Cross-Link Density, Mechanical and Thermal Properties of Chloroprene Rubber Cross-Linked with Silver(I) Oxide

Abstract

1. Introduction

2. Experimental Part

2.1. Materials

2.2. Research Methods

3. Results and Discussion

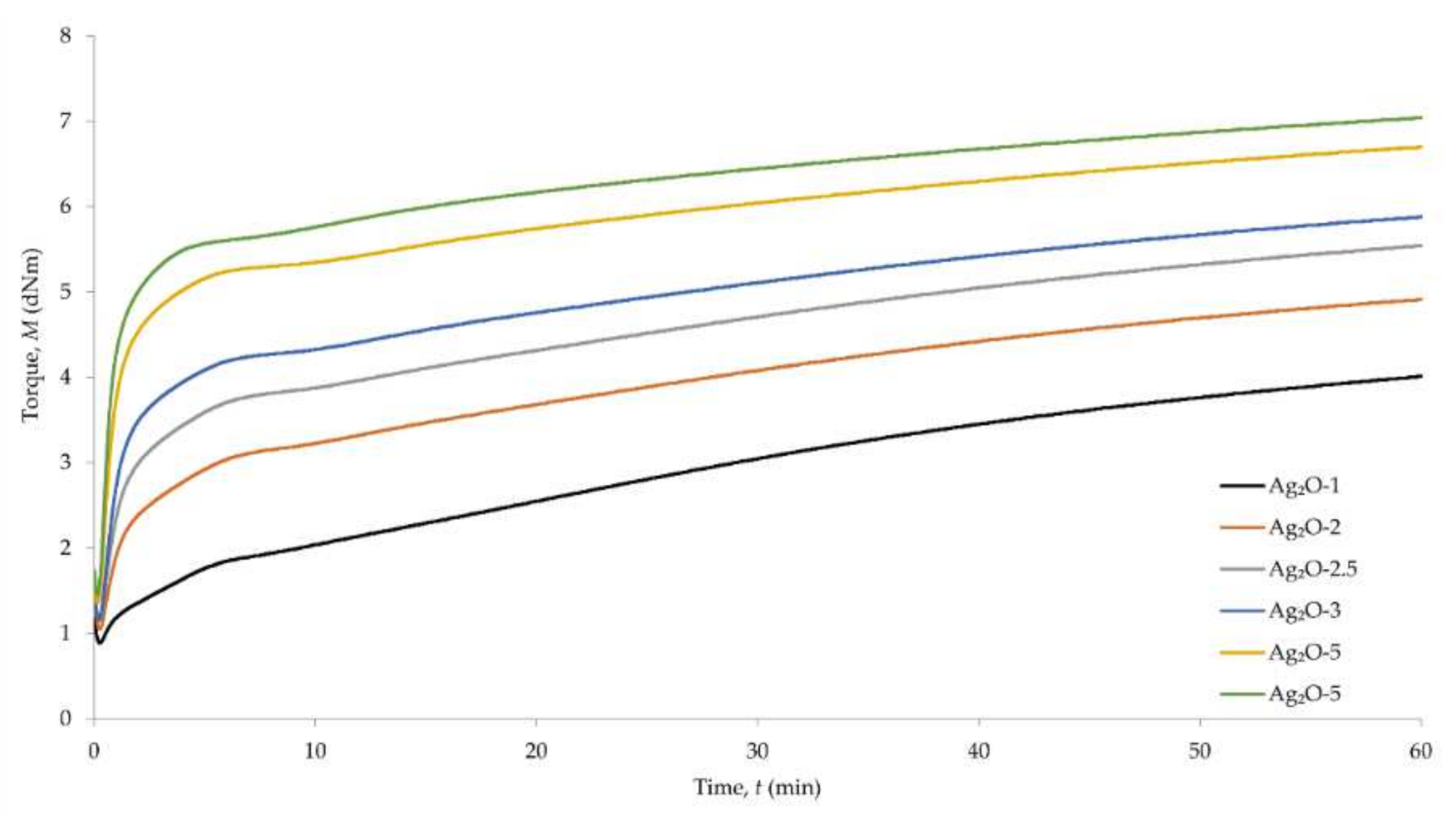

3.1. Vulcametric Parameters of CR Compositions Containing Silver(I) Oxide

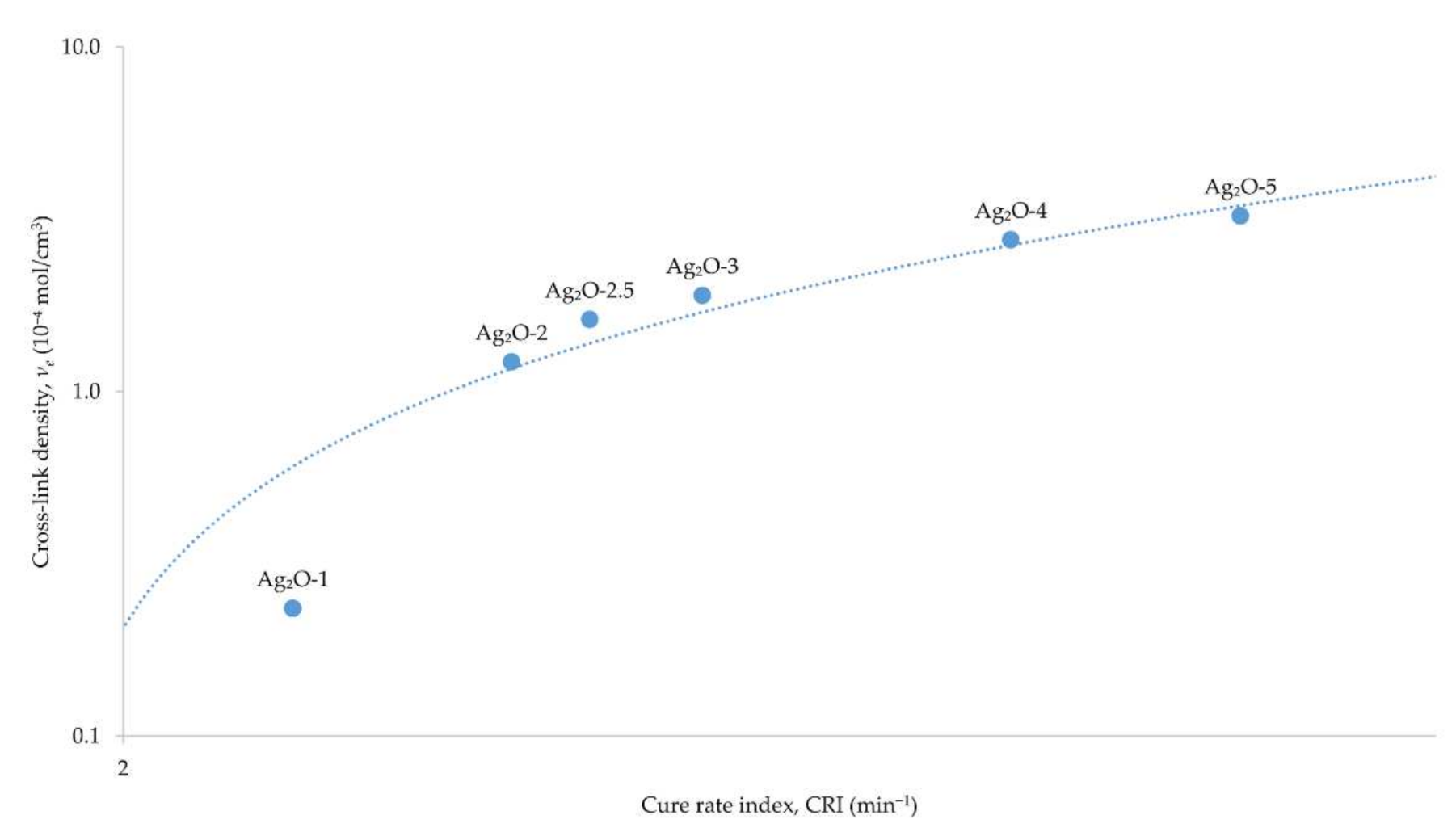

