Investigation of the Anisotropy of 4H-SiC Materials in Nanoindentation and Scratch Experiments

Abstract

:1. Introduction

2. Experiments

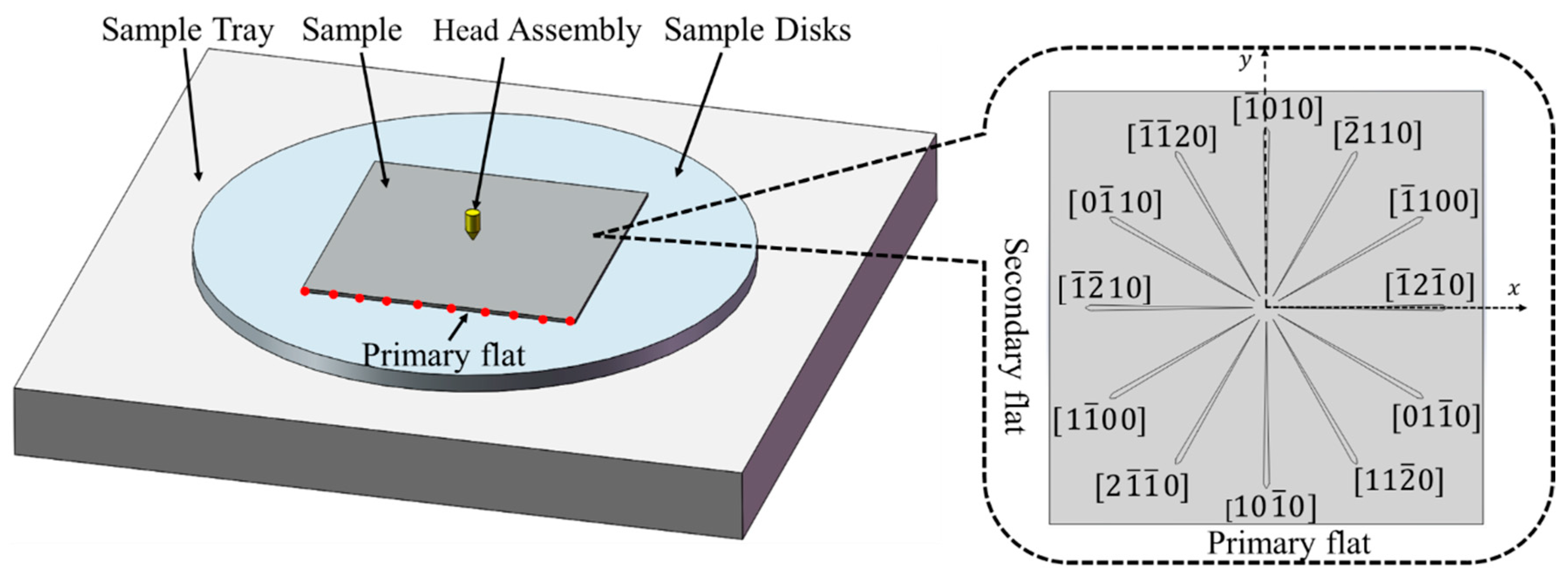

2.1. Experimental Platform

2.2. Experimental Details

2.3. Analysis of the Indentation Test Results of Monocrystalline Silicon Carbide Materials

