Effects of Preparation Procedures and Porosity on Thermoelectric Bulk Samples of Cu2SnS3 (CTS)

Abstract

:1. Introduction

2. Materials and Methods

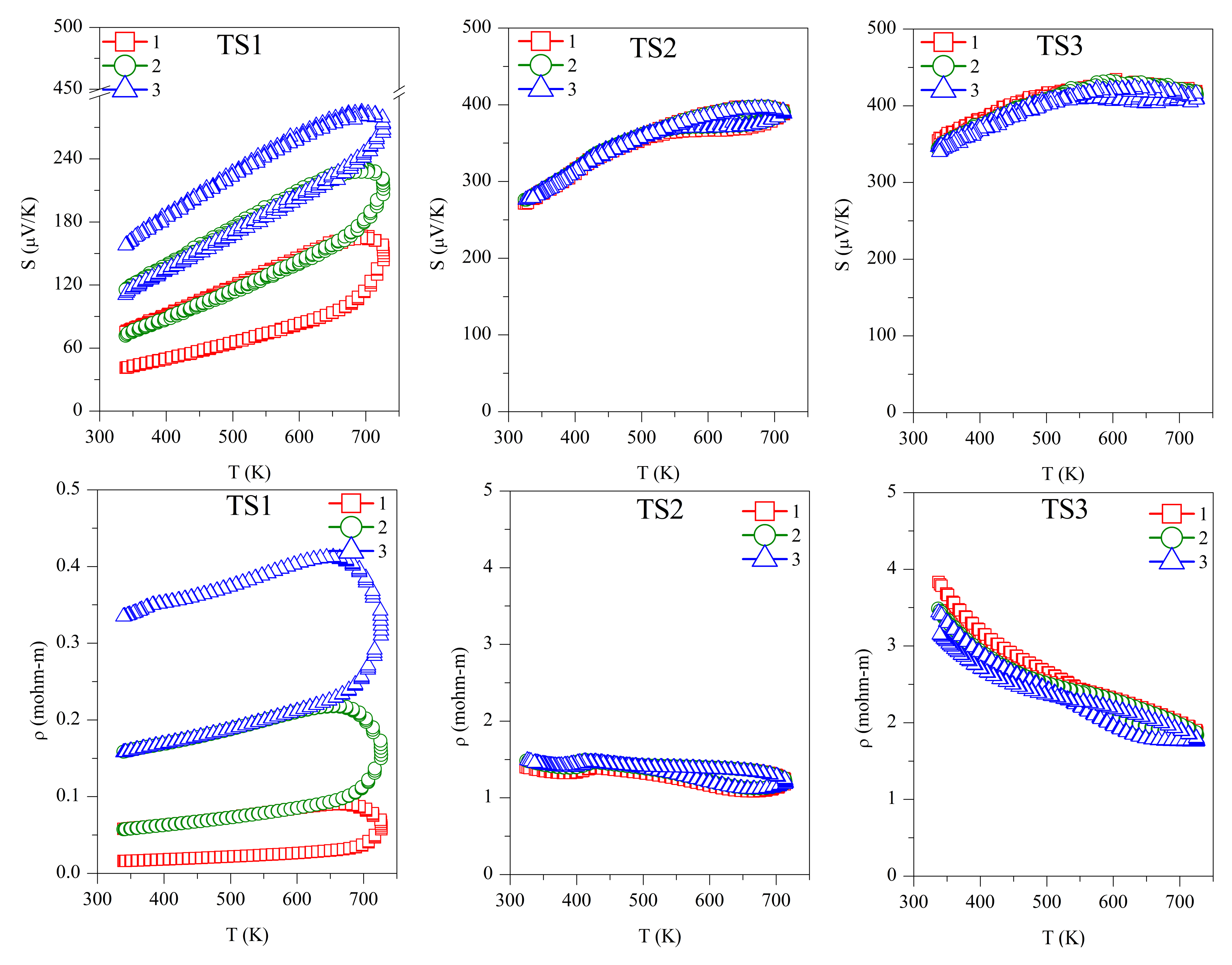

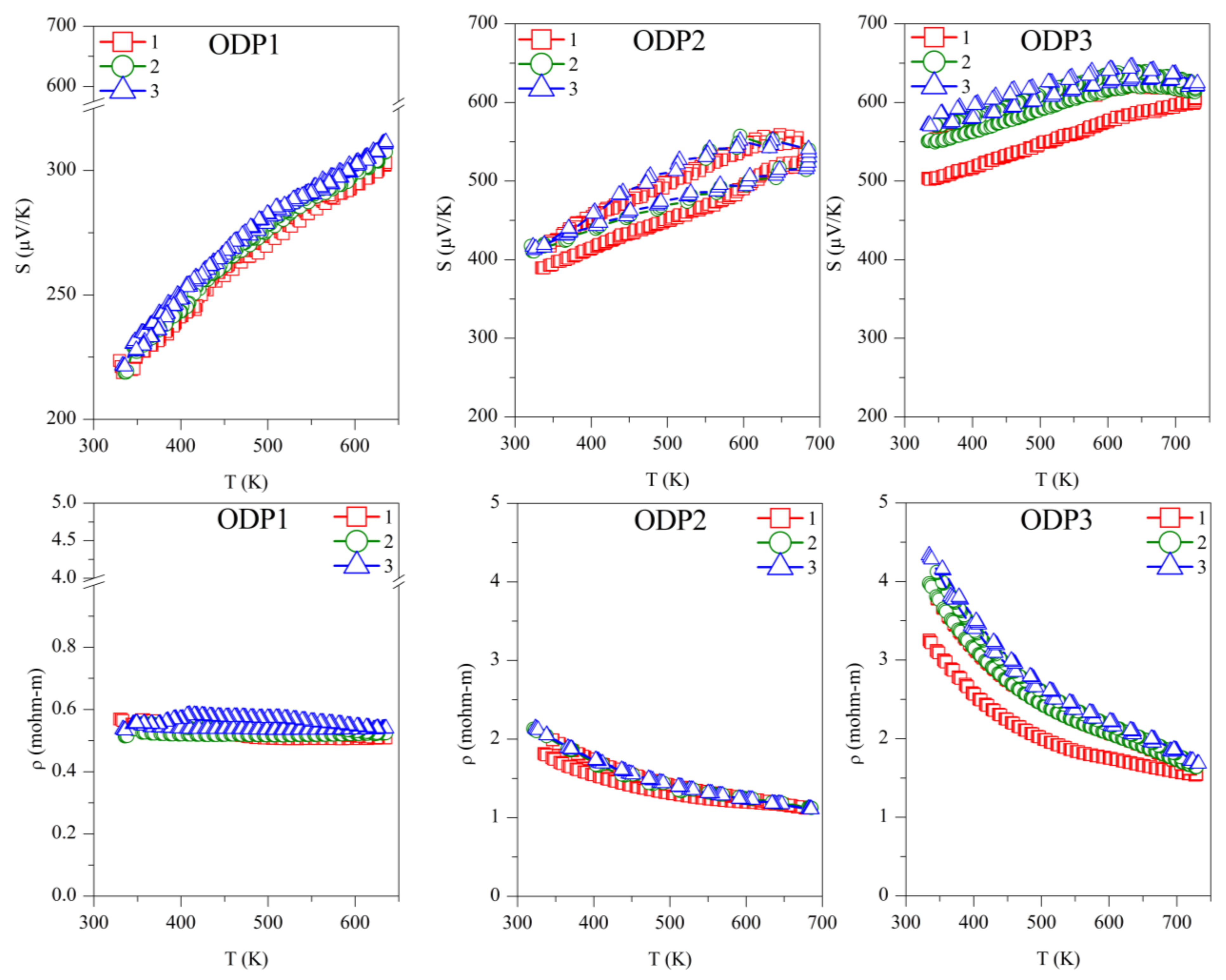

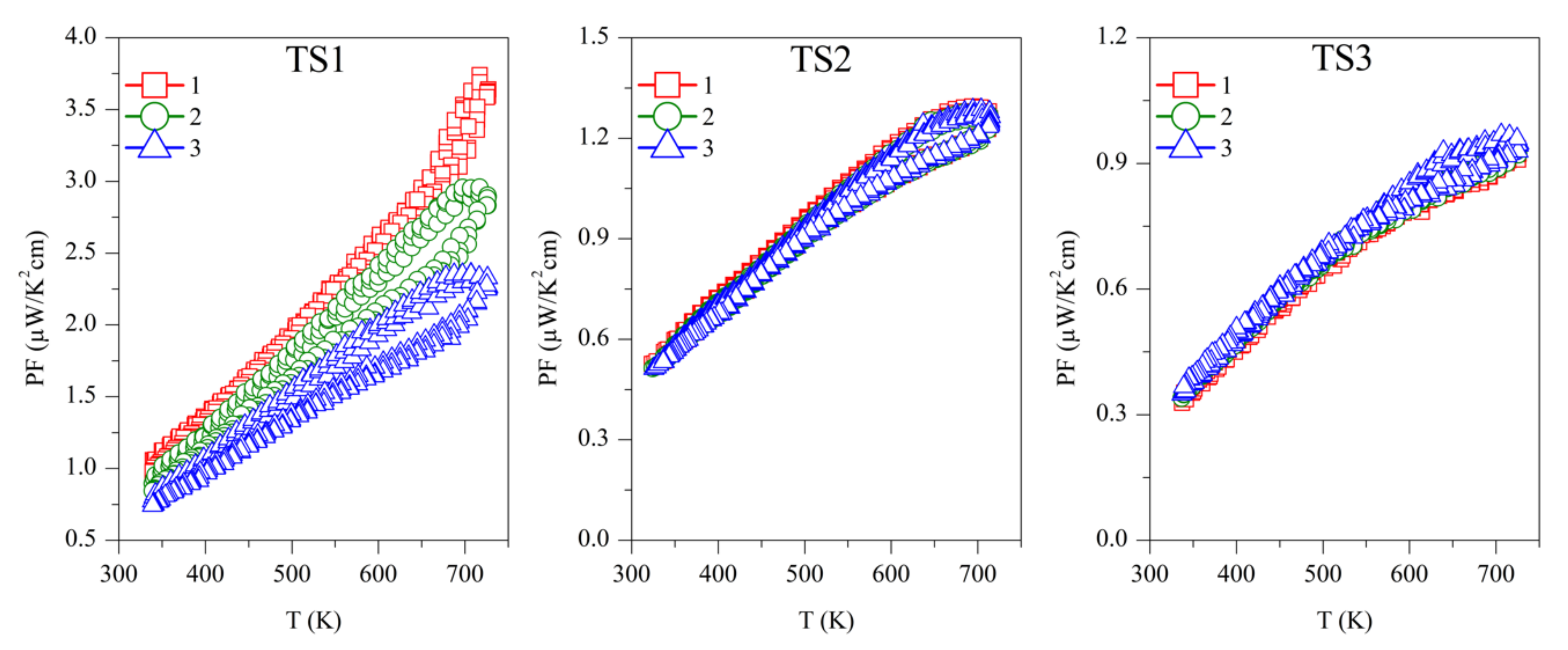

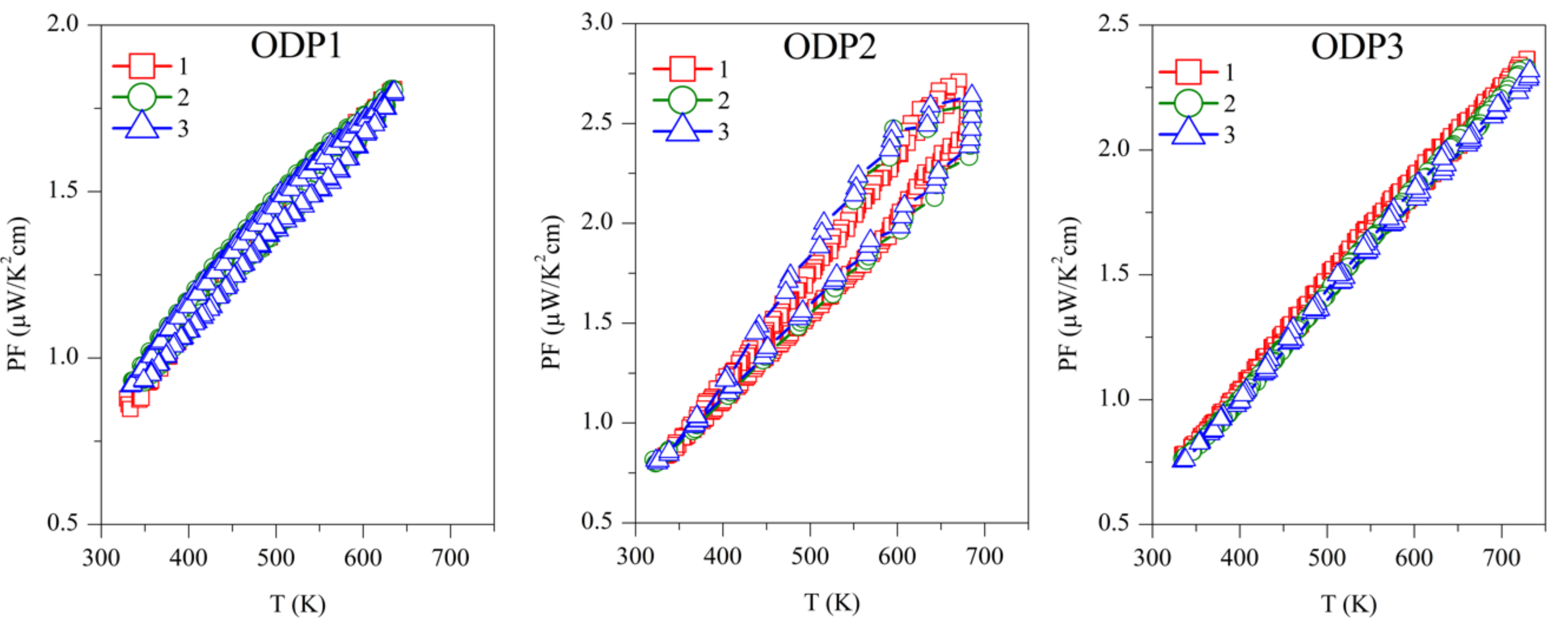

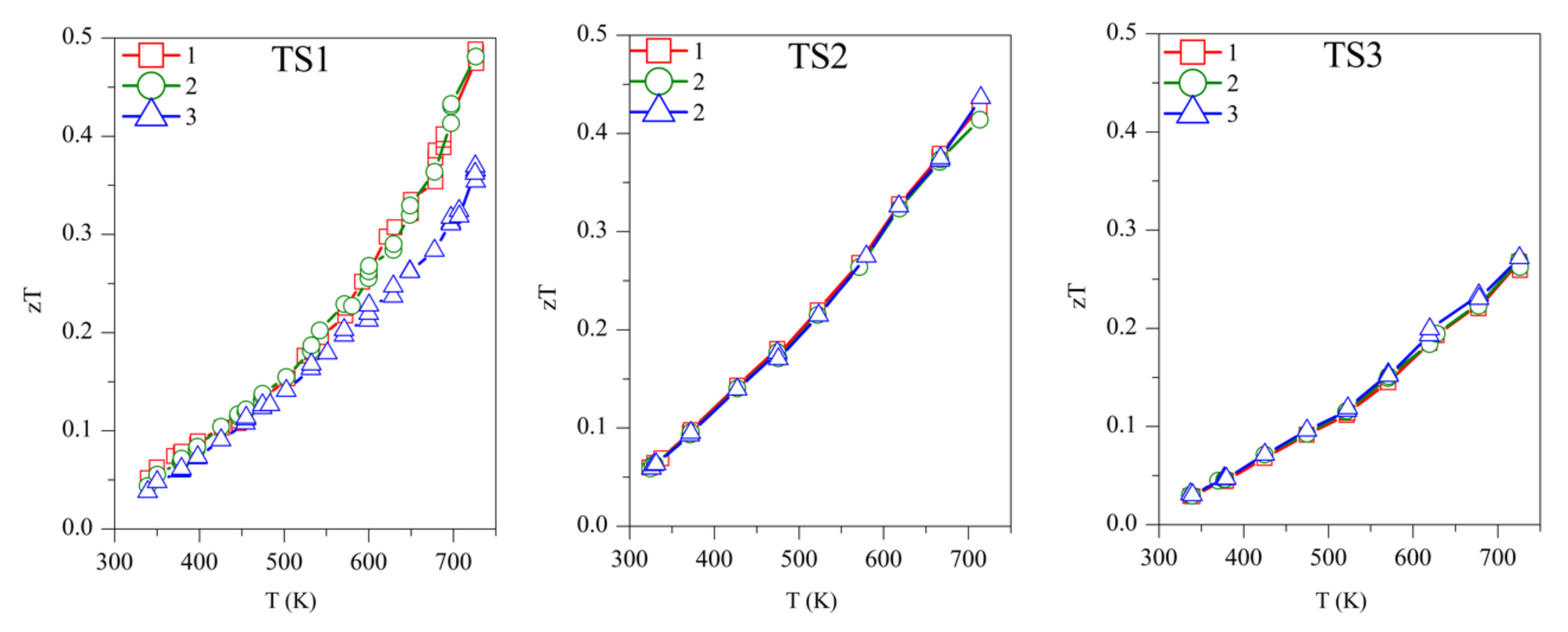

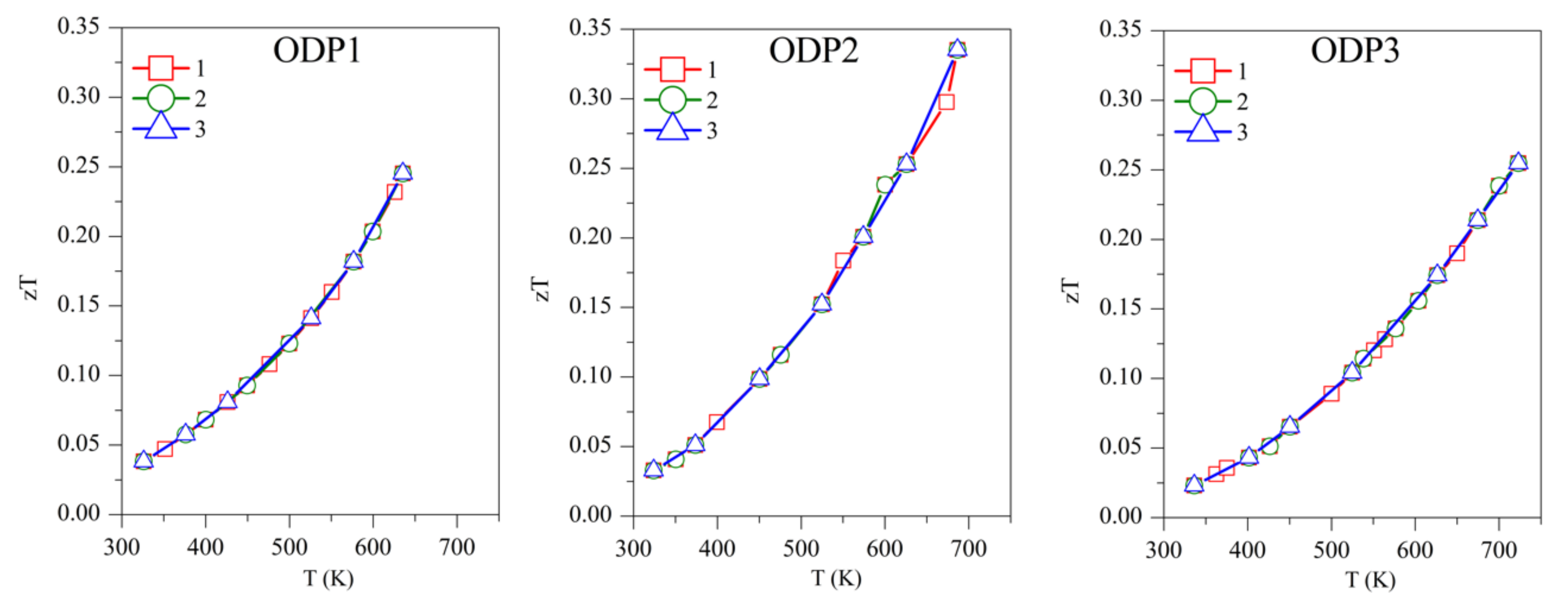

3. Results and Discussions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Vining, C.B. An inconvenient truth about thermoelectrics. Nat. Mater. 2009, 8, 83–85. [Google Scholar] [CrossRef] [PubMed]

