Dielectric Properties of Hybrid Polyethylene Composites Containing Cobalt Nanoparticles and Carbon Nanotubes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Co/MWCNT-PE Composites Preparation

2.2. Structure Characterization of Co/MWCNT-PE Composites

2.3. Electrophysical Characteristics of Co/MWCNT-PE Composites

3. Results

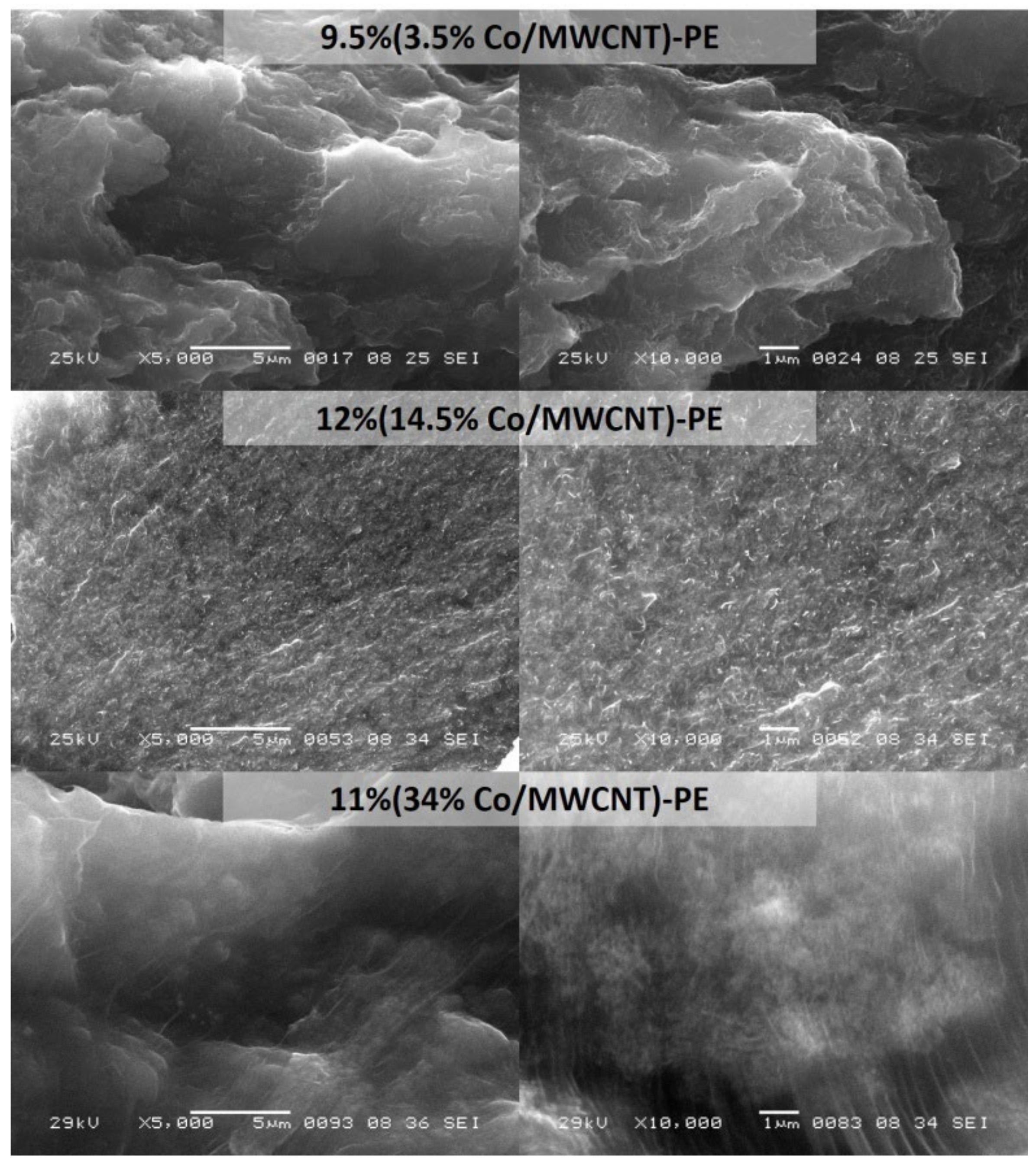

3.1. Structure of Composites

