Combustion Synthesis of High Density ZrN/ZrSi2 Composite: Influence of ZrO2 Addition on the Microstructure and Mechanical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Procedure

2.3. Characterization

3. Results and Discussion

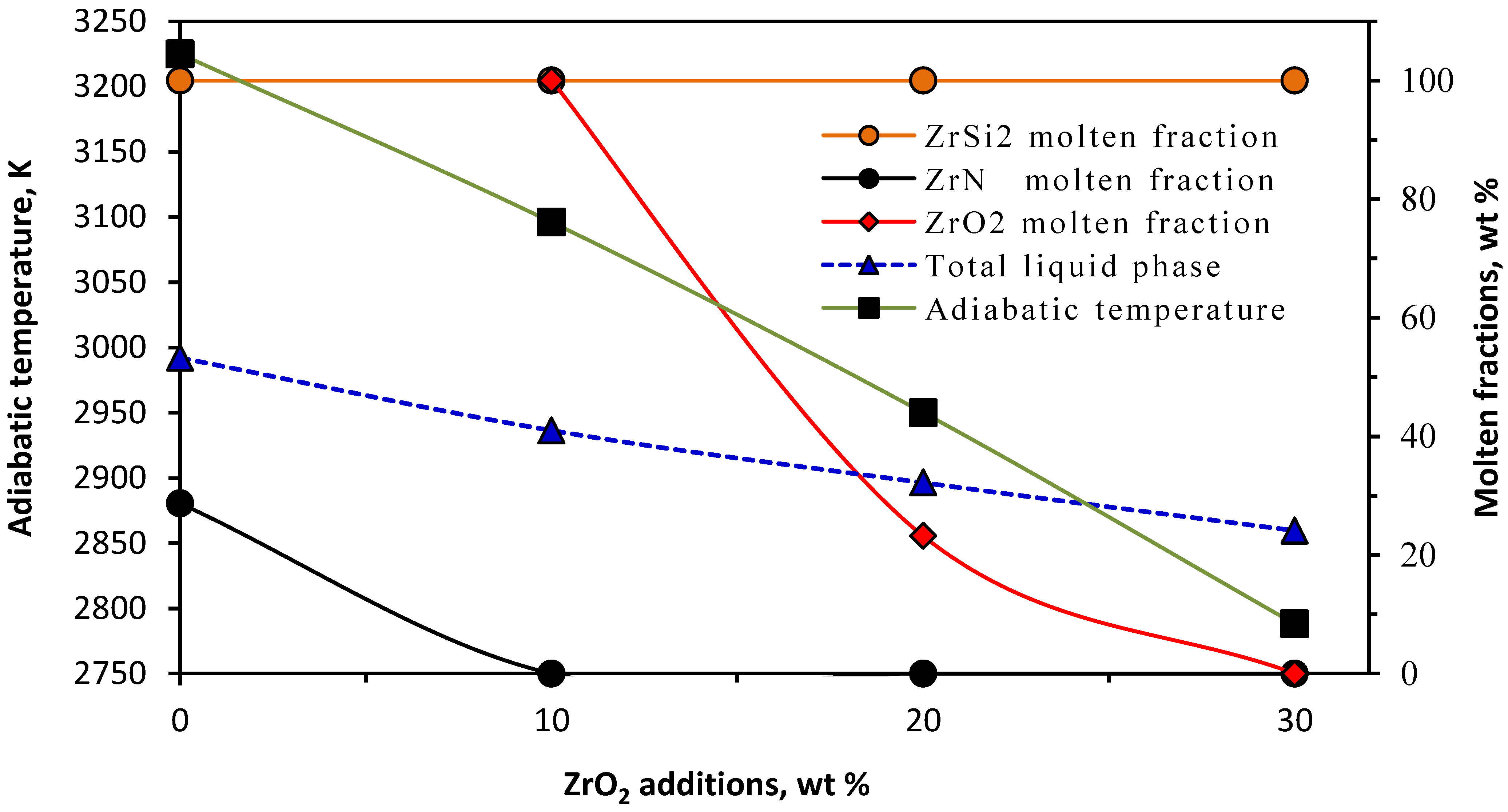

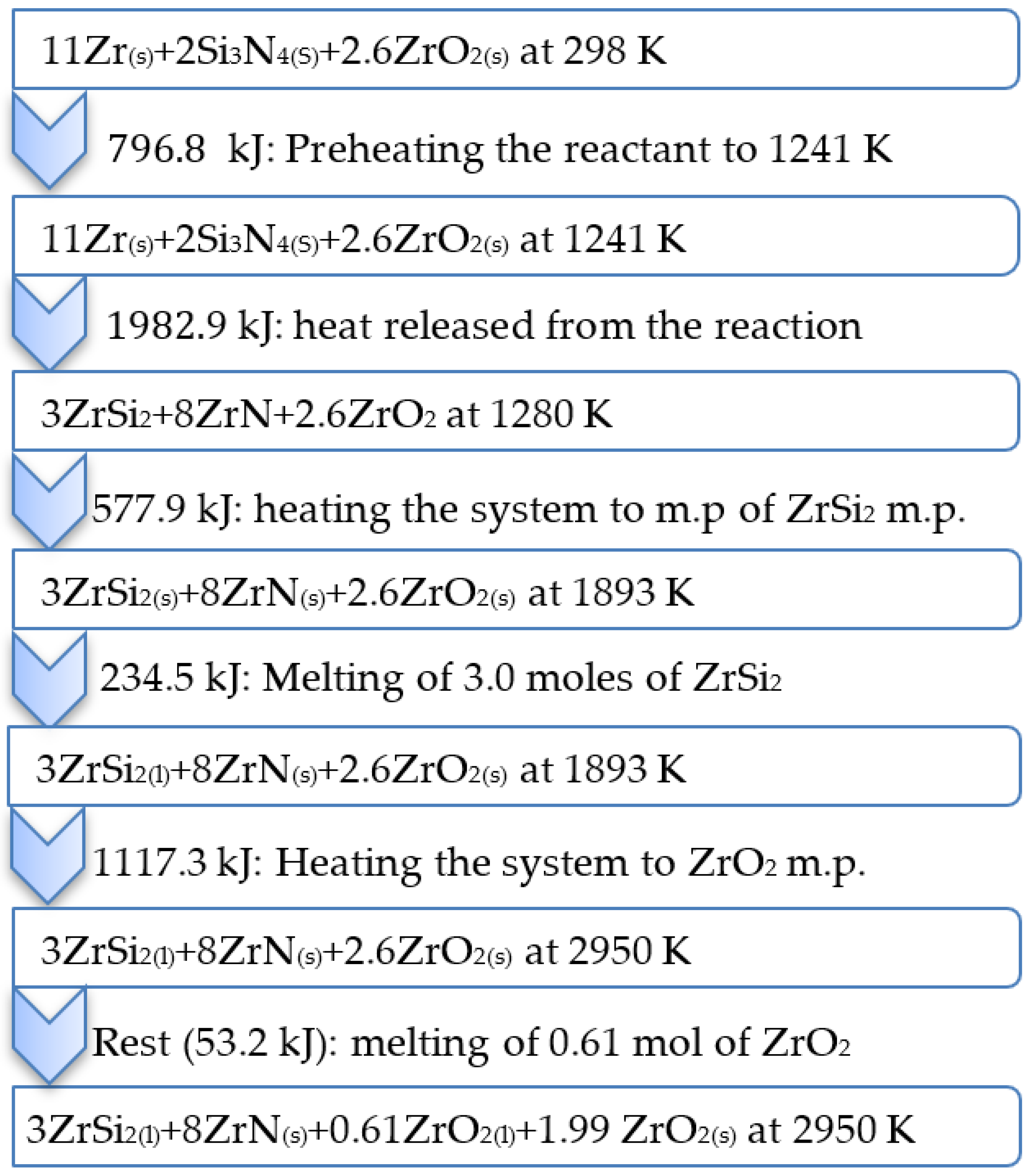

3.1. Thermodynamic Study of the ZrN-ZrSi2 with xZrO2 Additions

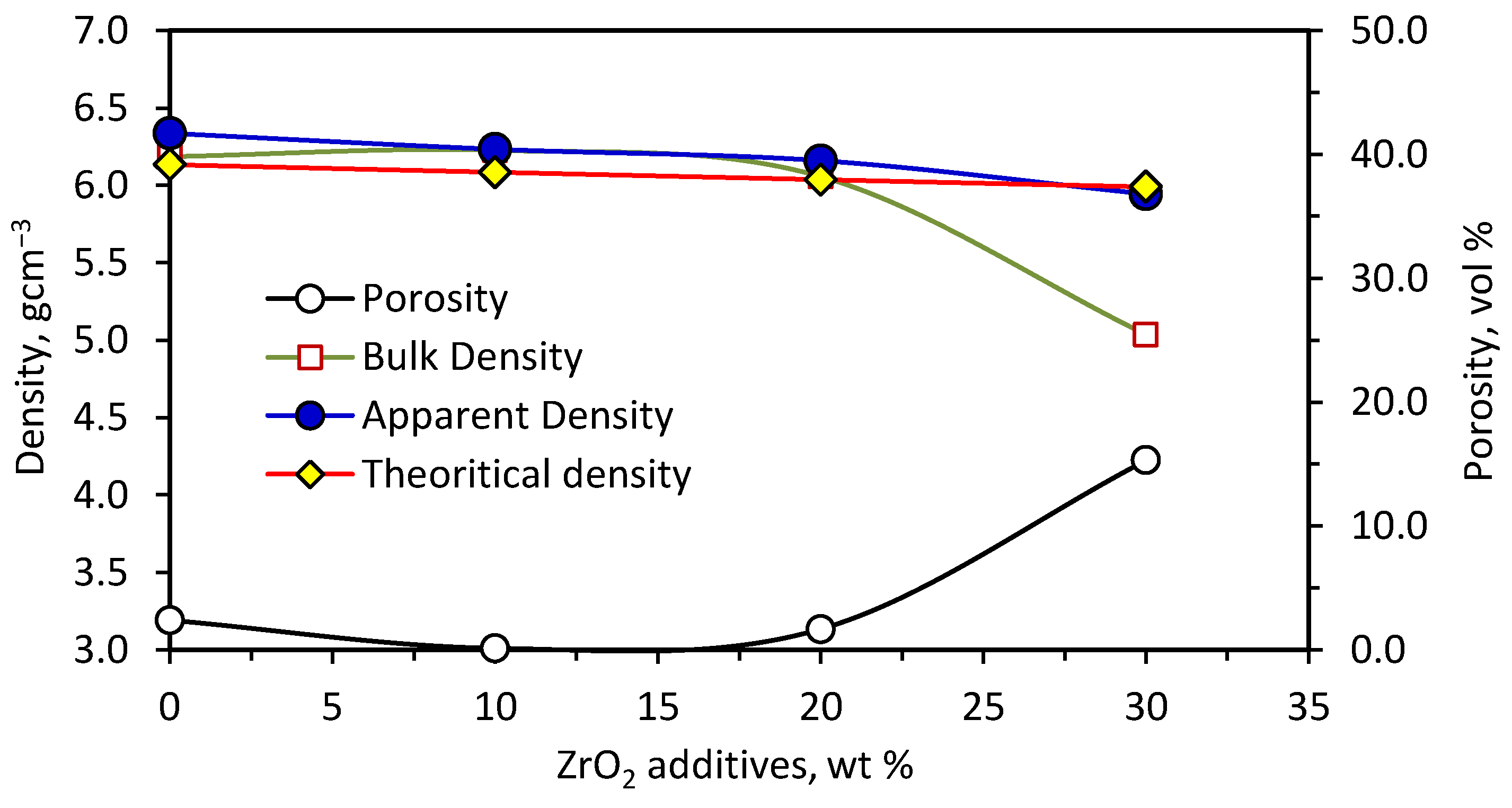

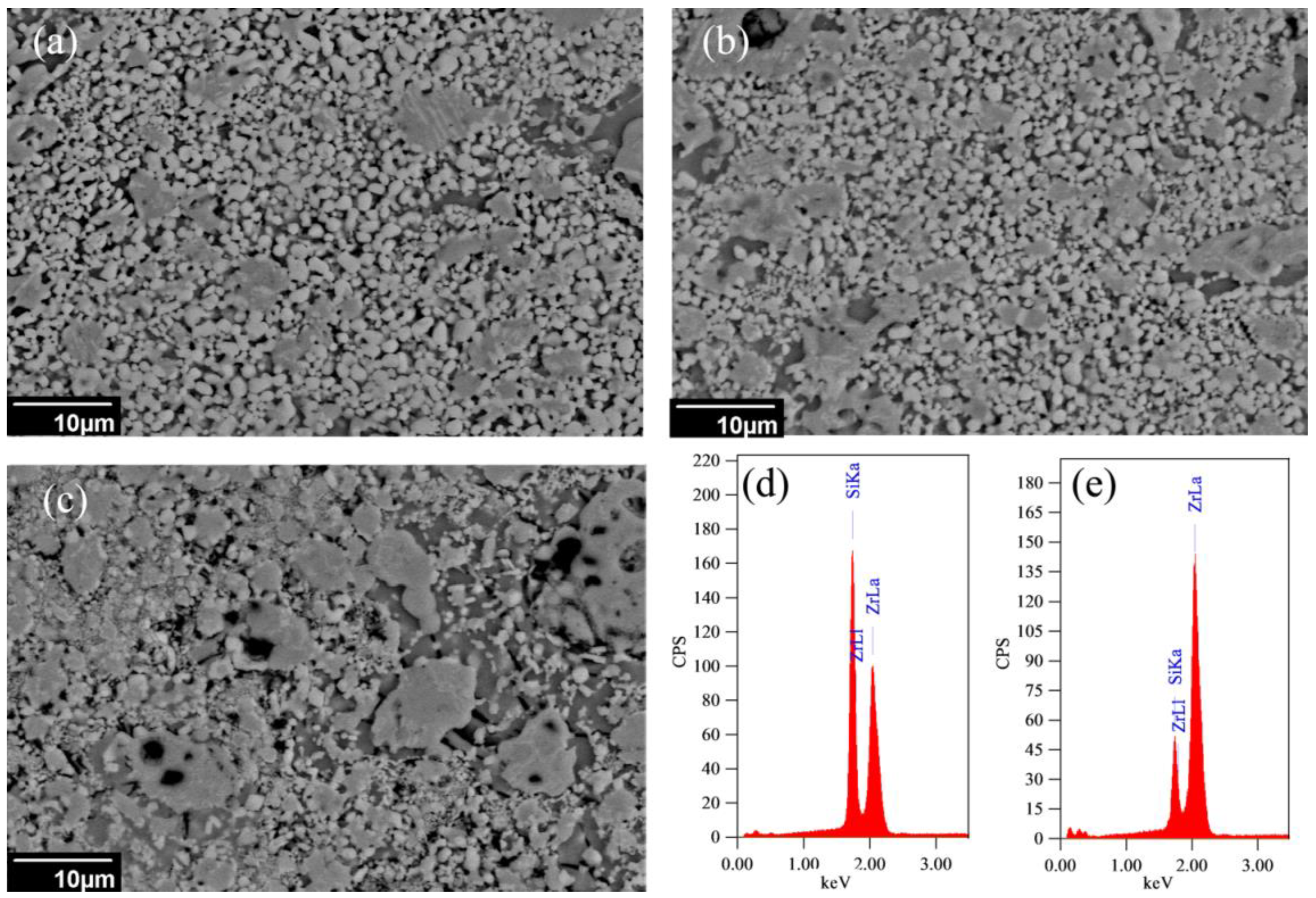

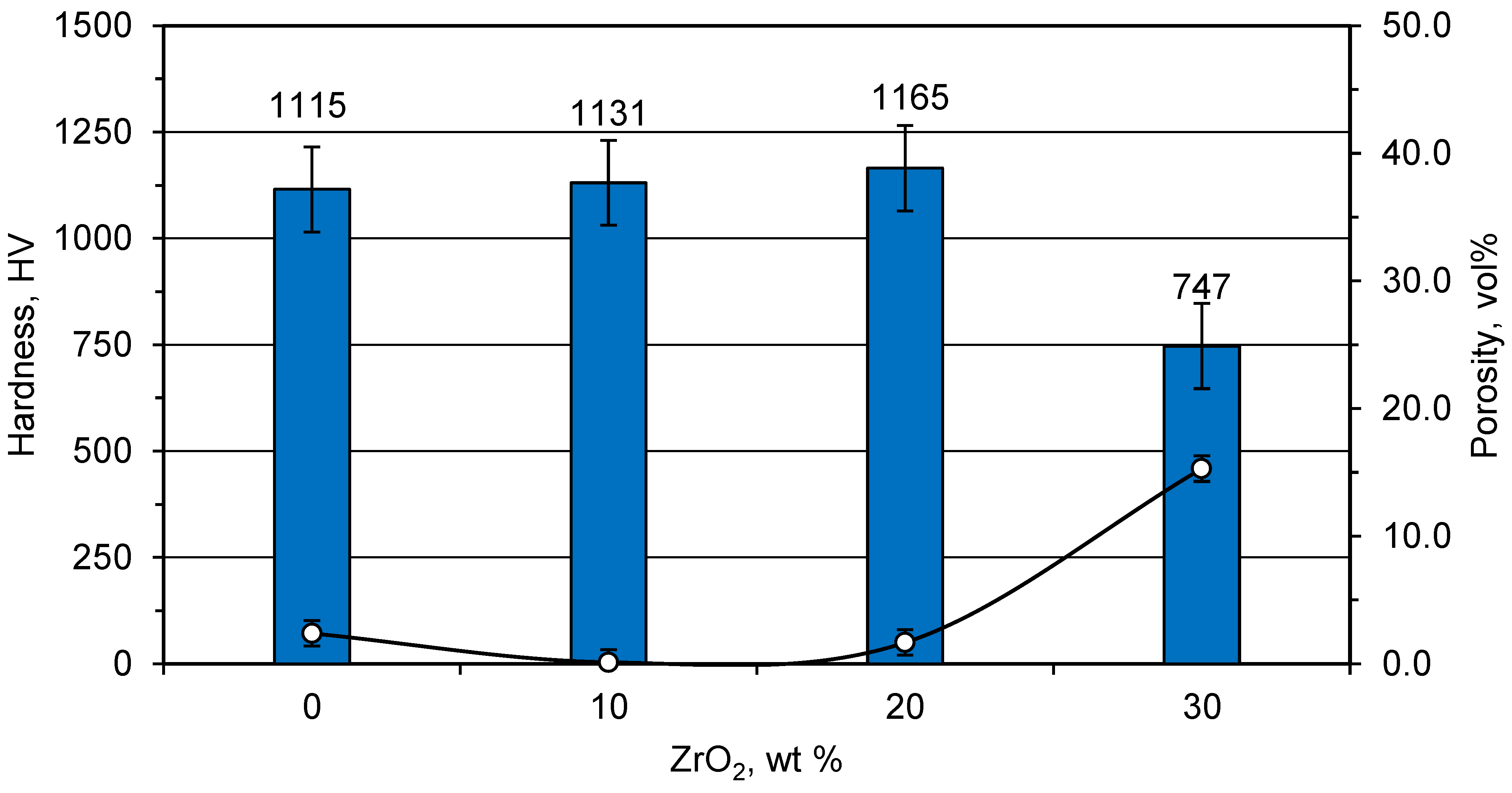

3.2. Effect of ZrO2 Weight Ratios

