Spectroscopic Ellipsometry Studies on Solution-Processed OLED Devices: Optical Properties and Interfacial Layers

Abstract

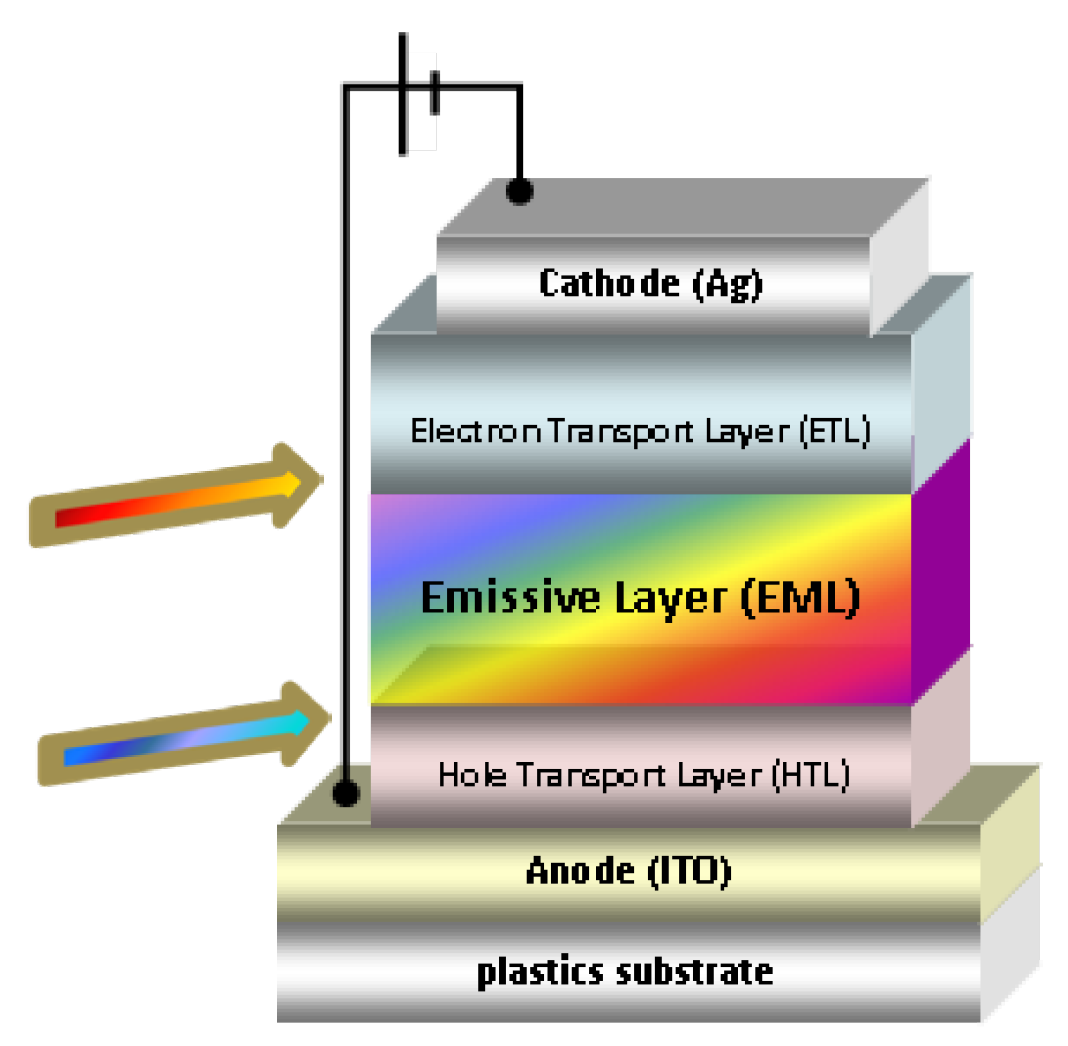

1. Introduction

2. Materials and Methods

2.1. Inks Preparation

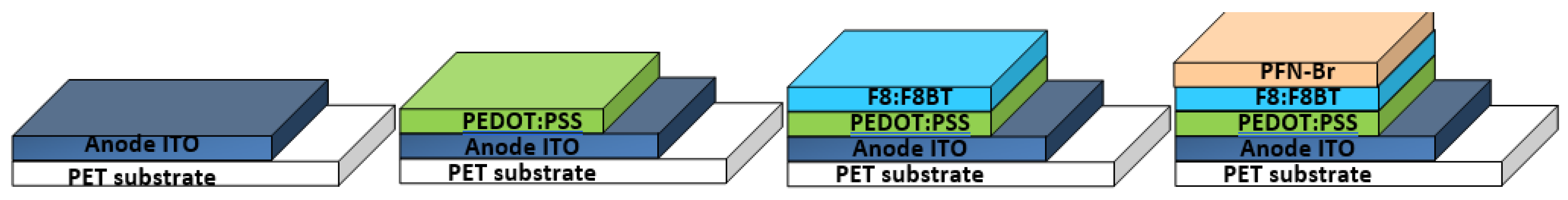

2.2. OLED Fabrication

2.3. Characterization Techniques

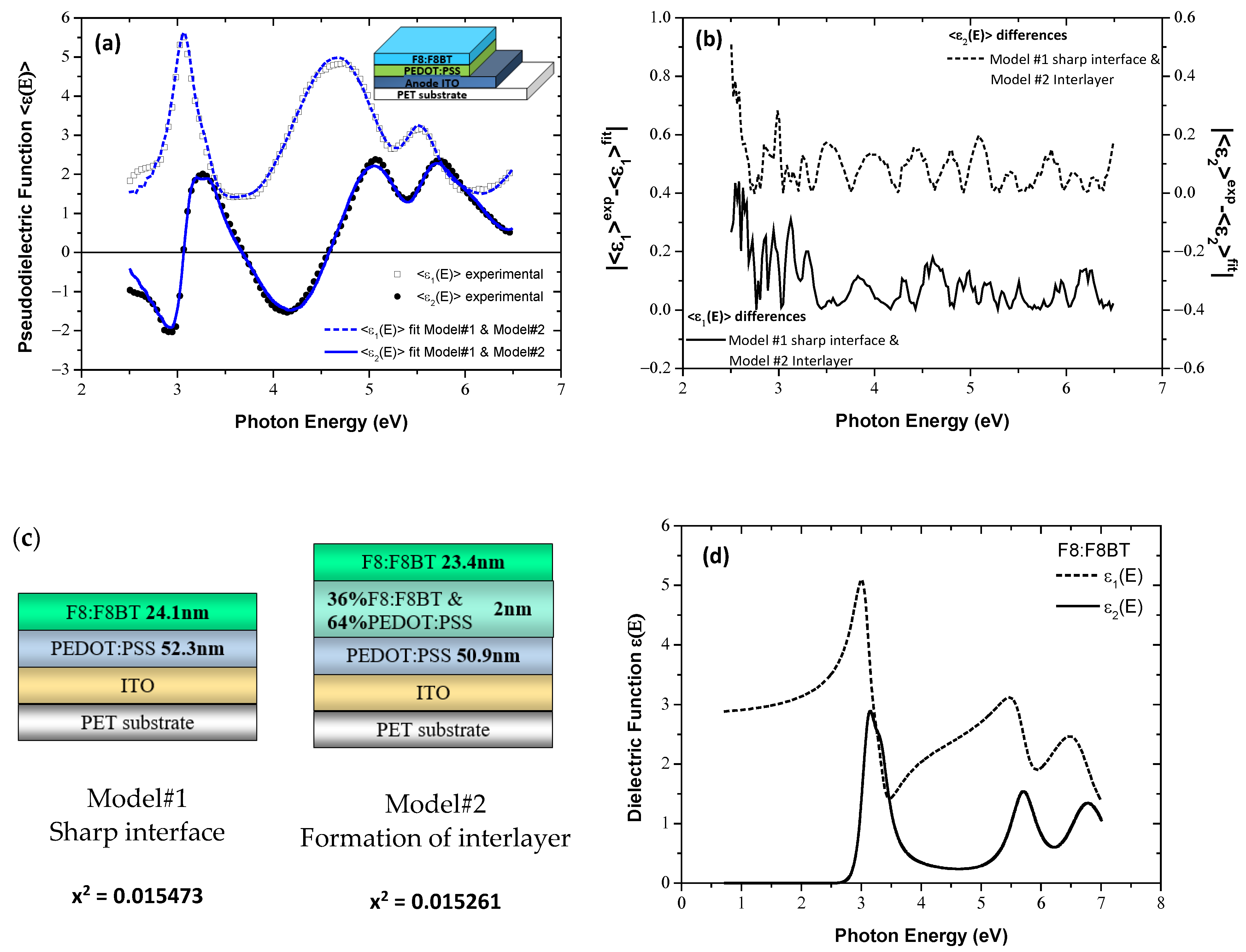

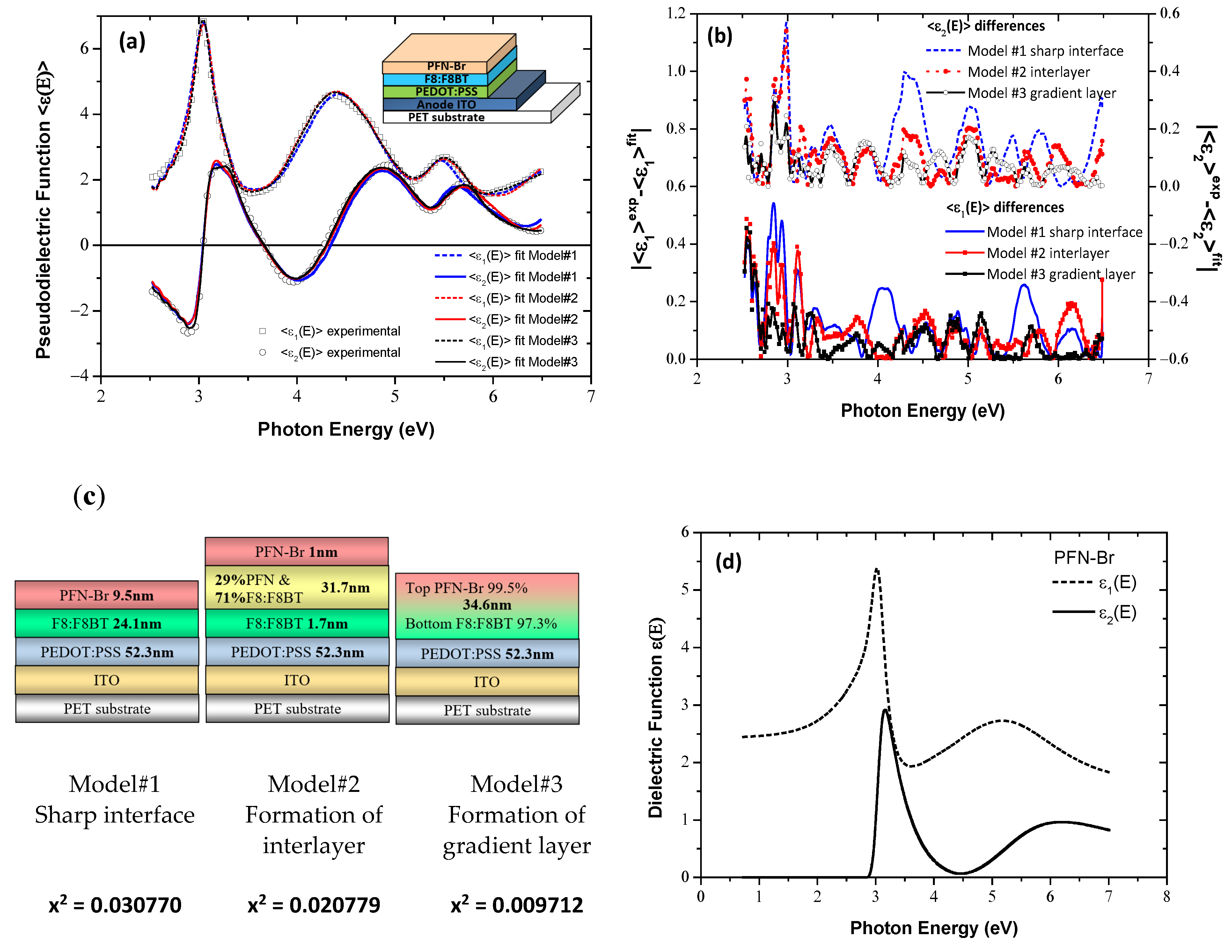

2.4. SE Modelling

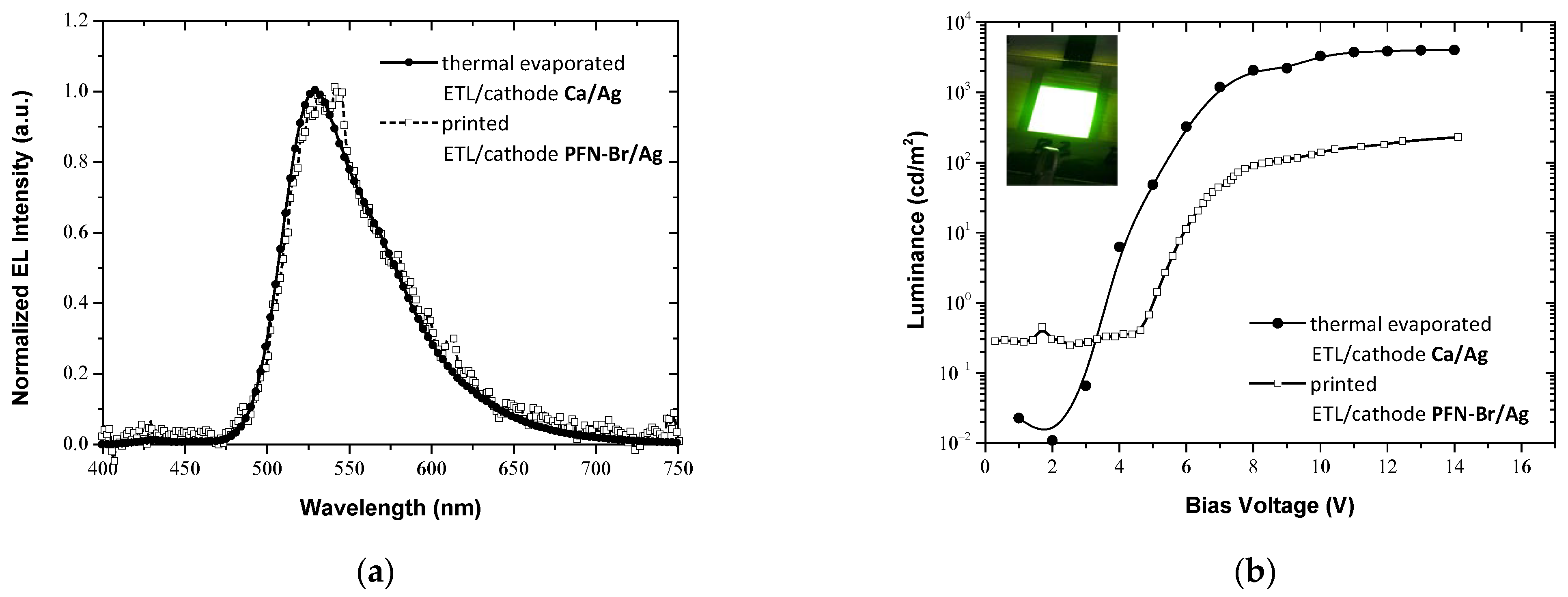