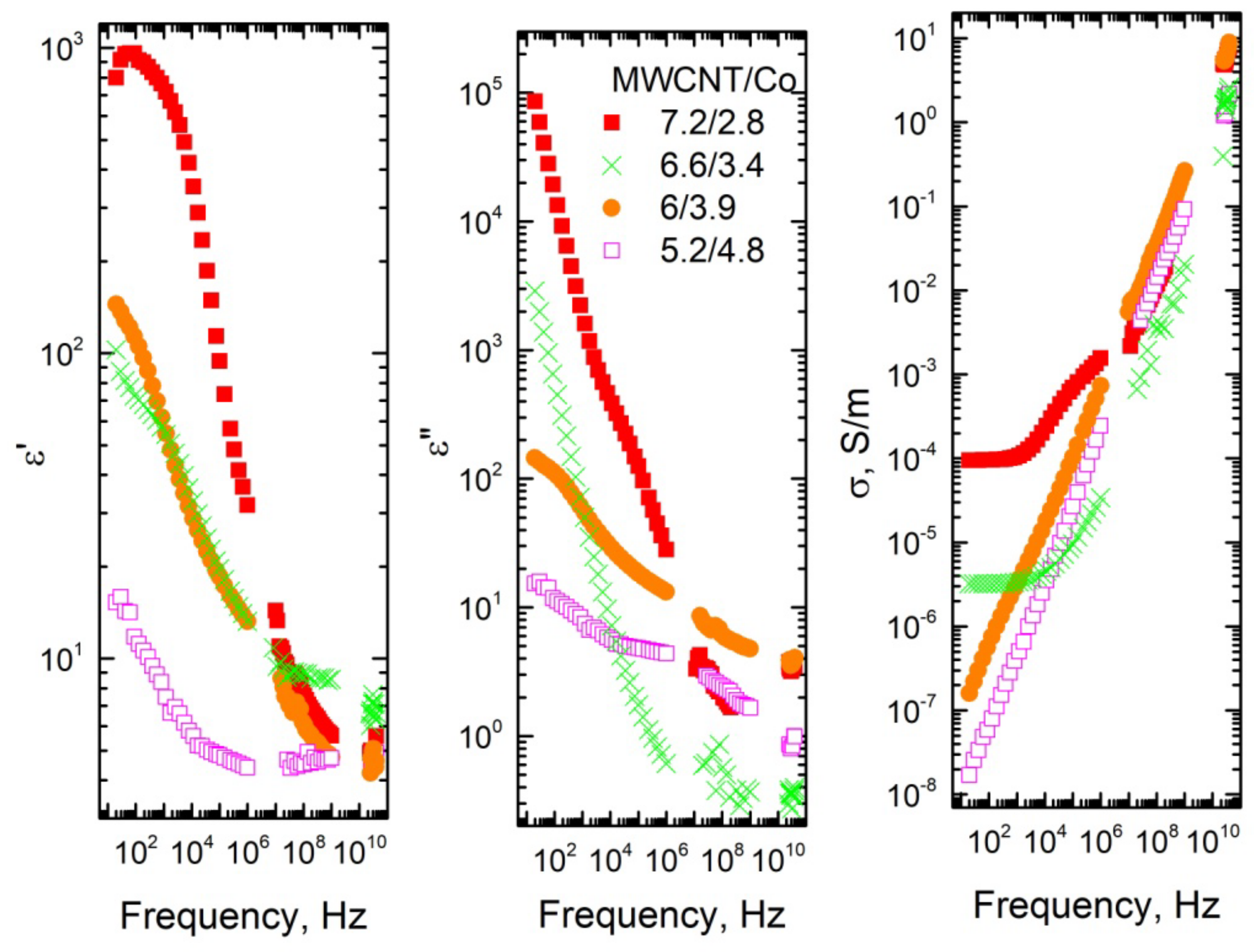

3.2. Dielectric Properties at Room Temperature

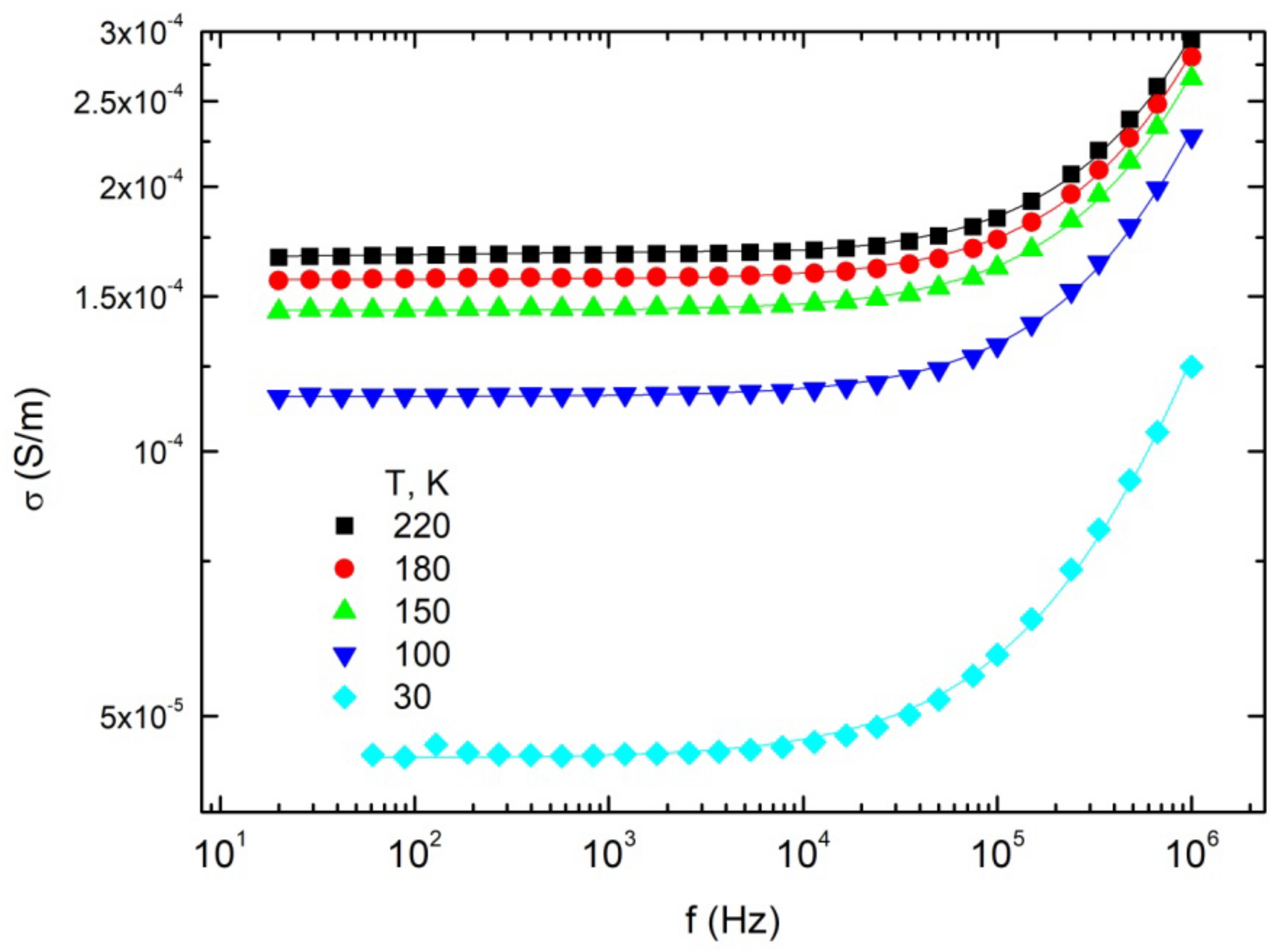

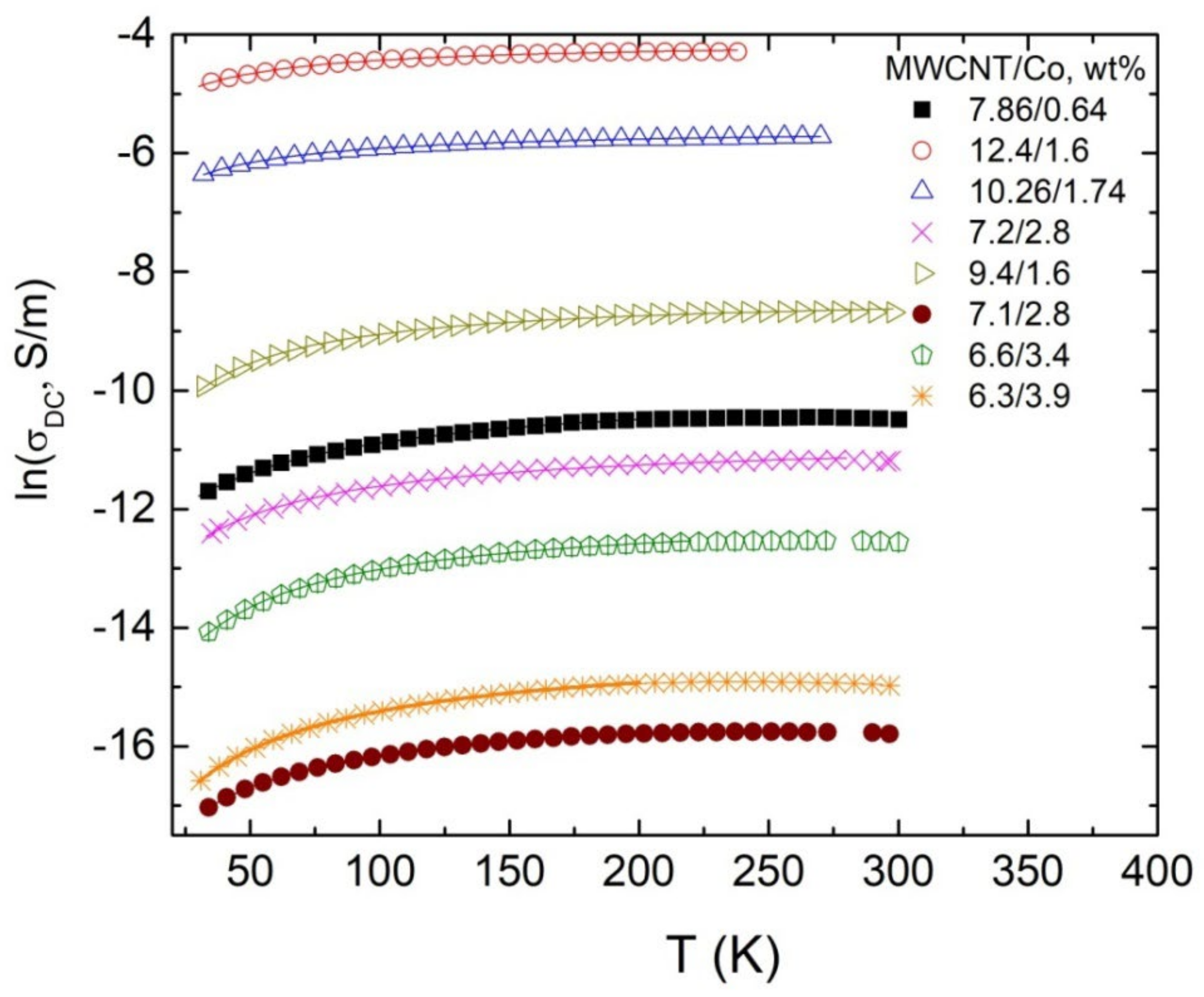

3.3. Electrical Conductivity at Low Temperatures

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chung, D.D.L. Electromagnetic interference shielding effectiveness of carbon materials. Carbon 2001, 39, 279–285. [Google Scholar] [CrossRef]

