High-Power Diode Laser Surface Transformation Hardening of Ferrous Alloys

Abstract

:1. Introduction

2. Materials and Methods

3. Results

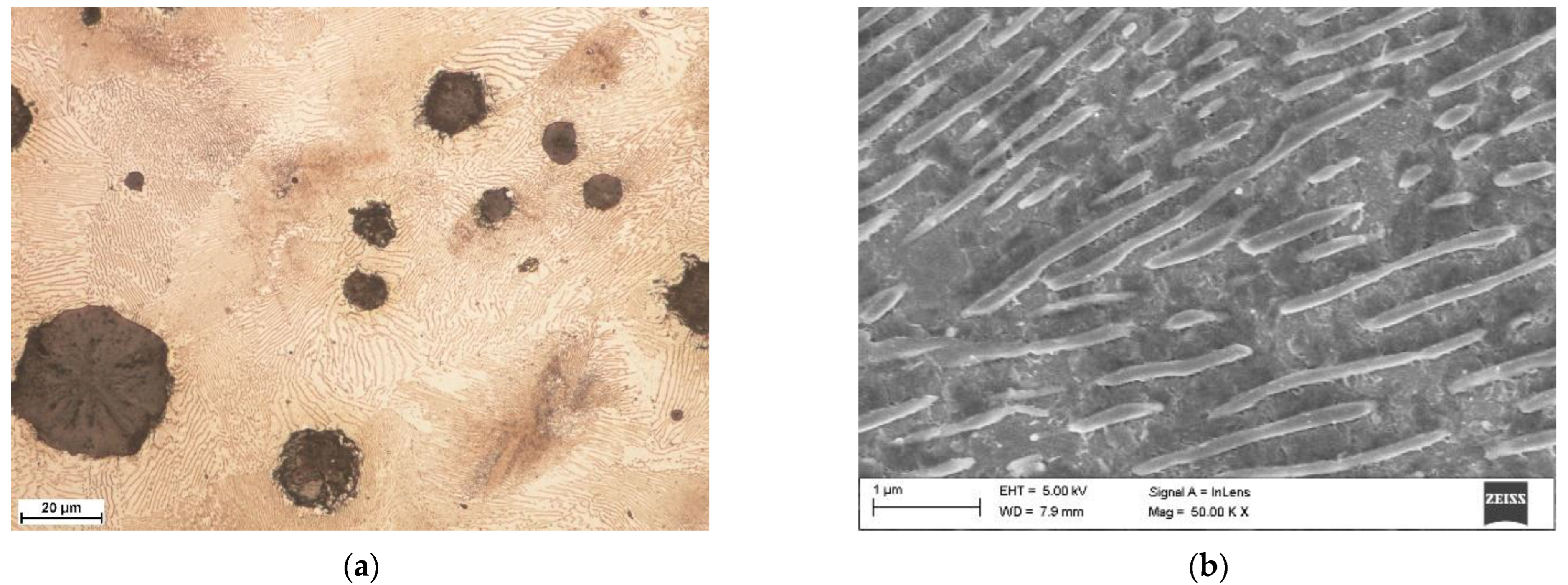

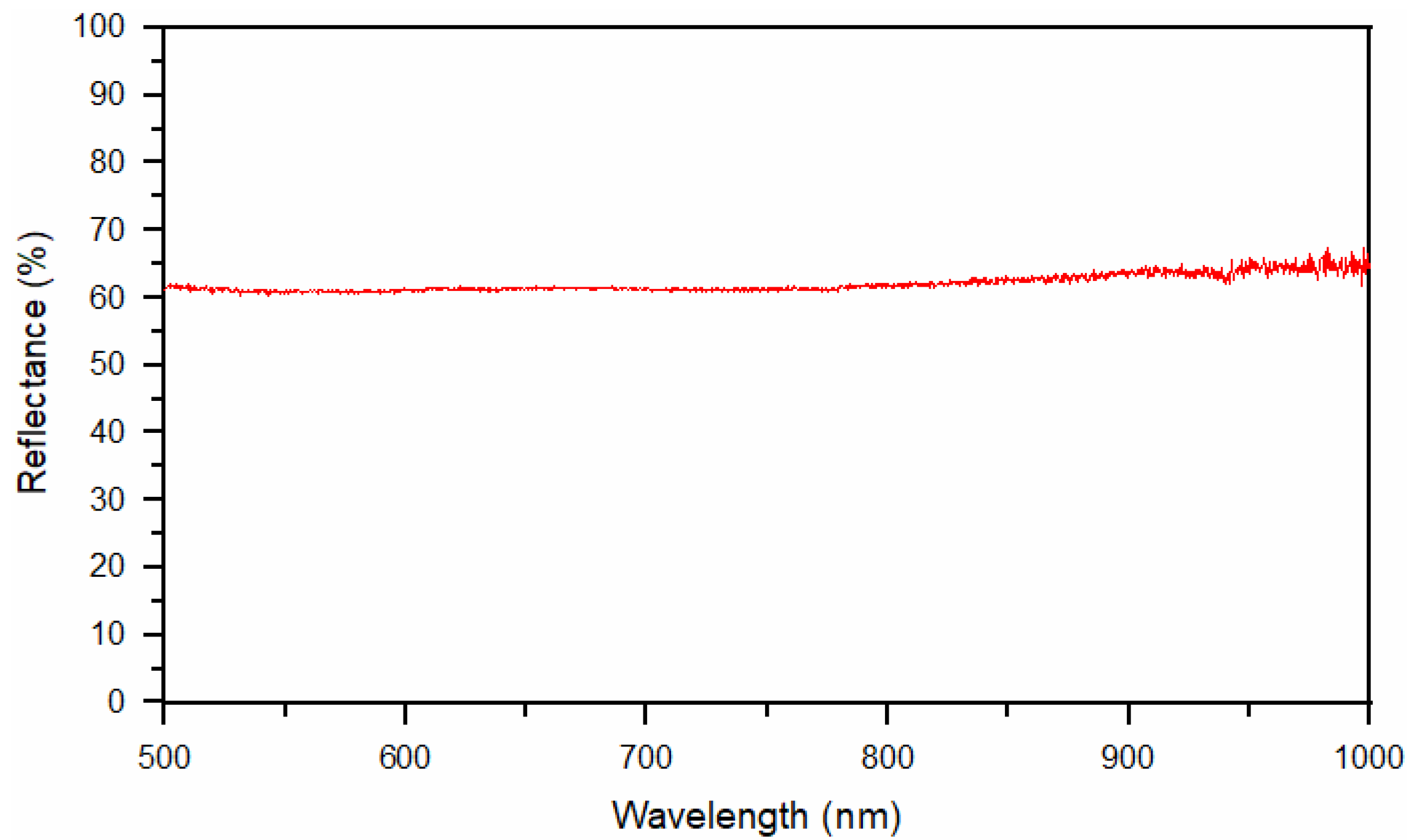

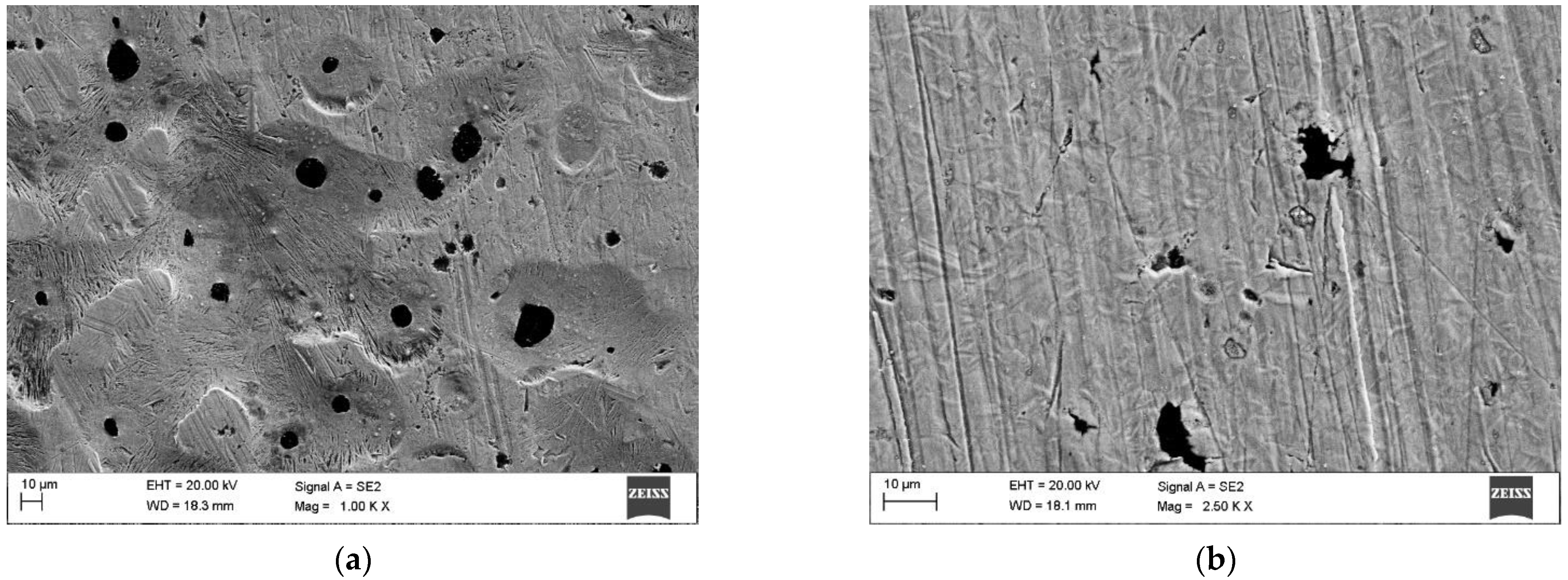

3.1. Surface Condition Analysis

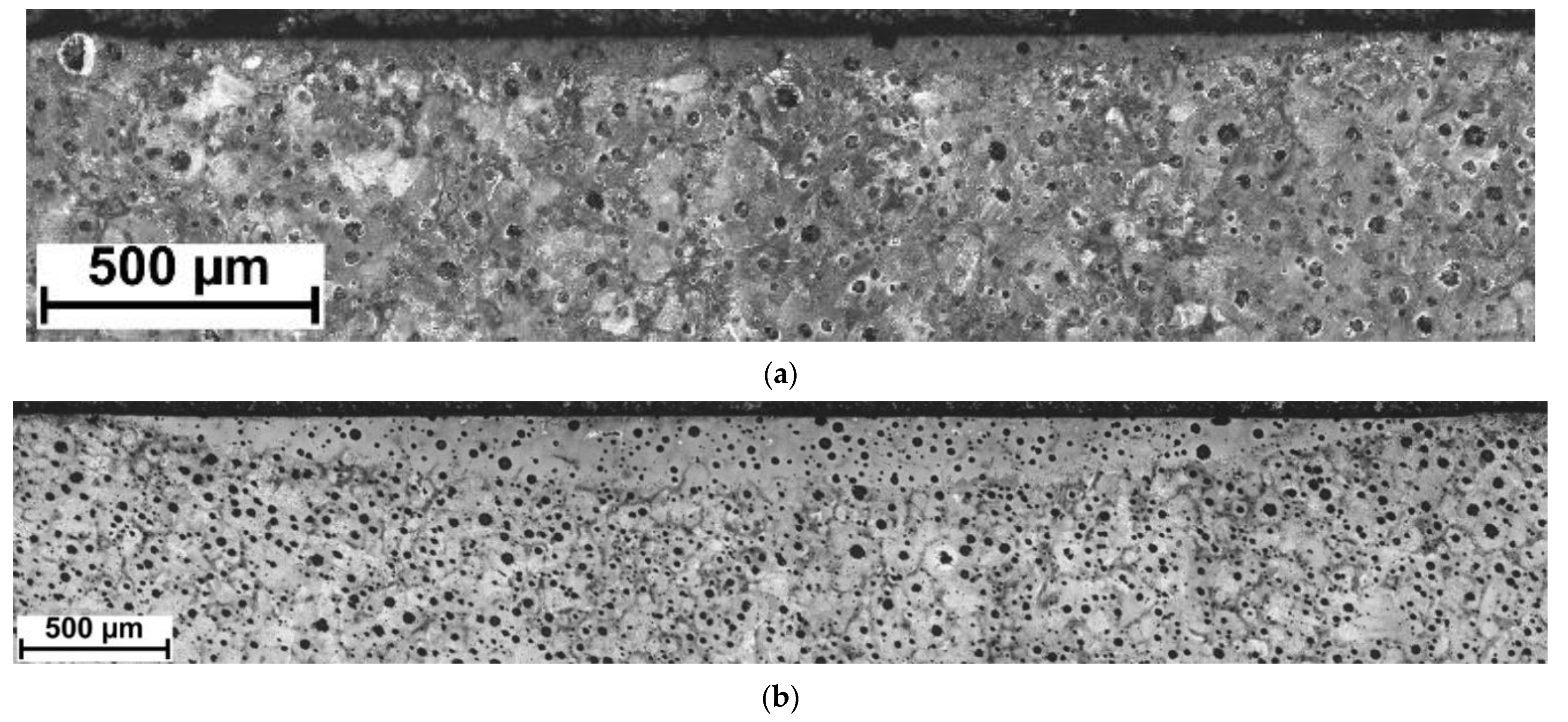

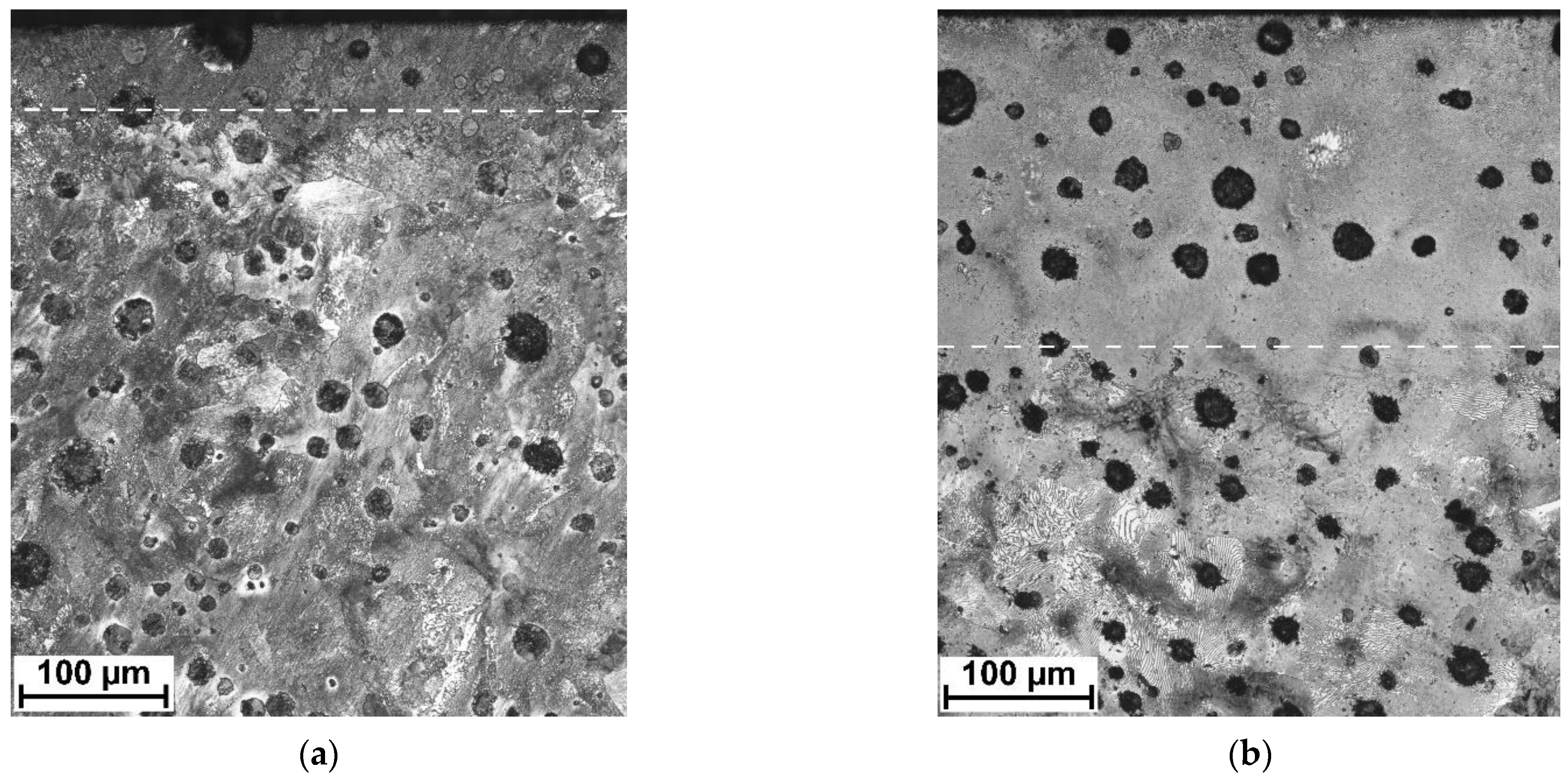

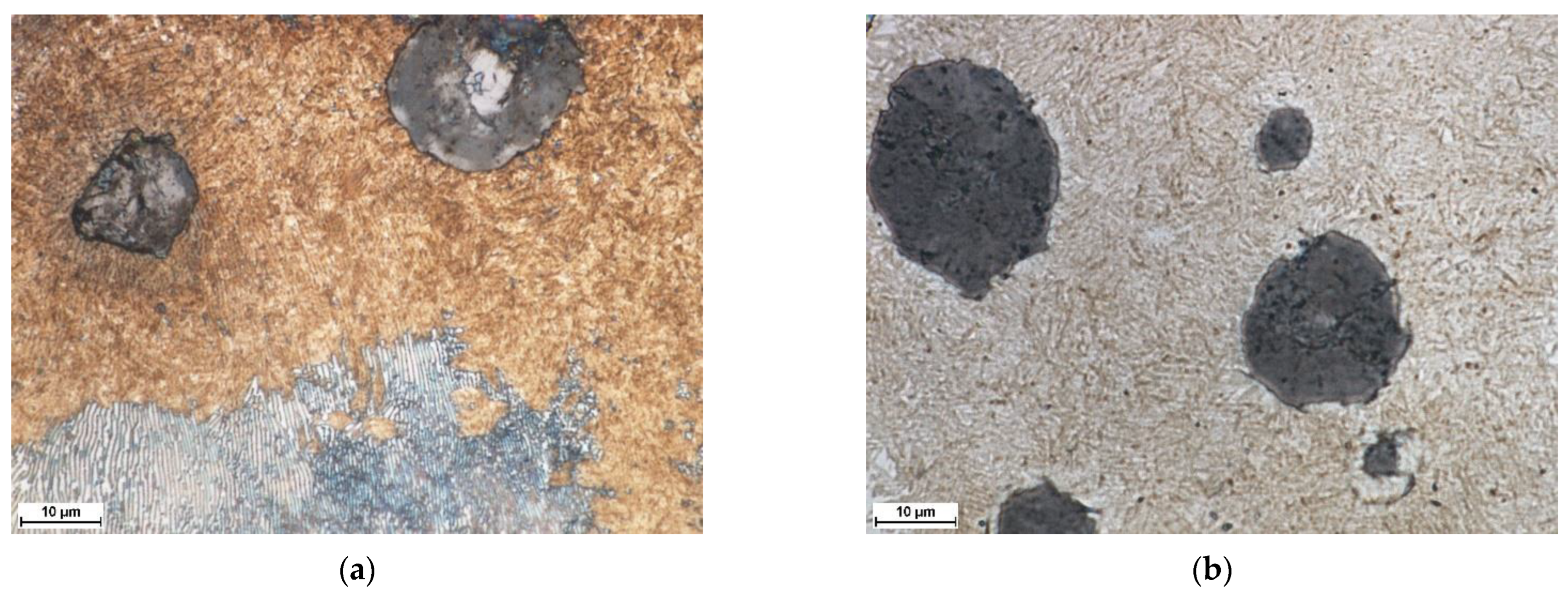

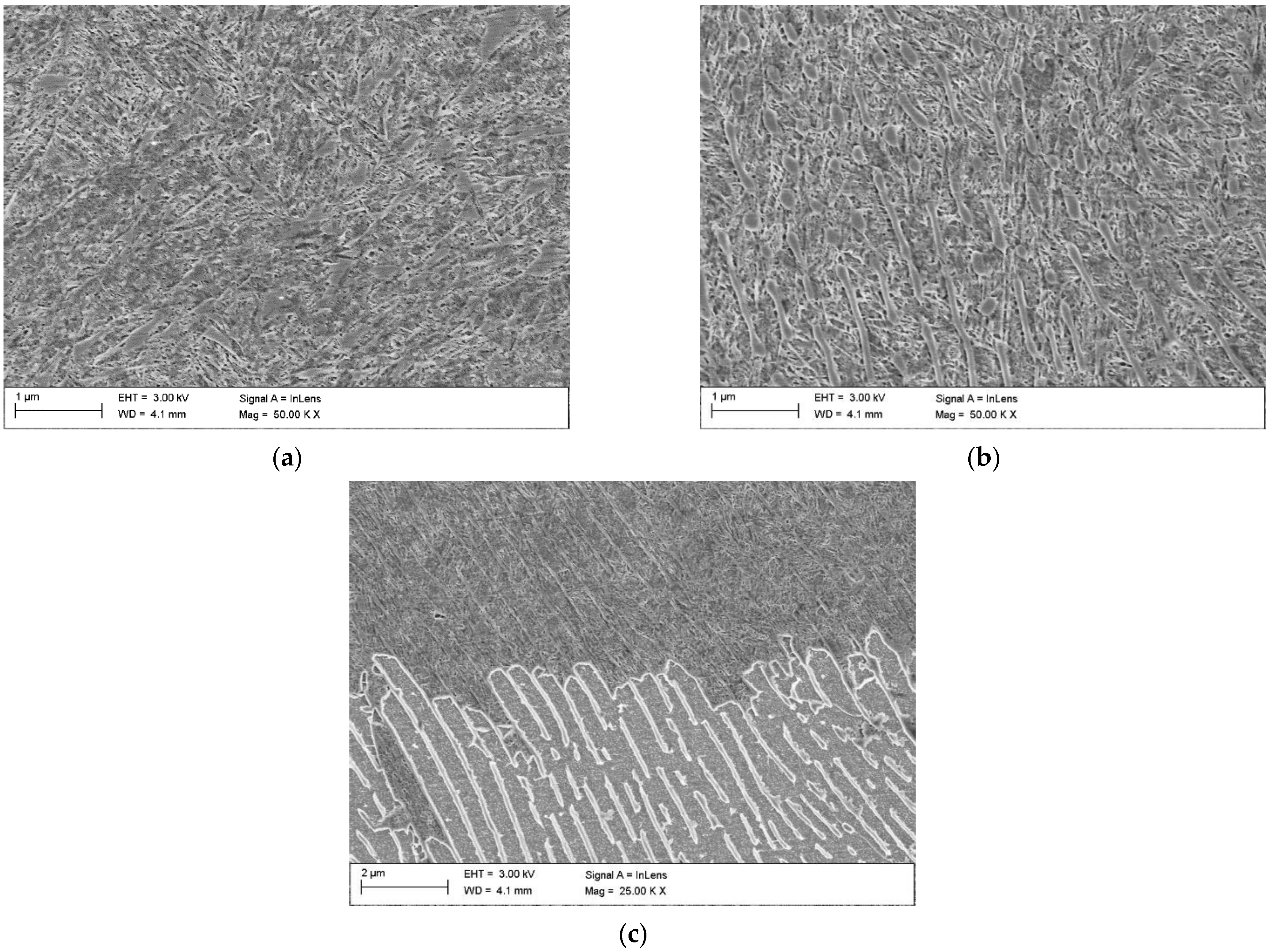

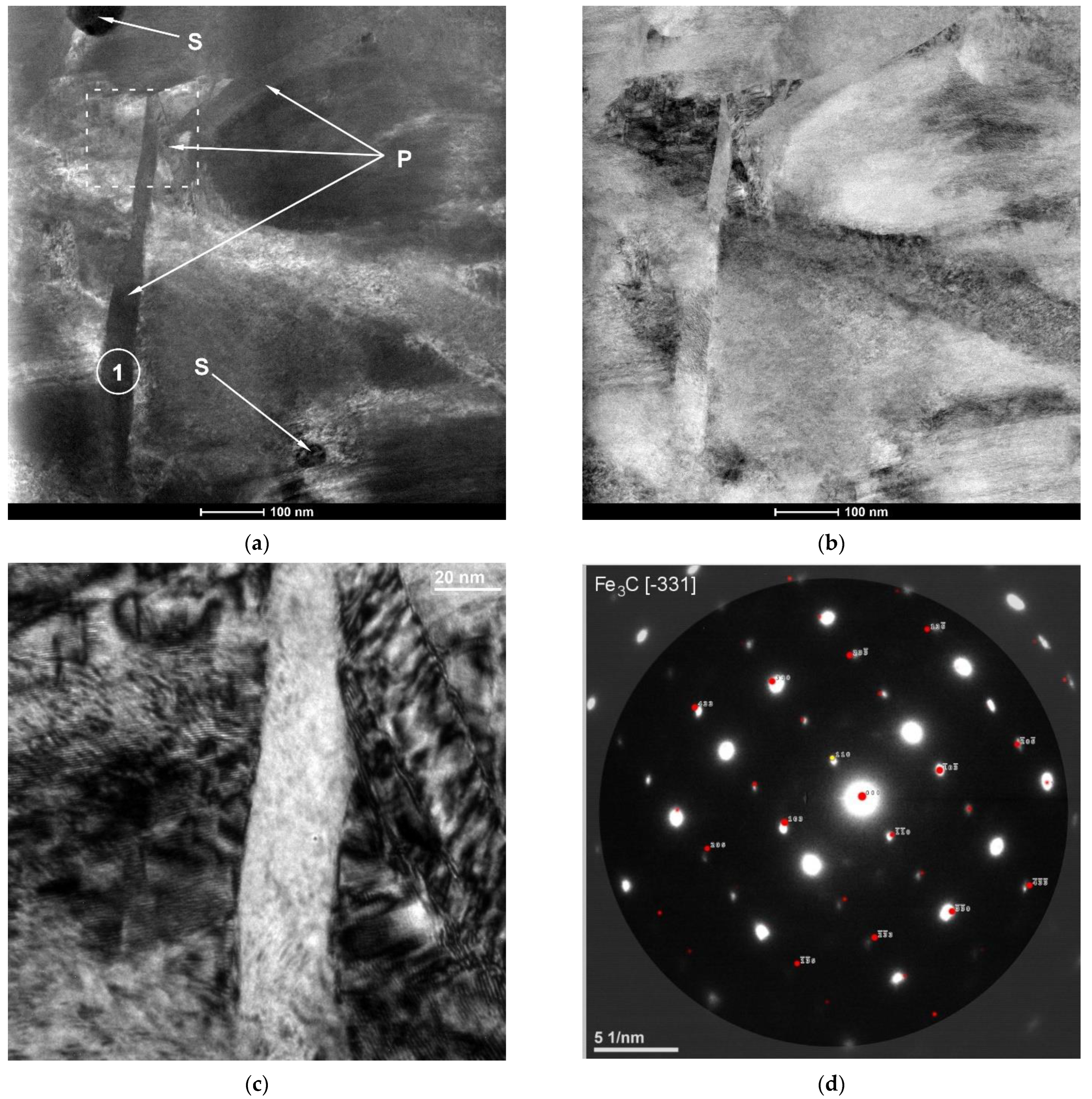