3.2. Equilibrium Swelling of CR Cross-Linked with Silver(I) Oxide

3.3. Elasticity Constants of CR Cross-Linked with Silver(I) Oxide

3.4. Real Extract of CR Cross-Linked with Silver(I) Oxide

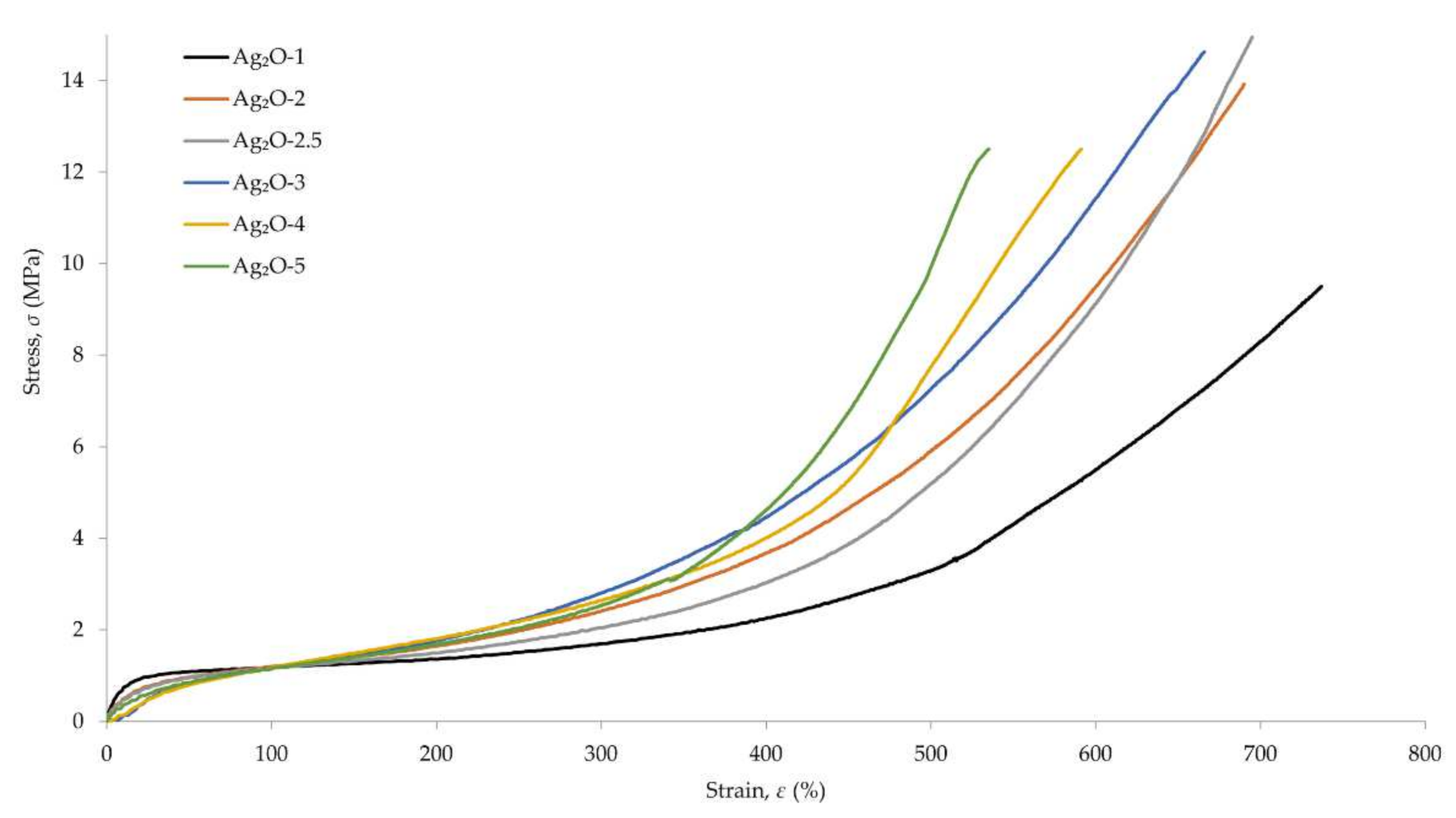

3.5. Mechanical Properties of CR Cross-Linked with Silver(I) Oxide

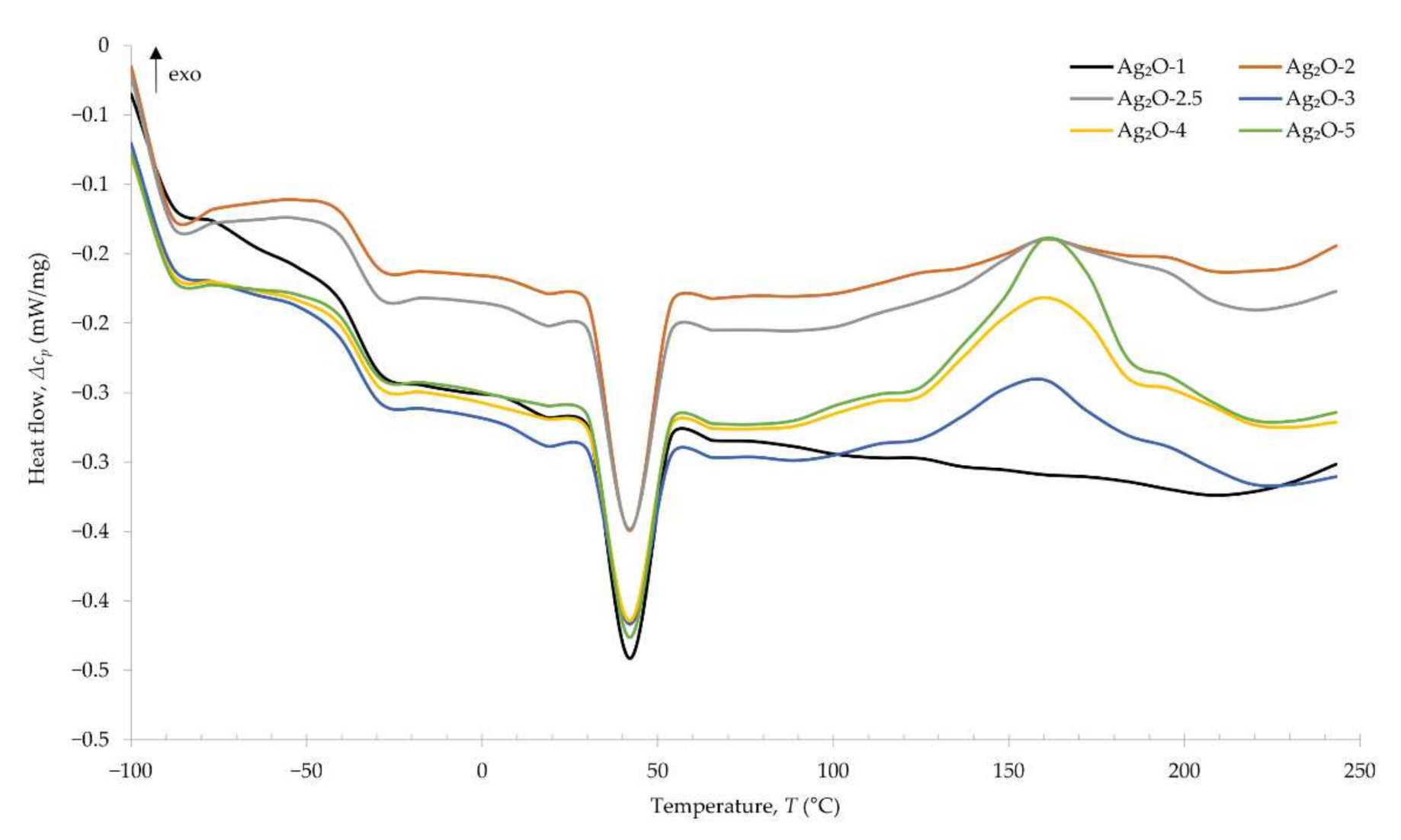

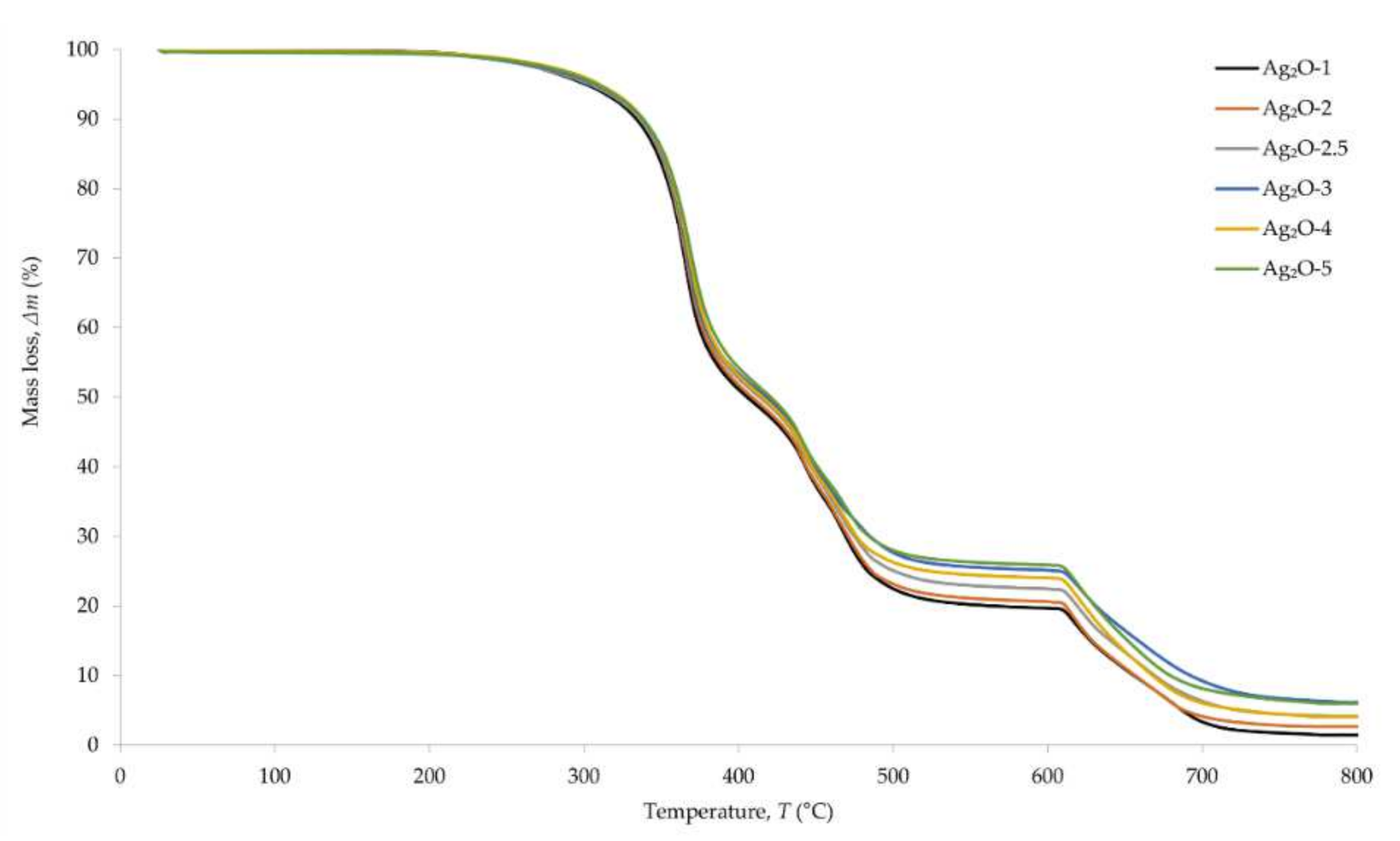

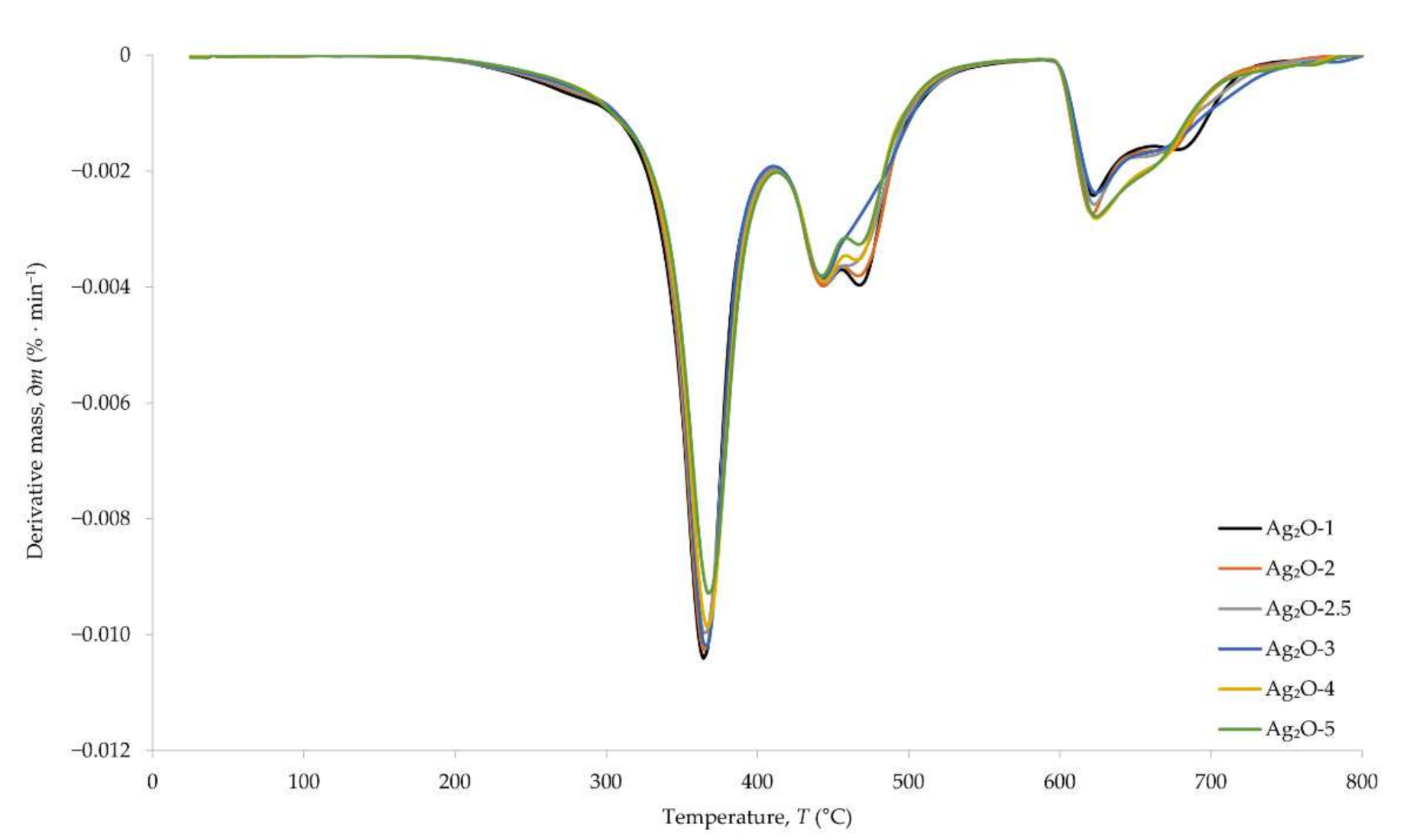

