Research on Dewatering Characteristics of Waste Slurry from Pipe Jacking Construction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Slurry

2.2. Conditioners

2.3. Solidification Agent

2.4. Flocculation-Settling Experiment

2.5. Solidification Experiment

2.6. Unconfined Compressive Strength Experiment

2.7. Zeta Potential Experiment

3. Results

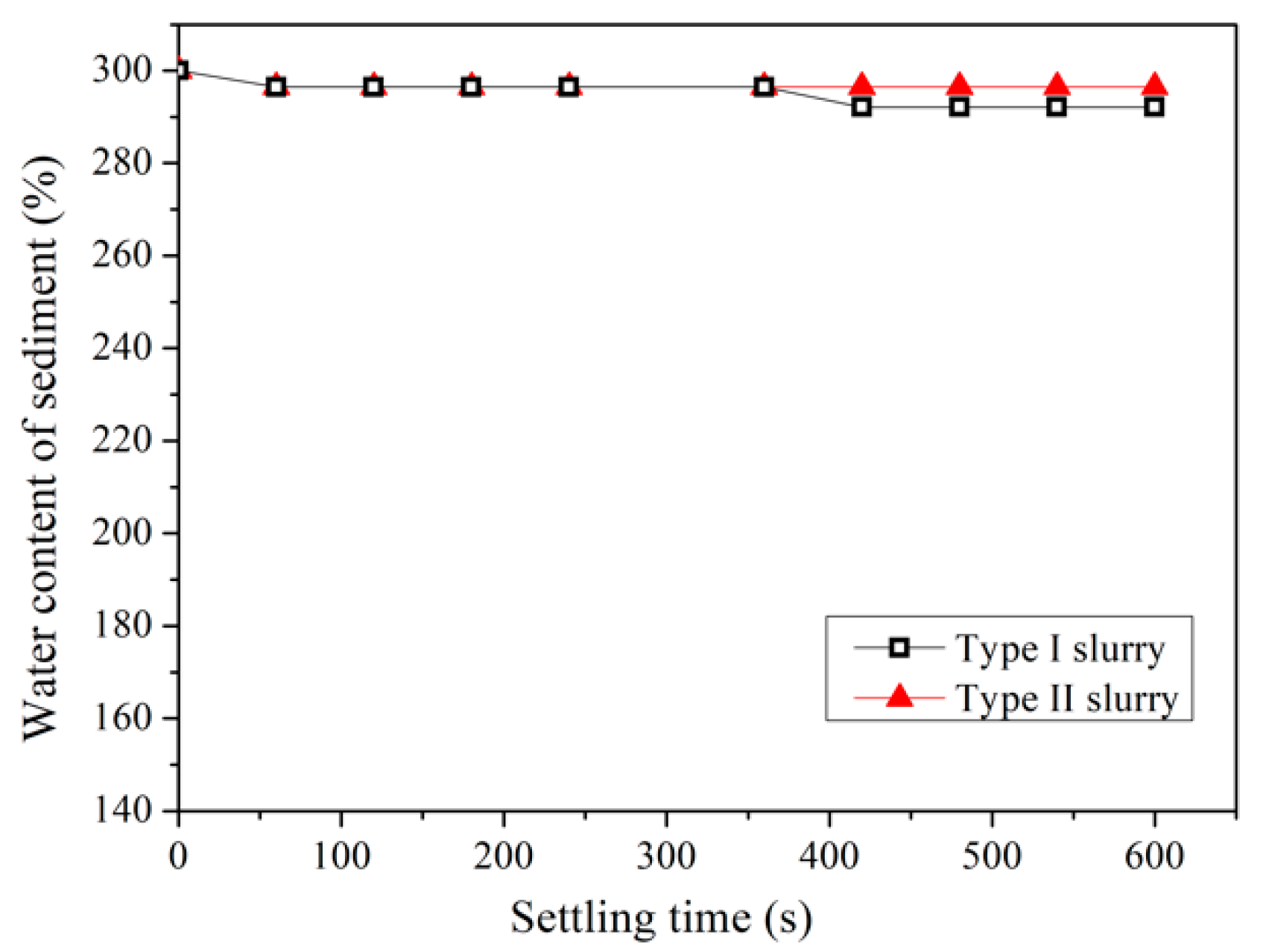

3.1. Sedimentation Results without Flocculation

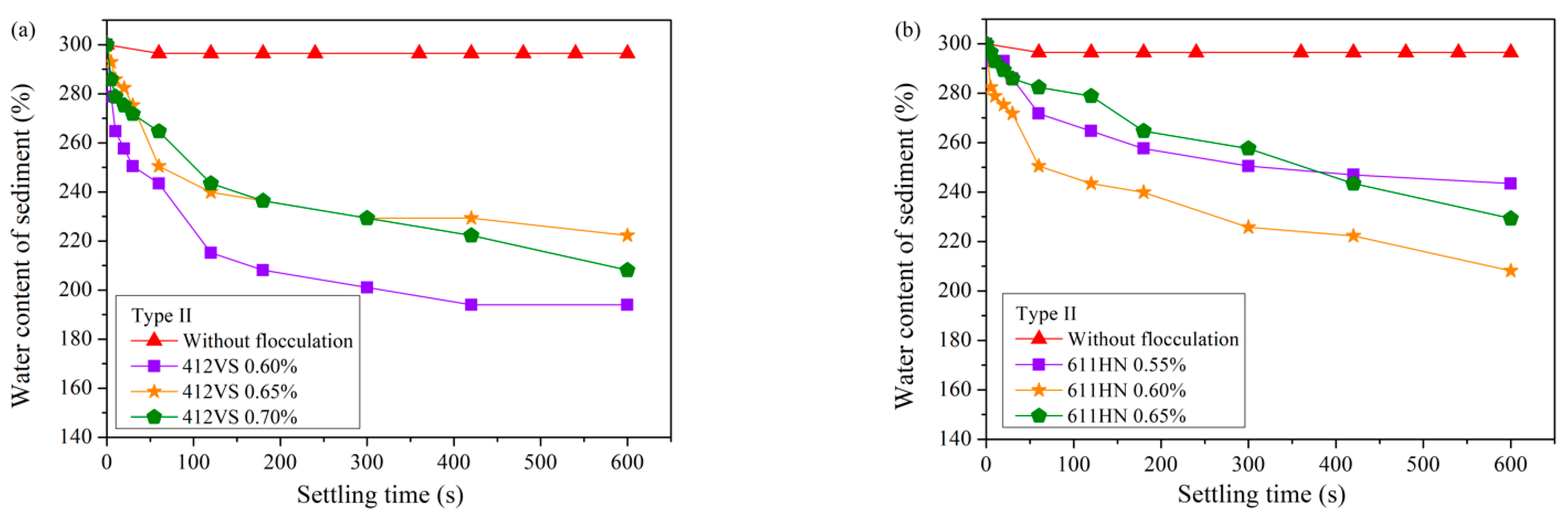

