dam construction. Des. Hydroelectr. Power Stn. 2012, 28, 111–113. [Google Scholar]

- Liu, Y.C. The Research and Application of Highway Engineering Quality Control and Supervision. Master’s Thesis, South-West Jiaotong University, Chengdu, China, 2000. [Google Scholar]

- Liu, H.; Xue, R. On legal affairs concerning side-standing supervision. J. Shanxi Univ. Philos. Soc. Sci. 2005, 28, 50–53. [Google Scholar]

- Xie, Y.Y.; Zeng, G.S. Exploration and practice on the construction supervision of Jin’anqiao hydropower station. Water Power. 2011, 37, 4–6. [Google Scholar]

- Zhang, Y.Q. Discussion on several problems in compaction quality control of roller compacted earth-rock dam. China Rural. Water Hydropower 2007, 6, 122–124. [Google Scholar]

- Guo, L.X. Some factors influencing the compaction effect of highway’s roadbed. Sci. Tech. Inf. Dev. Economy. 2006, 16, 268–269. [Google Scholar]

- Guo, X.L. Research of Compaction Quality Control and Rapid Detection Technology of the Natural Gravel Subgrade. Master’s Thesis, Chang’an University, Xi’An, China, 2014. [Google Scholar]

- Liu, D.H.; Li, Z.L.; Wang, A.G. Correlation analysis of rolling parameters and real-time monitoring index for rockfill dam compaction quality evaluation. J. Tianjin Univ. Sci. Technol. 2013, 46, 361–366. [Google Scholar]

- Tokiharu, N.; Akitoshi, M.; Osamu, S. Evaluation of density from compaction tests on coarse grained soils. Doboku Gakkai Ronbunshu 1994, 28, 177–185. [Google Scholar]

- Sitharam, T.G.; Nimbkar, M.S. Micromechanical Modelling of Granular Materials: Effect of Particle Size and Gradation. Geotech. Geol. Eng. 2000, 18, 91–117. [Google Scholar] [CrossRef]

- Liu, L.P.; She, X.S. Study on compaction property of earth-rock mixture. Chin. J. Rock Mech. Eng. 2006, 25, 206–210. [Google Scholar]

- Feng, Y.Q.; Jiang, H.H.; Wu, L.L.; Xiang, W.G. Research progress of continuous compaction control technology for filling projects. Railw. Stand. Des. 2020, 64, 50–58. [Google Scholar]

- Liu, B.; Zhao, Y.F.; Wang, W.B.; Liu, B.W. Compaction density evaluation model of sand-gravel dam based on Elman neural network with modified particle swarm optimization. Front. Phys-Lausanne. 2022, 9, 806231. [Google Scholar]

- Thurner, H.F.; Sandström, A. Compaction meter and compaction documentation system. Unbound Aggreg. Roads 1989, 46–51. [Google Scholar]

- Pampagnin, L.H.; Peyret, F.; Garcia, G. Architecture of a GPS-based guiding system for road compaction. In Proceedings of the 1988 IEEE International Conference on Robotics and Automation, Philadelphia, PA, USA, 24–29 April 1988; pp. 2422–2427. [Google Scholar]

- Mooney, M.A.; Rinehart, R.V. Field Monitoring of Roller Vibration during Compaction of Subgrade Soil. J. Geotech. Geoenvironmental Eng. 2007, 133, 257–265. [Google Scholar] [CrossRef]

- Rinehart, R.V.; Mooney, M.A. Instrumentation of a roller compactor to monitor vibration behavior during earthwork compaction. Autom. Constr. 2008, 17, 144–150. [Google Scholar] [CrossRef]

- Liu, D.H.; Cui, B.; Liu, Y.G.; Zhong, D.H. Automatic control and real-time monitoring system for earth-rock dam material truck watering. Autom. Constr. 2013, 30, 70–80. [Google Scholar] [CrossRef]

- Liu, D.; Chen, J.; Li, S. Collaborative operation and real-time control of roller fleet for asphalt pavement compaction. Autom. Constr. 2018, 98, 16–29. [Google Scholar] [CrossRef]

- Zhong, D.H.; Li, X.C.; Cui, B.; Wu, B.P.; Liu, Y.X. Technology and application of real-time compaction quality monitoring for earth-rockfill dam construction in deep narrow valley. Autom. Constr. 2018, 90, 23–38. [Google Scholar] [CrossRef]

- Zeng, H.E.; Liu, J.P. Preliminary experiment study on Georobot/WLAN-based intelligent monitoring system for roller compaction. Water Resour. Hydropower Eng. 2018, 49, 141–147. [Google Scholar]

- Huang, S.; Zhang, W. A fast calculation method of rolling times in the GNSS real-time compaction quality supervisory system. Adv. Eng. Softw. 2018, 128, 20–33. [Google Scholar] [CrossRef]

- Xu, J.; Liu, F.P.; Wang, J.X. Research and application of continuous compaction monitoring system based on BDS. Agric. Eng. 2020, 10, 59–63. [Google Scholar]

- Meehan, C.L.; Khosravi, M.; Cacciola, D. Monitoring Field Lift Thickness Using Compaction Equipment Instrumented with Global Positioning System (GPS) Technology. Geotech. Test. J. 2013, 36, 755–767. [Google Scholar] [CrossRef]

- Yu, Y.; Cui, B.; Zhou, L. Application of real-time monitoring and control system of roller compaction quality to construction of South Xinzheng Section of Mid-Route of South-to-North Water Transfer Project. Water Resour. Hydro. Power Eng. 2013, 44, 73–76. [Google Scholar]

- Ma, H.Q. Key technologies on construction quality control of rockfill dam with core wall filled by clay soil mixed with gravel in Nuozhadu hydropower station project. Water Power. 2012, 38, 12–15. [Google Scholar]

- White, D.J.; Thompson, M.J.; Vennapusa, P. Field Validation of Intelligent Compaction Monitoring Technology for Un-Bound Materials; Final Report; Minnesota Department of Transportation: Maplewood, MN, USA, 2007; pp. 1–12. [Google Scholar]

- Mooney, M.; Adam, D. Vibratory roller integrated measurement of earthwork compaction: An overview. In Proceedings of the FMGM 2007: Seventh International Symposium on Field Measurement in Geomechanics, Boston, MA, USA, 27 September 2017; pp. 1–12. [Google Scholar]

- Hu, W.; Shu, X.; Jia, X.Y.; Huang, B.S. Geostatistical analysis of intelligent compaction measurements for asphalt pavement compaction. Autom. Constr. 2018, 89, 162–169. [Google Scholar] [CrossRef]