3.6. Thermal Analysis of CR Cross-Linked with Silver(I) Oxide

4. Conclusions

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, J.; Isayev, A.I.; Ren, X.; Soucek, M.D. Effect of norbornyl modified soybean oil on CB-filled chloroprene rubber. J. Appl. Polym. Sci. 2016, 133, 43809. [Google Scholar] [CrossRef]

- Zhang, P.; Huang, G.; Qu, L.; Nie, Y.; Weng, G.; Wu, J. Strain-induced crystallization behavior of polychloroprene rubber. J. Appl. Polym. Sci. 2011, 121, 37–42. [Google Scholar] [CrossRef]

- Bĕhal, M.; Duchăček, V. Thermovulcanization of polychloroprene rubber and its blends with poly(vinyl chloride). J. Appl. Polym. Sci. 1988, 35, 507–515. [Google Scholar] [CrossRef]

- De, S.K.; White, J.R. Rubber Technologist’s Handbook, 1st ed.; Rapra Technology Limited: Shrewbury, UK, 2001; pp. 39–203. [Google Scholar]

- Maya, M.G.; Soney, G.C.; Thomasukutty, J.; Lekshmi, K.; Sabu, T. Development of a flexible and conductive elastomeric composite based on chloroprene rubber. Polym. Test. 2018, 65, 256–263. [Google Scholar] [CrossRef]

- Tchalla, S.T.; Le Gac, P.-Y.; Maurin, R.; Créac’Hcadec, R. Polychloroprene behaviour in a marine environment: Role of silica fillers. Polym. Degrad. Stab. 2017, 139, 28–37. [Google Scholar] [CrossRef]