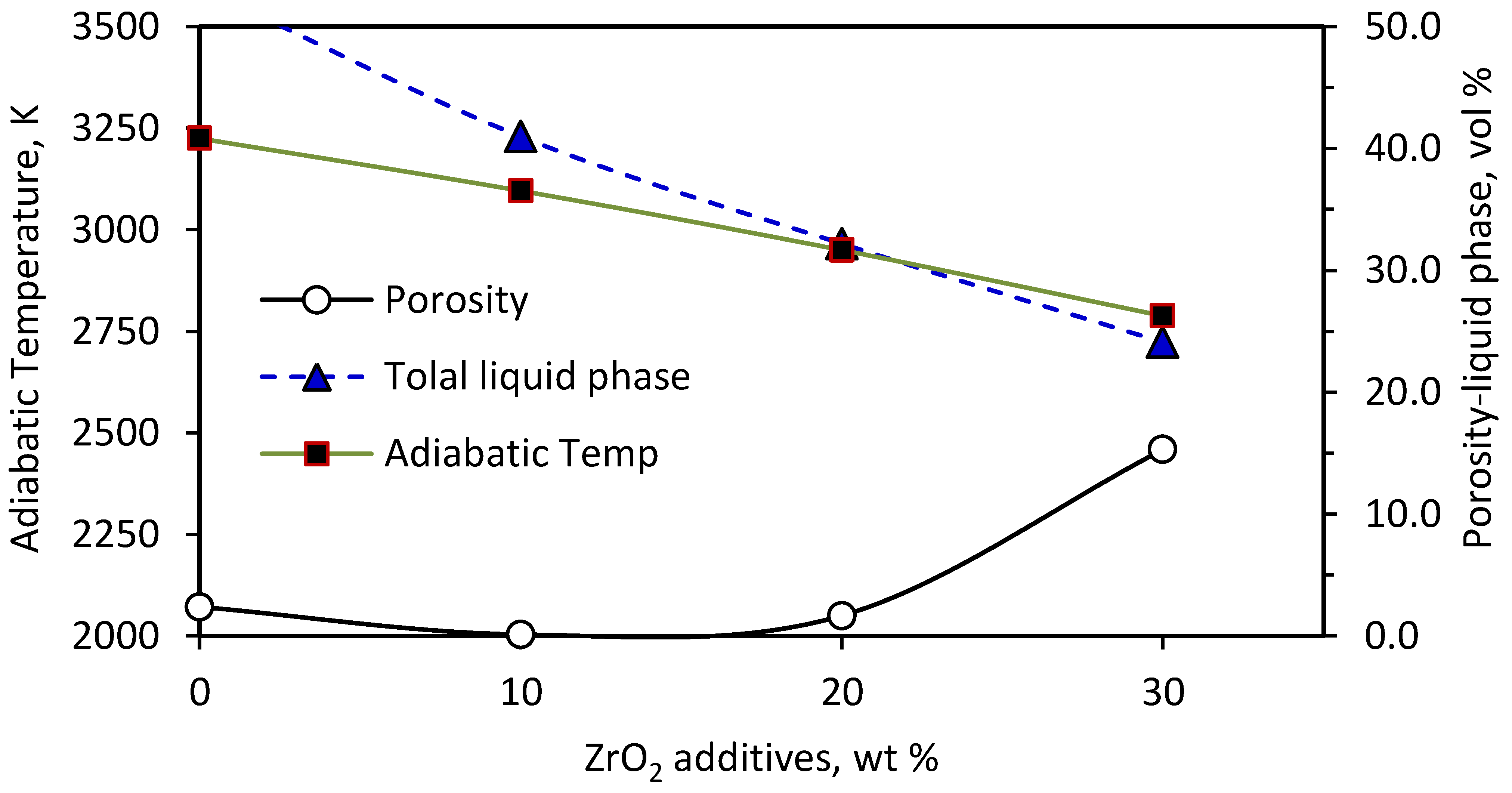

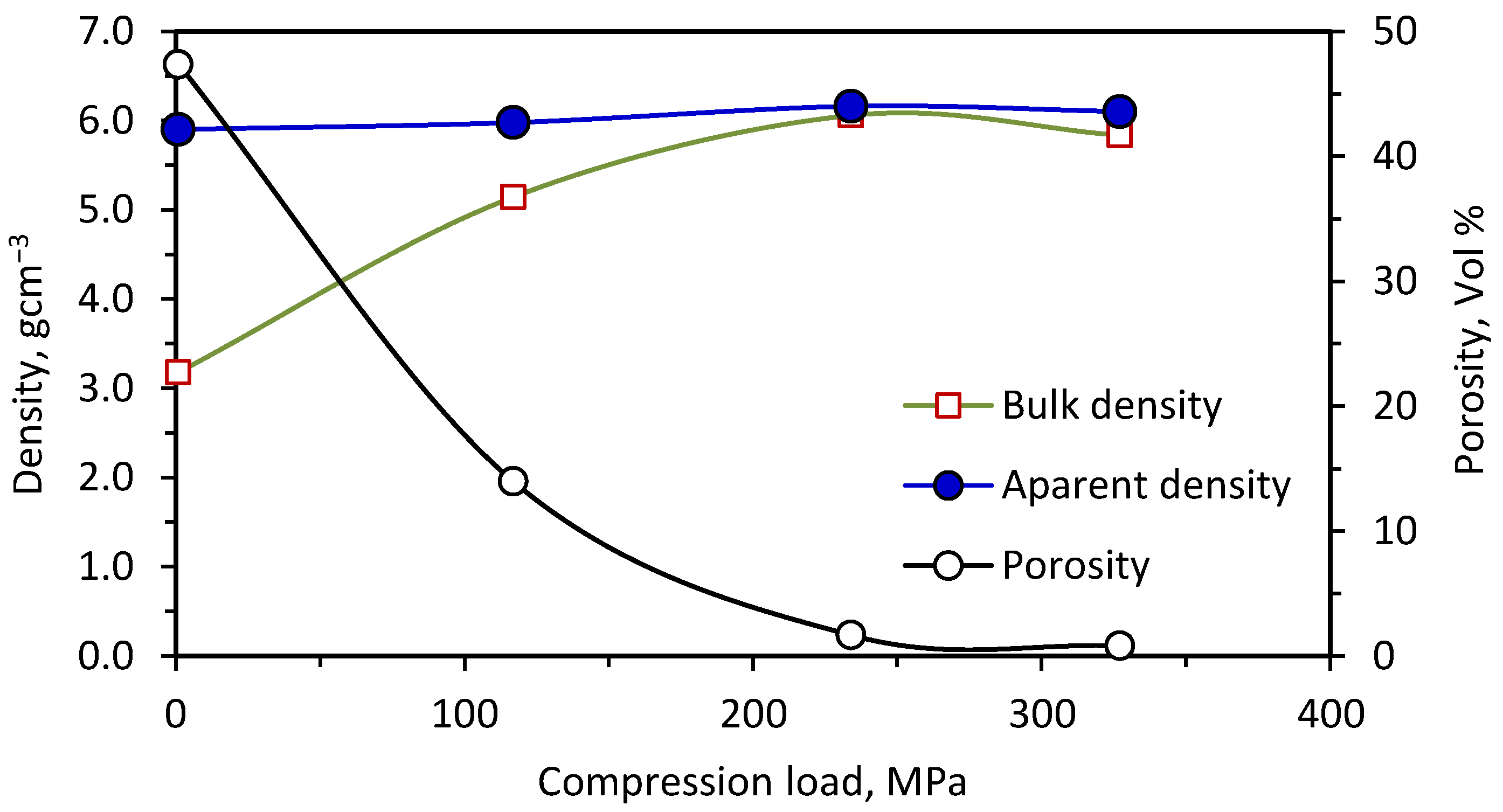

3.3. Effect of Compression Load on ZrN/ZrSi2 Composite Having 20 wt% ZrO2

3.4. Delay Time

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lengauer, W. Nitrides: Transition Metal Solid-State Chemistry. In Encyclopedia of Inorganic and Bioinorganic Chemistry; Scott, R.A., Ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2015; pp. 1–24. [Google Scholar]

- Adachi, J.; Kurosaki, K.; Uno, M.; Yamanaka, S. Porosity influence on the mechanical properties of polycrystalline zirconium nitride ceramics. J. Nucl. Mater. 