- Wang, S.Q.; Zhao, S.; Al-Qadi, I.L. Continuous real-time monitoring of flexible pavement layer density and thickness using ground penetrating radar. NDT E INT. 2018, 100, 48–54. [Google Scholar] [CrossRef]

- Barman, M.; Nazari, M.; Imran, S.A.; Commuri, S.; Zaman, M. Quality Improvement of Subgrade through Intelligent Compaction. Transp. Res. Rec. J. Transp. Res. Board 2016, 2579, 59–69. [Google Scholar] [CrossRef]

- Soomin, L.; Sangil, P.; Riho, L.; Jongwon, S. Development of intelligent compaction system for efficient quality control. J. Korean Soc. Civ. Eng. 2018, 38, 751–760. [Google Scholar]

- Inim, I.J.; Tijani, M.N.; Affiah, U.E. Experimental assessment of electrical properties of lateritic soils as an alternative non-destructive method for compaction monitoring. Int. J. Geotech. Eng. 2016, 12, 252–257. [Google Scholar] [CrossRef]

- Hua, T.; Yang, Z.; Yang, X.; Huang, H.; Yao, Q.; Wu, G.; Li, H. Assessment of geomaterial compaction using the pressure-wave fundamental frequency. Transp. Geotech. 2020, 22, 100318. [Google Scholar] [CrossRef]

- Wersäll, C.; Nordfelt, I.; Larsson, S. Roller compaction of rock-fill with automatic frequency control. Proc. Inst. Civ. Eng. Geotech. Eng. 2020, 173, 339–347. [Google Scholar] [CrossRef] [Green Version]

- Xu, T.Y.; Zhou, Z.J.; Yan, R.P.; Zhang, Z.P.; Zhu, L.X.; Chen, C.R.; Xu, F.; Liu, T. Real-time monitoring method for layered compaction quality of loess subgrade based on hydraulic compactor reinforcement. Sensors 2020, 20, 4288. [Google Scholar] [CrossRef]

- Li, X.; Zhu, G.Q. Application of wave detection technology in compaction quality inspection for stone-filled embankment used large sized particles. J. Chongqing Jiaotong Univ. Nat. Sci. 2011, 30, 790–793. [Google Scholar]

- Wu, L.L. Research on Continuous Compaction Control Technology of Roadbed Based on Energy Dissipation. Ph.D. Thesis, China Academy of Railway Sciences: China, Beijing, 2020. [Google Scholar]

- Liu, D.H.; Wang, A.G.; Liu, Y.G.; Li, B.Y. Real-time monitoring and assessment of compaction quality for earth-rock dam basing on roller vibration behavior analysis. J. Hydraul. Eng. 2014, 45, 163–170. [Google Scholar]

- Liu, D.H.; Li, Z.L.; Wang, A.G. Roller working-based real-time monitoring and rapid assessment of rock-fill dam compaction quality. J. Hydraul. Eng. 2014, 45, 1223–1230. [Google Scholar]

- Liu, D.H.; Gong, S.T.; Wei, H.Y. Fast assessment on compaction quality of highway subgrade based on real-time monitoring. China Civ. Eng. J. 2014, 47, 138–144. [Google Scholar]

- Gao, L. Study on Real-Time Compaction Quality Monitoring Indexes of Earth-Rock Dam Based on Intelligent Compaction Theory. Ph.D. Thesis, Tianjin University: Tianjin, China, 2017. [Google Scholar]

- Xu, G.H.; Gao, H.; Wang, Z.R. Analysis of continuous dynamic monitoring on vibrating compaction process of graded broken stone. Chin. J. Geotech. Eng. 2005, 27, 1270–1272. [Google Scholar]

- Wu, Y. Study on Real-Time Paving and Compaction Quality Control for Rockfill Dam with Asphalt Concrete Core Wall. Ph.D. Thesis, Tianjin University: Tianjin, China, 2018. [Google Scholar]

- Zhou, J.P.; Wang, K.; Liu, Y.L. Application of surface wave exploration method in quality detection of filling embankment compaction. J. Chongqing Jiaotong Univ. Nat. Sci. 2013, 32, 50–53. [Google Scholar]

- Liu, D.H.; Wu, Y. Fuzzy comprehensive evaluation of earth-rock dam compaction quality based on real-time monitoring. J. Hydroelectr. Eng. 2019, 38, 142–153. [Google Scholar]

- Liu, D.H.; Sun, Y.Z.; Gong, S.T.; Lin, M. Real-time subgrade compaction quality monitoring system of appropriative highway to hydropower project site. Water Power. 2015, 41, 81–86. [Google Scholar]

- Hua, T.; Yang, X.; Yao, Q.; Li, H. Assessment of Real-Time Compaction Quality Test Indexes for Rockfill Material Based on Roller Vibratory Acceleration Analysis. Adv. Mater. Sci. Eng. 2018, 2018, 1–15. [Google Scholar] [CrossRef] [Green Version]

- Xu, G.H.; Gao, H.; Wang, Z.R. Continuous dynamic monitor technology on subgrade compaction quality. China J. Highw. Transp. 2007, 20, 17–22. [Google Scholar]

- Guo, H.J.; Jiang, H.H.; Gao, M.X.; Wu, L.L. Study on the influence of water content of fine-grained fillers for dam construction on continuous compaction indexes. J. Hydroelectr. Eng. 2021, 40, 1–9. [Google Scholar]

- Kimmel, S.C.; Mooney, M.A. Real-Time Soil Compaction Monitoring through Pad Strain Measurements: Modeling to Inform Strain Gage Placement, SPIE 7981, Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems; The International Society for Optics and Photonics: San Diego, CA, USA, 2011; Article No. 79815F; pp. 1–7. [Google Scholar]

- Singh, D.; Beainy, F.; Commuri, S.; Zaman, M. Application of intelligent compaction technology for estimation of effective modulus for a multilayered asphalt pavement. J. Test. Eval. 2015, 43, 308–318. [Google Scholar] [CrossRef]

- Barman, M.; Zazari, M.; Imran, S.A.; Commuri, S.; Zaman, M.; Beainy, F.; Singh, D. Quality control of subgrade soil using intelligent compaction. Innov. Infrastruct. Solut. 2016, 1, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Imran, S.A.; Barman, M.; Commuri, S.; Zaman, M.; Nazari, M. Artificial Neural Network–Based Intelligent Compaction Analyzer for Real-Time Estimation of Subgrade Quality. Int. J. Géoméch. 2018, 18, 04018048. [Google Scholar] [CrossRef]

