Programming Soft Shape-Morphing Systems by Harnessing Strain Mismatch and Snap-Through Bistability: A Review

Abstract

:1. Introduction

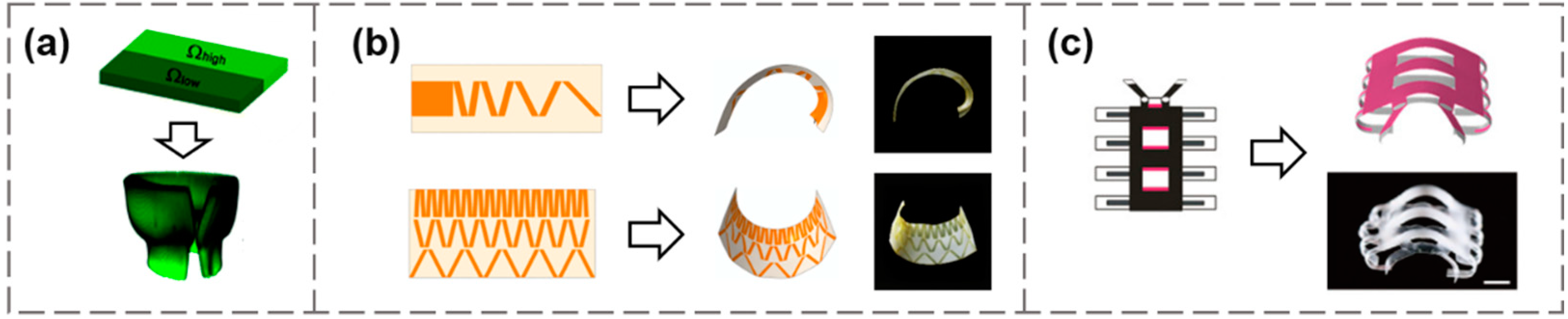

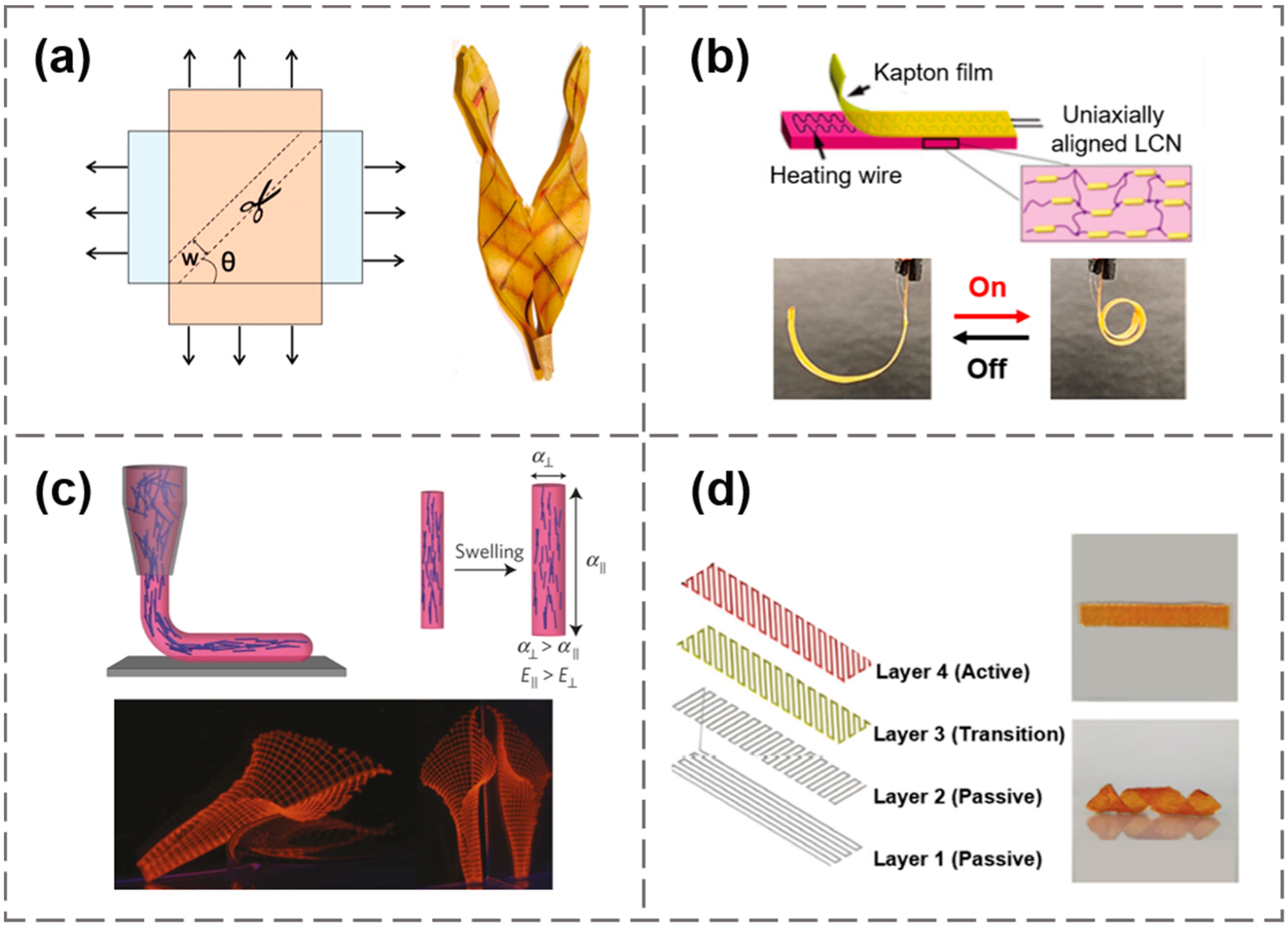

2. Heterogeneous Material Composition

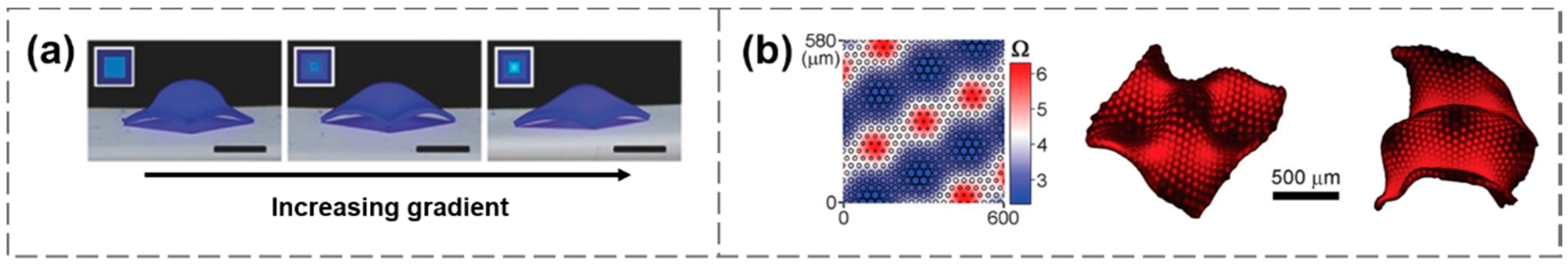

2.1. In-Plane Inhomogeneity

2.2. Through-Thickness Inhomogeneity

3. Structural Instability

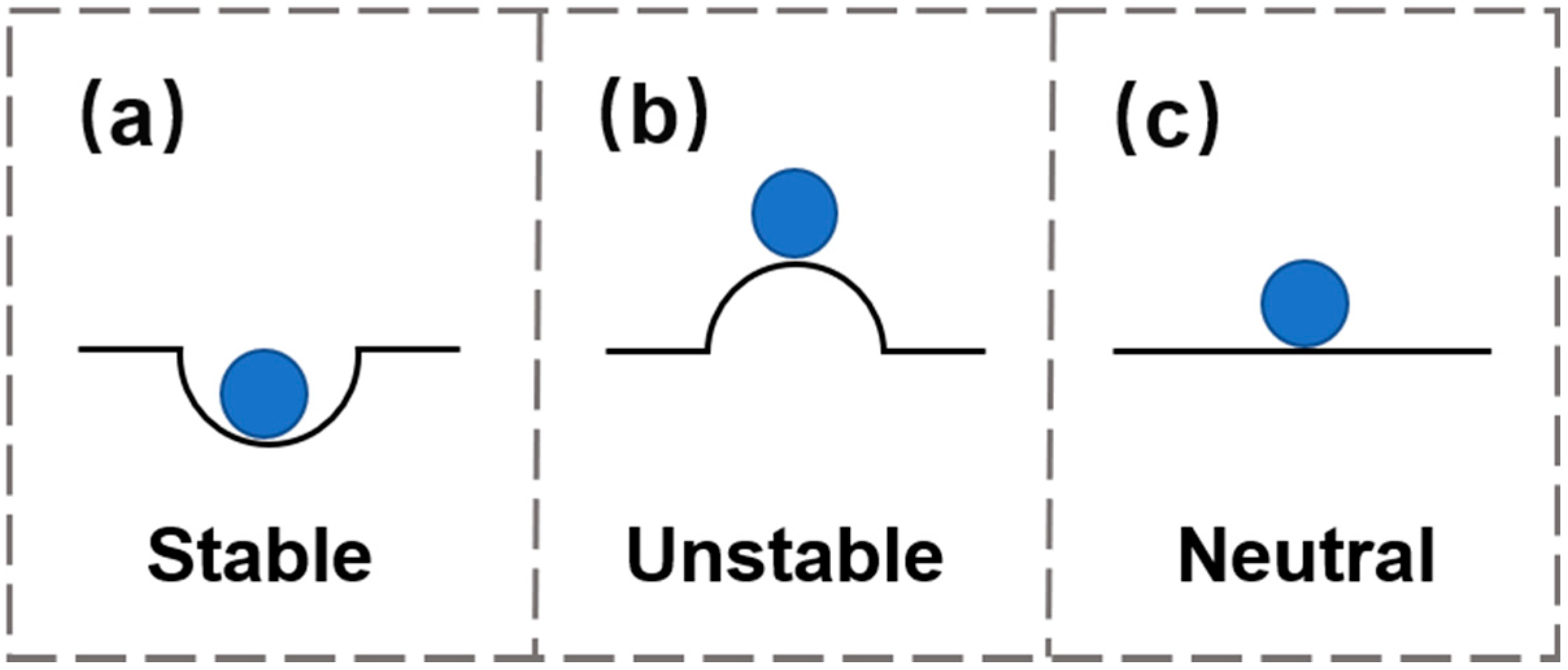

3.1. Energy and Stability of Shape-Morphing Structures

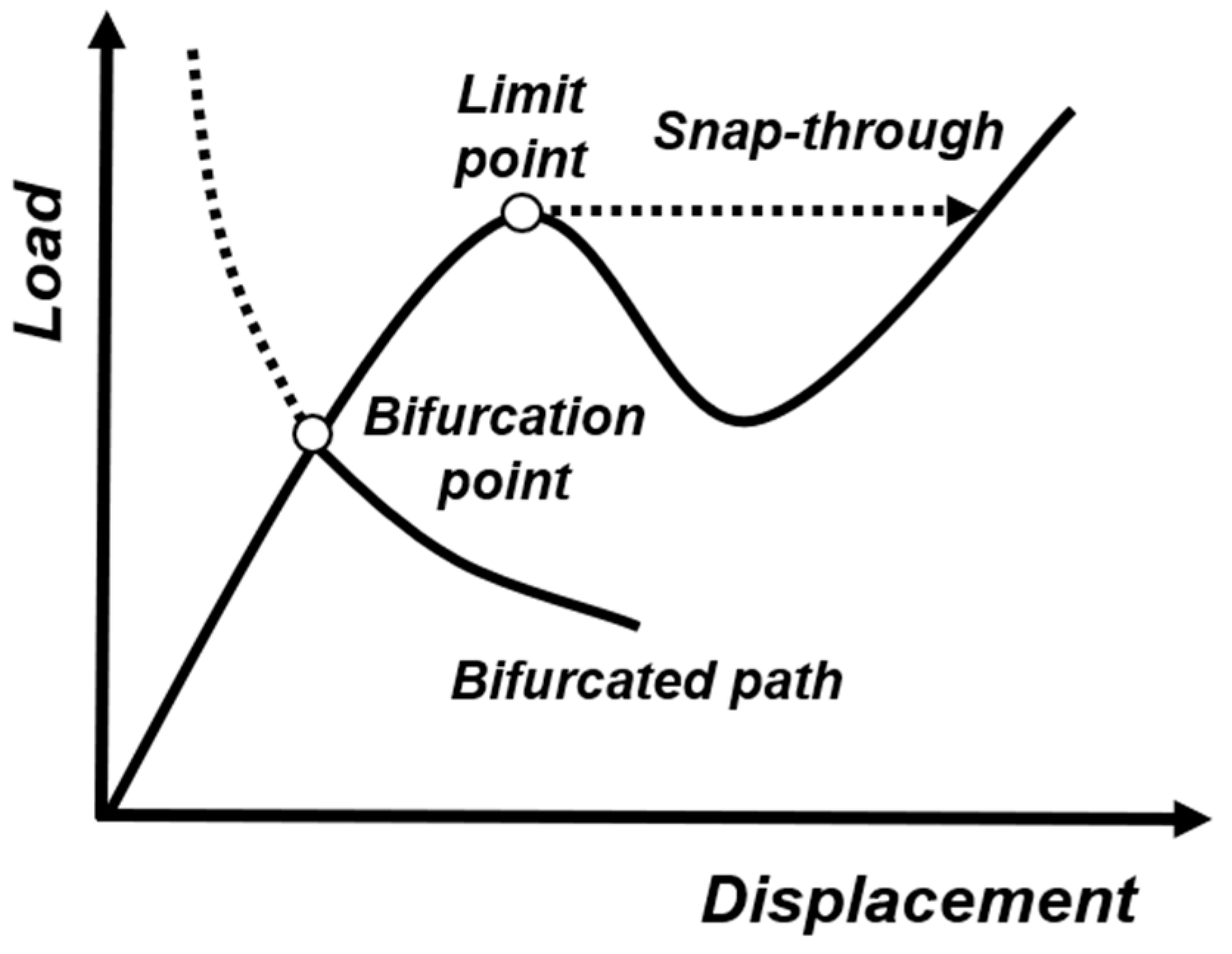

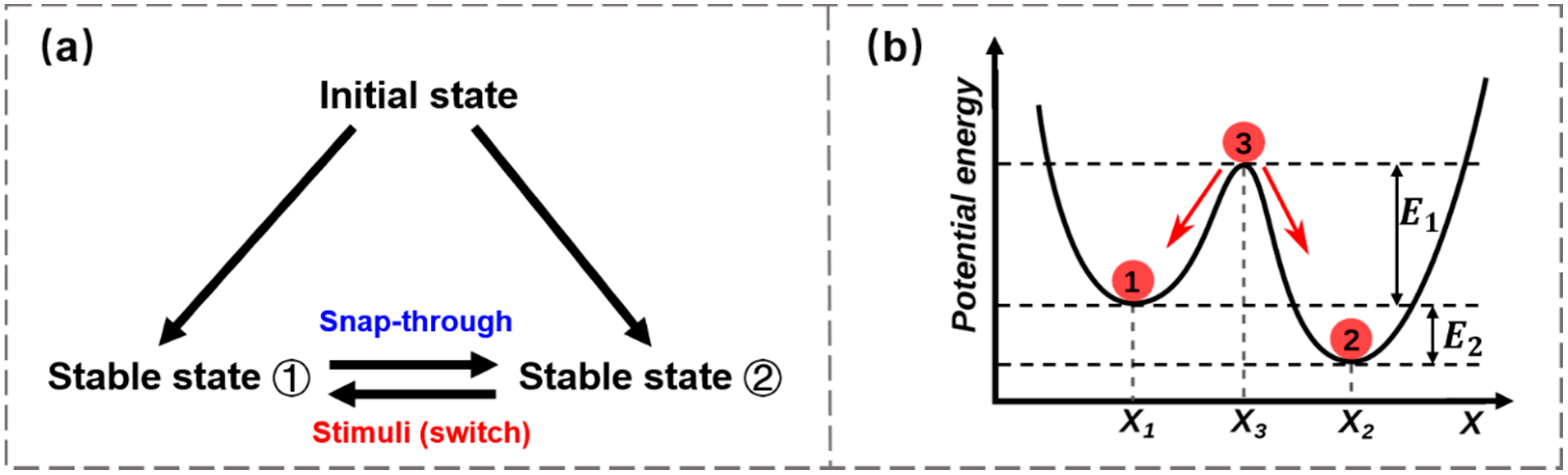

3.2. Bifurcation and Snap-Through Instability

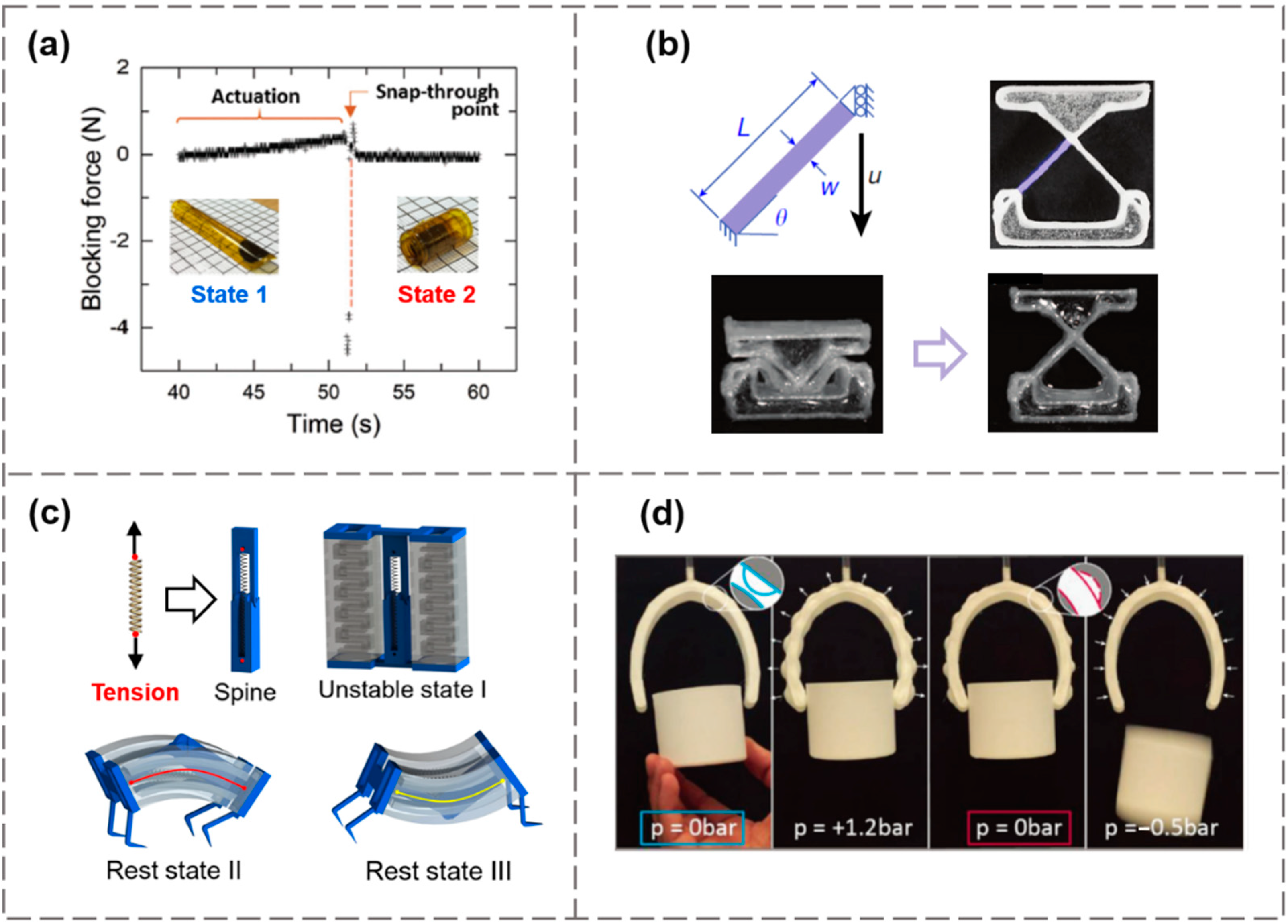

3.3. Snap-Through Bistability in Soft Actuators

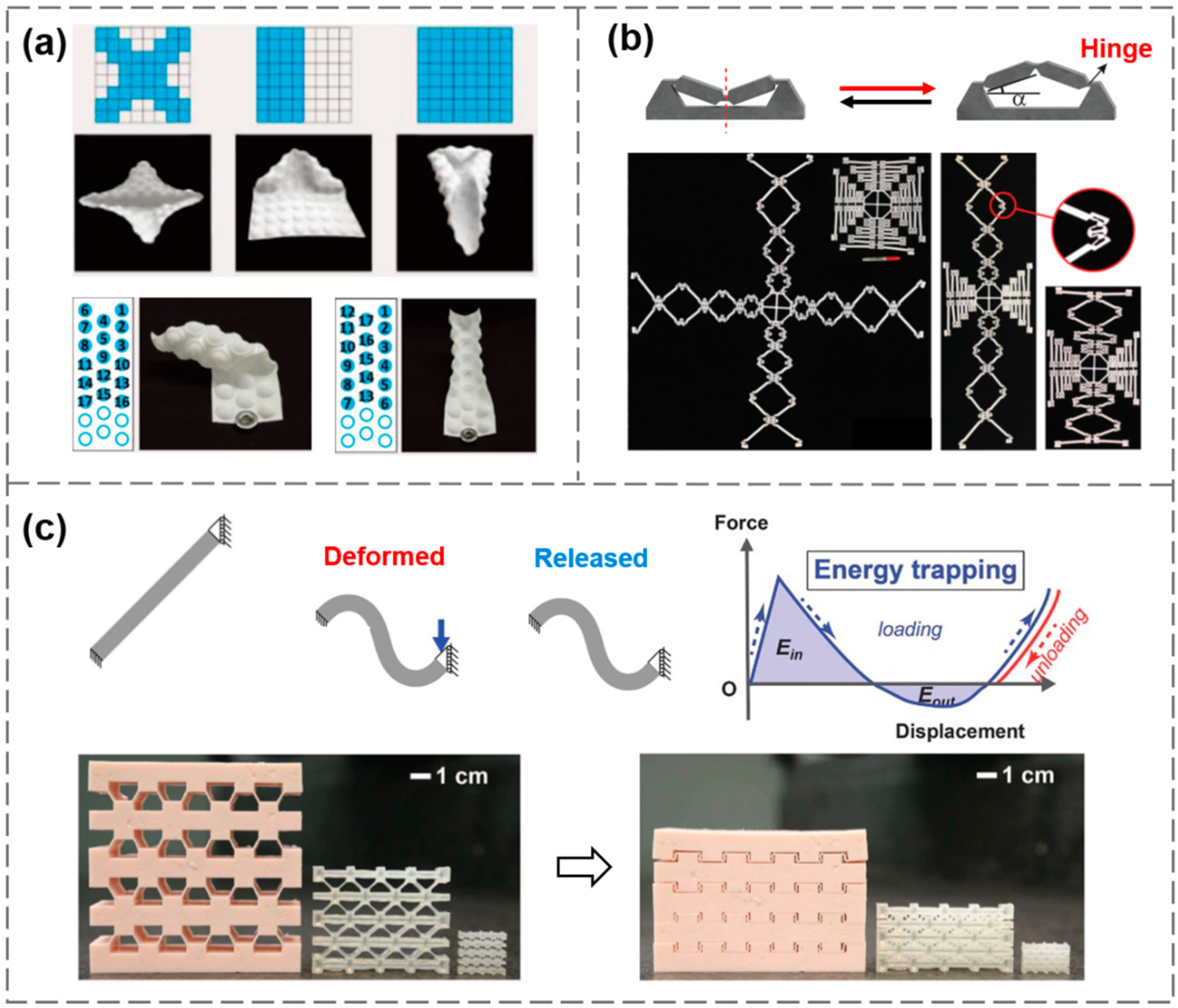

3.4. Structural Bistability in Mechanical Metamaterials

4. Conclusions

- Mismatch strains caused by in-plane or through-thickness heterogeneity of material composition can generate two fundamental deformation modes, buckling and bending, which can be combined to achieve complex deformations.