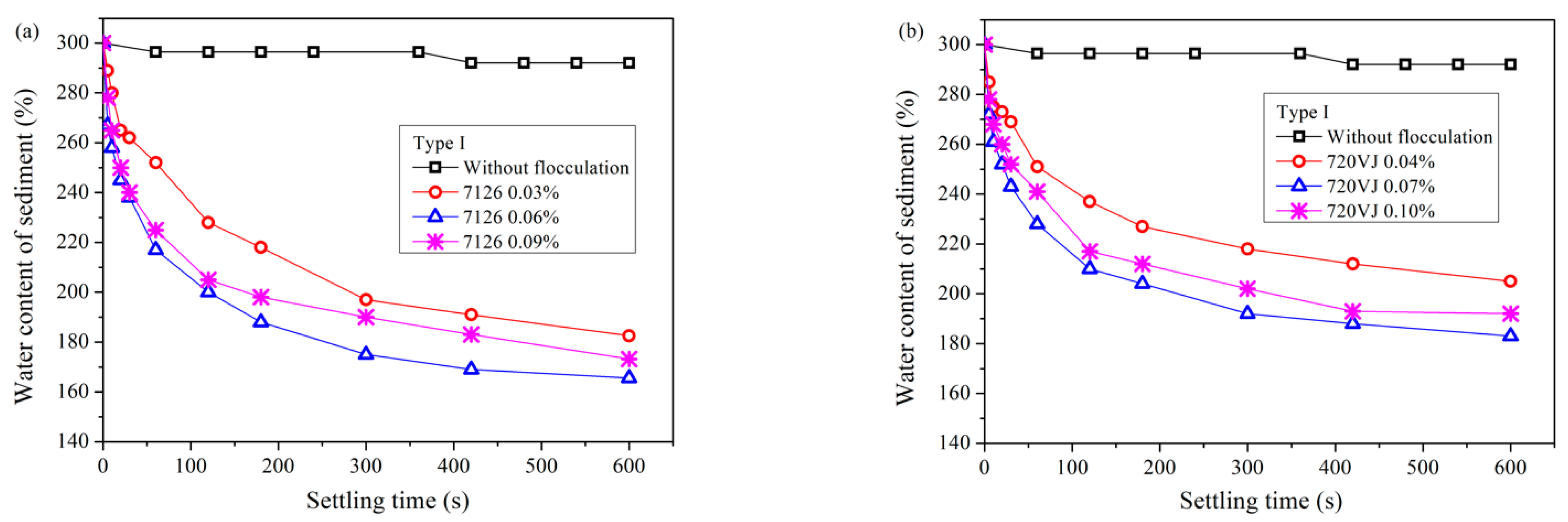

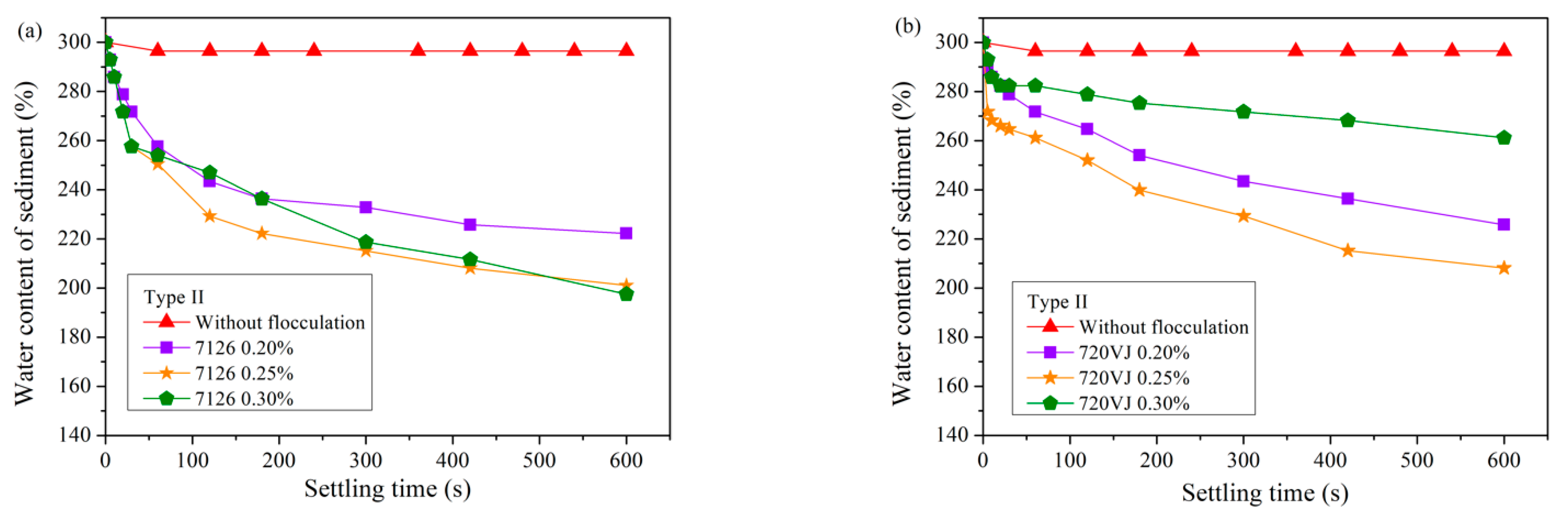

3.2. Sedimentation Results with PAM Pretreatment

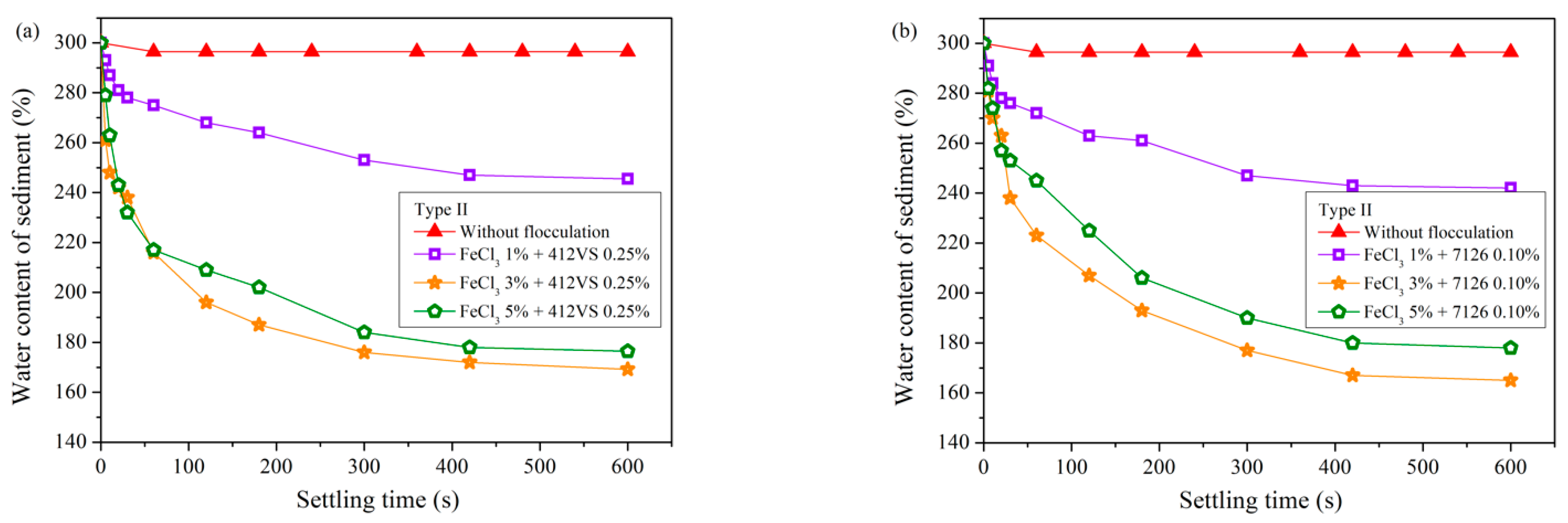

3.3. Sedimentation Results with Compound Pretreatment

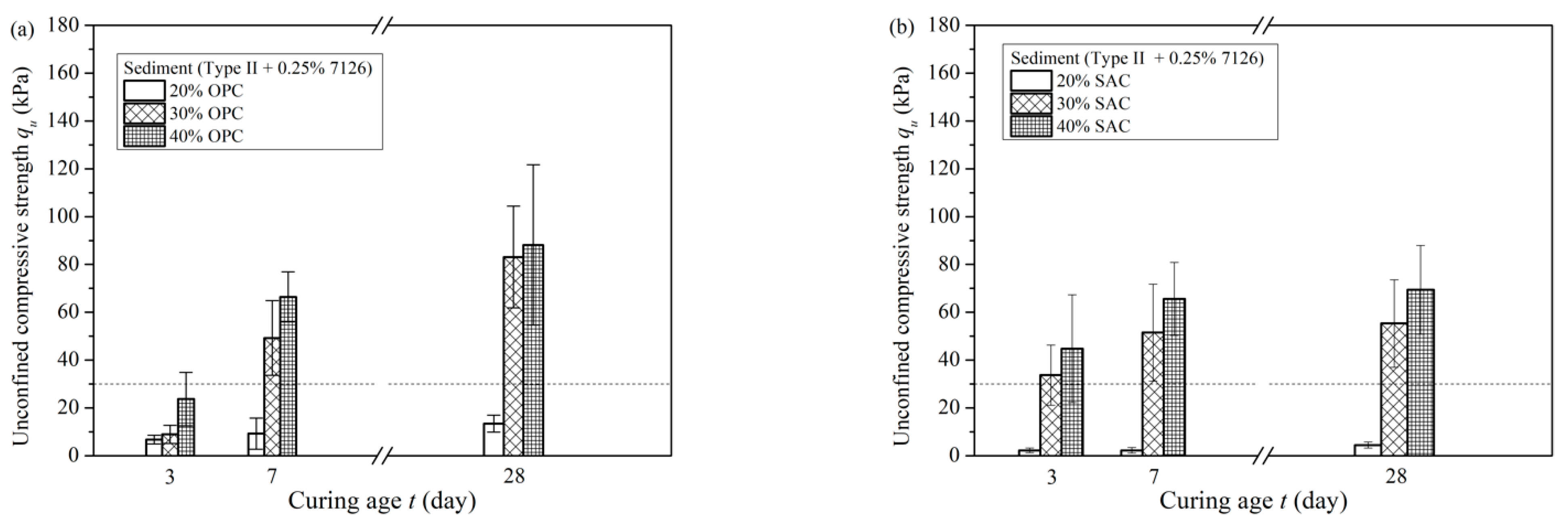

3.4. Solidification Results

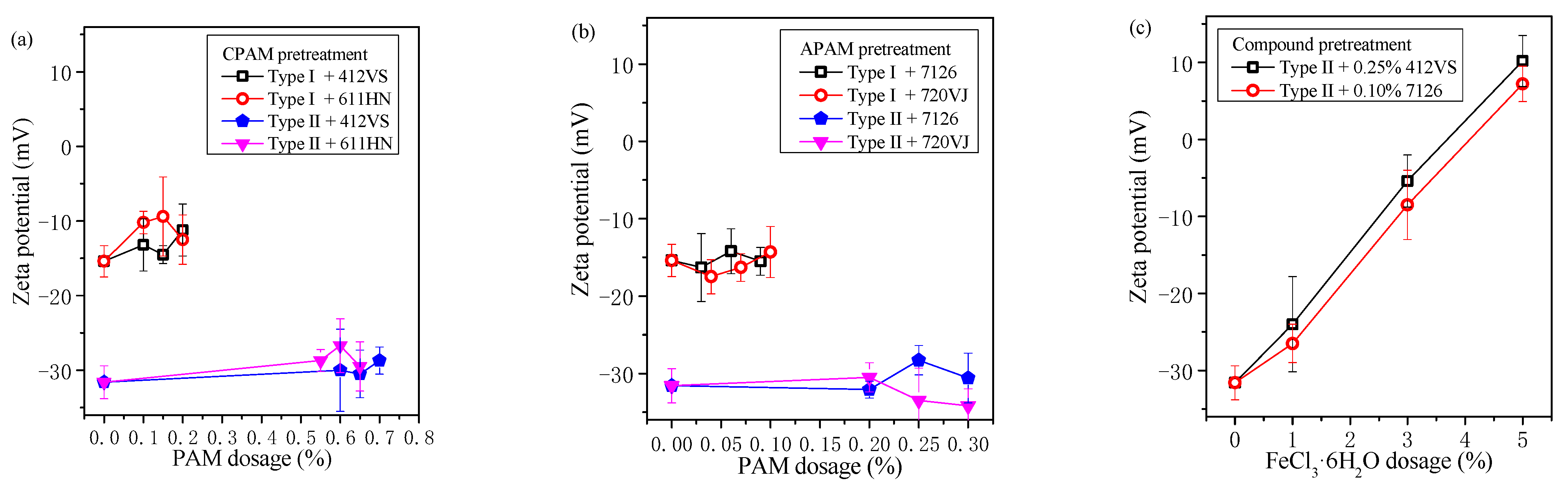

3.5. Zeta Potential after Pretreatment

4. Discussion

4.1. Flocculation-Settling Characteristics of Pipe Jacking Waste Slurry

