Crystallography and Microstructure of 7M Martensite in Ni-Mn-Ga Thin Films Epitaxially Grown on (1 1

Abstract

:1. Introduction

2. Materials and Methods

2.1. Thin Films Preparation

2.2. Structure and Microstructure Characterization

3. Results and Discussion

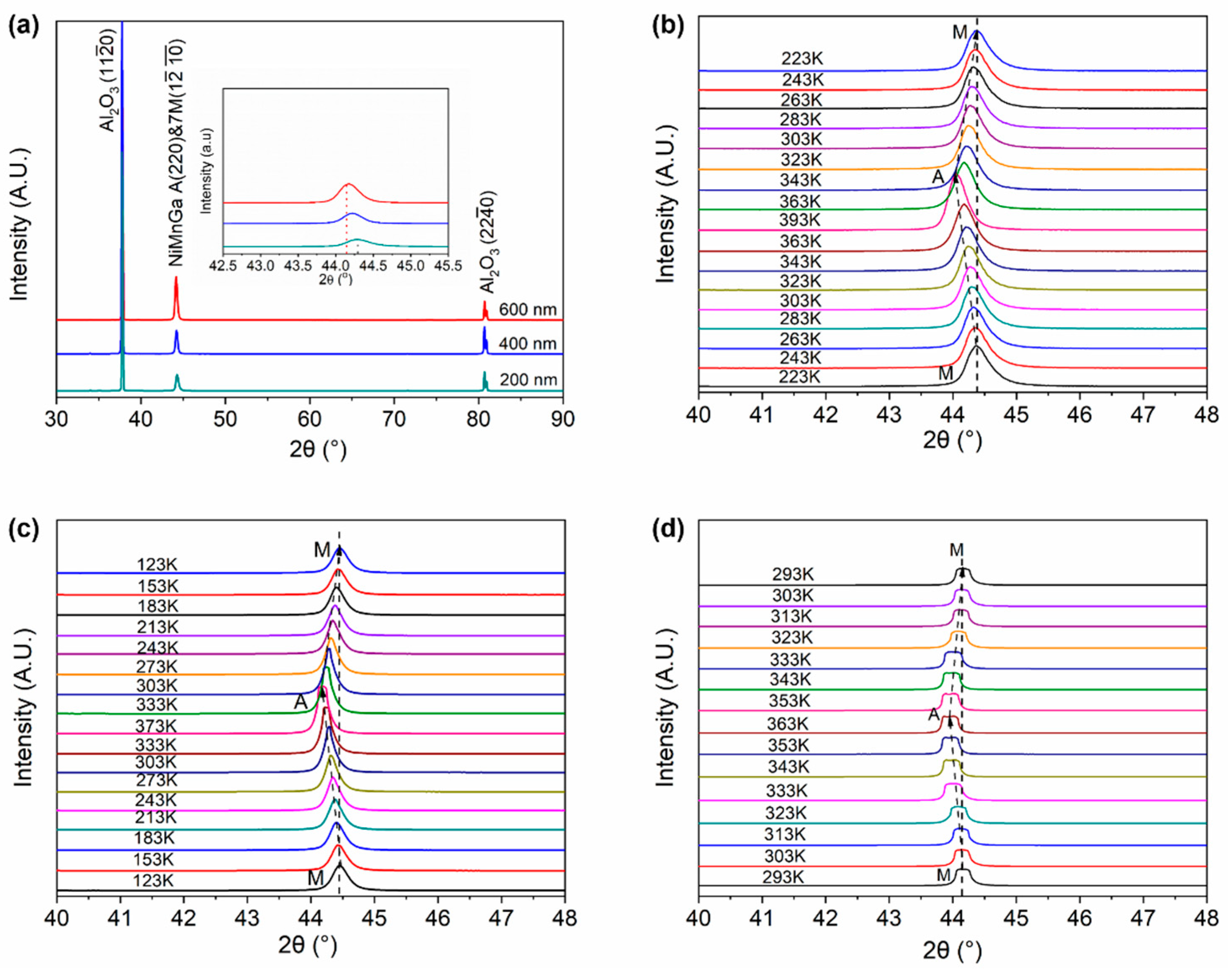

3.1. Crystal Structure and Microstructure

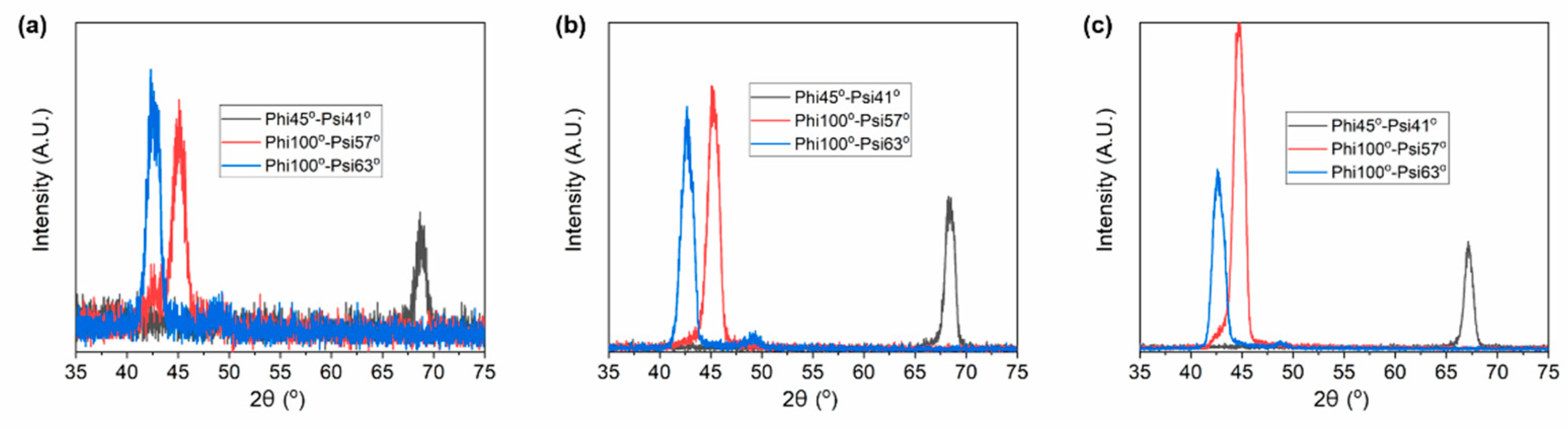

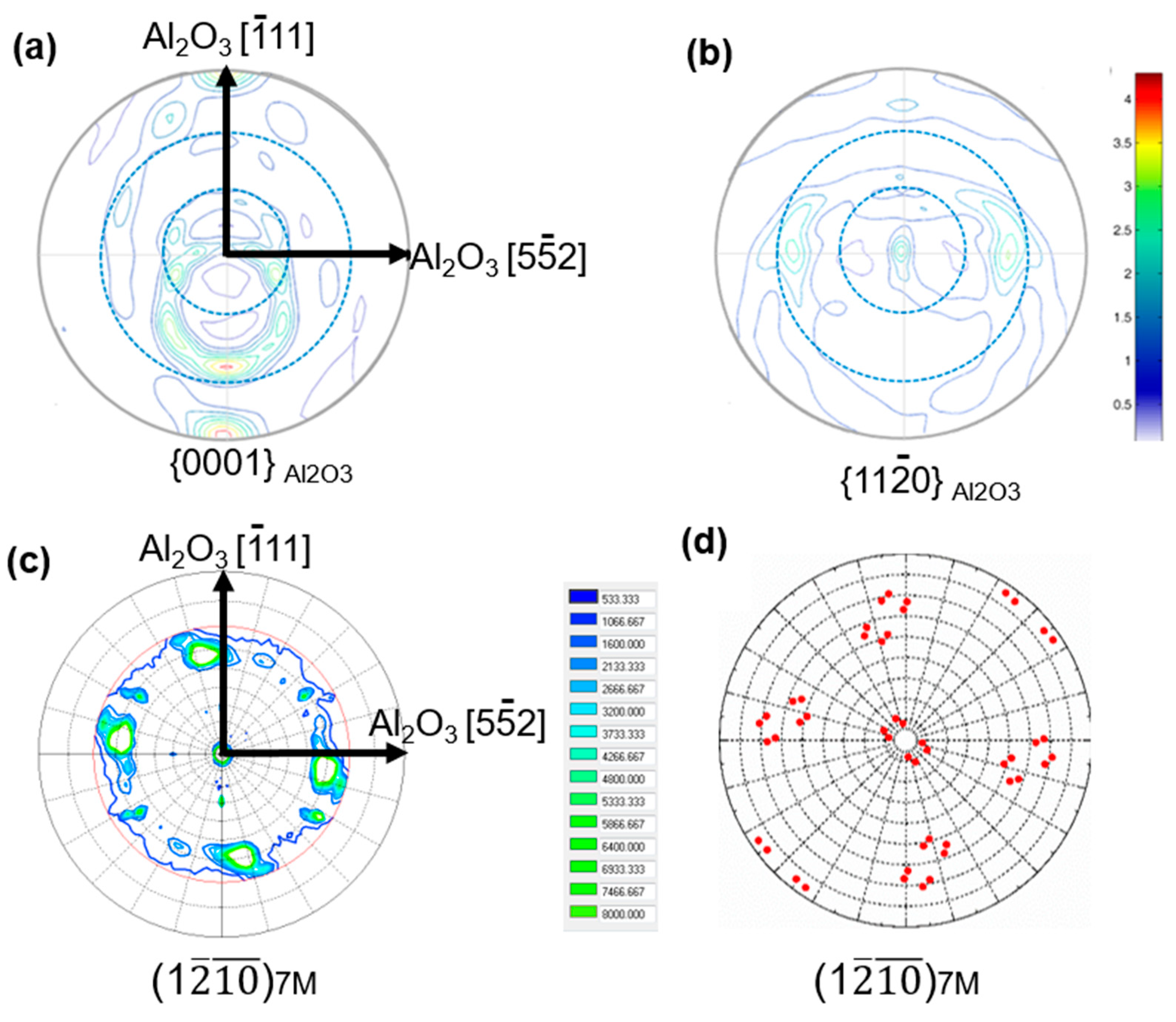

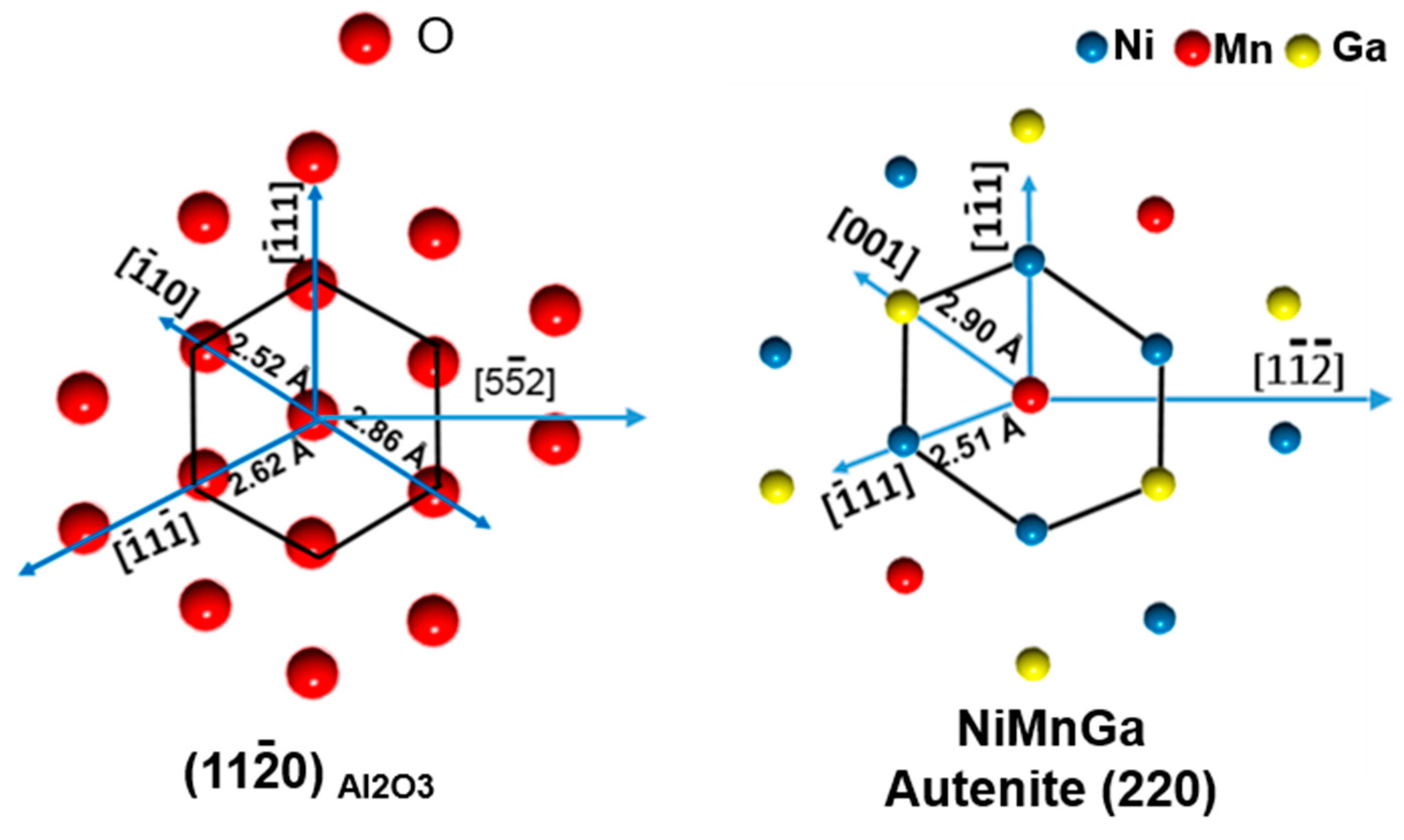

3.2. Macroscopic Texture

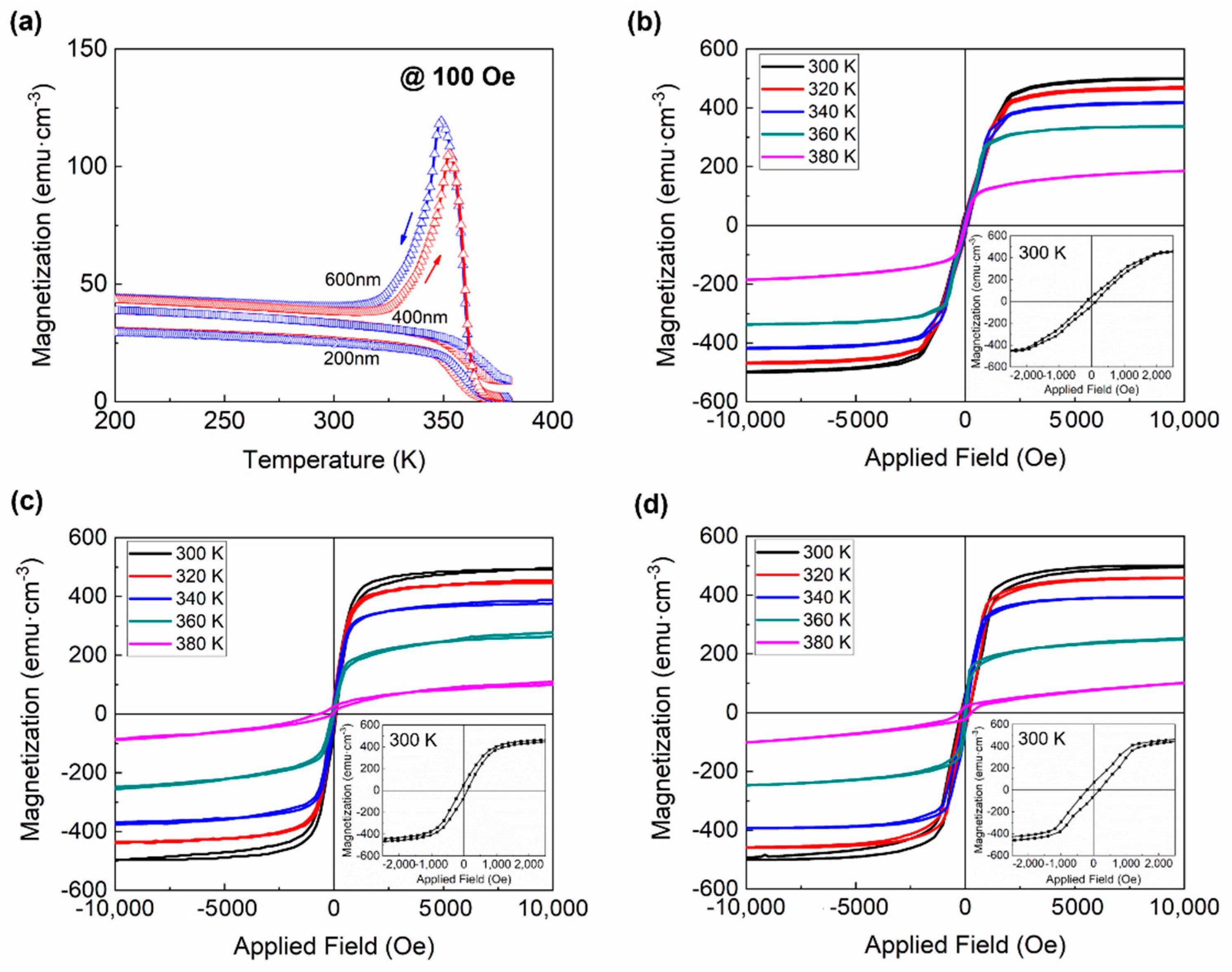