- Due to the intrinsic characteristics of soft materials, the mismatch-induced shape-morphing in soft materials typically exhibits slow locomotion speed and low mechanical strength, limiting their applications in many scenarios.

- As an alternative programming strategy of soft morphing structures/devices, structural bistability has been widely used in the design of soft actuators due to the fast snap-through transition between bistable states.

- During the snap-through transition, large-magnitude deformations or dramatic shape changes arise within a short period of time (tens of milliseconds) due to the sudden release of stored strain energy, resulting in relatively large output forces at relatively low energy inputs.

- Structural bistability also provides a self-locking mechanism to maintain the deformed shape without external input, which can be employed in programmable metamaterials.

- It would be promising to integrate strain mismatch and snap-through bistability strategies to increase the richness and utility of shape transformations for practical applications.

5. Future Prospects

- Reasonable layout design of responsive materials in bistable structures is still difficult and lacks effective theoretical and numerical guidance. Spatial arrangements such as proportions and positions of active and passive components can greatly affect the trigger sensitivity of snap-through movements.

- The selected smart materials should generate sufficient energy output under external stimuli to overcome the energy barrier. The development of new soft materials with high energy and power densities is of particular importance.

- Existing studies mostly focused on simple bistable structures, such as beams and shells, with little effort made to explore multi-stable structures with multiple equilibrium configurations that offer more shape transformation possibilities, which may endow actuators with richer working modes.

- When integrating a certain number of binary bistable units to construct a multi-stable system, it is challenging to use a single (or fewer) actuation input without sacrificing the rich reconfigurability. As the number of units increases, the individual control and sequential actuation of each bistable unit become intricate.

