Spark Plasma Sintering of WC-Based 10wt%Co Hard Alloy: A Study of Sintering Kinetics and Solid-Phase Processes

Abstract

:1. Introduction

2. Materials and Methods

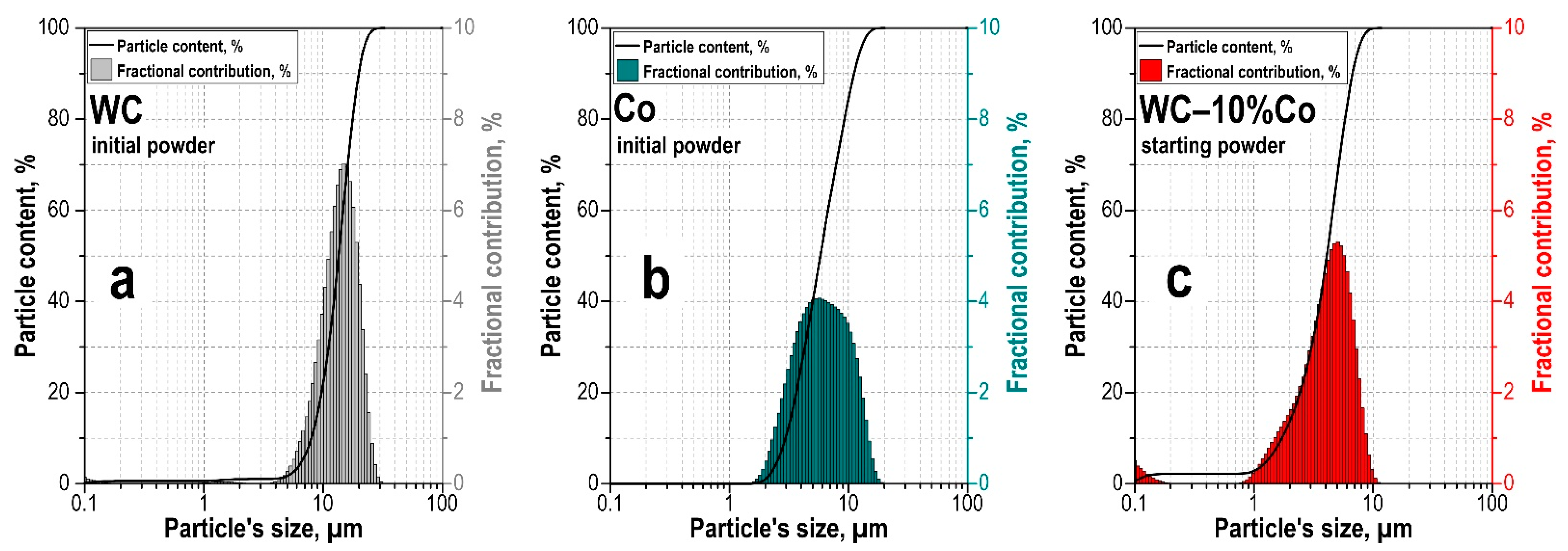

2.1. Materials

2.2. Initial Powder Production

2.3. SPS Consolidation

2.4. Characteristics of Research Methods

3. Results and Discussion

3.1. WC Grinding

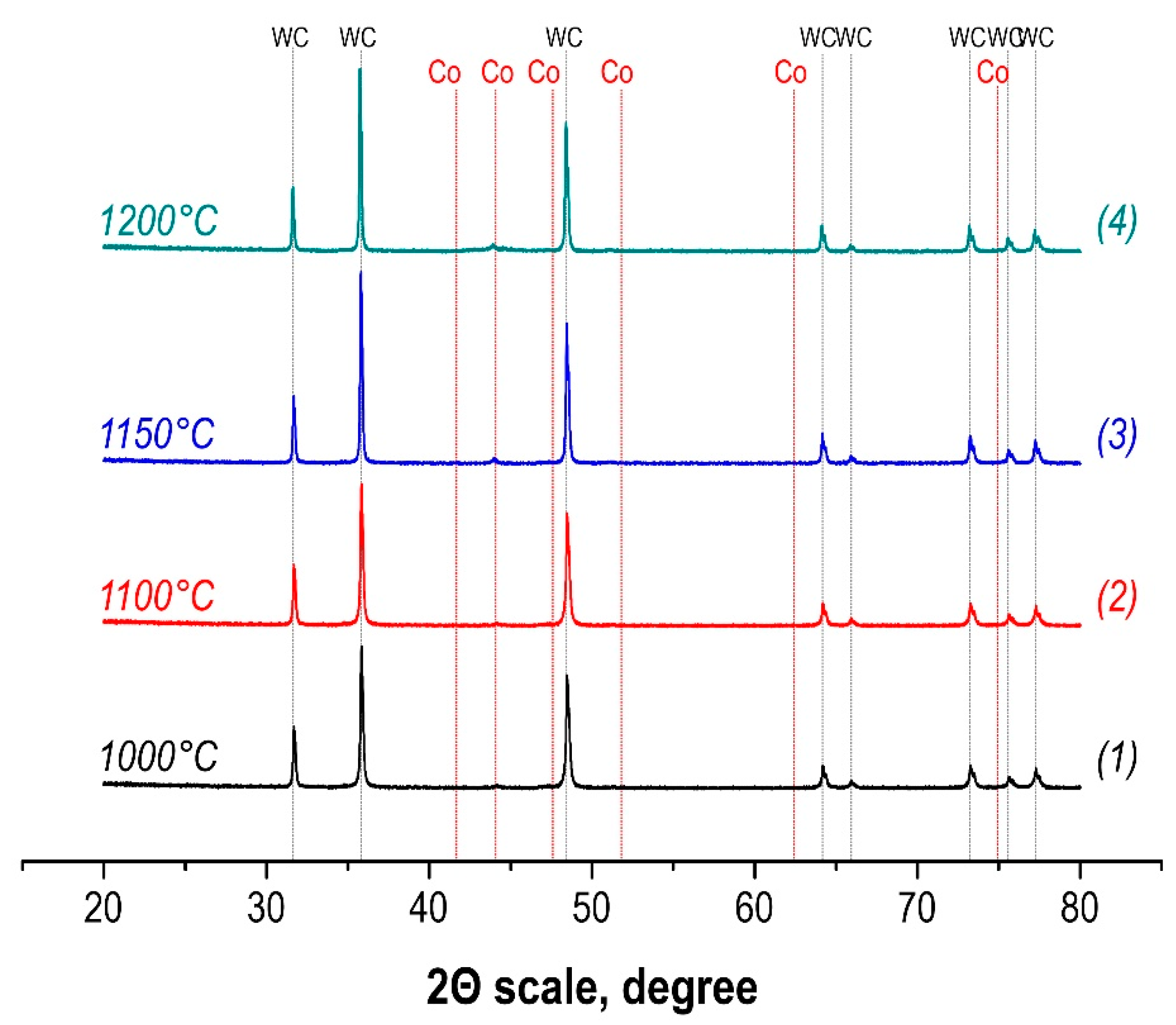

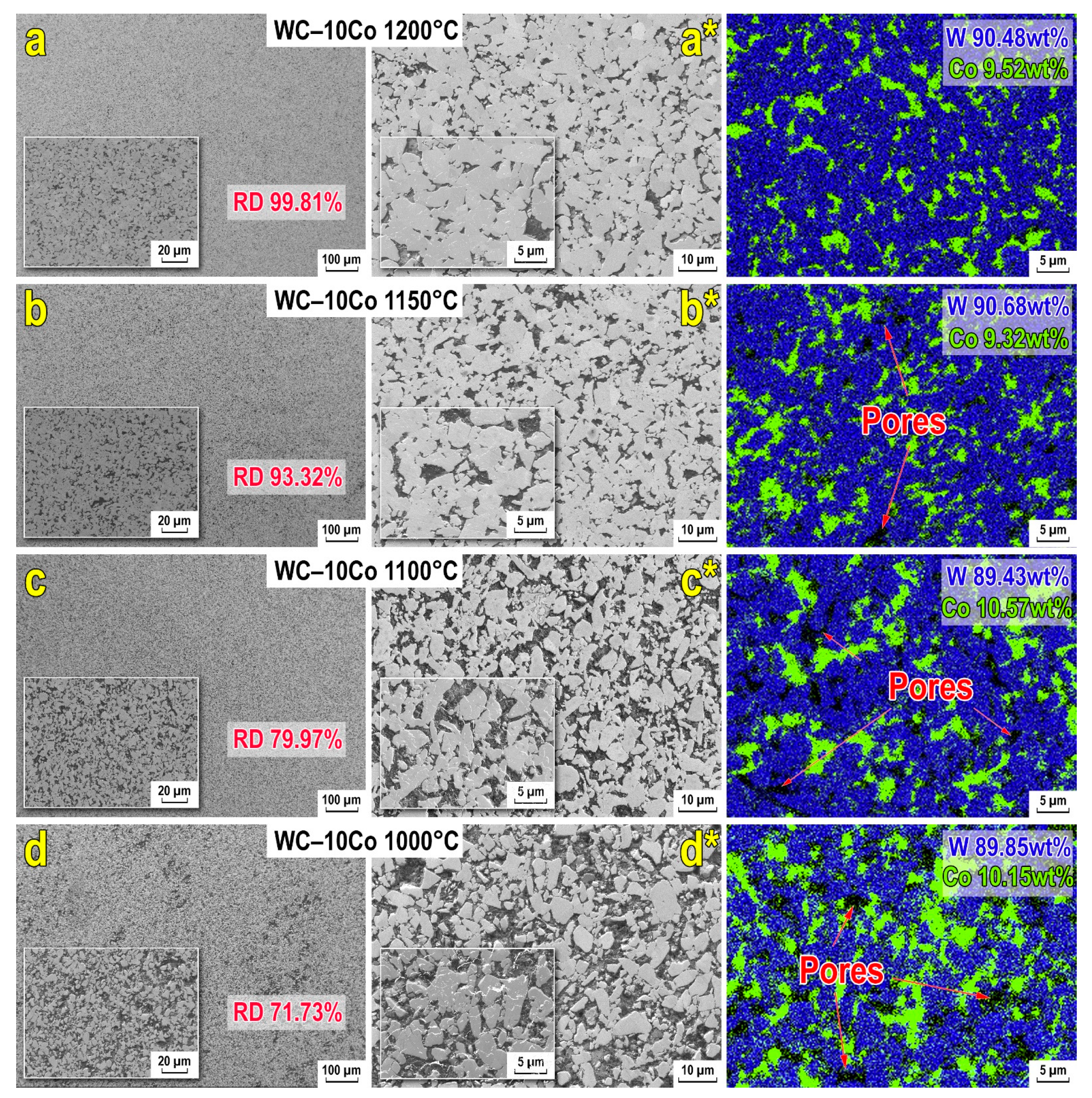

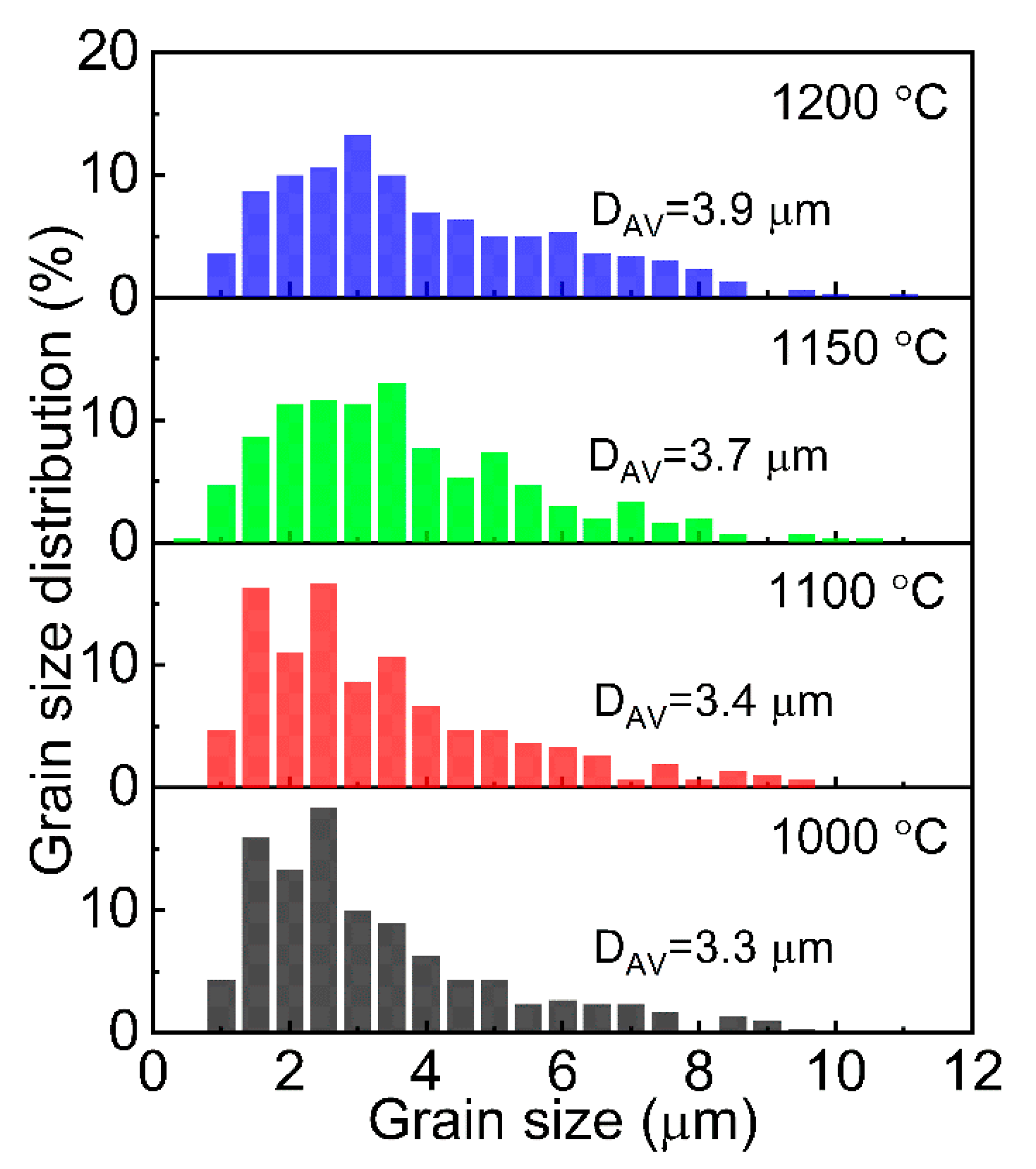

3.2. SPS Consolidation of Powder of the WC-10Co System

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Ettmayer, P.; Kolaska, H.; Ortner, H.M. History of hardmetals. In Comprehensive Hard Materials; Elsevier: Amsterdam, The Netherlands, 2014; pp. 3–27. [Google Scholar]