- Mohammed Ali Mutar, M.A. A Study in Vulcanization of Neoprene Rubber(WRT) by Polymethylol Resin(RESOL). Al-Nahrain J. Sci. 2010, 13, 1–6. [Google Scholar]

- Kong, L.; Zhu, Y.; Huang, G.; Wu, J. Carbon nanodots as dual role of crosslinking and reinforcing chloroprene rubber. Compos. Commun. 2020, 22, 100441. [Google Scholar] [CrossRef]

- Kaur, A.; Gautrot, J.E.; Cavalli, G.; Watson, D.; Bickley, A.; Akutagawa, K.; Busfield, J.J.C. Novel Crosslinking System for Poly-Chloroprene Rubber to Enable Recyclability and Introduce Self-Healing. Polymers 2021, 13, 3347. [Google Scholar] [CrossRef]

- Xiang, H.P.; Rong, M.Z.; Zhang, M.Q. Self-healing, Reshaping, and Recycling of Vulcanized Chloroprene Rubber: A Case Study of Multitask Cyclic Utilization of Cross-linked Polymer. ACS Sustain. Chem. Eng. 2016, 4, 2715–2724. [Google Scholar] [CrossRef]

- Dziemidkiewicz, A.; Anyszka, R.; Blume, A.; Maciejewska, M. Reaction mechanism of halogenated rubber crosslinking using a novel environmentally friendly curing system. Polym. Test. 2020, 84, 106354. [Google Scholar] [CrossRef]

- Mammadov, S.M.; Asadova, A.A.; Khankishiyeva, R.F.; Akbarov, O.H.; Duruskari, G.S.; Maharramov, M.N.; Mamedov, J.M.; Akhundzada, H.N. Radiation Crosslinking of Neoprene W with Diallyl Etherofmaleic Acid and Epoxy Resins. Am. J. Polym. Sci. 2016, 6, 68–74. [Google Scholar]

- Olejnik, A.; Smejda-Krzewicka, A.; Strzelec, K.; Szynkowska, M.I. Curing and properties of chloroprene and butadiene rubber (CR/BR) blends cross-linked with copper(I) oxide or copper(II) oxide. Int. J. Polym. Anal. Charact. 2019, 24, 18–31. [Google Scholar] [CrossRef]

- Olejnik, A.; Smejda-Krzewicka, A.; Strzelec, K. Effect of antioxidants on aging of the chloroprene rubber/butadiene rubber (CR/BR) blends. Int. J. Polym. Anal. Charact. 2019, 24, 475–486. [Google Scholar] [CrossRef]

- Kobędza, P.; Smejda-Krzewicka, A.; Olejnik, A.; Strzelec. K. Flame retardant and durable chloroprene rubber and styrene-butadiene rubber blends crosslinked with copper(I) oxide. Iran. Polym. J. 2021, 30, 149–165. [Google Scholar] [CrossRef]

- Smejda-Krzewicka, A.; Olejnik, A.; Strzelec, K. The role of iron(III) oxide in chloroprene and butadiene rubber blends’ cross-linking, structure, thermal and mechanical characteristics. Iran. Polym. J. 2019, 28, 313–323. [Google Scholar] [CrossRef]

- Smejda-Krzewicka, A.; Olejnik, A.; Strzelec, K. The effect of metal oxide on the cure, morphology, thermal and mechanical characteristics of chloroprene and butadiene rubber blends. Polym. Bull. 2020, 77, 4131–4146. [Google Scholar] [CrossRef]

- Surya, I.; Ginting, M.; Ismail, H. Cure characteristics, swelling behaviour and tensile properties of carbon black-filled Natural Rubber (NR)/Chloroprene Rubber (CR) blends in the presence of alkanolamide. MATEC Web Conf. 2018, 197, 12005. [Google Scholar] [CrossRef][Green Version]

- Mohanadas, P.N.; Mukundan, T.; Santhanakrishnan, T. Low Temperature Vulcanisation: Technique for CR-BIIR Blend for Encapsulation of Oceanic Sensors. Def. Sci. J. 2020, 70, 207–213. [Google Scholar] [CrossRef]

- Lide, D.R. CRC Handbook of Chemistry and Physics, 90th ed.; CRC Press: Boca Raton, FL, USA, 2009; pp. 4–89. [Google Scholar]

- Cotton, F.A.; Wilkinson, G. Advanced Inorganic Chemistry, 2nd ed.; John Wiley & Sons: New York, NY, USA, 1966; p. 1042. [Google Scholar]

- Glemser, O.; Sauer, H. Silver Oxide. In Handbook of Preparative Inorganic Chemistry, 2nd ed.; Brauer, G., Ed.; Academic Press: New York, NY, USA, 1963; Volume 1, p. 1037. [Google Scholar]

- Janssen, D.E.; Wilson, C.V. 4 -Iodoveratrole. Org. Synth. 1956, 36, 46. [Google Scholar]

- De Rooij, A. The Oxidation of Silver by Atomic Oxygen. ESA J. 1989, 13, 363–382. [Google Scholar]

- Naik, K.; Kowshik, M. The silver lining: Towards the responsible and limited usage of silver. J. Appl. Microbiol. 2017, 123, 1068–1087. [Google Scholar] [CrossRef] [PubMed]

