Face Mask Wastes as Cementitious Materials: A Possible Solution to a Big Concern

Abstract

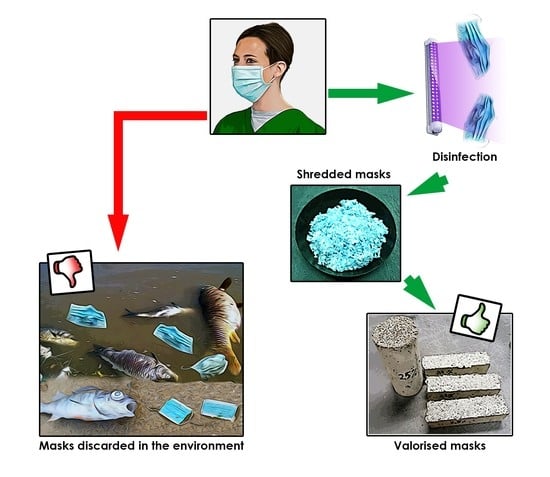

:1. Introduction

2. Materials and Methods

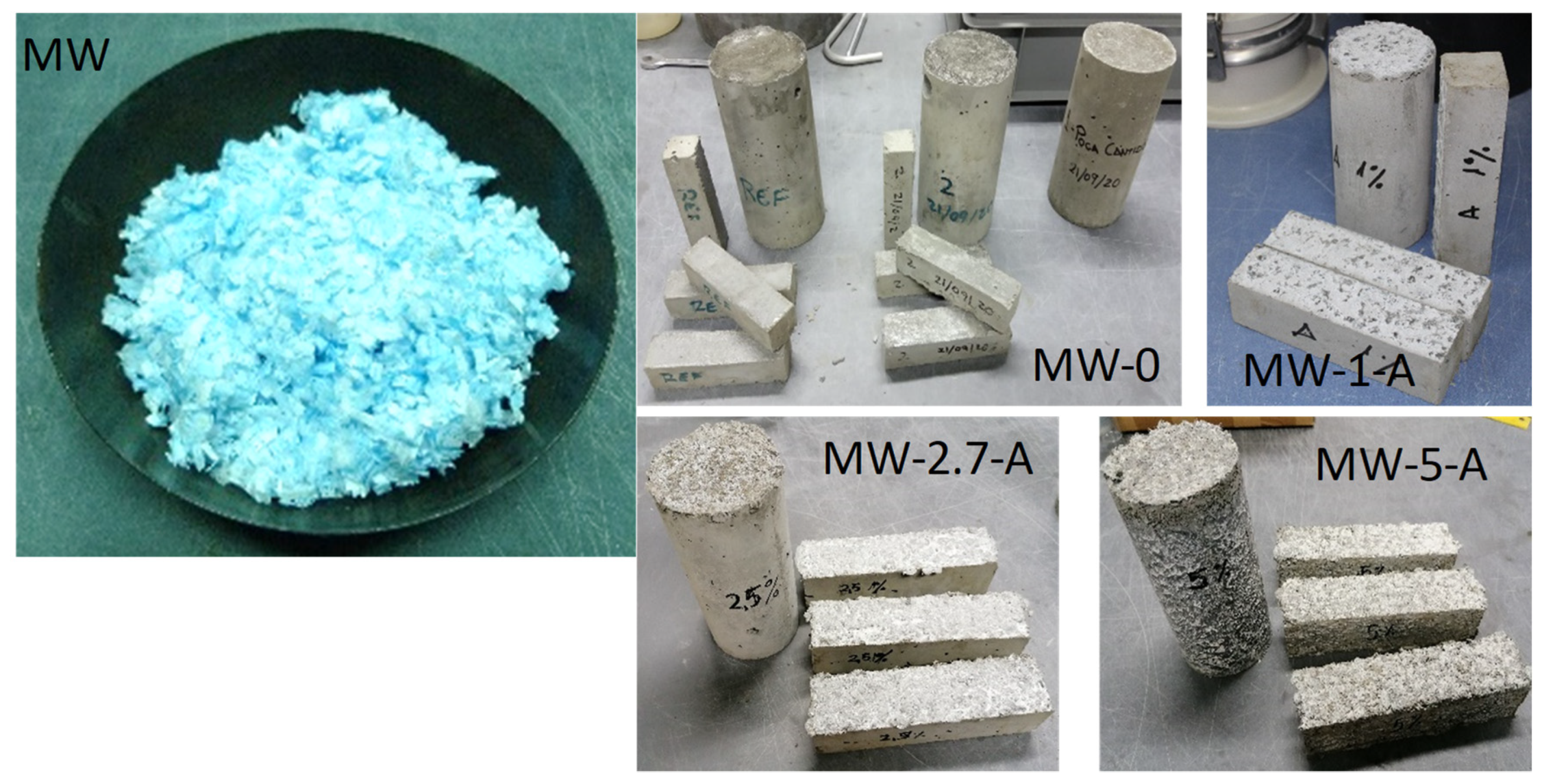

2.1. Materials and Samples Preparation

2.2. Experimental Program

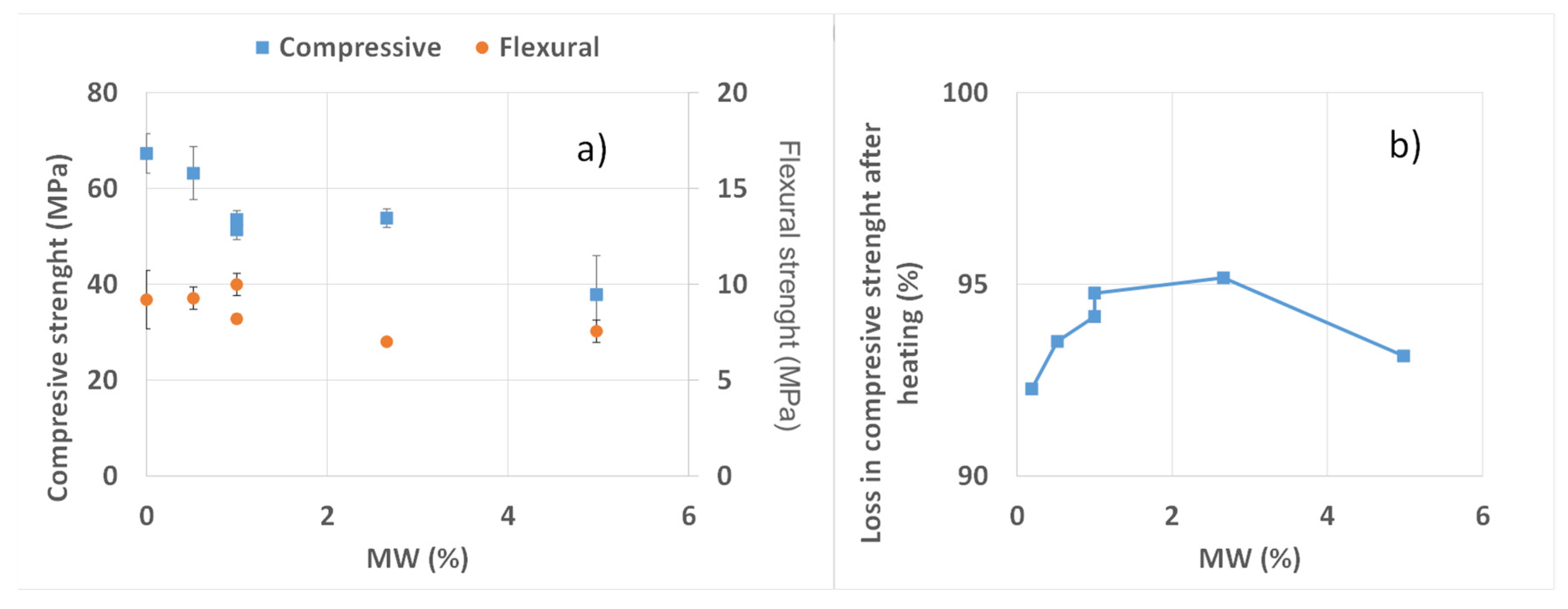

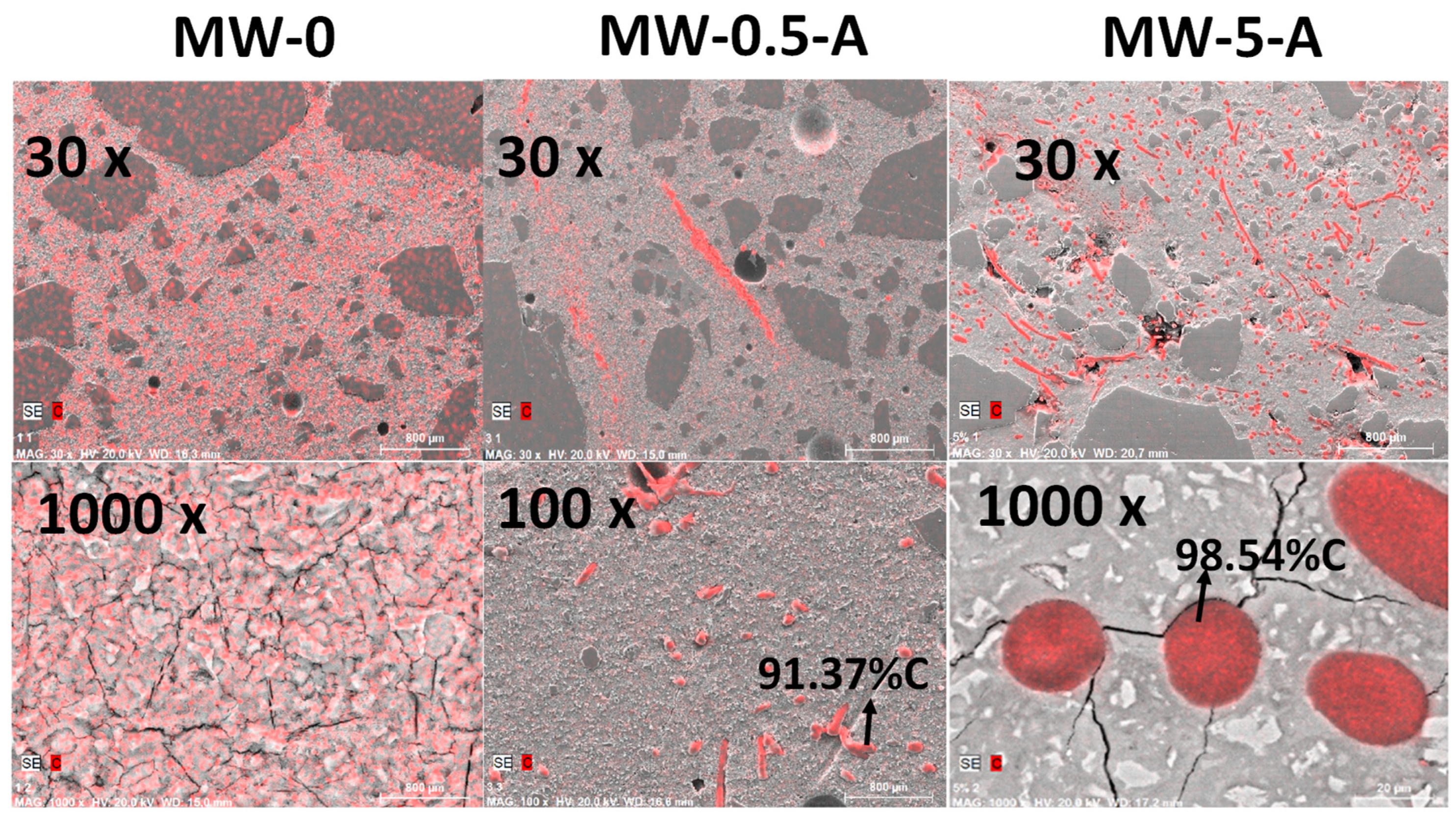

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Torkashvand, J.; Jafari, A.J.; Godini, K.; Kazemi, Z.; Kazemi, Z.; Farzadkia, M. Municipal solid waste management during COVID-19 pandemic: A comparison between the current activities and guidelines. J. Environ. Health Sci. Eng. 2021, 19, 173–179. [Google Scholar] [CrossRef] [PubMed]