- Gee, M.G.; Gant, A.; Roebuck, B. Wear mechanisms in abrasion and erosion of WC/Co and related hardmetals. Wear 2007, 263, 137–148. [Google Scholar] [CrossRef]

- Rizzo, A.; Goel, S.; Grilli, M.L.; Iglesias, R.; Jaworska, L.; Lapkovskis, V.; Novak, P.; Postolnyi, B.O.; Valerini, D. The critical raw materials in cutting tools for machining applications: A review. Materials 2020, 13, 1377. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Humphry-Baker, S.A.; Ramanujam, P.; Smith, G.D.W.; Binner, J.; Lee, W.E. Ablation resistance of tungsten carbide cermets under extreme conditions. Int. J. Refract. Met. Hard Mater. 2020, 93, 105356. [Google Scholar] [CrossRef]

- Humphry-Baker, S.A.; Harrison, R.W.; Greaves, G.; Knowles, A.J.; Smith, G.D.W.; Donnelly, S.E.; Lee, W.E. A candidate fusion engineering material, WC-FeCr. Scr. Mater. 2018, 155, 129–133. [Google Scholar] [CrossRef]

- Pittari, J.J.; Murdoch, H.A.; Kilczewski, S.M.; Hornbuckle, B.C.; Swab, J.J.; Darling, K.A.; Wright, J.C.; Materials, H.; Pittari, J.J.; Murdoch, H.A.; et al. Sintering of tungsten carbide cermets with an iron-based ternary alloy binder: Processing and thermodynamic considerations. Int. J. Refract. Met. Hard Mater. 2018, 76, 1–11. [Google Scholar] [CrossRef]

- Windsor, C.G.; Morgan, J.G.; Buxton, P.F.; Costley, A.E.; Smith, G.D.W.; Sykes, A. Modelling the power deposition into a spherical tokamak fusion power plant. Nucl. Fusion 2017, 57, 036001. [Google Scholar] [CrossRef]

- Windsor, C.G.; Marshall, J.M.; Morgan, J.G.; Fair, J.; Smith, G.D.W.; Rajczyk-Wryk, A.; Tarragó, J.M. Design of cemented tungsten carbide and boride-containing shields for a fusion power plant. Nucl. Fusion 2018, 58, 076014. [Google Scholar] [CrossRef] [Green Version]

