Comparative Study on the Behavior of Keyhole in Analogy Welding and Real Deep Penetration Laser Welding

Abstract

1. Introduction

1.1. Keyhole Observation and Theoretical Research

1.2. Numerical Simulation of Keyhole

2. Materials and Methods

2.1. Interaction between Gas Jet and Liquid

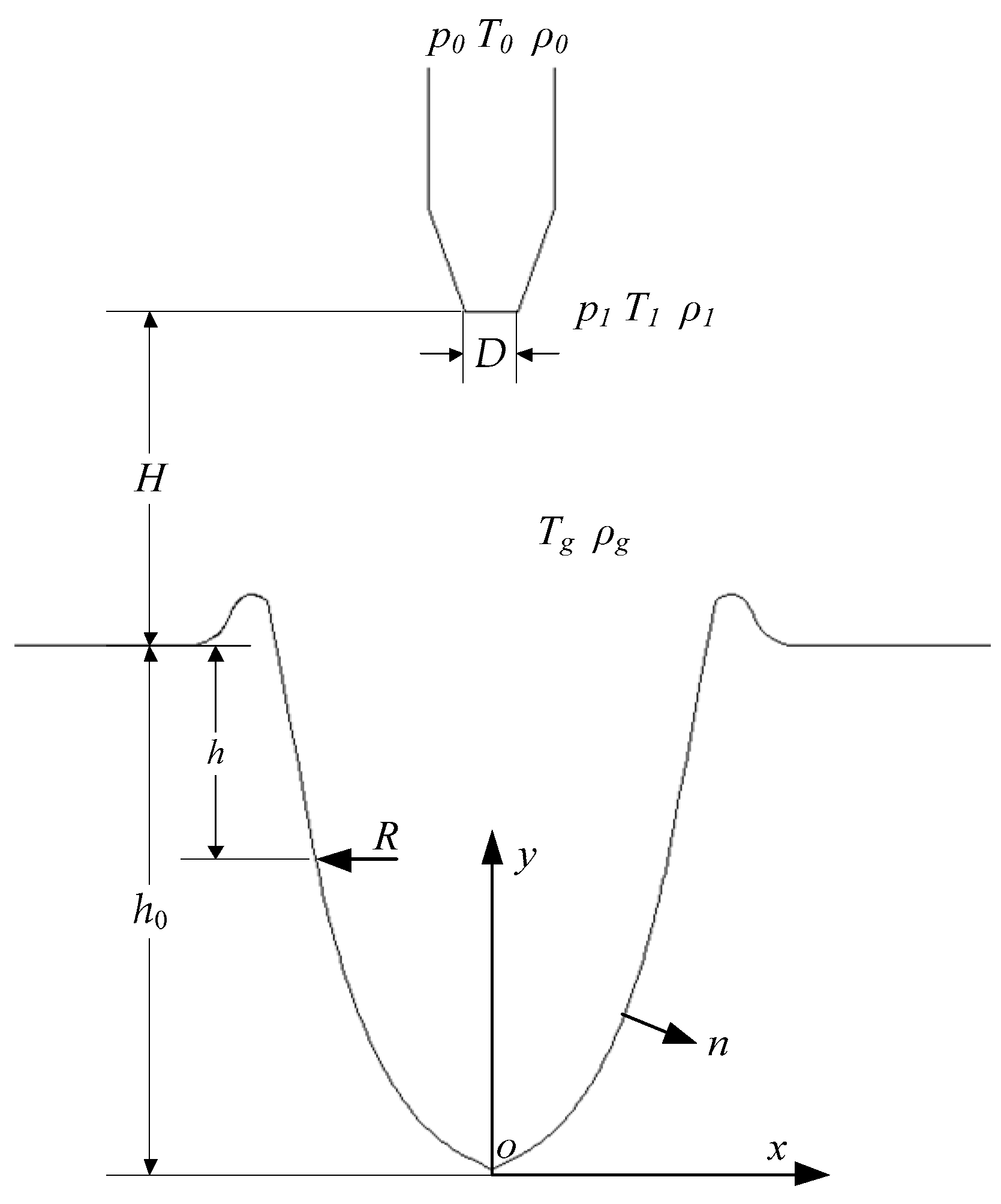

2.2. Pressure Balance in the Keyhole Formed in Laser Welding

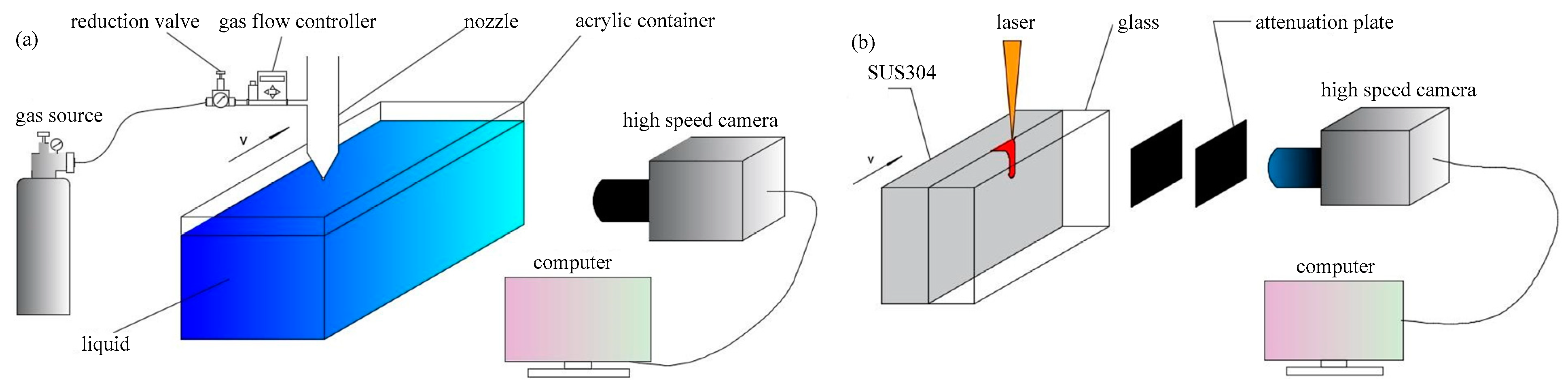

2.3. Experimental Setup

2.4. Procedure

- (1)

- The liquid surface was suddenly impacted by the gas jet, and the formation process of the keyhole recorded by the high-speed camera. The gas flow changed, and the change of keyhole depth when the nozzle was stationary was recorded.

- (2)

- The nozzle moved horizontally relative to the container at a certain speed v to simulate the laser welding process. The corresponding parameters of analogy welding (moving speed, gas flow rate, distance between nozzle outlet and liquid level, etc.) changed, and the behavior of the formed keyhole was recorded.

- (3)

- Different liquid materials were used, and the above experimental process was repeated for each, and the behavior of the keyhole recorded.

- (4)

- During the experiment in real deep penetration laser welding with the sandwich method, the position of the laser head was adjusted so that the center of the laser beam was located at the interface between the workpiece and the glass. The laser beam was moved at a constant speed along the interface, and the keyhole behavior in welding recorded.