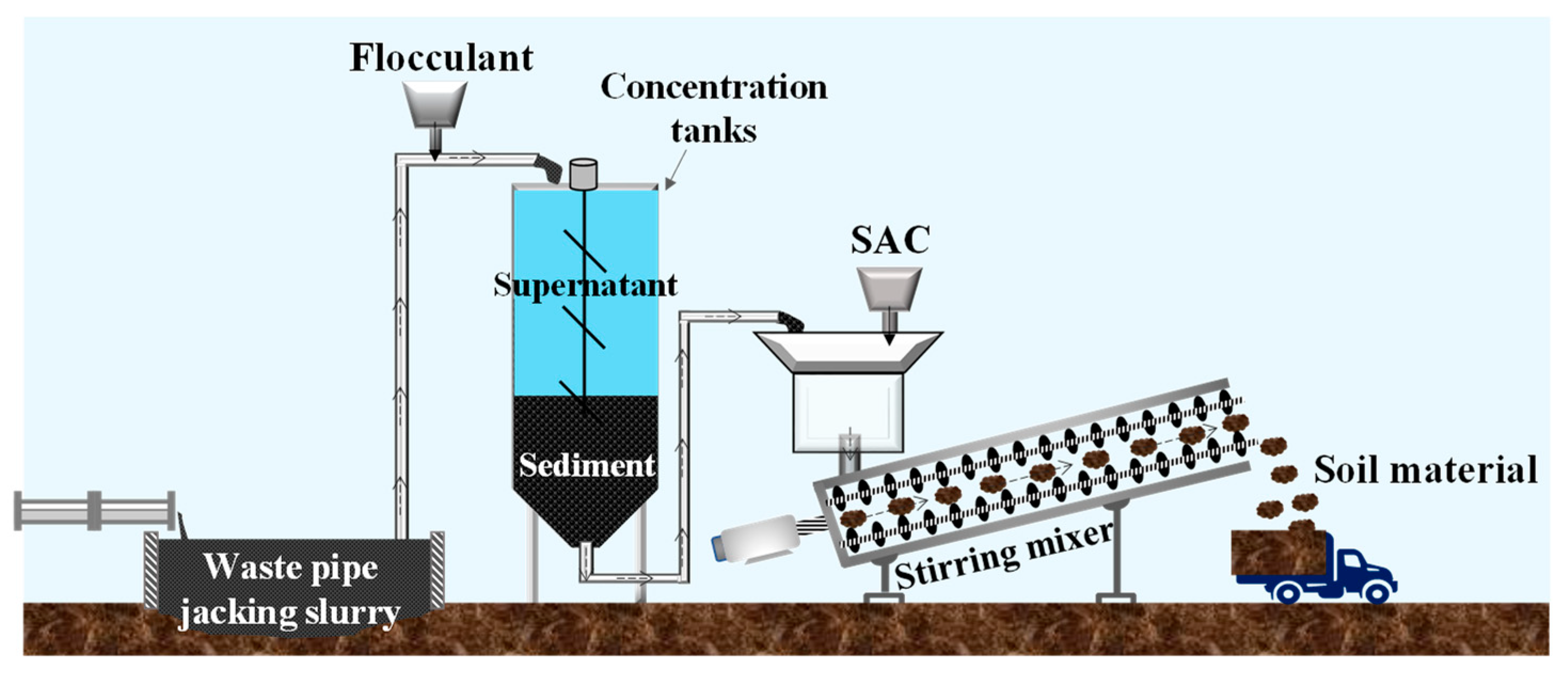

4.2. New Method for Rapid Dewatering

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, P.; Ma, B.; Zeng, C.; Xie, H.M.; Li, X.; Wang, D.W. Key techniques for the largest curved pipe jacking roof to date: A case study of Gongbei tunnel. Tunn. Undergr. Space Technol. 2016, 59, 134–145. [Google Scholar] [CrossRef]

- Cheng, W.C.; Ni, J.C.; Shen, J.S.; Huang, H.W. Investigation into factors affecting jacking force: A case study. ICE Proc. Geotech. Eng. 2017, 170, 322–334. [Google Scholar] [CrossRef]