2006, 358, 106–110. [Google Scholar] [CrossRef]

- Harrison, R.W.; Lee, W.E. Processing and properties of ZrC, ZrN and ZrCN ceramics: A review. Adv. Appl. Ceram. 2016, 115, 294–307. [Google Scholar] [CrossRef] [Green Version]

- Hu, C.; Sakka, Y.; Tanaka, H.; Nishimura, T.; Grasso, S. Synthesis, microstructure and mechanical properties of (Zr,Ti)B2-(Zr,Ti)N composites prepared by spark plasma sintering. J. Alloys Compd. 2010, 494, 266–270. [Google Scholar] [CrossRef]

- Klostermann, H.; Fietzke, F.; Modes, T.; Zywitzki, O. Zr-Al-N nanocomposite coatings deposited by pulse magnetron sputtering. Rev. Adv. Mater. Sci. 2007, 15, 33–37. [Google Scholar]

- Ribbing, C.G.; Roos, A. Zirconium Nitride (ZrN) Hafnium Nitride (HfN). In Handbook of Optical Constants of Solids; Academic Press: Burlington, MA, USA, 1997; pp. 351–369. [Google Scholar]

- Cheng, B.; Zhang, Z.; Wu, X.; Min, X.; Huang, Z.; Tao, T.; Zhao, H.; Fang, M.; Liu, Y.-G. Research on slag-resistance of ZrN-SiAlON-SiC-C composite refractory in different atmospheres. Int. J. Appl. Ceram. Technol. 