Studies on the Ageing of Cement Stabilized Rammed Earth Material in Different Exposure Conditions

Abstract

1. Introduction

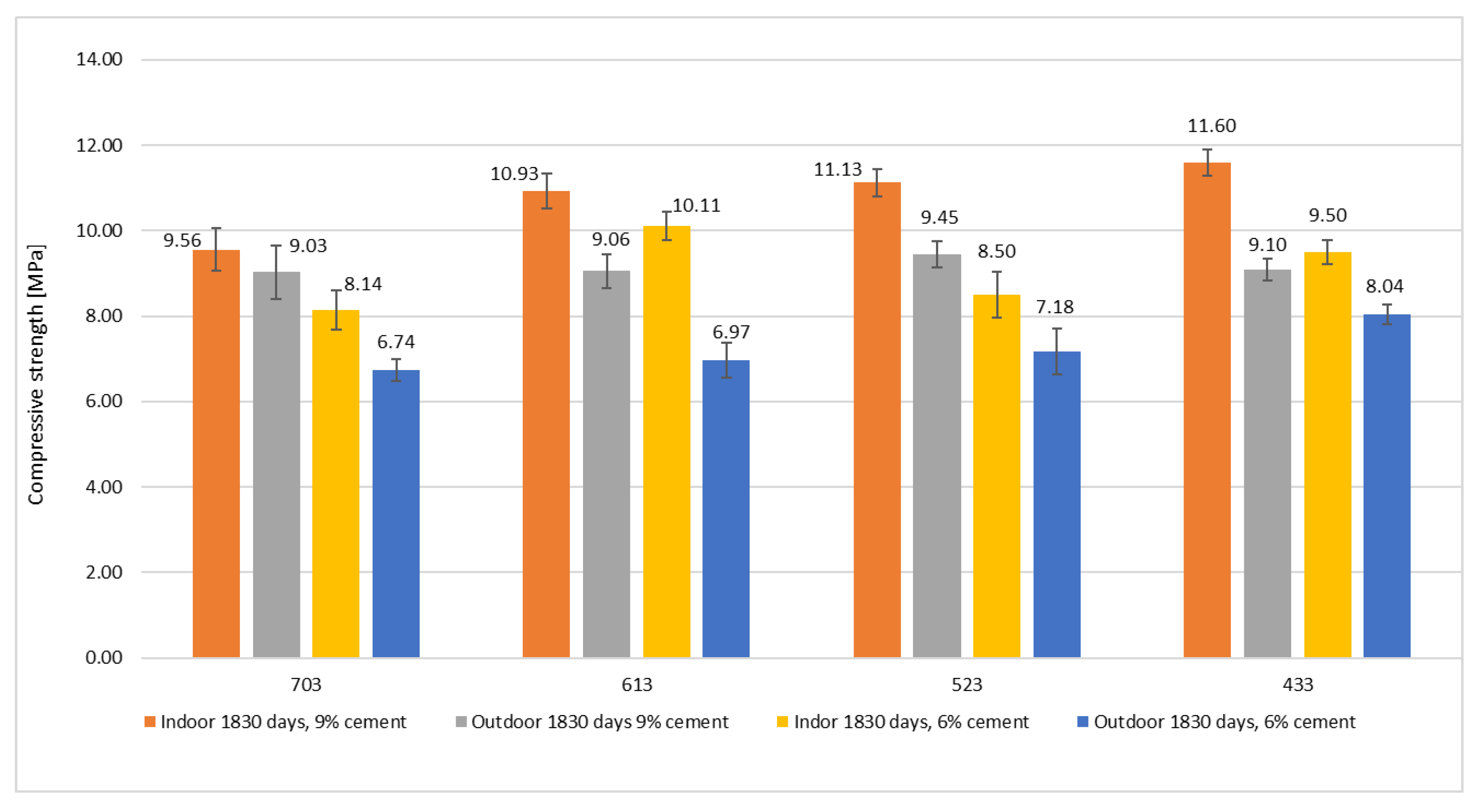

2. Materials and Methods

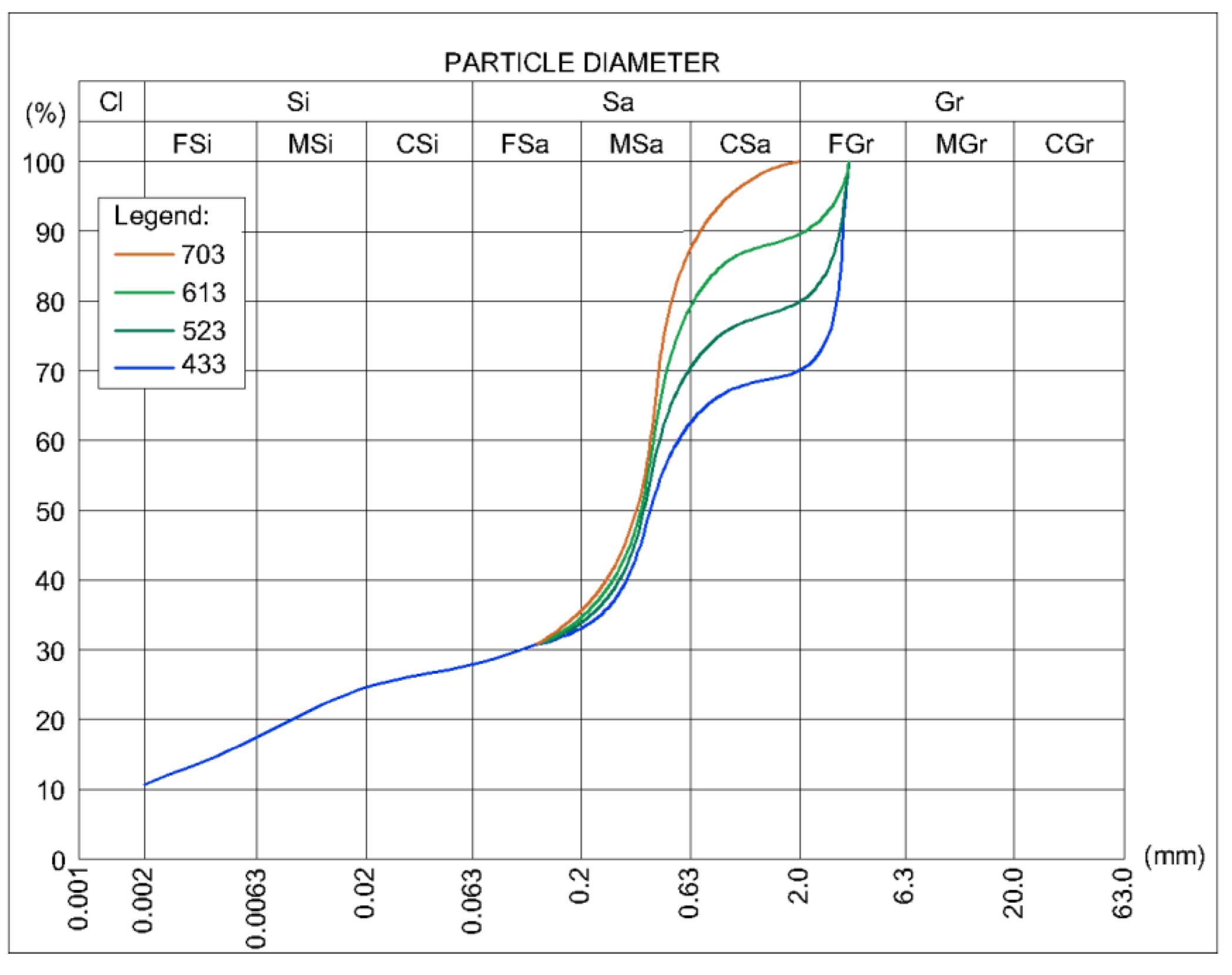

2.1. Materials

2.2. Methods

2.2.1. Specimen Preparation

2.2.2. Curing Conditions

2.2.3. Cutting Specimens for Strength Tests

2.2.4. UCS Calculation

- fc—compressive strength of single specimen

- N—destructive force recorded during test

- D—diameter of specimen (arithmetic mean of 3 measurements)

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arrigoni, A.; Beckett, C.; Ciancio, D.; Dotelli, G. Life cycle analysis of environmental impact vs. durability of stabilised rammed earth. Constr. Build. Mater. 2017, 142, 128–136. [Google Scholar] [CrossRef]

- Bui, Q.B.; Morel, J.C.; Reddy, B.V.V.; Ghayad, W. Durability of rammed earth walls exposed for 20 years to natural weathering. Build. Environ. 2009, 44, 912–919. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Amin, M.; Hadzima-Nyarko, M.; Agwa, I.S.; Zeyad, A.M.; Tayeh, B.A.; Adesina, A. Possibilities for the application of agro-industrial wastes in cementitious materials: A brief review of the Brazilian perspective. Clean. Mater. 2022, 3, 100040. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K.; Basarkar, S.S. Concrete using agro-waste as fine aggregate for sustainable built environment–A review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Jaeel, A.J. A novel use of undesirable wild giant reed biomass to replace aggregate in concrete. Constr. Build. Mater. 2014, 67, 68–73. [Google Scholar] [CrossRef]