- Thurner, H.F.; Sandström, Å.K.E. Continuous Compaction Control, CCC, European Workshop Compaction of Soils and Granular Materials. In Proceedings of the European Workshop Compaction Of Soils And Granular Materials, Paris, France, 19 May 2000; pp. 237–246. [Google Scholar]

- Solla, M.; Lorenzo, H.; Martínez-Sánchez, J.; Perez-Gracia, V. Applications of GPR in Association with Other Non-destructive Testing Methods in Surveying of Transport Infrastructures. In Civil Engineering Applications of Ground Penetrating Radar; Springer: Cham, Switzerland, 2015; pp. 327–342. [Google Scholar] [CrossRef]

- Wang, P.; Hu, Z.; Zhao, Y.; Li, X. Experimental study of soil compaction effects on GPR signals. J. Appl. Geophys. 2016, 126, 128–137. [Google Scholar] [CrossRef]

- Kim, D.-S.; Shin, M.-K.; Park, H.-C. Evaluation of density in layer compaction using SASW method. Soil Dyn. Earthq. Eng. 2001, 21, 39–46. [Google Scholar] [CrossRef]

- Mitchell, M.R.; Link, R.E.; Lai, J.; Wu, S.; Chiang, C.-H. Evaluating the Compaction Quality of Backfills by Stress Wave Velocities. J. Test. Evaluation 2011, 39, 785–791. [Google Scholar] [CrossRef]

- Jafri, N.J.S.; Ab Rahim, M.A.; Mohd Zahid, M.Z.A.; Bawadi, N.F.; Ahmad, M.M.; Mansor, A.F.; Wan Omar, W.M.S. Assessment of soil compaction properties based on surface wave techniques. E3S Web Conf. 2018, 34, 01002. [Google Scholar] [CrossRef] [Green Version]

- Kröber, W.; Floss, R.; Wallrath, W. Dynamic Soil Stiffness as Quality Criterion for Soil Compaction, Geotechnics for Roads, Rail Tracks and Earth Structures; A.A. Balkema Publishers: Lisse, Netherlands, 2001; pp. 189–199. [Google Scholar]

- Camargo, F.; Larsen, B.; Chadbourn, B.; Roberson, R.; Siekmeier, J. Intelligent compaction: A Minnesota case history. In Proceedings of the 54th Annual University of Minnesota Geotechnical Conference, Minneapolis, MN, USA, 17 February 2006; pp. 1–20. [Google Scholar]

- Peterson, R.; Pertersen, L. Intelligent Compaction and In-Situ Testing at Mn/DOT TH53, Final Report MN/RC-2006-13; Minnesota Department of Transportation: Minnesota, MN, USA, 2006; pp. 1–50. [Google Scholar]

- Ling, J.M.; Lin, S.; Qian, J.S.; Zhang, J.K.; Han, B.Y.; Liu, M. Continuous compaction control technology for granite residual subgrade compaction. J. Mater. Civ. Eng. 2018, 30, 04018316. [Google Scholar] [CrossRef]

- Thompson, M.J.; Schmitt, R.L. Calibration of Roller-Integrated Machine Drive Power Measurements Using Soil Compaction Forecasting Model. Geotech. Test. J. 2013, 36, 626–635. [Google Scholar] [CrossRef]

- Meehan, C.L.; Tehrani, F.S. A comparison of simultaneously recorded machine drive power and compactometer measurements. Geotech. Test. J. 2011, 34, 208–218. [Google Scholar]

- Thompson, M.J.; White, D.J. Estimating Compaction of Cohesive Soils from Machine Drive Power. J. Geotech. Geoenvironmental Eng. 2008, 134, 1771–1777. [Google Scholar] [CrossRef]

- Thompson, M.J.; White, D.J. Field Calibration and Spatial Analysis of Compaction-Monitoring Technology Measurements. Transp. Res. Rec. J. Transp. Res. Board 2007, 2004, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Roodposhti, H.R.; Hafizi, M.K.; Kermani, M.R.S. Ground Penetrating Radar for water content and compaction evaluation: A laboratory test on construction material. J. Environ. Eng. Geoph. 2020, 25, 169–179. [Google Scholar] [CrossRef]

- Paulmichl, I.; Adam, D.; Adam, C.; Völkel, W. Assessment of a compaction indictor for oscillation rollers with a lumped parameter model. Geotech. Eng. 2020, 173, 302–318. [Google Scholar]

- Karray, M.; Lefebvre, G.; Ethier, Y.; Bigras, A. Assessment of deep compaction of the Péribonka dam foundation using “modal analysis of surface waves” (MASW). Can. Geotech. J. 2010, 47, 312–326. [Google Scholar] [CrossRef]

- Ilori, A.O.; Okwueze, E.E.; Obianwu, V.I. Evaluating Compaction Quality Using Elastic Seismic P Wave. J. Mater. Civ. Eng. 2013, 25, 693–700. [Google Scholar] [CrossRef]

- Ni, S.H.; Chang, W.J.; Yang, Y.Z.; Fan, E.S. Evaluating compaction quality during earth dam construction using multi-channel analysis of surface wave. In Proceedings of the 5th Geotechnical Earthquake Engineering and Soil Dynamics Conference, Austin, TX, USA, 7 June 2018; pp. 432–442. [Google Scholar]

- Roslan, M.A.; Madun, A.; Zainalabidin, M.H.; Danazlan, M.F.M.; Abu Talib, M.K.; Zahari, M.N.H.; Ambak, K.; Ismail, M.A.M. Soil Compaction Assessment Using Spectral Analysis of Surface Waves (SASW). J. Physics Conf. Ser. 2018, 995, 012119. [Google Scholar] [CrossRef]

- Moro, G.D.; Al-Arifi, N.; Moustafa, S.S.R. Assessing ground compaction via time lapse surface wave analysis. Acta Geodyn. Geomater. 2016, 13, 249–256. [Google Scholar] [CrossRef] [Green Version]

- Bitri, A.; Samyn, K.; Brule, S.; Javelaud, E. Assessment of ground compaction using multi-channel analysis of surface wave data and cone penetration tests. Near Surf. Geophys. 2013, 11, 683–690. [Google Scholar] [CrossRef] [Green Version]

- Donohue, S.; Forristal, D.; Donohue, L.A. Detection of soil compaction using seismic surface waves. Soil Tillage Res. 2013, 128, 54–60. [Google Scholar] [CrossRef] [Green Version]

- Pistrol, J.; Adam, D. Fundamentals of roller integrated compaction control for oscillatory rollers and comparison with conventional testing methods. Transp. Geotech. 2018, 17, 75–84. [Google Scholar] [CrossRef]

