Response Surface Methodology and Artificial Neural Network Modelling of Membrane Rotating Biological Contactors for Wastewater Treatment

Abstract

1. Introduction

2. Materials and Methods

2.1. Wastewater Preparation

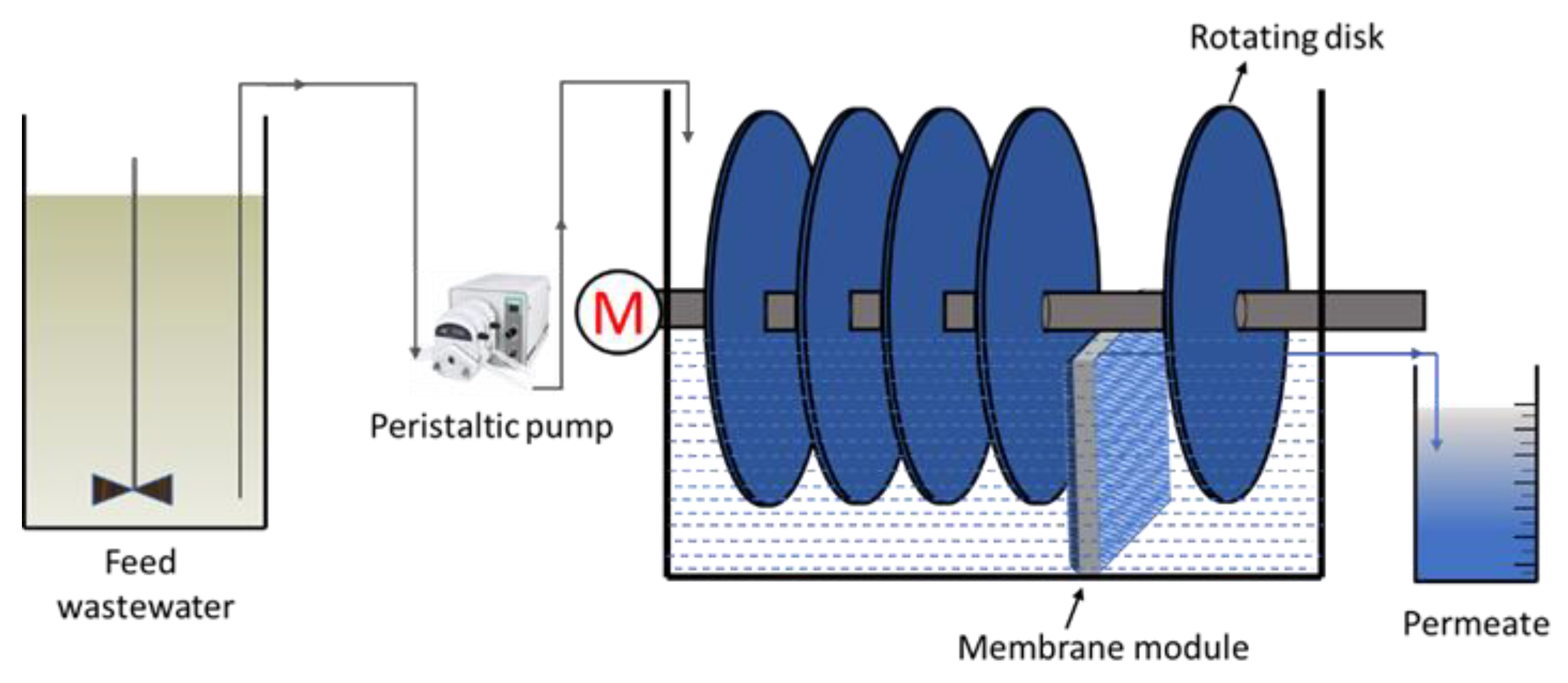

2.2. Bioreactor Set-Up and Operation

2.3. Analytical Methods

2.4. Experimental Design Using the Response Surface Methodology Method

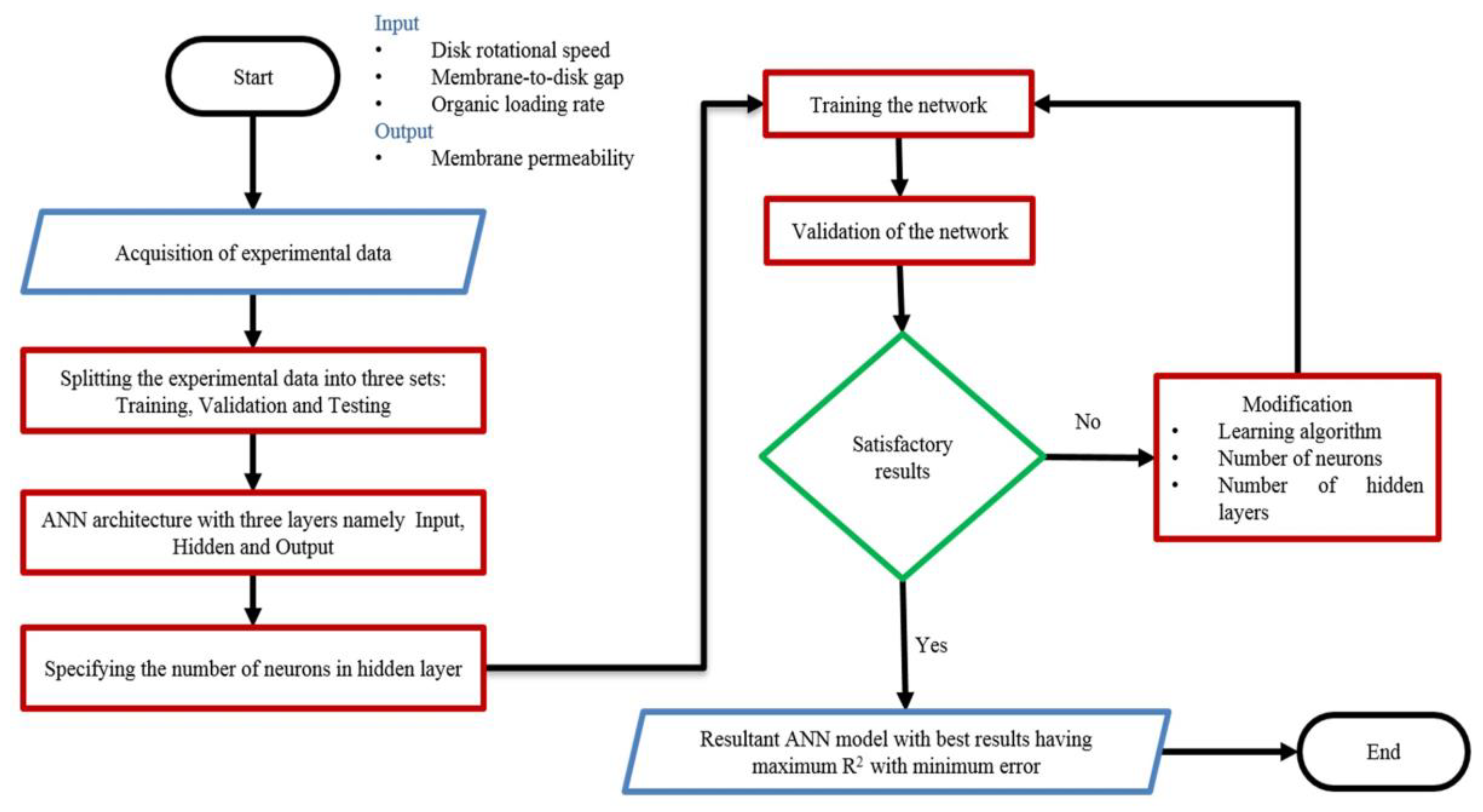