- Khan, A.; Gupta, R.; Garg, M. Determining material characteristics of “Rammed Earth” using Non-Destructive Test methods for structural design. Structures 2019, 20, 399–410. [Google Scholar] [CrossRef]

- Guettala, A.; Abibsi, A.; Houari, H. Durability study of stabilized earth concrete under both laboratory and climatic conditions exposure. Constr. Build. Mater. 2006, 20, 119–127. [Google Scholar] [CrossRef]

- Hall, M.; Damms, P.; Djerbib, Y. Stabilised rammed earth and the building regulations (2000): Part A-Structural stability. Build. Eng. 2004, 79, 18–21. [Google Scholar]

- Jayasinghe, C.; Kamaladasa, N. Compressive strength characteristics of cement stabilized rammed earth walls. Constr. Build. Mater. 2007, 21, 1971–1976. [Google Scholar] [CrossRef]

- Miccoli, L.; Müller, U.; Fontana, P. Mechanical behaviour of earthen materials: A comparison between earth block masonry, rammed earth and cob. Constr. Build. Mater. 2014, 61, 327–339. [Google Scholar] [CrossRef]

- Silva, R.A.; Oliveira, D.V.; Miranda, T.; Cristelo, N.; Escobar, M.C.; Soares, E. Rammed earth construction with granitic residual soils: The case study of northern Portugal. Constr. Build. Mater. 2013, 47, 181–191. [Google Scholar] [CrossRef]

- Galán-Marín, C.; Rivera-Gómez, C.; Petric, J. Clay-based composite stabilized with natural polymer and fibre. Constr. Build. Mater. 2010, 24, 1462–1468. [Google Scholar] [CrossRef]

- Bui, Q.B.; Morel, J.C.; Hans, S.; Walker, P. Effect of moisture content on the mechanical characteristics of rammed earth. Constr. Build. Mater. 2014, 54, 163–169. [Google Scholar] [CrossRef]

- Reddy, B.V.V.; Kumar, P.P. Embodied energy in cement stabilised rammed earth walls. Energy Build. 2010, 42, 380–385. [Google Scholar] [CrossRef]

- Raj, S.; Sharma, A.K.; Anand, K.B. Performance appraisal of coal ash stabilized rammed earth. J. Build. Eng. 2018, 18, 51–57. [Google Scholar] [CrossRef]

- Meimaroglou, N.; Mouzakis, C. Cation Exchange Capacity (CEC), texture, consistency and organic matter in soil assessment for earth construction: The case of earth mortars. Constr. Build. Mater. 2019, 221, 27–39. [Google Scholar] [CrossRef]

- Narloch, P.L.; Woyciechowski, P.; Jęda, P. The Influence of Loam Type and Cement Content on the Compressive Strength of Rammed Earth. Arch. Civ. Eng. 2015, 61, 73–88. [Google Scholar] [CrossRef][Green Version]

- Ciancio, D.; Jaquin, P.; Walker, P. Advances on the assessment of soil suitability for rammed earth. Constr. Build. Mater. 2013, 42, 40–47. [Google Scholar] [CrossRef]

- ISO 1920-4; Testing of Concrete—Part 4: Strength of Hardened Concrete. The International Organization for Standardization, Vernier: Geneva, Switzerland, 2020.

- ACI 318-19; Building Code Requirements for Structural Concrete and Commentary. American Concrete Institute: Farmington Hills, MI, USA, 2019. [CrossRef]

- NZS 3104: 2003; Specification for Concrete Production. Standards New Zealand: Wellington, New Zealand, 2003.

- Luo, Y.; Zhou, P.; Ni, P.; Peng, X.; Ye, J. Degradation of rammed earth under soluble salts attack and drying-wetting cycles: The case of Fujian Tulou, China. Appl. Clay Sci. 2021, 212, 106202. [Google Scholar] [CrossRef]

- Heathcote, K.A. Durability of earthwall buildings. Constr. Build. Mater. 1995, 9, 185–189. [Google Scholar] [CrossRef]

- Lepakshi, R.; Reddy, B.V.V. Shear strength parameters and Mohr-Coulomb failure envelopes for cement stabilised rammed earth. Constr. Build. Mater. 2020, 249, 118708. [Google Scholar] [CrossRef]