3. Results and Discussion

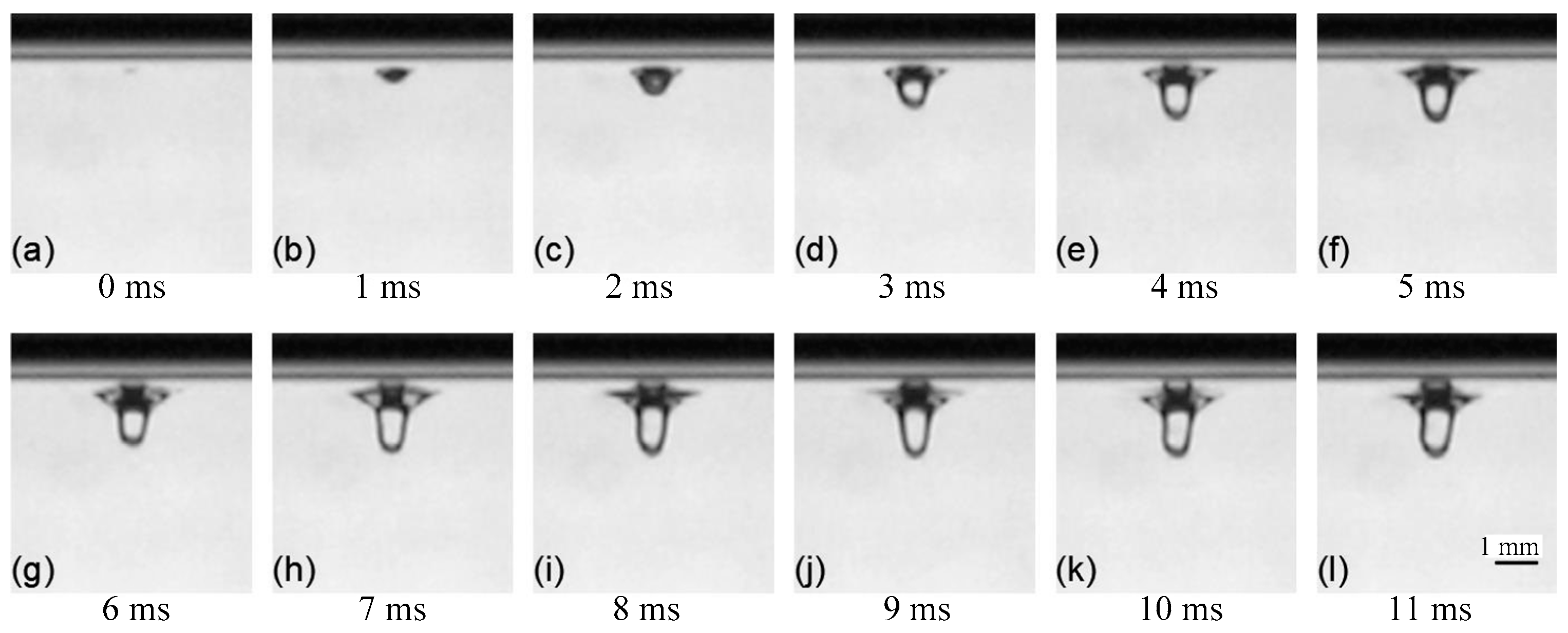