- Chen, Z.P.; Xu, C.; Ma, C.Q.; Ren, W.C.; Cheng, H.M. Lightweight and flexible graphene foam composites for high-performance electromagnetic interference shielding. Adv. Mater. 2013, 25, 1296–1300. [Google Scholar] [CrossRef] [PubMed]

- Van der Togt, R.; van Lieshout, E.J.; Hensbroek, R.; Beinat, E.; Binnekade, J.M.; Bakker, P.J.M. Electromagnetic interference from radio frequency identification inducing potentially hazardous incidents in critical care medical equipment. JAMA-J. Am. Med. Assoc. 2008, 299, 2884–2890. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gonzalez, M.; Pozuelo, C.; Baselga, J. Electromagnetic shielding materials in GHz range. Chem. Rec. 2018, 18, 1000–1009. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Saadeh, W.H.; Sundararaj, U. EMI shielding effectiveness of carbon based nanostructured polymeric materials: A comparative study. Carbon 2013, 60, 146–156. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. Electromagnetic interference shielding mechanisms of CNT/polymer composites. Carbon 2009, 47, 1738–1746. [Google Scholar] [CrossRef]

- Qin, F.; Brosseau, C. A review and analysis of microwave absorption in polymer composites filled with carbonaceous particles. J. Appl. Phys. 2012, 111, 061301. [Google Scholar] [CrossRef]

- Liang, J.J.; Wang, Y.; Huang, Y.; Ma, Y.F.; Liu, Z.F.; Cai, J.M.; Zhang, C.D.; Gao, H.J.; Chen, Y.S. Electromagnetic interference shielding of graphene/epoxy composites. Carbon 2009, 47, 922–925. [Google Scholar] [CrossRef]

- Sandler, J.K.W.; Kirk, J.E.; Kinloch, I.A.; Shaffer, M.S.P.; Windle, A.H. Ultra-low electrical percolation threshold in carbon-nanotube-epoxy composites. Polymer 2003, 44, 5893–5899. [Google Scholar] [CrossRef]

- Adrianse, L.J.; Reedijk, J.A.; Teunissen, P.A.A.H.; Brom, B.; Michels, M.A.J.; Brokken-Zijp, J.C.M. High-dilution carbon-black/polymer composites: Hierarchical percolating network derived from Hz to THz ac conductivity. Phys. Rev. Lett. 1997, 78, 1755. [Google Scholar] [CrossRef]

- Deng, H.; Lin, L.; Ji, M.; Zhang, S.; Yang, M.; Fu, Q. Progress on the morphological control of conductive network in conductive polymer composites and the use as electroactive multifunctional materials. Prog. Polym. Sci. 2014, 39, 627–655. [Google Scholar] [CrossRef]

- Bertasius, P.; Meisak, D.; Macutkevic, J.; Kuzhir, P.; Selskis, A.; Volnyanko, E.; Banys, J. Fine tuning of electrical transport and dielectric properties of epoxy/carbon nanotubes composites via magnesium oxide additives. Polymers 2019, 11, 2044. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Singh, K.; Ohlan, A.; Pham, V.H.; Balasubramaniyan, R.; Varshney, S.; Jang, J.; Hur, S.H.; Choi, W.M.; Kumar, M.; Dhawan, S.K.; et al. Nanostructured graphene/Fe3O4 incorporated polyaniline as a high performance shield against electromagnetic pollution. Nanoscale 2013, 5, 2411–2420. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.L.; Yang, G.D.; Schubert, D.W. Electrically conductive polymer composite containing hybrid graphene nanoplatelets and carbon nanotubes: Synergistic effect and tunable conductivity anisotropy. Adv. Compos. Hybrid Mater. 2021, 1–13. [Google Scholar] [CrossRef]

- Gbaguidi, A.; Namilae, S.; Kim, D. Synergy effect in nanocomposites based on carbon nanotubes and graphene nanoplatelets. Nanotechnology 2020, 31, 255704. [Google Scholar] [CrossRef]