- Krylova, T.A.; Chumakov, Y.A.; Vasilyeva, M.P. Microstructure and properties of WC-Ni3Al composite coatings fabricated by non-vacuum electron beam cladding. Mater. Lett. 2022, 308, 131117. [Google Scholar] [CrossRef]

- Hasan, M.; Zhao, J.; Huang, Z.; Wu, H.; Jia, F.; Jiang, Z. Effects of holding time on the sintering of cemented tungsten carbide powder and bonding with high-strength steel wire. J. Mater. Eng. Perform. 2019, 28, 4074–4085. [Google Scholar] [CrossRef]

- Wang, W.; Wang, Z.; Li, Y.; Wang, D.; Li, M.; Chen, Q. Wear behavior of Fe-WC/metal double layer coatings fabricated by resistance seamweld method. Jinshu Xuebao Acta Metall. Sin. 2019, 55, 537–546. [Google Scholar] [CrossRef]

- Kozyrev, E.N.; Kumykov, V.K.; Kushhabiev, A.S.; Manukyants, A.R.; Kasumov, Y.N.; Sozaev, V.A. Development of diamond–metal compositions for diamond tools. J. Surf. Investig. X-ray Synchrotron Neutron Tech. 2020, 14, 639–642. [Google Scholar] [CrossRef]

- Sharin, P.P.; Akimova, M.P.; Yakovleva, S.P.; Popov, V.I. The structure and microhardness of binding for diamond tools based on tungsten carbide obtained by impregnation with an iron–carbon melt. Inorg. Mater. Appl. Res. 2021, 12, 1562–1571. [Google Scholar] [CrossRef]

- Vokhmyanin, D.S.; Oglezneva, S.A. Growth features of diamond films on the tungsten carbide surface with a copper sublayer. Russ. J. Non-Ferrous Met. 2019, 60, 754–761. [Google Scholar] [CrossRef]

- Radek, N.; Pietraszek, J.; Gądek-Moszczak, A.; Orman, Ł.J.; Szczotok, A. The morphology and mechanical properties of ESD coatings before and after laser beam machining. Materials 2020, 13, 2331. [Google Scholar] [CrossRef]

- Yadlapalli, B.K.; Maharana, H.S.; Basu, A. Structure and properties of pulse electrodeposited Cr–WC coating. Surf. Topogr. Metrol. Prop. 2020, 8, 025023. [Google Scholar] [CrossRef]

- Pak, A.Y.; Shanenkov, I.I.; Mamontov, G.Y.; Kokorina, A.I. Vacuumless synthesis of tungsten carbide in a self-shielding atmospheric plasma of DC arc discharge. Int. J. Refract. Met. Hard Mater. 2020, 93, 105343. [Google Scholar] [CrossRef]

- Kamimoto, Y.; Kasuga, R.; Takeshita, K.; Hagio, T.; Kuroda, K.; Ichino, R.; Deevanhxay, P. Electrochemical behavior of tungsten carbide-cobalt alloy using molten hydroxide as electrolyte under low temperature. J. Mater. Cycles Waste Manag. 2020, 22, 348–353. [Google Scholar] [CrossRef]

- Mostajeran, A.; Shoja-Razavi, R.; Hadi, M.; Erfanmanesh, M.; Barekat, M.; Savaghebi Firouzabadi, M. Evaluation of the mechanical properties of WC-FeAl composite coating fabricated by laser cladding method. Int. J. Refract. Met. Hard Mater. 2020, 88, 105199. [Google Scholar] [CrossRef]

- Peng, Y.; Li, T.; Long, J.; Li, H.; Lu, B.; Chen, F.; Du, Y. Effect of bimodal WC particle size and binder composition on the morphology of WC grains in WC–Co–Ni3Al cemented carbides. J. Mater. Res. Technol. 2021, 12, 1747–1754. [Google Scholar] [CrossRef]

- Shichalin, O.O.; Buravlev, I.Y.; Portnyagin, A.S.; Dvornik, M.I.; Mikhailenko, E.A.; Golub, A.V.; Zakharenko, A.M.; Sukhorada, A.E.; Talskikh, K.Y.; Buravleva, A.A.; et al. SPS hard metal alloy WC-8Ni-8Fe fabrication based on mechanochemical synthetic tungsten carbide powder. J. Alloys Compd. 2020, 816, 152547. [Google Scholar] [CrossRef]

- Shichalin, O.O.; Buravlev, I.Y.; Papynov, E.K.; Golub, A.V.; Belov, A.A.; Buravleva, A.A.; Sakhnevich, V.N.; Dvornik, M.I.; Vlasova, N.M.; Gerasimenko, A.V.; et al. Comparative study of WC-based hard alloys fabrication via spark plasma sintering using Co, Fe, Ni, Cr, and Ti binders. Int. J. Refract. Met. Hard Mater. 2022, 102, 105725. [Google Scholar] [CrossRef]

- Edtmaier, C.; Wolf, M.; de Oro Calderon, R.; Schubert, W.-D. Effect of nickel on the formation of γ/γ′ microstructures in WC/Co-Ni–Al–W. Int. J. Refract. Met. Hard Mater. 2021, 100, 105652. [Google Scholar] [CrossRef]

- Ratov, B.T.; Bondarenko, M.O.; Mechnik, V.A.; Strelchuk, V.V.; Prikhna, T.A.; Kolodnitskyi, V.M.; Nikolenko, A.S.; Lytvyn, P.M.; Danylenko, I.M.; Moshchil, V.E.; et al. Structure and properties of WC–Co composites with different CrB2 concentrations, sintered by vacuum hot pressing, for drill bits. J. Superhard Mater. 2021, 43, 344–354. [Google Scholar] [CrossRef]

- Wu, H.; Zheng, Y.; Zhang, J.; Ke, Z.; Xu, X. Influence of WC content on microstructure and mechanical properties of Mo2FeB2-based cermets fabricated by multi-step sintering. Ceram. Int. 2021, 47, 20562–20569. [Google Scholar] [CrossRef]

