Leaching of Copper Contained in Waste Printed Circuit Boards, Using the Thiosulfate—Oxygen System: A Kinetic Approach

Abstract

1. Introduction

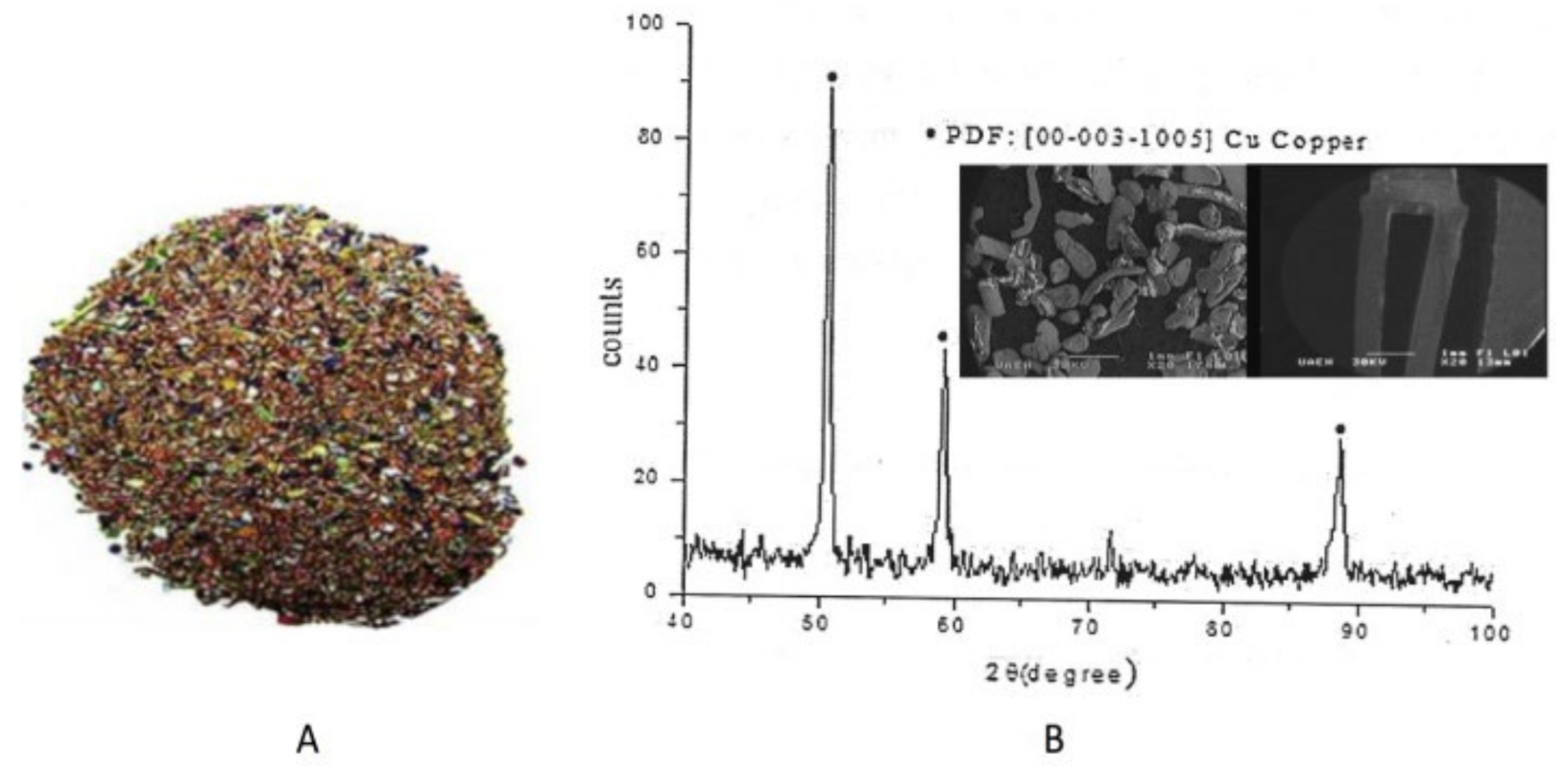

2. Materials and Methods

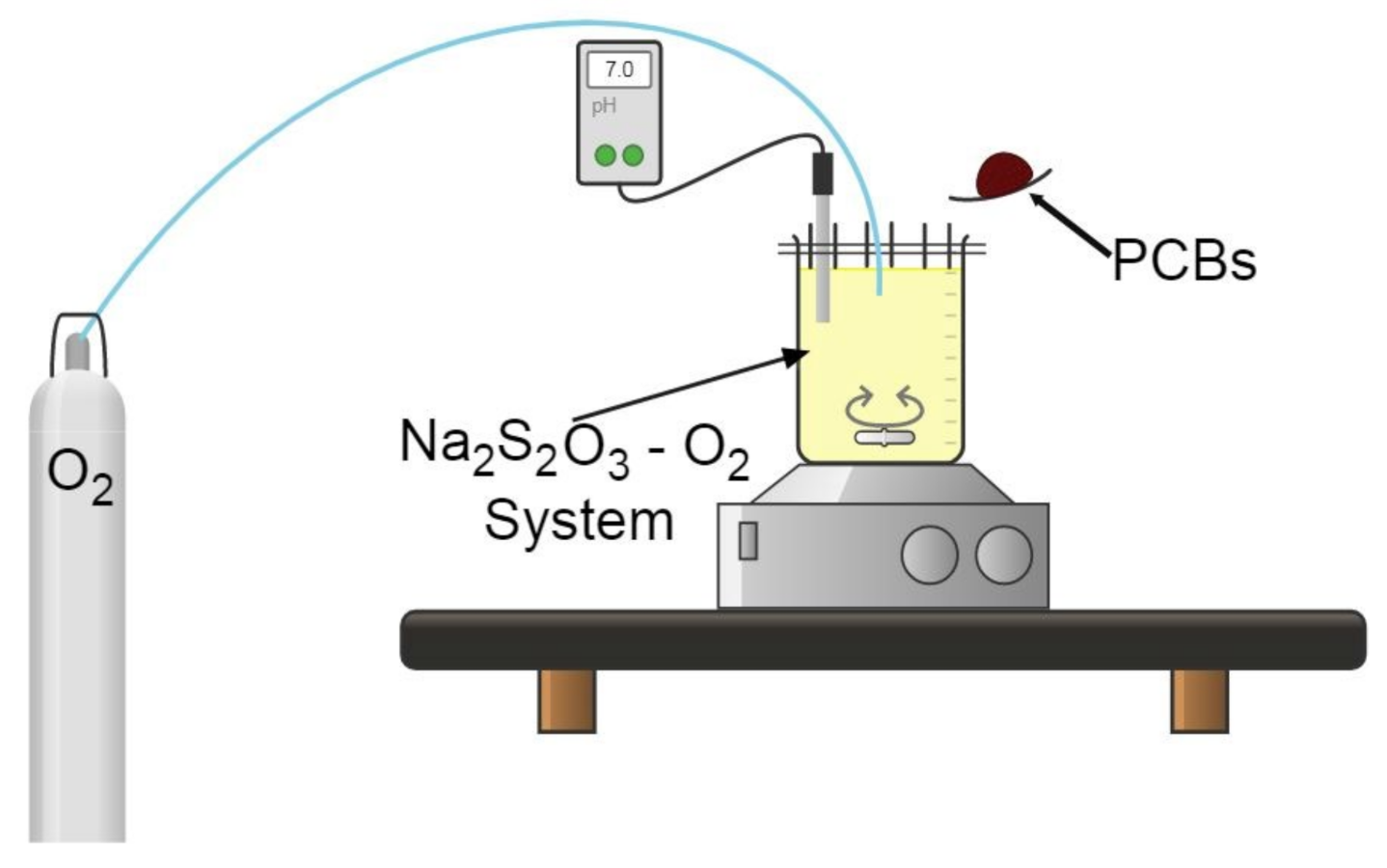

2.1. Alkali Dynamic Leaching ( Medium)

2.2. Atomic Absorption Spectrometry

3. Results

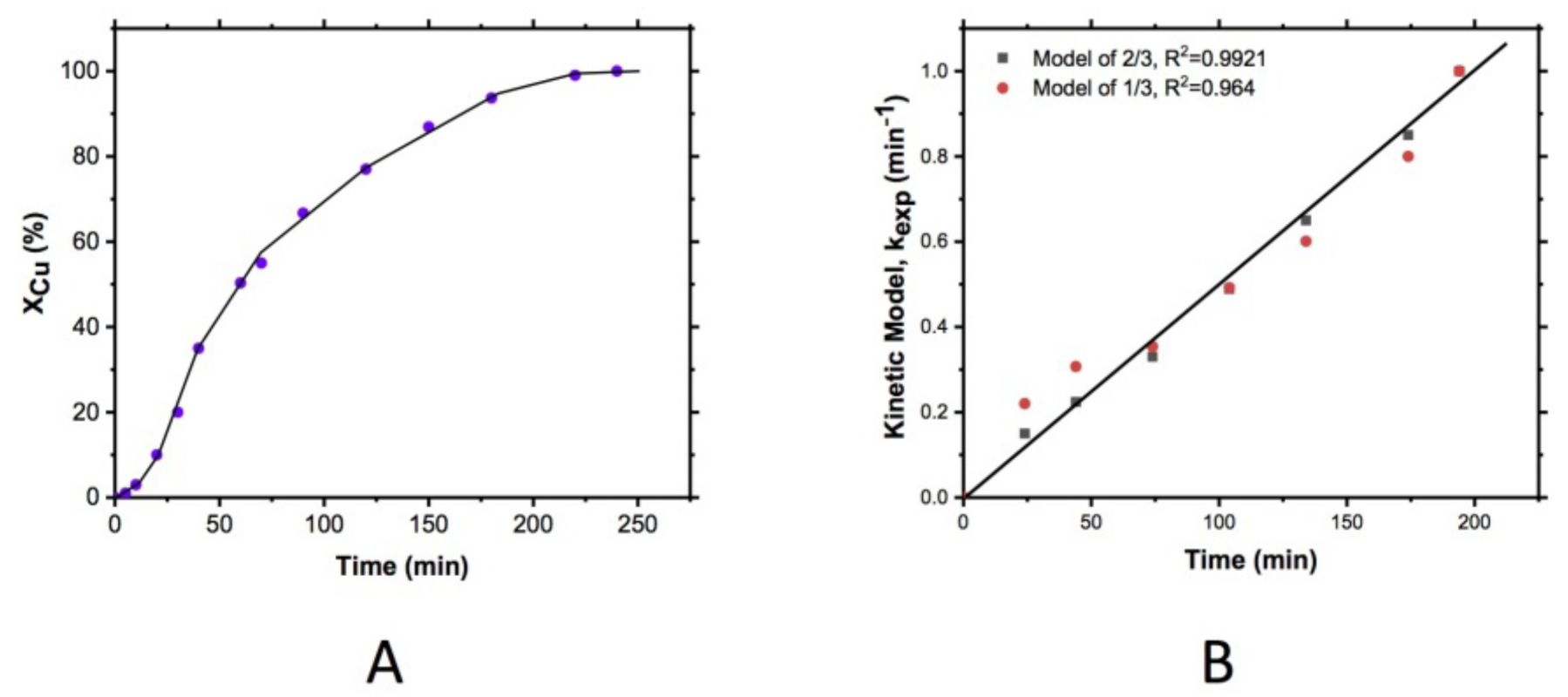

3.1. Kinetic Study of Leaching of Cu in Medium

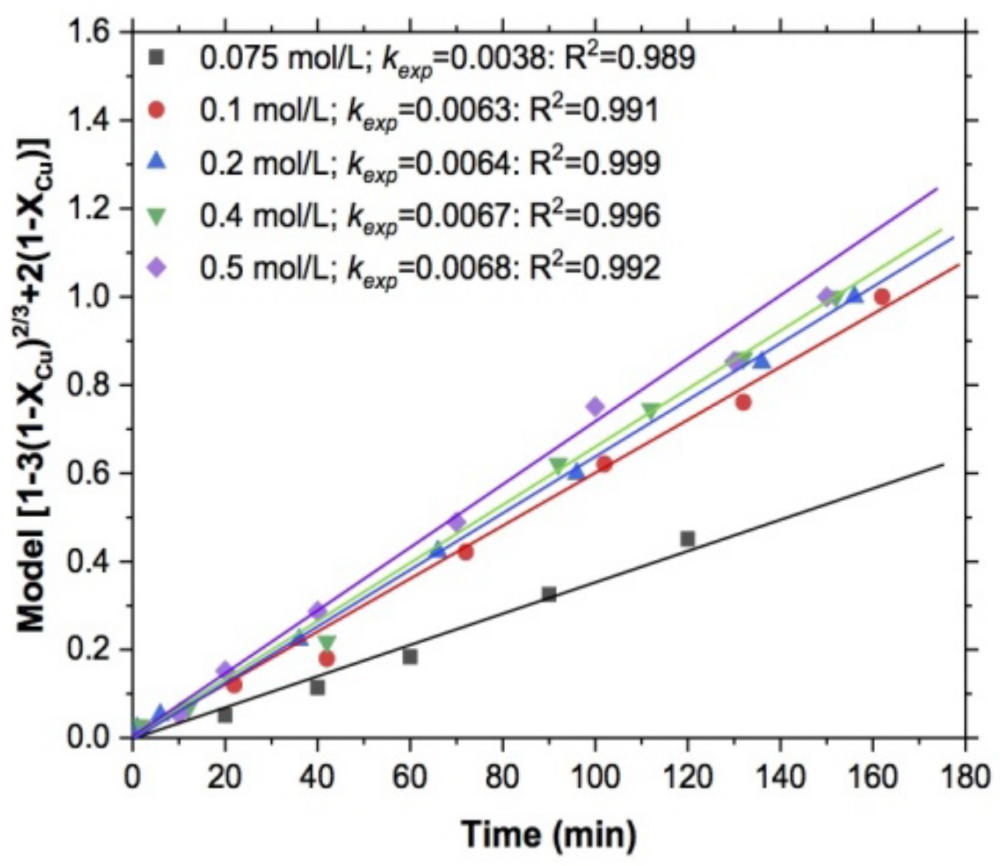

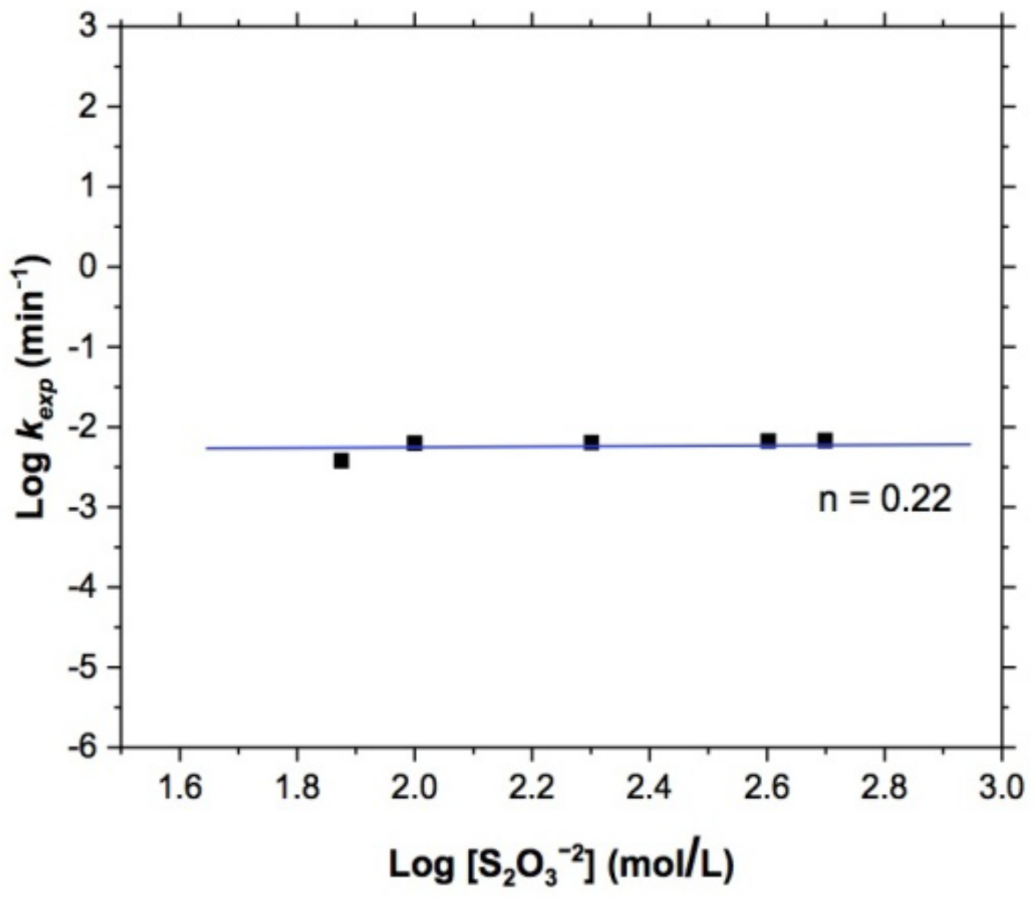

3.1.1. Effect of Reagent Concentration

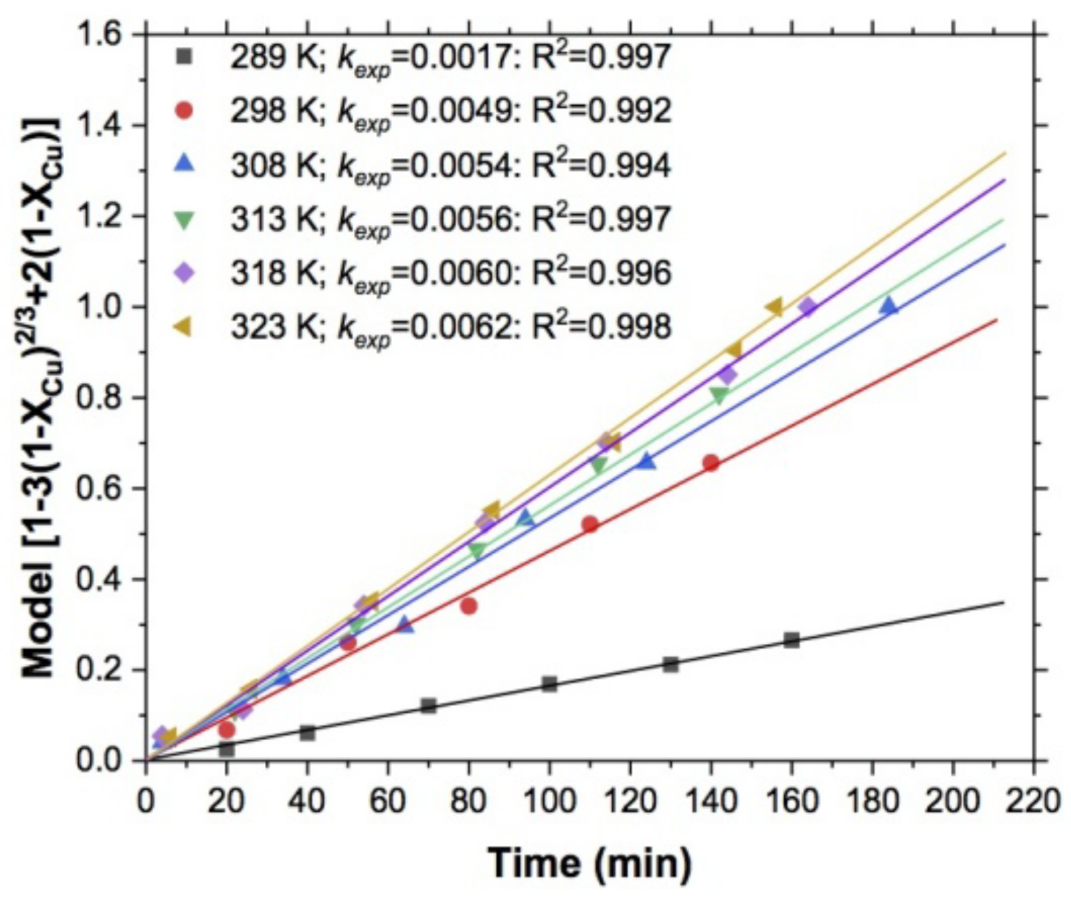

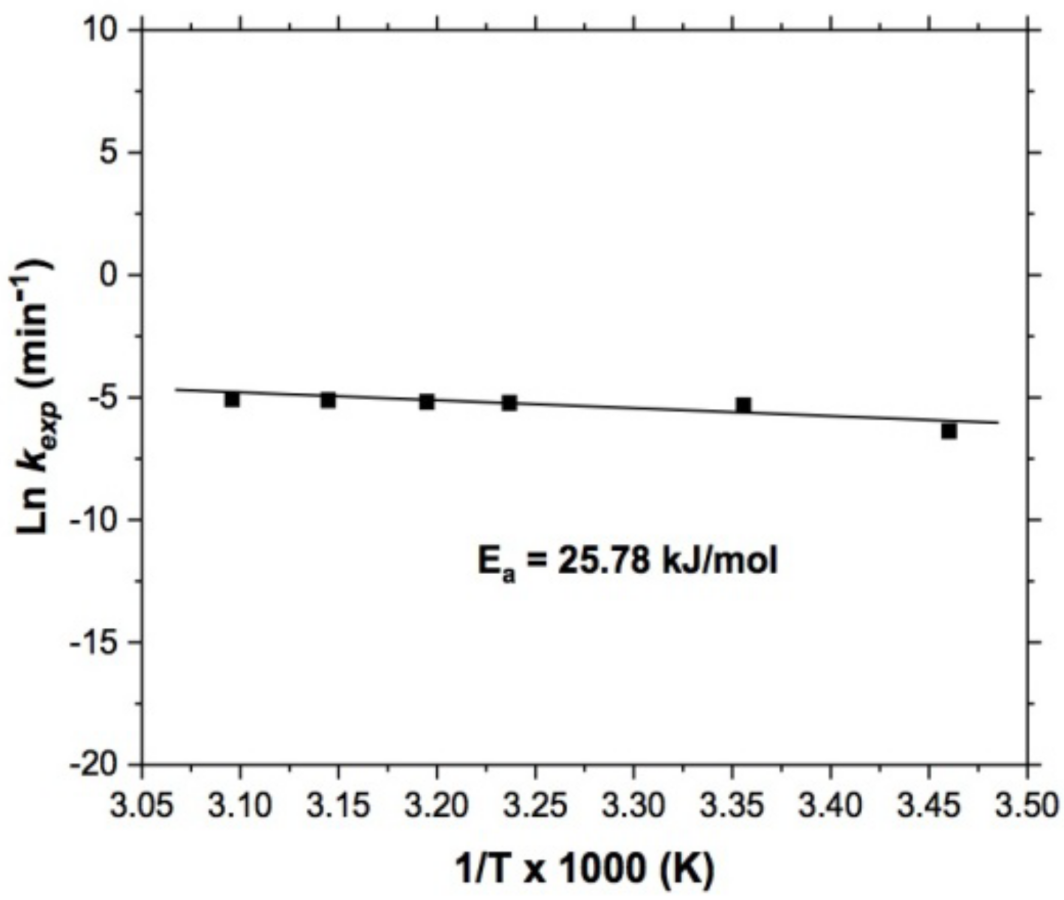

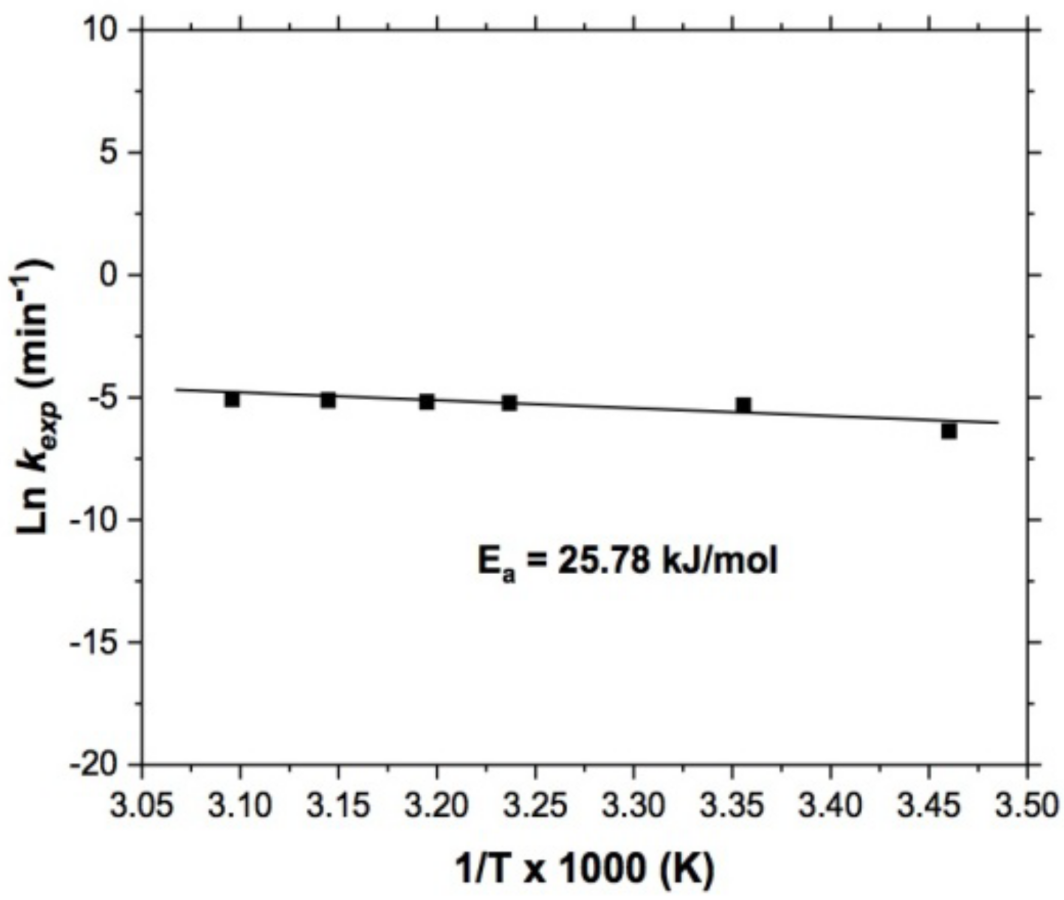

3.1.2. Effect of the Temperature

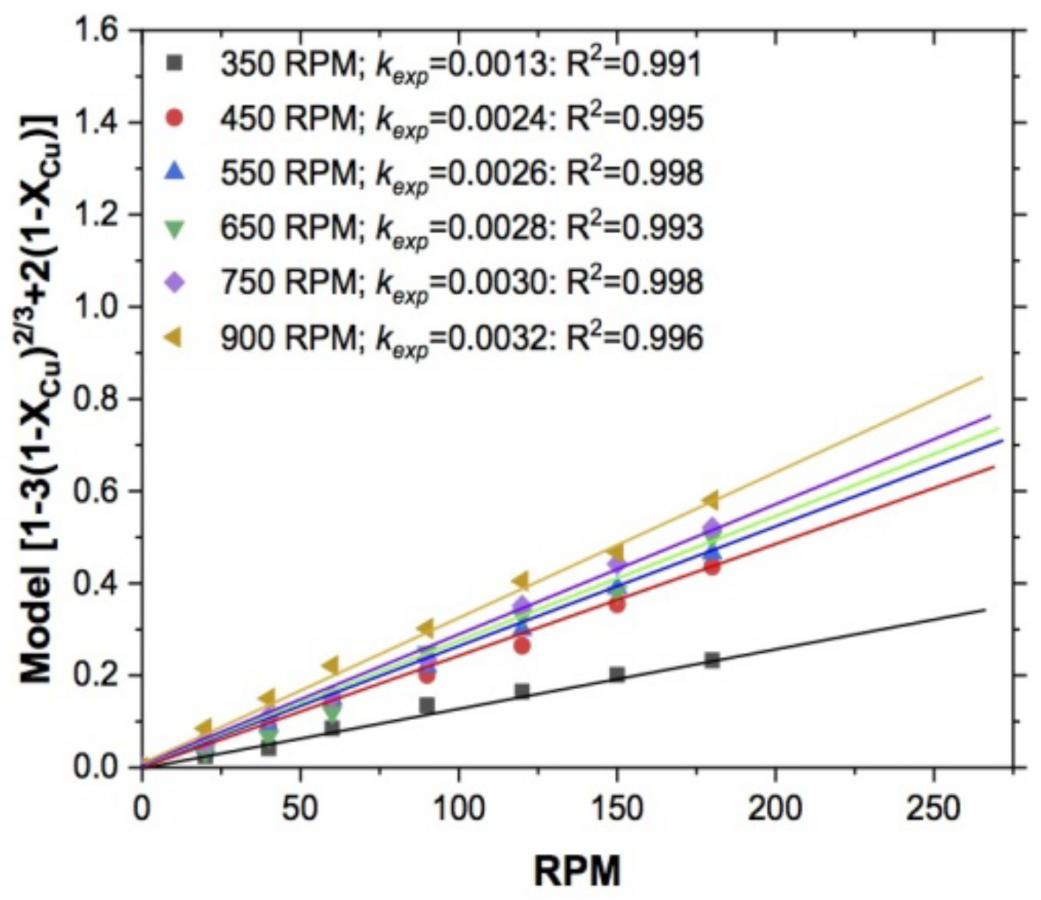

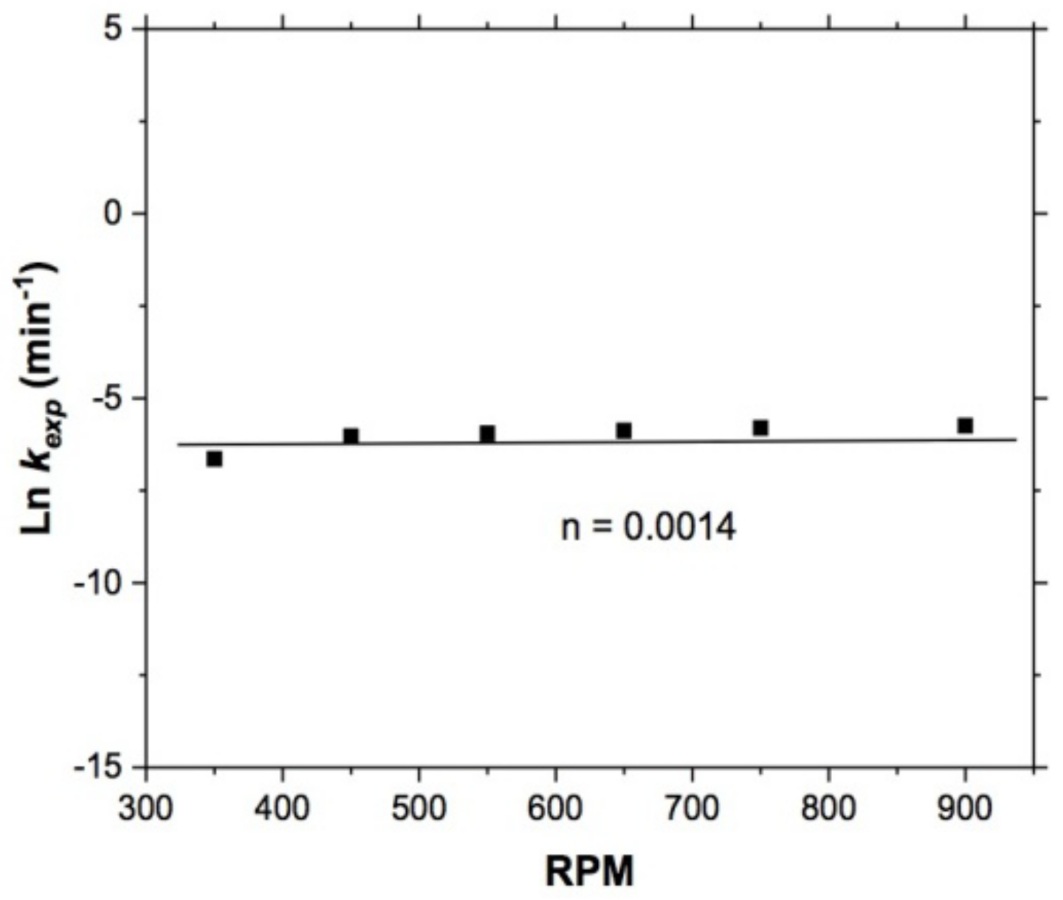

3.1.3. Effect of Stirring Rate

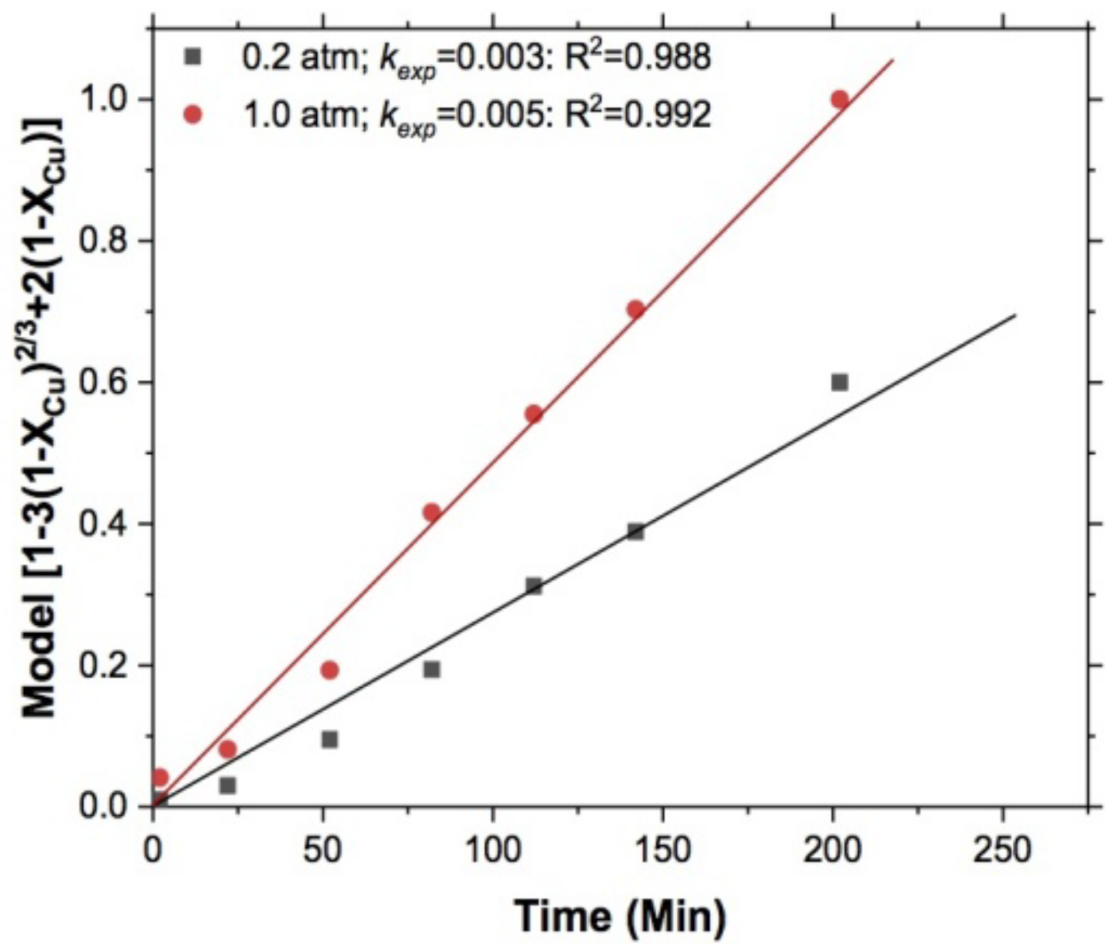

3.1.4. Effect of Oxygen Partial Pressure

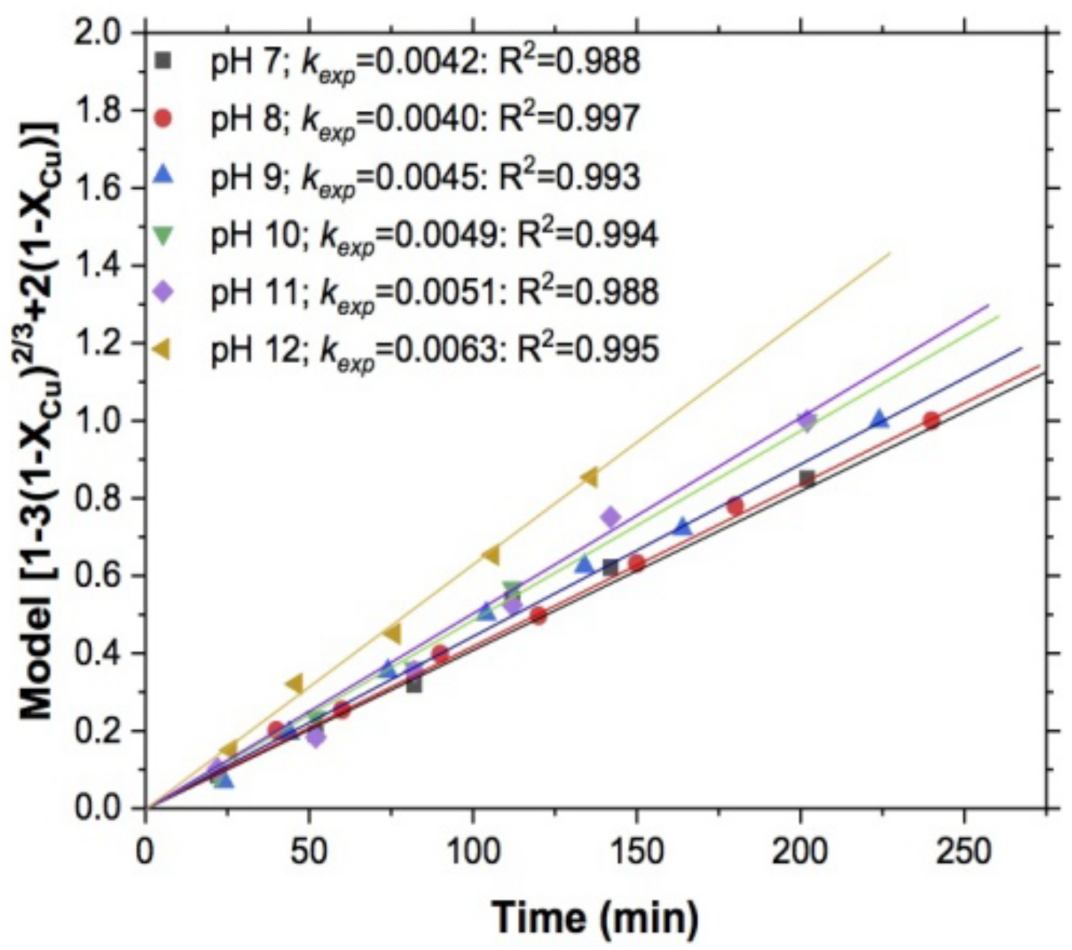

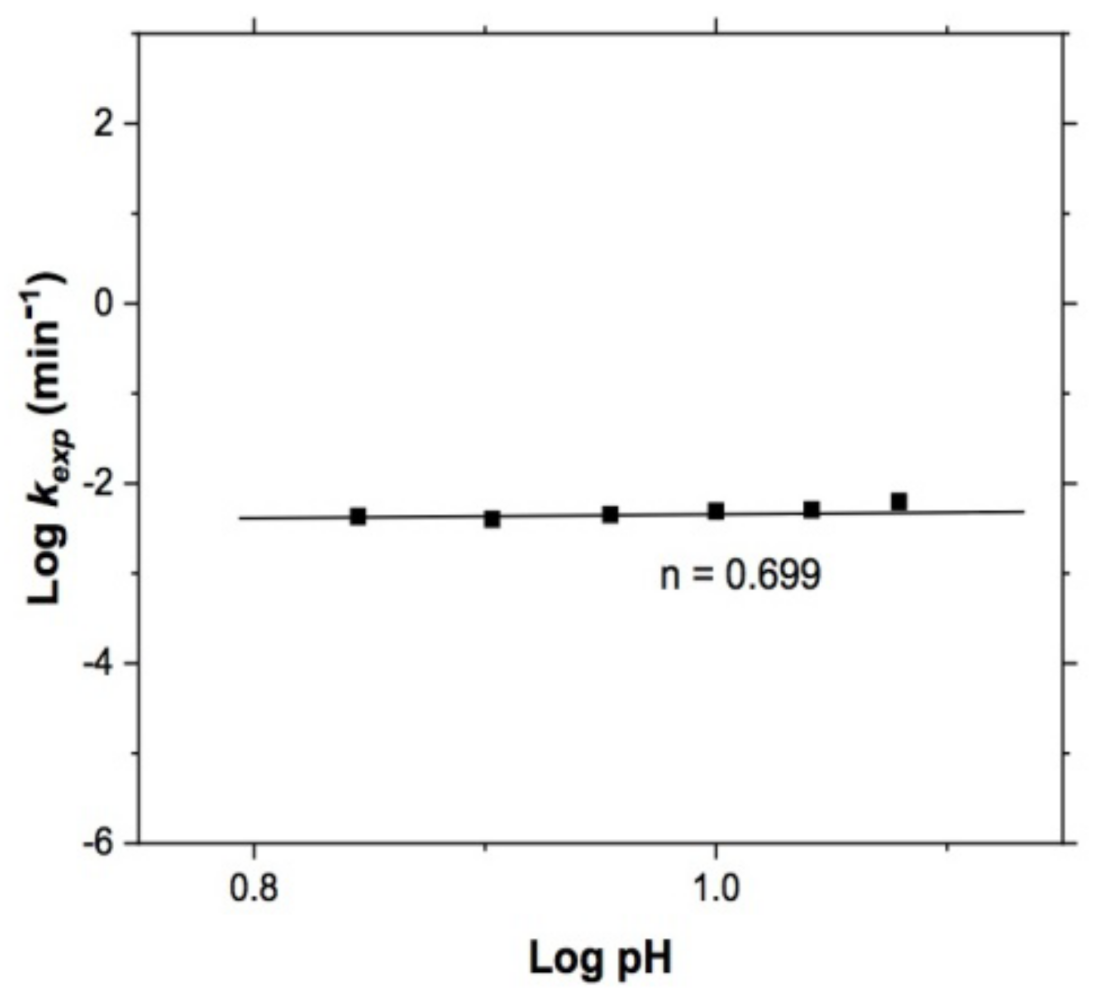