- Lam, Y.L.; Kan, C.W.; Yuen, C.W. Effect of metal oxide on anti-microbial finishing of cotton fabric. BioResources 2012, 7, 3960–3983. [Google Scholar]

- Roberts, J.D.; Stewart, R.; Caserio, M.C. Organic Chemistry: Methane to Macromolecules, 1st ed.; W.A. Benjamin, Inc.: New York, NY, USA, 1971; p. 292. [Google Scholar]

- Gallardo, O.A.D.; Moiraghi, R.; Macchione, M.A.; Godoy, J.A.; Perez, M.A.; Coronado, E.A.; Macagno, V.A. Silver oxide particles/silver nanoparticles interconversion: Susceptibility of forward/backward reactions to the chemical environment at room temperature. RCS Adv. 2012, 2, 2923–2929. [Google Scholar] [CrossRef]

- Limbitot, M.; Kalyane, S.; Sharanappa, N.; Lagali, K. Synthesis and Characterization of Ag2O Doped Polyaniline. Int. J. Emerg. Technol. 2016, 7, 207–211. [Google Scholar]

- Nwanya, A.C.; Ugwuoke, P.E.; Ezekoye, B.A.; Osuji, R.U.; Ezema, F.I. Structural and Optical Properties of Chemical Bath Deposited Silver Oxide Thin Films: Role of Deposition Time. Adv. Mater. Sci. Eng. 2013, 2013, 450820. [Google Scholar] [CrossRef]

- Lu, C.-A.; Lin, P.; Lin, H.-C.; Wang, S.-F. Effects of Silver Oxide Addition on the Electrical Resistivity and Microstructure of Low-Temperature-Curing Metallo-Organic Decomposition Silver Pastes. Jpn. J. Appl. Phys. 2007, 46, 4179–4183. [Google Scholar] [CrossRef]

- Taufik, A.; Saleha, R. The Influence of Graphene on Silver Oxide Synthesis Through Microwave Assisted Method. AIP Conf. Proc. 2018, 2023, 020018. [Google Scholar]

- Marhoon, I.I.; Rasool, D.A.; Dhumad, K.A.; Tlaiaa, Y.S.; Abdulrehman, M.A. Study Effect of Silver Oxide Addition on Mechanical Properties of Epoxy Composites. Eur. J. Eng. Res. Sci. 2018, 3, 38–41. [Google Scholar] [CrossRef]

- Owczarek, M.; Zaborski, M. The properties of aminosilane-crosslinked chloroprene rubbers. Przemysl Chem. 2003, 82, 1311–1313. [Google Scholar]

- Desai, H.; Hendrikse, K.G.; Woolard, C.D. Vulcanization of polychloroprene rubber. I. A revised cationic mechanism for ZnO crosslinking. J. Appl. Polym. Sci. 2007, 105, 865–876. [Google Scholar] [CrossRef]

- Coran, A.Y. Chemistry of the Vulcanization and Protection of Elastomers: A Review of the Achievements. J. Appl. Polym. Sci. 2003, 87, 24–30. [Google Scholar] [CrossRef]

- Kell, R.M.; Bennett, B.; Stickney, P.B. Transition behavior of polychloroprene and polychloroprene/styrene-butadiene blends. J. Appl. Polym. Sci. 1959, 2, 8–13. [Google Scholar] [CrossRef]

- Maeda, S.; Yoshida, J.; Ura, Y.; Haraguchi, H.; Sugawara, J. Air Springs for Railways Available for Very Cold Environments. SEI Tech. Rev. 2015, 51, 63–66. [Google Scholar]

| CR (phr) | Ag2O (phr) | Stearic Acid (phr) | Symbol |

|---|---|---|---|

| 100 | 1 | 1 | Ag2O-1 |

| 100 | 2 | 1 | Ag2O-2 |

| 100 | 2.5 | 1 | Ag2O-2.5 |

| 100 | 3 | 1 | Ag2O-3 |

| 100 | 4 | 1 | Ag2O-4 |

| 100 | 5 | 1 | Ag2O-5 |

| Symbol | t02 (min) | t90 (min) | Mmin (dN⋅m) | ∆M30 (dN⋅m) | CRI (min−1) |

|---|---|---|---|---|---|

| Ag2O-1 | 6.93 | 53.36 | 0.89 | 2.16 | 2.15 |

| Ag2O-2 | 1.18 | 43.55 | 1.05 | 3.03 | 2.36 |

| Ag2O-2.5 | 0.85 | 41.91 | 1.15 | 3.55 | 2.44 |

| Ag2O-3 | 0.71 | 39.70 | 1.16 | 3.95 | 2.56 |

| Ag2O-4 | 0.50 | 34.72 | 1.46 | 4.68 | 2.92 |

| Ag2O-5 | 0.45 | 31.55 | 1.45 | 4.99 | 3.22 |

| Symbol | QVT (cm3/cm3) | QVH (cm3/cm3) | −QWT (mg/mg) | −QWH (mg/mg) | VrT | VrH | αc | νe (10−4 mol/cm3) |