- Making the snap-through actuation repeatable and reversible is the key to transforming shape changes into a continuous motion. The current solution is to adopt pneumatic control systems, but this is not suitable for smart material systems.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gu, G.Y.; Zou, J.; Zhao, R.K.; Zhao, X.H. Soft wall-climbing robots. Sci. Robot. 2018, 3, eaat2874. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alapan, Y.; Karacakol, A.C.; Guzelhan, S.N.; Isik, I.; Sitti, M. Reprogrammable shape morphing of magnetic soft machines. Sci. Adv. 2020, 6, eabc6414. [Google Scholar] [CrossRef] [PubMed]

- Cui, J.; Huang, T.Y.; Luo, Z.; Testa, P.; Gu, H.; Chen, X.Z.; Nelson, B.J.; Heyderman, L.J. Nanomagnetic encoding of shape-morphing micromachines. Nature 2019, 575, 164–168. [Google Scholar] [CrossRef] [PubMed]

- Carrico, J.D.; Tyler, T.; Leang, K.K. A comprehensive review of select smart polymeric and gel actuators for soft mechatronics and robotics applications: Fundamentals, freeform fabrication, and motion control. Int. J. Smart Nano Mater. 2017, 8, 144–213. [Google Scholar] [CrossRef] [Green Version]