- Meisak, D.; Macutkevic, J.; Plyushch, A.; Kuzhir, P.; Selskis, A.; Banys, J. Dielectric relaxation in hybrid Epoxy/MWCNT/MnFe2O4 composites. Polymers 2020, 12, 697. [Google Scholar] [CrossRef] [Green Version]

- Kumar, R.; Choudhary, H.K.; Anupama, A.V.; Menon, A.V.; Pawar, S.P.; Bose, S.; Sahoo, B. Nitrogen doping as a fundamental way to enhance the EMI shielding behavior of cobalt particle-embedded carbonaceous nanostructures. New J. Chem. 2019, 43, 5568–5580. [Google Scholar] [CrossRef]

- He, Q.L.; Yuan, T.T.; Zhang, X.; Luo, Z.P.; Haldolaarachchige, N.; Sun, L.; Young, D.; Wei, S.; Guo, Z. Magnetically soft and hard polypropylene/cobalt nanocomposites: Role of maleic anhydride grafted polypropylene. Macromolecules 2013, 46, 2357–2368. [Google Scholar] [CrossRef]

- Hussain, T.; Ahmad, M.N.; Nawaz, A.; Mujahid, A.; Bashir, F.; Mustafa, G. Surfactant incorporated Co nanoparticles with uniform dispersion and double percolation. J. Chem. 2017, 2017, 7191590. [Google Scholar] [CrossRef]

- Andreev, A.S.; Kazakova, M.A.; Ishchenko, A.V.; Selyutin, A.G.; Lapina, O.B.; Kuznetsov, V.L.; d’Espinose de Lacaillerie, J.-B. Magnetic and dielectric properties of Carbon Nanotubes with embedded Cobalt nanoparticles. Carbon 2017, 114, 39–49. [Google Scholar] [CrossRef] [Green Version]

- Kazakova, M.A.; Semikolenova, N.V.; Korovin, E.Y.; Zhuravlev, V.A.; Selyutin, A.G.; Velikanov, D.A.; Moseenkov, S.I.; Andreev, A.S.; Lapina, O.B.; Suslyaev, V.I.; et al. Co/Multi-walled carbon nanotubes/Polyethylene composites for microwave absorption: Tuning the effectiveness of electromagnetic shielding by varying the components ratio. Compos. Sci. Technol. 2021, 207, 108731. [Google Scholar] [CrossRef]

- Vasundhara, K.; Mandal, B.P.; Tyagi, A.K. Enhancement of dielectric permittivity and ferroelectricity of a modiefied cobalt nanoparticle and polyvynilidene fluoride based composite. RSC Adv. 2015, 5, 8591–8597. [Google Scholar] [CrossRef]

- Golubtsov, G.V.; Kazakova, M.A.; Selyutin, A.G.; Ishchenko, A.V.; Kuznetsov, V.L. Mono-, bi- and trimetallic catalysts for the synthesis of multi-walled carbon nanotubes based on iron subgroup metals. J. Struct. Chem. 2020, 61, 640–651. [Google Scholar] [CrossRef]

- Kazakova, M.A.; Koul, A.; Golubtsov, G.V.; Selyutin, A.G.; Ishchenko, A.V.; Kvon, R.I.; Kolesov, B.A.; Schuhmann, W.; Morales, D.M. Nitrogen and oxygen functionalization of multi-walled carbon nanotubes for tuning bifunctional oxygen reduction/oxygen evolution performance of supported FeCo oxide nanoparticles. ChemElectroChem 2021, 8, 2803–2816. [Google Scholar] [CrossRef]

- Andreev, A.S.; Krasnikov, D.V.; Zaikovskii, V.I.; Cherepanova, S.V.; Kazakova, M.A.; Lapina, O.B.; Kuznetsov, V.L.; de Lacaillerie, J.B.D.E. Internal field 59Co NMR study of cobalt-iron nanoparticles during the activation of CoFe2/CaO catalyst for carbon nanotube synthesis. J. Catal. 2018, 358, 62–70. [Google Scholar] [CrossRef]