- Fernandes, C.M.; Senos, A.M.R. Cemented carbide phase diagrams: A review. Int. J. Refract. Met. Hard Mater. 2011, 29, 405–418. [Google Scholar] [CrossRef]

- Kim, H.C.; Shon, I.J.; Yoon, J.K.; Doh, J.M.; Munir, Z.A. Rapid sintering of ultrafine WC–Ni cermets. Int. J. Refract. Met. Hard Mater. 2006, 24, 427–431. [Google Scholar] [CrossRef]

- Reva, V.P.; Onishchenko, D.V.; Petrov, V.V.; Kim, V.A.; Evstigneev, A.I. Formation of hard alloy VK8 using tungsten carbide powder synthesized by mechanochemical technology. Refract. Ind. Ceram. 2013, 54, 295–298. [Google Scholar] [CrossRef]

- Samokhin, A.; Alekseev, N.; Astashov, A.; Dorofeev, A.; Fadeev, A.; Sinayskiy, M.; Kalashnikov, Y. Preparation of W–C–Co composite micropowder with spherical shaped particles using plasma technologies. Materials 2021, 14, 4258. [Google Scholar] [CrossRef]

- Dvornik, M.; Mikhailenko, E.; Nikolenko, S.; Vlasova, N.; Skiruta, A. Production of ultrafine-grained spherical β-WC–W2C–Co microparticles by electro discharge erosion of WC–15Co alloy in glycerol and their solutions. Mater. Res. Express 2020, 7, 096504. [Google Scholar] [CrossRef]

- Pak, A.Y.; Kokorina, A.I. Effect of energy on the phase composition of the product of arc discharge synthesis in the tungsten–carbon system obtained in a self-shielding autonomous gas environment. Inorg. Mater. Appl. Res. 2021, 12, 544–550. [Google Scholar] [CrossRef]

- Raihanuzzaman, R.M.; Rosinski, M.; Xie, Z.; Ghomashchi, R. Microstructure and mechanical properties and of pulse plasma compacted WC–Co. Int. J. Refract. Met. Hard Mater. 2016, 60, 58–67. [Google Scholar] [CrossRef]

- SIWAK, P.; GARBIEC, D. Microstructure and mechanical properties of WC–Co, WC–Co–Cr3C2 and WC–Co–TaC cermets fabricated by spark plasma sintering. Trans. Nonferrous Met. Soc. China 2016, 26, 2641–2646. [Google Scholar] [CrossRef]

- Liu, K.; Wang, Z.; Yin, Z.; Cao, L.; Yuan, J. Effect of Co content on microstructure and mechanical properties of ultrafine grained WC–Co cemented carbide sintered by spark plasma sintering. Ceram. Int. 2018, 44, 18711–18718. [Google Scholar] [CrossRef]

- Munir, Z.A.; Ohyanagi, M. Perspectives on the spark plasma sintering process. J. Mater. Sci. 2021, 56, 1–15. [Google Scholar] [CrossRef]

- Papynov, E.K.; Shichalin, O.O.; Medkov, M.A.; Grishchenko, D.N.; Tkachenko, I.A.; Fedorets, A.N.; Pechnikov, V.S.; Golub, A.V.; Buravlev, I.Y.; Tananaev, I.G.; et al. Spark plasma sintering of special-purpose functional ceramics based on UO2, ZrO2, Fe3O4/α-Fe2O3. Glas. Phys. Chem. 2018, 44, 632–640. [Google Scholar] [CrossRef]

- Rong, H.; Peng, Z.; Ren, X.; Peng, Y.; Wang, C.; Fu, Z.; Qi, L.; Miao, H. Ultrafine WC–Ni cemented carbides fabricated by spark plasma sintering. Mater. Sci. Eng. A 2012, 532, 543–547. [Google Scholar] [CrossRef]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-assisted sintering technology/spark plasma sintering: Mechanisms, materials, and technology developments. Adv. Eng. 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Morsi, K. Combustion synthesis and the electric field: A review. Int. J. Self-Propagating High-Temp. Synth. 2017, 26, 199–209. [Google Scholar] [CrossRef]

- Mamedov, V. Spark plasma sintering as advanced PM sintering method. Powder Metall. 2002, 45, 322–328. [Google Scholar] [CrossRef]

- Dvornik, M.I.; Zaitsev, A.V. Variation in strength, hardness, and fracture toughness in transition from medium-grained to ultrafine hard alloy. Russ. J. Non-Ferrous Met. 2018, 27, 3610–3618. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, A.; Huang, L.; Du, Y.; Jin, Y.; Yang, X.; Zhang, J. Effects of metal binder content and carbide grain size on the microstructure and properties of SPS manufactured WC–Fe composites. J. Alloys Compd. 2019, 784, 519–526. [Google Scholar] [CrossRef]

- Chuvil’deev, V.N.; Blagoveshchenskiy, Y.V.; Nokhrin, A.V.; Sakharov, N.V.; Boldin, M.S.; Isaeva, N.V.; Shotin, S.V.; Lopatin, Y.G.; Smirnova, E.S.; Popov, A.A.; et al. Sparking plasma sintering of tungsten carbide nanopowders. Nanotechnol. Russ. 2015, 10, 434–448. [Google Scholar] [CrossRef]

- Chuvil’deev, V.N.; Blagoveshchenskii, Y.V.; Boldin, M.S.; Moskvicheva, A.V.; Sakharov, N.V.; Nokhrin, A.V.; Isaeva, N.V.; Shotin, S.V.; Lopatin, Y.G.; Pisklov, A.V.; et al. High-speed electropulse plasma sintering of nanostructured tungsten carbide: Part 1. Experiment. Russ. J. Non-Ferrous Met. 2014, 55, 592–598. [Google Scholar] [CrossRef]

