Porous Glass Microspheres from Alkali-Activated Fiber Glass Waste

Abstract

:1. Introduction

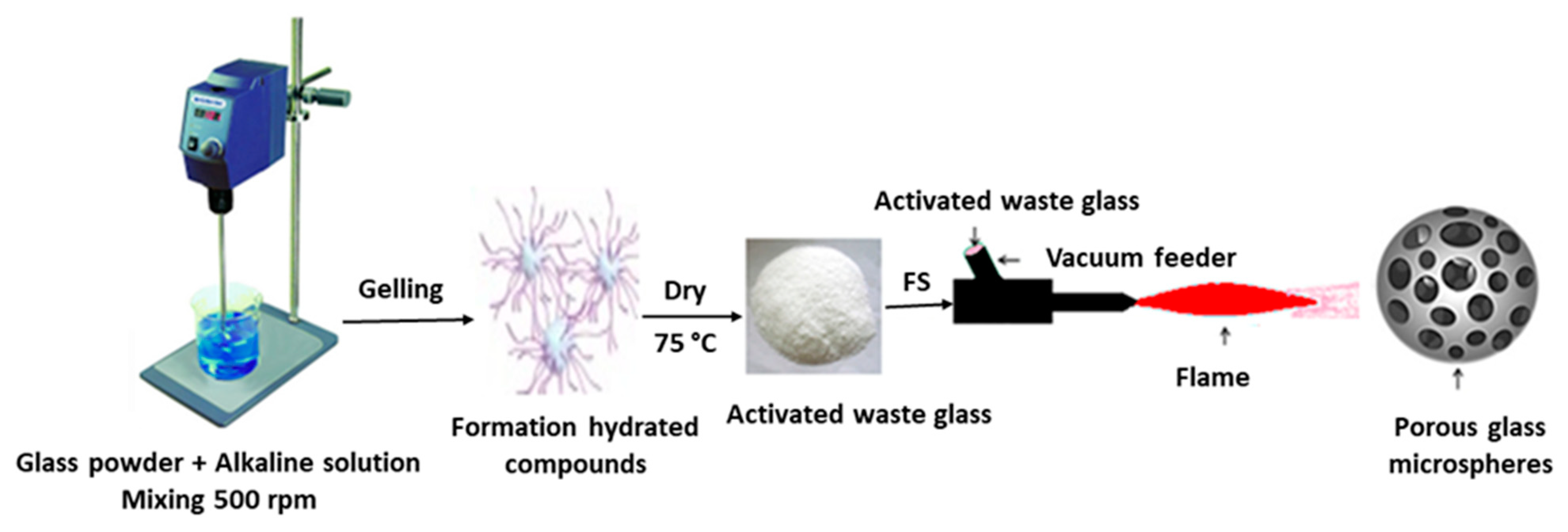

2. Materials and Methods

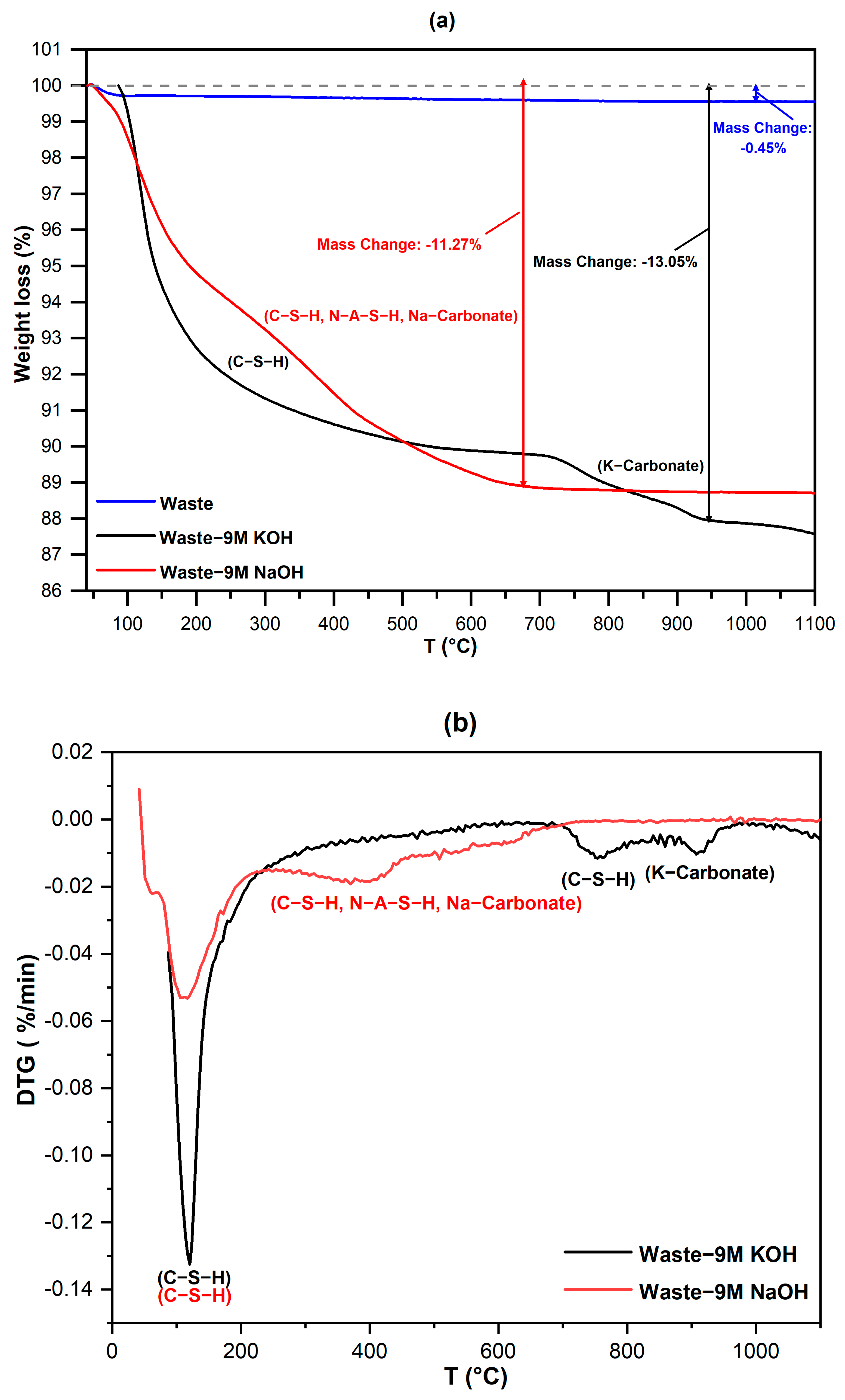

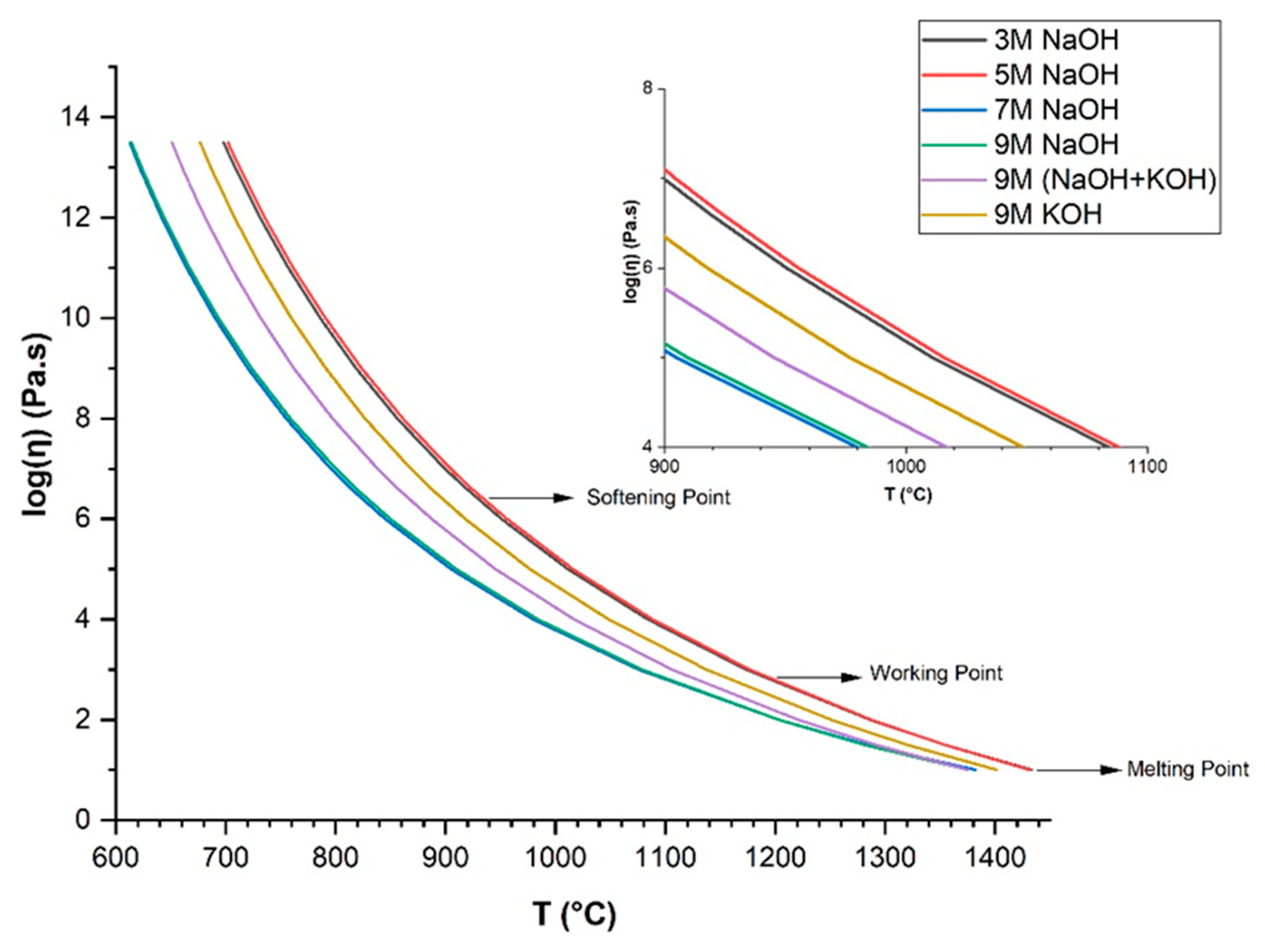

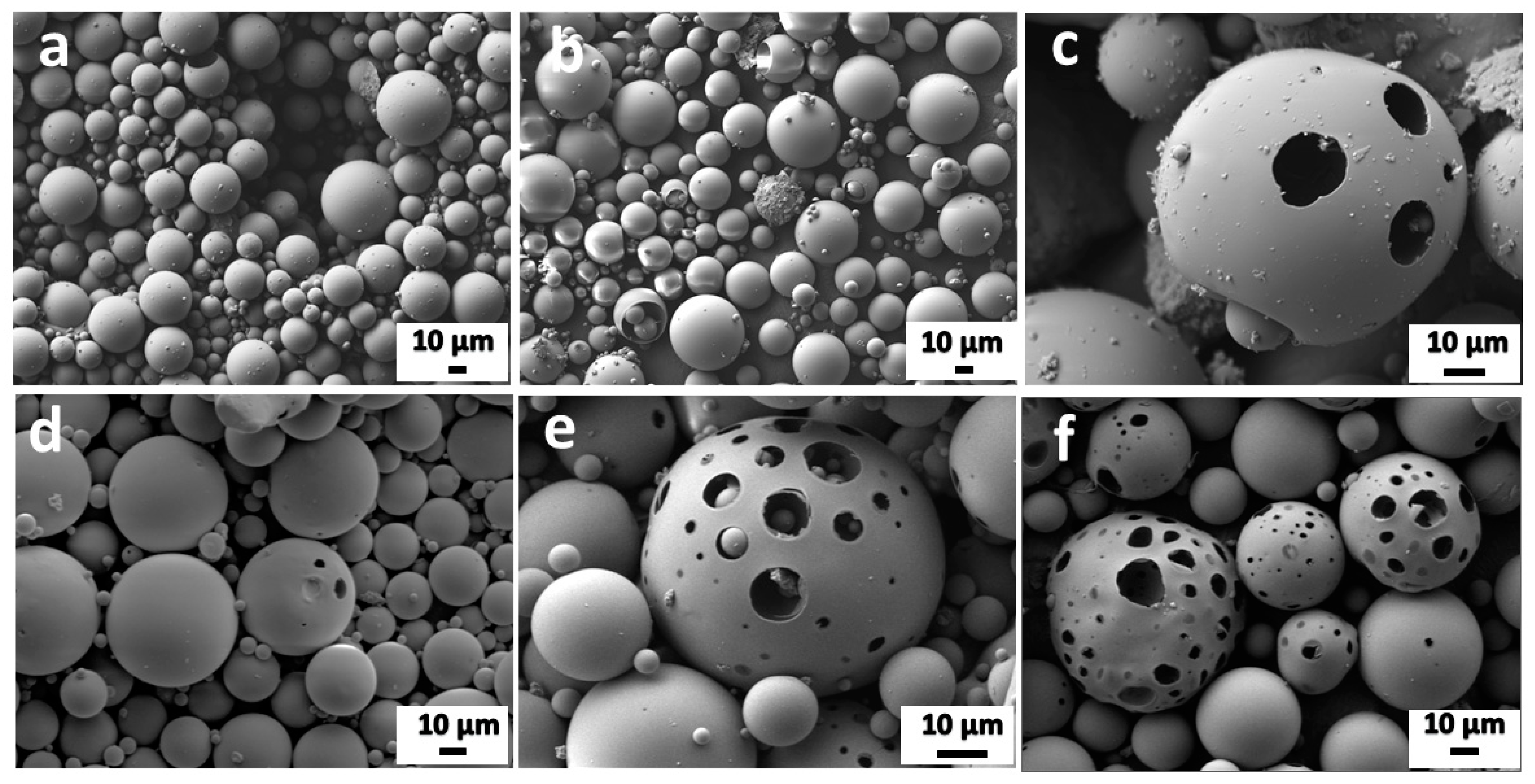

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meyer, C.; Baxter, S.; Jin, W. Alkali-Aggregate Reaction in Concrete with Waste Glass as Aggregate. In Proceedings of the 4th Materials Engineering Conference, Mate. for the New Mille, Washington, DC, USA, 10–14 November 1996; pp. 1388–1394. [Google Scholar]

- Rivera, J.F.; Cuarán-Cuarán, Z.I.; Vanegas-Bonilla, N.; de Gutiérrez, R.M. Novel use of waste glass powder: Production of geopolymeric tiles. Adv. Powder Technol. 2018, 29, 3448–3454. [Google Scholar] [CrossRef]

- Ogundairo, T.O.; Adegoke, D.D.; Akinwumi, I.I.; Olofinnade, O.M. Sustainable use of recycled waste glass as an alternative material for building construction–A review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 640, 012073. [Google Scholar] [CrossRef] [Green Version]

- Ramteke, D.D.; Hujova, M.; Kraxner, J.; Galusek, D.; Romero, A.R.; Falcone, R.; Bernardo, E. Up-cycling of ‘unrecyclable’ glasses in glass-based foams by weak alkali-activation, gel casting and low-temperature sintering. J. Clean. Prod. 2021, 278, 123985. [Google Scholar] [CrossRef]