3.3. Magnetic Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Murray, S.J.; Marioni, M.; Allen, S.M.; O’Handley, R.C.; Lograsso, T.A. 6% magnetic-field-induced strain by twin-boundary motion in ferromagnetic Ni-Mn-Ga. Appl. Phys. Lett. 2000, 77, 886–888. [Google Scholar] [CrossRef] [Green Version]

- Sozinov, A.; Likhachev, A.A.; Lanska, N.; Ullakko, K. Giant magnetic-field-induced strain in NiMnGa seven-layered martensitic phase. Appl. Phys. Lett. 2002, 80, 1746–1748. [Google Scholar] [CrossRef]

- Sozinov, A.; Lanska, N.; Soroka, A.; Zou, W. 12% magnetic field-induced strain in Ni-Mn-Ga-based non-modulated martensite. Appl. Phys. Lett. 2013, 102, 021902. [Google Scholar] [CrossRef]

- Gaitzsch, U.; Pötschke, M.; Roth, S.; Rellinghaus, B.; Schultz, L. A 1% magnetostrain in polycrystalline 5M Ni-Mn-Ga. Acta Mater. 2009, 57, 365–370. [Google Scholar] [CrossRef]

- Li, Z.Z.; Li, Z.B.; Yang, B.; He, X.J.; Gan, W.M.; Zhang, Y.L.; Li, Z.; Zhang, Y.D.; Esling, C.; Zhao, X.; et al. Over 2% magnetic-field-induced strain