Effect of Deformation Parameters on Recrystallization Behavior and Long-Period Stacking-Ordered Phase of Mg-9Gd-4Y-2Zn-0.5Zr Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Microstructure Analysis of Alloy before Deformation

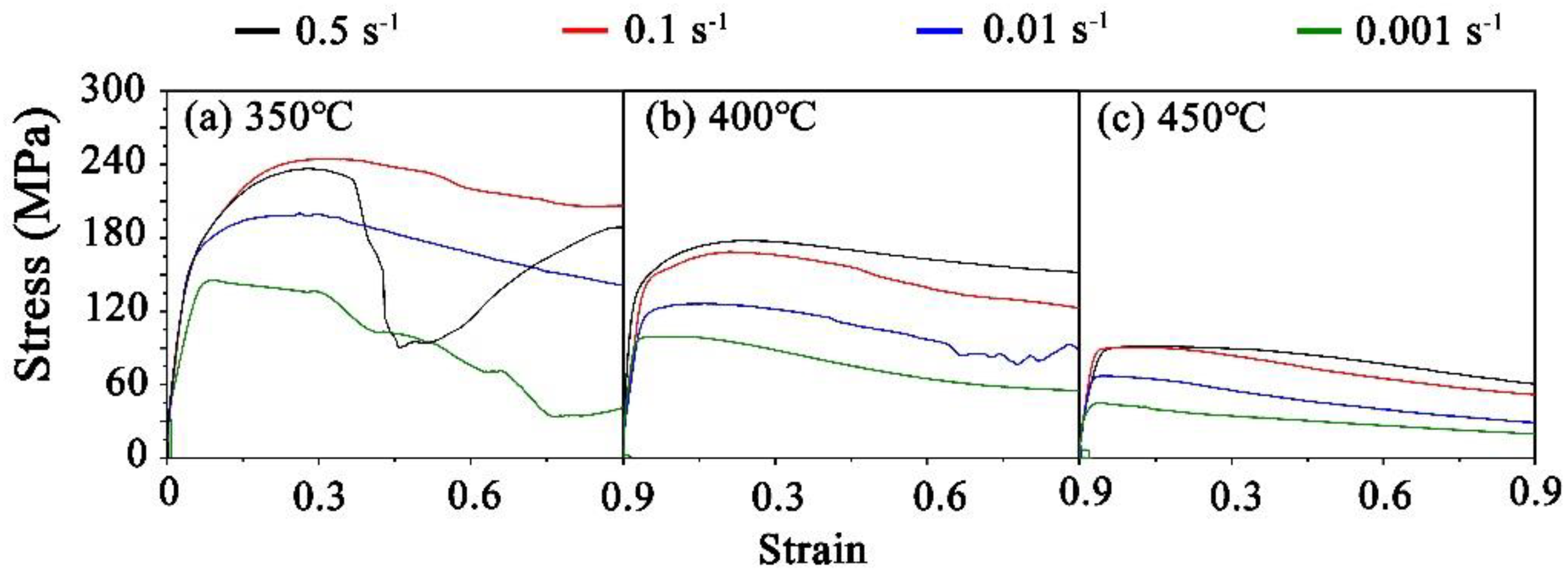

3.2. Stress–Strain Curve Analysis

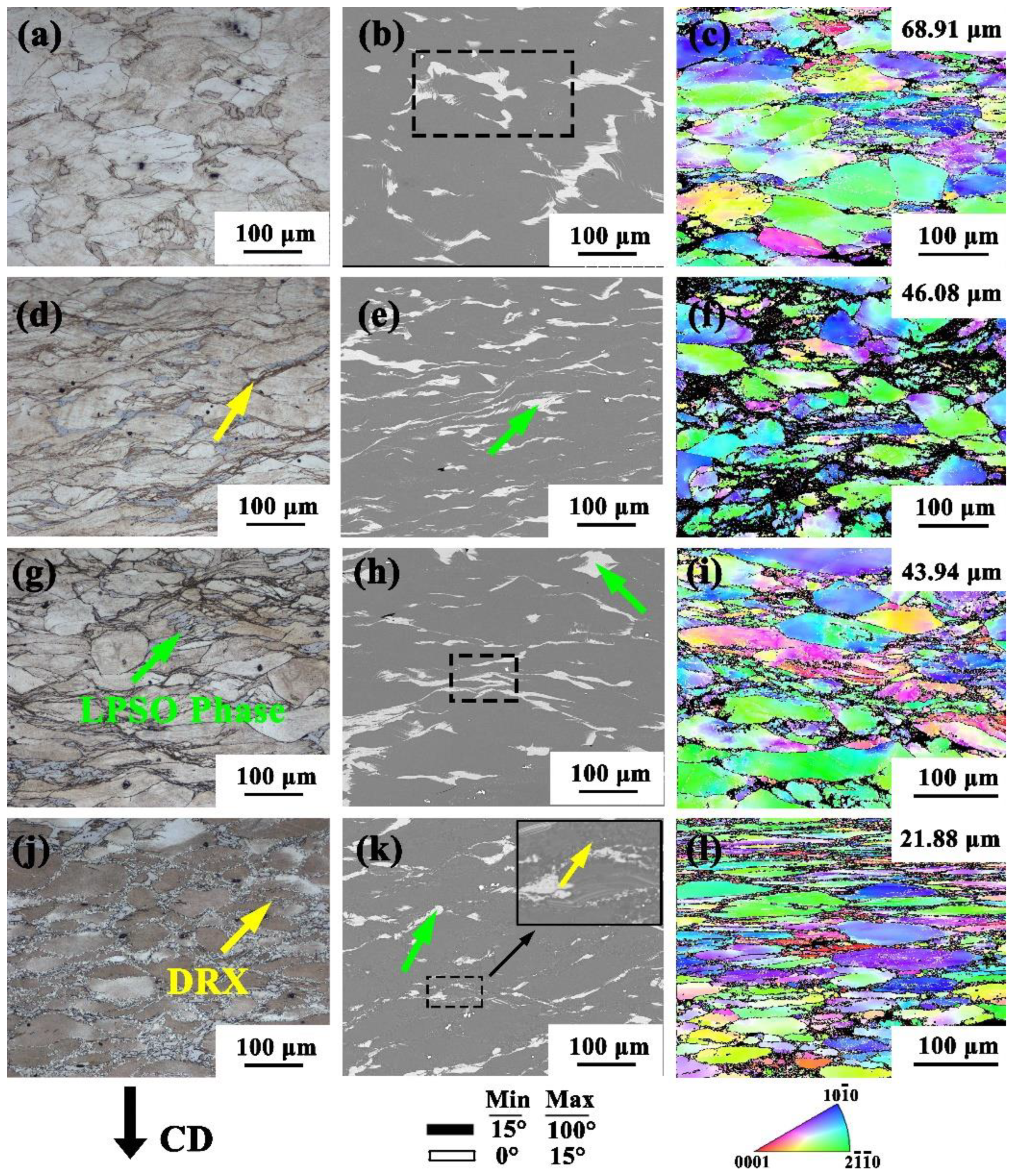

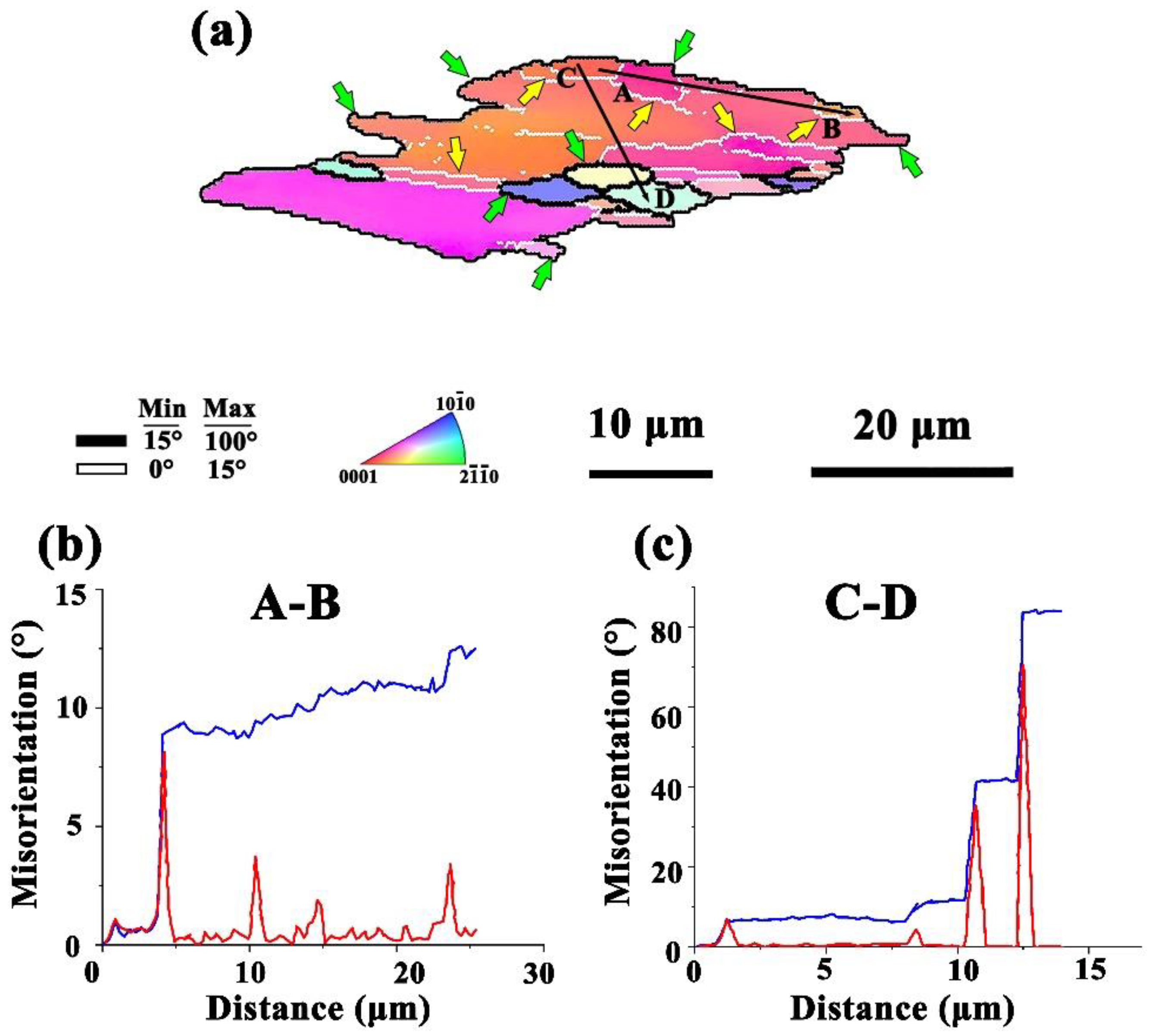

3.3. Microstructure Changes at Different Strain Rates