2019, 16, 69–76. [Google Scholar] [CrossRef] [Green Version]

- Patsalas, P. Zirconium nitride: A viable candidate for photonics and plasmonics? Thin Solid Films 2019, 688, 137438. [Google Scholar] [CrossRef]

- Schwarz, K.; Williams, A.R.; Cuomo, J.J.; Harper, J.H.E.; Hentzell, H.T.G. Zirconium nitride—A new material for Josephson junctions. Phys. Rev. B 1985, 32, 8312–8316. [Google Scholar] [CrossRef]

- Hintermann, H.E. Tribological and protective coatings by chemical vapour deposition. Thin Solid Films 1981, 84, 215–243. [Google Scholar] [CrossRef]

- Li, X.Y.; Li, G.B.; Wang, F.J.; Ma, T.C.; Yang, D.Z.; Zhu, Y.C. Investigation on properties of ceramic coatings of ZrN. Vacuum 1992, 43, 653–656. [Google Scholar] [CrossRef]

- Singh, A.; Kuppusami, P.; Khan, S.; Sudha, C.; Thirumurugesan, R.; Ramaseshan, R.; Divakar, R.; Mohandas, E.; Dash, S. Influence of nitrogen flow rate on microstructural and nanomechanical properties of Zr–N thin films prepared by pulsed DC magnetron sputtering. Appl. Surf. Sci. 2013, 280, 117–123. [Google Scholar] [CrossRef]