- Flood, M.; Fennessy, L.; Lockrey, S.; Avendano, A.; Glover, J.; Kandare, E.; Bhat, T. Glass Fines: A review of cleaning and up-cycling possibilities. J. Clean. Prod. 2020, 267, 121875. [Google Scholar] [CrossRef]

- Bernardo, E.; Cedro, R.; Florean, M.; Hreglich, S. Reutilization and stabilization of wastes by the production of glass foams. Ceram. Int. 2007, 33, 963–968. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Puertas, F. Waste glass in the geopolymer preparation. Mechanical and microstructural characterisation. J. Clean. Prod. 2015, 90, 397–408. [Google Scholar] [CrossRef]

- Kraxner, J.; Michalek, M.; Romero, A.R.; Elsayed, H.; Bernardo, E.; Boccaccini, A.; Galusek, D. Porous bioactive glass microspheres prepared by flame synthesis process. Mater. Lett. 2019, 256, 126625. [Google Scholar] [CrossRef]

- Righini, G.C. Glassy Microspheres for Energy Applications. Micromachines 2018, 9, 379. [Google Scholar] [CrossRef] [Green Version]

- Redden, R.; Neithalath, N. Microstructure, strength, and moisture stability of alkali activated glass pow-der-based binders. Cem. Concr. Compos. 2014, 45, 46–56. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Castro-Gomes, J.; Jalali, S. Alkali-activated binders: A review: Part Historical background, terminology, reaction mechanisms and hydration products. Constr. Build. Mater. 2008, 22, 1305–1314. [Google Scholar] [CrossRef] [Green Version]

- Moghadam, M.J.; Ajalloeian, R.; Hajiannia, A. Preparation and application of alkali-activated materials based on waste glass and coal gangue: A review. Constr. Build. Mater. 2019, 221, 84–98. [Google Scholar] [CrossRef]

- Rincón, A.; Giacomello, G.; Pasetto, M.; Bernardo, E. Novel ‘inorganic gel casting’ process for the manufacturing of glass foams. Eur. Ceram. Soc. 2017, 37, 2227–2234. [Google Scholar] [CrossRef]

- Gin, S.; Delaye, J.-M.; Angeli, F.; Schuller, S. Aqueous alteration of silicate glass: State of knowledge and perspectives. npj Mater. Degrad. 2021, 5, 42. [Google Scholar] [CrossRef]

- Novais, R.M.; Ascensão, G.; Seabra, M.; Labrincha, J. Waste glass from end-of-life fluorescent lamps as raw material in geopolymers. Waste Manag. 2016, 52, 245–255. [Google Scholar] [CrossRef] [PubMed]

- Panias, D.; Giannopoulou, I.P.; Perraki, T. Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2007, 301, 246–254. [Google Scholar] [CrossRef]

- Bashir, S.T.; Yang, L.; Liggat, J.; Thomason, J.L. Kinetics of dissolution of glass fibre in hot alkaline solution. J. Mater. Sci. 2018, 53, 1710–1722. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.; Ye, G. Dehydration kinetics of Portland cement paste at high temperature. J. Therm. Anal. 2012, 110, 153–158. [Google Scholar] [CrossRef] [Green Version]

- Studart, A.R.; Gonzenbach, U.T.; Tervoort, E.; Gauckler, L.J. Processing Routes to Macroporous Ceramics: A Review. J. Am. Ceram. Soc. 2006, 89, 1771–1789. [Google Scholar] [CrossRef]

- Jeremy, P.W.W. Reuse of Silicate Wastes: Process Development and Property Measurements of Dense and Porous Glass-Ceramics. Ph.D. Thesis, Imperial College London, London, UK, 2006. [Google Scholar]

- Fluegel, A. Glass viscosity calculation based on a global statistical modeling approach. Glass Technol. Eur. J. Glass Sci. Technol. A 2007, 48, 13–30. [Google Scholar]

