Hardening and Fresh State Behaviour of Ternary Cement for Marine Environments: Modification through Nanoadditives

Abstract

:1. Introduction

2. Materials and Methods

2.1. Nanomaterials

2.1.1. Graphene Oxide (GO)

2.1.2. Microfibrillated Cellulose (MFC)

2.1.3. Nanosilica (NS)

2.2. Cement

2.3. Aggregates

2.4. Superplasticiser (SP)

2.5. Samples Formulation Design

2.6. Samples Preparation

2.6.1. Nanoadditives Solution

2.6.2. Samples for Setting Time Test

2.6.3. Samples for Isothermal Calorimetry

2.6.4. Mortars

2.7. Testing Methods

2.7.1. Setting Time Measurements

2.7.2. Isothermal Calorimetry Tests

2.7.3. Workability at Fresh State: Mini-Slump Test

2.8. Mechanical Tests

3. Results and Discussion

3.1. Modifications of Setting Time

3.2. Influence of Nanoadditives on Isothermal Calorimetry

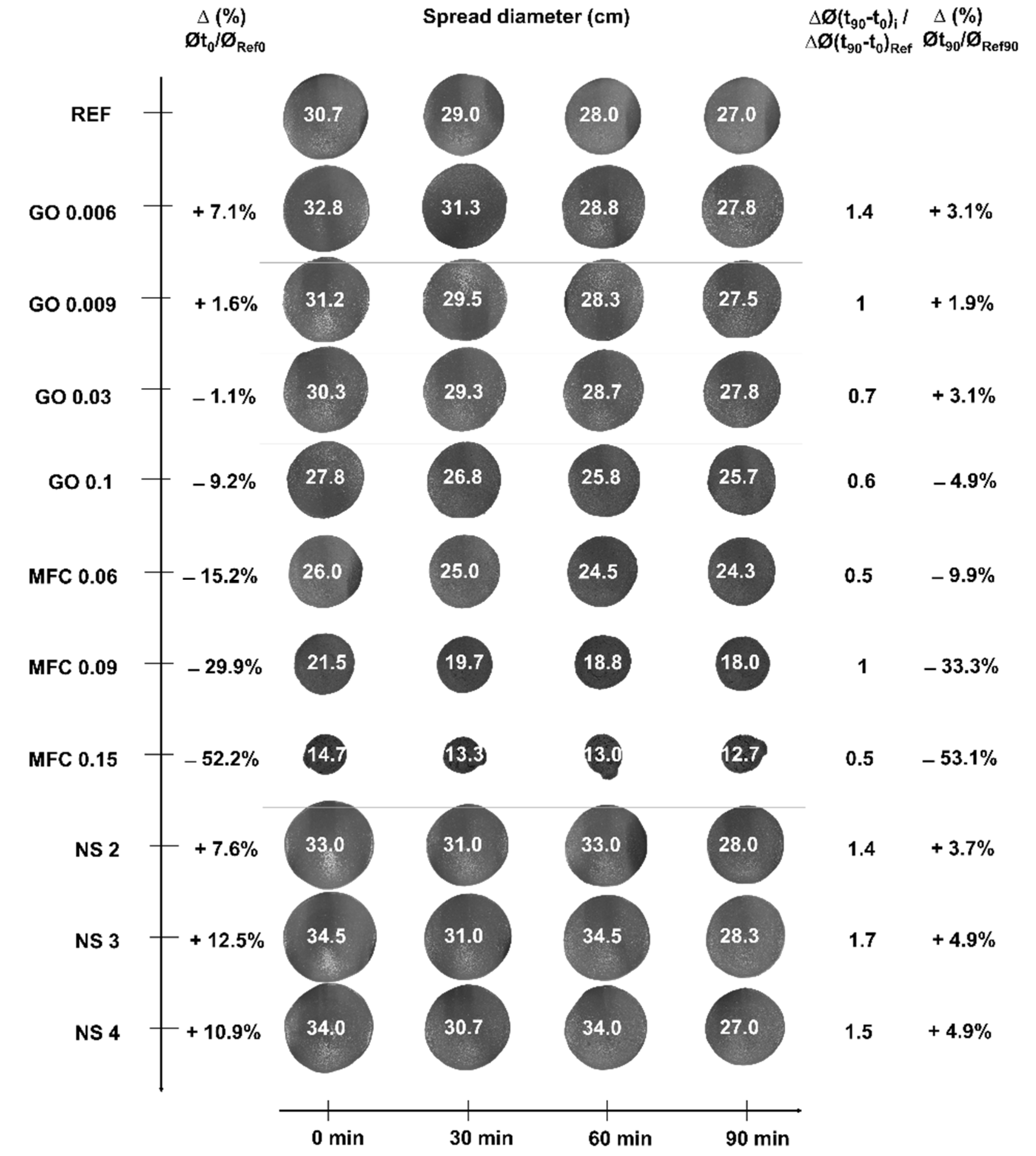

3.3. Workability Changes with Nanoadditives

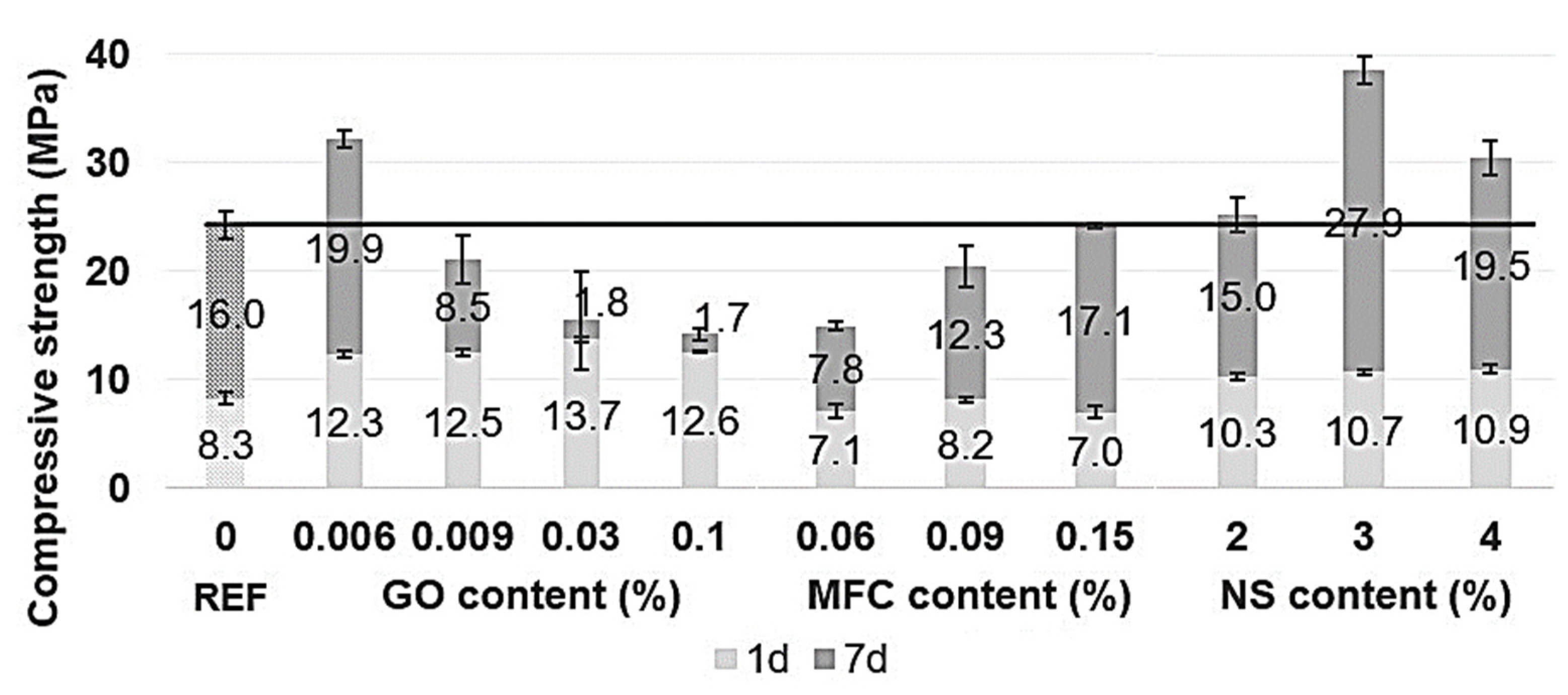

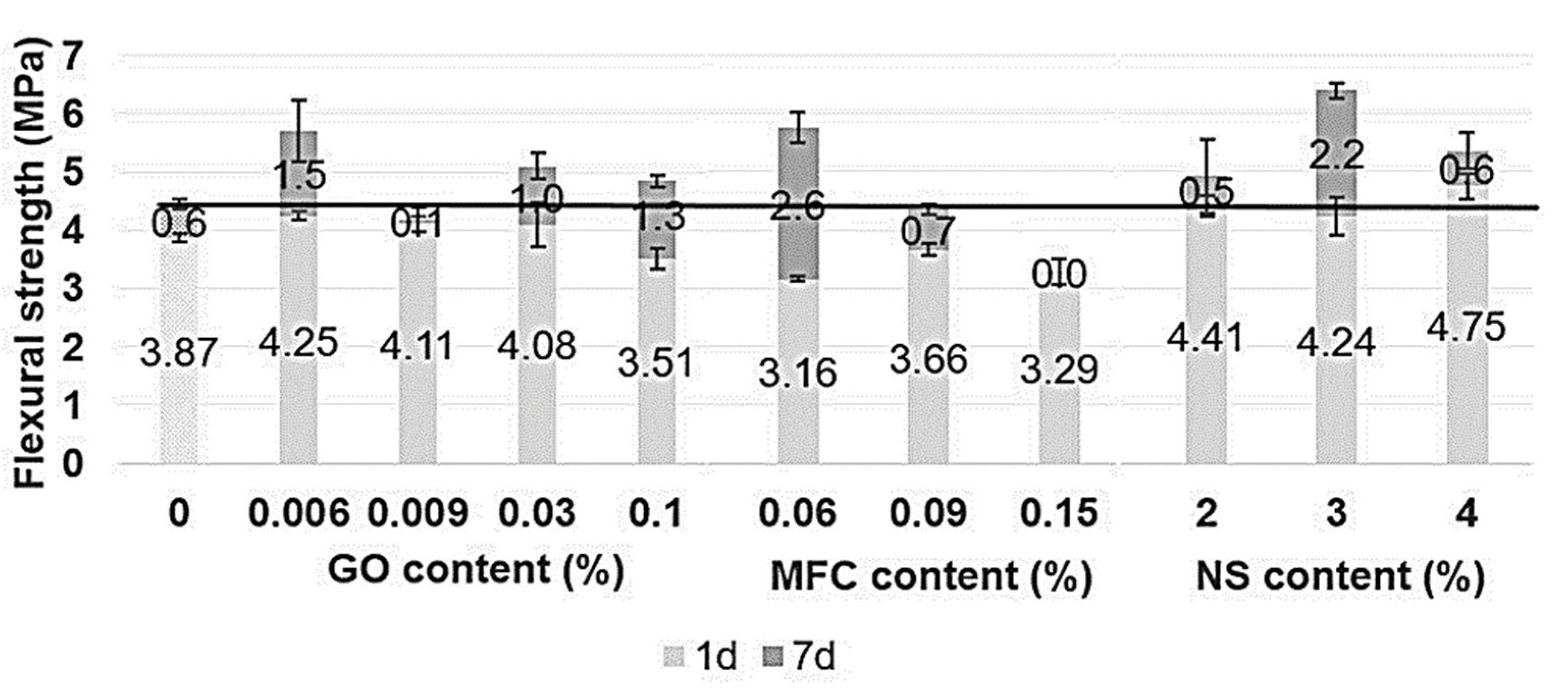

3.4. Mechanical Behaviour at an Early Age

3.5. Analysis of Nanoadditive Effect on the Studied Properties

4. Conclusions

- Nanoadditives modify the hydration kinetics. At a mortar scale, it could be observed on the workability.