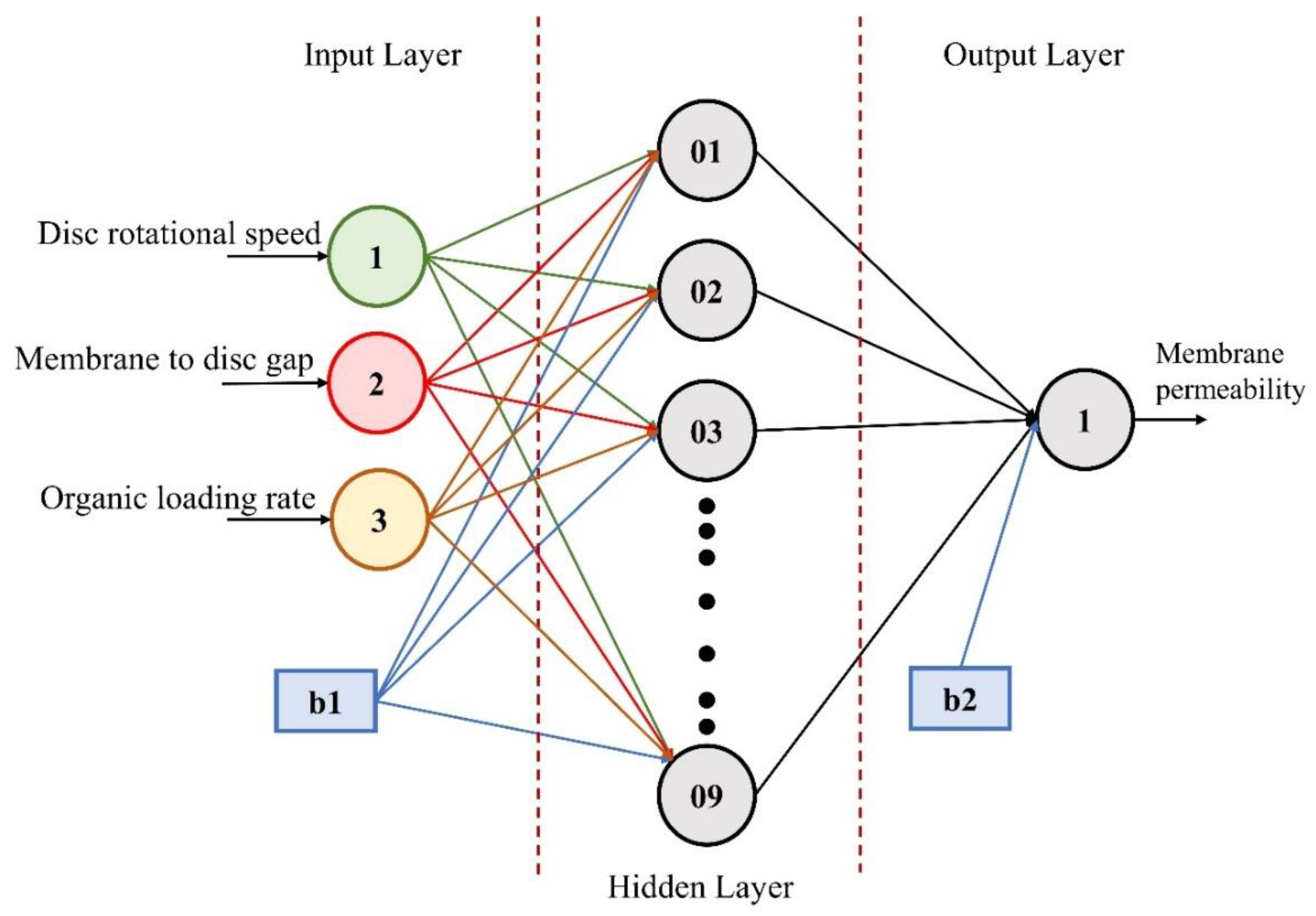

2.5. Artificial Intelligence and Machine Learning Approach

3. Results and Discussion

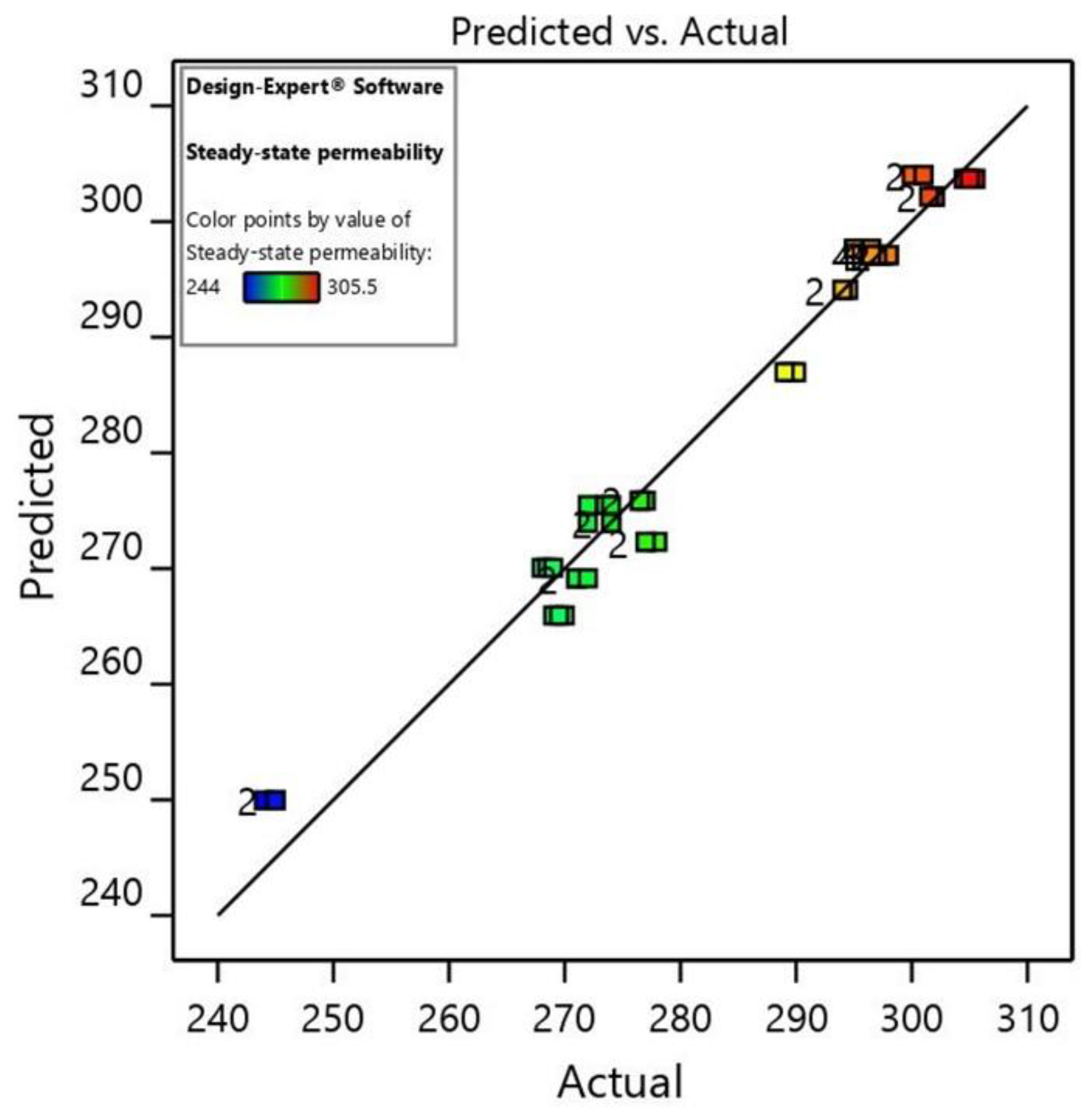

3.1. Statistical Analysis and Model Development

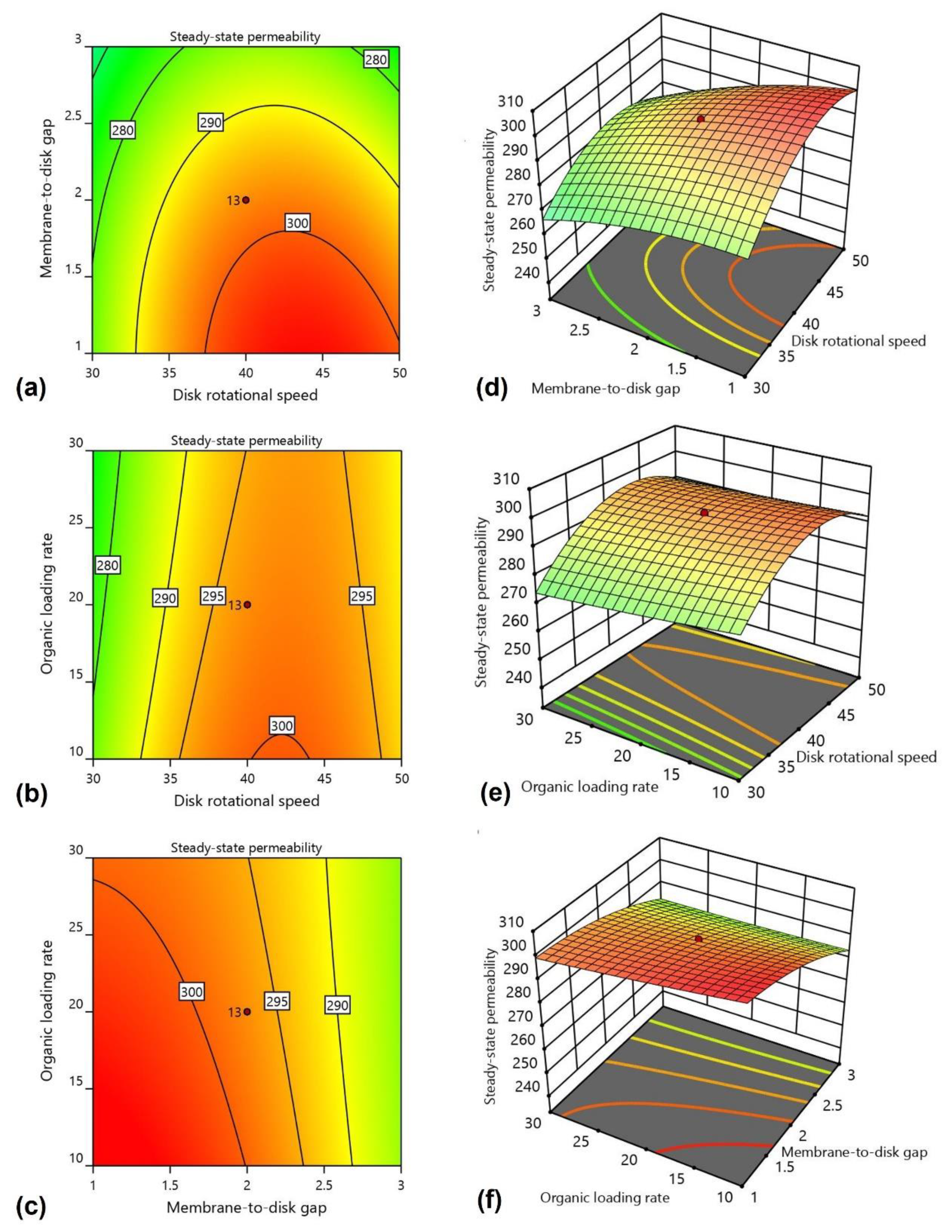

3.2. RSM Model Optimization

3.3. Process Analysis

3.4. Process Optimization

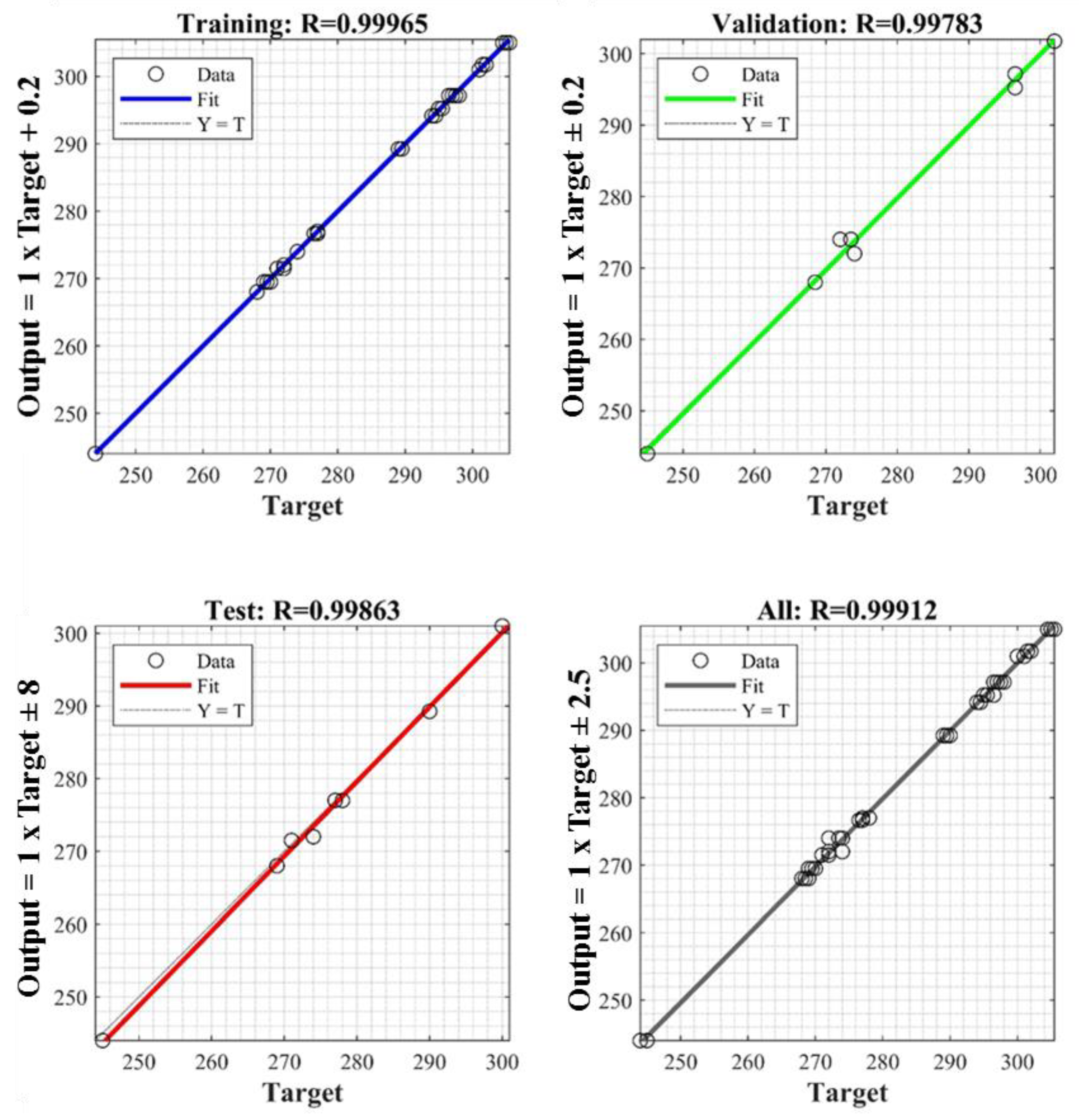

3.5. Artificial Neural Networks (ANN)

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, B.; Zhang, R.; Huang, D.; Shen, Y.; Gao, X.; Shi, W. Membrane fouling in microfiltration of alkali/surfactant/polymer flooding oilfield wastewater: Effect of interactions of key foulants. J. Colloid Interface Sci. 2020, 570, 20–30. [Google Scholar] [CrossRef] [PubMed]

- Waqas, S.; Bilad, M.R.; Man, Z.B. Performance and energy consumption evaluation of rotating biological contactor for domestic wastewater treatment. Indones. J. Sci. Technol. 2021, 6, 101–112. [Google Scholar] [CrossRef]

- Drews, A. Membrane fouling in membrane bioreactors—Characterisation, contradictions, cause and cures. J. Membr. Sci. 2010, 363, 1–28. [Google Scholar] [CrossRef]

- Kim, J.; Shin, J.; Kim, H.; Lee, J.-Y.; Yoon, M.-H.; Won, S.; Lee, B.-C.; Song, K.G. Membrane fouling control using a rotary disk in a submerged anaerobic membrane sponge bioreactor. Bioresour. Technol. 2014, 172, 321–327. [Google Scholar] [CrossRef] [PubMed]