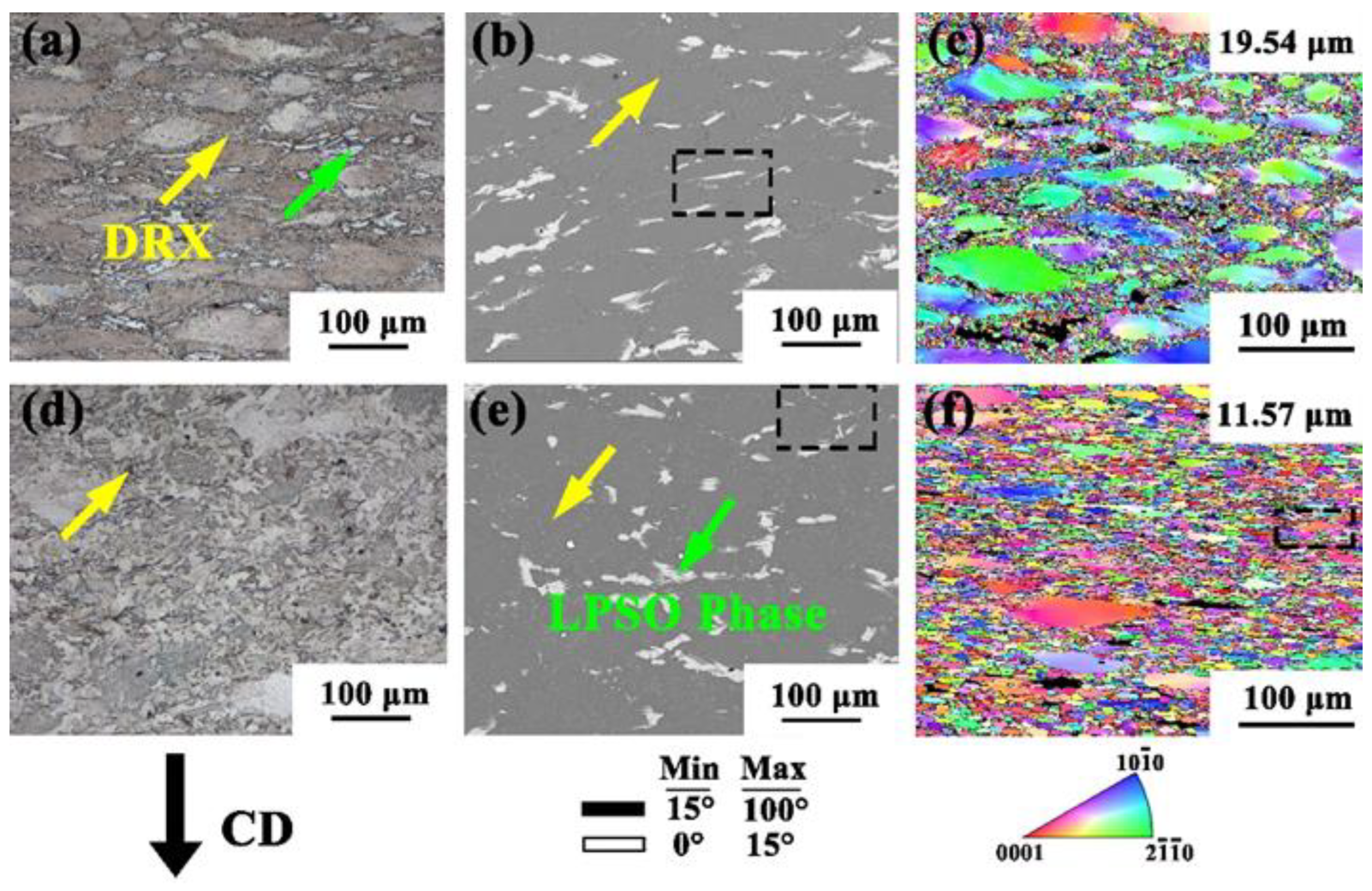

3.4. Microstructure Changes at Different Deformation Temperatures

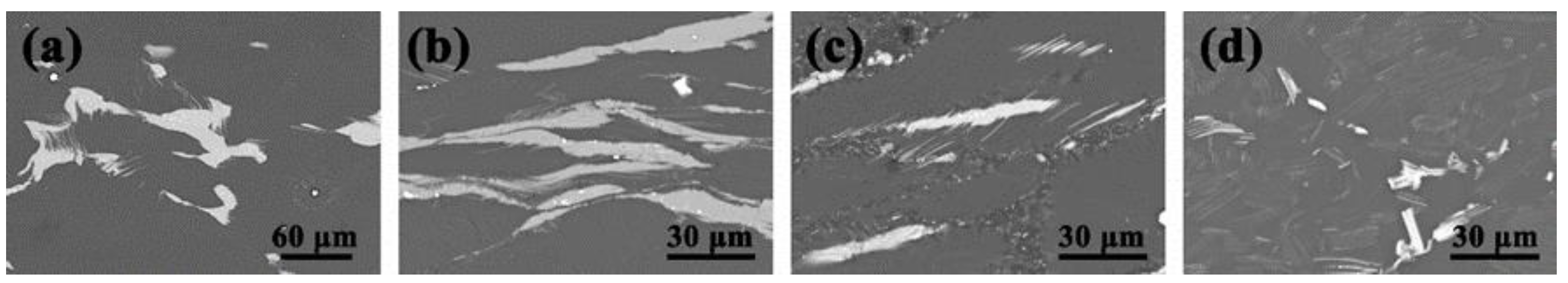

3.5. The Evolution of the LPSO Phase

4. Discussion

5. Conclusions

- With the increase in deformation temperature and the decrease in strain rate, the degree of recrystallization gradually increased, so the degree of recrystallization was largest at 450 °C/0.001 s−1 in the experimental range.