- Hantoko, D.; Li, X.; Pariatamby, A.; Yoshikawa, K.; Horttanainen, M.; Yan, M. Challenges and practices on waste management and disposal during COVID-19 pandemic. J. Environ. Manag. 2021, 286, 112140. [Google Scholar] [CrossRef] [PubMed]

- Allison, A.L.; Ambrose-Dempster, E.; Bawn, M.; Casas Arredondo, M.; Chau, C.; Chandler, K.; Dobrijevic, D.; Domenech Aparisi, T.; Hailes, H.C.; Lettieri, P.; et al. The impact and effectiveness of the general public wearing masks to reduce the spread of pandemics in the UK: A multidisciplinary comparison of single-use masks versus reusable face masks. UCL Open Environ. 2020, 3, 1. [Google Scholar] [CrossRef]

- WHO. Shortage of Personal Protective Equipment Endangering Health Workers Worldwide. 2020; News Release. Available online: https://www.who.int/news/item/03-03-2020-shortage-of-personal-protective-equipment-endangering-health-workers-worldwide (accessed on 20 January 2022).

- Aragaw, T.A. Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar. Pollut. Bull. 2020, 159, 111517. [Google Scholar] [CrossRef]

- Roberts, K.P.; Bowyer, C.; Kolstoe, S.; Fletcher, S. Coronavirus Face Masks: An Environmental Disaster that Might Last Generations. The Conversation. 2020. Available online: https://theconversation.com/coronavirus-face-masks-an-environmental-disaster-that-might-last-generations-144328 (accessed on 17 November 2020).