- França, B.R.; Azevedo, A.R.G.; Monteiro, S.N.; Da Costa, F.; Filho, G.; Marvila, M.T.; Alexandre, J.; Zanelato, E.B. Durability of soil-Cement blocks with the incorporation of limestone residues from the processing of marble. Mater. Res. 2018, 21, 1–6. [Google Scholar] [CrossRef]

- Luo, Y.; Yang, M.; Ni, P.; Peng, X.; Yuan, X. Degradation of rammed earth under wind-driven rain: The case of Fujian Tulou, China. Constr. Build. Mater. 2020, 261, 119989. [Google Scholar] [CrossRef]

- Wu, F.; Yu, Q.; Liu, C. Creep characteristics and constitutive model of bio-based concrete in aqueous environment. Constr. Build. Mater. 2022, 320, 126213. [Google Scholar] [CrossRef]

- Leon, P.; Woyciechowski, P.; Rosicki, Ł.; Cichocki, D.; Lądowej, W.I.; Warszawska, P. Ziemia ubijana stabilizowana cementem jako materiał konstrukcyjny–ocena nasiąkliwości. Przegląd Bud. 2015, 86, 22–25. [Google Scholar]

- Traoré, L.B.; Ouellet-Plamondon, C.; Fabbri, A.; McGregor, F.; Rojat, F. Experimental assessment of freezing-thawing resistance of rammed earth buildings. Constr. Build. Mater. 2021, 274, 121917. [Google Scholar] [CrossRef]

- Serrano, S.; de Gracia, A.; Cabeza, L.F. Adaptation of rammed earth to modern construction systems: Comparative study of thermal behavior under summer conditions. Appl. Energy 2016, 175, 180–188. [Google Scholar] [CrossRef]

- Narloch, P.; Protchenko, K.; Cichocki, D. Hydro-thermal Analysis of Building Envelope Walls with Cement- Stabilized Rammed Earth Structural Layer and Different Thermal Insulators and Their Positioning in Humid Continental Climate Hydro-thermal Analysis of Building Envelope Walls with Cement-Stabi. IOP Conf. Ser. Mater. Sci. Eng. 2019, 661, 012078. [Google Scholar] [CrossRef]

- Reddy, B.V.V.; Leuzinger, G.; Sreeram, V.S. Low embodied energy cement stabilised rammed earth building-A case study. Energy Build. 2014, 68, 541–546. [Google Scholar] [CrossRef]

- Soudani, L.; Woloszyn, M.; Fabbri, A.; Morel, J.C.; Grillet, A.C. Energy evaluation of rammed earth walls using long term in-situ measurements. Sol. Energy 2017, 141, 70–80. [Google Scholar] [CrossRef]

- Rodríguez-Mariscal, J.D.; Canivell, J.; Solís, M. Evaluating the performance of sonic and ultrasonic tests for the inspection of rammed earth constructions. Constr. Build. Mater. 2021, 299, 123854. [Google Scholar] [CrossRef]

- Beckett, C.T.S.; Jaquin, P.A.; Morel, J.C. Weathering the storm: A framework to assess the resistance of earthen structures to water damage. Constr. Build. Mater. 2020, 242, 118098. [Google Scholar] [CrossRef]

- Canivell, J.; Martin-del-Rio, J.J.; Alejandre, F.J.; García-Heras, J.; Jimenez-Aguilar, A. Considerations on the physical and mechanical properties of lime-stabilized rammed earth walls and their evaluation by ultrasonic pulse velocity testing. Constr. Build. Mater. 2018, 191, 826–836. [Google Scholar] [CrossRef]

- Anysz, H.; Brzozowski, Ł.; Kretowicz, W.; Narloch, P. Feature importance of stabilised rammed earth components affecting the compressive strength calculated with explainable artificial intelligence tools. Materials 2020, 13, 2317. [Google Scholar] [CrossRef]

- Arto, I.; Gallego, R.; Cifuentes, H.; Puertas, E.; Gutiérrez-Carrillo, M.L. Fracture behavior of rammed earth in historic buildings. Constr. Build. Mater. 2021, 289, 123167. [Google Scholar] [CrossRef]

- Pavan, G.S.; Ullas, S.N.; Rao, K.S.N. Interfacial behavior of cement stabilized rammed earth: Experimental and numerical study. Constr. Build. Mater. 2020, 257, 119327. [Google Scholar] [CrossRef]

- Narloch, P.L.; Lidner, M.; Kunicka, E.; Bielecki, M. Flexural tensile strength of construction elements made out of cement stabilized rammed earth. Procedia Eng. 2015, 111, 589–595. [Google Scholar] [CrossRef]