- Kazakova, M.A.; Andreev, A.S.; Selyutin, A.G.; Ishchenko, A.V.; Shuvaev, A.V.; Kuznetsov, V.L.; Lapina, O.B.; de Lacaillerie, J.B.D.E. Co metal nanoparticles deposition inside or outside multi-walled carbon nanotubes via facile support pretreatment. Appl. Surf. Sci. 2018, 456, 657–665. [Google Scholar] [CrossRef]

- Zhdanov, A.A.; Kazakova, M.A. Use of Carbon Materials of Different Nature in Determining Metal Concentrations in Carbon Nanotubes by X-Ray Fluorescence Spectrometry. J. Anal. Chem. 2020, 75, 312–319. [Google Scholar] [CrossRef]

- Kazakova, M.A.; Selyutin, A.G.; Semikolenova, N.V.; Ishchenko, A.V.; Moseenkov, S.I.; Matsko, M.A.; Zakharov, V.A.; Kuznetsov, V.L. Structure of the in situ produced polyethylene based composites modified with multi-walled carbon nanotubes: In situ synchrotron X-ray diffraction and differential scanning calorimetry study. Compos. Sci. Technol. 2018, 167, 148–154. [Google Scholar] [CrossRef]

- Kazakova, M.A.; Semikolenova, N.V.; Korovin, E.Y.; Moseenkov, S.I.; Andreev, A.S.; Kachalov, A.S.; Kuznetsov, V.L.; Suslyaev, V.I.; Mats’ko, M.A.; Zakharov, V.A. In situ Polymerization Technique for Obtaining Composite Materials Based on Polyethylene, Multi-walled Carbon Nanotubes and Cobalt Nanoparticles. Russ. J. Appl. Chem. 2018, 91, 127–135. [Google Scholar] [CrossRef]

- Kazakova, M.A.; Kuznetsov, V.L.; Semikolenova, N.V.; Moseenkov, S.I.; Krasnikov, D.V.; Matsko, M.A.; Ishchenko, A.V.; Zakharov, V.A.; Romanenko, A.I.; Anikeeva, O.B.; et al. Comparative study of multiwalled carbon nanotubes/polyethylene composites produced via different techniques. Phys. Status Solidi B 2014, 251, 2437–2443. [Google Scholar] [CrossRef]

- Popok, V.N. Polymer films with ion synthesized cobalt and iron nanoparticles: Conductance and magnetism. Rev. Adv. Mater. 2014, 36, 1–12. [Google Scholar]

- Plyushch, A.; Macutkevic, J.; Kuzhir, P.; Sokal, A.; Lapko, K.; Selskis, A.; Banys, J. Synergy effects in electromagnetic properties of phosphate ceramics with silicon carbide whiskers and carbon nanotubes. Appl. Sci. 2019, 9, 4388. [Google Scholar] [CrossRef] [Green Version]

- Zeranska-Chudek, K.; Siemion, A.; Palka, N.; Mdarhi, A.; Elaboudi, I.; Brosseau, C.; Zdrojek, M. Terahertz shielding properties of carbon black based polymer nanocomposites. Materials 2021, 14, 835. [Google Scholar] [CrossRef]

- Liu, J.; Duan, C.G.; Yin, W.G.; Mei, W.N.; Smith, R.W.; Hardy, J.R. Large dielectric constant and Maxwell-Wagner relaxation in Bi2/3Cu3Ti4O12. Phys. Rev. B 2004, 70, 144106. [Google Scholar] [CrossRef]

- Jonsher, A.K. The universal dielectric response and its physical significance. EEE Trans. Electr. Insul. 1992, 27, 407–423. [Google Scholar] [CrossRef]

- Almond, D.P.; Vainas, B.; Uvarov, N.F. A new analysis of the bulk ac electrical response of ionic conductors. Solid State Ion. 1998, 111, 253–261. [Google Scholar] [CrossRef]

- Sheng, P. Fluctuation-induced tunneling conduction in disordered materials. Phys. Rev. B 1980, 21, 2180. [Google Scholar] [CrossRef] [Green Version]