- Fadare, O.O.; Okoffo, E.D. COVID-19 face masks: A potential source of microplastic fibers in the environment. Sci. Total Environ. 2020, 737, 140279. [Google Scholar] [CrossRef]

- Chowdhury, H.; Chowdhury, T.; Sait, S.M. Estimating marine plastic pollution from COVID-19 face masks in coastal regions. Mar. Pollut. Bull. 2021, 168, 112419. [Google Scholar] [CrossRef]

- Neto, H.G.; Bantel, C.G.; Browning, J.; Della Fina, N.; Ballabio, T.A.; de Santana, F.T.; Britto, M.d.K.e.; Barbosa, C.B. Mortality of a juvenile Magellanic penguin (Spheniscus magellanicus, Spheniscidae) associated with the ingestion of a PFF-2 protective mask during the COVID-19 pandemic. Mar. Pollut. Bull. 2021, 166, 112232. [Google Scholar] [CrossRef]

- Torres-Agullo, A.; Karanasiou, A.; Moreno, T.; Lacorte, S. Overview on the occurrence of microplastics in air and implications from the use of face masks during the COVID-19 pandemic. Sci. Total Environ. 2021, 800, 149555. [Google Scholar] [CrossRef]

- Liao, Z.; Ji, X.; Ma, Y.; Lv, B.; Huang, W.; Zhu, X.; Fang, M.; Wang, Q.; Wang, X.; Dahlgren, R.; et al. Airborne microplastics in indoor and outdoor environments of a coastal city in Eastern China. J. Hazard. Mater. 2021, 417, 126007. [Google Scholar] [CrossRef]

- Ma, J.; Chen, F.; Xu, H.; Jiang, H.; Liu, J.; Li, P.; Chen, C.C.; Pan, K. Face masks as a source of nanoplastics and microplastics in the environment: Quantification, characterization, and potential for bioaccumulation. Environ. Pollut. 2021, 288, 117748. [Google Scholar] [CrossRef]

- Singh, N.; Tang, Y.; Ogunseitan, O.A. Environmentally Sustainable Management of Used Personal Protective Equipment. Environ. Sci. Technol. 2020, 54, 8500–8502. [Google Scholar] [CrossRef] [PubMed]

- Haque, M.S.; Uddin, S.; Sayem, S.M.; Mohib, K.M. Coronavirus disease 2019 (COVID-19) induced waste scenario: A short overview. J. Environ. Chem. Eng. 2020, 9, 104660. [Google Scholar] [CrossRef]

- Sangkham, S. Face mask and medical waste disposal during the novel COVID-19 pandemic in Asia. Case Stud. Chem. Environ. Eng. 2020, 2, 100052. [Google Scholar] [CrossRef]

- Torres, F.G.; De-la-Torre, G.E. Face mask waste generation and management during the COVID-19 pandemic: An overview and the Peruvian case. Sci. Total Environ. 2021, 786, 147628. [Google Scholar] [CrossRef]

- Xu, E.G.; Ren, Z.J. Preventing masks from becoming the next plastic problem. Front. Environ. Sci. Eng. 2021, 15, 125. [Google Scholar] [CrossRef] [PubMed]

- Ray, S.S.; Lee, H.K.; Huyen, D.T.T.; Chen, S.-S.; Kwon, Y.-N. Microplastics waste in environment: A perspective on recycling issues from PPE kits and face masks during the COVID-19 pandemic. Environ. Technol. Innov. 2022, 26, 102290. [Google Scholar] [CrossRef]

- Siwal, S.S.; Chaudhary, G.; Saini, A.K.; Kaur, H.; Saini, V.; Mokhta, S.K.; Chand, R.; Chandel, U.K.; Christie, G.; Thakur, V.K. Key ingredients and recycling strategy of personal protective equipment (PPE): Towards sustainable solution for the COVID-19 like pandemics. J. Environ. Chem. Eng. 2021, 9, 106284. [Google Scholar] [CrossRef] [PubMed]

- Lee, A.W.L.; Neo, E.R.K.; Khoo, Z.-Y.; Yeo, Z.; Tan, Y.S.; Chng, S.; Yan, W.; Lok, B.K.; Low, J.S.C. Life cycle assessment of single-use surgical and embedded filtration layer (EFL) reusable face mask. Resour. Conserv. Recycl. 2021, 170, 105580. [Google Scholar] [CrossRef] [PubMed]

- Bennet, D.; Harris, A.F.; Lacombe, J.; Brooks, C.; Bionda, N.; Strickland, A.D.; Eisenhut, T.; Zenhausern, F. Evaluation of supercritical CO2 sterilization efficacy for sanitizing personal protective equipment from the coronavirus SARS-CoV-2. Sci. Total Environ. 2021, 780, 146519. [Google Scholar] [CrossRef] [PubMed]

- Sookaromdee, P.; Wiwanitkit, V. Surgical face masks and n95 respirators: Is reuse after decontamination treatment justified? Med. J. DY Patil Vidyapeeth 2021, 14, 362. [Google Scholar] [CrossRef]