- Chuvil’deev, V.N.; Blagoveshchenskiy, Y.V.; Nokhrin, A.V.; Boldin, M.S.; Sakharov, N.V.; Isaeva, N.V.; Shotin, S.V.; Belkin, O.A.; Popov, A.A.; Smirnova, E.S.; et al. Spark plasma sintering of tungsten carbide nanopowders obtained through DC arc plasma synthesis. J. Alloys Compd. 2017, 708, 547–561. [Google Scholar] [CrossRef]

- Biesuz, M.; Grasso, S.; Sglavo, V.M. What’s new in ceramics sintering? A short report on the latest trends and future prospects. Curr. Opin. Solid State Mater. Sci. 2020, 24, 100868. [Google Scholar] [CrossRef]

- Ghasali, E.; Alizadeh, M.; Niazmand, M.; Ebadzadeh, T. Fabrication of magnesium-boron carbide metal matrix composite by powder metallurgy route: Comparison between microwave and spark plasma sintering. J. Alloys Compd. 2017, 697, 200–207. [Google Scholar] [CrossRef]

- Munir, Z.A.; Anselmi-Tamburini, U.; Ohyanagi, M. The effect of electric field and pressure on the synthesis and consolidation of materials: A review of the spark plasma sintering method. J. Mater. Sci. 2006, 41, 763–777. [Google Scholar] [CrossRef]

- Papynov, E.K.; Shichalin, O.O.; Mayorov, V.Y.; Modin, E.B.; Portnyagin, A.S.; Tkachenko, I.A.; Belov, A.A.; Gridasova, E.A.; Tananaev, I.G.; Avramenko, V.A. Spark plasma sintering as a high-tech approach in a new generation of synthesis of nanostructured functional ceramics. Nanotechnol. Russ. 2017, 12, 49–61. [Google Scholar] [CrossRef]

- Simonenko, T.L.; Kalinina, M.V.; Simonenko, N.P.; Simonenko, E.P.; Glumov, O.V.; Mel’nikova, N.A.; Murin, I.V.; Shichalin, O.O.; Papynov, E.K.; Shilova, O.A.; et al. Spark plasma sintering of nanopowders in the CeO2-Y2O3 system as a promising approach to the creation of nanocrystalline intermediate-temperature solid electrolytes. Ceram. Int. 2018, 44, 19879–19884. [Google Scholar] [CrossRef]

- Chuvil’deev, V.N.; Blagoveshchenskii, Y.V.; Sakharov, N.V.; Boldin, M.S.; Nokhrin, A.V.; Isaeva, N.V.; Shotin, S.V.; Lopatin, Y.G.; Smirnova, E.S. Preparation and investigation of ultrafine-grained tungsten carbide with high hardness and fracture toughness. Dokl. Phys. 2015, 60, 288–291. [Google Scholar] [CrossRef]

- Chuvil’Deev, V.N.; Blagoveshchenskii, Y.V.; Boldin, M.S.; Sakharov, N.V.; Nokhrin, A.V.; Isaeva, N.V.; Shotin, S.V.; Lopatin, Y.G.; Belkin, O.A.; Smirnovaa, E.S. High-strength ultrafine-grained tungsten-carbide-based materials obtained by spark plasma sintering. Tech. Phys. Lett. 2015, 41, 397–400. [Google Scholar] [CrossRef]

- Ghasali, E.; Ebadzadeh, T.; Alizadeh, M.; Razavi, M. Mechanical and microstructural properties of WC-based cermets: A comparative study on the effect of Ni and Mo binder phases. Ceram. Int. 2018, 44, 2283–2291. [Google Scholar] [CrossRef]

- Panov, V.S. Nanostructured sintered WC–Co hard metals (review). Powder Metall. Met. Ceram. 2015, 53, 643–654. [Google Scholar] [CrossRef]

- Papynov, E.K.; Shichalin, O.O.; Mironenko, A.Y.; Ryakov, A.V.; Manakov, I.V.; Makhrov, P.V.; Buravlev, I.Y.; Tananaev, I.G.; Avramenko, V.A.; Sergienko, V.I. Synthesis of high-density pellets of uranium dioxide by spark plasma sintering in dies of different types. Radiochemistry 2018, 60, 362–370. [Google Scholar] [CrossRef]

- Papynov, E.K.; Shichalin, O.O.; Buravlev, I.Y.; Portnyagin, A.S.; Belov, A.A.; Maiorov, V.Y.; Skurikhina, Y.E.; Merkulov, E.B.; Glavinskaya, V.O.; Nomerovskii, A.D.; et al. Reactive spark plasma synthesis of porous bioceramic wollastonite. Russ. J. Inorg. Chem. 2020, 65, 263–270. [Google Scholar] [CrossRef]

- Blagoveshchenskiy, Y.V.; Isayeva, N.V.; Blagoveshchenskaya, N.V.; Melnik, Y.I.; Chuvildeyev, V.N.; Nokhrin, A.V.; Sakharov, N.V.; Boldin, M.S.; Smirnov, Y.S.; Shotin, S.V.; et al. Methods of compacting nanostructured tungsten–cobalt alloys from Nanopowders obtained by plasma chemical synthesis. Inorg. Mater. Appl. Res. 2015, 6, 415–426. [Google Scholar] [CrossRef]

- Lantcev, E.; Nokhrin, A.; Malekhonova, N.; Boldin, M.; Chuvil’deev, V.; Blagoveshchenskiy, Y.; Isaeva, N.; Andreev, P.; Smetanina, K.; Murashov, A. A study of the impact of graphite on the kinetics of SPS in nano- and submicron WC-10%Co powder compositions. Ceramics 2021, 4, 331–363. [Google Scholar] [CrossRef]

- Ghasali, E.; Orooji, Y.; Tahamtan, H.; Asadian, K.; Alizadeh, M.; Ebadzadeh, T. The effects of metallic additives on the microstructure and mechanical properties of WC–Co cermets prepared by microwave sintering. Ceram. Int. 2020, 46, 29199–29206. [Google Scholar] [CrossRef]