- Chang, I.-S.; Lee, C.-H. Membrane filtration characteristics in membrane-coupled activated sludge system—The effect of physiological states of activated sludge on membrane fouling. Desalination 1998, 120, 221–233. [Google Scholar] [CrossRef]

- Wang, Z.; Wu, Z.; Yin, X.; Tian, L. Membrane fouling in a submerged membrane bioreactor (MBR) under sub-critical flux operation: Membrane foulant and gel layer characterization. J. Membr. Sci. 2008, 325, 238–244. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B.; Klaysom, C.; Jaafar, J.; Khan, A.L. An integrated rotating biological contactor and membrane separation process for domestic wastewater treatment. Alex. Eng. J. 2020, 59, 4257–4265. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Aqsha, A.; Harun, N.Y.; Ayoub, M.; Wirzal, M.D.H.; Jaafar, J.; Mulyati, S.; Elma, M. Effect of membrane properties in a membrane rotating biological contactor for wastewater treatment. J. Environ. Chem. Eng. 2020, 9, 104869. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Zhang, K.; Qian, Y.; Yuan, X.; Ji, B.; Han, W. Membrane fouling mitigation in different biofilm membrane bioreactors with pre-anoxic tanks for treating mariculture wastewater. Sci. Total Environ. 2020, 724, 138311. [Google Scholar] [CrossRef]

- Bilad, M.R.; Mezohegyi, G.; Declerck, P.; Vankelecom, I.F. Novel magnetically induced membrane vibration (MMV) for fouling control in membrane bioreactors. Water Res. 2012, 46, 63–72. [Google Scholar] [CrossRef]

- Ma, B.; Xue, W.; Bai, Y.; Liu, R.; Chen, W.; Liu, H.; Qu, J. Enhanced alleviation of ultrafiltration membrane fouling by regulating cake layer thickness with pre-coagulation during drinking water treatment. J. Membr. Sci. 2020, 596, 117732. [Google Scholar] [CrossRef]

- Huang, X.; Wei, C.-H.; Yu, K.-C. Mechanism of membrane fouling control by suspended carriers in a submerged membrane bioreactor. J. Membr. Sci. 2008, 309, 7–16. [Google Scholar] [CrossRef]

- Sun, H.; Yang, X.; Zhang, Y.; Cheng, X.; Xu, Y.; Bai, Y.; Shao, L. Segregation-induced in situ hydrophilic modification of poly (vinylidene fluoride) ultrafiltration membranes via sticky poly (ethylene glycol) blending. J. Membr. Sci. 2018, 563, 22–30. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.; Wibisono, Y.; Jaafar, J.; Mahlia, T.M.I.; Khan, A.L.; Aslam, M. Recent progress in integrated fixed-film activated sludge process for wastewater treatment: A review. J. Environ. Manag. 2020, 268, 110718. [Google Scholar] [CrossRef] [PubMed]

- Belgada, A.; Charik, F.Z.; Achiou, B.; Kambuyi, T.N.; Younssi, S.A.; Beniazza, R.; Dani, A.; Benhida, R.; Ouammou, M. Optimization of phosphate/kaolinite microfiltration membrane using Box-Behnken design for treatment of industrial wastewater. J. Environ. Chem. Eng. 2020, 9, 104972. [Google Scholar] [CrossRef]

- Arshad, U.; Taqvi, S.A.A.; Buang, A.; Awad, A. SVM, ANN, and PSF modelling approaches for prediction of iron dust minimum ignition temperature (MIT) based on the synergistic effect of dispersion pressure and concentration. Process Saf. Environ. Prot. 2021, 152, 375–390. [Google Scholar] [CrossRef]

- Khan, J.A.; Al-Kayiem, H.H.; Aleem, W.; Saad, A.B. Influence of alkali-surfactant-polymer flooding on the coalescence and sedimentation of oil/water emulsion in gravity separation. J. Pet. Sci. Eng. 2019, 173, 640–649. [Google Scholar] [CrossRef]

- Al-Kayiem, H.H.; Khan, J.A. Evaluation of alkali/surfactant/polymer flooding on separation and stabilization of water/oil emulsion by statistical modeling. Energy Fuels 2017, 31, 9290–9301. [Google Scholar] [CrossRef]

- Khan, M.K.A.; Khan, J.A.; Ullah, H.; Al-Kayiem, H.H.; Irawan, S.; Irfan, M.; Glowacz, A.; Liu, H.; Glowacz, W.; Rahman, S. De-emulsification and gravity separation of micro-emulsion produced with enhanced oil recovery chemicals flooding. Energies 2021, 14, 2249. [Google Scholar] [CrossRef]

- Baneshi, M.M.; Ghaedi, A.M.; Vafaei, A.; Emadzadeh, D.; Lau, W.J.; Marioryad, H.; Jamshidi, A. A high-flux P84 polyimide mixed matrix membranes incorporated with cadmium-based metal organic frameworks for enhanced simultaneous dyes removal: Response surface methodology. Environ. Res. 2020, 183, 109278. [Google Scholar] [CrossRef]

- Sheth, Y.; Dharaskar, S.; Khalid, M.; Sonawane, S. An environment friendly approach for heavy metal removal from industrial wastewater using chitosan based biosorbent: A review. Sustain. Energy Technol. Assess. 2021, 43, 100951. [Google Scholar] [CrossRef]

- Bezirgiannidis, A.; Marinakis, N.; Ntougias, S.; Melidis, P. Membrane bioreactor performance during processing of a low carbon to nitrogen ratio municipal wastewater. Environ. Processes 2018, 5, 87–100. [Google Scholar] [CrossRef]

- Di Trapani, D.; Mannina, G.; Torregrossa, M.; Viviani, G. Comparison between hybrid moving bed biofilm reactor and activated sludge system: A pilot plant experiment. Water Sci. Technol. 2010, 61, 891–902. [Google Scholar] [CrossRef] [PubMed]

- Leyva-Díaz, J.; Martín-Pascual, J.; Poyatos, J. Moving bed biofilm reactor to treat wastewater. Int. J. Environ. Sci. Technol. 2017, 14, 881–910. [Google Scholar] [CrossRef]