- The changes in the deformation conditions during compression resulted in precipitation, dissolution and kinking of the LPSO phase. At 350 °C/0.5 s−1, the LPSO phase presented a dendritic morphology similar to that of the as-cast state. At 350/0.01 s−1, the twist and breakage of the LPSO phase were generated. At 450 °C/0.001 s−1, the LPSO phase was broken into small pieces.

- The CDRX and DDRX mechanisms were the dominant deformation behaviors during the thermal compression, which contributed to texture weakening and grain refinement.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Che, X.; Wang, Q.; Dong, B.; Meng, M.; Gao, Z.; Liu, K.; Ma, J.; Yang, F.; Zhang, Z. The evolution of microstructure and texture of AZ80 Mg alloy cup-shaped pieces processed by rotating backward extrusion. J. Magnes. Alloy. 2021, 9, 1677–1691. [Google Scholar] [CrossRef]

- Li, J.; Dong, S.; Zhao, C.; Zeng, J.; Jin, L.; Wang, F.; Wang, F.; Dong, J. Multi-directional Forging of Large-Scale Mg-9Gd-3Y-2Zn-0.5 Zr Alloy Guided By 3D Processing Maps and Finite Element Analysis. Res. Sq. 2021, 826–832. [Google Scholar] [CrossRef]

- Hoseini-Athar, M.M.; Mahmudi, R.; Babu, R.P.; Hedström, P. Effect of Zn addition on dynamic recrystallization behavior of Mg-2Gd alloy during high-temperature deformation. J. Alloys Compd. 2019, 806, 1200–1206. [Google Scholar] [CrossRef]

- Xue, Z.; Luo, W.; Zhao, Z.; Ren, Y. Thermal compression, processing maps and microstructural evolution of as-cast Mg-Gd-Y-Zn-Zr alloy with long period stacking ordered phase. Mater. Res. Express 2020, 7, 056512. [Google Scholar] [CrossRef]

- Somekawa, H.; Yamasaki, M.; Kawamura, Y.; Inoue, T. Wrought-procedure memory in caliber rolled Mg-Y-Zn alloy containing LPSO phase. Mater. Charact. 2021, 175, 111080. [Google Scholar] [CrossRef]

- Xin, T.; Zhao, Y.; Mahjoub, R.; Jiang, J.; Yadav, A.; Nomoto, K.; Niu, R.; Tang, S.; Ji, F.; Quadir, Z.; et al. Ultrahigh specific strength in a magnesium alloy strengthened by spinodal decomposition. Sci. Adv. 2021, 7, 23–30. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, S.; Jiang, B.; Jin, Z.; Zhao, L.; He, J.; Zhang, D.; Huang, G.; Pan, F. Grain size dependence of annealing strengthening of an extruded Mg-Gd-Zn alloy subjected to pre-compression deformation. J. Magnes. Alloy. 2021, 18, 53. [Google Scholar] [CrossRef]

- Wang, G.; Xiao, Z.; Yang, Z.; Liu, P. The evolution of LPSO phase and its influence on grain size during cooling free forging. Mater. Res. Express 2021, 8, 076508. [Google Scholar] [CrossRef]

- Somekawa, H.; Nakasuji, Y.; Yuasa, M.; Miyamoto, H.; Yamasaki, M.; Kawamura, Y. Hot compression deformation behavior of Mg–Y–Zn alloys containing LPSO phase—ScienceDirect. Mater. Sci. Eng. A 2020, 792, 139777. [Google Scholar] [CrossRef]