- GO: Influences the cement hydration reaction, leading to a reduction of the setting time. The workability increases at a low amount of GO, while at higher dosages, GO leads to an increasing reduction of the workability.

- MFC: Had a significant impact on the workability due to their interaction with mixing water and observed in the reduction of spread diameters in the slump test. The effect on mechanical properties was dose dependent. At higher dosages, the compressive strength increased; the result was more important at 7 days than at 1 day, which means a further hydration reaction with the water kept on the MFC. The absorption of water around its surroundings enhanced hydration, and consequently reduced the setting time.

- NS: It is highly reactive, and promotes and accelerates the cement particles’ hydration reaction due to its large specific surface. This was shown in isothermal calorimetry and setting time experiments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lothenbach, B.; Scrivener, K.; Hooton, R.D. Supplementary cementitious materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Li, G.Y.; Wang, P.M.; Zhao, X. Mechanical behavior and microstructure of cement composites incorporating surface-treated multi-walled carbon nanotubes. Carbon 2005, 43, 1239–1245. [Google Scholar] [CrossRef]

- de Souza, L.O.; Cordazzo, M.; de Souza, L.M.S.; Tonoli, G.; Silva, F.D.A.; Mechtcherine, V. Investigation of dispersion methodologies of microcrystalline and nano-fibrillated cellulose on cement pastes. Cem. Concr. Compos. 2021, 126, 104351. [Google Scholar] [CrossRef]

- Wu, J.; Ding, Q.; Yang, W.; Wang, L.; Wang, H. Influence of Submicron Fibrillated Cellulose Fibers from Cotton on Hydration and Microstructure of Portland Cement Paste. Molecules 2021, 26, 5831. [Google Scholar] [CrossRef] [PubMed]

- Barbhuiya, G.H.; Moiz, M.A.; Hasan, S.D.; Zaheer, M.M. Effects of the nanosilica addition on cement concrete: A review. Mater. Today Proc. 2020, 32, 560–566. [Google Scholar] [CrossRef]

- Björnström, J.; Martinelli, A.; Matic, A.; Börjesson, L.; Panas, I. Accelerating effects of colloidal nano-silica for beneficial calcium–silicate–hydrate formation in cement. Chem. Phys. Lett. 2004, 392, 242–248. [Google Scholar] [CrossRef]

- Dubey, N.; Rajan, S.S.; Bello, Y.D.; Min, K.-S.; Rosa, V. Graphene Nanosheets to Improve Physico-Mechanical Properties of Bioactive Calcium Silicate Cements. Materials 2017, 10, 606. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Goracci, G.; Dolado, S.J. Elucidation of Conduction Mechanism in Graphene Nanoplatelets (GNPs)/Cement Composite Using Dielectric Spectroscopy. Materials 2020, 13, 275. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.-Y.; Que, L.; Cui, Z.; Lambert, P. Physical Properties of Concrete Containing Graphene Oxide Nanosheets. Materials 2019, 12, 1707. [Google Scholar] [CrossRef] [Green Version]

- Galao, O.; Baeza, F.J.; Zornoza, E.; Garcés, P. Carbon Nanofiber Cement Sensors to Detect Strain and Damage of Concrete Specimens Under Compression. Nanomaterials 2017, 7, 413. [Google Scholar] [CrossRef] [Green Version]

- Vegas, I.; Gaitero, J.; Urreta, J.; García, R.; Frías, M. Aging and durability of ternary cements containing fly ash and activated paper sludge. Constr. Build. Mater. 2014, 52, 253–260. [Google Scholar] [CrossRef]

- Giménez, R.G.; De La Villa, R.V.; Rubio, V.; Vegas, I.; Frías, M. Forced Aging and Ionic Mobility of Ternary Cements Exposed to Aggressive Saline Marine Environments and Cryoclastic Processes. Water Air Soil Pollut. 2015, 226, 267. [Google Scholar] [CrossRef] [Green Version]