in a polycrystalline Ni50Mn28.5Ga21.5 alloy prepared by directional solidification. Mater. Sci. Eng. A 2020, 780, 139170. [Google Scholar] [CrossRef]

- Guan, Z.; Jiang, X.; Gu, J.; Bai, J.; Liang, X.; Yan, H.; Zhang, Y.; Esling, C.; Zhao, X.; Zuo, L. Large magnetocaloric effect and excellent mechanical properties near room temperature in Ni-Co-Mn-Ti non-textured polycrystalline alloys. Appl. Phys. Lett. 2021, 119, 051904. [Google Scholar] [CrossRef]

- Kuang, Y.F.; Ai, Z.R.; Yang, B.; Hao, X.W.; Li, Z.B.; Yan, H.L.; Zhang, Y.D.; Esling, C.; Zhao, X.; Zuo, L. Simultaneously achieved good mechanical properties and large magnetocaloric effect in spark plasma sintered Ni-Mn-In alloys. Intermetallics 2020, 124, 106868. [Google Scholar] [CrossRef]

- Cong, D.Y.; Huang, L.; Hardy, V.; Bourgault, D.; Sun, X.M.; Nie, Z.H.; Wang, M.G.; Ren, Y.; Entel, P.; Wang, Y.D. Low-field-actuated giant magnetocaloric effect and excellent mechanical properties in a NiMn-based multiferroic alloy. Acta Mater. 2018, 146, 142–151. [Google Scholar] [CrossRef]