3.1.5. Effect of pH

4. Discussion

5. Conclusions

- In this study, the leaching reaction according to the kinetic values found corresponded to a mixed controlled process, with, for both chemical and diffusion controls, the reaction depending of reagent concentration and temperature. The magnitude of the order of reaction found, showed a slight dependence of this variable on the reaction rate and this was also observed for the temperature, stirring rate, and pH effects.

- Varying the temperature, it was observed that according the temperature increases, the reaction rate also increased slightly but progressively. Regularly, kinetics studies show that when there is no dependence of temperature during leaching, it is because the rate is controlled by diffusion and in the contrary case the rate is controlled by chemical reaction. In this case, due to the poor effect of temperature, both cases could be acting, giving a mixed control of reaction, which was confirmed by the activation energy found, Ea = 25.78 kJ/mol.

- In the case of stirring rate, the results indicated that once particles had reached a suspended condition, both chemical reaction and diffusion could begin smoothly, and here the speed of agitation appeared to have a very poor effect on copper leaching.

- The effect of oxygen partial pressure indicated the marked influence of this variable on the copper leaching rate. The effect of O2 can also help to determine if the process improves with a more oxidizing or more reducing environment, and depending of the amount of dissolved oxygen into the solution, rapid oxidation of Cu (I) to Cu (II) occurs with some oxidation of the thiosulfate to produce sulfate and trithionate. An excess of oxygen is detrimental for the extraction of gold, but beneficial for the oxidation of thiosulfate and the its complexation with Cu; the main role of excess of oxygen is to degrade thiosulfate, possibly via di-sulfite . The rapid rate reduction of copper (II) by thiosulfate compared to the slow oxidation of Cu (I) by oxygen allows to the determination of the rate of oxidation of thiosulfate using steady state kinetics.

- The effect of pH showed that the thiosulfate was stable within the range of pH values evaluated and also, that this reagent works better at alkali pH values. In addition, it was expected that this effect would not influence the copper-leaching rate, since as was observed in the Eh - pH diagram [56], thiosulfate is stable in the evaluated range. In the case of our study, according to the pH range studied, the pH of solution working under oxidizing conditions, and the formation of water-soluble metal sulfates (in this case, Cu) was facilitated by the presence of metal cations. At low pH, the amount of H+ ions is greater, so that many are lodged in the active sites of the leaching reagent, limiting the absorption of metal ions as the pH increases, and the disposition of these sites increases. This is why the leaching rate of Cu was not strongly dependent on pH values, and was found to be related to the mixed control.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Magalini, F.; Kuehr, R.; Baldé, C.P. EWaste en América Latina; GSMA Latin America: Buenos Aires, Argentina, 2015; pp. 1–38. [Google Scholar]

- Flandinet, L.; Tedjar, F.; Ghetta, V.; Fouletier, J. Metals Recovering from Waste Printed Circuit Boards (WPCBs) Using Molten Salts. J. Hazard. Mater. 2012, 213, 485–490. [Google Scholar] [CrossRef] [PubMed]

- Gurung, M.; Adhikari, B.B.; Kawakita, H.; Ohto, K.; Inoue, K.; Alam, S. Recovery of Gold and Silver from Spent Mobile Phones by Means of Acidothiourea Leaching Followed by Adsorption Using Biosorbent Prepared from Persimmon Tannin. Hydrometallurgy 2013, 133, 84–93. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, S.; Xie, H.; Zeng, X.; Li, J. Current Status on Leaching Precious Metals from Waste Printed Circuit Boards. Procedia Environ. Sci. 2012, 16, 560–568. [Google Scholar] [CrossRef]

- Sitando, O.; Dai, X.; Senanayake, G.; Nikoloski, A.N.; Breuer, P. A Fundamental Study of Gold Leaching in a Thiosulfate oxygen copper System in the Presence of Activated Carbon. Hydrometallurgy 2020, 192, 105232. [Google Scholar] [CrossRef]

- Huang, J.; Deng, Y.; Han, Y.; Shu, J.; Wang, R.; Huang, S.; Ogunseitan, O.A.; Yu, K.; Shang, M.; Liu, Y.; et al. Toxic footprint and materials profile of electronic components in printed circuit boards. Waste Manag. 2022, 141, 154–162. [Google Scholar] [CrossRef]

- Garlapati, V.K. E-Waste in India and Developed Countries: Management, Recycling, Business and Biotechnological Initiatives. Renew. Sustain. Energy Rev. 2016, 54, 874–881. [Google Scholar] [CrossRef]

- Arya, S.; Patel, A.; Kumar, S.; Pau-Loke, S. Urban mining of obsolete computers by manual dismantling and waste printed circuit boards by chemical leaching and toxicity assessment of its waste residues. Environ. Pollut. 2021, 285, 117033. [Google Scholar] [CrossRef]