- Lantsev, E.; Malekhonova, N.; Nokhrin, A.; Chuvil’deev, V.; Boldin, M.; Blagoveshchenskiy, Y.; Andreev, P.; Smetanina, K.; Isaeva, N.; Shotin, S. Influence of oxygen on densification kinetics of WC nanopowders during SPS. Ceram. Int. 2021, 47, 4294–4309. [Google Scholar] [CrossRef]

- Buravlev, I.Y.; Shichalin, O.O.; Papynov, E.K.; Golub, A.V.; Gridasova, E.A.; Buravleva, A.A.; Yagofarov, V.Y.; Dvornik, M.I.; Fedorets, A.N.; Reva, V.P.; et al. WC-5TiC-10Co hard metal alloy fabrication via mechanochemical and SPS techniques. Int. J. Refract. Met. Hard Mater. 2021, 94, 105385. [Google Scholar] [CrossRef]

- Papynov, E.K.; Shichalin, O.O.; Apanasevich, V.I.; Portnyagin, A.S.; Yu, M.V.; Yu, B.I.; Merkulov, E.B.; Kaidalova, T.A.; Modin, E.B.; Afonin, I.S.; et al. Sol-gel (template) synthesis of osteoplastic CaSiO3/HAp powder biocomposite: “In vitro” and “in vivo” biocompatibility assessment. Powder Technol. 2020, 367, 762–773. [Google Scholar] [CrossRef]

- Yarusova, S.B.; Shichalin, O.O.; Belov, A.A.; Azon, S.A.; Buravlev, I.Y.; Golub, A.V.; Mayorov, V.Y.; Gerasimenko, A.V.; Papynov, E.K.; Ivanets, A.I.; et al. Synthesis of amorphous KAlSi3O8 for cesium radionuclide immobilization into solid matrices using spark plasma sintering technique. Ceram. Int. 2022, 48, 3808–3817. [Google Scholar] [CrossRef]

- Papynov, E.K.K.; Mayorov, V.Y.Y.; Portnyagin, A.S.S.; Shichalin, O.O.O.; Kobylyakov, S.P.; Kaidalova, T.A.A.; Nepomnyashiy, A.V.V.; Sokol׳nitskaya, T.A.; Zub, Y.L.L.; Avramenko, V.A.A.; et al. Application of carbonaceous template for porous structure control of ceramic composites based on synthetic wollastonite obtained via Spark Plasma Sintering. Ceram. Int. 2015, 41, 1171–1176. [Google Scholar] [CrossRef]

- Papynov, E.K.; Portnyagin, A.S.; Modin, E.B.; Mayorov, V.Y.; Shichalin, O.O.; Golikov, A.P.; Pechnikov, V.S.; Gridasova, E.A.; Tananaev, I.G.; Avramenko, V.A. A complex approach to assessing porous structure of structured ceramics obtained by SPS technique. Mater. Charact. 2018, 145, 294–302. [Google Scholar] [CrossRef]

- Shapkin, N.P.; Papynov, E.K.; Shichalin, O.O.; Buravlev, I.Y.; Simonenko, E.P.; Simonenko, N.P.; Zavjalov, A.P.; Belov, A.A.; Portnyagin, A.S.; Gerasimenko, A.V.; et al. Spark plasma sintering-reactive synthesis of SiC and SiC–HfB2 ceramics based on natural renewable raw materials. Russ. J. Inorg. Chem. 2021, 66, 629–637. [Google Scholar] [CrossRef]

- Papynov, E.K.; Shichalin, O.O.; Buravlev, I.Y.; Belov, A.A.; Portnyagin, A.S.; Fedorets, A.N.; Azarova, Y.A.; Tananaev, I.G.; Sergienko, V.I. Spark plasma sintering-reactive synthesis of SrWO4 ceramic matrices for 90Sr immobilization. Vacuum 2020, 180, 109628. [Google Scholar] [CrossRef]

- Papynov, E.K.; Belov, A.A.; Shichalin, O.O.; Buravlev, I.Y.; Azon, S.A.; Gridasova, E.A.; Parotkina, Y.A.; Yagofarov, V.Y.; Drankov, A.N.; Golub, A.V.; et al. Synthesis of perovskite-like SrTiO3 ceramics for radioactive strontium immobilization by spark plasma sintering-reactive synthesis. Russ. J. Inorg. Chem. 2021, 66, 645–653. [Google Scholar] [CrossRef]

- Papynov, E.K.; Shichalin, O.O.; Belov, A.A.; Buravlev, I.Y.; Portnyagin, A.S.; Azon, S.A.; Shlyk, D.K.; Buravleva, A.A.; Parot’kina, Y.A.; Nepomnyushchaya, V.A.; et al. Synthesis of mineral-like SrWO4 ceramics with the scheelite structure and a radioisotope product based on it. Russ. J. Inorg. Chem. 2021, 66, 1434–1446. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Gordeev, A.N.; Kolesnikov, A.F.; Papynov, E.K.; Shichalin, O.O.; Tal’skikh, K.Y.; Gridasova, E.A.; Avramenko, V.A.; Sevastyanov, V.G.; et al. Impact of a supersonic dissociated air flow on the surface of HfB2–30 vol % SiC UHTC produced by the Sol–Gel method. Russ. J. Inorg. Chem. 2018, 63, 1484–1493. [Google Scholar] [CrossRef]

- Simonenko, E.P.; Simonenko, N.P.; Gordeev, A.N.; Papynov, E.K.; Shichalin, O.O.; Kolesnikov, A.F.; Avramenko, V.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Study of the thermal behavior of wedge-shaped samples of HfB2–45 vol % SiC ultra-high-temperature composite in a high-enthalpy air flow. Russ. J. Inorg. Chem. 2018, 63, 421–432. [Google Scholar] [CrossRef]