- Alaghebandian, N.; Mirvalad, S.; Javid, A.A.S. Durability of self-consolidating concrete and mortar mixtures containing ternary and quaternary cement blends exposed to simulated marine environment. Constr. Build. Mater. 2020, 259, 119767. [Google Scholar] [CrossRef]

- Thomas, M.; Shehata, M.; Shashiprakash, S.; Hopkins, D.; Cail, K. Use of ternary cementitious systems containing silica fume and fly ash in concrete. Cem. Concr. Res. 1999, 29, 1207–1214. [Google Scholar] [CrossRef]

- De Weerdt, K.; Ben Haha, M.; LE Saout, G.; Kjellsen, K.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Dodson, V.H. Concrete Admixtures; Springer: New York, NY, USA, 2013. [Google Scholar]

- Sant, G.; Lothenbach, B.; Juilland, P.; LE Saout, G.; Weiss, W.; Scrivener, K. The origin of early age expansions induced in cementitious materials containing shrinkage reducing admixtures. Cem. Concr. Res. 2011, 41, 218–229. [Google Scholar] [CrossRef]

- Zhu, W.; Bartos, P.J.; Porro, A. Application of nanotechnology in construction. Mater. Struct. 2004, 37, 649–658. [Google Scholar] [CrossRef]

- Long, W.-J.; Zheng, D.; Duan, H.-B.; Han, N.; Xing, F. Performance enhancement and environmental impact of cement composites containing graphene oxide with recycled fine aggregates. J. Clean. Prod. 2018, 194, 193–202. [Google Scholar] [CrossRef]

- Reches, Y. Nanoparticles as concrete additives: Review and perspectives. Constr. Build. Mater. 2018, 175, 483–495. [Google Scholar] [CrossRef]

- Cao, Y.; Zavaterri, P.; Youngblood, J.; Moon, R.; Weiss, W. The influence of cellulose nanocrystal additions on the performance of cement paste. Cem. Concr. Compos. 2015, 56, 73–83. [Google Scholar] [CrossRef]

- Sanchez, F.; Sobolev, K. Nanotechnology in concrete—A review. Constr. Build. Mater. 2010, 24, 2060–2071. [Google Scholar] [CrossRef]

- Mohammed, A.; Sanjayan, J.; Duan, W.H.; Nazari, A. Incorporating graphene oxide in cement composites: A study of transport properties. Constr. Build. Mater. 2015, 84, 341–347. [Google Scholar] [CrossRef]

- Hawreen, A.; Bogas, J.A. Influence of carbon nanotubes on steel–concrete bond strength. Mater. Struct. 2018, 51, 155. [Google Scholar] [CrossRef]

- Chuah, S.; Pan, Z.; Sanjayan, J.; Wang, C.; Duan, W.H. Nano reinforced cement and concrete composites and new perspective from graphene oxide. Constr. Build. Mater. 2014, 73, 113–124. [Google Scholar] [CrossRef]

- Arshad, A.; Jabbal, M.; Yan, Y.; Reay, D. A review on graphene based nanofluids: Preparation, characterization and applications. J. Mol. Liq. 2019, 279, 444–484. [Google Scholar] [CrossRef]

- Hou, D.; Lu, Z.; Li, X.; Ma, H.; Li, Z. Reactive molecular dynamics and experimental study of graphene-cement composites: Structure, dynamics and reinforcement mechanisms. Carbon 2017, 115, 188–208. [Google Scholar] [CrossRef]

- Ho, V.D.; Ng, C.-T.; Ozbakkaloglu, T.; Goodwin, A.; McGuckin, C.; Karunagaran, R.U.; Losic, D. Influence of pristine graphene particle sizes on physicochemical, microstructural and mechanical properties of Portland cement mortars. Constr. Build. Mater. 2020, 264, 120188. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, J.; Ouyang, D. Effect of Graphene Oxide on Mechanical Properties of Cement Mortar and its Strengthening Mechanism. Materials 2019, 12, 3753. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ghazizadeh, S.; Duffour, P.; Skipper, N.T.; Bai, Y. Understanding the behaviour of graphene oxide in Portland cement paste. Cem. Concr. Res. 2018, 111, 169–182. [Google Scholar] [CrossRef] [Green Version]