- Werber, J.R.; Osuji, C.O.; Elimelech, M. Materials for next-generation desalination and water purification membranes. Nat. Rev. Mater. 2016, 1, 16018. [Google Scholar] [CrossRef]

- Geng, Z.; Yang, X.; Boo, C.; Zhu, S.; Lu, Y.; Fan, W.; Huo, M.; Elimelech, M.; Yang, X. Self-cleaning anti-fouling hybrid ultrafiltration membranes via side chain grafting of poly (aryl ether sulfone) and titanium dioxide. J. Membr. Sci. 2017, 529, 1–10. [Google Scholar] [CrossRef]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W.; Thomaidis, N.S.; Xu, J. Progress in the biological and chemical treatment technologies for emerging contaminant removal from wastewater: A critical review. J. Hazard. Mater. 2017, 323, 274–298. [Google Scholar] [CrossRef]

- McCarty, P.; Bae, J.; Kim, J. Domestic wastewater treatment as a net energy producer-can this be achieved? Environ. Sci. Technol. 2011, 45, 7100–7106. [Google Scholar] [CrossRef]

- Askari, N.; Farhadian, M.; Razmjou, A. Simultaneous effects of pH, concentration, pressure on dye removal by a polyamide nanofilter membrane; optimization through response surface methodology. Environ. Nanotechnol. Monit. Manag. 2018, 10, 223–230. [Google Scholar] [CrossRef]

- Nuansawan, N.; Boonnorat, J.; Chiemchaisri, W.; Chiemchaisri, C. Effect of hydraulic retention time and sludge recirculation on greenhouse gas emission and related microbial communities in two-stage membrane bioreactor treating solid waste leachate. Bioresour. Technol. 2016, 210, 35–42. [Google Scholar] [CrossRef]

- Deng, L.; Guo, W.; Ngo, H.H.; Du, B.; Wei, Q.; Tran, N.H.; Nguyen, N.C.; Chen, S.-S.; Li, J. Effects of hydraulic retention time and bioflocculant addition on membrane fouling in a sponge-submerged membrane bioreactor. Bioresour. Technol. 2016, 210, 11–17. [Google Scholar] [CrossRef] [PubMed]

- Waqas, S.; Bilad, M.R. A review on rotating biological contactors. Indones. J. Sci. Technol. 2019, 4, 241–256. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B. Effect of organic and nitrogen loading rate in a rotating biological contactor for wastewater treatment. J. Phys. Conf. Ser. 2021, 1793, 012063. [Google Scholar] [CrossRef]

- Aber, S.; Amani-Ghadim, A.; Mirzajani, V. Removal of Cr (VI) from polluted solutions by electrocoagulation: Modeling of experimental results using artificial neural network. J. Hazard. Mater. 2009, 171, 484–490. [Google Scholar] [CrossRef] [PubMed]

- Pendashteh, A.R.; Fakhru’l-Razi, A.; Chaibakhsh, N.; Abdullah, L.C.; Madaeni, S.S.; Abidin, Z.Z. Modeling of membrane bioreactor treating hypersaline oily wastewater by artificial neural network. J. Hazard. Mater. 2011, 192, 568–575. [Google Scholar] [CrossRef]

- Lee, J.-W.; Suh, C.; Hong, Y.-S.T.; Shin, H.-S. Sequential modelling of a full-scale wastewater treatment plant using an artificial neural network. Bioprocess Biosyst. Eng. 2011, 34, 963–973. [Google Scholar] [CrossRef] [PubMed]

- Geissler, S.; Wintgens, T.; Melin, T.; Vossenkaul, K.; Kullmann, C. Modelling approaches for filtration processes with novel submerged capillary modules in membrane bioreactors for wastewater treatment. Desalination 2005, 178, 125–134. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Man, Z.B.; Suleman, H.; Nordin, N.A.H.; Jaafar, J.; Othman, M.H.D.; Elma, M. An energy-efficient membrane rotating biological contactor for wastewater treatment. J. Clean. Prod. 2021, 282, 124544. [Google Scholar] [CrossRef]

- Waqas, S.; Harun, N.Y.; Bilad, M.R.; Samsuri, T.; Nordin, N.A.H.M.; Shamsuddin, N.; Nandiyanto, A.B.D.; Huda, N.; Roslan, J. Response surface methodology for optimization of rotating biological contactor combined with external membrane filtration for wastewater treatment. Membranes 2022, 12, 271. [Google Scholar] [CrossRef]

- APHA. Standard Methods for the Examination of Water and Wastewater, 19th ed.; American Public Health Association: Washington, DC, USA, 1997. [Google Scholar]

- Zulfiqar, M.; Samsudin, M.F.R.; Sufian, S. Modelling and optimization of photocatalytic degradation of phenol via TiO2 nanoparticles: An insight into response surface methodology and artificial neural network. J. Photochem. Photobiol. A Chem. 2019, 384, 112039. [Google Scholar] [CrossRef]

- Arshad, U.; Buang, A.; Khanafiah, K. Combined effect of dispersion pressure and concentration on minimum ignition temperature of corn dust using response surface methodology—Preliminary investigation. E3S Web Conf. 2021, 287, 03006. [Google Scholar] [CrossRef]

- Hafeez, A.; Taqvi, S.A.A.; Fazal, T.; Javed, F.; Khan, Z.; Amjad, U.S.; Bokhari, A.; Shehzad, N.; Rashid, N.; Rehman, S.; et al. Optimization on cleaner intensification of ozone production using artificial neural network and response surface methodology: Parametric and comparative study. J. Clean. Prod. 2020, 252, 119833. [Google Scholar] [CrossRef]

- Zhang, W.; Grimi, N.; Jaffrin, M.Y.; Ding, L. Leaf protein concentration of alfalfa juice by membrane technology. J. Membr. Sci. 2015, 489, 183–193. [Google Scholar] [CrossRef]

- Luo, J.; Ding, L.; Wan, Y.; Jaffrin, M.Y. Flux decline control in nanofiltration of detergent wastewater by a shear-enhanced filtration system. Chem. Eng. J. 2012, 181–182, 397–406. [Google Scholar] [CrossRef]

