Fibers of Thermoplastic Copolyamides with Carbon Nanotubes for Electromagnetic Shielding Applications

Abstract

:1. Introduction

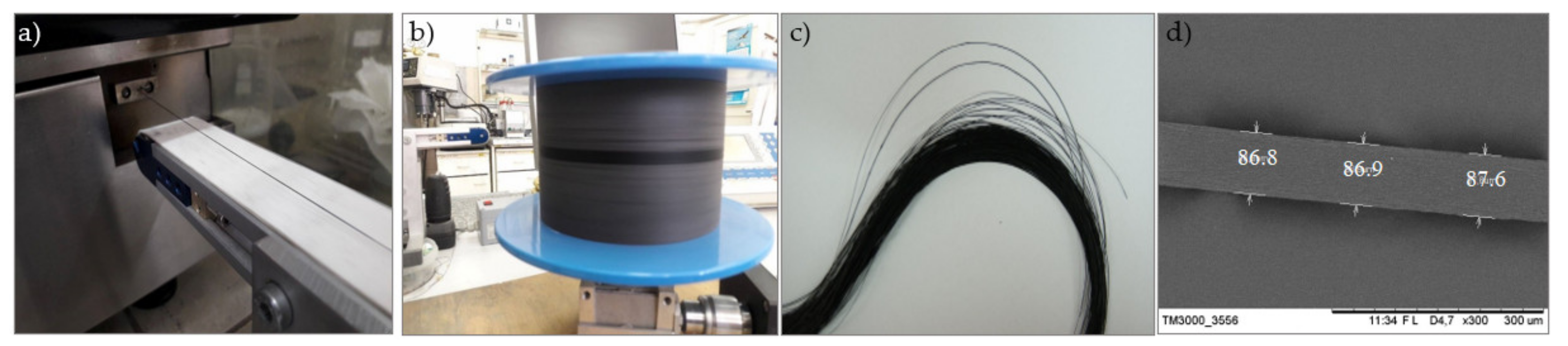

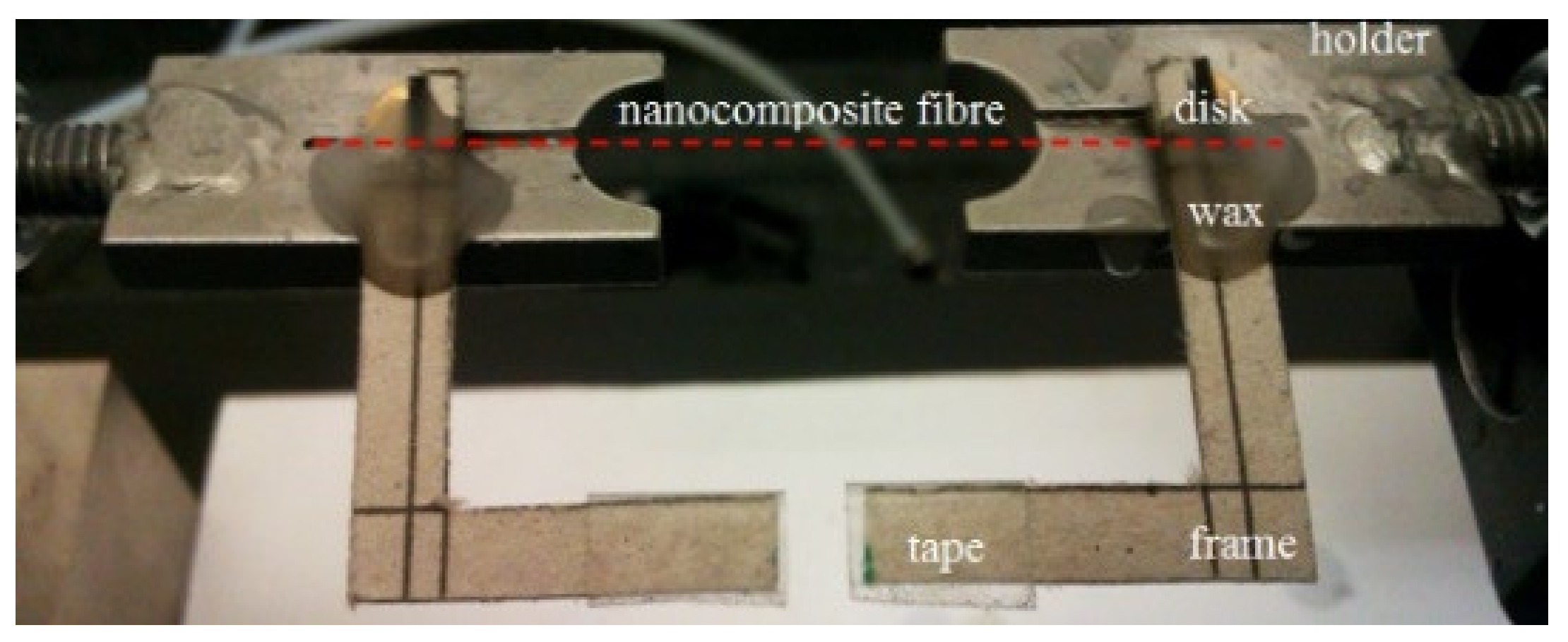

2. Materials and Methods

3. Results

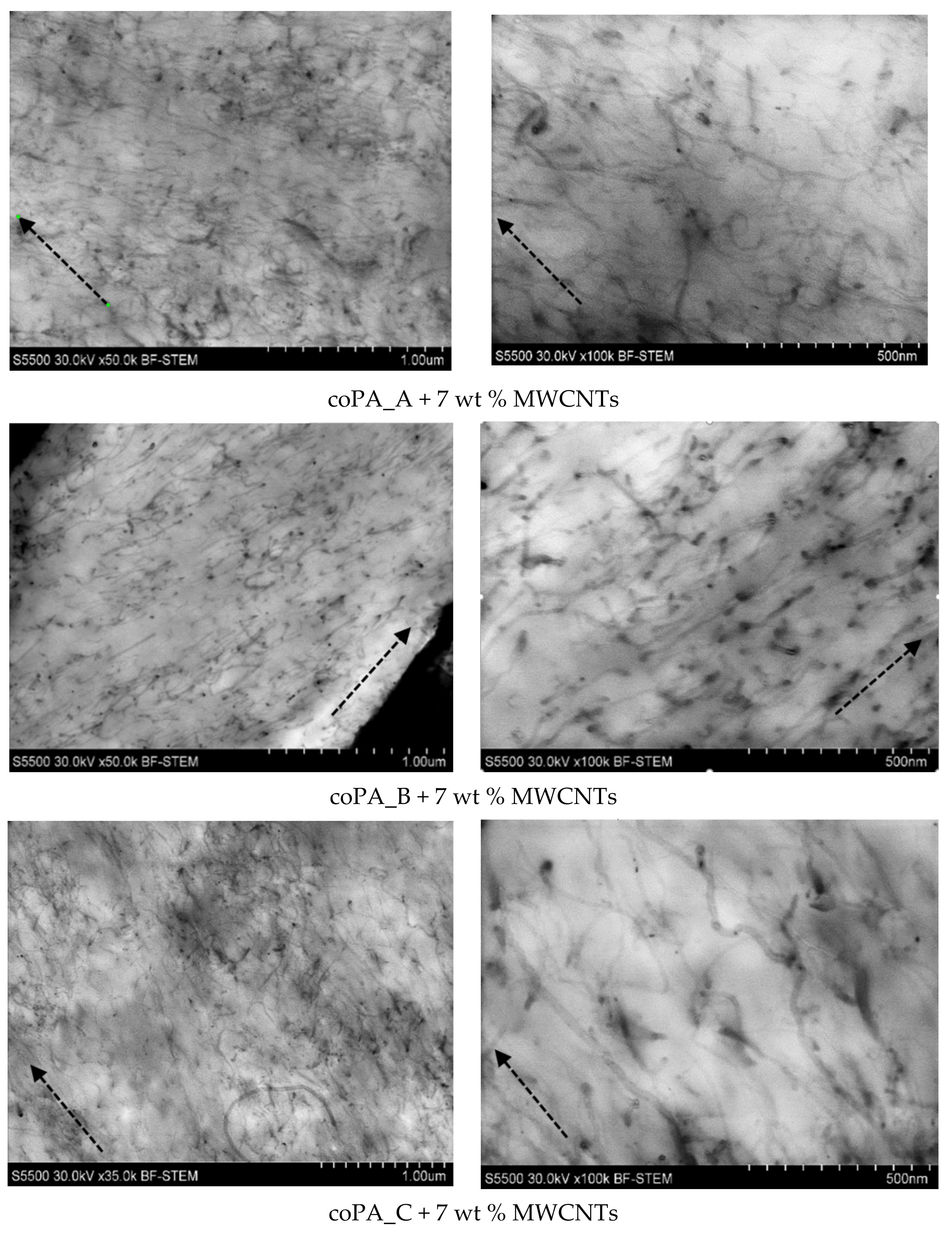

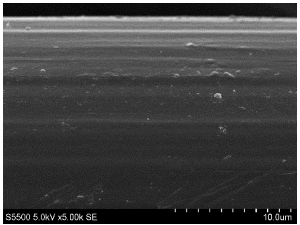

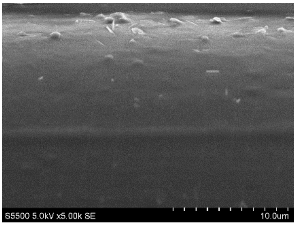

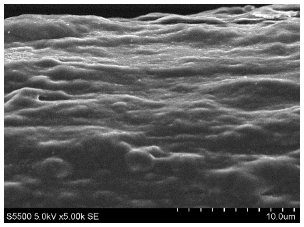

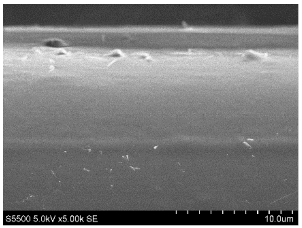

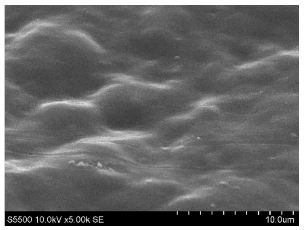

3.1. Microstructure

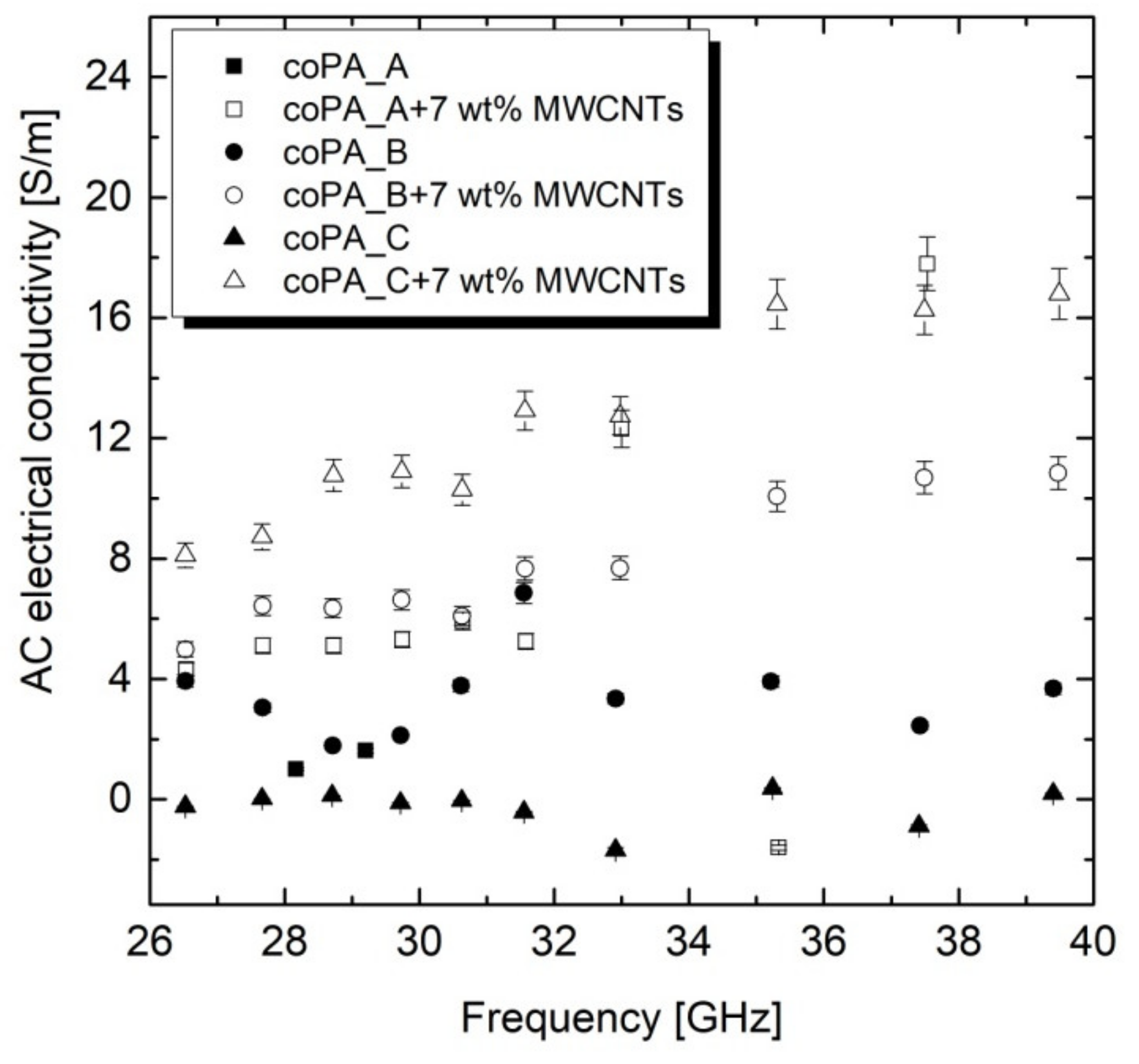

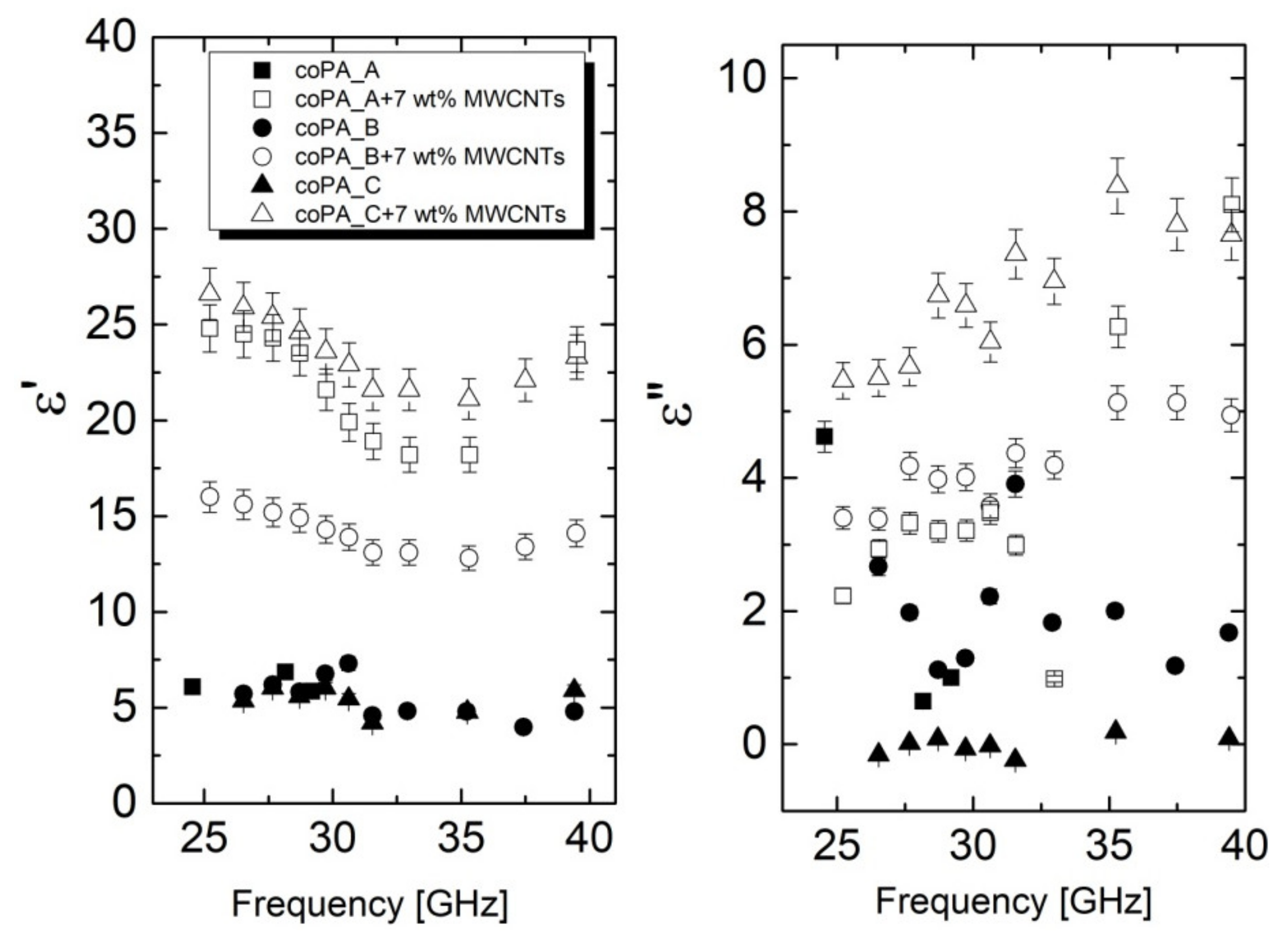

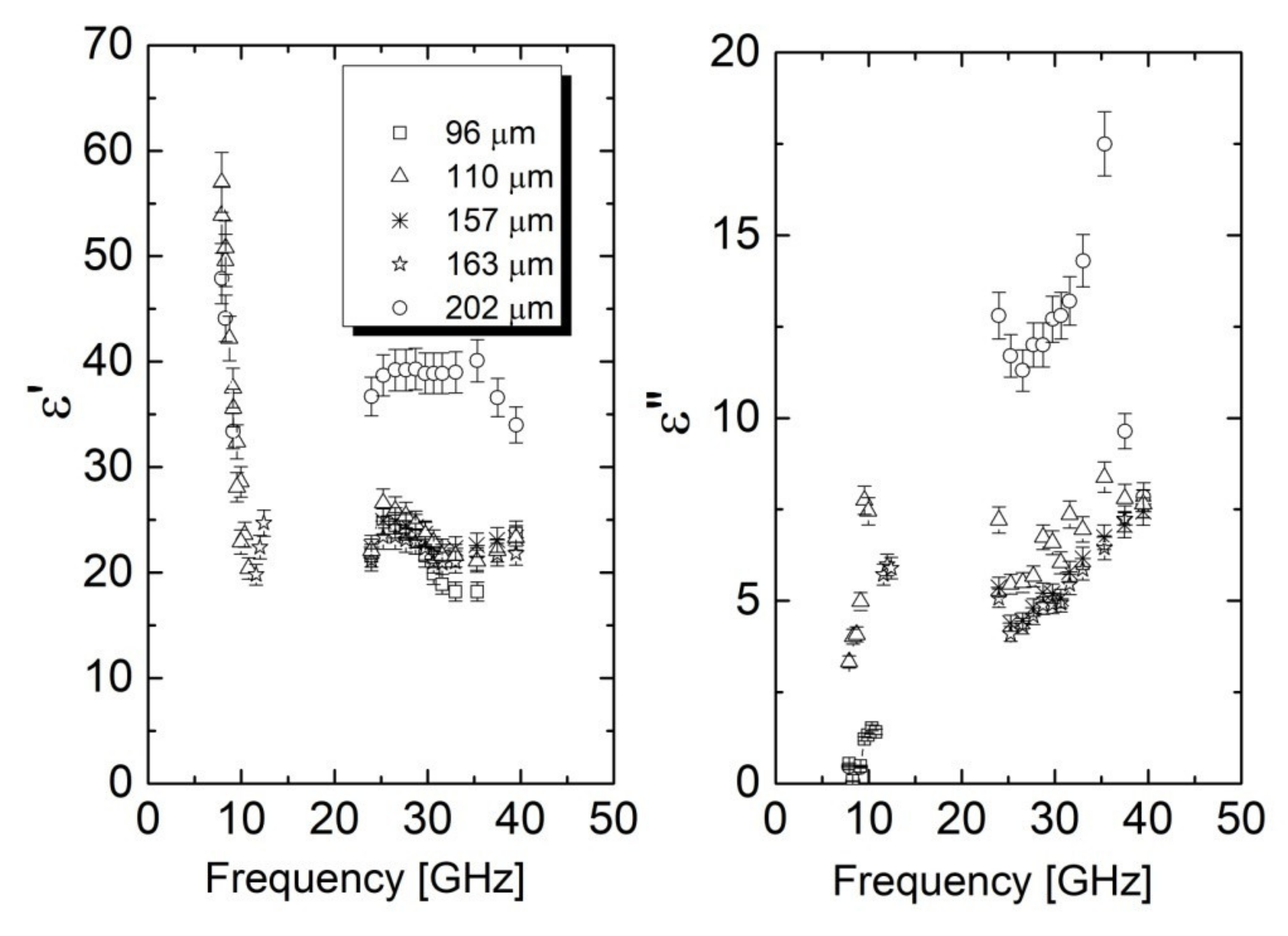

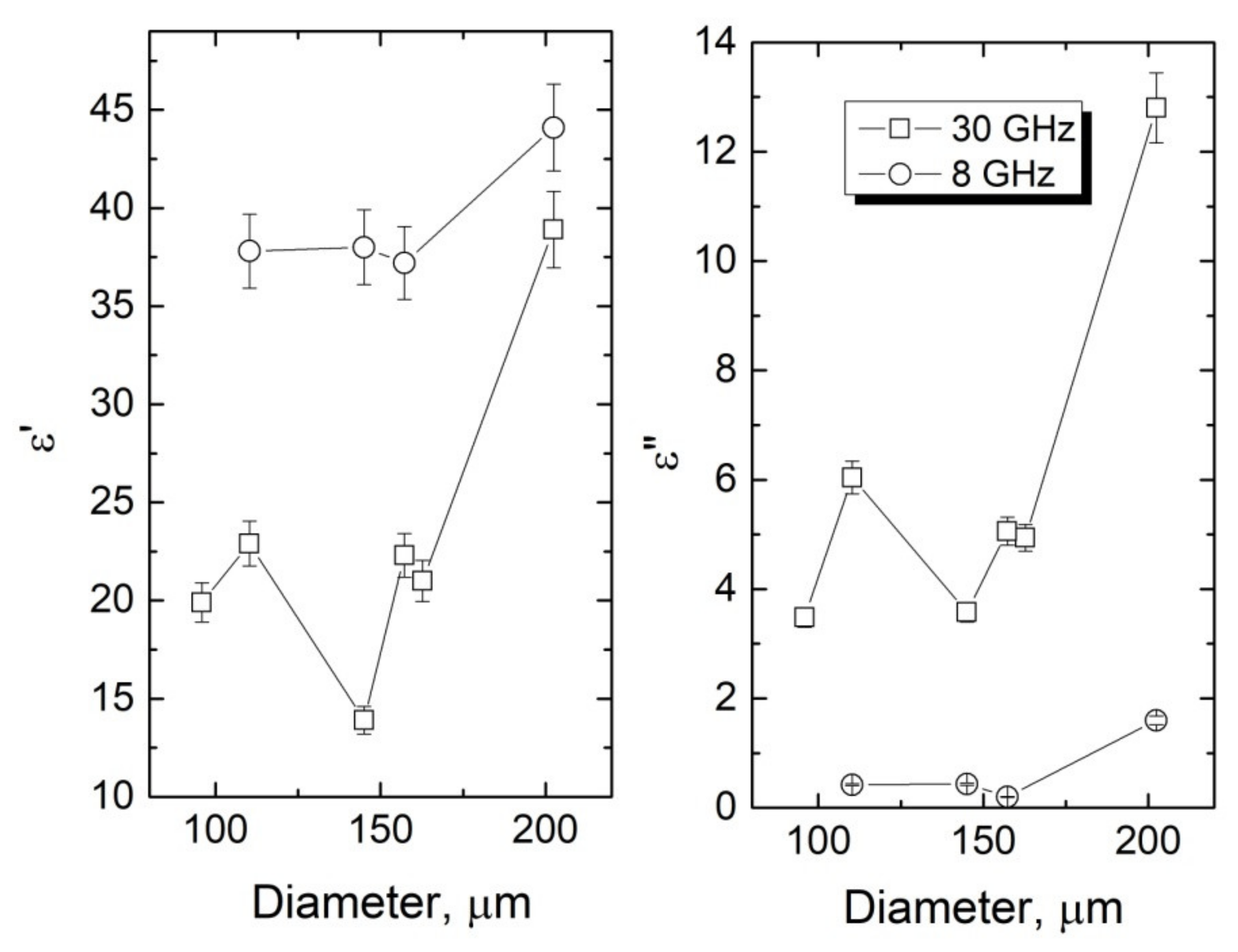

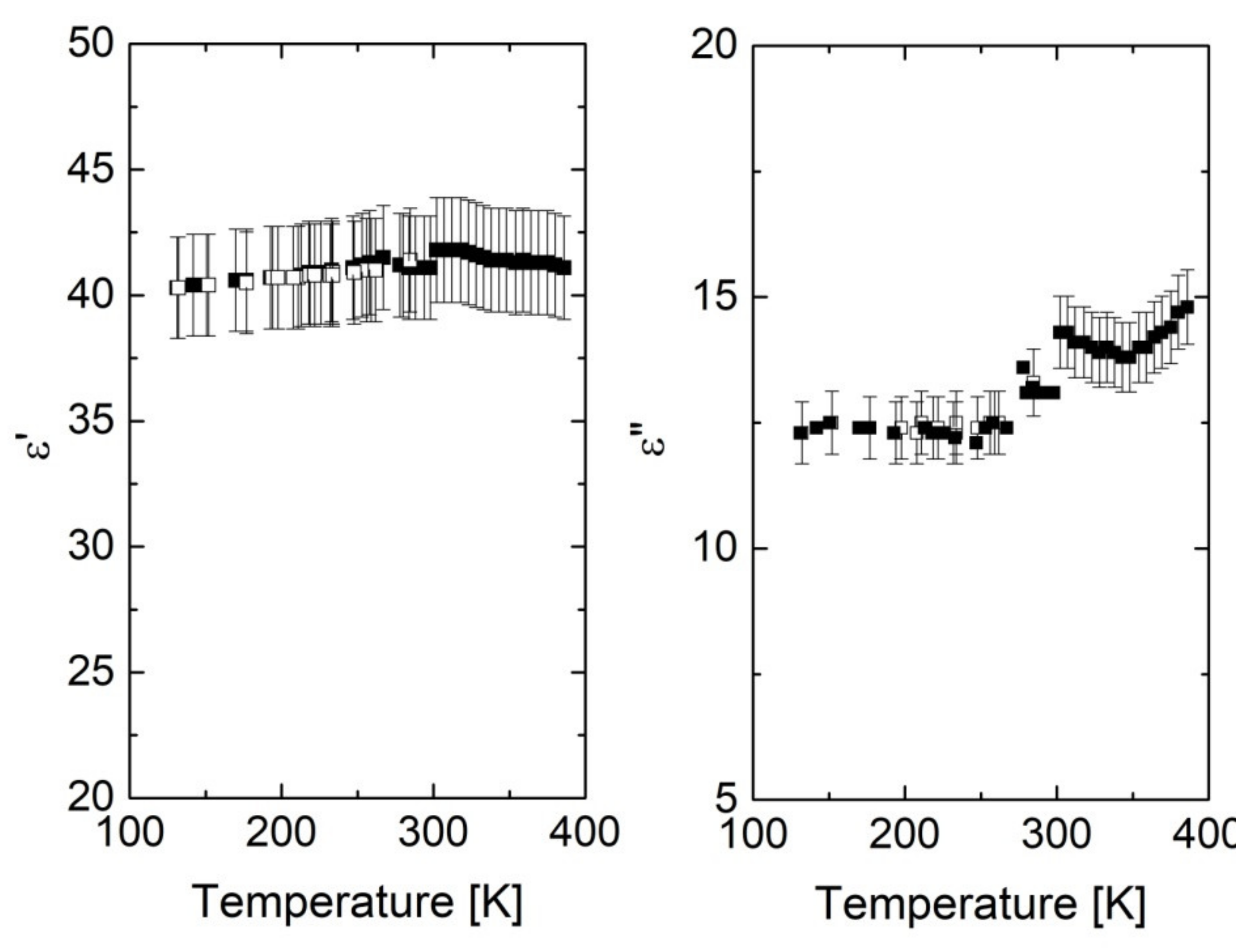

3.2. Dielectric Properties