- Lu, Z.; Hanif, A.; Ning, C.; Shao, H.; Yin, R.; Li, Z. Steric stabilization of graphene oxide in alkaline cementitious solutions: Mechanical enhancement of cement composite. Mater. Des. 2017, 127, 154–161. [Google Scholar] [CrossRef]

- Yang, H.; Monasterio, M.; Cui, H.; Han, N. Experimental study of the effects of graphene oxide on microstructure and properties of cement paste composite. Compos. Part A Appl. Sci. Manuf. 2017, 102, 263–272. [Google Scholar] [CrossRef]

- Du, H.; Gao, H.J.; Pang, S.D. Improvement in concrete resistance against water and chloride ingress by adding graphene nanoplatelet. Cem. Concr. Res. 2016, 83, 114–123. [Google Scholar] [CrossRef]

- Du, H.; Pang, S.D. Enhancement of barrier properties of cement mortar with graphene nanoplatelet. Cem. Concr. Res. 2015, 76, 10–19. [Google Scholar] [CrossRef]

- Pei, C.; Ueda, T.; Zhu, J. Investigation of the effectiveness of graphene/polyvinyl alcohol on the mechanical and electrical properties of cement composites. Mater. Struct. 2020, 53, 66. [Google Scholar] [CrossRef]

- Yang, H.; Cui, H.; Tang, W.; Li, Z.; Han, N.; Xing, F. A critical review on research progress of graphene/cement based composites. Compos. Part A Appl. Sci. Manuf. 2017, 102, 273–296. [Google Scholar] [CrossRef]

- Fu, T.; Moon, R.J.; Zavattieri, P.; Youngblood, J.; Weiss, W.J. Cellulose nanomaterials as additives for cementitious materials. In Cellulose-Reinforced Nanofibre Composites; Jawaid, M., Boufi, S., Abdul Khalil, H.P.S., Eds.; Elsevier Ltd.: Amsterdam, The Netherlands, 2017; Volume C, pp. 455–482. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Mariano, M.; Gopakumar, D.; Ahmad, I.; Thomas, S.; Dufresne, A.; Huang, J.; Lin, N. Advances in cellulose nanomaterials. Cellulose 2018, 25, 2151–2189. [Google Scholar] [CrossRef]

- Kolour, H.H.; Ashraf, W.; Landis, E.N. Hydration and Early Age Properties of Cement Pastes Modified with Cellulose Nanofibrils. Transp. Res. Rec. J. Transp. Res. Board 2020, 2675, 38–46. [Google Scholar] [CrossRef]

- Aitcin, P. The durability characteristics of high performance concrete: A review. Cem. Concr. Compos. 2003, 25, 409–420. [Google Scholar] [CrossRef]

- Monasterio, M.; Gaitero, J.J.; Erkizia, E.; Bustos, A.G.; Miccio, L.A.; Dolado, J.S.; Cerveny, S. Effect of addition of silica- and amine functionalized silica-nanoparticles on the microstructure of calcium silicate hydrate (C–S–H) gel. J. Colloid Interface Sci. 2015, 450, 109–118. [Google Scholar] [CrossRef] [Green Version]

- Gaitero, J.; Campillo, I.; Guerrero, A. Reduction of the calcium leaching rate of cement paste by addition of silica nanoparticles. Cem. Concr. Res. 2008, 38, 1112–1118. [Google Scholar] [CrossRef] [Green Version]

- Liu, X.; Feng, P.; Shu, X.; Ran, Q. Effects of highly dispersed nano-SiO2 on the microstructure development of cement pastes. Mater. Struct. 2019, 53, 4. [Google Scholar] [CrossRef]