- Zheng, S.Y.; Ding, H.; Qian, J.; Yin, J.; Wu, Z.L.; Song, Y.H.; Zheng, Q. Metal-coordination complexes mediated physical hydrogels with high toughness, stick-slip tearing behavior, and good processability. Macromolecules 2016, 49, 9637–9646. [Google Scholar] [CrossRef]

- Jeon, S.J.; Hauser, A.W.; Hayward, R.C. Shape-morphing materials from stimuli-responsive hydrogel hybrids. Acc. Chem. Res. 2017, 50, 161–169. [Google Scholar] [CrossRef]

- Liu, X.G.; Zhang, F.; Jing, X.X.; Pan, M.C.; Liu, P.; Li, W.; Zhu, B.W.; Li, J.; Chen, H.; Wang, L.H.; et al. Complex silica composite nanomaterials templated with DNA origami. Nature 2018, 559, 593–598. [Google Scholar] [CrossRef]

- Zhu, F.B.; Cheng, L.B.; Wang, Z.J.; Hong, W.; Wu, Z.L.; Yin, J.; Qian, J.; Zheng, Q. 3D-printed ultratough hydrogel structures with titin-like domains. ACS Appl. Mater. Interfaces 2017, 9, 11363–11367. [Google Scholar] [CrossRef]

- Gladman, A.S.; Matsumoto, E.A.; Nuzzo, R.G.; Mahadevan, L.; Lewis, J.A. Biomimetic 4D printing. Nat. Mater. 2016, 15, 413–418. [Google Scholar] [CrossRef]

- Cao, K.; Yang, H.K.; Gao, L.B.; Han, Y.; Feng, J.Y.; Yang, H.W.; Zhang, H.Y.; Wang, W.D. In situ mechanical characterization of silver nanowire/graphene hybrids films for flexible electronics. Int. J. Smart Nano Mater. 2020, 11, 265–276. [Google Scholar] [CrossRef]

- Zhu, F.B.; Zheng, S.Y.; Lin, J.; Wu, Z.L.; Yin, J.; Qian, J.; Qu, S.X.; Zheng, Q. Integrated multifunctional flexible electronics based on tough supramolecular hydrogels with patterned silver nanowires. J. Mater. Chem. C 2020, 8, 7688–7697. [Google Scholar] [CrossRef]

- Zhong, R.B.; Tang, Q.; Wang, S.P.; Zhang, H.B.; Zhang, F.; Xiao, M.S.; Man, T.T.; Qu, X.M.; Li, L.; Zhang, W.J.; et al. Self-assembly of enzyme-like nanofibrous G-molecular hydrogel for printed flexible electrochemical sensors. Adv. Mater. 2018, 30, 1706887. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Khademhosseini, A. Advances in engineering hydrogels. Science 2017, 356, eaaf3627. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Wang, Y.; Chuang, K.; Wu, F.; Wang, Q.; Lin, W.; Jiang, H. A brief review of dynamic mechanical metamaterials for mechanical energy manipulation. Mater. Today 2021, 44, 168–193. [Google Scholar] [CrossRef]

- Zhai, Z.; Wu, L.; Jiang, H. Mechanical metamaterials based on origami and kirigami. Appl. Phys. Rev. 2021, 8, 041319. [Google Scholar] [CrossRef]

- Zhang, H.; Guo, X.G.; Wu, J.; Fang, D.N.; Zhang, Y.H. Soft mechanical metamaterials with unusual swelling behavior and tunable stress-strain curves. Sci. Adv. 2018, 4, eaar8535. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kadic, M.; Milton, G.W.; van Hecke, M.; Wegener, M. 3D metamaterials. Nat. Rev. Phys. 2019, 1, 198–210. [Google Scholar] [CrossRef]

- Kolken, H.M.; Zadpoor, A.A. Auxetic mechanical metamaterials. RSC Adv. 2017, 7, 5111–5129. [Google Scholar] [CrossRef] [Green Version]

- Rafsanjani, A.; Jin, L.S.; Deng, B.L.; Bertoldi, K. Propagation of pop ups in kirigami shells. Proc. Natl. Acad. Sci. USA 2019, 116, 8200–8205. [Google Scholar] [CrossRef]

- van Manen, T.; Janbaz, S.; Zadpoor, A.A. Programming the shape-shifting of flat soft matter. Mater. Today 2018, 21, 144–163. [Google Scholar] [CrossRef]

- De Gennes, P.G. Soft matter. Rev. Mod. Phys. 1992, 64, 645. [Google Scholar] [CrossRef]

- Truby, R.L.; Lewis, J.A. Printing soft matter in three dimensions. Nature 2016, 540, 371–378. [Google Scholar] [CrossRef] [PubMed]

- Lendlein, A.; Jiang, H.Y.; Jünger, O.; Langer, R. Light-induced shape-memory polymers. Nature 2005, 434, 879–882. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Y.C.; Lu, H.C.; Lee, X.; Zeng, H.; Priimagi, A. Kirigami-based light-induced shape-morphing and locomotion. Adv. Mater. 2020, 32, 1906233. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, J.; Huang, J.; Zhang, H.; Hu, Y.H. A photoresponsive hydrogel with enhanced photoefficiency and the decoupled process of light activation and shape changing for precise geometric control. ACS Appl. Mater. Interfaces 2020, 12, 38647–38654. [Google Scholar] [CrossRef] [PubMed]

- Nojoomi, A.; Arslan, H.; Lee, K.; Yum, K. Bioinspired 3D structures with programmable morphologies and motions. Nat. Commun. 2018, 9, 3705. [Google Scholar] [CrossRef]

- Xia, Y.L.; He, Y.; Zhang, F.H.; Liu, Y.J.; Leng, J.S. A review of shape memory polymers and composites: Mechanisms, materials, and applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Z.A.; Kuang, X.; Yuan, C.; Qi, H.; Fang, D.N. Hydrophilic/hydrophobic composite shape-shifting structures. ACS Appl. Mater. Interfaces 2018, 10, 19932–19939. [Google Scholar] [CrossRef] [PubMed]

- Wani, O.M.; Verpaalen, R.; Zeng, H.; Priimagi, A.; Schenning, A.P. An artificial nocturnal flower via humidity-gated photoactuation in liquid crystal networks. Adv. Mater. 2019, 31, 1805985. [Google Scholar] [CrossRef]

- Andres, C.M.; Zhu, J.; Shyu, T.; Flynn, C.; Kotov, N.A. Shape-morphing nanocomposite origami. Langmuir 2014, 30, 5378–5385. [Google Scholar] [CrossRef]

- Lin, Q.M.; Li, L.Y.; Tang, M.; Hou, X.S.; Ke, C.F. Rapid macroscale shape morphing of 3D-printed polyrotaxane monoliths amplified from pH-controlled nanoscale ring motions. J. Mater. Chem. C 2018, 6, 11956–11960. [Google Scholar] [CrossRef]