- Mdarhi, A.; Brosseau, C.; Zaghrioui, M.; El Aboudi, I. Electronic conduction and microstructure in polymer composites filled with carbonaceous particles. J. Appl. Phys. 2012, 112, 034118. [Google Scholar] [CrossRef]

| Total Concentration/MWCNT/Co, wt% | σDC | fcr | ωH, THz | s |

|---|---|---|---|---|

| 7.5/6.95/0.56 | 0.24 mS/m | 42 kHz | 5.64 | 0.92 |

| 8.5/7.86/0.64 | 0.17 mS/m | 2.7 kHz | 32.8 | 0.82 |

| 9.5/9.2/0.3 | 0.21 S/m | 2.39 MHz | 175.7 | 1.04 |

| 9.5/7.5/2 | 0.04 µS/m | 1.4 kHz | 0.06 | 0.74 |

| 9.7/9.7/0 | 0.55 mS/m | 17.7 kHz | 251.2 | 1.05 |

| 9.9/6/3.9 | 2.2 µS/m | 0.16 kHz | 0.06 | 0.67 |

| 10/7.2/2.8 | 97.6 µS/m | 1.2 kHz | 102.7 | 0.91 |

| 10/6.6/3.4 | 3.19 µS/m | 2.43 kHz | 0.22 | 0.73 |

| 10.5/10.5/0 | 2.1 mS/m | 37.2 kHz | 995.7 | 1.26 |

| 11/9.4/1.6 | 0.92 mS/m | 91.2 kHz | 24.4 | 0.99 |

| 11.5/11.5/0 | 20 mS/m | 356.6 kHz | 1265 | 1.49 |

| 12/11.1/0.9 | 46.6 mS/m | 596 kHz | 832.9 | 1.32 |

| 14/12.4/1.6 | 71 mS/m | 459.7 kHz | 859.3 | 1.16 |

| 14.5/13.4/1.1 | 0.62 S/m | 4.01 MHz | 476.9 | 1.06 |

| 14.7/13.6/1.1 | 2.1 mS/m | 470.7 kHz | 556.6 | 1.84 |

| MWCNT Concentration/Co Concentration, wt% | Ln {σ0, S/m} | T1, K | T0, K | T1/T0 |

|---|---|---|---|---|

| 7.86/0.64 | −9.89 | 136 | 43 | 3.13 |

| 10.26/1.74 | −5.57 | 41 | 20 | 2.05 |

| 12.4/1.6 | −4.11 | 37 | 19 | 1.9 |

| 7.2/2.8 | −10.78 | 109 | 32 | 3.41 |

| 9.4/1.6 | −8.37 | 100 | 28 | 3.57 |

| 7.1/2.8 | −15.28 | 114 | 31 | 3.68 |

| 6.6/3.4 | −12.03 | 123 | 26 | 4.73 |

| 6/3.9 | −14.27 | 154 | 36 | 4.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vanskevičė, I.; Kazakova, M.A.; Macutkevic, J.; Semikolenova, N.V.; Banys, J. Dielectric Properties of Hybrid Polyethylene Composites Containing Cobalt Nanoparticles and Carbon Nanotubes. Materials 2022, 15, 1876. https://doi.org/10.3390/ma15051876

Vanskevičė I, Kazakova MA, Macutkevic J, Semikolenova NV, Banys J. Dielectric Properties of Hybrid Polyethylene Composites Containing Cobalt Nanoparticles and Carbon Nanotubes. Materials. 2022; 15(5):1876. https://doi.org/10.3390/ma15051876

Chicago/Turabian StyleVanskevičė, Ieva, Mariya A. Kazakova, Jan Macutkevic, Nina V. Semikolenova, and Juras Banys. 2022. "Dielectric Properties of Hybrid Polyethylene Composites Containing Cobalt Nanoparticles and Carbon Nanotubes" Materials 15, no. 5: 1876. https://doi.org/10.3390/ma15051876

APA StyleVanskevičė, I., Kazakova, M. A., Macutkevic, J., Semikolenova, N. V., & Banys, J. (2022). Dielectric Properties of Hybrid Polyethylene Composites Containing Cobalt Nanoparticles and Carbon Nanotubes. Materials, 15(5), 1876. https://doi.org/10.3390/ma15051876