- Holdsworth, J.; Preston, A.; Gentile, P.; Rider, P.; Yallew, W.; Juno, Z. Process for disinfection of N95 respirators during COVID-19 utilizing sterile processing department: A single center acute care hospital. Am. J. Infect. Control 2021, 49, 489–491. [Google Scholar] [CrossRef] [PubMed]

- Hamzavi, I.H.; Lyons, A.B.; Kohli, I.; Narla, S.; Parks-Miller, A.; Gelfand, J.M.; Lim, H.W.; Ozog, D.M. Ultraviolet germicidal irradiation: Possible method for respirator disinfection to facilitate reuse during the COVID-19 pandemic. J. Am. Acad. Dermatol. 2020, 82, 1511–1512. [Google Scholar] [CrossRef] [PubMed]

- Ibáñez-Cervantes, G.; Bravata-Alcántara, J.C.; Nájera-Cortés, A.S.; Meneses-Cruz, S.; Delgado-Balbuena, L.; Cruz-Cruz, C.; Durán-Manuel, E.M.; Cureño-Díaz, M.A.; Gómez-Zamora, E.; Chávez-Ocaña, S.; et al. Disinfection of N95 masks artificially contaminated with SARS-CoV-2 and ESKAPE bacteria using hydrogen peroxide plasma: Impact on the reutilization of disposable devices. Am. J. Infect. Control 2020, 48, 1037–1041. [Google Scholar] [CrossRef] [PubMed]

- Battegazzore, D.; Cravero, F.; Frache, A. Is it Possible to Mechanical Recycle the Materials of the Disposable Filtering Masks? Polymers 2020, 12, 2726. [Google Scholar] [CrossRef] [PubMed]

- Jang, E.S.; Kang, C.W. Do face masks become worthless after only one use in the COVID-19 pandemic? Infect. Chemother. 2020, 52, 583–591. [Google Scholar] [CrossRef]

- Peinador, R.I.; Calvo, J.I.; Ben Aim, R. Comparison of Capillary Flow Porometry (CFP) and Liquid Extrusion Porometry (LEP) Techniques for the Characterization of Porous and Face Mask Membranes. Appl. Sci. 2020, 10, 5703. [Google Scholar] [CrossRef]

- Crespo, C.; Ibarz, G.; Sáenz, C.; Gonzalez, P.; Roche, S. Study of Recycling Potential of FFP2 Face Masks and Characterization of the Plastic Mix-Material Obtained. A Way of Reducing Waste in Times of COVID-19. Waste Biomass Valorization 2021, 12, 6423–6432. [Google Scholar] [CrossRef]

- Hu, X.; Lin, Z. Transforming waste polypropylene face masks into S-doped porous carbon as the cathode electrode for supercapacitors. Ionics 2021, 27, 2169–2179. [Google Scholar] [CrossRef] [PubMed]

- Caniato, M.; Marzi, A.; Gasparella, A. How much COVID-19 face protections influence speech intelligibility in classrooms? Appl. Acoust. 2021, 178, 108051. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; Acedo-Fuentes, P.; García-Cobos, F.J.; Sánchez-Delgado, F.J.; Mota-López, M.I.; Meneses-Rodríguez, J.M. The recycling of surgical face masks as sound porous absorbers: Preliminary evaluation. Sci. Total Environ. 2021, 786, 147461. [Google Scholar] [CrossRef]

- Varghese, P.J.G.; David, D.A.; Karuth, A.; Jafferali, J.F.M.; Begum, S.P.M.; George, J.J.; Rasulev, B. Experimental and Simulation Studies on Nonwoven Polypropylene–Nitrile Rubber Blend: Recycling of Medical Face Masks to an Engineering Product. ACS Omega 2022. [Google Scholar] [CrossRef]

- Jain, S.; Lamba, B.Y.; Kumar, S.; Singh, D. Strategy for repurposing of disposed PPE kits by production of biofuel: Pressing priority amidst COVID-19 pandemic. Biofuels 2020, 1–5. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Kilmartin-Lynch, S.; Boroujeni, M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021, 769, 145527. [Google Scholar] [CrossRef]

- Puertas, F.; Amat, T.; Jimenez, A.M.F.; Vázquez, T. Mechanical and durable behaviour of alkaline cement mortars reinforced with polypropylene fibres. Cem. Concr. Res. 2003, 33, 2031–2036. [Google Scholar] [CrossRef]

- Elkatatny, S.; Ahmed, A.; Gajbhiye, R.; Rahman, M.K.; Sarmah, P.; Yadav, P. Enhancing the cement quality using polypropylene fiber. J. Pet. Explor. Prod. Technol. 2020, 10, 1097–1107. [Google Scholar] [CrossRef] [Green Version]