- He, W.; Li, G.; Ma, X.; Wang, H.; Huang, J.; Xu, M.; Huang, C. WEEE Recovery Strategies and the WEEE Treatment Status in China. J. Hazard. Mater. 2006, 136, 502–512. [Google Scholar] [CrossRef]

- Salinas, A.C. Material Informático y Contaminación Medioambiental; Universidad de Argentina: Buenos Aires, Argentina, 2008; pp. 1–21. [Google Scholar]

- Wu, G.Q.; Zhang, Z.K. Recycling of Waste Printed Circuit Boards. Circuit World 2010, 36, 35–39. [Google Scholar] [CrossRef]

- Huang, T.; Zhu, J.; Huang, X.; Ruan, J.; Xu, Z. Assessment of precious metals positioning in waste printed circuit boards and the economic benefits of recycling. Waste Manag. 2022, 139, 105–115. [Google Scholar] [CrossRef]

- Ippolito, N.M.; Medici, F.; Pietrelli, L.; Piga, L. Effect of Acid Leaching Pre-Treatment on Gold Extraction from Printed Circuit Boards of Spent Mobile Phones. Materials 2021, 14, 362. [Google Scholar] [CrossRef]

- Xing, W.; Lee, M. Chemical Leaching of Silver from Diverse Resources. J. Korean Inst. Resour. Recycl. 2017, 26, 3–10. [Google Scholar] [CrossRef][Green Version]

- Menad, N.; Guignot, S.; van Houwelingen, J.A. New Characterisation Method of Electrical and Electronic Equipment Wastes (WEEE). Waste Manag. 2013, 33, 706–713. [Google Scholar] [CrossRef]

- Ning, C.; Lin, C.S.K.; Hui, D.C.W.; McKay, G. Waste Printed Circuit Board (PCB) Recycling Techniques. Top. Curr. Chem. 2017, 375, 21–56. [Google Scholar] [CrossRef]

- Hong, Y.; Valix, M. Transforming the Recycling of E-Wastes with Thiosulfate. In ATINER Conference Paper Series; No: ENV2015; Athens Institute for Education and Research: Athens, Greece, 2015; Volume 1723, pp. 1–17. [Google Scholar]

- Konaté, F.O.; Ancia, P.; Soma, F.; Bougouma, M.; Buess-Herman, C.; Yonli, A.H.; Vitry, V. Waste electrical and electronic equipments as urban mines in Burkina Faso: Characterization and release of metal particles. Waste Manag. 2022, 139, 17–24. [Google Scholar] [CrossRef]

- Marques, A.C.; Cabrera, J.M.; de Fraga Malfatti, C. Printed Circuit Boards: A Review on the Perspective of Sustainability. J. Environ. Manag. 2013, 131, 298–306. [Google Scholar] [CrossRef]

- Barragan, J.A.; Ponce De León, C.; Alemán Castro, J.R.; Peregrina-Lucano, A.; Gómez-Zamudio, F.; Larios-Durán, E.R. Copper and Antimony Recovery from Electronic Waste by Hydrometallurgical and Electrochemical Techniques. ACS Omega 2020, 5, 12355–12363. [Google Scholar] [CrossRef]

- LaDou, J. Printed Circuit Board Industry. Int. J. Hyg. Environ. Health 2006, 209, 211–219. [Google Scholar] [CrossRef]

- Behnamfard, A.; Salarirad, M.M.; Veglio, F. Process Development for Recovery of Copper and Precious Metals from Waste Printed Circuit Boards with Emphasize on Palladium and Gold Leaching and Precipitation. Waste Manag. 2013, 33, 2354–2363. [Google Scholar] [CrossRef]

- Fogarasi, S.; Imre-Lucaci, F.; Egedy, A.; Imre-Lucaci, Á.; Ilea, P. Eco-Friendly Copper Recovery Process from Waste Printed Circuit Boards Using Fe3+/Fe2+ Redox System. Waste Manag. 2015, 40, 136–143. [Google Scholar] [CrossRef]

- Sethurajan, M.; van Hullebusch, E.D.; Fontana, D.; Akcil, A.; Deveci, H.; Batinic, B.; Leal, J.P.; Gasche, T.A.; Kucuker, M.A.; Kuchta, K.; et al. Recent Advances on Hydrometallurgical Recovery of Critical and Precious Elements from End of Life Electronic Wastes—A Review. Crit. Rev. Environ. Sci. Technol. 2019, 49, 212–275. [Google Scholar] [CrossRef]

- Eswaraiah, C.; Kavitha, T.; Vidyasagar, S.; Narayanan, S.S. Classification of Metals and Plastics from Printed Circuit Boards (PCB) Using Air Classifier. Chem. Eng. Process. Process Intensif. 2008, 47, 565–576. [Google Scholar] [CrossRef]

- Guiachetti Torres, D. Consumo de Ácido Sulfúrico y Cinética de Lixiviación de Un Mineral Oxidado de Cobre. Bachelor’s Thesis, Facultad de Ciencias Físicas y Matemáticas, Santiago, Chile, 2011; pp. 1–99. Available online: https://repositorio.uchile.cl/handle/2250/104139 (accessed on 20 January 2022).

- Işıldar, A.; van de Vossenberg, J.; Rene, E.R.; van Hullebusch, E.D.; Lens, P.N.L. Two-Step Bioleaching of Copper and Gold from Discarded Printed Circuit Boards (PCB). Waste Manag. 2016, 57, 149–157. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Liu, J.; Yang, J. Leaching Copper from Shredded Particles of Waste Printed Circuit Boards. J. Hazard. Mater. 2011, 187, 393–400. [Google Scholar] [CrossRef] [PubMed]

- Habashi, F. (Ed.) Principles of Extractive Metallurgy: Pyrometallurgy; Gordon and Breach: London, UK, 1993; Volume 3. [Google Scholar]

- Koyama, K.; Tanaka, M.; Lee, J.C. Copper Leaching Behavior from Waste Printed Circuit Board in Ammoniacal Alkaline Solution. Mater. Trans. 2006, 47, 1788–1792. [Google Scholar] [CrossRef]

- Rivera, I.; Juárez, G.; Patiño, F.; Reyes, I.A.; Roca, A.; Reyes, M.I. Silver Precipitation Using Sodium Dithionite in Cyanide Media. J. Mex. Chem. Soc. 2012, 56, 156–162. [Google Scholar] [CrossRef]

- Rao, M.D.; Shahin, C.; Jha, R. Optimization of leaching of copper to enhance the recovery of gold from liberated metallic layers of WPCBs. Mater. Proc. 2021, 46, 1515–1518. [Google Scholar] [CrossRef]

- Brožova, S.; Lisińska, M.; Saternus, M.; Gajda, B.; Martynková, G.S.; Slíva, A. Hydrometallurgical Recycling Process for Mobile Phone Printed Circuit Boards Using Ozone. Metals 2021, 11, 820. [Google Scholar] [CrossRef]

- Sousa, P.M.S.; Martelo, L.M.; Marques, A.T.; Bastos, M.M.S.M.; Soares, H.M.V.M. A closed and zero-waste loop strategy to recycle the main raw materials (gold, copper and fiber glass layers) constitutive of waste printed circuit boards. Chem. Eng. J. 2022, 434, 134604. [Google Scholar] [CrossRef]

- Barrueto, Y.; Hernández, P.; Jiménez, Y.; Morales, J. Leaching of metals from printed circuit boards using ionic liquids. J. Mater. Cycles Waste Manag. 2021, 23, 2028–2036. [Google Scholar] [CrossRef]

- De Andrade, L.M.; de Alves, C.M.; Kohler, C.M.P.; Romano, E.D.C.; Soares, T.J.A. Recovery of copper and silver of Printed Circuit Boards from obsolete computers by one-step acid leaching. Detritus 2021, 4, 86–91. [Google Scholar] [CrossRef]

- Park, Y.; Eom, Y.; Yoo, K.; Jha, M.K. Leaching of copper from Waste-Printed Circuit Boards (PCBs) in Sulfate Medium Using Cupric Ion and Oxygen. Metals 2021, 11, 1369. [Google Scholar] [CrossRef]