- Ji, X.B.; Zhao, W.; Ni, P.P.; Barla, M.; Han, J.Y.; Jia, P.J.; Chen, Y.; Zhang, C.Z. A method to estimate the jacking force for pipe jacking in sandy soils. Tunn. Undergr. Space Technol. 2019, 90, 119–130. [Google Scholar] [CrossRef]

- Reilly, C.C.; Orr, T.L. Physical modelling of the effect of lubricants in pipe jacking. Tunn. Undergr. Space Technol. 2017, 63, 44–53. [Google Scholar] [CrossRef]

- Yao, Z.S.; Wang, C.; Xue, W.P.; Zhang, P.; Fang, Y. Experimental study on the dynamic mechanical properties of high-performance hybrid fiber-reinforced concrete of mine shaft lining. J. Mater. Res. Technol. 2021, 14, 888–900. [Google Scholar] [CrossRef]

- Lee, K.E.; Morad, N.; Teng, T.T.; Poh, B.T. Development, characterization and the application of hybrid materials in coagulation/flocculation of wastewater: A review. Chem. Eng. J. 2012, 203, 370–386. [Google Scholar] [CrossRef]

- Igwegbe, C.A.; Ighalo, J.O.; Onukwuli, O.D.; Obiora-Okafo, I.A.; Anastopoulos, I. Coagulation-flocculation of aquaculture wastewater using green coagulant from Garcinia kola seeds: Parametric studies, kinetic modelling and cost analysis. Sustainability 2021, 13, 9177. [Google Scholar] [CrossRef]

- Maćczak, P.; Kaczmarek, H.; Ziegler-Borowska, M.; Węgrzynowska-Drzymalska, K.; Burkowska-But, A. The use of chitosan and starch-based flocculants for filter backwash water treatment. Materials 2022, 15, 1056. [Google Scholar] [CrossRef]