- Waqas, S.; Bilad, M.R.; Huda, N.; Harun, N.Y.; Md Nordin, N.A.H.; Shamsuddin, N.; Wibisono, Y.; Khan, A.L.; Roslan, J. Membrane filtration as post-treatment of rotating biological contactor for wastewater treatment. Sustainability 2021, 13, 7287. [Google Scholar] [CrossRef]

- Arshad, U.; Taqvi, S.A.A.; Buang, A. Modelling of the minimum ignition temperature (MIT) of corn dust using statistical analysis and artificial neural networks based on the synergistic effect of concentration and dispersion pressure. Process Saf. Environ. Prot. 2021, 147, 742–755. [Google Scholar] [CrossRef]

- Aghilesh, K.; Mungray, A.; Agarwal, S.; Ali, J.; Garg, M.C. Performance optimisation of forward-osmosis membrane system using machine learning for the treatment of textile industry wastewater. J. Clean. Prod. 2021, 289, 125690. [Google Scholar]

- Rahmawati, R.; Bilad, M.; Laziz, A.M.; Nordin, N.; Jusoh, N.; Putra, Z.A.; Mahlia, T.; Jaafar, J. Finned spacer for efficient membrane fouling control in produced water filtration. J. Environ. Manag. 2019, 249, 109359. [Google Scholar] [CrossRef]

- Coetzee, G.; Malandra, L.; Wolfaardt, G.; Viljoen-Bloom, M. Dynamics of a microbial biofilm in a rotating biological contactor for the treatment of winery effluent. Water SA 2004, 30, 407–412. [Google Scholar] [CrossRef][Green Version]

- Yang, M.; Yu, D.; Liu, M.; Zheng, L.; Zheng, X.; Wei, Y.; Wang, F.; Fan, Y. Optimization of MBR hydrodynamics for cake layer fouling control through CFD simulation and RSM design. Bioresour. Technol. 2017, 227, 102–111. [Google Scholar] [CrossRef]

- Borea, L.; Naddeo, V.; Belgiorno, V. Application of electrochemical processes to membrane bioreactors for improving nutrient removal and fouling control. Environ. Sci. Pollut. Res. 2017, 24, 321–333. [Google Scholar] [CrossRef] [PubMed]

- Khan, S.J.; Rehman, Z.U.; Visvanathan, C.; Jegatheesan, V. Influence of biofilm carriers on membrane fouling propensity in moving biofilm membrane bioreactor. Bioresour. Technol. 2012, 113, 161–164. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Kim, K.; Ye, H.; Lee, E.; Shin, C.; McCarty, P.L.; Bae, J. Anaerobic fluidized bed membrane bioreactor for wastewater treatment. Environ. Sci. Technol. 2010, 45, 576–581. [Google Scholar] [CrossRef] [PubMed]

| Sr # | Contaminant | Unit | Concentration |

|---|---|---|---|

| 1 | COD | mg/L | 298 ± 45.6 |

| 2 | TN | mg/L | 2.4 ± 0.2 |

| 3 | Ammonium | mg/L | 0.92 ± 0.07 |

| 4 | Nitrate | mg/L | 0.52 ± 0.08 |

| 5 | Turbidity | NTU | 15.2 ± 0.6 |

| 6 | pH | -- | 6.35 ± 0.18 |

| Levels | Independent Variable | Low Level (−1) | Medium Level (0) | High Level (+1) |

|---|---|---|---|---|

| 1 | Disk rotational speed | 30 | 40 | 50 |

| 2 | Membrane-to-disk gap | 1 | 2 | 3 |

| 3 | Organic loading rate | 10 | 20 | 30 |

| Run | Independent Variables | Permeability (L/m2 h bar) | |||

|---|---|---|---|---|---|

| Disk Rotational Speed (rpm) | Membrane-to-Disk Gap (cm) | Organic Loading Rate (g COD/m2 d) | Actual Value | Predicted Value | |