- Vennapusa, P.K.R.; White, D.J.; Morris, M.D. Geostatistical Analysis for Spatially Referenced Roller-Integrated Compaction Measurements. J. Geotech. Geoenvironmental Eng. 2010, 136, 813–822. [Google Scholar] [CrossRef] [Green Version]

- Vennapusa, P.K.R.; White, D.J. Interpretation of Dual Roller-Integrated Compaction Measurements on Layered Granular Fill. Geo. Congr. 2014, 2426–2435. [Google Scholar] [CrossRef]

- Mazari, M.; Tirado, C.; Nazarian, S.; Aldouri, R. Impact of geospatial classification method on interpretation of intelligent compaction data. Transport. Res. Rec. 2017, 2657, 37–46. [Google Scholar] [CrossRef]

- Chen, Z.G.; Wang, B.S.; Liu, W.Q.; Wei, Z.G. Distributed pavement subgrade shape monitoring based on FBG sensing technique. In Proceedings of the 8th International Symposium on Advanced Optical Manufacturing and Testing Technologies: Optical Test, Measurement Technology, and Equipment, 96840R, Suzhou, China, 27 September 2016; pp. 1–15. [Google Scholar]

- Furuya, H.; Fujiyama, T. Development of soil stiffness evaluation equipment alfa-system using acceleration response of vibratory roller. In Proceedings of the 28th International Symposium on Automation and Robotics in Construction, Seoul, Korea, 29 June–2 July 2011; pp. 337–342. [Google Scholar]

- Dou, P.; Nie, Z.H.; Wang, X. Correlation verification of railway subgrade compaction quality test value between CMV and E_vd. J. Railw. Sci. Eng. 2014, 11, 90–94. [Google Scholar]

- Ye, Y.S.; Cai, D.G.; Zhu, H.W.; Wei, S.W.; Yang, W.L.; Lin, G. Research on new continuous compaction control index of high-speed railway subgrade based on vibration energy. J. China Railw. Soc. 2020, 42, 127–132. [Google Scholar]

- Nie, Z.H.; Jiao, T.; Wang, X. Study on continuous compaction indicator of railway subgrade based on harmonic balance identification method. China Railw. Sci. 2016, 37, 1–8. [Google Scholar]

- Nie, Z.H.; Xie, Y.; Tan, J. Robust design of continuous compaction measured value based on dual response surface methodology. J. China Railw. Soc. 2016, 38, 93–99. [Google Scholar]

- Fan, J.; Song, X.D.; Tian, L.F.; Nie, Z.H. Study on factors of continuous compaction measured value in subgrade of high-speed railway. J. Railw. Sci. Eng. 2015, 12, 463–474. [Google Scholar]

- Liu, D.H.; Liu, Z.L.; Feng, Y.W. Analysis on applicability and influence factors of real-time monitoring compaction indexes for rockfill dam materials. J. Hydroelectr. Eng. 2019, 38, 1–10. [Google Scholar]

- Zhang, W.G.; Hou, Z.J.; Zhong, Z.L.; Bie, C.Y. Assessment of dynamic compaction effect on gravel soil foundation based on comprehensive test. Eng. J. Wuhan Univ. 2019, 52, 788–795. [Google Scholar]

- Yang, H.N. A New Approach to Quality Detecting and Measuring of Earth-Fill Dam. Appl. Mech. Mater. 2013, 303–306, 421–425. [Google Scholar] [CrossRef]

- Mooney, M.A.; Gorman, P.B.; Gonzalez, J.N. Vibration-based Health Monitoring of Earth Structures. Struct. Health Monit. 2005, 4, 137–152. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.C.; Dai, J.L.; Li, X.Z. Compactness automatic detecting method of subgrade for intelligent impact roller. J. Traffic Transp. Eng. 2007, 7, 63–67. [Google Scholar]

- Uyanik, O.; Ulugergerli, E.U. Quality control of compacted grounds using seismic velocities. Near Surf. Geophys. 2007, 6, 299–306. [Google Scholar] [CrossRef]

- Ni, H.G.; Li, P.S.; Li, G.H. On testing high embankment with weathered granite fills treated by dynamic compaction. J. Basic Sci. Eng. 2014, 22, 150–159. [Google Scholar]

- Börner, F.; Müllerhuber, E.; Branka, D.; Rücker, C. The effect of compaction on complex electrical resistivity of shaly sands. Near Surf. Geophys. 2017, 15, 633–643. [Google Scholar] [CrossRef]

- Kowalczyk, S.; Maslakowski, M.; Tucholka, P. Determination of the correlation between the electrical resistivity of non-cohesive soils and the degree of compaction. J. Appl. Geophys. 2014, 110, 43–50. [Google Scholar] [CrossRef]

- Cai, J.N.; Gao, Q.Y.; Chun, H.; Cai, H.; Nantung, T. Spatial autocorrelation in soil compaction and its impact on earth-work acceptance testing. Transport. Res. Rec. 2019, 2673, 332–342. [Google Scholar] [CrossRef]

- White, D.J.; Morris, M.; Thompson, M. Power-Based Compaction Monitoring Using Vibratory Padfoot Roller. GeoCongress 2006, 2006, 1–6. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Bai, S.J.; Xue, G.P.; Yang, J.; Cai, Y.S.; Hu, W.; Jia, X.Y.; Huang, B.S. Assessment of compaction quality of multi-layer pavement structure based on intelligent compaction technology. Constr. Build. Mater. 2018, 161, 316–329. [Google Scholar] [CrossRef]

- Liu, M.; Wang, X.; Wang, J.; Cui, B.; Deng, B.; Shi, M. Comprehensive Evaluation for Real-Time Compaction Quality Using i-AHP and i-GAM: Case Study of Earth-Rock Dam. Appl. Sci. 2019, 9, 1543. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Zhong, D.; Wu, B.; Shi, M. Evaluation of Compaction Quality Based on SVR with CFA: Case Study on Compaction Quality of Earth-Rock Dam. J. Comput. Civ. Eng. 2018, 32, 05018001. [Google Scholar] [CrossRef]

- Wang, J.; Zhong, D.; Adeli, H.; Wang, D.; Liu, M. Smart bacteria-foraging algorithm-based customized kernel support vector regression and enhanced probabilistic neural network for compaction quality assessment and control of earth-rock dam. Expert Syst. 2018, 35, e12357. [Google Scholar] [CrossRef]

- Wang, F.; Zhong, D.-H.; Yan, Y.-L.; Ren, B.-Y.; Wu, B.-P. Rockfill dam compaction quality evaluation based on cloud-fuzzy model. J. Zhejiang Univ. A 2018, 19, 289–303. [Google Scholar] [CrossRef]