3. Results and Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yu, D.X. Light-emitting devices with conjugated polymers. Int. J. Mol. Sci. 2011, 12, 1575–1594. [Google Scholar] [CrossRef] [PubMed]

- Alsalhi, M.S.; Alam, J.; Dass, L.A.; Raja, M. Recent advances in conjugated polymers for light emitting devices. Int. J. Mol. Sci. 2011, 12, 2036–2054. [Google Scholar] [CrossRef]

- Voigt, M.; Chappell, J.; Rowson, T.; Cadby, A.; Geoghegan, M.; Jones, R.A.L.; Lidzey, D.G. The interplay between the optical and electronic properties of light-emitting-diode applicable conjugated polymer blends and their phase-separated morphology. Org. Electr. 2005, 6, 35–45. [Google Scholar] [CrossRef]

- Abbel, R.; de Vries, I.; Langen, A.; Kirchner, G.; t’Mannetje, H.; Gorter, H.; Wilson, J.; Groen, P. Toward high volume solution based roll-to-roll processing of OLEDs. J. Mater. Res. 2017, 32, 2219–2229. [Google Scholar] [CrossRef]

- Raupp, S.M.; Siebel, D.K.; Kitz, P.G.; Scharfer, P.; Schabel, W. Interdiffusion in Polymeric Multilayer Systems Studied by Inverse Micro-Raman Spectroscopy. Macromolecules 2017, 50, 6819–6828. [Google Scholar] [CrossRef]

- Gioti, M.; Kokkinos, D.; Chaidou, C.; Laskarakis, A.; Andreopoulou, A.; Kallitsis, J.; Logothetidis, S. A comprehensive study of the optical properties of emitting polymers for efficient flexible OLED devices. Phys. Status Solidi A 2016, 213, 2947–2953. [Google Scholar] [CrossRef]

- Gioti, M. Optical, photophysical, and electrooptical studies on slot-die polyfluorene-based flexible OLED devices. Opt. Mater. Express 2021, 11, 1442–1456. [Google Scholar] [CrossRef]