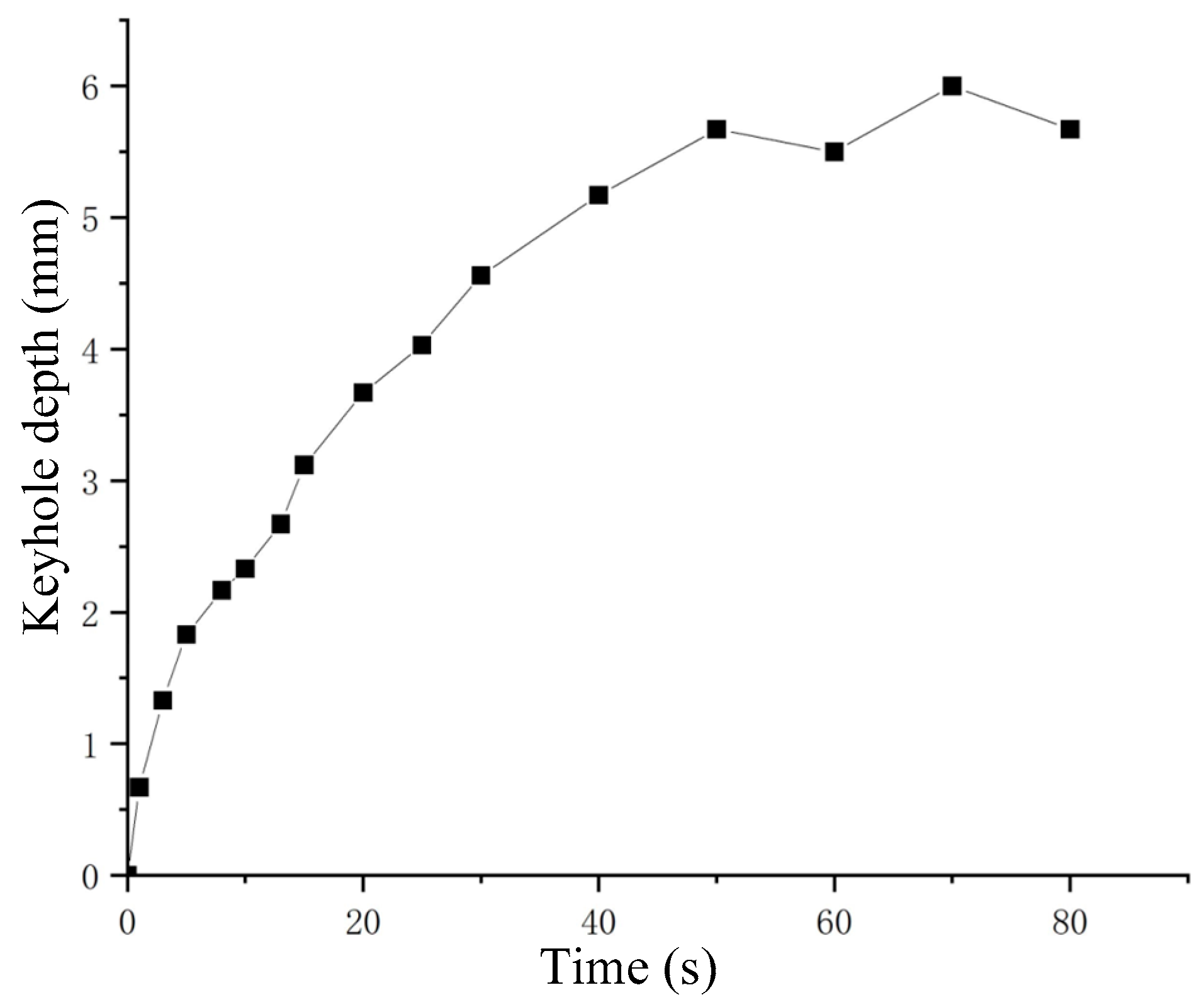

3.1. Keyhole Formation Process

- (1)

- Fast-drilling stage.