3.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kruželák, J.; Kvasničáková, A.; Hložeková, K.; Hudec, I. Progress in polymers and polymer composites used as efficient materials for EMI shielding. Nanoscale Adv. 2021, 3, 123–172. [Google Scholar] [CrossRef]

- Hossmann, K.A.; Hermann, D.M. Effects of Electromagnetic Radiation of Mobile Phones on the Central Nervous System. Bioelectromagnetics 2003, 24, 49–62. [Google Scholar] [CrossRef] [PubMed]

- González, M.; Pozuelo, J.; Baselga, J. Electromagnetic Shielding Materials in GHz Range. Chem. Rec. 2018, 18, 1000–1009. [Google Scholar] [CrossRef] [PubMed]

- Wu, N.; Hu, Q.; Wei, R.; Mai, X.; Naik, N.; Pan, D.; Guo, Z.; Shi, Z. Review on the electromagnetic interference shielding properties of carbon based materials and their novel composites: Recent progress, challenges and prospects. Carbon N. Y. 2021, 176, 88–105. [Google Scholar] [CrossRef]

- Kallumottakkal, M.; Hussein, M.I.; Iqbal, M.Z. Recent Progress of 2D Nanomaterials for Application on Microwave Absorption: A Comprehensive Study. Front. Mater. 2021, 8, 1–19. [Google Scholar] [CrossRef]

- Chen, Y.; Li, J.; Li, T.; Zhang, L.; Meng, F. Recent advances in graphene-based films for electromagnetic interference shielding: Review and future prospects. Carbon N. Y. 2021, 180, 163–184. [Google Scholar] [CrossRef]

- Gupta, S.; Tai, N.H. Carbon materials and their composites for electromagnetic interference shielding effectiveness in X-band. Carbon N. Y. 2019, 152, 159–187. [Google Scholar] [CrossRef]