- Mao, J.; Liu, Z.; Zhou, J.; Zhu, H.; Zhang, Q.; Chen, G.; Ren, Z. Advances in thermoelectrics. Adv. Phys. 2018, 67, 69–147. [Google Scholar] [CrossRef]

- Lohani, K.; Isotta, E.; Ataollahi, N.; Fanciulli, C.; Chiappini, A.; Scardi, P. Ultra-low thermal conductivity and improved thermoelectric performance in disordered nanostructured copper tin sulphide (Cu2SnS3, CTS). J. Alloys Compd. 2020, 830, 154604. [Google Scholar] [CrossRef]

- He, T.; Lin, N.; Du, Z.; Chao, Y.; Cui, J. The role of excess Sn in Cu 4 Sn 7 S 16 for modification of the band structure and a reduction in lattice thermal conductivity. J. Mater. Chem. C 2017, 5, 4206–4213. [Google Scholar] [CrossRef] [Green Version]

- Lohani, K.; Nautiyal, H.; Ataollahi, N.; Fanciulli, C.; Sergueev, I.; Etter, M.; Scardi, P. Experimental and Ab Initio Study of Cu 2 SnS 3 (CTS) Polymorphs for Thermoelectric Applications. J. Phys. Chem. C 2021, 125, 178–188. [Google Scholar] [CrossRef]

- Shen, Y.; Li, C.; Huang, R.; Tian, R.; Ye, Y.; Pan, L.; Koumoto, K.; Zhang, R.; Wan, C.; Wang, Y. Eco-friendly p-type Cu2SnS3 thermoelectric material: Crystal structure and transport properties. Sci. Rep. 2016, 6, 32501. [Google Scholar] [CrossRef] [Green Version]

- Lokhande, A.C.; Shelke, A.; Babar, P.T.; Kim, J.; Lee, D.J.; Kim, I.C.; Lokhande, C.D.; Kim, J.H. Novel antibacterial application of photovoltaic Cu2SnS3 (CTS) nanoparticles. RSC Adv. 2017, 7, 33737–33744. [Google Scholar] [CrossRef] [Green Version]

- Oliva, F.; Arqués, L.; Acebo, L.; Guc, M.; Sánchez, Y.; Alcobé, X.; Pérez-Rodríguez, A.; Saucedo, E.; Izquierdo-Roca, V. Characterization of Cu 2 SnS 3 polymorphism and its impact on optoelectronic properties. J. Mater. Chem. A 2017, 5, 23863–23871. [Google Scholar] [CrossRef]

- Jathar, S.B.; Rondiya, S.R.; Jadhav, Y.A.; Nilegave, D.S.; Cross, R.W.; Barma, S.V.; Nasane, M.P.; Gaware, S.A.; Bade, B.R.; Jadkar, S.R.; et al. Ternary Cu2SnS3: Synthesis, Structure, Photoelectrochemical Activity, and Heterojunction Band Offset and Alignment. Chem. Mater. 2021, 33, 1983–1993. [Google Scholar] [CrossRef]