- (2)

- Slow-drilling stage.

- (3)

- Quasi-steady state stage.

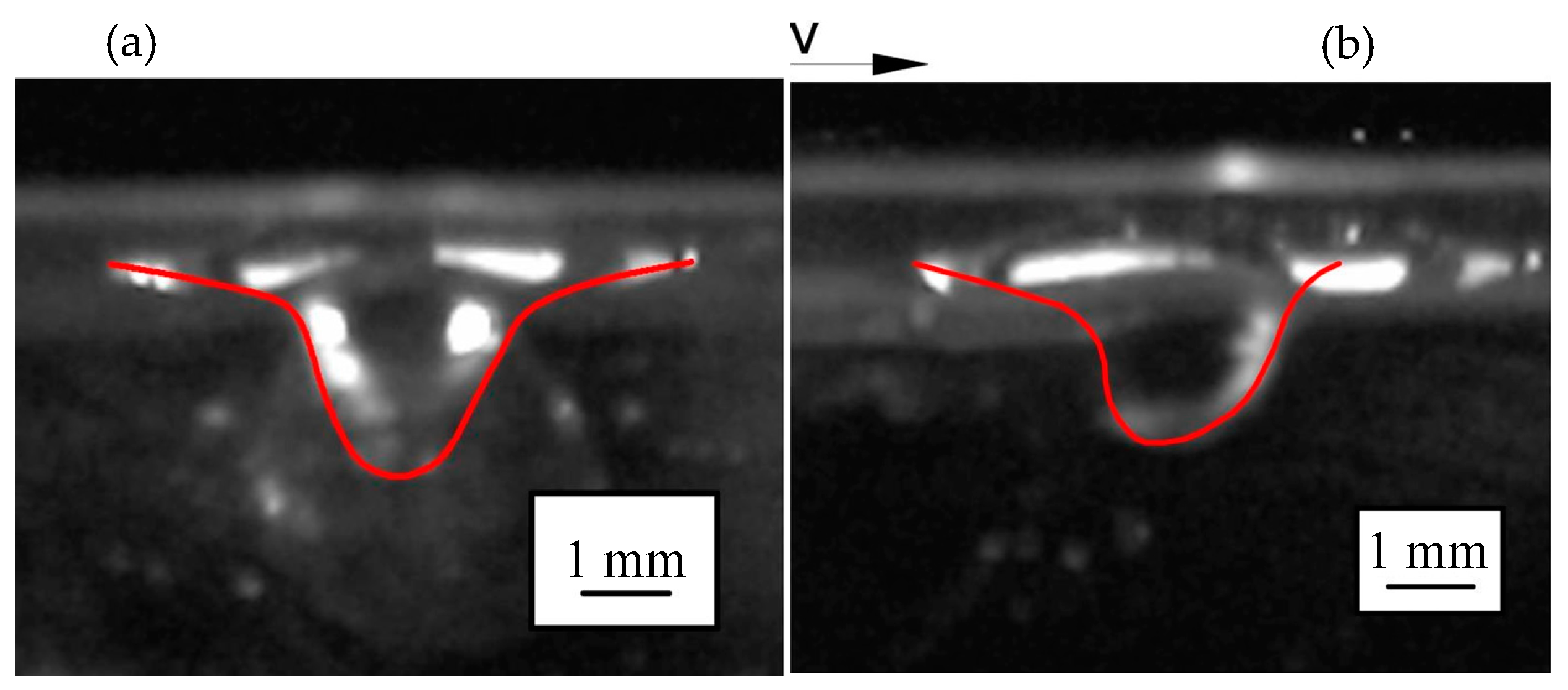