- Toutanji, H.A. Properties of polypropylene fiber reinforced silica fume expansive-cement concrete. Constr. Build. Mater. 1999, 13, 171–177. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shi, F.; Combe, M.; Collister, T.; Sivakugan, N. Use of macro plastic fibres in concrete: A review. Constr. Build. Mater. 2015, 93, 180–188. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Combe, M.; Collister, T.; Jacob, M.; Shanks, R.A. Mechanical properties of recycled plastic fibres for reinforcing concrete. In Proceedings of the Fibre Concrete 2013, Prague, Czech Republic, 12–13 September 2013. [Google Scholar]

- Awoyera, P.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Rehman, Z.U.; Khalid, U. Optimization of COVID-19 face mask waste fibers and silica fume as a balanced mechanical ameliorator of fat clay using response surface methodology. Environ. Sci. Pollut. Res. 2021. [Google Scholar] [CrossRef] [PubMed]

- Kilmartin-Lynch, S.; Saberian, M.; Li, J.; Roychand, R.; Zhang, G. Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J. Clean. Prod. 2021, 296, 126460. [Google Scholar] [CrossRef] [PubMed]

- Castellote, M.; Andrade, C.; Alonso, C. Measurement of the steady and non-steady-state chloride diffusion coefficients in a migration test by means of monitoring the conductivity in the anolyte chamber. Comp. Nat. Diffus. Tests. Cem. Concr. Res. 2001, 31, 1411–1420. [Google Scholar]

- Castellote, M.; Andrade, C. Round-Robin test on methods for determining chloride transport parameters in concrete. Mater. Struct. 2006, 39, 955–990. [Google Scholar] [CrossRef]

- Baroghel-Bouny, V.J.S. Technical document. In Concrete Design for a Given Structure Service Life; Association Française de Génie Civil (AFGC): Paris, France, 2007. [Google Scholar]

- Lee, J.; Bong, C.; Lim, W.; Bae, P.K.; Abafogi, A.T.; Baek, S.H.; Shin, Y.-B.; Bak, M.S.; Park, S. Fast and Easy Disinfection of Coronavirus-Contaminated Face Masks Using Ozone Gas Produced by a Dielectric Barrier Discharge Plasma Generator. Environ. Sci. Technol. Lett. 2021, 8, 339–344. [Google Scholar] [CrossRef]

- Rubio-Romero, J.C.; del Carmen Pardo-Ferreira, M.; Torrecilla-Garci, J.A.; Calero-Castro, S. Disposable masks: Disinfection and sterilization for reuse, and non-certified manufacturing, in the face of shortages during the COVID-19 pandemic. Saf. Sci. 2020, 129, 104830. [Google Scholar] [CrossRef]

- Teo, J.Y.; Kng, J.; Periaswamy, B.; Liu, S.; Lim, P.; Lee, C.E.; Tan, B.H.; Loh, X.J.; Ni, X.; Tiang, D.; et al. Exploring Reusability of Disposable Face Masks: Effects of Disinfection Methods on Filtration Efficiency, Breathability, and Fluid Resistance. Glob. Chall. 2021, 5, 2100030. [Google Scholar] [CrossRef]

| Cement I 52.5 R | Water | Sand | Superplasticiser (Master Ease 3690) | % MW Weight vs. Cem | |