| 1 | 50 | 3 | 10 | 274 | 273.95 |

| 2 | 40 | 2 | 20 | 296.5 | 297.10 |

| 3 | 50 | 1 | 10 | 300 | 304.03 |

| 4 | 40 | 2 | 20 | 298 | 297.10 |

| 5 | 40 | 2 | 20 | 297 | 297.10 |

| 6 | 30 | 1 | 30 | 276.5 | 275.86 |

| 7 | 30 | 3 | 30 | 269 | 265.95 |

| 8 | 50 | 3 | 10 | 274 | 273.95 |

| 9 | 40 | 2 | 37 | 294 | 294.10 |

| 10 | 57 | 2 | 20 | 277 | 272.31 |

| 11 | 30 | 1 | 10 | 289.5 | 286.99 |

| 12 | 23 | 2 | 20 | 245 | 249.95 |

| 13 | 50 | 3 | 30 | 273.5 | 275.49 |

| 14 | 40 | 2 | 20 | 297.5 | 297.10 |

| 15 | 40 | 0.3 | 20 | 305 | 303.70 |

| 16 | 40 | 2 | 20 | 296.5 | 297.10 |

| 17 | 50 | 3 | 30 | 274 | 275.49 |

| 18 | 30 | 1 | 10 | 289 | 286.99 |

| 19 | 40 | 2 | 20 | 298 | 297.10 |

| 20 | 40 | 3.7 | 20 | 268 | 270.07 |

| 21 | 40 | 2 | 3.2 | 302 | 302.16 |

| 22 | 40 | 2 | 37 | 294 | 294.10 |

| 23 | 40 | 2 | 20 | 297 | 297.10 |

| 24 | 30 | 3 | 10 | 271 | 269.16 |

| 25 | 57 | 2 | 20 | 277 | 272.31 |

| 26 | 50 | 1 | 30 | 295 | 297.66 |

| 27 | 40 | 2 | 20 | 297.5 | 297.10 |

| 28 | 40 | 2 | 37 | 294.5 | 294.10 |

| 29 | 30 | 1 | 10 | 290 | 286.99 |

| 30 | 30 | 3 | 10 | 271 | 269.16 |

| 31 | 40 | 0.3 | 20 | 304.5 | 303.70 |

| 32 | 50 | 3 | 30 | 272 | 275.49 |

| 33 | 50 | 3 | 10 | 272 | 273.95 |

| 34 | 30 | 3 | 30 | 269.5 | 265.95 |

| 35 | 30 | 3 | 30 | 270 | 265.95 |

| 36 | 40 | 2 | 3.2 | 301.5 | 302.16 |

| 37 | 30 | 1 | 30 | 277 | 275.86 |

| 38 | 40 | 3.7 | 20 | 269 | 270.07 |

| 39 | 57 | 2 | 20 | 278 | 272.31 |

| 40 | 23 | 2 | 20 | 244 | 249.95 |

| 41 | 50 | 1 | 30 | 295.5 | 297.66 |

| 42 | 50 | 1 | 10 | 301 | 304.03 |

| 43 | 30 | 3 | 10 | 272 | 269.16 |

| 44 | 40 | 2 | 20 | 296.5 | 297.10 |

| 45 | 30 | 1 | 30 | 276.5 | 275.86 |

| 46 | 40 | 0.3 | 20 | 305.5 | 303.70 |

| 47 | 40 | 2 | 20 | 297 | 297.10 |

| 48 | 40 | 3.7 | 20 | 268.5 | 270.07 |

| 49 | 40 | 2 | 3.2 | 302 | 302.16 |

| 50 | 23 | 2 | 20 | 245 | 249.95 |

| 51 | 40 | 2 | 20 | 297.5 | 297.10 |

| 52 | 40 | 2 | 20 | 297 | 297.10 |

| 53 | 50 | 1 | 10 | 301 | 304.03 |

| 54 | 50 | 1 | 30 | 296.5 | 297.66 |

| 55 | 40 | 2 | 20 | 296.5 | 297.10 |

| Source | Sum of Squares | Df | Mean Square | F-Value | p-Value | Parameter Significance |

|---|---|---|---|---|---|---|

| Model | 13,229.15 | 9 | 1469.91 | 204.66 | <0.0001 | Significant |

| A-Disk rotational speed | 1809.98 | 1 | 1809.98 | 252.01 | <0.0001 | - |

| B-Membrane-to-disk gap | 4096.07 | 1 | 4096.07 | 570.32 | <0.0001 | - |

| C-Organic loading rate | 235.28 | 1 | 235.28 | 32.76 | <0.0001 | - |

| AB | 225.09 | 1 | 225.09 | 31.34 | <0.0001 | - |

| AC | 33.84 | 1 | 33.84 | 4.71 | 0.0353 | - |

| BC | 94.01 | 1 | 94.01 | 13.09 | 0.0007 | - |

| A² | 6316.25 | 1 | 6316.25 | 879.45 | <0.0001 | - |

| B² | 510.08 | 1 | 510.08 | 71.02 | <0.0001 | - |

| C² | 5.15 | 1 | 5.15 | 0.7173 | 0.4015 | - |

| Residual | 323.19 | 45 | 7.18 | - | - | - |

| Lack of Fit | 308.45 | 5 | 61.69 | 167.37 | <0.0001 | significant |

| Pure Error | 14.74 | 40 | 0.3686 | - | - | - |

| Cor Total | 13,552.35 | 54 | - | |||

| Other statistical parameters | ||||||

| R2 | Adjusted R2 | S.D. | A.P. | C.V. (%) | - | - |

| 0.9762 | 0.9714 | 2.68 | 47.3233 | 0.9396 | - | - |

| Variables | Optimum Values | Steady-State Permeability (L/m2 h Bar) | Error (%) | Standard Deviation | |

|---|---|---|---|---|---|

| Predictive | Experimental | ||||

| Disk rotational speed | 44 rpm | 309 | 309.5 | 0.16 | 2.68 |

| Membrane-to-disk gap | 1.07 cm | ||||

| Organic loading rate | 10.2 g COD/m2 d | ||||

| Steady-State Permeability (L/m2 h Bar) | ||||

|---|---|---|---|---|

| Run | Predictive | Experimental | Error (%) | Standard Deviation |

| 1 | 143.5 | 143.00 | 0.35 | 0.26 |

| 2 | 137.3 | 137 | 0.18 | 0.13 |

| Statistical Performance Index | RSM | ANN |

|---|---|---|

| R2 | 0.9762 | 0.9982 |

| MSE | 5.8709 | 0.4680 |

| RMSE | 2.4230 | 0.6840 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Irfan, M.; Waqas, S.; Arshad, U.; Khan, J.A.; Legutko, S.; Kruszelnicka, I.; Ginter-Kramarczyk, D.; Rahman, S.; Skrzypczak, A. Response Surface Methodology and Artificial Neural Network Modelling of Membrane Rotating Biological Contactors for Wastewater Treatment. Materials 2022, 15, 1932. https://doi.org/10.3390/ma15051932

Irfan M, Waqas S, Arshad U, Khan JA, Legutko S, Kruszelnicka I, Ginter-Kramarczyk D, Rahman S, Skrzypczak A. Response Surface Methodology and Artificial Neural Network Modelling of Membrane Rotating Biological Contactors for Wastewater Treatment. Materials. 2022; 15(5):1932. https://doi.org/10.3390/ma15051932

Chicago/Turabian StyleIrfan, Muhammad, Sharjeel Waqas, Ushtar Arshad, Javed Akbar Khan, Stanislaw Legutko, Izabela Kruszelnicka, Dobrochna Ginter-Kramarczyk, Saifur Rahman, and Anna Skrzypczak. 2022. "Response Surface Methodology and Artificial Neural Network Modelling of Membrane Rotating Biological Contactors for Wastewater Treatment" Materials 15, no. 5: 1932. https://doi.org/10.3390/ma15051932

APA StyleIrfan, M., Waqas, S., Arshad, U., Khan, J. A., Legutko, S., Kruszelnicka, I., Ginter-Kramarczyk, D., Rahman, S., & Skrzypczak, A. (2022). Response Surface Methodology and Artificial Neural Network Modelling of Membrane Rotating Biological Contactors for Wastewater Treatment. Materials, 15(5), 1932. https://doi.org/10.3390/ma15051932