3.2. Keyhole in Analogy Welding

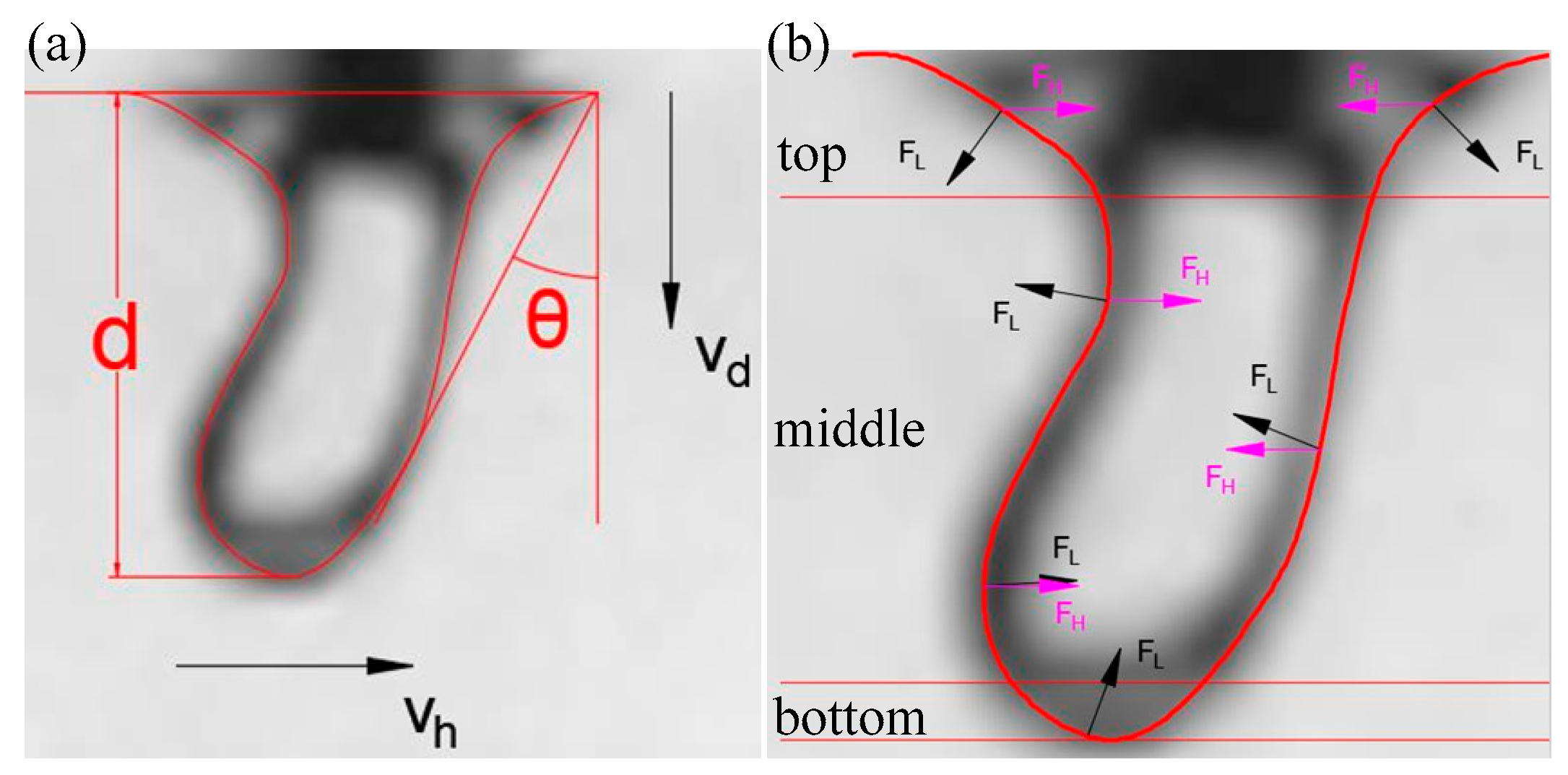