- Wang, C.; Tian, H.; Jiang, J.; Zhou, T.; Zeng, Q.; He, X.; Huang, P.; Yao, Y. Facile Synthesis of Different Morphologies of Cu2SnS3 for High-Performance Supercapacitors. ACS Appl. Mater. Interfaces 2017, 9, 26038–26044. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Zhou, Z.; Jiang, P.; Zheng, S.; Xiong, Q.; Zhang, B.; Wang, G.; Lu, X.; Han, G.; Zhou, X. Phase Composition Manipulation and Twin Boundary Engineering Lead to Enhanced Thermoelectric Performance of Cu 2 SnS 3. ACS Appl. Energy Mater. 2021, 4, 9240–9247. [Google Scholar] [CrossRef]

- Li, C.; Song, H.; Cheng, Y.; Qi, R.; Huang, R.; Cui, C.; Wang, Y.; Zhang, Y.; Miao, L. Highly Suppressed Thermal Conductivity in Diamond-like Cu 2 SnS 3 by Dense Dislocation. ACS Appl. Energy Mater. 2021, 4, 8728–8733. [Google Scholar] [CrossRef]

- Gu, Y.; Ai, W.; Zhao, Y.; Hu, X.; Pan, L.; Zong, P.; Lu, C.; Xu, Z.; Wang, Y. Remarkable thermoelectric property enhancement in Cu2SnS3-CuCo2S4 nanocomposites via 3D modulation doping. J. Mater. Chem. A 2021, 9, 1928–16935. [Google Scholar] [CrossRef]

- Zhao, Y.; Gu, Y.; Zhang, P.; Hu, X.; Wang, Y.; Zong, P.; Pan, L.; Lyu, Y.; Koumoto, K. Enhanced thermoelectric performance in polymorphic heavily Co-doped Cu 2 SnS 3 through carrier compensation by Sb substitution. Sci. Technol. Adv. Mater. 2021, 22, 363–372. [Google Scholar] [CrossRef]

- Deng, T.; Qiu, P.; Xing, T.; Zhou, Z.; Wei, T.R.; Ren, D.; Xiao, J.; Shi, X.; Chen, L. A low-cost and eco-friendly Br-doped Cu7Sn3S10thermoelectric compound withzTaround unity. J. Mater. Chem. A 2021, 9, 7946–7954. [Google Scholar] [CrossRef]

- Tan, Q.; Sun, W.; Li, Z.; Li, J.F. Enhanced thermoelectric properties of earth-abundant Cu2SnS3 via In doping effect. J. Alloys Compd. 2016, 672, 558–563. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, H.; Wang, Y.; Hu, X.; Lyu, Y.; Cheng, C.; Pan, L.; Lu, C. Role of crystal transformation on the enhanced thermoelectric performance in Mn-doped Cu2SnS3. J. Alloys Compd. 2019, 780, 618–625. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, H.; Hu, X.; Pan, L.; Chen, C.; Li, D.; Wang, Y. Synergistic role of Ni-doping in electrical and phonon transport properties of Cu2Sn1-xNixS3. J. Alloys Compd. 2017, 728, 701–708. [Google Scholar] [CrossRef]

- Zhao, L.; Chen, C.; Pan, L.; Hu, X.; Lu, C.; Wang, Y. Magnetic iron doping in Cu 2 SnS 3 ceramics for enhanced thermoelectric transport properties. J. Appl. Phys. 2019, 125, 095107. [Google Scholar] [CrossRef]

- Zhao, H.; Xu, X.; Li, C.; Tian, R.; Zhang, R.; Huang, R.; Lyu, Y.; Li, D.; Hu, X.; Pan, L.; et al. Cobalt-doping in Cu2SnS3: Enhanced thermoelectric performance by synergy of phase transition and band structure modification. J. Mater. Chem. A 2017, 5, 23267–23275. [Google Scholar] [CrossRef]

- Deng, T.; Qiu, P.; Song, Q.; Chen, H.; Wei, T.-R.; Xi, L.; Shi, X.; Chen, L. Thermoelectric properties of non-stoichiometric Cu2+ xSn1−xS3 compounds. J. Appl. Phys. 2019, 126, 085111. [Google Scholar] [CrossRef]

- Pavan Kumar, V.; Lemoine, P.; Carnevali, V.; Guélou, G.; Lebedev, O.I.; Boullay, P.; Raveau, B.; Al Rahal Al Orabi, R.; Fornari, M.; Prestipino, C.; et al. Ordered sphalerite derivative Cu 5 Sn 2 S 7: A degenerate semiconductor with high carrier mobility in the Cu–Sn–S diagram. J. Mater. Chem. A 2021, 9, 10812–10826. [Google Scholar] [CrossRef]

- Baláž, P.; Dutková, E.; Levinský, P.; Daneu, N.; Kubíčková, L.; Knížek, K.; Baláž, M.; Navrátil, J.; Kašparová, J.; Ksenofontov, V.; et al. Enhanced thermoelectric performance of chalcopyrite nanocomposite via co-milling of synthetic and natural minerals. Mater. Lett. 2020, 275, 128107. [Google Scholar] [CrossRef]

- Deng, T.; Wei, T.R.; Song, Q.; Xu, Q.; Ren, D.; Qiu, P.; Shi, X.; Chen, L. Thermoelectric properties of n-type Cu4Sn7S16-based compounds. RSC Adv. 2019, 9, 7826–7832. [Google Scholar] [CrossRef] [Green Version]

- Siyar, M.; Cho, J.Y.; Youn, Y.; Han, S.; Kim, M.; Bae, S.H.; Park, C. Effect of annealing temperature on the phase transition, band gap and thermoelectric properties of Cu2SnSe3. J. Mater. Chem. C 2018, 6, 1780–1788. [Google Scholar] [CrossRef]

- Giulia, P. Thermoelectric materials: The power of pores. Nat. Rev. Mater. 2017, 2, 17006. [Google Scholar] [CrossRef]

- Goldsmid, H. Porous Thermoelectric Materials. Materials 2009, 2, 903–910. [Google Scholar] [CrossRef]

- Xu, B.; Feng, T.; Li, Z.; Pantelides, S.T.; Wu, Y. Constructing Highly Porous Thermoelectric Monoliths with High-Performance and Improved Portability from Solution-Synthesized Shape-Controlled Nanocrystals. Nano Lett. 2018, 18, 4034–4039. [Google Scholar] [CrossRef]