- Li, B.B.; Shi, G.L.; Zhang, K.; Wang, K.K.; Li, X.G.; Li, Y.J.; Ma, M.L.; Yuan, J.W. Hot deformation behavior and processing map of Mg-12Gd-1MM-0.6Zr magnesium alloy. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 770, p. 012097. [Google Scholar]

- Chongliang, L.; Gaofeng, Q.; Mingyang, Z.; Yangyang, G.; Lingling, F. Constitutive Behavior and Processing Map of As-cast Mg-8Y-6Gd-1Nd-0.17Zn Magnesium Alloy Compressed at Elevated Temperatures. Rare Met. Mater. Eng. 2020, 49, 2591–2598. [Google Scholar]

- Zheng, J.; Chen, Z.; Yan, Z.; Zhang, Z.; Wang, Q.; Xue, Y. Preparation of ultra-high strength Mg-Gd-Y-Zn-Zr alloy by pre-ageing treatment prior to extrusion. J. Alloys Compd. 2021, 894, 162490. [Google Scholar] [CrossRef]

- Li, K.; Chen, Z.; Chen, T.; Shao, J.; Wang, R.; Liu, C. Hot deformation and dynamic recrystallization behaviors of Mg-Gd-Zn alloy with LPSO phases. J. Alloys Compd. 2019, 792, 894–906. [Google Scholar] [CrossRef]

- Prakash, P.; Toscano, D.; Shaha, S.K.; Wells, M.A.; Jahed, H.; Williams, B.W. Effect of temperature on the hot deformation behavior of AZ80 magnesium alloy. Mater. Sci. Eng. A 2020, 794, 139923. [Google Scholar] [CrossRef]

- Zheng, J.; Yan, Z.; Ji, J.; Shi, Y.; Zhang, H.; Zhang, Z.; Xue, Y. Effect of heat treatment on mechanical properties and microstructure evolution of Mg-9.5Gd-4Y-2.2Zn-0.5Zr alloy. J. Magnes. Alloy. 2021, 21, 27. [Google Scholar] [CrossRef]

- Xia, X.; Zhang, K.; Ma, M.; Li, T. Constitutive modeling of flow behavior and processing maps of Mg–8.1 Gd–4.5Y–0.3Zr alloy. J. Magnes. Alloy. 2020, 8, 917–928. [Google Scholar] [CrossRef]

- Fan, J.; Ma, M.; Zhang, K.; Li, Y.; Li, X.; Shi, G.; Yuan, J. Hot deformation behavior and finite element simulation of Mg–8.3Gd–4.4Y–1.5Zn–0.8Mn alloy. J. Rare Earths 2021, in press. [Google Scholar] [CrossRef]

- Zhang, G.; Meng, Y.; Yan, F.; Gao, Z.; Yan, Z.; Zhang, Z. Microstructure and texture evolution of Mg-RE-Zn alloy prepared by repetitive upsetting-extrusion under different decreasing temperature degrees. J. Alloys Compd. 2019, 815, 152452. [Google Scholar] [CrossRef]

- Wang, X.L.; Wang, Q.; Yang, Y.B.; Zhang, Z.M.; Zhang, L. Processing map and microstructure of as-cast AZ80 + 0.4%Ce magnesium alloy. J. Plast. Eng. 2017, 24, 174–179. [Google Scholar]

- Wang, Y.; Chen, W.; Huang, S.; Hu, C.; Wu, Y.; Xia, X. Hot Deformation Behavior and Microstructure Evolution of Rare Earth Magnesium Alloy. J. Netshape Form. Eng. 2020, 12, 123–129. [Google Scholar]

- Lu, R.; Xu, Z.; Jiang, F.; Xu, S.; Fu, D.; Zhang, H.; Teng, J. Revealing the grain size dependent hot workability and deformation mechanisms in a Mg-Zn-Y alloy. J. Magnes. Alloy. 2021, 14, 3. [Google Scholar] [CrossRef]