- Andersson, K.E.; Veszelei, M.; Roos, A. Zirconium nitride based transparent heat mirror coatings—Preparation and characterisation. Sol. Energy Mater. Sol. Cells 1994, 32, 199–212. [Google Scholar] [CrossRef]

- Streit, M.; Ingold, F.; Pouchon, M.; Gauckler, L.J.; Ottaviani, J.P. Zirconium nitride as inert matrix for fast systems. J. Nucl. Mater. 2003, 319, 51–58. [Google Scholar] [CrossRef]

- Walker, C.T.; Nicolaou, G. Transmutation of neptunium and americium in a fast neutron flux: EPMA results and KORIGEN predictions for the superfact fuels. J. Nucl. Mater. 1995, 218, 129–138. [Google Scholar] [CrossRef]

- Rogozkin, B.D.; Stepennova, N.M.; Proshkin, A.A. Mononitride Fuel for Fast Reactors. At. Energy 2003, 95, 624–636. [Google Scholar] [CrossRef]

- Meyer, M.K.; Fielding, R.; Gan, J. Fuel development for gas-cooled fast reactors. J. Nucl. Mater. 2007, 371, 281–287. [Google Scholar] [CrossRef] [Green Version]

- Chubb, W.; Hilbert, R.F.; Storhok, V.W.; Keller, D.L. Fission gas swelling of refractory nuclear fuels. Mater. Sci. Eng. 1972, 9, 293–300. [Google Scholar] [CrossRef]

- Muta, H.; Kurosaki, K.; Uno, M.; Yamanaka, S. Thermophysical properties of several nitrides prepared by spark plasma sintering. J. Nucl. Mater. 2009, 389, 186–190. [Google Scholar] [CrossRef]

- Ma, B.; Gao, Z.; Su, C.; Ren, X.; Li, G.; Zhu, Q. Recycling of coal ash for production of dense β-Sialon/ZrN/ZrON-based ceramics without sintering aids via pressureless sintering. Int. J. Appl. Ceram. Technol. 2020, 17, 175–183. [Google Scholar] [CrossRef] [Green Version]

- Tsuchida, T.; Kawaguchi, M.; Kodaira, K. Synthesis of ZrC and ZrN in air from mechanically activated ZrC powder mixtures. Solid State Ion. 1997, 101–103, 149–154. [Google Scholar] [CrossRef]

- Tang, Y.; Zhang, G.-J.; Xue, J.-X.; Wang, X.-G.; Xu, C.-M.; Huang, X. Densification and mechanical properties of hot-pressed ZrN ceramics doped with Zr or Ti. J. Eur. Ceram. Soc. 2013, 33, 1363–1371. [Google Scholar] [CrossRef]

- Egorov, F.F.; Matsera, V.E. Densification and structure formation in the sintering of composite materials based on nitrides of the IV–V group transition metals II. Sintering of (ZrN, HfN)’MCr composites. Powder Metall. Met. Ceram. 1998, 37, 593–596. [Google Scholar] [CrossRef]

- Guo, S.-Q.; Kagawa, Y.; Nishimura, T. Mechanical behavior of two-step hot-pressed ZrB2-based composites with ZrSi2. J. Eur. Ceram. Soc. 2009, 29, 787–794. [Google Scholar] [CrossRef]

- Meng, S.; Chen, H.; Hu, J.; Wang, Z. Radiative properties characterization of ZrB2–SiC-based ultrahigh temperature ceramic at high temperature. Mater. Des. 2011, 32, 377–381. [Google Scholar] [CrossRef]

- Wang, M.; Wang, C.-A.; Zhang, X. Effects of SiC platelet and ZrSi2 additive on sintering and mechanical properties of ZrB2-based ceramics by hot-pressing. Mater. Des. 2012, 34, 293–297. [Google Scholar] [CrossRef]

- Zaki, Z.I.; Alotaibi, S.H.; Alhajji, B.A.; Mostafa, N.Y.; Amin, M.A.; Mohsen, Q. ZrN/ZrSi2/Co Cermet by Combustion Synthesis under Pressure: Influence of Co Addition. Int. J. Self-Propag. High-Temp. Synth. 2020, 29, 225–232. [Google Scholar] [CrossRef]

- Shao, G.; Zhao, X.; Wang, H.; Chen, J.; Zhang, R.; Fan, B.; Lu, H.; Xu, H.; Chen, D. ZrB2-ZrSi2-SiC composites prepared by reactive spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2016, 60, 104–107. [Google Scholar] [CrossRef]

- Guo, S.-Q.; Kagawa, Y.; Nishimura, T.; Tanaka, H. Pressureless sintering and physical properties of ZrB2-based composites with ZrSi2 additive. Scr. Mater. 2008, 58, 579–582. [Google Scholar] [CrossRef]

- Grigoriev, O.N.; Galanov, B.A.; Kotenko, V.A.; Ivanov, S.M.; Koroteev, A.V.; Brodnikovsky, N.P. Mechanical properties of ZrB2–SiC(ZrSi2) ceramics. J. Eur. Ceram. Soc. 2010, 30, 2173–2181. [Google Scholar] [CrossRef]