- Meek, A.H.; Beckett, C.T.S.; Carsana, M.; Ciancio, D. Corrosion protection of steel embedded in cement-stabilised rammed earth. Constr. Build. Mater. 2018, 187, 942–953. [Google Scholar] [CrossRef]

- Lepakshi, R.; Reddy, B.V.V. Bond strength of rebars in cement stabilised rammed earth. Constr. Build. Mater. 2020, 255, 119405. [Google Scholar] [CrossRef]

- Lepakshi, R.; Reddy, B.V.V. Bond Strength of Rebars in Cement-Stabilised Rammed Earth BT Earthen Dwellings and Structures: Current Status in Their Adoption; Reddy, B.V.V., Mani, M., Walker, P., Eds.; Springer: Singapore, 2019; pp. 39–50. ISBN 978-981-13-5883-8. [Google Scholar]

- Kaliszuk-Wietecka, A.; Leon, P. Konstrukcyjne zastosowanie surowej ziemi jako materiału budowlanego. Przegląd Bud. 2014, 85, 21–23. [Google Scholar]

- Woyciechowski, P.; Narloch, P.L.; Cichocki, D. Shrinkage characteristics of cement stabilized rammed earth. MATEC Web Conf. 2017, 117, 00178. [Google Scholar] [CrossRef]

- Kariyawasam, K.K.G.K.D.; Jayasinghe, C. Cement stabilized rammed earth as a sustainable construction material. Constr. Build. Mater. 2016, 105, 519–527. [Google Scholar] [CrossRef]

- Narloch, P.; Woyciechowski, P.; Kotowski, J.; Gawriuczenkow, I.; Wójcik, E. The effect of soil mineral composition on the compressive strength of cement stabilized rammed earth. Materials 2020, 13, 324. [Google Scholar] [CrossRef] [PubMed]

- Rogala, W.; Anysz, H.; Narloch, P. Designing the Composition of Cement-Stabilized Rammed Earth with the Association Analysis Application. Materials 2021, 14, 1390. [Google Scholar] [CrossRef] [PubMed]

- Ávila, F.; Puertas, E.; Gallego, R. Characterization of the mechanical and physical properties of unstabilized rammed earth: A review. Constr. Build. Mater. 2020, 270, 121435. [Google Scholar] [CrossRef]

- Saeid, G.; Vahab, T. Durability of Rammed Earth Materials. Int. J. Geomech. 2020, 20, 4020201. [Google Scholar] [CrossRef]

- Narloch, P.L.; Woyciechowski, P.; Dmowska, E.; Halemba, K. Durability Assessment of Monolithic Rammed Earth Walls. Arch. Civ. Eng. 2015, 61, 73–88. [Google Scholar] [CrossRef]

- Peel, M.C.; Finlayson, B.L.; McMahon, T.A. Updated world map of the Köppen-Geiger climate classification. Hydrol. Earth Syst. Sci. 2007, 11, 1633–1644. [Google Scholar] [CrossRef]

- Błażejczyk, K.; Baranowski, J.; Jendritzky, G.; Błażejczyk, A.; Bröde, P.; Fiala, D. Regional features of the bioclimate of central and southern europe against the background of the köppen-geiger climate classification. Geogr. Pol. 2015, 88, 439–453. [Google Scholar] [CrossRef]

- Luo, Y.; Zhong, H.; Bao, F.; Guo, Z.; Ni, P. Insights into natural and carbonation curing of ancient Chinese rammed earth mixed with brown sugar. Constr. Build. Mater. 2022, 317, 125969. [Google Scholar] [CrossRef]

- Martín-del-Rio, J.J.; Canivell, J.; Torres-González, M.; Mascort-Albea, E.J.; Romero-Hernández, R.; Alducin-Ochoa, J.M.; Alejandre-Sánchez, F.J. Analysis of the materials and state of conservation of the medieval rammed earth walls of Seville (Spain). J. Build. Eng. 2021, 44, 103381. [Google Scholar] [CrossRef]

- Cid-Falceto, J.; Mazarrón, F.R.; Cañas, I. Assessment of compressed earth blocks made in Spain: International durability tests. Constr. Build. Mater. 2012, 37, 738–745. [Google Scholar] [CrossRef]

- Anysz, H.; Narloch, P. Designing the composition of cement stabilized rammed earth using artificial neural networks. Materials 2019, 12, 1396. [Google Scholar] [CrossRef] [PubMed]