- Zuo, L.; Li, Z.; Yan, H.; Yang, B.; Zhao, X. Texturation and Functional Behaviors of Polycrystalline Ni-Mn-X Phase Transformation Alloys. Acta Metall. Sin. 2021, 57, 1396–1415. [Google Scholar]

- Liu, J.; Gottschall, T.; Skokov, K.P.; Moore, J.D.; Gutfleisch, O. Giant magnetocaloric effect driven by structural transitions. Nat. Mater. 2012, 11, 620–626. [Google Scholar] [CrossRef]

- Kainuma, R.; Imano, Y.; Ito, W.; Sutou, Y.; Morito, H.; Okamoto, S.; Kitakami, O.; Oikawa, K.; Fujita, A.; Kanomata, T.; et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 2006, 439, 957–960. [Google Scholar] [CrossRef] [PubMed]

- Krenke, T.; Duman, E.; Acet, M.; Wassermann, E.F.; Moya, X.; Manosa, L.; Planes, A. Inverse magnetocaloric effect in ferromagnetic Ni-Mn-Sn alloys. Nat. Mater. 2005, 4, 450–454. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Buschbeck, J.; Niemann, R.; Heczko, O.; Thomas, M.; Schultz, L.; Fähler, S. In situ studies of the martensitic transformation in epitaxial Ni–Mn–Ga films. Acta Mater. 2009, 57, 2516–2526. [Google Scholar] [CrossRef]

- Eichhorn, T.; Hausmanns, R.; Jakob, G. Microstructure of freestanding single-crystalline Ni2MnGa thin films. Acta Mater. 2011, 59, 5067–5703. [Google Scholar] [CrossRef] [Green Version]

- Ranzieri, P.; Fabbrici, S.; Nasi, L.; Righi, L.; Casoli, F.; Chernenko, V.A.; Villa, E.; Albertini, F. Epitaxial Ni–Mn–Ga/MgO(100) thin films ranging in thickness from 10 to 100nm. Acta Mater. 2013, 61, 263–272. [Google Scholar] [CrossRef]

- Backen, A.; Yeduru, S.R.; Diestel, A.; Schultz, L.; Kohl, M.; Fähler, S. Epitaxial Ni-Mn-Ga Films for Magnetic Shape Memory Alloy Microactuators. Adv. Eng. Mater. 2012, 14, 696–709. [Google Scholar] [CrossRef]

- Ranzieri, P.; Campanini, M.; Fabbrici, S.; Nasi, L.; Casoli, F.; Cabassi, R.; Buffagni, E.; Grillo, V.; Magen, C.; Celegato, F.; et al. Achieving Giant Magnetically Induced Reorientation of Martensitic Variants in Magnetic Shape-Memory Ni-Mn-Ga Films by Microstructure Engineering. Adv. Mater. 2015, 27, 4760–4766. [Google Scholar] [CrossRef]

- Heczko, O.; Thomas, M.; Buschbeck, J.; Schultz, L.; Fähler, S. Epitaxial Ni–Mn–Ga films deposited on SrTiO3 and evidence of magnetically induced reorientation of martensitic variants at room temperature. Appl. Phys. Lett. 2008, 92, 072502. [Google Scholar] [CrossRef]

- Thomas, M.; Heczko, O.; Buschbeck, J.; Rößler, U.K.; McCord, J.; Scheerbaum, N.; Schultz, L.; Fähler, S. Magnetically induced reorientation of martensite variants in constrained epitaxial Ni–Mn–Ga films grown on MgO(001). New J. Phys. 2008, 10, 023040. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Hughes, R.A.; Britten, J.F.; Preston, J.S.; Botton, G.A.; Niewczas, M. Self-activated reversibility in the magnetically induced reorientation of martensitic variants in ferromagnetic Ni-Mn-Ga films. Phys. Rev. B 2010, 81, 054406. [Google Scholar] [CrossRef]

- Yang, B.; Soldatov, I.; Chen, F.; Zhang, Y.; Li, Z.; Yan, H.; Schäfer, R.; Wang, D.; Esling, C.; Zhao, X.; et al. Observation of magnetic domain evolution in constrained epitaxial Ni–Mn–Ga thin films on MgO(001) substrate. J. Mater. Sci. Technol. 2022, 102, 56–65. [Google Scholar] [CrossRef]