- Gohardani, O.; Elola, M.C.; Elizetxea, C. Potential and prospective implementation of carbon nanotubes on next generation aircraft and space vehicles: A review of current and expected applications in aerospace sciences. Prog. Aerosp. Sci. 2014, 70, 42–68. [Google Scholar] [CrossRef]

- Grigas, J. Microwave Dielectric Spectroscopy of Ferroelectrics. Ferroelectrics 2009, 380, 37–41. [Google Scholar] [CrossRef]

- Letellier, M.; Macutkevic, J.; Kuzhir, P.; Banys, J.; Fierro, V.; Celzard, A. Electromagnetic properties of model vitreous carbon foams. Carbon N. Y. 2017, 122, 217–227. [Google Scholar] [CrossRef]

- Manna, R.; Srivastava, S.K. Reduced Graphene Oxide/Fe3O4/Polyaniline Ternary Composites as a Superior Microwave Absorber in the Shielding of Electromagnetic Pollution. ACS Omega 2021, 6, 9164–9175. [Google Scholar] [CrossRef]

- Kaushal, A.; Singh, V. Analysis of mechanical, thermal, electrical and EMI shielding properties of graphite/carbon fiber reinforced polypropylene composites prepared via a twin screw extruder. J. Appl. Polym. Sci. 2022, 139, 1–10. [Google Scholar] [CrossRef]

- Choi, W.H.; Choe, H.S.; Nam, Y.W. Space hypervelocity impact-shielding and microwave absorbing composite composed of cobalt-coated aramid fibers. Compos. Struct. 2021, 266, 113875. [Google Scholar] [CrossRef]

- Kumar, R.; Sahoo, S.; Joanni, E.; Singh, R.K.; Tan, W.K.; Kar, K.K.; Matsuda, A. Recent progress on carbon-based composite materials for microwave electromagnetic interference shielding. Carbon N. Y. 2021, 177, 304–331. [Google Scholar] [CrossRef]

- Khan, S.u.D.; Arora, M.; Wahab, M.A.; Saini, P. Permittivity and Electromagnetic Interference Shielding Investigations of Activated Charcoal Loaded Acrylic Coating Compositions. J. Polym. 2014, 2014, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Abbasi, H.; Antunes, M.; Velasco, J.I. Recent advances in carbon-based polymer nanocomposites for electromagnetic interference shielding. Prog. Mater. Sci. 2019, 103, 319–373. [Google Scholar] [CrossRef]

- Han, J.H.; Zhang, H.; Chen, M.J.; Wang, D.; Liu, Q.; Wu, Q.L.; Zhang, Z. The combination of carbon nanotube buckypaper and insulating adhesive for lightning strike protection of the carbon fiber/epoxy laminates. Carbon N. Y. 2015, 94, 101–113. [Google Scholar] [CrossRef]