- Wu, S.L.; Zhu, Y.Y.; Zhu, W.; Shu, S.; Cui, Y. A study on the differences in the flocculation of dredged slurries and the influencing mechanisms. Water Sci. Technol. 2019, 80, 1751–1762. [Google Scholar] [CrossRef]

- Song, Z.Z.; Zhang, W.J.; Gao, H.Y.; Wang, D.S. Comprehensive assessment of flocculation conditioning of dredged sediment using organic polymers: Dredged sediment dewaterability and release of pollutants. Sci. Total Environ. 2020, 739, 139884. [Google Scholar] [CrossRef]

- Botha, L.; Soares, J.B. The influence of tailings composition on flocculation. Can. J. Chem. Eng. 2015, 93, 1514–1523. [Google Scholar] [CrossRef]

- Wang, D.L.; Zhang, Q.L.; Chen, Q.S.; Qi, C.C.; Feng, Y.; Xiao, C.C. Temperature variation characteristics in flocculation settlement of tailings and its mechanism. Int. J. Miner. Metall. Mater. 2020, 27, 1438–1448. [Google Scholar] [CrossRef]

- Wang, D.X.; Di, S.J.; Wu, L.F.; Tan, Y.Z.; Tang, Y.K. Sedimentation behavior of organic, inorganic, and composite flocculant-treated waste slurry from construction works. J. Mater. Civil Eng. 2021, 33, 04021134. [Google Scholar] [CrossRef]

- He, J.; Chu, J.; Tan, S.K.; Vu, T.T. Sedimentation behavior of flocculant-treated soil slurry. Mar. Georesources Geotechnol. 2017, 35, 593–602. [Google Scholar] [CrossRef]

- Wei, H.; Gao, B.Q.; Ren, J.; Li, A.M.; Yang, H. Coagulation/flocculation in dewatering of sludge: A review. Water Res. 2018, 143, 608–631. [Google Scholar] [CrossRef]

- Wang, S.; Song, X.P.; Wang, X.J.; Chen, Q.S.; Qin, J.C.; Ke, Y.X. Influence of coarse tailings on flocculation settlement. Int. J. Miner. Metall. Mater. 2020, 27, 1065–1074. [Google Scholar] [CrossRef]

- Cui, Y.; Zhu, W.; Wu, S.L.; Liu, J.M.; Hou, H.; Lin, N.X. The role of lime in dredged mud dewatered by a plate and frame filter press and potential substitutes. Environ. Sci. Pollut. Res. Int. 2021, 28, 17331–17342. [Google Scholar] [CrossRef]

- Ding, A.; Qu, F.S.; Liang, H.; Guo, S.D.; Ren, Y.H.; Xu, G.R.; Li, G.B. Effect of adding wood chips on sewage sludge dewatering in a pilot-scale plate-and-frame filter press process. RSC Adv. 2014, 4, 24762–24768. [Google Scholar] [CrossRef]

- Oh, J.Y.; Park, H.; Chang, S.; Lee, S. Enhancement of slurry treatment efficiency in slurry shield TBM tunneling by optimal application of coagulant agent. In Proceedings of the 2017 World Congress on Advances in Structural Engineering and Mechanics (ASEM17), Seoul, Korea, 28 August–1 September 2017. [Google Scholar]

- Yoobanpot, N.; Jamsawang, P.; Poorahong, H.; Jongpradist, P.; Likitlersuang, S. Multiscale laboratory investigation of the mechanical and microstructural properties of dredged sediments stabilized with cement and fly ash. Eng. Geol. 2020, 267, 105491. [Google Scholar] [CrossRef]

- Huang, X.W.; Yao, Z.S.; Cai, H.B.; Li, X.W.; Chen, H.Q. Performance evaluation of coaxial borehole heat exchangers considering ground non-uniformity based on analytical solutions. Int. J. Therm. Sci. 2021, 170, 107162. [Google Scholar] [CrossRef]

- Reddy, V.A.; Solanki, C.H.; Kumar, S.; Reddy, K.R.; Du, Y.J. Stabilization/solidification of Zinc-and lead-contaminated soil using limestone calcined clay cement (LC3): An environmentally friendly alternative. Sustainability 2020, 12, 3725. [Google Scholar] [CrossRef]