- Jo, B.-W.; Kim, C.-H.; Tae, G.-H.; Park, J.-B. Characteristics of cement mortar with nano-SiO2 particles. Constr. Build. Mater. 2007, 21, 1351–1355. [Google Scholar] [CrossRef]

- Land, G.; Stephan, D. Controlling cement hydration with nanoparticles. Cem. Concr. Compos. 2015, 57, 64–67. [Google Scholar] [CrossRef]

- NF EN 196-3-Septembre 2017. AFNOR, S.A.N. 2020. Available online: https://www.boutique.afnor.org/norme/nf-en-196-3/methodes-d-essai-des-ciments-partie-3-determination-du-temps-de-prise-et-de-la-stabilite/article/904098/fa186374 (accessed on 23 June 2021).

- NF EN 196-1-Septembre 2016. Available online: https://www.boutique.afnor.org/norme/nf-en-196-1/methodes-d-essais-des-ciments-partie-1-determination-des-resistances/article/866862/fa184622 (accessed on 23 June 2021).

- NF EN 196-11-December 2018. Available online: https://www.boutique.afnor.org/norme/pr-nf-en-196-11/methods-of-testing-cement-part-11-heat-of-hydration-isothermal-conduction-calorimetry-method/article/905598/fa189490 (accessed on 10 November 2020).

- Roussel, N.; Stefani, C.; Leroy, R. From mini-cone test to Abrams cone test: Measurement of cement-based materials yield stress using slump tests. Cem. Concr. Res. 2005, 35, 817–822. [Google Scholar] [CrossRef]

- Kong, D.; Huang, S.; Corr, D.; Yang, Y.; Shah, S.P. Whether do nano-particles act as nucleation sites for C-S-H gel growth during cement hydration? Cem. Concr. Compos. 2018, 87, 98–109. [Google Scholar] [CrossRef]

- Abbasi, S.; Jannaty, M.H.; Faraj, R.H.; ShahbazPanahi, S.; Mosavi, A. The Effect of Incorporating Silica Stone Waste on the Mechanical Properties of Sustainable Concretes. Materials 2020, 13, 3832. [Google Scholar] [CrossRef]

- Karen Scrivener, R.S.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

| GRAPHENE OXIDE, GO | |||||

| Chemical element | C | O | S | H | N |

| Mass weight (%) | 49–56 | 41–50 | 2–4 | 0–1 | 0–1 |

| MICROFIBRILLATED CELLULOSE, MFC | |||||

| Specific surface area (m2/g) | 31–33 | Nominal fibre width (nm) | 50 | ||

| NANOSILICA, NS | |||||

| Particles size (nm) | 15 | Loss of ignition after 2 h 1000 °C (%) | 7 | ||

| Specific surface area (m2/g) | 140 | pH (5 wt%, aqueous slurry) | 4 | ||

| CEMENT CEM V/A | |||||

| Chemical compound | CaO | SiO2 | Al2O3 | Fe2O3 | MgO |

| Mass weight (%) | 46.2 | 31.1 | 10.2 | 3.6 | 2.7 |

| Blaine surface (m2/kg) | 502.3 | Hydration heat (J/g) | 275 at 41 h, 309 at 120 h | ||

| Initial setting time (min) | 223 | Consistency (water in cement paste) | 29.50% | ||

| AGGREGATES: SAND | |||||

| Grain size (mm) | 0/2 | Density (at 20 °C, kg/m3) | 2600 | ||

| SUPERPLASTICISER, SP | |||||

| pH (aqueous solution) | 3.7 | Density (g/cm3) | 1.06 | ||

| Solid content (%) | 40 | Water content (%) | 60 | ||

| Sample Name | Nano-Additive/Cement Ratio [% in Weight of Cement] | Nano-Additive [mg] | Mixing Water [g] |