- Niu, Y.; Hou, J.; Ning, F.; Chen, X.; Jia, Y.; Le, Q. Hot deformation behavior and processing map of Mg-2Zn-1Al-0.2RE alloy. J. Rare Earths 2020, 38, 665–675. [Google Scholar] [CrossRef]

- Xu, W.; Yu, J.; Jia, L.; Wu, G.; Zhang, Z. Deformation behavior of Mg-13Gd-4Y-2Zn-0.5Zr alloy on the basis of LPSO kinking, dynamic recrystallization and twinning during compression-torsion. Mater. Charact. 2021, 178, 111215. [Google Scholar] [CrossRef]

- Liu, H.; Ju, J.; Bai, J.; Sun, J.; Song, D.; Yan, J.; Jiang, J.; Ma, A. Preparation, Microstructure Evolutions, and Mechanical Property of an Ultra-Fine Grained Mg-10Gd-4Y-1.5Zn-0.5Zr Alloy. Metals 2017, 7, 398. [Google Scholar] [CrossRef] [Green Version]

- Yan, L.; Zhang, Z.; Li, G.; Xue, Y.; Xu, J. Evolution of the microstructure, texture and mechanical properties of ZK60 alloy during processing by rotating shear extrusion. J. Alloys Compd. 2021, 877, 160229. [Google Scholar] [CrossRef]

- Meng, Y.; Yu, J.; Zhang, G.; Wu, Y.; Zhang, Z.; Shi, Z. Effect of circumferential strain rate on dynamic recrystallization and texture of Mg-13Gd-4Y-2Zn-0.5Zr alloy during rotary backward extrusion. J. Magnes. Alloy. 2020, 8, 1228–1237. [Google Scholar] [CrossRef]

- Dong, B.; Che, X.; Wang, Q.; Meng, M.; Gao, Z.; Ma, J.; Yang, F.; Zhang, Z. Refining the microstructure and modifying the texture of the AZ80 alloy cylindrical tube by the rotating backward extrusion with different rotating revolutions. J. Alloys Compd. 2020, 836, 155442. [Google Scholar] [CrossRef]

- Yan, Z.; Li, X.; Zheng, J.; Zhang, Z.; Wang, Q.; Xu, K.; Fan, H.; Zhang, G.; Zhu, J.; Xue, Y. Microstructure evolution, texture and mechanical properties of a Mg–Gd–Y–Zn–Zr alloy fabricated by cyclic expansion extrusion with an asymmetrical extrusion cavity: The influence of passes and processing route. J. Magnes. Alloy. 2021, 9, 964–982. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, R.; Zheng, J.; Yan, Z.; Jia, L.; Jia, J.; Liu, L.; Zhang, Z.; Xue, Y. Effect of Deformation Parameters on Recrystallization Behavior and Long-Period Stacking-Ordered Phase of Mg-9Gd-4Y-2Zn-0.5Zr Alloy. Materials 2022, 15, 1822. https://doi.org/10.3390/ma15051822

Han R, Zheng J, Yan Z, Jia L, Jia J, Liu L, Zhang Z, Xue Y. Effect of Deformation Parameters on Recrystallization Behavior and Long-Period Stacking-Ordered Phase of Mg-9Gd-4Y-2Zn-0.5Zr Alloy. Materials. 2022; 15(5):1822. https://doi.org/10.3390/ma15051822

Chicago/Turabian StyleHan, Rui, Jie Zheng, Zhaoming Yan, Leichen Jia, Jingjing Jia, Liang Liu, Zhimin Zhang, and Yong Xue. 2022. "Effect of Deformation Parameters on Recrystallization Behavior and Long-Period Stacking-Ordered Phase of Mg-9Gd-4Y-2Zn-0.5Zr Alloy" Materials 15, no. 5: 1822. https://doi.org/10.3390/ma15051822

APA StyleHan, R., Zheng, J., Yan, Z., Jia, L., Jia, J., Liu, L., Zhang, Z., & Xue, Y. (2022). Effect of Deformation Parameters on Recrystallization Behavior and Long-Period Stacking-Ordered Phase of Mg-9Gd-4Y-2Zn-0.5Zr Alloy. Materials, 15(5), 1822. https://doi.org/10.3390/ma15051822