- Liu, D.H.; Gao, L.; Lin, M.; Li, Z.L. Real-time monitoring and assessment of compaction quality for highway asphalt pavements. J. Hohai Univ. Nat. Sci. 2018, 46, 307–313. [Google Scholar]

- Yao, Y.P.; Liu, B.Y. An evaluation algorithm of compaction quality for high embankments airports. Ind. Constr. 2016, 46, 42–45. [Google Scholar]

- Wu, L.L.; Jiang, H.H.; Tang, J.W.; Gao, M.X.; Fan, S.F.; Yan, X.X. Continuous compaction monitoring technology based on multiple regression analysis. Rock Soil Mech. 2020, 41, 2081–2090. [Google Scholar]

- Wang, J.J.; Zhong, D.H.; Wu, B.P.; Liu, M.H.; Zhang, Z.L. Method of updating compaction quality evaluation model of earth-rock dam using concept drift detection. J. Tianjin Univ. Sci. Technol. 2019, 52, 492–500. [Google Scholar]

- Chen, J.; Yan, H.; Tang, D. Research on evaluation of compaction quality of soil-rock mixed subgrade based on continuous vibration compaction value. Subgrade Eng. 2020, 6, 167–170. [Google Scholar]

- Cui, B.; Zhang, H.G.; Wang, J.J.; Yu, J. Real time evaluation of compaction quality of gravelly soil core wall based on construction process parameters. Water Resour. Hydropower Eng. 2021, 52, 109–118. [Google Scholar]

- Wang, X.L.; Zhou, L.; Ren, B.Y.; Cui, B.; Zhang, N.M. Dual evaluation on rolling compaction quality of rock-fill dam based on real-time monitoring. J. Hydroelectr. Eng. 2015, 34, 164–170. [Google Scholar]

- Lin, W.W.; Zhong, D.H.; Hu, W.; Lü, P.; Yan, Y.L.; Ren, B.Y. Study on dynamic evaluation of compaction quality of earth rock dam based on random forest. J. Hydraul. Eng. 2018, 49, 945–955. [Google Scholar]

- Liu, D.H.; Wang, Q.; Cui, B.; Shen, S.Y.; Liu, X.N.; Wang, Q.F. Control standards for compaction parameters of earth-rock dams under continuous construction process monitoring. Chin. J. Geotech. Eng. 2013, 35, 1712–1716. [Google Scholar]

- Wang, J.J.; Zhong, D.H.; Guan, T.; Tong, D.W.; Deng, S.H. Real-time evaluation of compaction quality of earth-rock dams using fuzzy logic based on KM and AC-BFA. J. Hydroelectr. Eng. 2019, 38, 165–178. [Google Scholar]

- Huang, S.; Zhang, W.; Wu, G. Research on Real-Time Supervisory System for Compaction Quality in Face Rockfill Dam Engineering. J. Sensors 2018, 2018, 1–11. [Google Scholar] [CrossRef]

- Kuenzel, R.; Teizer, J.; Mueller, M.; Blickle, A. SmartSite: Intelligent and autonomous environments, machinery, and processes to realize smart road construction projects. Autom. Constr. 2016, 71, 21–33. [Google Scholar] [CrossRef]

- Hwang, J.; Yun, H.; Kim, J.; Suh, Y.; Hong, S.; Lee, D. Development of soil compaction analysis software (SCAN) integrating a low cost GPS receiver and compactometer. Sensors 2012, 12, 2351–2372. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Chang, G.K. Evaluation of intelligent compaction for asphalt materials. Autom. Constr. 2013, 30, 104–112. [Google Scholar] [CrossRef]

- Adam, D.; Brandl, H. Sophisticated roller integrated continuous compaction control. In Proceedings of the 12th Asian Regional Conference on Soil Mechanics and Geotechnical Engineering-Geotechnical Infrastructure for the New Millennium, Singapore, 4 August 2003; pp. 427–430. [Google Scholar]

- Komandi, G. An evaluation of the concept of rolling resistance. J. Terramechanics 1999, 36, 159–166. [Google Scholar] [CrossRef]

- Anderegg, R.; von Felten, D.A.; Kaufmann, K. Compaction Monitoring Using Intelligent Soil Compactors; Geotechnical Engineering in the Information Technology Age: Atlanta, GA, USA, 2006. [Google Scholar]

- Commuri, S.; Zaman, M. A novel neural network-based asphalt compaction analyzer. Int. J. Pavement Eng. 2008, 9, 177–188. [Google Scholar] [CrossRef] [Green Version]

- Sun, M. Automatic control device and rolling driving method of Japanese road rolling machinery. Road Mach. Constr. Mech. 1985, 4, 34–37. [Google Scholar]

- Yao, D.; Xie, H.; Qiang, W.; Liu, Y.; Xiong, S. Accurate trajectory tracking with disturbance-resistant and heading estimation method for self-driving vibratory roller. IFAC PapersOnLine 2018, 51, 754–758. [Google Scholar] [CrossRef]

- Song, E.-B.; Zhang, X. Research on the path optimization of unmanned rolling impaction for high embankment of airport. Jpn. Geotech. Soc. Spéc. Publ. 2020, 8, 142–148. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Luo, T.; Song, E.B.; Geng, Y. Algorithm for optimal path planning of impact roller in high-embankment air-port. Jpn. Geotech. Soc. Spec. Publ. 2020, 8, 159–163. [Google Scholar]

- Husemann, J.; Wolf, P.; Vierling, A.; Berns, K.; Decker, P. Towards high-quality road construction: Using autonomous tandem rollers for asphalt compaction optimization. In Proceedings of the 37th International Symposium on Automation and Robotics in Construction, Kitakyshu, Japan, 27 October 2020. [Google Scholar]

- Song, K.; Xie, H. Path-following control for unmanned rollers: A composite disturbance rejection-based framework. In Proceedings of the 2020 IEEE 9th Data Driven Control and Learning Systems Conference, Liuzhou, China, 20–22 November 2020. [Google Scholar]

- Zhang, Q.L.; Liu, T.Y.; Li, Q.B.; An, Z.Z.; Fan, L. Automatic rolling system based on closed-loop feedback control and RTK-GPS. J. Hydroelectr. Eng. 2018, 37, 151–160. [Google Scholar]

- Huang, W.Z.; Wang, D.; Xiao, Z.D.; Yao, Q.; Du, D.J. Design and implementation of PLC-based autonomous construction system of unmanned vibratory roller. Comput. Mater. Continua. 2020, 65, 897–912. [Google Scholar] [CrossRef]