- Grigoriev, O.N.; Galanov, B.A.; Lavrenko, V.A.; Panasyuk, A.D.; Ivanov, S.M.; Koroteev, A.V.; Nickel, K.G. Oxidation of ZrB2–SiC–ZrSi2 ceramics in oxygen. J. Eur. Ceram. Soc. 2010, 30, 2397–2405. [Google Scholar] [CrossRef]

- Ko, I.-Y.; Park, J.-H.; Yoon, J.-K.; Nam, K.-S.; Shon, I.-J. ZrSi2–SiC composite obtained from mechanically activated ZrC+3Si powders by pulsed current activated combustion synthesis. Ceram. Int. 2010, 36, 817–820. [Google Scholar] [CrossRef]

- Adachi, J.; Kurosaki, K.; Uno, M.; Yamanaka, S. Effect of porosity on thermal and electrical properties of polycrystalline bulk ZrN prepared by spark plasma sintering. J. Alloys Compd. 2007, 432, 7–10. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, X.; Shi, J. Additive manufacturing of zirconia ceramics: A state-of-the-art review. J. Mater. Res. Technol. 2020, 9, 9029–9048. [Google Scholar] [CrossRef]

- Yeh, C.L.; Wang, Y.H. Formation of zirconium silicide–Al2O3 composites from PTFE-assisted ZrO2/Si/Al combustion synthesis. Vacuum 2021, 184, 109877. [Google Scholar] [CrossRef]

- Zaki, Z.I.; Al-qahtani, M.; Alotaibi, S.H.; El-Sadek, M.H.; Ahmed, H.; Ahmed, Y.M.Z. Combustion synthesis of NbC/ZrO2 composites: Influence of Cr additives on the microstructure and mechanical properties. Int. J. Appl. Ceram. Technol. 2021, 18, 1502–1509. [Google Scholar] [CrossRef]

- Zaki, Z.I.; Mostafa, N.Y.; Rashad, M.M. High pressure synthesis of magnesium aluminate composites with MoSi2 and Mo5Si3 in a self-sustaining manner. Ceram. Int. 2012, 38, 5231–5237. [Google Scholar] [CrossRef]

- ASTM, C1327-15(2019); Standard Test Method for Vickers Indentation Hardness of Advanced Ceramics. ASTM International: West Conshohocken, PA, USA, 2019. Available online: https://www.astm.org/c1327-15r19.html (accessed on 25 November 2021).

- ASTM, C693-93(2019); Standard Test Method for Density of Glass by Buoyancy. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Mazón, P.; De Aza, P.N. Porous scaffold prepared from α′L-Dicalcium silicate doped with phosphorus for bone grafts. Ceram. Int. 2018, 44, 537–545. [Google Scholar] [CrossRef]

- Jaworska, L.; Cyboron, J.; Cygan, S.; Zwolinski, A.; Onderka, B.; Skrzekut, T. Zirconium Phase Transformation under Static High Pressure and ω-Zr Phase Stability at High Temperatures. Materials 2019, 12, 2244. [Google Scholar] [CrossRef] [Green Version]

- Sriraman, K.R.; Ganesh Sundara Raman, S.; Seshadri, S.K. Influence of crystallite size on the hardness and fatigue life of steel samples coated with electrodeposited nanocrystalline Ni–W alloys. Mater. Lett. 2007, 61, 715–718. [Google Scholar] [CrossRef]

| Phases | Crystallite Size, nm | |||

|---|---|---|---|---|

| 0% ZrO2 | 10% ZrO2 | 20% ZrO2 | 30% ZrO2 | |

| ZrN | 21.0 | 26.1 | 20.8 | 23.8 |

| ZrSi2 | 24.7 | 22.4 | 22.2 | 22.4 |

| ZrO2 | --- | 248.6 | 247.3 | 245.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaki, Z.I.; Alotaibi, S.H.; Alhejji, B.A.; Mostafa, N.Y.; Amin, M.A.; Qhatani, M.M. Combustion Synthesis of High Density ZrN/ZrSi2 Composite: Influence of ZrO2 Addition on the Microstructure and Mechanical Properties. Materials 2022, 15, 1698. https://doi.org/10.3390/ma15051698

Zaki ZI, Alotaibi SH, Alhejji BA, Mostafa NY, Amin MA, Qhatani MM. Combustion Synthesis of High Density ZrN/ZrSi2 Composite: Influence of ZrO2 Addition on the Microstructure and Mechanical Properties. Materials. 2022; 15(5):1698. https://doi.org/10.3390/ma15051698

Chicago/Turabian StyleZaki, Zaki I., Saad H. Alotaibi, Bashayer A. Alhejji, Naser Y. Mostafa, Mohammed A. Amin, and Mohsen M. Qhatani. 2022. "Combustion Synthesis of High Density ZrN/ZrSi2 Composite: Influence of ZrO2 Addition on the Microstructure and Mechanical Properties" Materials 15, no. 5: 1698. https://doi.org/10.3390/ma15051698

APA StyleZaki, Z. I., Alotaibi, S. H., Alhejji, B. A., Mostafa, N. Y., Amin, M. A., & Qhatani, M. M. (2022). Combustion Synthesis of High Density ZrN/ZrSi2 Composite: Influence of ZrO2 Addition on the Microstructure and Mechanical Properties. Materials, 15(5), 1698. https://doi.org/10.3390/ma15051698