- Suhail, M.; Fang, C.W.; Khan, A.; Minhas, M.U.; Wu, P.C. Fabrication and in vitro evaluation of pH-sensitive polymeric hydrogels as controlled release carriers. Gels 2021, 7, 110. [Google Scholar] [CrossRef] [PubMed]

- Shao, H.; Wei, S.; Jiang, X.; Holmes, D.P. Bioinspired electrically activated soft bistable actuators. Adv. Funct. Mater. 2018, 28, 1802999. [Google Scholar] [CrossRef]

- Xu, X.; Jerca, V.V.; Hoogenboom, R. Bioinspired double network hydrogels: From covalent double network hydrogels via hybrid double network hydrogels to physical double network hydrogels. Mater. Horiz. 2021, 8, 1173–1188. [Google Scholar] [CrossRef] [PubMed]

- Xue, P.; Bisoyi, H.K.; Chen, Y.H.; Zeng, H.; Yang, J.J.; Yang, X.; Lv, P.F.; Zhang, X.M.; Priimagi, A.; Wang, L.; et al. Near-infrared light-driven shape-morphing of programmable anisotropic hydrogels enabled by MXene nanosheets. Angew. Chem. Int. Ed. 2021, 60, 3390–3396. [Google Scholar] [CrossRef] [PubMed]

- Kirillova, A.; Maxson, R.; Stoychev, G.; Gomillion, C.T.; Lonov, L. 4D biofabrication using shape-morphing hydrogels. Adv. Mater. 2017, 29, 1703443. [Google Scholar] [CrossRef]

- Naficy, S.; Gately, R.; Gorkin, R., III; Xin, H.; Spinks, G.M. 4D printing of reversible shape morphing hydrogel structures. Macromol. Mater. Eng. 2017, 302, 1600212. [Google Scholar] [CrossRef]

- Xin, X.Z.; Liu, L.W.; Liu, Y.J.; Lemg, J.S. 4D pixel mechanical metamaterials with programmable and reconfigurable properties. Adv. Funct. Mater. 2021, 32, 2107795. [Google Scholar] [CrossRef]

- Liu, R.Y.; Kuang, X.; Deng, J.N.; Wang, Y.C.; Wang, A.C.; Ding, W.B.; Lai, Y.C.; Chen, J.; Wang, P.H.; Lin, Z.Q.; et al. Shape memory polymers for body motion energy harvesting and self-powered mechanosensing. Adv. Mater. 2018, 30, 1705195. [Google Scholar] [CrossRef]

- Zhao, Q.; Zou, W.K.; Luo, Y.W.; Xie, T. Shape memory polymer network with thermally distinct elasticity and plasticity. Sci. Adv. 2016, 2, e1501297. [Google Scholar] [CrossRef] [Green Version]

- Zare, M.; Davoodi, P.; Ramakrishna, S. Electrospun shape memory polymer micro-/nanofibers and tailoring their roles for biomedical applications. Nanomaterials 2021, 11, 933. [Google Scholar] [CrossRef] [PubMed]

- Ford, M.J.; Ambulo, C.P.; Kent, T.A.; Markvicka, E.J.; Pan, C.F.; Malen, J.; Ware, T.H.; Majidi, C. A multifunctional shape-morphing elastomer with liquid metal inclusions. Proc. Natl. Acad. Sci. USA 2019, 116, 21438–21444. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kotikian, A.; Truby, R.L.; Boley, J.W.; White, T.J.; Lewis, J.A. 3D printing of liquid crystal elastomeric actuators with spatially programed nematic order. Adv. Mater. 2018, 30, 1706164. [Google Scholar] [CrossRef] [PubMed]

- Davidson, E.C.; Kotikian, A.; Li, S.C.; Aizenberg, J.; Lewis, J.A. 3D printable and reconfigurable liquid crystal elastomers with light-induced shape memory via dynamic bond exchange. Adv. Mater. 2020, 32, 1905682. [Google Scholar] [CrossRef] [PubMed]

- Hajiesmaili, E.; Clarke, D.R. Reconfigurable shape-morphing dielectric elastomers using spatially varying electric fields. Nat. Commun. 2019, 10, 183. [Google Scholar] [CrossRef] [Green Version]

- Carpi, F.; Bauer, S.; De Rossi, D. Stretching dielectric elastomer performance. Science 2010, 330, 1759–1761. [Google Scholar] [CrossRef] [PubMed]

- Shian, S.; Bertoldi, K.; Clarke, D.R. Dielectric elastomer based “grippers” for soft robotics. Adv. Mater. 2015, 27, 6814–6819. [Google Scholar] [CrossRef] [PubMed]

- Gong, J.P.; Katsuyama, Y.; Kurokawa, T.; Osada, Y. Double-network hydrogels with extremely high mechanical strength. Adv. Mater. 2003, 15, 1155–1158. [Google Scholar] [CrossRef]

- Nonoyama, T.; Gong, J.P. Tough double network hydrogel and its biomedical applications. Annu. Rev. Chem. Biomol. Eng. 2021, 12, 393–410. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Wang, X.; Yang, F.; Shen, H.; Wu, D.C. A universal soaking strategy to convert composite hydrogels into extremely tough and rapidly recoverable double-network hydrogels. Adv. Mater. 2016, 28, 7178–7184. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, S.; Samanta, S.K. Soft-nanocomposites of nanoparticles and nanocarbons with supramolecular and polymer gels and their applications. Chem. Rev. 2016, 116, 11967–12028. [Google Scholar] [CrossRef] [PubMed]

- Nardecchia, S.; Jiménez, A.; Morillas, J.R.; Vicente, J.D. Synthesis and rheological properties of 3D structured self-healing magnetic hydrogels. Polymer 2021, 218, 123489. [Google Scholar] [CrossRef]

- Li, Y.; Huang, G.; Zhang, X.; Li, B.; Chen, Y.M.; Lu, T.L.; Lu, T.J.; Xu, F. Magnetic hydrogels and their potential biomedical applications. Adv. Funct. Mater. 2013, 23, 660–672. [Google Scholar] [CrossRef]

- Jiang, Y.; Korpas, L.M.; Raney, J.R. Bifurcation-based embodied logic and autonomous actuation. Nat. Commun. 2019, 10, 128. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cao, Y.; Derakhshani, M.; Fang, Y.H.; Huang, G.L.; Cao, C.Y. Bistable structures for advanced functional systems. Adv. Funct. Mater. 2021, 31, 2106231. [Google Scholar] [CrossRef]

- Qi, J.X.; Chen, Z.H.; Jiang, P.; Hu, W.X.; Wang, Y.H.; Zhao, Z.A.; Cao, X.F.; Zhang, S.S.; Tan, R.; Li, Y.; et al. Recent progress in active mechanical metamaterials and construction principles. Adv. Sci. 2021, 9, 2102662. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Hanna, J.A.; Hayward, R.C.; Santangelo, C.D. Thermally responsive rolling of thin gel strips with discrete variations in swelling. Soft Matter 2012, 8, 2375–2381. [Google Scholar] [CrossRef]