- Bian, Y.M.; Fang, X.J.; Yang, M.; Zhao, Z. Automatic rolling control for unmanned vibratory roller based on fuzzy algorithm. J. Tongji Univ. Nat. Sci. 2017, 45, 1830–1838. [Google Scholar]

- Zou, B.; Yu, S.L.; Wang, K.W. Obstacle detection for automatic driving roller compacting vehicle. Digit. Manuf. Sci. 2019, 17, 245–250. [Google Scholar]

- Teng, Y.N.; Li, X.P.; Ma, H.; Wen, B.C. Study on Vibration Friction Mechanism and Vibration Response Analysis Based on Vibration Compaction System. Appl. Mech. Mater. 2009, 16–19, 84–87. [Google Scholar] [CrossRef]

- Beainy, F.; Commuri, S.; Zaman, M.; Syed, I. Viscoelastic-Plastic Model of Asphalt-Roller Interaction. Int. J. Géoméch. 2013, 13, 581–594. [Google Scholar] [CrossRef]

- Beainy, F.; Commuri, S.; Zaman, M. Dynamical Response of Vibratory Rollers during the Compaction of Asphalt Pavements. J. Eng. Mech. 2014, 140, 04014039. [Google Scholar] [CrossRef]

- Zhang, Q.Z. Study on the Model and Parameters of the Vibration Compaction System in the Soil Subgrade. Ph.D. Thesis, Chang’an University, Xi’An, China, 2010. [Google Scholar]

- Wersäll, C.; Nordfelt, I.; Larsson, S. Soil compaction by vibratory roller with variable frequency. Géotechnique 2017, 67, 272–278. [Google Scholar] [CrossRef]

- Wersäll, C.; Nordfelt, I.; Larsson, S. Resonant roller compaction of gravel in full-scale tests. Transp. Geotech. 2018, 14, 93–97. [Google Scholar] [CrossRef]

- Yoo, T.-S.; Selig, E.T. Dynamics of Vibratory-Roller Compaction. J. Geotech. Eng. Div. 1979, 105, 1211–1231. [Google Scholar] [CrossRef]

- Li, Q.B.; Zhang, Z.S.; Liu, T.Y.; Huangfu, Z.H.; Zhang, Q.L.; Ma, W.M.; Li, C.S.; An, Z.Z. Review of vibration compaction model of soil and rock materials. Yellow River. 2020, 42, 105–111. [Google Scholar]

- Qin, S.C.; Chen, Y.S.; Li, Z.; Dai, P.Q.; Bai, D. Observation study on line of the soil compaction in vibratory roller. Trans. CSAE. 2011, 17, 15–18. [Google Scholar]

- Gong, T. Dynamic Analysis and Vibration Comfort Research for Vibratory Roller. Ph.D. Thesis, Xiangtan University, Xiangtan, China, 2013. [Google Scholar]

- Zheng, S.H.; Lin, S.W. Dynamical property modeling and analysis on intelligent vibratory rollers. Chin. J. Constr. Mach. 2011, 9, 398–403. [Google Scholar]

- Shen, P.H.; Lin, S.W. Coupling analysis for integrated dynamics characteristics of intelligent compaction system. China Mech. Eng. 2008, 19, 2395–2399. [Google Scholar]

- Yan, S.Y.; Wen, B.C. Investigation of characteristics of one kind of nonlinear dynamics of a vibratory roller. J. Fuzhou Univ. Nat. Sci. 2000, 28, 64–67. [Google Scholar]

- Tian, L.M. Dynamic Analysis and Parameter Optimization of Vibratory Oscillating Roller. Master’s Thesis, Chang’an University, Xi’An, China, 2002. [Google Scholar]

- Fan, X.B.; Ma, W.; Du, F.R.; Zhang, H.Y. The model building and parameter optimize of vibratory roller. Road Mach. Constr. Mech. 2003, 20, 17–19. [Google Scholar]

- Kordestani, A. Ride Vibration and Compaction Dynamics of Vibratory Soil Compactors. Master’s Thesis, Concordia University, Montreal, QC, Canada, 2010. [Google Scholar]

- Xin, L.L.; Liang, J.H.; Wen, B.C. Dynamic property analysis on pulsating vibratory roller. Chin. J. Constr. Mach. 2008, 6, 161–166. [Google Scholar]

- He, C.; Zhang, Z.F. Numerical simulation of the condition of jump of the roller and choice of compactor’s mechanical and vibrational parameters. J. Wuhan Inst. Technol. 1992, 14, 7–19. [Google Scholar]

- Rose, K.D.; Kumar, K.; Rana, R.S.; Sahni, A.; Smith, T. Vibratory compaction of bituminous mixes in France. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1978, 15, A118. [Google Scholar]

- Wersäll, C.; Larsson, S.; Bodare, A. Dynamic Response of vertically oscillating foundations at large strain, Computer Methods and Recent Advances in Geomechanics. In Proceedings of the 14th International Conference of International Association for Computer Methods and Recent Advances in Geomechanics, London, UK, 13 December 2014; pp. 643–647. [Google Scholar]

- Shen, P.-H.; Lin, S.-W. Mathematic modeling and characteristic analysis for dynamic system with asymmetrical hysteresis in vibratory compaction. Meccanica 2008, 43, 505–515. [Google Scholar] [CrossRef]

- Guan, D.; Chen, L.S. Steady-state response of piecewise linear asymmetrical hysteretic system. J. Mech. Strength 2009, 31, 182–185. [Google Scholar]

- Han, Q.K.; Gong, Z.M.; Liu, S.Y.; Wen, B.C. Dynamic response of vibration compacting roller with consideration of materials’ asymmetrical hysteresis. J. Vib. Shock. 1998, 17, 5–8. [Google Scholar]

- Teng, Y.N.; Han, M. Study on nonlinear hysteretic model of vibration compaction-soil system. Vacuum 2016, 4, 61–64. [Google Scholar]

- Pietzsch, D.; Poppy, W. Simulation of soil compaction with vibratory rollers. J. Terramechanics 1992, 29, 585–597. [Google Scholar] [CrossRef]

- Gong, C.X.; Liu, B.X.; Gong, T. Dynamic modeling and parameter optimization of intelligent vibratory roller. Mech. Sci. Technol. Aerosp. Eng. 2014, 33, 27–31. [Google Scholar]

- Thurner, H. Quality assurance and self control in road construction, advanced measurement technology. In Proceedings of the 4th International Symposium Infrastructure Construction Systems and Technologies, Bauma, Munich, Germany; 2001; pp. 73–81. [Google Scholar]