2.3.1. Young’s Modulus and Hardness of the C- and Si-Planes of 4H-SiC

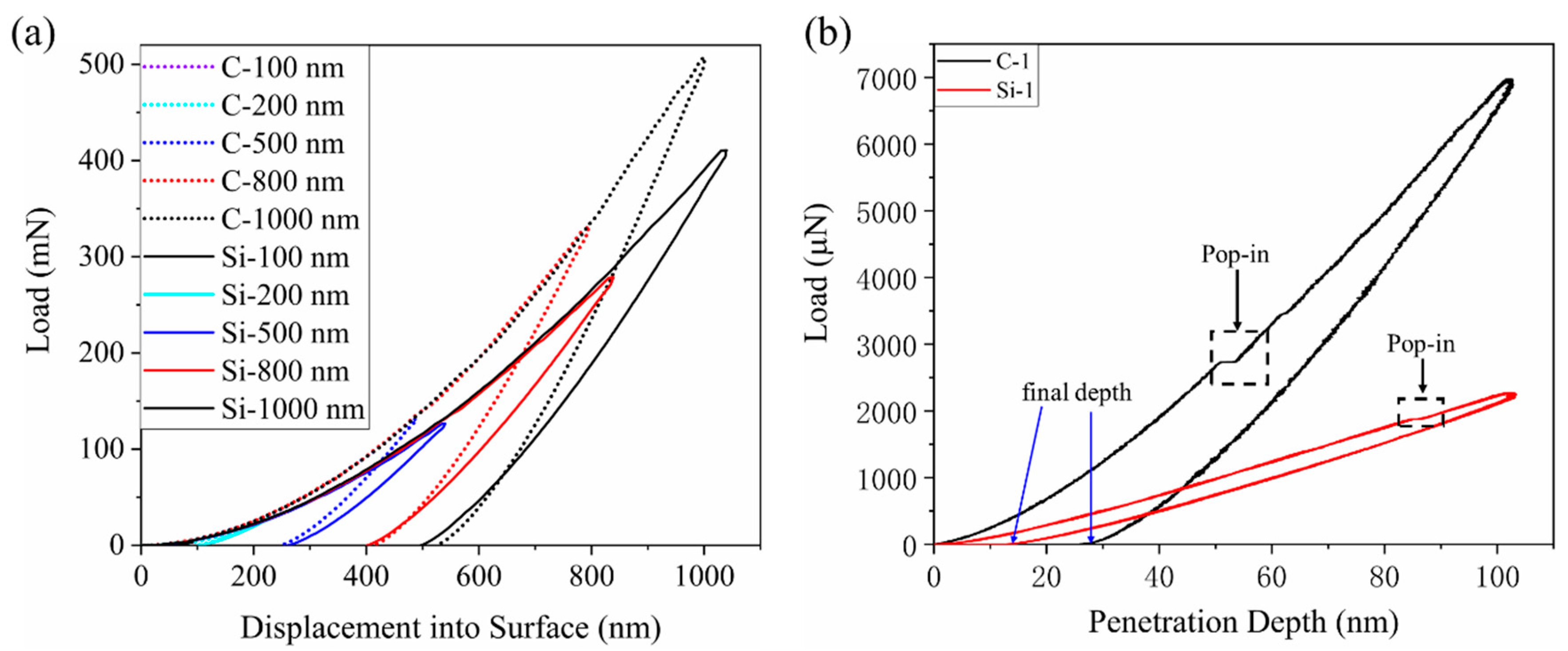

2.3.2. Load Displacement Curves

2.4. Analysis of Nanoscratch Test Results of Monocrystalline Silicon Carbide Materials

2.4.1. Lateral Force

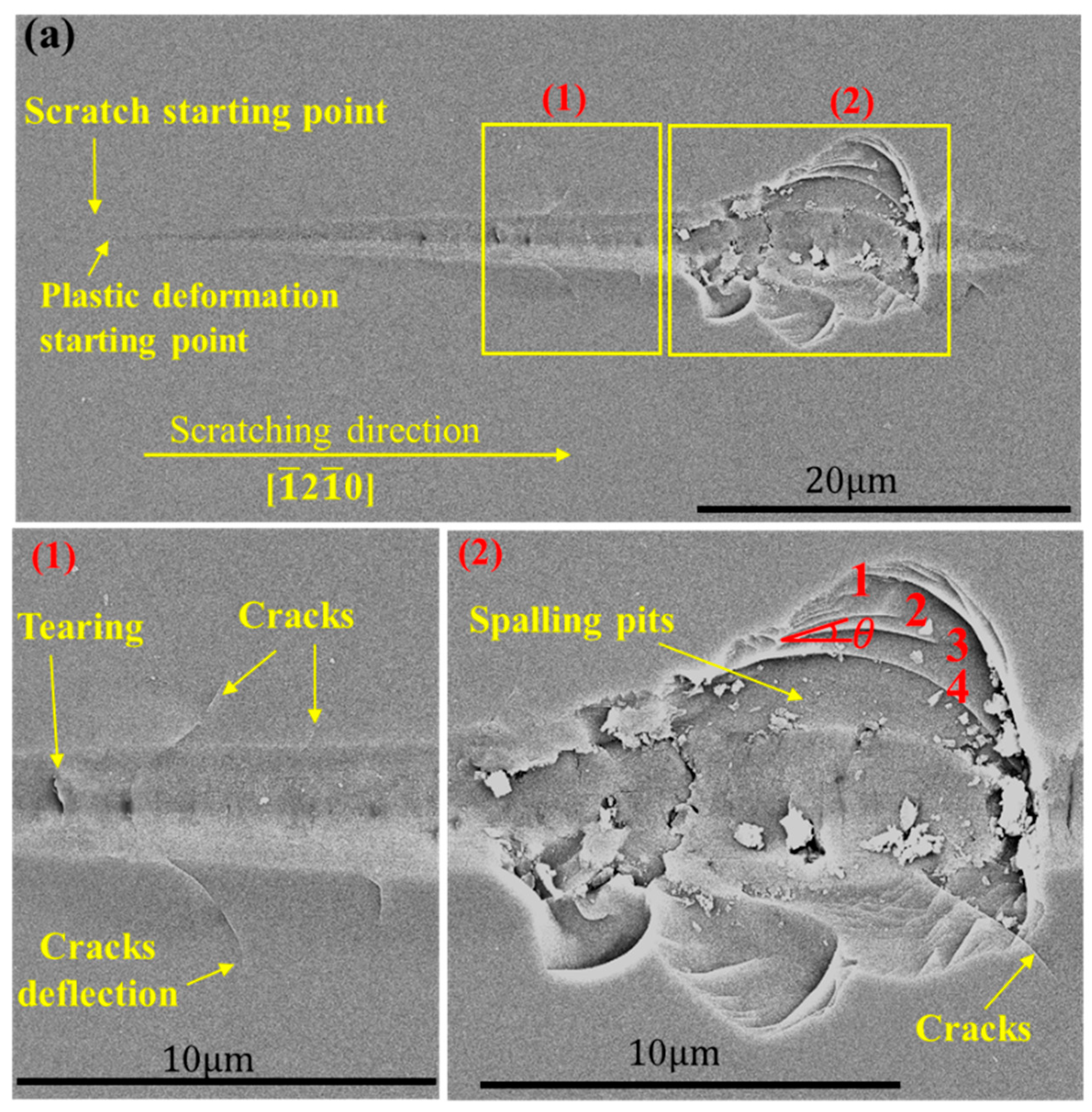

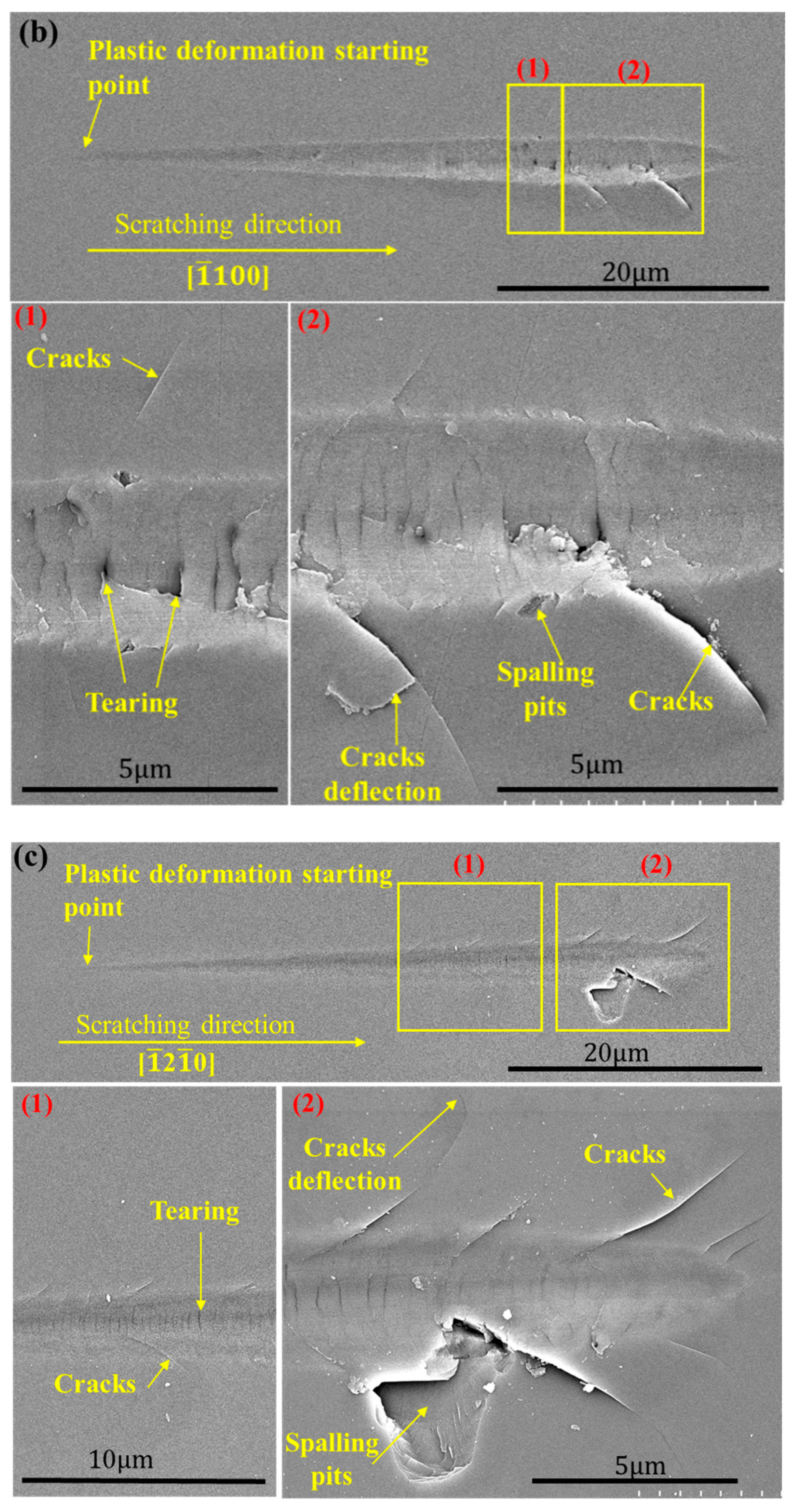