3.2. Macro and Microstructural Analysis

3.3. Hardness Analysis

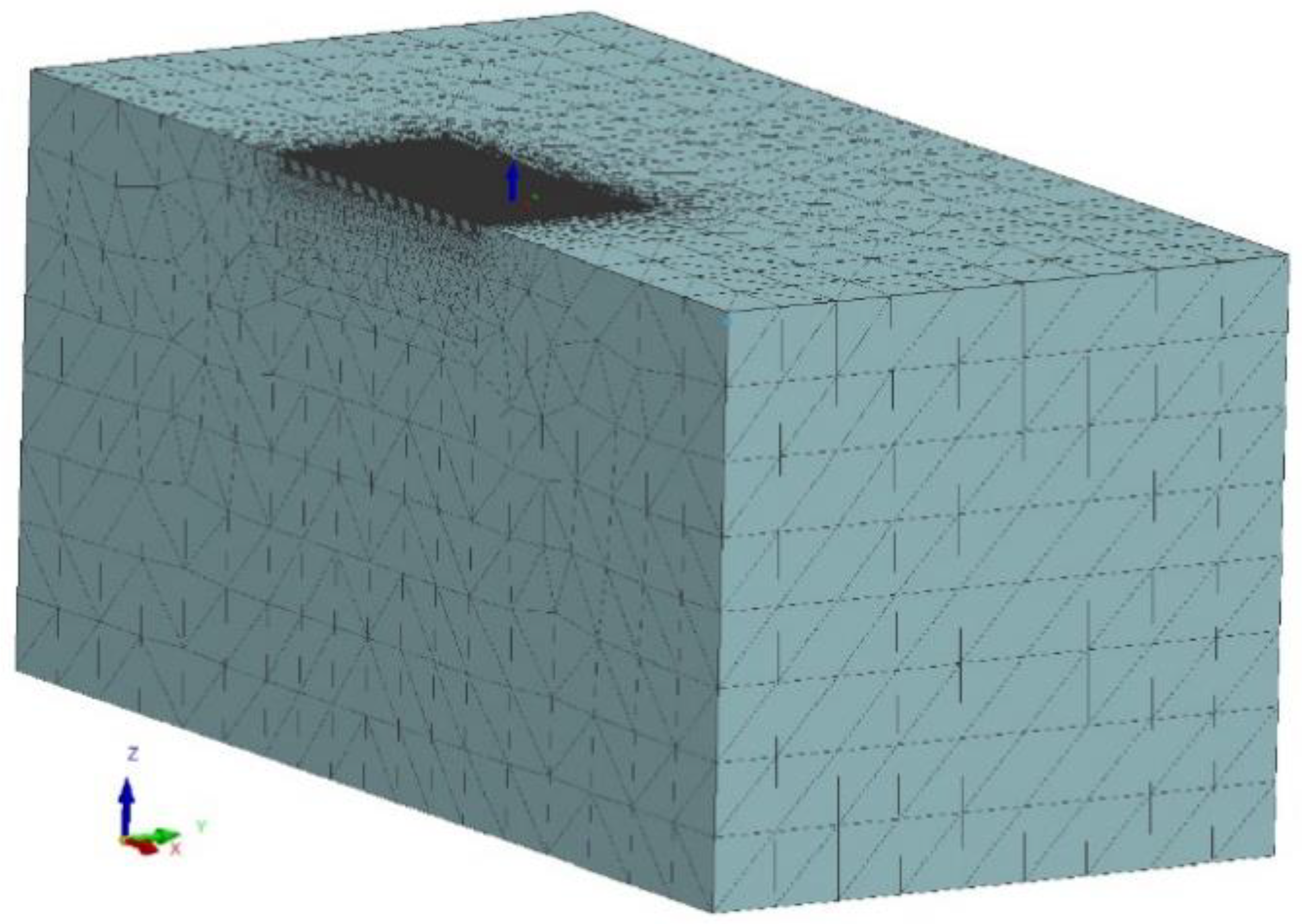

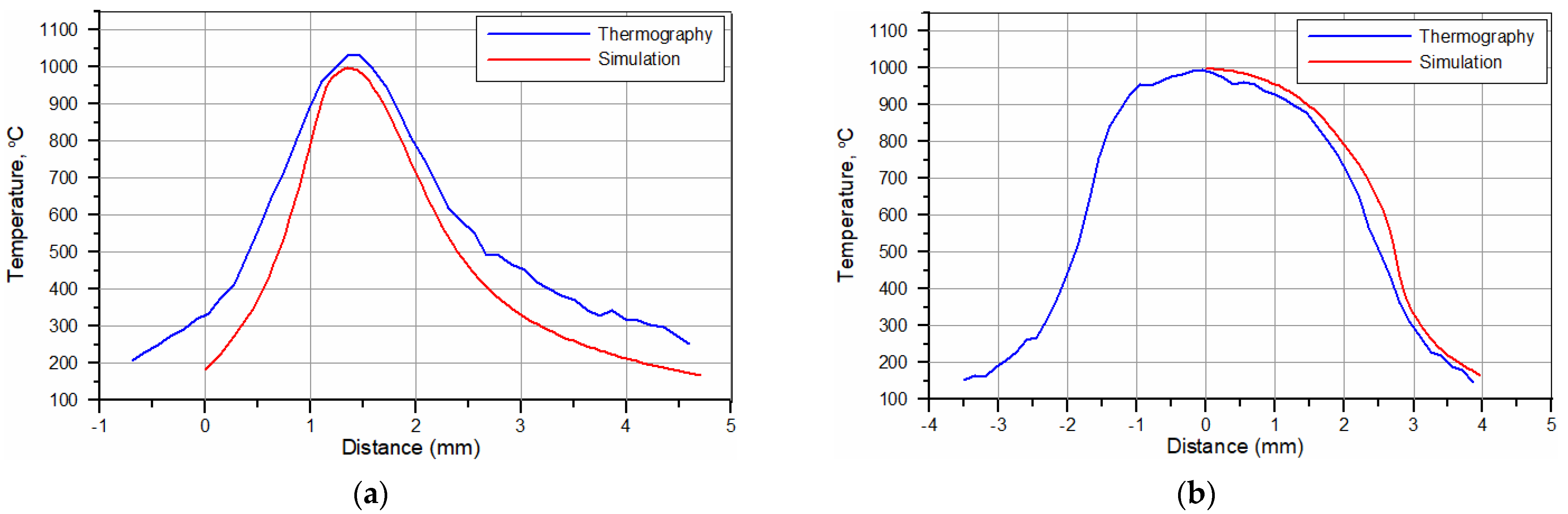

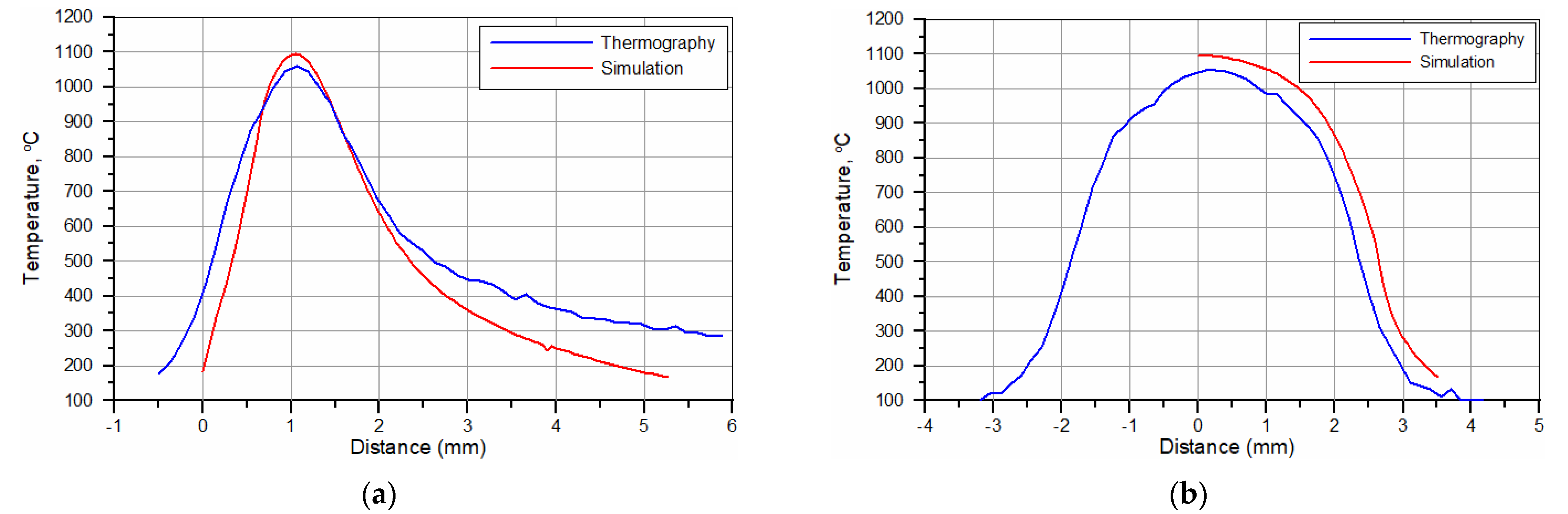

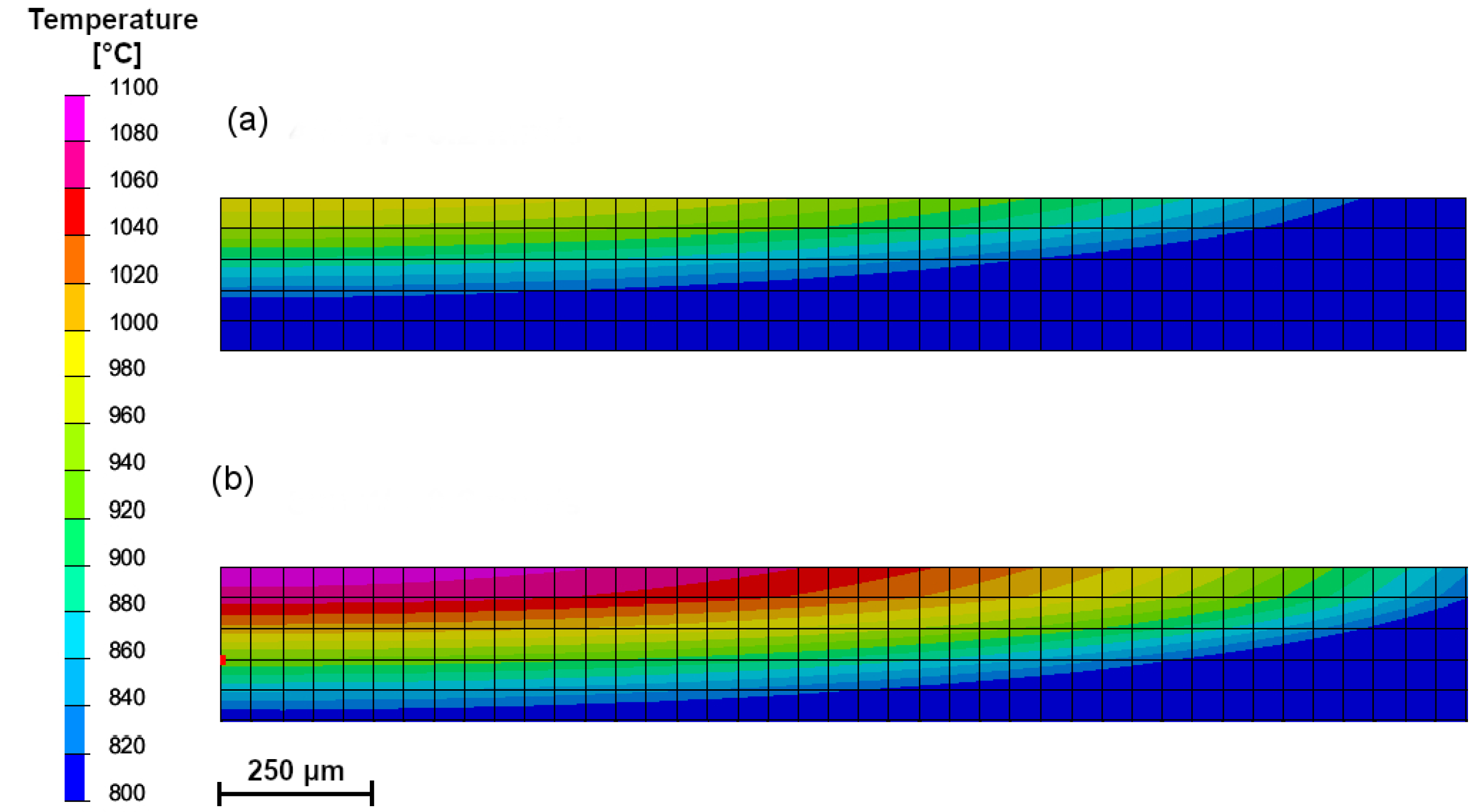

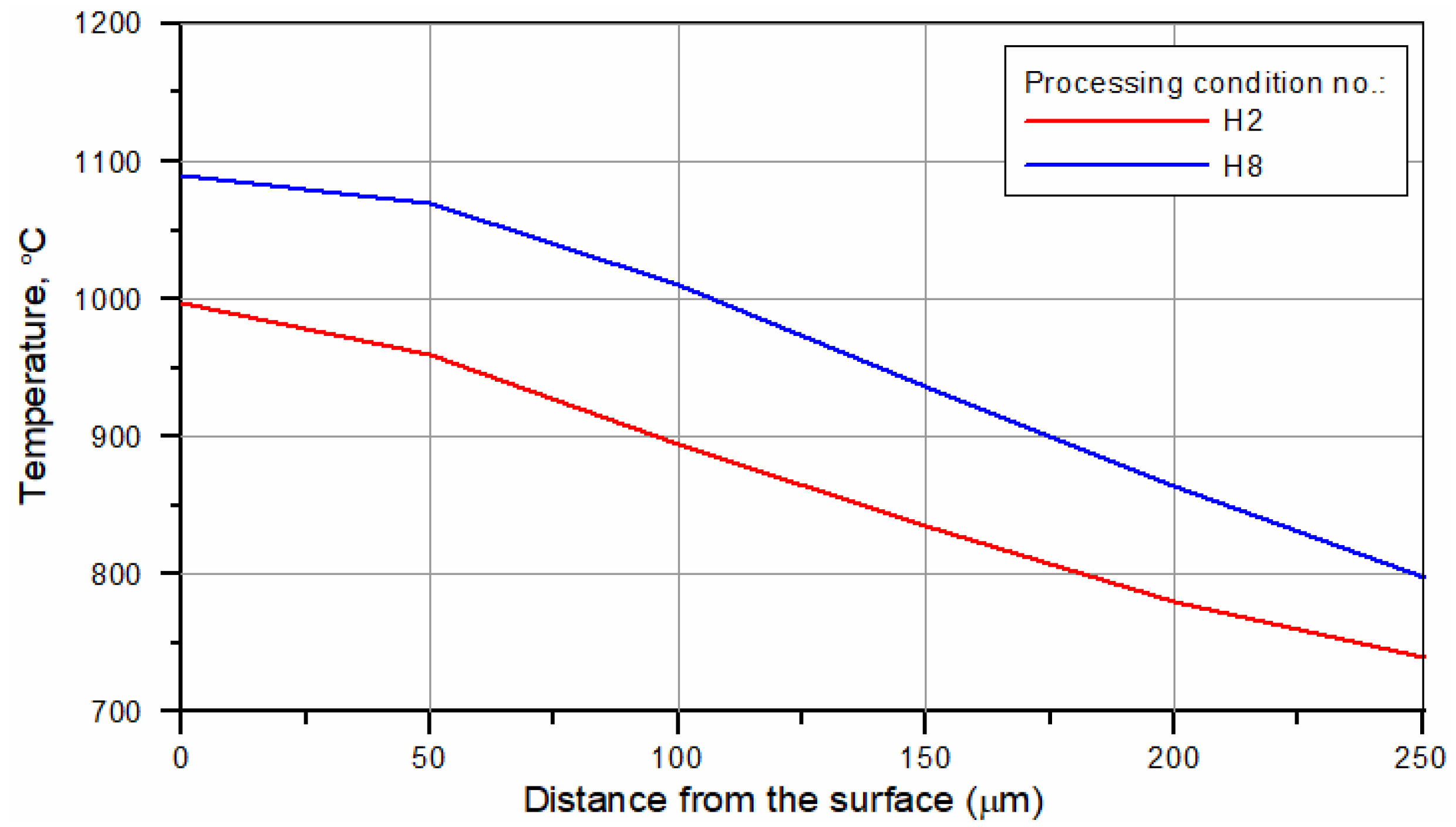

3.4. Examination of Thermal Conditions in the Hardened Zone

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grum, J.; Sturm, R. Microstructure analysis of nodular iron 400-12 after laser surface melt hardening. Mater. Charact. 1996, 37, 81–88. [Google Scholar] [CrossRef]