- Xu, B.; Feng, T.; Agne, M.T.; Zhou, L.; Ruan, X.; Snyder, G.J.; Wu, Y. Highly Porous Thermoelectric Nanocomposites with Low Thermal Conductivity and High Figure of Merit from Large-Scale Solution-Synthesized Bi 2 Te 2.5 Se 0.5 Hollow Nanostructures. Angew. Chem. Int. Ed. 2017, 56, 3546–3551. [Google Scholar] [CrossRef]

- Hong, M.-H.; Choi, H.; Kim, Y.; Shim, D., II; Cho, H.H.; Park, H.-H. Thermoelectric behaviors of ZnO mesoporous thin films affected by strain induced from the different dopants radii (Al, Ga, and In). Appl. Phys. Lett. 2021, 119, 193902. [Google Scholar] [CrossRef]

- Tiwari, D.; Chaudhuri, T.K.; Shripathi, T.; Deshpande, U. Synthesis of earth-abundant Cu2SnS3 powder using solid state reaction. J. Phys. Chem. Solids 2014, 75, 410–415. [Google Scholar] [CrossRef]

- Aversano, F.; Palumbo, M.; Ferrario, A.; Boldrini, S.; Fanciulli, C.; Baricco, M.; Castellero, A. Intermetallics Role of secondary phases and thermal cycling on thermoelectric properties of TiNiSn half-Heusler alloy prepared by different processing routes. Intermetallics 2020, 127, 106988. [Google Scholar] [CrossRef]

- Baranowski, L.L.; Zawadzki, P.; Lany, S.; Toberer, E.S.; Zakutayev, A. A review of defects and disorder in multinary tetrahedrally bonded semiconductors. Semicond. Sci. Technol. 2016, 31, 123004. [Google Scholar] [CrossRef]

- Fanciulli, C.; Coduri, M.; Boldrini, S.; Abedi, H.; Tomasi, C.; Famengo, A.; Ferrario, A.; Fabrizio, M.; Passaretti, F. Structural texture induced in SnSe thermoelectric compound via open die pressing. J. Nanosci. Nanotechnol. 2017, 17, 1571–1578. [Google Scholar] [CrossRef]

- McCusker, L.B.; Von Dreele, R.B.; Cox, D.E.; Louër, D.; Scardi, P. Rietveld refinement guidelines. J. Appl. Crystallogr. 1999, 32, 36–50. [Google Scholar] [CrossRef] [Green Version]

- Scardi, P.; Azanza Ricardo, C.L.; Perez-Demydenko, C.; Coelho, A.A. Whole powder pattern modelling macros for TOPAS. J. Appl. Crystallogr. 2018, 51, 1752–1765. [Google Scholar] [CrossRef]

- Coelho, A.A. TOPAS and TOPAS-Academic: An optimization program integrating computer algebra and crystallographic objects written in C++. J. Appl. Crystallogr. 2018, 51, 210–218. [Google Scholar] [CrossRef] [Green Version]

- Scardi, P. Diffraction Line Profiles in the Rietveld Method. Cryst. Growth Des. 2020, 20, 6903–6916. [Google Scholar] [CrossRef]

- Lohani, K.; Nautiyal, H.; Ataollahi, N.; Maji, K.; Guilmeau, E.; Scardi, P. Effects of Grain Size on the Thermoelectric Properties of Cu2SnS3: An Experimental and First-Principles Study. ACS Appl. Energy Mater. 2021, 4, 12604–12612. [Google Scholar] [CrossRef]

- Dong, Y.; He, J.; Li, X.; Zhou, W.; Chen, Y.; Sun, L.; Yang, P.; Chu, J. Synthesis and optimized sulfurization time of Cu2SnS3 thin films obtained from stacked metallic precursors for solar cell application. Mater. Lett. 2015, 160, 468–471. [Google Scholar] [CrossRef]

- Ming, H.; Zhu, C.; Qin, X.; Jabar, B.; Chen, T.; Zhang, J.; Xin, H.; Li, D.; Zhang, J. Improving the thermoelectric performance of Cu2SnSe3: Via regulating micro-and electronic structures. Nanoscale 2021, 13, 4233–4240. [Google Scholar] [CrossRef] [PubMed]