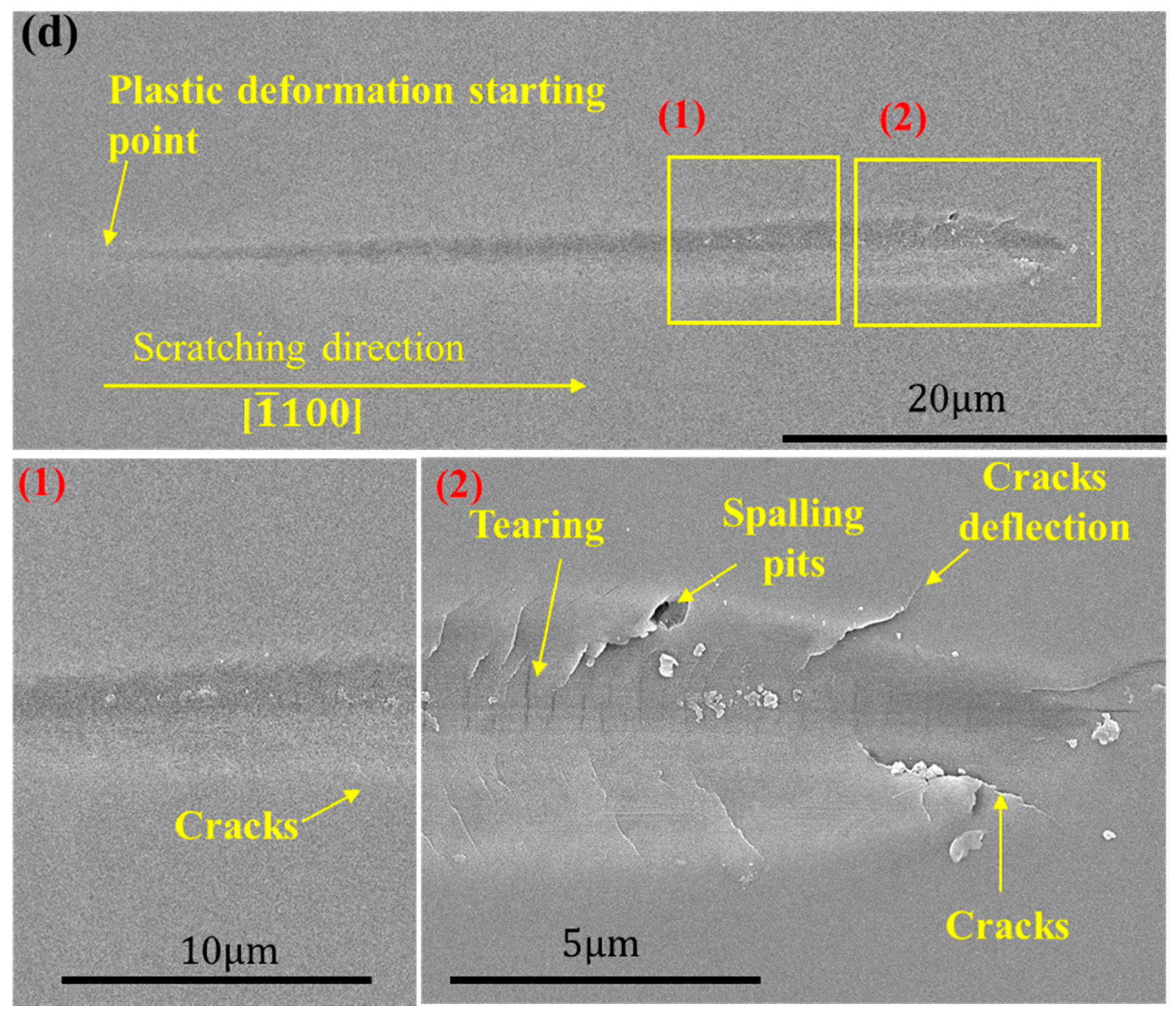

2.4.2. Scratch Morphology of 4H-SiC under SEM

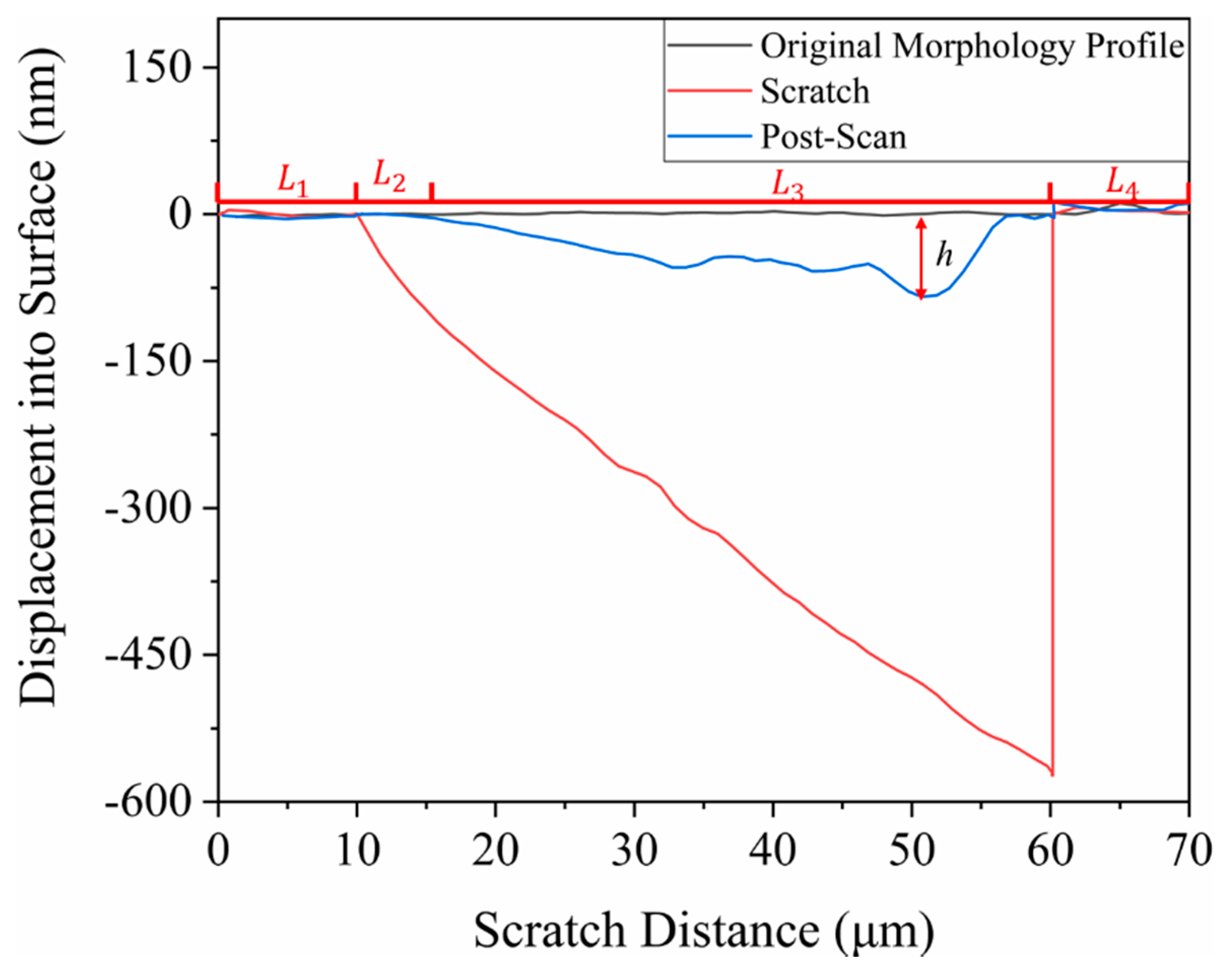

2.4.3. Deformation Length in the Elastic Phase

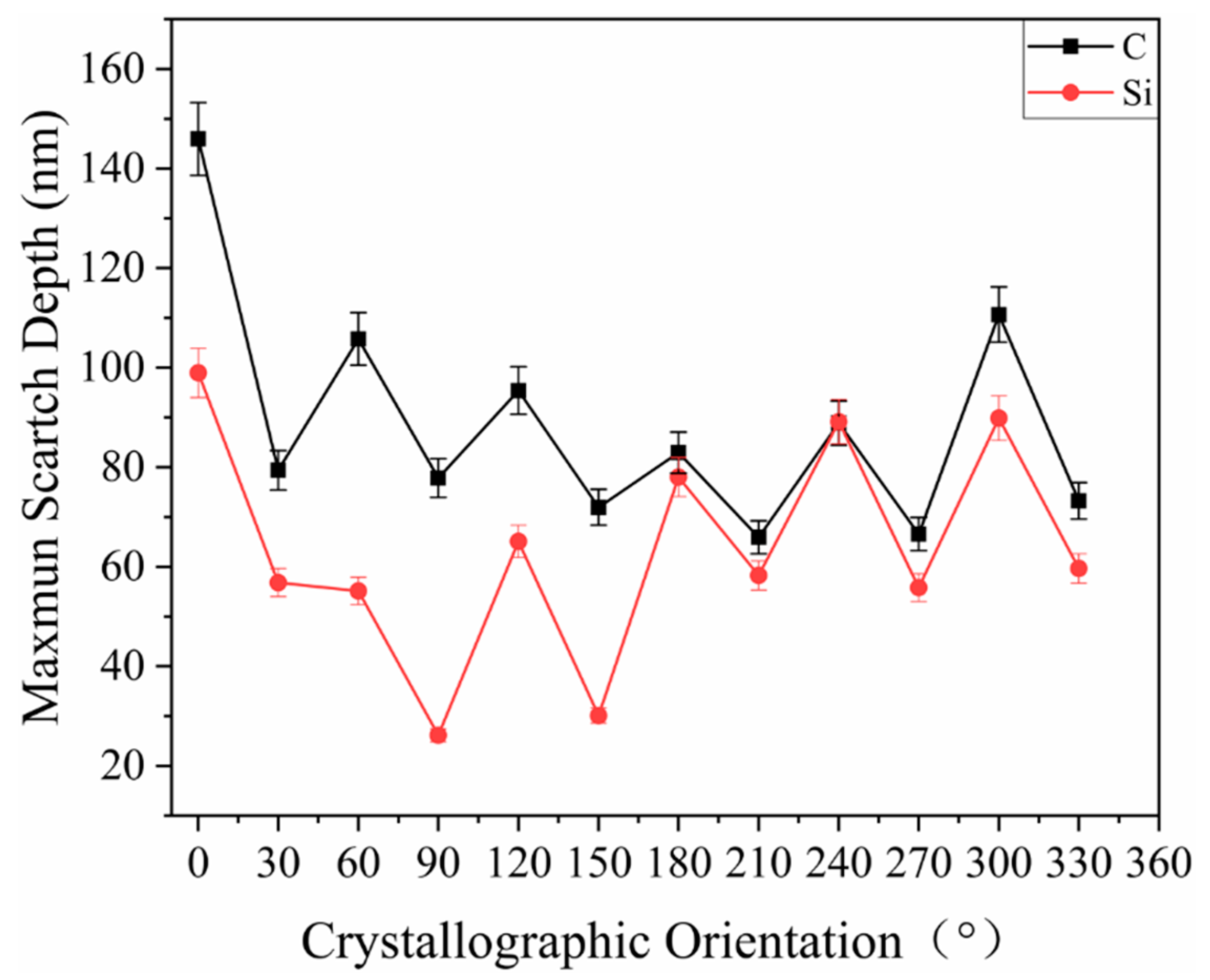

2.4.4. Maximum Scratch Depth

2.4.5. Maximum Width of Cracks Flanking the Scratch

3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