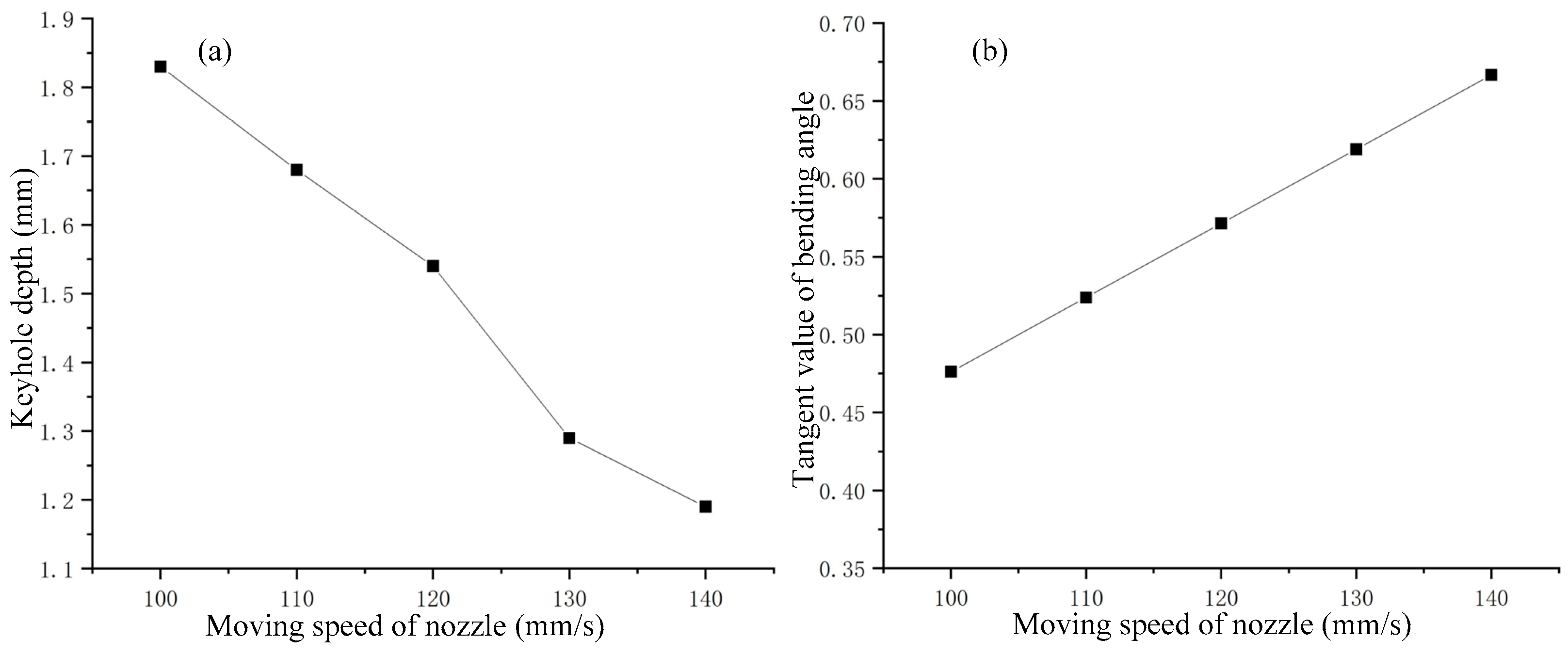

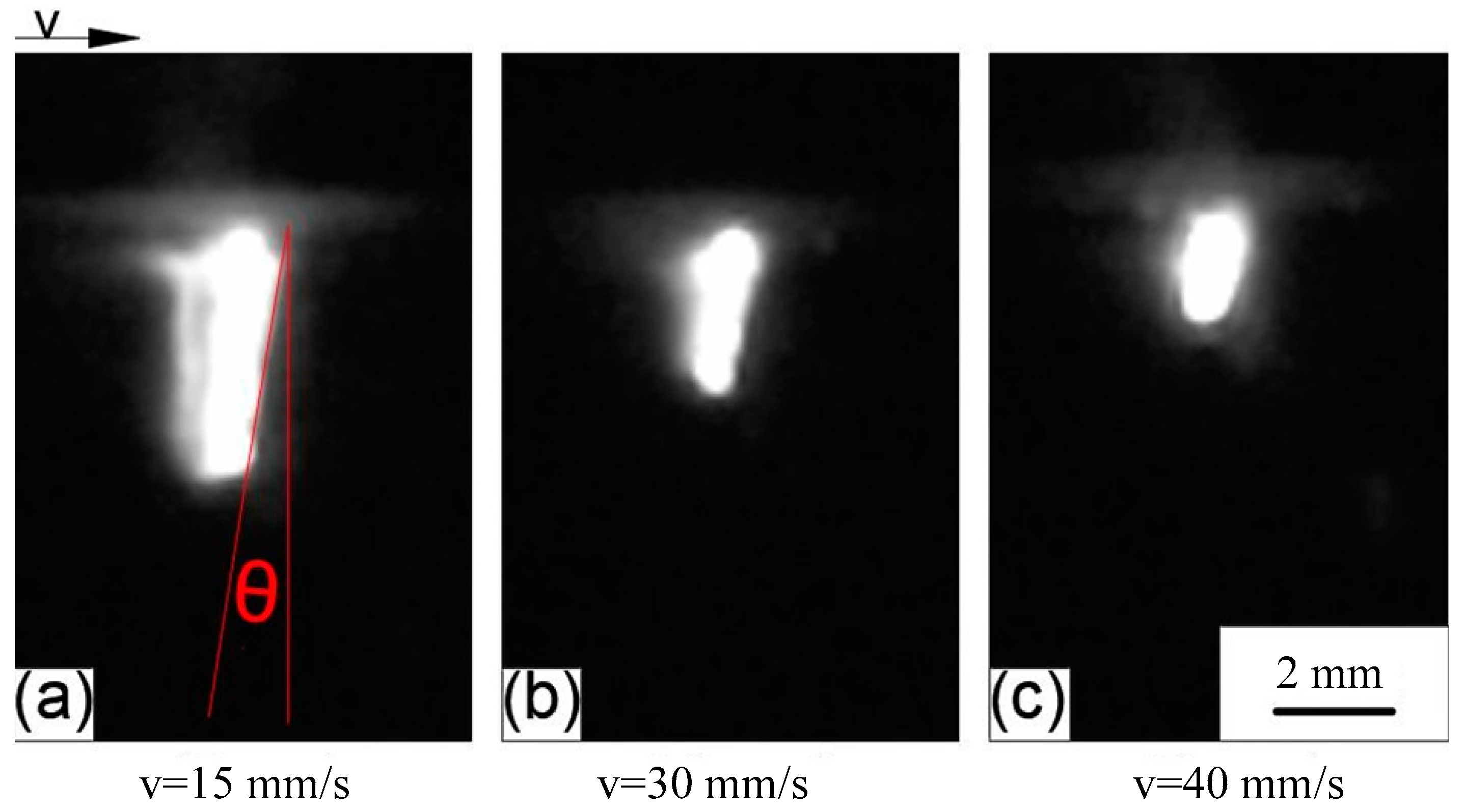

3.2.1. Effect