- Li, Z.B.; Yang, B.; Zou, N.F.; Zhang, Y.D.; Esling, C.; Gan, W.M.; Zhao, X.; Zuo, L. Crystallographic Characterization on Polycrystalline Ni-Mn-Ga Alloys with Strong Preferred Orientation. Materials 2017, 10, 463. [Google Scholar] [CrossRef]

- Ghahfarokhi, M.T.; Casoli, F.; Fabbrici, S.; Nasi, L.; Celegato, F.; Cabassi, R.; Trevisi, G.; Bertoni, G.; Calestani, D.; Tiberto, P.; et al. Martensite-enabled magnetic flexibility: The effects of post-growth treatments in magnetic-shape-memory Heusler thin films. Acta Mater. 2020, 187, 135–145. [Google Scholar] [CrossRef]

- Yang, B.; Li, Z.B.; Zhang, Y.D.; Qin, G.W.; Esling, C.; Perroud, O.; Zhao, X.; Zuo, L. Microstructural features and orientation correlations of non-modulated martensite in Ni-Mn-Ga epitaxial thin films. Acta Mater. 2013, 61, 6809–6820. [Google Scholar] [CrossRef]

- Yang, B.; Zhang, Y.D.; Li, Z.B.; Qin, G.W.; Zhao, X.; Esling, C.; Zuo, L. Insight into variant selection of seven-layer modulated martensite in Ni-Mn-Ga thin films grown on MgO(001) substrate. Acta Mater. 2015, 93, 205–217. [Google Scholar] [CrossRef]

- Jakob, G.; Eichhorn, T.; Kallmayer, M.; Elmers, H.J. Correlation of electronic structure and martensitic transition in epitaxial Ni2MnGa films. Phys. Rev. B 2007, 76, 174407. [Google Scholar] [CrossRef] [Green Version]

- Jakob, G.; Elmers, H.J. Epitaxial films of the magnetic shape memory material Ni2MnGa. J. Magn. Magn. Mater. 2007, 310, 2779–2781. [Google Scholar] [CrossRef]

- Sharma, A.; Mohan, S.; Suwas, S. Structural transformations in highly oriented seven modulated martensite Ni-Mn-Ga thin films on an Al2O3 (11–20) substrate. J. Mater. Res. 2016, 31, 3016–3026. [Google Scholar] [CrossRef]

- Sharma, A.; Mohan, S.; Suwas, S. Evidence of adaptive modulation and magnetic field induced reorientation of variants in epitaxially grown Ni-Mn-Ga thin film on Al2O3 (11–20) substrate. Mater. Sci. Eng. B 2019, 242, 6–16. [Google Scholar] [CrossRef]

| Thickness | Martensite | CS | a (Å) | b (Å) | c (Å) | β (°) | V (Å3) |

|---|---|---|---|---|---|---|---|

| 200 nm | 7M | Monoclinic | 4.188 | 5.446 | 42.46 | 93.12 | 966.9 |

| 400 nm | 7M | Monoclinic | 4.195 | 5.483 | 42.34 | 93.07 | 972.5 |

| 600 nm | 7M | Monoclinic | 4.164 | 5.566 | 42.63 | 93.03 | 986.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, B.; Li, Z.; Yan, H.; Zhang, Y.; Esling, C.; Zhao, X.; Zuo, L.

Crystallography and Microstructure of 7M Martensite in Ni-Mn-Ga Thin Films Epitaxially Grown on (1 1

Yang B, Li Z, Yan H, Zhang Y, Esling C, Zhao X, Zuo L.

Crystallography and Microstructure of 7M Martensite in Ni-Mn-Ga Thin Films Epitaxially Grown on (1 1

Yang, Bo, Zongbin Li, Haile Yan, Yudong Zhang, Claude Esling, Xiang Zhao, and Liang Zuo.

2022. "Crystallography and Microstructure of 7M Martensite in Ni-Mn-Ga Thin Films Epitaxially Grown on (1 1

Yang, B., Li, Z., Yan, H., Zhang, Y., Esling, C., Zhao, X., & Zuo, L.

(2022). Crystallography and Microstructure of 7M Martensite in Ni-Mn-Ga Thin Films Epitaxially Grown on (1 1