, V.; Verma, J.; Maan, A.S.; Akhtar, J.J.V. Epitaxial 4H–SiC based Schottky diode temperature sensors in ultra-low current range. Vacuum 2020, 182, 109590. [Google Scholar] [CrossRef]

- Kumar, V.; Maan, A.S.; Akhtar, J. Defect levels in high energy heavy ion implanted4H-SiC. Mater. Lett. 2022, 308, 131150. [Google Scholar] [CrossRef]

- Datye, A.; Schwarz, U.; Lin, H.-T. Fracture Toughness Evaluation and Plastic Behavior Law of a Single Crystal Silicon Carbide by Nanoindentation. Ceramics 2018, 1, 198–210. [Google Scholar] [CrossRef] [Green Version]

- Goel, S.; Luo, X.; Comley, P.; Reuben, R.L.; Cox, A. Brittle–ductile transition during diamond turning of single crystal silicon carbide. Int. J. Mach. Tools Manuf. 2013, 65, 15–21. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Li, B.; Kong, L. A molecular dynamics investigation into nanoscale scratching mechanism of polycrystalline silicon carbide. Comput. Mater. Sci. 2018, 148, 76–86. [Google Scholar] [CrossRef]

- Jacob, J. Numerical Simulations on Machining of Silicon Carbide; Western MichiganUniversity: Kalamazoo, MI, USA, 2006; p. 5028. [Google Scholar]

- Liu, Y.; Li, B.; Kong, L. Atomistic insights on the nanoscale single grain scratching mechanism of silicon carbide ceramic based on molecular dynamics simulation. AIP Adv. 2018, 8, 035109. [Google Scholar] [CrossRef] [Green Version]