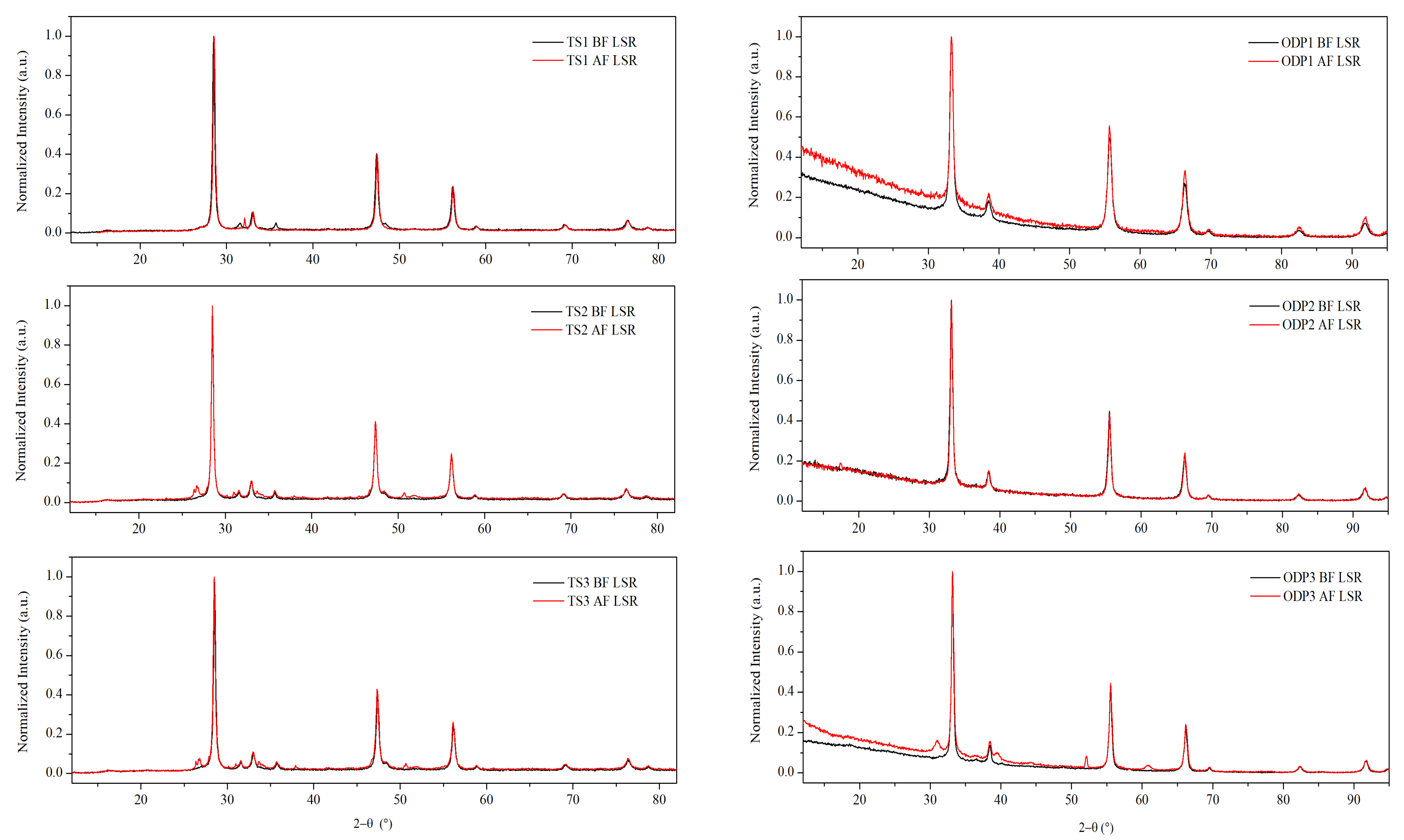

| Sample | Weight (±1%) | Average Domain Size (±10 nm) | Measured Density (±0.1 g/cm3) | Relative Density (%) | ||||