- Janicki, D.; Górka, J.; Kwaśny, W.; Pakieła, W.; Matus, K. Influence of Solidification Conditions on the Microstructure of Laser-Surface-Melted Ductile Cast Iron. Materials 2020, 13, 1174. [Google Scholar] [CrossRef] [Green Version]

- Hurtado-Delgado, E.; Huerta-Larumbe, L.; Miranda-Pérez, A.; Aguirre-Sánchez, A. Microcracks Reduction in Laser Hardened Layers of Ductile Iron. Coatings 2021, 11, 368. [Google Scholar] [CrossRef]

- Jeyaprakash, N.; Yang, C.; Duraiselvam, M.; Prabu, G.; Tseng, S.; Kumar, D.R. Investigation of high temperature wear performance on laser processed nodular iron using optimization technique. Results Phys. 2019, 15, 102585. [Google Scholar] [CrossRef]

- Janicki, D. Microstructure and sliding wear behaviour of in-situ TiC-reinforced composite surface layers fabricated on ductile cast iron by laser alloying. Materials 2018, 11, 75. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Janicki, D. Effect of Chromium and Molybdenum Addition on the Microstructure of In Situ TiC-Reinforced Composite Surface Layers Fabricated on Ductile Cast Iron by Laser Alloying. Materials 2020, 13, 5750. [Google Scholar] [CrossRef]

- Janicki, D. The friction and wear behaviour of in-situ titanium carbide reinforced composite layers manufactured on ductile cast iron by laser surface alloying. Surf. Coat. Technol. 2021, 406, 126634. [Google Scholar] [CrossRef]

- Paczkowska, M.; Makuch, N.; Kulka, M. The influence of various cooling rates during laser alloying on nodular iron surface layer. Opt. Laser. Technol. 2018, 102, 60–67. [Google Scholar] [CrossRef]

- Liu, Y.; Qu, W.; Su, Y. Reinforcement Composite Coating Produced Using Graphite of the Cast Iron by Laser Cladding. Materials 2016, 9, 815. [Google Scholar] [CrossRef] [Green Version]

- Putatunda, S.K.; Bartosiewicz, L.; Hull, R.J.; Lander, M. Laser hardening of austempered ductile cast iron (ADI). Mater. Manuf. Process. 1997, 12, 137–151. [Google Scholar] [CrossRef]

- Ocelik, V.; Tang, P.N.; De Boer, M.C.; De Oliveira, U.; De Hosson, J.T.M. Laser surface treatment of grey cast iron for automotive applications. In Computer Methods and Experimental Measurements for Surface Effects and Contact Mechanics VII; WIT Transactions on Engineering Sciences, 49; De Hosson, J.T.M., Brebbia, C.A., Nishida, S.I., Eds.; WIT Press: Ashurst, UK, 2005. [Google Scholar]

- Liu, A.; Previtaili, B. Laser surface treatment of grey cast iron by high power diode laser. Phys. Procedia 2010, 5, 439–448. [Google Scholar] [CrossRef] [Green Version]