- Narloch, P.; Hassanat, A.; Tarawneh, A.S.; Anysz, H.; Kotowski, J.; Almohammadi, K. Predicting compressive strength of cement-stabilized rammed earth based on SEM images using computer vision and deep learning. Appl. Sci. 2019, 9, 5131. [Google Scholar] [CrossRef]

- Narloch, P.; Woyciechowski, P. Assessing Cement Stabilized Rammed Earth Durability in A Humid Continental Climate. Buildings 2020, 10, 26. [Google Scholar] [CrossRef]

| Source | Shape of the Specimen | Stabilizer Type | Compressive Strength [MPa] | Seasoning Conditions |

|---|---|---|---|---|

| [7] | Cube | Cement 46 MPa, Lime ND (1) | 15.40–21.50 | Natural exposure, Period length ND (1) |

| [8] | ND (1) | None | 0.90–1.45 | Min. 28 days at 20 °C, 75% RH (2) |

| [9] | Wall-panel | ND (1) | 1.82–3.71 | Natural exposure, Period length ND (1) |

| [10] | Block/wall | ND (1) | 3.73 | 28 days at 23 °C, 50% RH (2) |

| [11] | Cylinder | None | 0.25–0.43 | 27–35 days after attaining equilibrium water content; 20 °C, 57% RH (2) |

| [12] | Beam | Natural polymer and fibre | 2.23–4.44 | According to UNE-EN 196-1 2005, UNE-EN 1015-2 and UNE-EN 12190 1998 |

| [13] | Cylinder | None | 0.75–2.00 | Normal atmosphere, when desired moisture reached wrapped in plastic film for a week |

| [14] | Prism | Ordinary Portland | 3.38–5.44 | Cured for 28 days, air dried for two weeks, dried at 50 °C to constant weight in an oven, soaked for 48 h in water, ca. 45 days |

| [15] | Prism | Ordinary Portland cement of M53 grade | 2.00–2.33 | Cured under water jug for 28 days |

| [16] | Beam | None | 0.60–7.20 | 28 days at 23 ± 5 °C, 50 ± 15% RH (2) |

| [17] | Cube | Portland cement CEM I 42.5 R | 1.72–4.99 | 28 days at 20 °C, 95% RH (2) |

| [18] | Cylinder | ND (1) | 2.52–6.68 | 1 day in formwork, 7 days in impermeable membrane, ambient condition for next 20 days (maximum mean monthly temperature 18 °C and minimum 7 °C; mean RH 68% (2)) |

| Specimen Series | Soil Mixture | Cement Addition (%) | Water Content (%) (Equal to OMC) |

|---|---|---|---|

| 703-6% | 703 | 6 | 10 |

| 613-6% | 613 | 6 | 10 |

| 523-6% | 523 | 6 | 9 |

| 433-6% | 433 | 6 | 9 |

| 703-9% | 703 | 9 | 10 |

| 613-9% | 613 | 9 | 10 |

| 523-9% | 523 | 9 | 9 |

| 433-9% | 433 | 9 | 9 |

| Year | Avg. Wind Speed [km/h] | Avg. Temperature [C] | Avg. Relative Humidity [%] | Precipitation [mm] | Number of Days with Avg. Temperature below Zero |

|---|---|---|---|---|---|

| 2019 | 3.58 | 10.93 | 72.07 | 390.20 | 28 |

| 2018 | 3.42 | 10.51 | 72.97 | 235.20 | 61 |

| 2017 | 3.53 | 9.45 | 77.51 | 339.80 | 42 |

| 2016 | 3.41 | 9.84 | 75.15 | 277.90 | 35 |

| 2015 | 3.51 | 10.39 | 71.79 | 172.00 | 30 |

| 2014 | 3.22 | 9.87 | 76.22 | 251.30 | 41 |

| Avg. | 3.45 | 10.17 | 74.29 | 277.73 | 39.50 |

| Mixture | Storing Conditions | Cement Content [%] | Standard Deviation | Standard Error | Confidence Intervals |