|---|---|---|---|---|---|---|---|---|

| CTS | WC | SnO2 | SnO | SnS | ||||

| TS1 before TE measurements | 96 | 2 | 2 | - | - | 40 | 3.52 | 74.7 |

| TS1 after TE measurements | 88 | 2 | 8 | - | 2 | 75 | ||

| TS2 before TE measurements | 98 | 2 | - | - | - | 75 | 3.48 | 73.8 |

| TS2 after TE measurements | 89 | 2 | 8 | 1 | - | 75 | ||

| TS3 before TE measurements | 98 | 2 | - | - | - | 70 | 3.68 | 78.1 |

| TS3 after TE measurements | 87 | 2 | 10 | 1 | - | 70 | ||

| ODP1 before TE measurements | 100 | - | - | - | - | 42 | 4.26 | 90.4 |

| ODP1 after TE measurements | 100 | - | - | - | - | 42 | ||

| ODP2 before TE measurements | 100 | - | - | - | - | 54 | 4.36 | 92.5 |

| ODP2 after TE measurements | 99 | 1 | - | - | - | 54 | ||

| ODP3 before TE measurements | 98 | 1 | 1 | - | - | 68 | 4.43 | 94.0 |

| ODP3 after TE measurements | 91 | 1 | 8 | - | - | 68 | ||

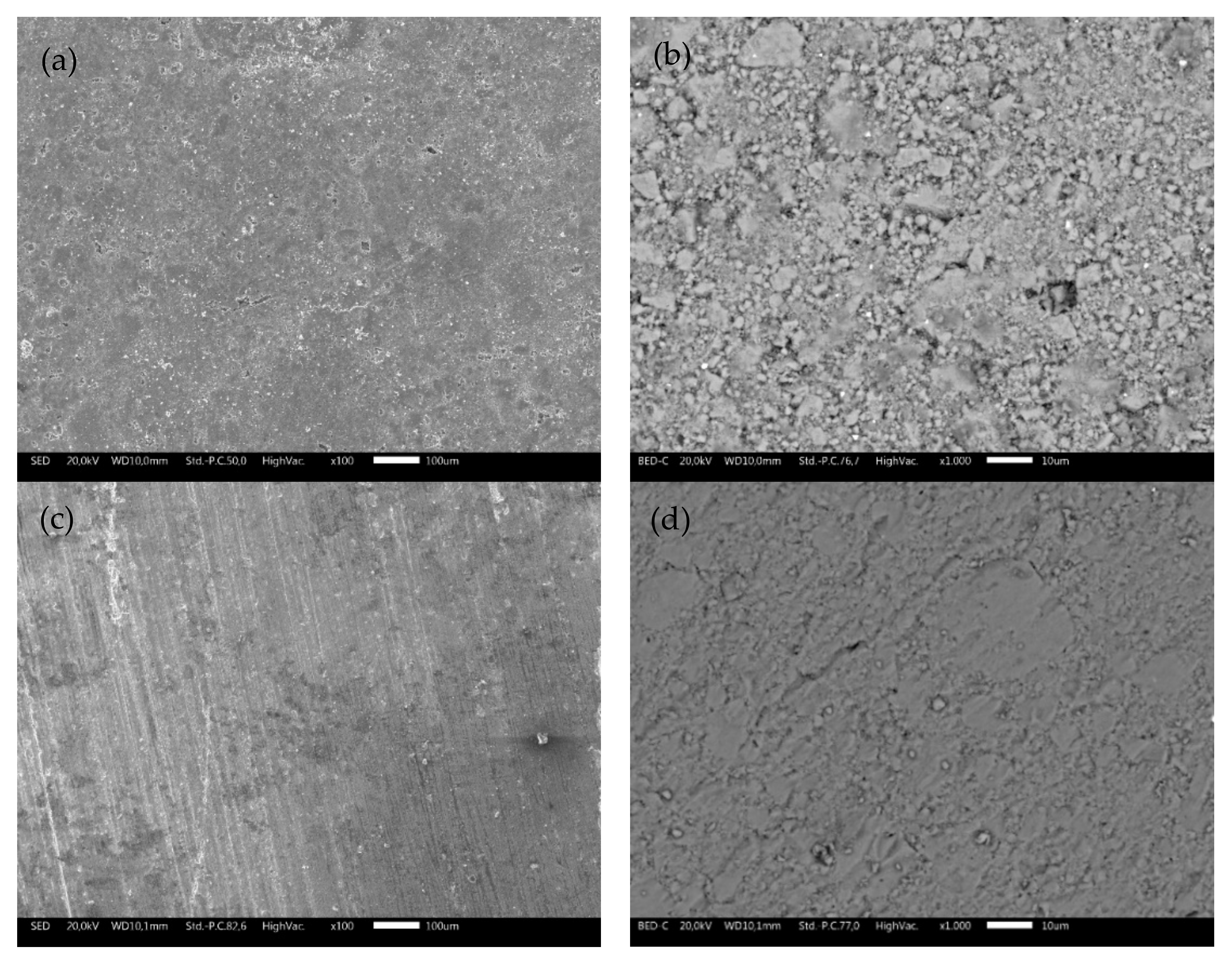

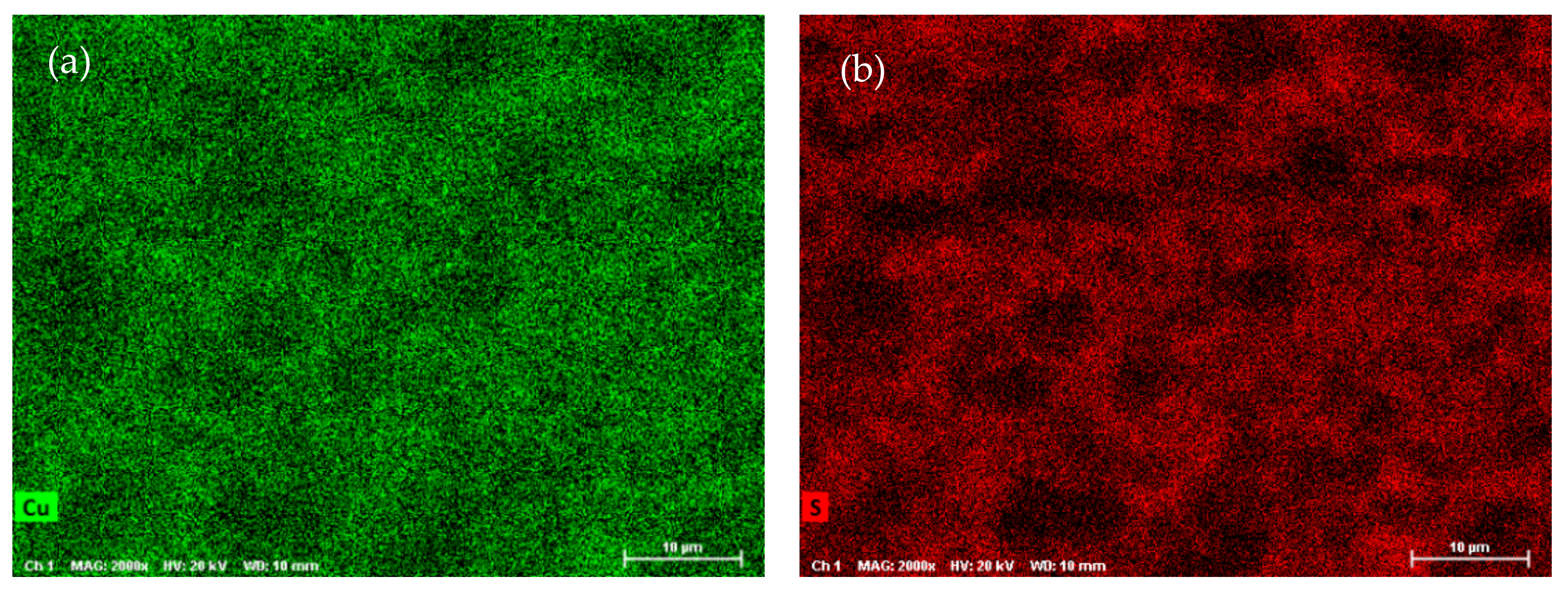

| Sample Name | Atomic Fraction (±1%) | |||

|---|---|---|---|---|

| Cu | Sn | S | O | |

| TS1 | 15.11 | 26.40 | 14.92 | 43.55 |

| TS2 | 40.09 | 16.64 | 41.55 | 1.7 |

| TS3 | 30.31 | 15.43 | 45.96 | 3.2 |

| Sample Name | Atomic Fraction (±1%) | |||

|---|---|---|---|---|

| Cu | Sn | S | O | |

| ODP1 | 16.90 | 32.03 | 46.92 | 4.05 |

| ODP2 | 15.46 | 30.13 | 45.11 | 9.27 |

| ODP3 | 16.82 | 31.68 | 49.21 | 2.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lohani, K.; Fanciulli, C.; Scardi, P. Effects of Preparation Procedures and Porosity on Thermoelectric Bulk Samples of Cu2SnS3 (CTS). Materials 2022, 15, 712. https://doi.org/10.3390/ma15030712

Lohani K, Fanciulli C, Scardi P. Effects of Preparation Procedures and Porosity on Thermoelectric Bulk Samples of Cu2SnS3 (CTS). Materials. 2022; 15(3):712. https://doi.org/10.3390/ma15030712

Chicago/Turabian StyleLohani, Ketan, Carlo Fanciulli, and Paolo Scardi. 2022. "Effects of Preparation Procedures and Porosity on Thermoelectric Bulk Samples of Cu2SnS3 (CTS)" Materials 15, no. 3: 712. https://doi.org/10.3390/ma15030712

APA StyleLohani, K., Fanciulli, C., & Scardi, P. (2022). Effects of Preparation Procedures and Porosity on Thermoelectric Bulk Samples of Cu2SnS3 (CTS). Materials, 15(3), 712. https://doi.org/10.3390/ma15030712