- Janicki, D. Fabrication of high chromium white iron surface layers on ductile cast iron substrate by laser surface alloying. Stroj. Vestn. 2017, 63, 705–714. [Google Scholar] [CrossRef] [Green Version]

- Xu, Y.; Liu, J. Laser surface hardening of ductile cast iron for vehicle die. Proc. SPIE 2010, 7843, 353–361. [Google Scholar] [CrossRef]

- Soriano, C.; Leunda, J.; Lambarri, J.; García Navas, V.; Sanz, C. Effect of laser surface hardening on the microstructure, hardness and residual stresses of austempered ductile iron grades. Appl. Surf. Sci. 2011, 257, 7101–7106. [Google Scholar] [CrossRef]

- Wanga, B.; Qiu, F.; Barber, G.C.; Pan, Y.; Cui, W.; Wang, R. Microstructure, wear behavior and surface hardening of austempered ductile iron. J. Mater. Res. Technol. 2020, 9, 9838–9855. [Google Scholar] [CrossRef]

- Malek Ghaini, F.; Ameri, M.H.; Torkamany, M.J. Surface transformation hardening of ductile cast iron by a 600w fiber laser. Optik 2020, 203, 163758. [Google Scholar] [CrossRef]

- Meijer, J.; van Sprang, I. Optimization of Laser Beam Transformation Hardening by One Single Parameter. CIRP Ann. 1991, 40, 183–186. [Google Scholar] [CrossRef] [Green Version]

- Ion, J.C. Laser Processing of Engineering Materials; Elsevier Butterworth-Heinemann: London, UK, 2005. [Google Scholar]

- Grum, J. Laser Surface Hardening. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.W., Eds.; Springer: Boston, MA, USA, 2013. [Google Scholar] [CrossRef]

- Czupryński, A.; Wyględacz, B. Comparative Analysis of Laser and Plasma Surfacing by Nickel-Based Superalloy of Heat Resistant Steel. Materials 2020, 13, 2367. [Google Scholar] [CrossRef]

- Kik, T. Heat Source Models in Numerical Simulations of Laser Welding. Materials 2020, 13, 2653. [Google Scholar] [CrossRef]

- Hung, T.P.; Shi, H.E. Temperature Modeling of AISI 1045 Steel during Surface Hardening Processes. Materials 2018, 11, 1815. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.S.; Na, J. A study on residual stresses in laser surface hardening of a medium carbon steel. Surf. Coat. Technol. 1989, 38, 311–324. [Google Scholar] [CrossRef]

- Zarubova, N.; Kraus, V.; Cermak, J. Mechanisms of phase transformations during laser treatment of grey cast iron. J. Mater. Sci. 1992, 27, 3487–3496. [Google Scholar] [CrossRef]

- Janus, A.; Stachowicz, M. Thermodynamic stability of austenitic Ni-Mn-Cu cast iron. Metalurgija 2014, 3, 353–356. [Google Scholar]

- Czupryński, A.; Pawlyta, M. Influence of Preheating Temperature on Structural and Mechanical Properties of a Laser-Welded MMC Cobalt Based Coating Reinforced by TiC and PCD Particles. Materials 2022, 15, 1400. [Google Scholar] [CrossRef] [PubMed]

- Sroka, M.; Jonda, E.; Pakieła, W. Laser Surface Modification of Aluminium Alloy AlMg9 with B4C Powder. Materials 2020, 13, 402. [Google Scholar] [CrossRef] [Green Version]

- Tayal, M.; Mukherjee, K. Thermal and microstructural analysis for laser surface hardening of steel. J. Appl. Phys. 1994, 75, 3855. [Google Scholar] [CrossRef]

- Tobar, M.J.; Álvarez, C.; Amado, J.M.; Ramil, A.; Saavedra, E.; Yáñez, A. Laser transformation hardening of a tool steel: Simulation-based parameter optimization and experimental results. Surf. Coat. Technol. 2006, 362–6367. [Google Scholar] [CrossRef]

- Gegner, J. Concentration-and temperature-dependent diffusion coefficient of carbon in FCC iron mathematically derived from literature data. In Mathematical Modeling and Computer Simulation of Materials Technologies; College of Judea and Samaria: Ariel, Israel, 2006; Volume 1, pp. 158–167. [Google Scholar]

| C | Si | Cu | Mn | Cr | Ni | S | P | Fe |

|---|---|---|---|---|---|---|---|---|

| 3.52 | 2.62 | 0.80 | 0.24 | 0.02 | 0.04 | 0.008 | 0.016 | balance |

| Processing Condition No./SHB No. | Laser Power (W) | Laser Power Density (W/mm2) | Traverse Speed (m/min) | Heat Input 1 (J/mm) | Surface Hardness HV0.5 | Layer Thickness 2 (µm) | Remarks/Quality 3 |

|---|---|---|---|---|---|---|---|

| H1 | 400 | 40.4 | 0.1 | 240 | 867 ± 60 | 458 ± 14 | PM |

| H2 | 0.2 | 120 | 755 ± 32 | 61 ± 11 | NM | ||

| H3 | 0.3 | 80 | 290 ± 15 | - | NH | ||

| H4 | 600 | 60.6 | 0.2 | 180 | 841 ± 54 | 437 ± 15 | PM |

| H5 | 0.4 | 90 | 724 ± 29 | 192 ± 11 | NM | ||

| H6 | 0.6 | 60 | 689 ± 31 | 78 ± 10 | NM | ||

| H7 | 800 | 80.8 | 0.4 | 120 | 796 ± 58 | 393 ± 16 | PM |

| H8 | 0.6 | 80 | 690 ± 28 | 196 ± 12 | NM | ||

| H9 | 0.8 | 60 | 684 ± 30 | 92 ± 11 | NM |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czupryński, A.; Janicki, D.; Górka, J.; Grabowski, A.; Wyględacz, B.; Matus, K.; Karski, W. High-Power Diode Laser Surface Transformation Hardening of Ferrous Alloys. Materials 2022, 15, 1915. https://doi.org/10.3390/ma15051915

Czupryński A, Janicki D, Górka J, Grabowski A, Wyględacz B, Matus K, Karski W. High-Power Diode Laser Surface Transformation Hardening of Ferrous Alloys. Materials. 2022; 15(5):1915. https://doi.org/10.3390/ma15051915

Chicago/Turabian StyleCzupryński, Artur, Damian Janicki, Jacek Górka, Andrzej Grabowski, Bernard Wyględacz, Krzysztof Matus, and Wojciech Karski. 2022. "High-Power Diode Laser Surface Transformation Hardening of Ferrous Alloys" Materials 15, no. 5: 1915. https://doi.org/10.3390/ma15051915

APA StyleCzupryński, A., Janicki, D., Górka, J., Grabowski, A., Wyględacz, B., Matus, K., & Karski, W. (2022). High-Power Diode Laser Surface Transformation Hardening of Ferrous Alloys. Materials, 15(5), 1915. https://doi.org/10.3390/ma15051915