|---|---|---|---|---|---|

| 433 | Indoor | 6 | 0.483 | 0.1527 | 0.280 |

| 523 | Indoor | 6 | 0.924 | 0.2922 | 0.535 |

| 613 | Indoor | 6 | 0.558 | 0.1765 | 0.323 |

| 703 | Indoor | 6 | 0.803 | 0.2539 | 0.465 |

| 523 | Outdoor | 6 | 0.924 | 0.2922 | 0.535 |

| 613 | Outdoor | 6 | 0.690 | 0.2182 | 0.399 |

| 433 | Outdoor | 6 | 0.386 | 0.1221 | 0.223 |

| 703 | Outdoor | 6 | 0.428 | 0.1353 | 0.248 |

| 433 | Indoor | 9 | 0.523 | 0.1654 | 0.303 |

| 523 | Indoor | 9 | 0.552 | 0.1746 | 0.319 |

| 613 | Indoor | 9 | 0.071 | 0.0225 | 0.041 |

| 703 | Indoor | 9 | 0.853 | 0.2697 | 0.494 |

| 523 | Outdoor | 9 | 0.542 | 0.1714 | 0.314 |

| 613 | Outdoor | 9 | 0.690 | 0.2182 | 0.399 |

| 433 | Outdoor | 9 | 0.441 | 0.1395 | 0.255 |

| 703 | Outdoor | 9 | 1.09 | 0.3447 | 0.631 |

| Mixture Type and Cement Content | Outside Layer Description | Core Description | Visual Rating |

|---|---|---|---|

| 703-9% | Smooth, no discoloration, no particle visible, homogenous | Homogenous | 5 |

| 613-9% | Smooth, minimal graining, discoloration, visible watermarks, visible layers, few particles missing | Few visible particles, slightly uneven edge, visible layers | 4 |

| 523-9% | Visible layers, minimal discoloration, minimal watermarks, rugged | Visible particles, uneven edge, visible layers | 4 |

| 433-9% | Rugged, minimal discoloration, visible layers, uneven, graining | Visible particles, loose particles on outside layer, uneven edge | 3 |

| 703-6% | Smooth, no discoloration, no particle visible, homogenous, few cracks on edges | Homogenous | 5 |

| 613-6% | Visible layers, minimal discoloration, minimal watermarks, graining, rugged, multiple cracks on edges, numerous particles missing | Few visible particles, slightly uneven edge, visible layers | 4 |

| 523-6% | Visible layers, minimal discoloration, minimal watermarks, graining, rugged, multiple cracks on edges, numerous particles missing | Visible particles, uneven edge, visible layer | 4 |

| 433-6% | Rugged, minimal discoloration, visible layers, uneven, visible erosion, multiple cracks on edges, numerous particles missing | Visible particles, loose particles on outside layer, uneven edge | 2 |

| - | Mixture | 703 | 613 | 523 | 433 | 703 | 433 | 703 | 613 | 703 | 433 | 703 | 613 | 703 | 433 | 703 | 613 | ||

| Mixture | - | Cement | 9% | 9% | 9% | 9% | 6% | 6% | 6% | 6% | 9% | 9% | 9% | 9% | 6% | 6% | 6% | 6% | |

| Cement | - | Curingcondition | IN | IN | IN | IN | IN | IN | IN | IN | OUT | OUT | OUT | OUT | OUT | OUT | OUT | OUT | |

| Curing condition | UCS [MPa} | 9.56 | 10.93 | 11.13 | 11.60 | 8.14 | 10.11 | 8.50 | 9.50 | 9.03 | 9.06 | 9.45 | 9.10 | 6.74 | 6.97 | 7.18 | 8.04 | ||

| 703 | 9% | IN | 9.56 | - | 0.87 | 0.86 | 0.82 | 1.17 | 0.95 | 1.12 | 1.01 | 1.06 | 1.06 | 1.01 | 1.05 | 1.42 | 1.37 | 1.33 | 1.19 |

| 613 | 9% | IN | 10.93 | 1.14 | - | 0.98 | 0.94 | 1.34 | 1.08 | 1.29 | 1.15 | 1.21 | 1.21 | 1.16 | 1.20 | 1.62 | 1.57 | 1.52 | 1.36 |

| 523 | 9% | IN | 11.13 | 1.16 | 1.02 | - | 0.96 | 1.37 | 1.10 | 1.31 | 1.17 | 1.23 | 1.23 | 1.18 | 1.22 | 1.65 | 1.60 | 1.55 | 1.38 |

| 433 | 9% | IN | 11.6 | 1.21 | 1.06 | 1.04 | - | 1.43 | 1.15 | 1.36 | 1.22 | 1.28 | 1.28 | 1.23 | 1.27 | 1.72 | 1.66 | 1.62 | 1.44 |

| 703 | 6% | IN | 8.14 | 0.85 | 0.74 | 0.73 | 0.70 | - | 0.81 | 0.96 | 0.86 | 0.90 | 0.90 | 0.86 | 0.89 | 1.21 | 1.17 | 1.13 | 1.01 |