- Peng, W.J.; Zhang, G.G.; Liu, J.; Nie, S.; Wu, Y.; Deng, S.H.; Fang, G.Q.; Zhou, J.; Song, J.Z.; Qian, J.; et al. Light-coded digital crystallinity patterns toward bioinspired 4D transformation of shape-memory polymers. Adv. Funct. Mater. 2020, 30, 2000522. [Google Scholar] [CrossRef]

- Na, J.H.; Evans, A.A.; Bae, J.; Chiappelli, M.C.; Santangelo, C.D.; Lang, R.J.; Hull, T.C.; Hayward, R.C. Programming reversibly self-folding origami with micropatterned photo-crosslinkable polymer trilayers. Adv. Mater. 2015, 27, 79–85. [Google Scholar] [CrossRef] [PubMed]

- Xiao, Y.Y.; Jiang, Z.C.; Tong, X.; Zhao, Y. Biomimetic locomotion of electrically powered “Janus” soft robots using a liquid crystal polymer. Adv. Mater. 2019, 31, 1903452. [Google Scholar] [CrossRef]

- Zheng, S.Y.; Shen, Y.Y.; Zhu, F.B.; Yin, J.; Qian, J.; Fu, J.Z.; Wu, Z.L.; Zheng, Q. Programmed deformations of 3D-printed tough physical hydrogels with high response speed and large output force. Adv. Funct. Mater. 2018, 28, 1803366. [Google Scholar] [CrossRef]

- Tang, Y.C.; Chi, Y.D.; Sun, J.F.; Huang, T.H.; Maghsoudi, O.H.; Spence, A.; Zhao, J.G.; Su, H.; Yin, J. Leveraging elastic instabilities for amplified performance: Spine-inspired high-speed and high-force soft robots. Sci. Adv. 2020, 6, eaaz6912. [Google Scholar] [CrossRef] [PubMed]

- Faber, J.A.; Udani, J.P.; Riley, K.S.; Studart, A.R.; Arrieta, A.F. Dome-patterned metamaterial sheets. Adv. Sci. 2020, 7, 2001955. [Google Scholar] [CrossRef]

- Lin, Y.Q.; Zhang, C.; Tang, W.; Jiao, Z.D.; Wang, J.R.; Wang, W.; Zhong, Y.D.; Zhu, P.G.; Hu, Y.; Yang, H.Y.; et al. A bioinspired stress-response strategy for high-speed soft grippers. Adv. Sci. 2021, 8, 2102539. [Google Scholar] [CrossRef] [PubMed]

- Hahn, M.S.; Taite, L.J.; Moon, J.J.; Rowland, M.C.; Ruffino, K.A.; West, J.L. Photolithographic patterning of polyethylene glycol hydrogels. Biomaterials 2006, 27, 2519–2524. [Google Scholar] [CrossRef] [PubMed]

- Rasch, D.; Gostl, R. Gated photoreactivity of pyrene copolymers in multiresponsive cross-linked starPEG-hydrogels. ACS Polym. Au 2021, 1, 59–66. [Google Scholar] [CrossRef]

- Lee, S.H.; Moon, J.J.; West, J.L. Three-dimensional micropatterning of bioactive hydrogels via two-photon laser scanning photolithography for guided 3D cell migration. Biomaterials 2008, 29, 2962–2968. [Google Scholar] [CrossRef] [Green Version]

- Byun, M.; Santangelo, C.D.; Hayward, R.C. Swelling-driven rolling and anisotropic expansion of striped gel sheets. Soft Matter 2013, 9, 8264–8273. [Google Scholar] [CrossRef]

- Ma, P.; Niu, B.F.; Lin, J.; Kang, T.; Qian, J.; Wu, Z.L.; Zheng, Q. Sequentially controlled deformations of patterned hydrogels into 3D configurations with multilevel structures. Macromol. Rapid Commun. 2019, 40, 1800681. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.F.; Shen, Y.; Yin, J.; Qian, J.; Huang, Y. Nanoclay-based self-supporting responsive nanocomposite hydrogels for printing applications. ACS Appl. Mater. Interfaces 2018, 10, 10461–10470. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.M.; Jiang, R.Q.; Wu, J.; Song, J.Z.; Bai, H.; Li, B.G.; Zhao, Q.; Xie, T. Ultrafast digital printing toward 4D shape changing materials. Adv. Mater. 2017, 29, 1605390. [Google Scholar] [CrossRef] [PubMed]

- Zou, W.K.; Jin, B.J.; Wu, Y.; Song, H.J.; Luo, Y.W.; Huang, F.H.; Qian, J.; Zhao, Q.; Xie, T. Light-triggered topological programmability in a dynamic covalent polymer network. Sci. Adv. 2020, 6, eaaz2362. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kohlmeyer, R.R.; Buskohl, P.R.; Deneault, J.R.; Durstock, M.F.; Vaia, R.A.; Chen, J. Shape-reprogrammable polymers: Encoding, erasing, and re-encoding. Adv. Mater. 2014, 26, 8114–8119. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Hanna, J.A.; Byun, M.; Santangelo, C.D.; Hayward, R.C. Designing responsive buckled surfaces by halftone gel lithography. Science 2012, 335, 1201–1205. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, Z.J.; Hong, W.; Wu, Z.L.; Zheng, Q. Site-specific pre-swelling-directed morphing structures of patterned hydrogels. Angew. Chem. Int. Ed. 2017, 56, 15974–15978. [Google Scholar] [CrossRef]

- Timoshenko, S. Analysis of bi-metal thermostats. Josa 1925, 11, 233–255. [Google Scholar] [CrossRef]

- Wu, Y.; Hao, X.P.; Xiao, R.; Lin, J.; Wu, Z.L.; Yin, J.; Qian, J. Controllable bending of bi-hydrogel strips with differential swelling. Acta Mech. Solida. Sin. 2019, 32, 652–662. [Google Scholar] [CrossRef]

- Zhang, Q.; Wommer, J.; O’Rourke, C.; Teitelma, J.; Tang, Y.C.; Robison, J.; Lin, G.J.; Yin, J. Origami and kirigami inspired self-folding for programming three-dimensional shape shifting of polymer sheets with light. Extrem. Mech. Lett. 2017, 11, 111–120. [Google Scholar] [CrossRef]

- Ding, Z.; Yuan, C.; Peng, X.R.; Wang, T.J.; Qi, H.; Dunn, M.L. Direct 4D printing via active composite materials. Sci. Adv. 2017, 3, e1602890. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, Z.A.; Wu, J.; Mu, X.; Chen, H.; Qi, H.J.; Fang, D.N. Origami by frontal photo-polymerization. Sci. Adv. 2017, 3, e1602326. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Duque, C.M.; Santangelo, C.D.; Hayward, R.C. Biasing buckling direction in shape-programmable hydrogel sheets with through-thickness gradients. Adv. Funct. Mater. 2019, 29, 1905273. [Google Scholar] [CrossRef]