|---|---|---|---|

| REF | - | - | 176.0 |

| GO 0.006 | 0.006 | 27 | 169.2 |

| GO 0.009 | 0.009 | 40 | 165.9 |

| GO 0.03 | 0.030 | 135 | 142.3 |

| GO 0.1 | 0.100 | 450 | 63.9 |

| MFC 0.06 | 0.060 | 270 | 162.7 |

| MFC 0.09 | 0.090 | 405 | 156.1 |

| MFC 0.15 | 0.150 | 675 | 142.9 |

| NS 2 | 2.000 | 9·103 | 176.0 |

| NS 3 | 3.000 | 13.5 103 | 176.0 |

| NS 4 | 4.000 | 18 103 | 176.0 |

| Sample | HF (qmin) [mW/g] | t (qmin) [h] | t (qmax) [h] | HF (qmax) [mW/g] | Cumulative Heat [J/g] |

|---|---|---|---|---|---|

| REF | 0.173 | 4.59 | 22.53 | 1.975 | 230.5 |

| GO 0.006 | 0.162 (−6%) | 4.73 (+3%) | 22.92 (+2%) | 1.981 (+1%) | 228.8 (−1%) |

| GO 0.009 | 0.161 (−6%) | 4.75 (+3%) | 22.83 (+1%) | 2.004 (+2%) | 234.0 (+1%) |

| GO 0.1 | 0.163 (−6%) | 4.67 (+2%) | 2.00 (−2%) | 1.982 (+1%) | 230.5 (=) |

| NS 2 | 0.283 (+64%) | 3.80 (−17%) | 19.67 (−15%) | 2.069 (+5%) | 226.5 (−2%) |

| NS 3 | 0.388 (+124%) | 3.77 (−18%) | 19.34 (−16%) | 2.129 (+7%) | 242.3 (+5%) |

| Sample | Reference | GO [0.006–0.1%] | MFC [0.06–0.15%] | NS [2–4%] |

|---|---|---|---|---|

| Setting time [min] | ||||

| Initial | 230 | 220–170 | 220–170 | 220–110 |

| Final | 260 | 260–210 | 190 | 230–130 |

| Isothermal calorimetry: | ||||

| Modification observed at high dosage and after deceleration period | Not measured | Heat flow increase and acceleration of the reaction | ||

| Cumulative heat at 6 days | 230.5 J/g | 228.8 J/g | 234 J/g | 230.5 J/g |

| Workability: Non-monotonic or linear relation | ||||

| Non-monotonic effect: reduction and improvement of the workability | Linear reduction of the workability | Non-monotonic increase of the workability | ||

| Spread diameter at t0 | 30.7 cm | 32.8–27.8 cm | 26–14.7 cm | 33–34 cm |

| Mechanical properties: Non-monotonic or linear relation | ||||

| Compression strength at 7 days | 24.3 MPa | Optimal dosage 0.006% 32.3 MPa | Linear relation 0.15% 24.1 MPa | Optimal dosage 3% 38.6 MPa |

| Flexural strength at 7 days | 3.87 MPa | Optimal dosage 0.006% 4.25 MPa | Optimal dosage 0.09% 3.66 MPa | Optimal dosage 4% 4.75 MPa |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matanza Corro, A.; Perlot, C.; Latapie, E.; Cerveny, S. Hardening and Fresh State Behaviour of Ternary Cement for Marine Environments: Modification through Nanoadditives. Materials 2022, 15, 1938. https://doi.org/10.3390/ma15051938

Matanza Corro A, Perlot C, Latapie E, Cerveny S. Hardening and Fresh State Behaviour of Ternary Cement for Marine Environments: Modification through Nanoadditives. Materials. 2022; 15(5):1938. https://doi.org/10.3390/ma15051938

Chicago/Turabian StyleMatanza Corro, Amaia, Céline Perlot, Ema Latapie, and Silvina Cerveny. 2022. "Hardening and Fresh State Behaviour of Ternary Cement for Marine Environments: Modification through Nanoadditives" Materials 15, no. 5: 1938. https://doi.org/10.3390/ma15051938

APA StyleMatanza Corro, A., Perlot, C., Latapie, E., & Cerveny, S. (2022). Hardening and Fresh State Behaviour of Ternary Cement for Marine Environments: Modification through Nanoadditives. Materials, 15(5), 1938. https://doi.org/10.3390/ma15051938