| 433 | 6% | IN | 10.11 | 1.06 | 0.92 | 0.91 | 0.87 | 1.24 | - | 1.19 | 1.06 | 1.12 | 1.12 | 1.07 | 1.11 | 1.50 | 1.45 | 1.41 | 1.26 |

| 703 | 6% | IN | 8.5 | 0.89 | 0.78 | 0.76 | 0.73 | 1.04 | 0.84 | - | 0.89 | 0.94 | 0.94 | 0.90 | 0.93 | 1.26 | 1.22 | 1.18 | 1.06 |

| 613 | 6% | IN | 9.5 | 0.99 | 0.87 | 0.85 | 0.82 | 1.17 | 0.94 | 1.12 | - | 1.05 | 1.05 | 1.01 | 1.04 | 1.41 | 1.36 | 1.32 | 1.18 |

| 703 | 9% | OUT | 9.03 | 0.94 | 0.83 | 0.81 | 0.78 | 1.11 | 0.89 | 1.06 | 0.95 | - | 1.00 | 0.96 | 0.99 | 1.34 | 1.30 | 1.26 | 1.12 |

| 433 | 9% | OUT | 9.06 | 0.95 | 0.83 | 0.81 | 0.78 | 1.11 | 0.90 | 1.07 | 0.95 | 1.00 | - | 0.96 | 1.00 | 1.34 | 1.30 | 1.26 | 1.13 |

| 703 | 9% | OUT | 9.45 | 0.99 | 0.86 | 0.85 | 0.81 | 1.16 | 0.93 | 1.11 | 0.99 | 1.05 | 1.04 | - | 1.04 | 1.40 | 1.36 | 1.32 | 1.18 |

| 613 | 9% | OUT | 9.1 | 0.95 | 0.83 | 0.82 | 0.78 | 1.12 | 0.90 | 1.07 | 0.96 | 1.01 | 1.00 | 0.96 | - | 1.35 | 1.31 | 1.27 | 1.13 |

| 703 | 6% | OUT | 6.74 | 0.71 | 0.62 | 0.61 | 0.58 | 0.83 | 0.67 | 0.79 | 0.71 | 0.75 | 0.74 | 0.71 | 0.74 | - | 0.97 | 0.94 | 0.84 |

| 433 | 6% | OUT | 6.97 | 0.73 | 0.64 | 0.63 | 0.60 | 0.86 | 0.69 | 0.82 | 0.73 | 0.77 | 0.77 | 0.74 | 0.77 | 1.03 | - | 0.97 | 0.87 |

| 703 | 6% | OUT | 7.18 | 0.75 | 0.66 | 0.65 | 0.62 | 0.88 | 0.71 | 0.84 | 0.76 | 0.80 | 0.79 | 0.76 | 0.79 | 1.07 | 1.03 | - | 0.89 |

| 613 | 6% | OUT | 8.04 | 0.84 | 0.74 | 0.72 | 0.69 | 0.99 | 0.80 | 0.95 | 0.85 | 0.89 | 0.89 | 0.85 | 0.88 | 1.19 | 1.15 | 1.12 | - |

| Legend: | |||||||||||||||||||

| UCS ratio between different mixtures, same cement content types, same curing condition | |||||||||||||||||||

| UCS ratio between same mixtures, different cement content, same curing condition | |||||||||||||||||||

| UCS ratio between same mixtures, same cement content, different curing condition | |||||||||||||||||||

| Extreme values of UCS ratio | |||||||||||||||||||

| IN | Indoor seasoned specimens | ||||||||||||||||||

| OUT | Outdoor seasoned specimens | ||||||||||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosicki, Ł.; Narloch, P. Studies on the Ageing of Cement Stabilized Rammed Earth Material in Different Exposure Conditions. Materials 2022, 15, 1090. https://doi.org/10.3390/ma15031090

Rosicki Ł, Narloch P. Studies on the Ageing of Cement Stabilized Rammed Earth Material in Different Exposure Conditions. Materials. 2022; 15(3):1090. https://doi.org/10.3390/ma15031090

Chicago/Turabian StyleRosicki, Łukasz, and Piotr Narloch. 2022. "Studies on the Ageing of Cement Stabilized Rammed Earth Material in Different Exposure Conditions" Materials 15, no. 3: 1090. https://doi.org/10.3390/ma15031090

APA StyleRosicki, Ł., & Narloch, P. (2022). Studies on the Ageing of Cement Stabilized Rammed Earth Material in Different Exposure Conditions. Materials, 15(3), 1090. https://doi.org/10.3390/ma15031090