- Simonenko, N.P.; Simonenko, E.P.; Mokrushin, A.S.; Popov, V.S.; Vasiliev, A.A.; Sevastyanov, V.G.; Kuznetsov, N.T. Thin films of the composition 8% Y2O3–92% ZrO2 (8YSZ) as gas-sensing materials for oxygen detection. Russ. J. Inorg. Chem. 2017, 62, 695–701. [Google Scholar] [CrossRef]

- Simonenko, T.L.; Kalinina, M.V.; Simonenko, N.P.; Simonenko, E.P.; Glumov, O.V.; Mel’nikova, N.A.; Murin, I.V.; Shichalin, O.O.; Papynov, E.K.; Shilova, O.A.; et al. Synthesis of BaCe0.9xZrxY0.1O3 nanopowders and the study of proton conductors fabricated on their basis by low-temperature spark plasma sintering. Int. J. Hydrogen Energy 2019, 44, 20345–20354. [Google Scholar] [CrossRef]

- Papynov, E.K.; Shichalin, O.O.; Mayorov, V.Y.; Kuryavyi, V.G.; Kaidalova, T.A. SPS technique for ionizing radiation source fabrication based on dense cesium-containing core. J. Hazard. Mater. 2019, 369, 25–30. [Google Scholar] [CrossRef] [PubMed]

- Kosyanov, D.Y.; Yavetskiy, R.P.; Vorona, I.O.; Shichalin, O.O.; Papynov, E.K.; Vornovskikh, A.A.; Kuryavyi, V.G.; Vovna, V.I.; Golokhvast, K.S.; Tolmachev, A.V. Transparent 4 at% Nd3+:Y3Al5O12 ceramic by reactive spark plasma sintering. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2017; Volume 1874, p. 040020. [Google Scholar]

- Golovkina, L.S.; Orlova, A.I.; Chuvil’deev, V.N.; Boldin, M.S.; Lantcev, E.A.; Nokhrin, A.V.; Sakharov, N.V.; Zelenov, A.Y. Spark plasma sintering of high-density fine-grained Y2.5Nd0.5Al5O12+SiC composite ceramics. Mater. Res. Bull. 2018, 103, 211–215. [Google Scholar] [CrossRef]

- Zavjalov, A.P.; Nikiforov, P.A.; Kosyanov, D.Y.; Zakharenko, A.M.; Trukhin, V.O.; Talskikh, K.Y.; Shichalin, O.O.; Papynov, E.K. Phase formation and densification peculiarities of Hf–C–N solid solution ceramics during reactive spark plasma sintering. Adv. Eng. Mater. 2020, 22, 2000482. [Google Scholar] [CrossRef]

- Kosyanov, D.Y.; Liu, X.; Vornovskikh, A.A.; Kosianova, A.A.; Zakharenko, A.M.; Zavjalov, A.P.; Shichalin, O.O.; Mayorov, V.Y.; Kuryavyi, V.G.; Qian, X.; et al. Al2O3–Ce:YAG and Al2O3–Ce:(Y,Gd)AG composite ceramics for high brightness lighting: Effect of microstructure. Mater. Charact. 2021, 172, 110883. [Google Scholar] [CrossRef]

- Mendelson, M.I. Average grain size in polycrystalline ceramics. J. Am. Ceram. Soc. 1969, 52, 443–446. [Google Scholar] [CrossRef]

- Rahaman, M.N. Ceramic Processing and Sintering; Dekker: New York, NY, USA, 2003. [Google Scholar]

- Liu, X.; Song, X.; Zhao, S.; Zhang, J. Spark plasma sintering densification mechanism for cemented carbides with different WC particle sizes. J. Am. Ceram. Soc. 2010, 93, 3153–3158. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Buravleva, A.A.; Fedorets, A.N.; Vornovskikh, A.A.; Ognev, A.V.; Nepomnyushchaya, V.A.; Sakhnevich, V.N.; Lembikov, A.O.; Kornakova, Z.E.; Kapustina, O.V.; Tarabanova, A.E.; et al. Spark Plasma Sintering of WC-Based 10wt%Co Hard Alloy: A Study of Sintering Kinetics and Solid-Phase Processes. Materials 2022, 15, 1091. https://doi.org/10.3390/ma15031091

Buravleva AA, Fedorets AN, Vornovskikh AA, Ognev AV, Nepomnyushchaya VA, Sakhnevich VN, Lembikov AO, Kornakova ZE, Kapustina OV, Tarabanova AE, et al. Spark Plasma Sintering of WC-Based 10wt%Co Hard Alloy: A Study of Sintering Kinetics and Solid-Phase Processes. Materials. 2022; 15(3):1091. https://doi.org/10.3390/ma15031091

Chicago/Turabian StyleBuravleva, Anastasia A., Alexander N. Fedorets, Anastasia A. Vornovskikh, Alexey V. Ognev, Valeria A. Nepomnyushchaya, Vladimir N. Sakhnevich, Aleksey O. Lembikov, Zlata E. Kornakova, Olesya V. Kapustina, Anna E. Tarabanova, and et al. 2022. "Spark Plasma Sintering of WC-Based 10wt%Co Hard Alloy: A Study of Sintering Kinetics and Solid-Phase Processes" Materials 15, no. 3: 1091. https://doi.org/10.3390/ma15031091

APA StyleBuravleva, A. A., Fedorets, A. N., Vornovskikh, A. A., Ognev, A. V., Nepomnyushchaya, V. A., Sakhnevich, V. N., Lembikov, A. O., Kornakova, Z. E., Kapustina, O. V., Tarabanova, A. E., Reva, V. P., & Buravlev, I. Y. (2022). Spark Plasma Sintering of WC-Based 10wt%Co Hard Alloy: A Study of Sintering Kinetics and Solid-Phase Processes. Materials, 15(3), 1091. https://doi.org/10.3390/ma15031091