- Hao, J.; Wang, X.; Wang, Y.; Wu, Y.; Guo, F. Optimizing the leaching Parameters and Studying the kinetics of Copper Recovery from Waste Printed Circuit Boards. ASC Omega 2022, 7, 3689–3699. [Google Scholar] [CrossRef] [PubMed]

- Nie, C.-C.; Zhang, H.; Qi, X.-F.; Shang, H.-Y.; Li, T.-Y.; Xue, P.; Wang, J.-X.; Zhu, X.-N. Environment-friendly flotation technology of waste printed circuit boards assisted by pyrolysis pretreatment. Proc. Safety Environ. Prot. 2021, 152, 58–65. [Google Scholar] [CrossRef]

- Arslan, V. Bacterial leaching of copper, zinc, nickel and aluminium from discarded printed circuit boards using acidophilic bacteria. J. Mater. Cycles Waste 2021, 23, 2005–2015. [Google Scholar] [CrossRef]

- Shi, S.-X.; Nie, C.-C.; Chang, H.-H.; Wu, P.; Piao, Z.-J.; Zhu, X.-N. Physical pre-concentration and ammonium leaching of metal copper from waste printed circuit boards. J. Clean. Prod. 2021, 318, 128512. [Google Scholar] [CrossRef]

- Jadhao, P.R.; Pandey, A.; Pant, K.K.; Nigam, K.D.P. Efficient recovery of Cu and Ni from WPCB via alkali leaching approach. J. Environ. Manag. 2021, 296, 113154. [Google Scholar] [CrossRef]

- Income, K.; Boonpo, S.; Kruatian, T.; Sooksamiti, P.; Kungwankunakon, S. Gold Recovery from Copper-Gold Tailings by Ammoniacal Thiosulfate Leaching. Curr. Appl. Sci. Tech. 2021, 21, 4. [Google Scholar] [CrossRef]

- Bae, M.; Kim, S.; Sohn, J.; Yang, D.; Lee, H. Leaching Behavior of Gold and Silver from Concentrated Sulfide Ore Using Ammonium Thiosulfate. Metals 2020, 10, 1029. [Google Scholar] [CrossRef]

- Li, K.; Li, Q.; Xu, B.; Yang, Y.; Jiang, T. An Electrochemical Study of Gold Dissolution in Thiosulfate Solution with Cobalt-Ammonia Catalysis. Metals 2022, 12, 317. [Google Scholar] [CrossRef]

- Byerley, J.J.; Fuoda, S.A. Activation of Copper(II) Ammine Complexes by Molecular Oxygen for the Oxidation of Thiosulphate Ions. J. Chem. Soc. Dalton Trans. 1975, 29, 13. [Google Scholar] [CrossRef]

- Zhang, S.; Nicol, M.J. An Electrochemical Study of the Dissolution of Gold in Thiosulfate Solutions. Part II. Effect of Copper. J. Appl. Electrochem. 2005, 35, 339–345. [Google Scholar] [CrossRef]

- Huang, K.; Guo, J.; Xu, Z. Recycling of Waste Printed Circuit Boards: A Review of Current Technologies and Treatment Status in China. J. Hazard. Mater. 2009, 164, 399–408. [Google Scholar] [CrossRef]

- Akcil, A.; Chandra, C.E.; Gahan, S.; Ozgun, M.; Sahin, M. Precious metal recovery from waste printed circuit boards using cyanide and non-cyanide lixiviants—A review. Waste Manag. 2015, 45, 258–271. [Google Scholar] [CrossRef]

- Puente-Siller, D.M.; Fuentes-Aceituno, J.C.; Nava-Alonso, F. A kinetic-Thermodynamic Study of Silver Leaching in Thiosulfate -Copper-Ammonia-EDTA Solutions. Hydrometallurgy 2013, 134, 124–131. [Google Scholar] [CrossRef]

- Alymore, M.G.; Muir, D.M. Thiosulfate leaching of gold. A review. Miner. Eng. 2001, 14, 135–174. [Google Scholar] [CrossRef]

- Sohn, H.Y.; Wadworth, M.E. (Eds.) Cinética de los Procesos de la Metalurgia Extractiva; Editorial Trillas: Bogota, Colombia, 1986; pp. 141–148. (In Spanish) [Google Scholar]

- Ballester, A.; Verdeja, L.F.; Sancho, J. Metalurgia Extractiva, Fundamentos; Editorial Síntesis: Madrid, Spain, 2000; Volume 1, pp. 182–189. (In Spanish) [Google Scholar]

- Salinas-Rodríguez, E.; Hernández-Ávila, J.; Rivera-Landero, I.; Cerecedo-Sáenz, E.; Reyes-Valderrama, M.I.; Correa-Cruz, M.; Rubio-Mihi, D. Leaching of Silver Contained in Mining Tailings, Using Sodium Thiosulfate: A Kinetic Study. Hydrometallurgy 2016, 160, 6–11. [Google Scholar] [CrossRef]

- Oh, C.J.; Lee, S.O.; Yang, H.S.; Ha, T.J.; Kim, M.J. Selective Leaching of Valuable Metals from Waste Printed Circuit Boards. J. Air Waste Manag. Assoc. 2003, 53, 897–902. [Google Scholar] [CrossRef]

- Rivera, I.; Patiño, F.; Roca, A.; Cruells, M. Kinetics of metallic silver leaching in the O2-thiosulfate system. Hydrometallurgy 2015, 156, 63–70. [Google Scholar] [CrossRef]

| Element | mg/g |

|---|---|

| Copper (Cu) | 744.2 |

| Iron (Fe) | 24.75 |

| Zinc (Zn) | 22.21 |

| Parameters | Experimental Conditions |

|---|---|

| (mol/L) | 0.075, 0.1, 0.2, 0.4, and 0.5 |

| pH | 7, 8, 9, 10, 11, and 12 |

| Sample weight (g) | 5.0 |

| Temperature (K) | 289, 298, 308, 313, 318, and 323 |

| Oxygen partial pressure (pure O2) (atm) | 0.2 and 1.0 |

| Stirring rate (RPM) | 350, 450, 550, 650, 750, and 900 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salinas-Rodríguez, E.; Hernández-Ávila, J.; Cerecedo-Sáenz, E.; Arenas-Flores, A.; Veloz-Rodríguez, M.A.; Toro, N.; Gutiérrez-Amador, M.d.P.; Acevedo-Sandoval, O.A. Leaching of Copper Contained in Waste Printed Circuit Boards, Using the Thiosulfate—Oxygen System: A Kinetic Approach. Materials 2022, 15, 2354. https://doi.org/10.3390/ma15072354

Salinas-Rodríguez E, Hernández-Ávila J, Cerecedo-Sáenz E, Arenas-Flores A, Veloz-Rodríguez MA, Toro N, Gutiérrez-Amador MdP, Acevedo-Sandoval OA. Leaching of Copper Contained in Waste Printed Circuit Boards, Using the Thiosulfate—Oxygen System: A Kinetic Approach. Materials. 2022; 15(7):2354. https://doi.org/10.3390/ma15072354

Chicago/Turabian StyleSalinas-Rodríguez, Eleazar, Juan Hernández-Ávila, Eduardo Cerecedo-Sáenz, Alberto Arenas-Flores, Maria A. Veloz-Rodríguez, Norman Toro, Maria del P. Gutiérrez-Amador, and Otilio A. Acevedo-Sandoval. 2022. "Leaching of Copper Contained in Waste Printed Circuit Boards, Using the Thiosulfate—Oxygen System: A Kinetic Approach" Materials 15, no. 7: 2354. https://doi.org/10.3390/ma15072354

APA StyleSalinas-Rodríguez, E., Hernández-Ávila, J., Cerecedo-Sáenz, E., Arenas-Flores, A., Veloz-Rodríguez, M. A., Toro, N., Gutiérrez-Amador, M. d. P., & Acevedo-Sandoval, O. A. (2022). Leaching of Copper Contained in Waste Printed Circuit Boards, Using the Thiosulfate—Oxygen System: A Kinetic Approach. Materials, 15(7), 2354. https://doi.org/10.3390/ma15072354