- Adam, D.; Kopf, F. Theoretical Analysis of Dynamically Loaded Soil, European Workshop Compaction of Soils and Granular Materials; Presses Ponts et Chaussies: Paris, France, 2000; pp. 207–220. [Google Scholar]

- Imran, S.A.; Commuri, S.; Zaman, M. A 2 dimensional dynamic model of asphalt-roller interaction during vibratory compaction. In Proceedings of the 12th International Conference on Informatics in Control, Automation and Robotics (ICINCO), Colmar, France, 10 December 2015; pp. 533–540. [Google Scholar]

- Imran, S.A. Modeling and Analysis of the Interaction between Roller Drum and Pavement Material during Compaction. Ph.D. Thesis, University of Oklahoma: Oklahoma, Norman, 2016. [Google Scholar]

- Li, J. Study on Control Techniques of the Vibratory Roller Based on Soil Compactness Characteristic. Ph.D. Thesis, Xi’an University of Technology, Xi’an, China, 2012. [Google Scholar]

- Zhang, W.G.; Goh, A.T.C. Multivariate adaptive regression splines and neural network models for prediction of pile drivability. Geosci. Front. 2016, 7, 45–52. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Goh, A. Multivariate adaptive regression splines for analysis of geotechnical engineering systems. Comput. Geotech. 2012, 48, 82–95. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, J.; Shu, X.Z.; Guo, L.; Shi, Y.; Liu, X.B. Optimization of intelligent compactness control rule of vibratory roller based on genetic algorithm method. In Proceedings of the 2009 Fifth International Joint Conference on INC, IMS and IDC, Seoul, Korea, 25–27 August 2009; pp. 1943–1947. [Google Scholar]

- Isik, F.; Ozden, G. Estimating compaction parameters of fine- and coarse-grained soils by means of artificial neural net-works. Environ. Earth. Sci. 2013, 69, 2287–2297. [Google Scholar] [CrossRef]

- Günaydin, O. Estimation of soil compaciton parameters by using statistical analyses and artificial neural networks. Environ. Geol. 2009, 57, 203–215. [Google Scholar] [CrossRef]

- Ranasinghe, R.A.T.M.; Jaksa, M.B.; Nejad, F.P.; Kuo, Y.L. Prediction of the effectiveness of rolling dynamic compaction using artificial neural networks and cone penetration test data. Chin. J. Rock. Mech. Eng. 2019, 38, 153–170. [Google Scholar]

- Ranasinghe, R.; Jaksa, M.; Kuo, Y.; Nejad, F.P. Application of artificial neural networks for predicting the impact of rolling dynamic compaction using dynamic cone penetrometer test results. J. Rock Mech. Geotech. Eng. 2017, 9, 340–349. [Google Scholar] [CrossRef] [Green Version]

- Prokopev, A.P.; Nabizhanov, I.Z.; Emelyanov, R.T.; Ivanchura, I.V. Concept of a new method for continuous non-destructive control of asphalt road pavements compaction. J. Phys. Conf. Ser. 2020, 1515, 1–6. [Google Scholar] [CrossRef]

- An, Z.; Liu, T.; Zhang, Z.; Zhang, Q.; Huangfu, Z.; Li, Q. Dynamic optimization of compaction process for rockfill materials. Autom. Constr. 2019, 110, 103038. [Google Scholar] [CrossRef]

- Zhang, Q.L.; An, Z.Z.; Liu, T.Y.; Zhang, Z.S.; Huangfu, Z.H.; Li, Q.B. Intelligent control theory of earth-rock dam compaction. J. Hydroelectr. Eng. 2020, 39, 34–40. [Google Scholar]

- Liu, T.Y.; Zhang, Q.L.; Li, Y.D.; Zhang, Z.S.; Huangfu, Z.H. An Intelligent Rolling Compaction Robot. CN Patent CN105002810B, 2017. [Google Scholar]

| References | Parameter Type | System | Contribution | ||

|---|---|---|---|---|---|

| Material Properties | Mechanical Parameters | Construction Parameters | |||

| [97] | - | √ | √ | CDS | Compaction documentation system for unbound aggregates |

| [98] | - | - | √ | CIRCOM | Computer integrated road construction of compaction |

| [99] | - | √ | - | MSEEF | Monitoring system for the eccentric excitation force |

| [100] | - | √ | - | CIS | Monitor the three-dimensional vibration |

| [101] | √ | - | √ | ACRM | Automatic control and monitoring for truck watering |

| [102] | - | √ | √ | MRCM | Cyber-physical monitoring for multi-roller compaction |

| [103] | - | √ | √ | CQMS | Theory and mathematical model of CQMS based on PCT |

| [104] | - | - | √ | GWIMS | Georobot/WLAN-based intelligent monitoring |

| [105] | - | - | √ | RCQSS | Monitoring the number of compaction times |

| [106] | - | √ | √ | CCMS | Continuous compaction monitoring system based BDS |

| [107] | - | - | √ | CEGPS | Monitoring field lift thickness |

| [108] | - | √ | √ | CQMCS | Monitoring and control of compaction quality |

| [109] | - | √ | √ | RDCQMS | GPS-based monitoring for construction quality |

| Method | CCI | Application Scenarios | Related Research | |||||

|---|---|---|---|---|---|---|---|---|

| Road | Railway | Airport | Dam | Embankment | ||||

| Acceleration | CMV | √ | √ | √ | √ | √ | [1,16,23,25,37,97,112,127,129,133,147,149,151,161,162,163,164,167,168,169,170,171,181] | |

| RMV | √ | - | - | √ | √ | [112,118,162,172] | ||

| CCV | √ | - | - | √ | - | [2,133,147,172] | ||

| CV | √ | - | √ | - | [24,91,122,124,125,130,172] | |||

| CF | - | - | - | √ | - | [131] | ||

| √ | - | - | - | - | [119] | |||

| OMV | √ | - | - | - | - | [138] | ||

| AA | √ | - | - | - | - | [147] | ||

| √ | - | √ | - | - | [166] | |||

| THD | - | - | - | √ | - | [100,123,172,175] | ||

| GPR | √ | √ | √ | √ | √ | [4,113,139,140,152,173,174] | ||

| SW | P | √ | - | √ | √ | - | [117,142,155,177] | |

| S | √ | - | √ | √ | - | [141,142,159,177] | ||

| Surface | √ | √ | √ | √ | √ | [6,120,128,143,154,156,157,158,173,174,176,178] | ||