- Fluegel, A. Statistical regression modeling of glass properties—A Tutorial. Glass Technol. Eur. J. Glass Sci. Technol. A 2009, 50, 25–46. [Google Scholar]

- Isard, J. The mixed alkali effect in glass. J. Non Cryst. Solids 1969, 1, 235–261. [Google Scholar] [CrossRef]

- Garai, M.; Sasmal, N.; Karmakar, B. Effects of M2+ (M = Ca, Sr, and Ba) Addition on Crystallization and Microstructure of SiO2-MgO-Al2O3-B2O3-K2O-F Glass. Indian J. Mater. Sci. 2015, 2015, 638341. [Google Scholar] [CrossRef] [Green Version]

- Sasmal, N.; Garai, M.; Karmakar, B. Preparation and characterization of novel foamed porous glass-ceramics. Mater. Charact. 2015, 103, 90–100. [Google Scholar] [CrossRef]

| Glass Microspheres | Oxides Ratio (Wt.%) | |||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | CaO | Al2O3 | B2O3 | Na2O | K2O | TiO2 | Fe2O3 | |

| FGW + 3 M NaOH | 61 ±3 | 24 ±2 | 13 ±1 | 0.40 ±0.01 |

0.1 ±0.02 | – | 0.50 ±0.02 | 0.30 ±0.03 |

| FGW + 5 M NaOH | 60 ±1 | 24.2 ±0.7 | 13.7 ±0.6 | – | 0.70 ±0.01 | – | 0.50 ±0.01 | 0.30 ±0.03 |

| FGW + 7 M NaOH | 58 ±2 | 19.8 ±0.5 | 11.0 ±0.6 | 1.8 ±0.1 | 7.8 ±0.2 | 0.20 ±0.02 | 0.40 ±0.01 | 0.30 ±0.01 |

| FGW + 9 M NaOH | 58 ±2 | 19.5 ±0.5 | 11.1 ±0.5 | 3.2 ±0.2 | 6.5 ±0.1 | 0.40 ±0.02 | 0.40 ±0.01 | 0.30 ±0.01 |

| FGW+ 9 M NaOH + KOH | 57 ±2 | 19.8 ±0.4 | 12.0 ±0.6 | 2.6 ±0.2 | 3.0 ±0.1 | 4.3 ±0.1 | 0.40 ±0.01 | 0.30 ±0.01 |

| FGW + 9 M KOH | 59 ±2 | 19.6 ±0.9 | 11.6 ±0.9 | 1.8 ±0.1 | 0.30 ±0.02 | 5.9 ±0.1 | 0.40 ±0.01 | 0.30 ±0.02 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmoud, M.; Kraxner, J.; Kaňková, H.; Hujová, M.; Chen, S.; Galusek, D.; Bernardo, E. Porous Glass Microspheres from Alkali-Activated Fiber Glass Waste. Materials 2022, 15, 1043. https://doi.org/10.3390/ma15031043

Mahmoud M, Kraxner J, Kaňková H, Hujová M, Chen S, Galusek D, Bernardo E. Porous Glass Microspheres from Alkali-Activated Fiber Glass Waste. Materials. 2022; 15(3):1043. https://doi.org/10.3390/ma15031043

Chicago/Turabian StyleMahmoud, Mokhtar, Jozef Kraxner, Hana Kaňková, Miroslava Hujová, Si Chen, Dušan Galusek, and Enrico Bernardo. 2022. "Porous Glass Microspheres from Alkali-Activated Fiber Glass Waste" Materials 15, no. 3: 1043. https://doi.org/10.3390/ma15031043

APA StyleMahmoud, M., Kraxner, J., Kaňková, H., Hujová, M., Chen, S., Galusek, D., & Bernardo, E. (2022). Porous Glass Microspheres from Alkali-Activated Fiber Glass Waste. Materials, 15(3), 1043. https://doi.org/10.3390/ma15031043