- Li, H.; Tuo, X.; Guo, B.; Yu, J. Comparison of Three Interfacial Conductive Networks Formed in Carbon Black-Filled PA6/PBT Blends. Polymers 2021, 13, 2926. [Google Scholar] [CrossRef]

- Pardoen, T.; Bailly, C.; Thomassin, J.; Je, C.; Huynen, I.; Detrembleur, C. Polymer/carbon based composites as electromagnetic interference (EMI) shielding materials. Mater. Sci. Eng. R Rep. 2013, 74, 211–232. [Google Scholar] [CrossRef]

- Baughman, R.H.; Zakhidov, A.A.; de Heer, W. Carbon nanotubes--the route toward applications. Science 2002, 297, 787–792. [Google Scholar] [CrossRef] [Green Version]

- Fu, K.; Ye, L.; Chang, L.; Yang, C.; Zhang, Z. Modelling of lightning strike damage to CFRP composites with an advanced protection system. Part I: Thermal—electrical transition. Compos. Struct. 2017, 165, 83–90. [Google Scholar] [CrossRef]

- Zhang, X.; Li, D.; Liu, K.; Tong, J.; Yi, X. Flexible graphene-coated carbon fiber veil/polydimethylsiloxane mats as electrothermal materials with rapid responsiveness. Int. J. Ligtweight Mater. Manuf. 2019, 2, 241–249. [Google Scholar] [CrossRef]

- Yin, C.; Dong, J.; Li, Z.; Zhang, Z.; Zhang, Q. Composites: Part B Large-scale fabrication of polyimide fibers containing functionalized multiwalled carbon nanotubes via wet spinning. Compos. Part B 2014, 58, 430–437. [Google Scholar] [CrossRef]

- Latko-Durałek, P.; Durałek, P.; Boczkowska, A.; Kozera, R.; Wróblewska, M.; Mazik, A. Characterization of thermoplastic nonwovens of copolyamide hot melt adhesives filled with carbon nanotubes produced by melt-blowing method. J. Ind. Text. 2020. [Google Scholar] [CrossRef]

- Yao, X.; Hawkins, S.C.; Falzon, B.G. An advanced anti-icing/de-icing system utilizing highly aligned carbon nanotube webs. Carbon N. Y. 2018, 136, 130–138. [Google Scholar] [CrossRef] [Green Version]

- Abdalla, M.; Dean, D.; Theodore, M.; Fielding, J.; Nyairo, E.; Price, G. Magnetically processed carbon nanotube/epoxy nanocomposites: Morphology, thermal, and mechanical properties. Polymer 2010, 51, 1614–1620. [Google Scholar] [CrossRef]

- Raza, A.; Faizan, M.; Sultana, I.; Mustafa, G.M.; Atiq, S.; Bashir, A.; Naveed-Ul-Haq, M.; Razaq, A. Morphology and Dielectric Studies of Natural Fibers and PbO2 Based Flexible Composite Sheets for Potential Energy Storage Applications. J. Electron. Mater. 2020, 49, 1896–1903. [Google Scholar] [CrossRef]

- Chae, H.G.; Sreekumar, T.V.; Uchida, T.; Kumar, S. A comparison of reinforcement efficiency of various types of carbon nanotubes in polyacrylonitrile fiber. Polymer 2005, 46, 10925–10935. [Google Scholar] [CrossRef]

- Latko-Durałek, P.; Kozera, R.; Macutkevič, J.; Dydek, K.; Boczkowska, A. Relationship between Viscosity, Microstructure and Electrical Conductivity in Copolyamide Hot Melt Adhesives Containing Carbon Nanotubes. Materials 2020, 13, 4469. [Google Scholar] [CrossRef] [PubMed]

- Abbasi, S.; Carreau, P.J.; Derdouri, A. Flow induced orientation of multiwalled carbon nanotubes in polycarbonate nanocomposites: Rheology, conductivity and mechanical properties. Polymer 2010, 51, 922–935. [Google Scholar] [CrossRef] [Green Version]

- Pötschke, P.; Brünig, H.; Janke, A.; Fischer, D.; Jehnichen, D. Orientation of multiwalled carbon nanotubes in composites with polycarbonate by melt spinning. Polymer 2005, 46, 10355–10363. [Google Scholar] [CrossRef]

- Madsen, F.B.; Yu, L.; Daugaard, A.E.; Hvilsted, S.; Skov, A.L. Silicone elastomers with high dielectric permittivity and high dielectric breakdown strength based on dipolar copolymers. Polymer 2014, 55, 6212–6219. [Google Scholar] [CrossRef]

- Latko-durałek, P.; Mcnally, T.; Macutkevic, J.; Kay, C.; Boczkowska, A. Hot-melt adhesives based on co-polyamide and multiwalled carbon nanotubes. J. Appl. Polym. Sci. 2017, 1, 1–15. [Google Scholar] [CrossRef]

- Gopalan, A.I.; Marquis, F.D.S.; Min, B.G.; Chae, H.G.; Minus, M.L.; Kumar, S. Polymer/carbon nanotube composite fibers—An overview. In Functional Composites of Carbon Nanotubes and Applications; Lee, K.P., Gopalan, A.I., Marquis, F.D.S., Eds.; Transworld Research Network: Kerala, India, 2009; pp. 43–73. ISBN 9788178954134. [Google Scholar]

- McCall, D.W.; Anderson, E.W. Dielectric properties of linear polyamides. J. Chem. Phys. 1960, 32, 237–241. [Google Scholar] [CrossRef]