- Pirouz, P.; Zhang, M.; Demenet, J.L.; Hobgood, H.M. Transition from brittleness to ductility in SiC. J. Phys. Condens. Matter 2002, 14, 12929. [Google Scholar] [CrossRef]

- Yu, M.; Jayanthi, C.S.; Wu, S.Y. Geometric and electronic structures of graphitic-like and tubular silicon carbides: Ab-initio studies. Phys. Rev. B 2010, 82, 075407. [Google Scholar] [CrossRef] [Green Version]

- Miyoshi, K.; Buckley, D.H. Anisotropic Tribological Properties of Silicon Carbide; NASA Technical Memorandumdum; NASA Dryden Flight Research Center: Edwards, CA, USA, 1981; p. 81547. [Google Scholar]

- Wang, J. Study on Damage Mechanism of SiC Single Crystal Wafer Based on Indentation/Scratch Technology; Zhengzhou University: Zhengzhou, China, 2019. [Google Scholar]

- Salem, Z.L.J.A.; Bradt, R.C. Thermal Expansion and Elastic Anisotropy in Single Crystal Al2O3 and SiC Reinforcements; NASA Techical Memorandum; NASA Dryden Flight Research Center: Edwards, CA, USA, 1986; p. 106516.

- Kunka, C.; Trachet, A.; Subhash, G.; Lara-Curzio, E. Interaction of Indentation-Induced Cracks on Single-Crystal Silicon Carbide. J. Am. Ceram. Soc. 2015, 98, 1891–1897. [Google Scholar] [CrossRef]

- Prasad, K.E.; Ramesh, K.T. Hardness and mechanical anisotropy of hexagonal SiC single crystal polytypes. J. Alloys Compd. 2019, 770, 158–165. [Google Scholar] [CrossRef]

- Zhang, L.; Xie, J.; Zhu, L.M. Experimental study on ductile-to-brittle behavior and crystal orientation in micro-crack induced severing of 4H-SiC and sapphire. Theor. Appl. Fract. Mech. 2020, 106, 102481. [Google Scholar] [CrossRef]

- Järrendahl, K.; Davis, R.F. Materials Properties and Characterization of SiC. In Semiconductors and Semimetals; Elsevier: Amsterdam, The Netherlands, 1998; p. 52. [Google Scholar]

| Main Technical Indicators | Parameter |

|---|---|

| XP mode displacement resolution | <0.01 nm |

| XP mode load resolution | <50 Nn |

| DCM mode displacement resolution | <0.0002 nm |

| DCM mode load resolution | <30 Nn |

| Scratch speed | 0.1 µm/s to 2.5 mm/s |

| Maximum lateral force resolution | 2 µN |

| Test Parameters | Numerical Value |

|---|---|

| Fillet radius of indenter | 5 |

| Maximum load | 200 Mn |

| Scratch speed | 10 /s |

| Length of scratches | 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, S.; Yu, Y.; Wang, N.; Zhang, Y.; Shi, W.; Liao, X.; Duan, N. Investigation of the Anisotropy of 4H-SiC Materials in Nanoindentation and Scratch Experiments. Materials 2022, 15, 2496. https://doi.org/10.3390/ma15072496

Shi S, Yu Y, Wang N, Zhang Y, Shi W, Liao X, Duan N. Investigation of the Anisotropy of 4H-SiC Materials in Nanoindentation and Scratch Experiments. Materials. 2022; 15(7):2496. https://doi.org/10.3390/ma15072496

Chicago/Turabian StyleShi, Suhua, Yiqing Yu, Ningchang Wang, Yong Zhang, Weibin Shi, Xinjiang Liao, and Nian Duan. 2022. "Investigation of the Anisotropy of 4H-SiC Materials in Nanoindentation and Scratch Experiments" Materials 15, no. 7: 2496. https://doi.org/10.3390/ma15072496

APA StyleShi, S., Yu, Y., Wang, N., Zhang, Y., Shi, W., Liao, X., & Duan, N. (2022). Investigation of the Anisotropy of 4H-SiC Materials in Nanoindentation and Scratch Experiments. Materials, 15(7), 2496. https://doi.org/10.3390/ma15072496