|---|---|---|---|---|---|

| MW-0 | 1 | 0.4 | 1 | 0.0065 | 0 |

| MW-0.5-A | 1 | 0.4 | 1 | 0.01 | 0.52 |

| MW-1-A | 1 | 0.4 | 1 | 0.01 | 1.0 |

| MW-1-B | 1 | 0.4 | 1 | 0.01 | 1.0 |

| MW-2.7-A | 1 | 0.4 | 1 | 0.01 | 2.66 |

| MW-5-A | 1 | 0.4 | 1 | 0.01 | 4.98 |

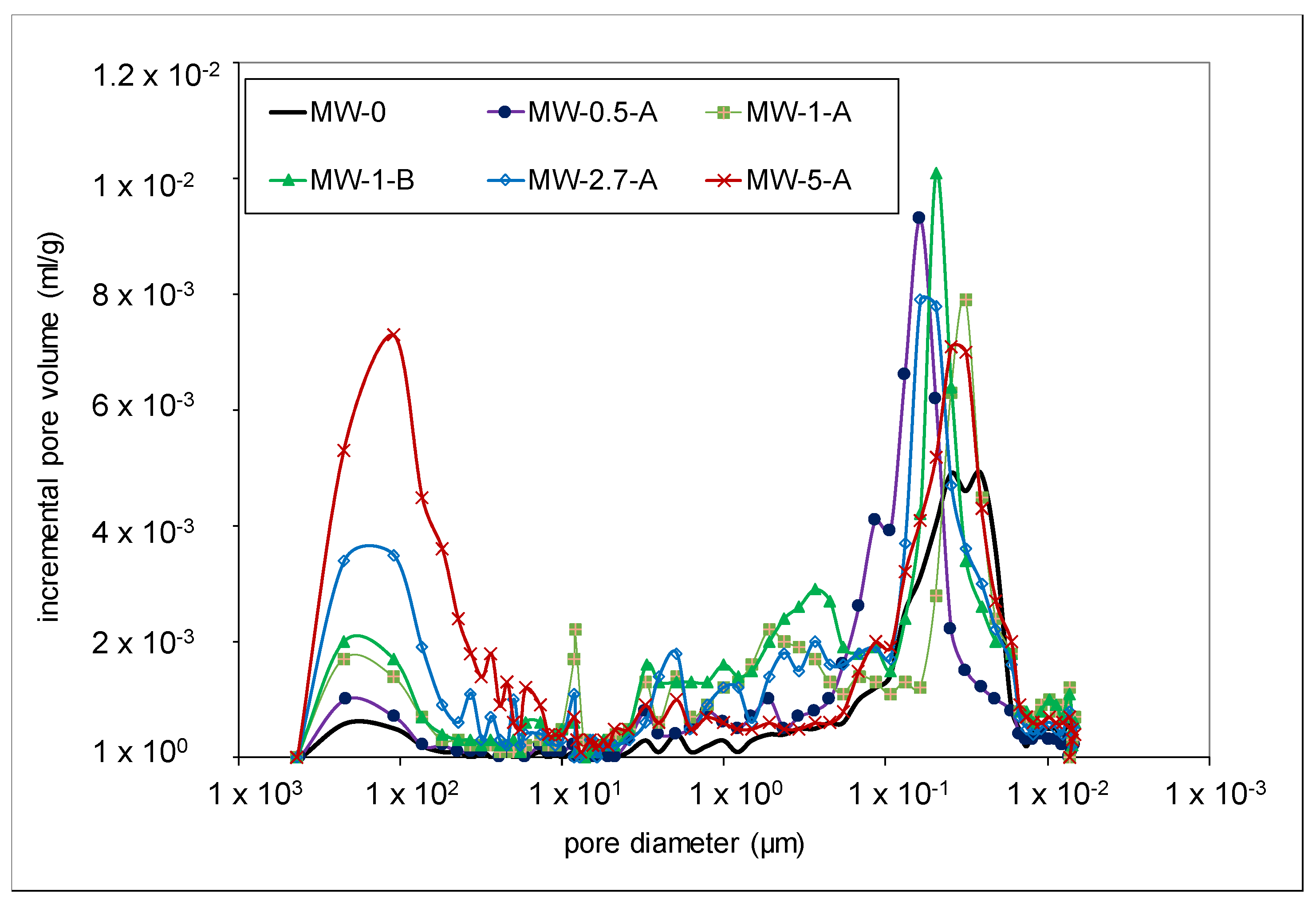

| Total Porosity (%vol) | Bulk Density (gr/mL) | Average Pore Diameter (µm) | |

|---|---|---|---|

| MW-0 | 9.58 | 2.19 | 0.033 |

| MW-0.5-A | 12.30 | 2.17 | 0.060 |

| MW-1-A | 14.46 | 1.99 | 0.044 |

| MW-1-B | 17.03 | 1.90 | 0.058 |

| MW-2.7-A | 15.73 | 1.94 | 0.058 |

| MW-5-A | 16.68 | 1.83 | 0.056 |

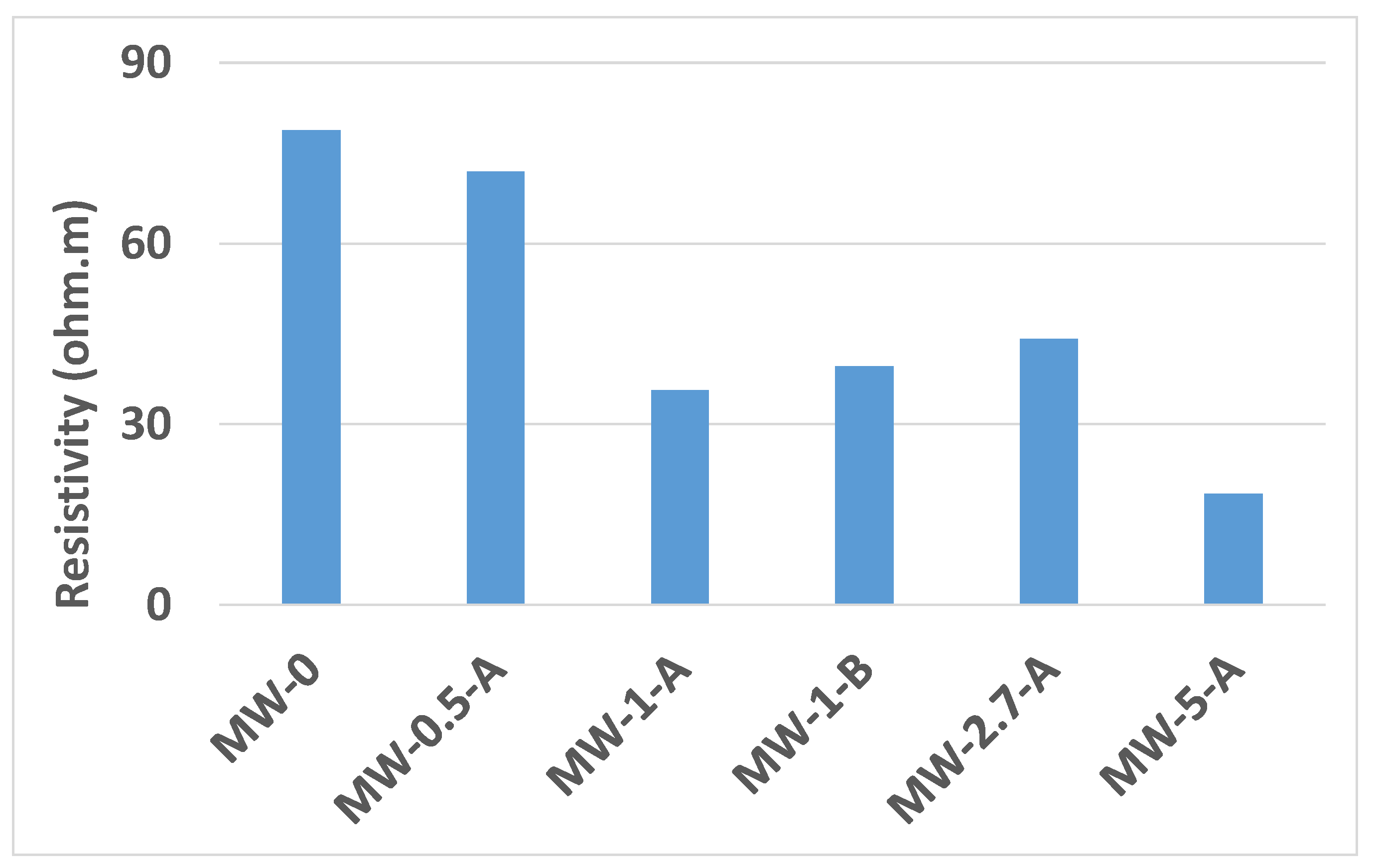

| Deff Calculated from Resistivity [45] | Deff Calculated from the Multiregime Method [44] | Dapp Calculated from the Multiregime Method [44] | |

|---|---|---|---|

| MW-0 | 2.54 | — | — |

| MW-0.5-A | 2.78 | — | — |

| MW-1-A | 5.61 | 3.06 | 5.50 |

| MW-1-B | 5.05 | 2.50 | 6.23 |

| MW-2.7-A | 4.52 | 2.53 | 5.64 |

| MW-5-A | 10.8 | 6.87 | 16.2 |

| INDICATOR * | MW-0 | MW-0.5-A | MW-1-A | MW-1-B | MW-2.7-A | MW-5-A |

|---|---|---|---|---|---|---|

| Total porosity (MIP) | Moderate | Moderate | Low | Very low | Low | Very low |