- Peng, X.; Liu, T.; Zhang, Q.; Shang, C.; Bai, Q.W.; Wang, H. Surface patterning of hydrogels for programmable and complex shape deformations by ion inkjet printing. Adv. Funct. Mater. 2017, 27, 1701962. [Google Scholar] [CrossRef]

- Chen, Z.; Huang, G.; Trase, I.; Han, X.; Mei, Y. Mechanical self-assembly of a strain-engineered flexible layer: Wrinkling, rolling, and twisting. Phys. Rev. Appl. 2016, 5, 017001. [Google Scholar] [CrossRef] [Green Version]

- Armon, S.; Efrati, E.; Kupferman, R.; Sharon, E. Geometry and mechanics in the opening of chiral seed pods. Science 2011, 333, 1726–1730. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Boley, J.W.; van Rees, W.M.; Lissandrello, C.; Horenstein, M.N.; Truby, R.L.; Kotikian, A.; Lewis, J.A.; Mahadevan, L. Shape-shifting structured lattices via multimaterial 4D printing. Proc. Natl. Acad. Sci. USA 2019, 116, 20856–20862. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Forterre, Y.; Skotheim, J.M.; Dumais, J.; Mahadevan, L. How the Venus flytrap snaps. Nature 2005, 433, 421–425. [Google Scholar] [CrossRef]

- Xu, F.; Fu, C.; Yang, Y. Water affects morphogenesis of growing aquatic plant leaves. Phys. Rev. Lett. 2020, 124, 038003. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wu, D.; Song, J.; Zhai, Z.; Hua, M.T.; Kim, C.; Frenkel, I.; Jiang, H.Q.; He, X.M. Visualizing morphogenesis through instability formation in 4-D printing. ACS Appl. Mater. Interfaces 2019, 11, 47468–47475. [Google Scholar] [CrossRef]

- Leahu-Aluas, I.; Abed-Meraim, F. A proposed set of popular limit-point buckling benchmark problems. Struct. Eng. Mech. 2011, 38, 767–802. [Google Scholar] [CrossRef]

- Holmes, D.P. Elasticity and stability of shape-shifting structures. Curr. Opin. Colloid. Interface Sci. 2019, 40, 118–137. [Google Scholar] [CrossRef] [Green Version]

- Farzaneh, A.; Pawar, N.; Portela, C.M.; Hopkins, J.B. Sequential metamaterials with alternating Poisson’s ratios. Nat. Commun. 2022, 13, 1041. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Gu, T.Y.; Shan, S.C.; Kang, S.H.; Weaver, J.C.; Bertoldi, K. Harnessing buckling to design architected materials that exhibit effective negative swelling. Adv. Mater. 2016, 28, 6619–6624. [Google Scholar] [CrossRef] [PubMed]

- Ha, C.S.; Lakes, R.S.; Plesha, M.E. Design, fabrication, and analysis of lattice exhibiting energy absorption via snap-through behavior. Mater. Des. 2018, 141, 426–437. [Google Scholar] [CrossRef]

- Hanaor, A.; Levy, R. Evaluation of deployable structures for space enclosures. Int. J. Space Struct. 2001, 16, 211–229. [Google Scholar] [CrossRef]

- Zhang, X.; Ye, H.; Wei, N.; Tao, R.; Luo, Z. Design optimization of multifunctional metamaterials with tunable thermal expansion and phononic bandgap. Mater. Des. 2021, 209, 109990. [Google Scholar] [CrossRef]

- Haghpanah, B.; Salari-Sharif, L.; Pourrajab, P.; Hopkins, J.; Valdevit, L. Multi-stable shape-reconfigurable architected materials. Adv. Mater. 2016, 28, 7915–7920. [Google Scholar] [CrossRef]

- Shan, S.C.; Kang, S.H.; Raney, J.R.; Wang, P.; Fang, L.C.; Candido, F.; Lewis, J.A.; Bertoldi, K. Multi-stable architected materials for trapping elastic strain energy. Adv. Mater. 2015, 27, 4296–4301. [Google Scholar] [CrossRef]

| Design Strategy | Material | Morphing Mode | Stimulus | Characteristics: Size and Response Time | Application | Ref. |

|---|---|---|---|---|---|---|

| Mismatch strain (heterogeneous material composition) | Hydrogel | Rolling (buckling) | Swelling | 500 × 300 × 12 μm, 30 min | Self-folding micro-device | [57] |

| SMP | Worm-like shape change | Heat | 20 × 25 × 0.12 mm, 90 s | Biomimetic 4D transformation | [58] | |

| Hydrogel | Folding | Swelling | 700 × 700 × 1.5 μm, 10 min | Microscale reconfigurable origami structure | [59] | |

| LCE | Bending | Electric field | 35 × 3 × 0.22 mm, 5 s | Soft actuator and robotic programmability | [60] | |

| Hydrogel | Twisting | Swelling | 60 × 10 × 1 mm, 50 s | Soft gripper | [61] | |

| Snap-through bistability | DE, polyimide, polyester | Snapping of 2D membrane | Electric field | 60 × 15 × 0.55 mm, 1.7 s | Soft bistable actuator | [33] |

| Hydrogel, PDMS | Buckling of 1D beam | Swelling | 7 × 0.7 × 0.25 mm, 0.6 s | Logic and autonomous actuation | [54] | |

| Polylactic acid, Ecoflex | Bending | Pneumatic control | 80 × 60 × 15 mm, 0.2~1 s | Soft robot with fast locomotion and high manipulation strength | [62] | |

| Ecoflex | Complex and multistep deformation | Mechanical manipulation/pneumatic control | ~10 × ~10 × (0.5~1.4) mm, <0.1 s | Soft gripper, programmable metamaterial, and logic gate | [63] | |

| Polyurethane system, polycarbonate | Bending | Pneumatic control | 100 × 20 × 10 mm, 0.8 s | Autonomous clamping actuator | [64] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, Y.; Guo, G.; Wei, Z.; Qian, J. Programming Soft Shape-Morphing Systems by Harnessing Strain Mismatch and Snap-Through Bistability: A Review. Materials 2022, 15, 2397. https://doi.org/10.3390/ma15072397

Wu Y, Guo G, Wei Z, Qian J. Programming Soft Shape-Morphing Systems by Harnessing Strain Mismatch and Snap-Through Bistability: A Review. Materials. 2022; 15(7):2397. https://doi.org/10.3390/ma15072397

Chicago/Turabian StyleWu, Yi, Gang Guo, Zhuxuan Wei, and Jin Qian. 2022. "Programming Soft Shape-Morphing Systems by Harnessing Strain Mismatch and Snap-Through Bistability: A Review" Materials 15, no. 7: 2397. https://doi.org/10.3390/ma15072397

APA StyleWu, Y., Guo, G., Wei, Z., & Qian, J. (2022). Programming Soft Shape-Morphing Systems by Harnessing Strain Mismatch and Snap-Through Bistability: A Review. Materials, 15(7), 2397. https://doi.org/10.3390/ma15072397