- Baji, A.; Mai, Y.W.; Wong, S.C. Effect of fiber diameter on the deformation behavior of self-assembled carbon nanotube reinforced electrospun Polyamide 6,6 fibers. Mater. Sci. Eng. A 2011, 528, 6565–6572. [Google Scholar] [CrossRef]

- Mahfuz, H.; Adnan, A.; Rangari, V.K.; Hasan, M.M.; Jeelani, S.; Wright, W.J.; Deteresa, S.J. Enhancement of strength and stiffness of Nylon 6 filaments through carbon nanotubes reinforcement. Appl. Phys. Lett. 2006, 88, 88–90. [Google Scholar] [CrossRef]

- Song, K.; Zhang, Y.; Meng, J.; Green, E.; Tajaddod, N.; Li, H.; Minus, M. Structural Polymer-Based Carbon Nanotube Composite Fibers: Understanding the Processing–Structure–Performance Relationship. Materials 2013, 6, 2543–2577. [Google Scholar] [CrossRef] [Green Version]

- Dydek, K.; Latko-Durałek, P.; Boczkowska, A.; Sałaciński, M.; Kozera, R. Carbon Fiber Reinforced Polymers modified with thermoplastic nonwovens containing multi-walled carbon nanotubes. Compos. Sci. Technol. 2019, 173, 110–117. [Google Scholar] [CrossRef]

- Latko-Durałek, P.; Dydek, K.; Bolimowski, P.; Golonko, E.; Durałek, P.; Kozera, R.; Boczkowska, A. Nonwoven fabrics with carbon nanotubes used as interleaves in CFRP. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Milano, Italy, 17–19 September 2018. [Google Scholar]

- Wagner, H.D.; Lourie, O.; Feldman, Y.; Tenne, R. Stress-induced fragmentation of multiwall carbon nanotubes in a polymer matrix. Appl. Phys. Lett. 1998, 72, 188–190. [Google Scholar] [CrossRef]

- So, H.H.; Cho, J.W.; Sahoo, N.G. Effect of carbon nanotubes on mechanical and electrical properties of polyimide/carbon nanotubes nanocomposites. Eur. Polym. J. 2007, 43, 3750–3756. [Google Scholar] [CrossRef]

- Wang, L.; Qiu, J.; Sakai, E.; Wei, X. The relationship between microstructure and mechanical properties of carbon nanotubes/polylactic acid nanocomposites prepared by twin-screw extrusion. Compos. Part A Appl. Sci. Manuf. 2016, 89, 18–25. [Google Scholar] [CrossRef]

- Sa, V.; Kornev, K.G. A method for wet spinning of alginate fibers with a high concentration of single-walled carbon nanotubes. Carbon N. Y. 2011, 49, 1859–1868. [Google Scholar] [CrossRef]

- Weng, B.; Xu, F.; Salinas, A.; Lozano, K. Mass production of carbon nanotube reinforced poly(methyl methacrylate) nonwoven nanofiber mats. Carbon N. Y. 2014, 75, 217–226. [Google Scholar] [CrossRef]

| Trade Name | Designation | Melting Range (°C) | Melt Viscosity (Pa⋅s) | Melt Volume Rate (cm3/10 min) 160 °C/2.16 kg |

|---|---|---|---|---|

| Griltex®1330A | coPA_A | 125–135 | 1200 | 9 |

| Griltex®2A | coPA_B | 120–130 | 600 | 18 |

| Griltex®1566 | coPA_C | 115–125 | 150 | 70 |

| Nanocomposite Fibers | Extrusion Temperature (°C) | Screw Velocity (rpm) | Winding Reel Velocity (rpm) | Average Diameter (µm) |

|---|---|---|---|---|

| coPA_A | 160 | 20 | 300 | 92.6 ± 9.5 |

| coPA_A + 7 wt% MWCNTs | 195 | 30 | 300 | 98.7 ± 19.1 |

| coPA_B | 145 | 20 | 300 | 71.5 ± 5.3 |

| coPA_B + 7 wt% MWCNTs | 195 | 30 | 260 | 157 ± 26.7 |

| coPA_C | 160 | 20 | 305 | 96.3 ± 8.5 |

| coPA_C + 7 wt% MWCNTs | 200 | 30 | 305 | 110 ± 14.9 |

| Polymer Matrix | Neat Fiber | With 7 wt% MWCNTs |

|---|---|---|

| coPA_A |  |  |

| coPA_B |  |  |

| coPA_C |  |  |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Latko-Durałek, P.; Bertasius, P.; Macutkevic, J.; Banys, J.; Boczkowska, A. Fibers of Thermoplastic Copolyamides with Carbon Nanotubes for Electromagnetic Shielding Applications. Materials 2021, 14, 5699. https://doi.org/10.3390/ma14195699

Latko-Durałek P, Bertasius P, Macutkevic J, Banys J, Boczkowska A. Fibers of Thermoplastic Copolyamides with Carbon Nanotubes for Electromagnetic Shielding Applications. Materials. 2021; 14(19):5699. https://doi.org/10.3390/ma14195699

Chicago/Turabian StyleLatko-Durałek, Paulina, Povilas Bertasius, Jan Macutkevic, Juras Banys, and Anna Boczkowska. 2021. "Fibers of Thermoplastic Copolyamides with Carbon Nanotubes for Electromagnetic Shielding Applications" Materials 14, no. 19: 5699. https://doi.org/10.3390/ma14195699

APA StyleLatko-Durałek, P., Bertasius, P., Macutkevic, J., Banys, J., & Boczkowska, A. (2021). Fibers of Thermoplastic Copolyamides with Carbon Nanotubes for Electromagnetic Shielding Applications. Materials, 14(19), 5699. https://doi.org/10.3390/ma14195699