- Li, Y.; Ni, W.; Gao, W.; Zhang, S.; Fu, P.; Li, Y. Study on solidification and stabilization of antimony-containing tailings with metallurgical slag-based binders. Materials 2022, 15, 1780. [Google Scholar] [CrossRef] [PubMed]

- Sato, T.; Kato, H. Application of the pneumatic flow mixing method to land development for Central Japan International Airport. In Proceedings of the 2002 International Symposium on Underwater Technology (Cat. No.02EX556), Tokyo, Japan, 16–19 April 2002. [Google Scholar]

- McLaughlin, R.A.; Bartholomew, N. Soil factors influencing suspended sediment flocculation by polyacrylamide. Soil Sci. Soc. Am. J. 2007, 71, 537–544. [Google Scholar] [CrossRef]

- Liu, J.J.; Zha, F.S.; Xu, L.; Yang, C.B.; Tan, X.H. Effect of chloride attack on strength and leaching properties of solidified/stabilized heavy metal contaminated soils. Eng. Geol. 2018, 246, 28–35. [Google Scholar] [CrossRef]

| Pipe Jacking Slurry | Specific Gravity | Liquid Limit (%) | Plastic Limit (%) | Organic Matter Content (%) |

|---|---|---|---|---|

| Type I | 2.58 | 42.16 | 22.18 | 4.68 |

| Type II | 2.61 | 71.22 | 32.76 | 4.12 |

| Flocculants | PAM Characteristics | Molecular Weight | Solid Content (%) | Charge Density (meq/g) |

|---|---|---|---|---|

| 412VS | cationic | ≥10 million | ≥89 | 1.8–2.2 |

| 611HN | cationic | ≥10 million | ≥91 | 2.5 |

| 7126 | anionic | 16 million | ≥89 | / |

| 720VJ | anionic | 12 million | ≥89 | / |

| Pipe Jacking Slurry | Water Content (%) | Conditioners | PAM Characteristics | Dosage 1 (%) |

|---|---|---|---|---|

| Type I | 300 | 412VS | cationic | 0.10, 0.15, 0.20 |

| Type I | 300 | 611HN | cationic | 0.10, 0.15, 0.20 |

| Type I | 300 | 7126 | anionic | 0.03, 0.06, 0.09 |

| Type I | 300 | 720VJ | anionic | 0.04, 0.07, 0.10 |

| Type II | 300 | 412VS | cationic | 0.60, 0.65, 0.70 |

| Type II | 300 | 611HN | cationic | 0.55, 0.60, 0.65 |

| Type II | 300 | 7126 | anionic | 0.20, 0.25, 0.30 |

| Type II | 300 | 720VJ | anionic | 0.20, 0.25, 0.30 |

| Type II | 300 | FeCl3 + 0.25% 412VS | cationic | 1, 3, 5 2 |

| Type II | 300 | FeCl3 + 0.10% 7126 | anionic | 1, 3, 5 |

| Conditioners | Solidification Agent | Dosage 1 (%) | Curing Time (day) |

|---|---|---|---|

| 0.25% 7126 | OPC | 20, 30, 40 | 3, 7, 28 |

| 0.25% 7126 | SAC | 20, 30, 40 | 3, 7, 28 |

| 3% FeCl3 + 0.10% 7126 | OPC | 20, 30, 40 | 3, 7, 28 |

| 3% FeCl3 + 0.10% 7126 | SAC | 20, 30, 40 | 3, 7, 28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, L.; Zhen, L.; Wang, J.; Zhang, T.; Huang, X. Research on Dewatering Characteristics of Waste Slurry from Pipe Jacking Construction. Materials 2022, 15, 2242. https://doi.org/10.3390/ma15062242

Jiang L, Zhen L, Wang J, Zhang T, Huang X. Research on Dewatering Characteristics of Waste Slurry from Pipe Jacking Construction. Materials. 2022; 15(6):2242. https://doi.org/10.3390/ma15062242

Chicago/Turabian StyleJiang, Libing, Liang Zhen, Jianfeng Wang, Tao Zhang, and Xianwen Huang. 2022. "Research on Dewatering Characteristics of Waste Slurry from Pipe Jacking Construction" Materials 15, no. 6: 2242. https://doi.org/10.3390/ma15062242

APA StyleJiang, L., Zhen, L., Wang, J., Zhang, T., & Huang, X. (2022). Research on Dewatering Characteristics of Waste Slurry from Pipe Jacking Construction. Materials, 15(6), 2242. https://doi.org/10.3390/ma15062242