- Nosidlak, N.; Dulian, P.; Mierzwinski, D.; Jaglarz, J. The Determination of the Electronic Parameters of Thin Amorphous Organic Films by Ellipsometric and Spectrophotometric Study. Coatings 2020, 10, 980. [Google Scholar] [CrossRef]

- Toudert, J. Spectroscopic ellipsometry in a broad spectral range on active nano- and meta-materials. Nanotechnol. Rev. 2014, 3, 223–245. [Google Scholar] [CrossRef]

- Kostruba, A.; Stetsyshyn, Y.; Vlokh, R. Method for determination of the parameters of transparent ultrathin films deposited on transparent substrates under conditions of low optical contrast. Appl. Opt. 2015, 54, 6208–6216. [Google Scholar] [CrossRef] [PubMed]

- Kostruba, A.; Stetsyshyn, Y.; Mayevska, S.; Yakovlev, M.; Vankevych, P.; Nastishin, Y.; Kravets, V. Composition, thickness and properties of grafted copolymer brush coatings determined by ellipsometry: Calculation and prediction. Soft Matter 2018, 14, 1016–1025. [Google Scholar] [CrossRef] [PubMed]

- Azzam, R.; Bashara, N. Ellipsometry and Polarized Light; North-Holland Pub: Amsterdam, The Netherlands, 1977. [Google Scholar]

- Tompkins, H.G.; Irene, E.A. Handbook of Ellipsometry; William Andrew: Norwich, NY, USA, 2005. [Google Scholar]

- Kong, M.; Garriga, M.; Reparaz, J.S.; Alonso, M.I. Advanced Optical Characterization of PEDOT:PSS by Combining Spectroscopic Ellipsometry and Raman Scattering. ACS Omega 2022, 7, 39429–39436. [Google Scholar] [CrossRef] [PubMed]

- Jellison, G.E.; Modine, F.A. Parameterization of the optical functions of amorphous materials in the interband region. Appl. Phys. Lett. 1996, 69, 71–373. [Google Scholar] [CrossRef]

- Farahzadi, A.; Beigmohamadi, M.; Niyamakom, P.; Kremers, S.; Meyer, N.; Heuken, M.; Wuttig, M. Characterization of amorphous organic thin films, determination of precise model for spectroscopic ellipsometry measurements. Appl. Surf. Sci. 2010, 256, 6612–6617. [Google Scholar] [CrossRef]

- Kim, C.C.; Garland, J.W.; Raccah, P.M. Modeling the optical dielectric function of semiconductors: Extension of the critical-point parabolic-band approximation. Phys. Rev. B 1992, 45, 011749–011767. [Google Scholar] [CrossRef] [PubMed]

- Fujiwara, H. Spectroscopic Ellipsometry: Principles and Applications; Wiley: Chichester, UK, 2007. [Google Scholar]

- Aspnes, D.E. Optical Properties of Thin Films. Thin Solid Film. 1982, 89, 249–262. [Google Scholar] [CrossRef]

- Karagiannidis, P.G.; Georgiou, D.; Pitsalidis, C.; Laskarakis, A.; Logothetidis, S. Evolution of vertical phase separation in P3HT:PCBM thin films induced by thermal annealing. Mater. Chem. Phys. 2011, 129, 1207–1213. [Google Scholar] [CrossRef]

- Kalas, B.; Zolnai, Z.; Sáfrán, G.; Serényi, M.; Agocs, E.; Lohner, T.; Nemeth, A.; Khánh, N.Q.; Fried, M.; Petrik, P. Micro-combinatorial sampling of the optical properties of hydrogenated amorphous Si1−xGex for the entire range of compositions towards a database for optoelectronics. Sci. Rep. 2020, 10, 19266. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gioti, M. Spectroscopic Ellipsometry Studies on Solution-Processed OLED Devices: Optical Properties and Interfacial Layers. Materials 2022, 15, 9077. https://doi.org/10.3390/ma15249077

Gioti M. Spectroscopic Ellipsometry Studies on Solution-Processed OLED Devices: Optical Properties and Interfacial Layers. Materials. 2022; 15(24):9077. https://doi.org/10.3390/ma15249077

Chicago/Turabian StyleGioti, Maria. 2022. "Spectroscopic Ellipsometry Studies on Solution-Processed OLED Devices: Optical Properties and Interfacial Layers" Materials 15, no. 24: 9077. https://doi.org/10.3390/ma15249077

APA StyleGioti, M. (2022). Spectroscopic Ellipsometry Studies on Solution-Processed OLED Devices: Optical Properties and Interfacial Layers. Materials, 15(24), 9077. https://doi.org/10.3390/ma15249077