|---|---|---|---|---|---|---|---|---|

| Ag2O-1 | 20.44 ± 0.53 | 0.39 ± 0.04 | 0.43 ± 0.02 | 0.05 ± 0.01 | 0.047 ± 0.001 | 0.722 ± 0.021 | 0.049 | 0.24 |

| Ag2O-2 | 7.52 ± 0.16 | 0.39 ± 0.06 | 0.24 ± 0.03 | 0.06 ± 0.01 | 0.117 ± 0.002 | 0.720 ± 0.030 | 0.133 | 1.22 |

| Ag2O-2.5 | 6.34 ± 0.22 | 0.37 ± 0.06 | 0.20 ± 0.01 | 0.06 ± 0.01 | 0.136 ± 0.004 | 0.732 ± 0.032 | 0.158 | 1.62 |

| Ag2O-3 | 5.77 ± 0.05 | 0.36 ± 0.03 | 0.23 ± 0.01 | 0.06 ± 0.01 | 0.148 ± 0.001 | 0.733 ± 0.017 | 0.173 | 1.90 |

| Ag2O-4 | 4.59 ± 0.11 | 0.35 ± 0.10 | 0.15 ± 0.01 | 0.07 ± 0.02 | 0.179 ± 0.003 | 0.746 ± 0.052 | 0.218 | 2.76 |

| Ag2O-5 | 4.15 ± 0.02 | 0.33 ± 0.01 | 0.13 ± 0.01 | 0.05 ± 0.01 | 0.194 ± 0.001 | 0.736 ± 0.012 | 0.241 | 3.24 |

| Symbol | C1 (kG/cm2) | C2 (kG/cm2) | ER (mg/mg) |

|---|---|---|---|

| Ag2O-1 | 0.57 | 0.67 | 0.043 |

| Ag2O-2 | 0.82 | 0.92 | 0.052 |

| Ag2O-2.5 | 0.98 | 0.72 | 0.050 |

| Ag2O-3 | 1.10 | 2.92 | 0.060 |

| Ag2O-4 | 1.46 | 2.89 | 0.081 |

| Ag2O-5 | 1.56 | 2.37 | 0.089 |

| Symbol | Se100 (MPa) | Se200 (MPa) | Se300 (MPa) | TSb (MPa) | Eb (%) |

|---|---|---|---|---|---|

| Ag2O-1 | 1.16 ± 0.02 | 1.36 ± 0.01 | 1.72 ± 0.07 | 9.40 ± 0.48 | 774 ± 56 |

| Ag2O-2 | 1.25 ± 0.09 | 1.68 ± 0.14 | 2.37 ± 0.17 | 13.9 ± 1.4 | 690 ± 48 |

| Ag2O-2.5 | 1.16 ± 0.03 | 1.48 ± 0.05 | 2.01 ± 0.08 | 14.9 ± 0.4 | 698 ± 10 |

| Ag2O-3 | 1.21 ± 0.04 | 1.73 ± 0.12 | 2.59 ± 0.28 | 14.6 ± 1.5 | 697 ± 97 |

| Ag2O-4 | 1.32 ± 0.09 | 2.02 ± 0.22 | 3.17 ± 0.44 | 12.5 ± 0.2 | 581 ± 97 |

| Ag2O-5 | 1.19 ± 0.02 | 1.75 ± 0.05 | 2.65 ± 0.10 | 12.5 ± 1.3 | 518 ± 78 |

| Symbol | Tg (°C) | TV Range (°C) | TV (°C) | ΔH (J/g) |

|---|---|---|---|---|

| Ag2O-1 | −37.91 | 111–199 | 124 | 0.26 |

| 180 | 0.51 | |||

| Ag2O-2 | −37.47 | 139–200 | 160 | 10 |

| Ag2O-2.5 | −37.83 | 124–211 | 161 | 20 |

| Ag2O-3 | −38.65 | 120–193 | 158 | 20 |

| Ag2O-4 | −38.11 | 123–191 | 161 | 29 |

| Ag2O-5 | −37.78 | 128–189 | 164 | 36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kobędza, P.; Smejda-Krzewicka, A.; Strzelec, K. Cross-Link Density, Mechanical and Thermal Properties of Chloroprene Rubber Cross-Linked with Silver(I) Oxide. Materials 2022, 15, 2006. https://doi.org/10.3390/ma15062006

Kobędza P, Smejda-Krzewicka A, Strzelec K. Cross-Link Density, Mechanical and Thermal Properties of Chloroprene Rubber Cross-Linked with Silver(I) Oxide. Materials. 2022; 15(6):2006. https://doi.org/10.3390/ma15062006

Chicago/Turabian StyleKobędza, Piotr, Aleksandra Smejda-Krzewicka, and Krzysztof Strzelec. 2022. "Cross-Link Density, Mechanical and Thermal Properties of Chloroprene Rubber Cross-Linked with Silver(I) Oxide" Materials 15, no. 6: 2006. https://doi.org/10.3390/ma15062006

APA StyleKobędza, P., Smejda-Krzewicka, A., & Strzelec, K. (2022). Cross-Link Density, Mechanical and Thermal Properties of Chloroprene Rubber Cross-Linked with Silver(I) Oxide. Materials, 15(6), 2006. https://doi.org/10.3390/ma15062006