| Electrical resistivity | Low | Low | Very low | Very low | Very low | Very low |

| Effective Cl diffusion coefficient-Deff | — | — | Low | Low | Low | Low |

| Apparent Cl diffusion coefficient-Dapp | — | — | Moderate | Moderate | Moderate | Low |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castellote, M.; Jiménez-Relinque, E.; Grande, M.; Rubiano, F.J.; Castillo, Á. Face Mask Wastes as Cementitious Materials: A Possible Solution to a Big Concern. Materials 2022, 15, 1371. https://doi.org/10.3390/ma15041371

Castellote M, Jiménez-Relinque E, Grande M, Rubiano FJ, Castillo Á. Face Mask Wastes as Cementitious Materials: A Possible Solution to a Big Concern. Materials. 2022; 15(4):1371. https://doi.org/10.3390/ma15041371

Chicago/Turabian StyleCastellote, Marta, Eva Jiménez-Relinque, María Grande, Francisco J. Rubiano, and Ángel Castillo. 2022. "Face Mask Wastes as Cementitious Materials: A Possible Solution to a Big Concern" Materials 15, no. 4: 1371. https://doi.org/10.3390/ma15041371

APA StyleCastellote, M., Jiménez-Relinque, E., Grande, M., Rubiano, F. J., & Castillo, Á. (2022). Face Mask Wastes as Cementitious Materials: A Possible Solution to a Big Concern. Materials, 15(4), 1371. https://doi.org/10.3390/ma15041371