| Force | VCV | √ | √ | - | - | √ | [12,34,126,132,133] | |

| - | - | - | √ | - | [125] | |||

| Deformation | √ | - | √ | - | - | [30,99,126,133,161] | ||

| √ | √ | √ | - | - | [111,144,145,146,161] | |||

| √ | - | - | - | - | [114,135,136,137] | |||

| Energy | MDP | √ | - | - | - | √ | [1,23,25,147,148,149,150,151,161,162,163,182] | |

| Omega | - | - | √ | - | - | [2] | ||

| E | √ | - | - | √ | - | [16,123] | ||

| DMV | - | - | √ | - | - | [121] | ||

| CEV | - | √ | - | - | - | [168] | ||

| FBG | √ | - | - | - | - | [165] | ||

| Acoustic wave | SCV | - | - | - | √ | - | [10,17,36] | |

| ER | √ | - | - | √ | [116,179,180] | |||

| Other | CSD | √ | - | - | √ | - | [134] | |

| NCI | - | - | - | - | - | [153] | ||

| References | Scenarios | Models | Indexes | Methods | Real-Time |

|---|---|---|---|---|---|

| [183] | Road | SLR/MLR | Compactness/ Deflection/CMV | ||

| [26] | Railway | SLR | CMV | Combination of and | |

| [159] | SLR | Cone resistance | |||

| [131] | Dam | SLR/SNR | CF/CMV | ||

| [24] | Dam | SLR/SNR/MNR | Dry density/ Compactness | Geostatistics with CV | |

| [10] | Dam | SLR/MLR/MNR | Dry density | Geostatistics with SCV | |

| [9] | Dam | MNR | Compactness | Geostatistics-based | |

| [184] | Dam | SVR with CFA | Compactness | Combination of i-AHP and i-GAM | √ |

| [185] | Dam | SVR with CFA | SVR with CFA | ||

| [186] | Dam | SBFA-CKSVR | CMV | SBFA-CKSVR | |

| [187] | Dam | Cloud-fuzzy | Cloud-fuzzy | ||

| [117] | Dam | SLR | |||

| [91] | Dam | MLR | CV | ||

| [188] | Road | SLR/MLR | Compactness | and E | |

| [189] | Airport | Equivalent additional stress | √ | ||

| [190] | SLR/MLR | Geostatistics with CMV or VCV | |||

| [191] | Dam | CDD | CDD-based | ||

| [192] | Road | SLR | CMV | ||

| [122] | Dam | SLR/MLR | Compactness | CV-based | |

| [123] | Dam | SLR/MLR/MNR | Dry density | Combination of E and THD | |

| [193] | Dam | B-ELM | Compactness | B-ELM | √ |

| [124] | Road | SLR | Compactness | Geostatistics with CV | |

| [194] | Dam | Dual coupled | Dry density | Coupled with dry density and reliability | |

| [37] | Dam | RBF | Relative density | ||

| [195] | Dam | MNR | Compactness | √ | |

| [129] | Dam | Fuzzy | CV | Fuzzy evaluation-based D-S | |

| [196] | Dam | ANN | Compactness/Dry density | Based-ANN | |

| [197] | Dam | KM+AC-BFA+FL | Compactness | √ |

| Author | Contribution | PP | OA | CR |

|---|---|---|---|---|

| Sun [206] | Automatic control devices and rolling driving methods | √ | - | - |

| Yao et al. [7] | HEMS, mainly including optimal path algorithm and unmanned vehicle control | √ | - | - |

| Yao et al. [207] | Accurate trajectory tracking for self-driving vibratory roller | √ | - | - |

| Song and Zhang [208] | A simulation model build based on the pure pursuit algorithm | √ | - | - |

| Zhang et al. [209] | Optimal path planning of impact roller | √ | - | - |

| Husemann et al. [210] | The evaluation of the impact of different road compaction strategie | √ | √ | √ |

| Yang et al. [40] | A novel and effective path tracking control of articulated road roller | √ | - | - |

| Song and Xie [211] | A composite disturbance rejection for the path-following control of rollers | √ | - | - |

| Fang et al. [39] | A path following control model for an unmanned vibratory roller | √ | - | - |

| Zhang et al. [17] | Unmanned rolling compaction system, including an unmanned roller, RTK-GPS system, wireless communication system, and remote monitoring center | √ | √ | √ |

| Huang et al. [213] | Autonomous construction system for an unmanned vibratory roller | √ | - | - |

| Chen et al. [41] | An improved technology for unmanned driving | √ | √ | - |

| Shi et al. [42] | Unmanned roller group collaborative complete coverage path planning | √ | √ | √ |

| Shi [43] | Unmanned rolling dam construction technology of high arch dams | √ | - | - |

| Bian et al. [214] | Path following a control method based on fuzzy algorithm | √ | - | - |

| Zou et al. [215] | A method of obstacle detection based on D-S evidence theory | √ | √ | - |

| System | Vibration Compaction Model | Prediction Model Based on AI | Compound Model |

|---|---|---|---|

| AC [46] | - | √ | - |

| IVRCS [47] | - | √ | - |

| IRCSP [44] | √ | √ | - |

| IRC [17] | √ | √ | √ |

| Solution | Conventional Compaction Methods | Digital Rolling Compaction Methods | Automatic Rolling Compaction Methods | Intelligent Control Compaction Methods | |

|---|---|---|---|---|---|

| Problem | |||||

| The number of compaction times is not up to standard | - | √ | √ | √ | |

| Rolling omission, cross rolling, and hypervelocity | - | - | √ | √ | |

| Quality detection of the entire working area | - | √ | - | √ | |

| Feedback control is not accurate and timely | - | - | - | √ | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; An, Z.; Huangfu, Z.; Li, Q. A Review on Roller Compaction Quality Control and Assurance Methods for Earthwork in Five Application Scenarios. Materials 2022, 15, 2610. https://doi.org/10.3390/ma15072610

Zhang Q, An Z, Huangfu Z, Li Q. A Review on Roller Compaction Quality Control and Assurance Methods for Earthwork in Five Application Scenarios. Materials. 2022; 15(7):2610. https://doi.org/10.3390/ma15072610

Chicago/Turabian StyleZhang, Qinglong, Zaizhan An, Zehua Huangfu, and Qingbin Li. 2022. "A Review on Roller Compaction Quality Control and Assurance Methods for Earthwork in Five Application Scenarios" Materials 15, no. 7: 2610. https://doi.org/10.3390/ma15072610

APA StyleZhang, Q., An, Z., Huangfu, Z., & Li, Q. (2022). A Review on Roller Compaction Quality Control and Assurance Methods for Earthwork in Five Application Scenarios. Materials, 15(7), 2610. https://doi.org/10.3390/ma15072610