of Moving Speed on Keyhole

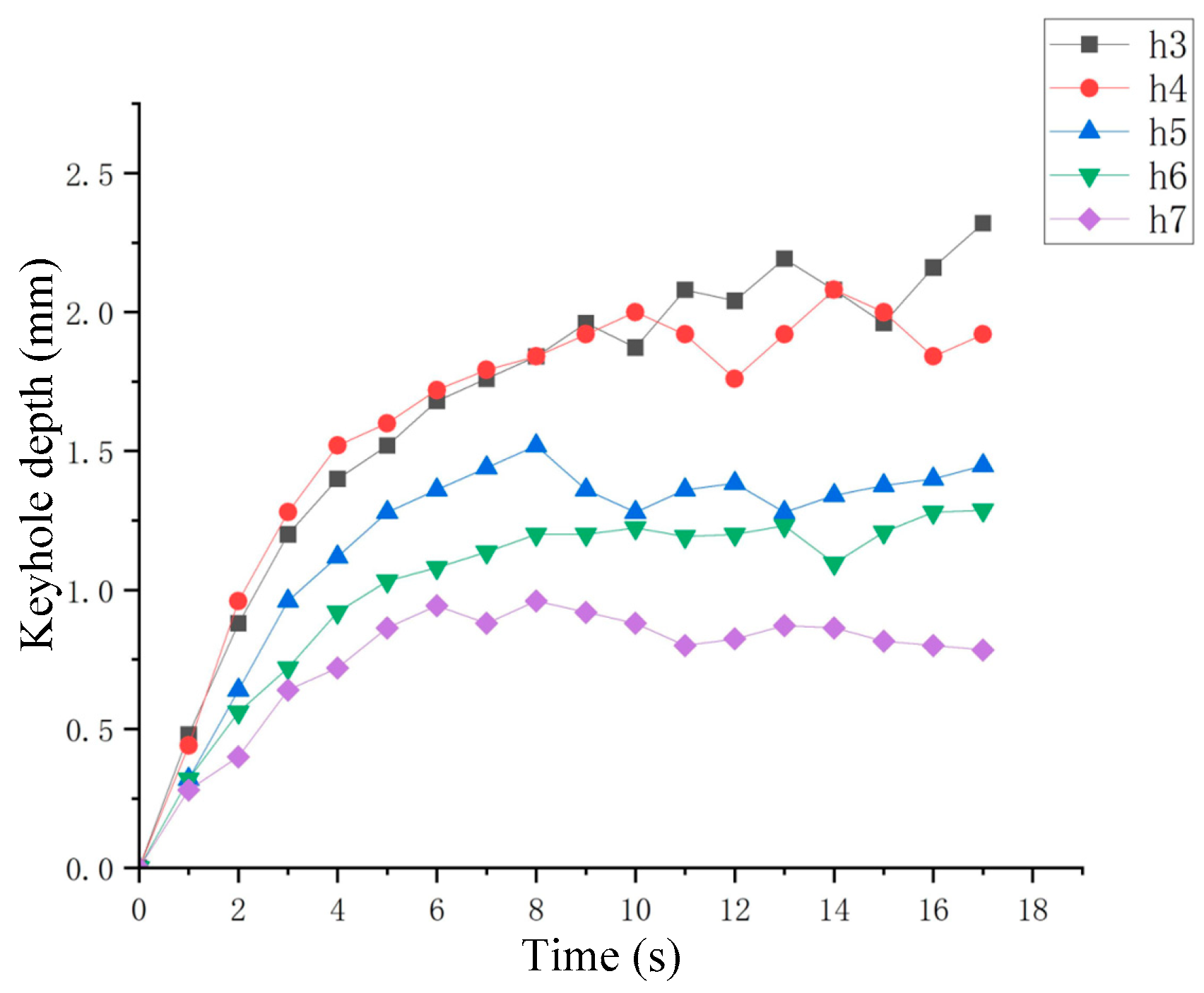

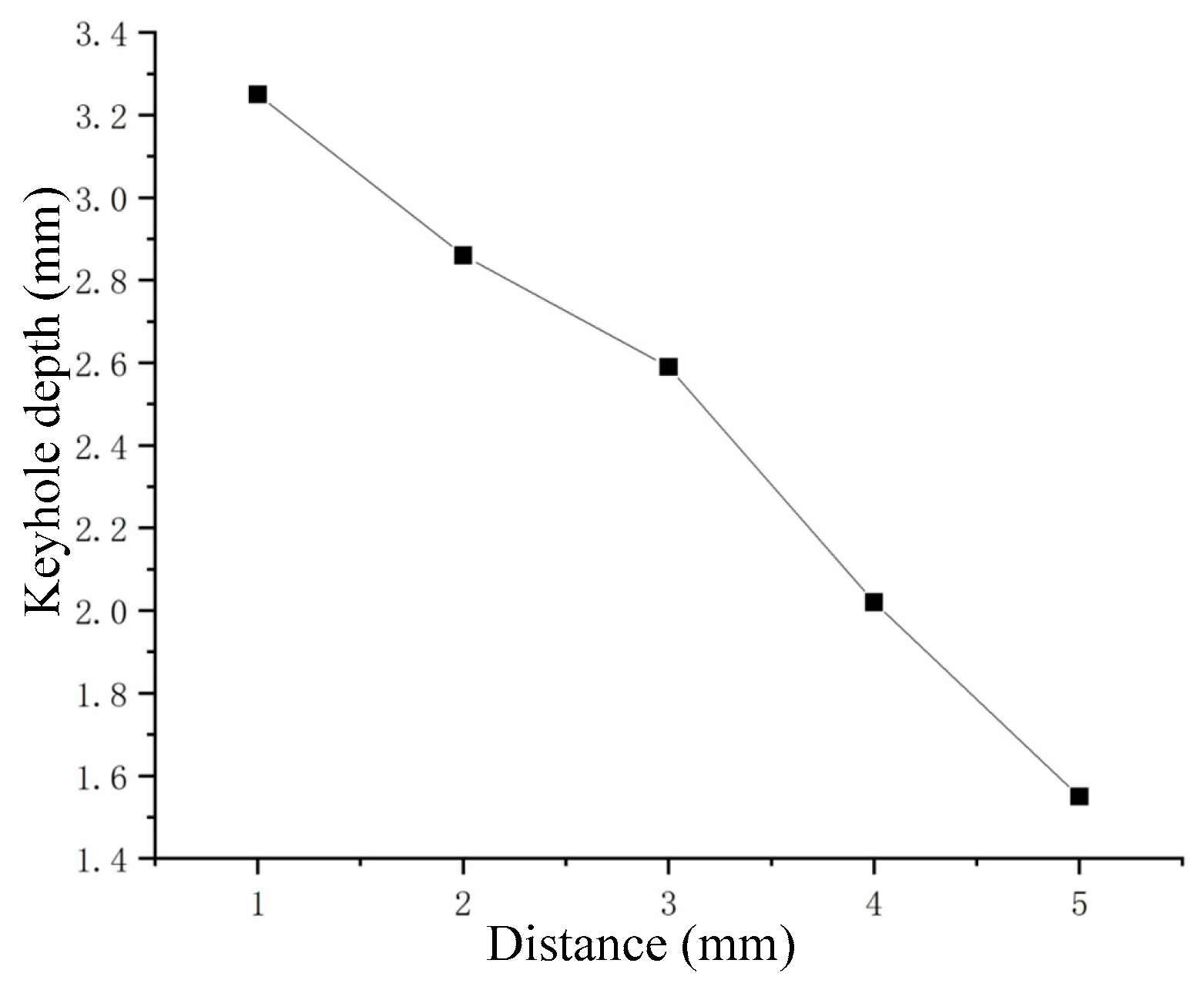

3.2.2. Effect of Distance between Nozzle Outlet and Liquid Level on Keyhole

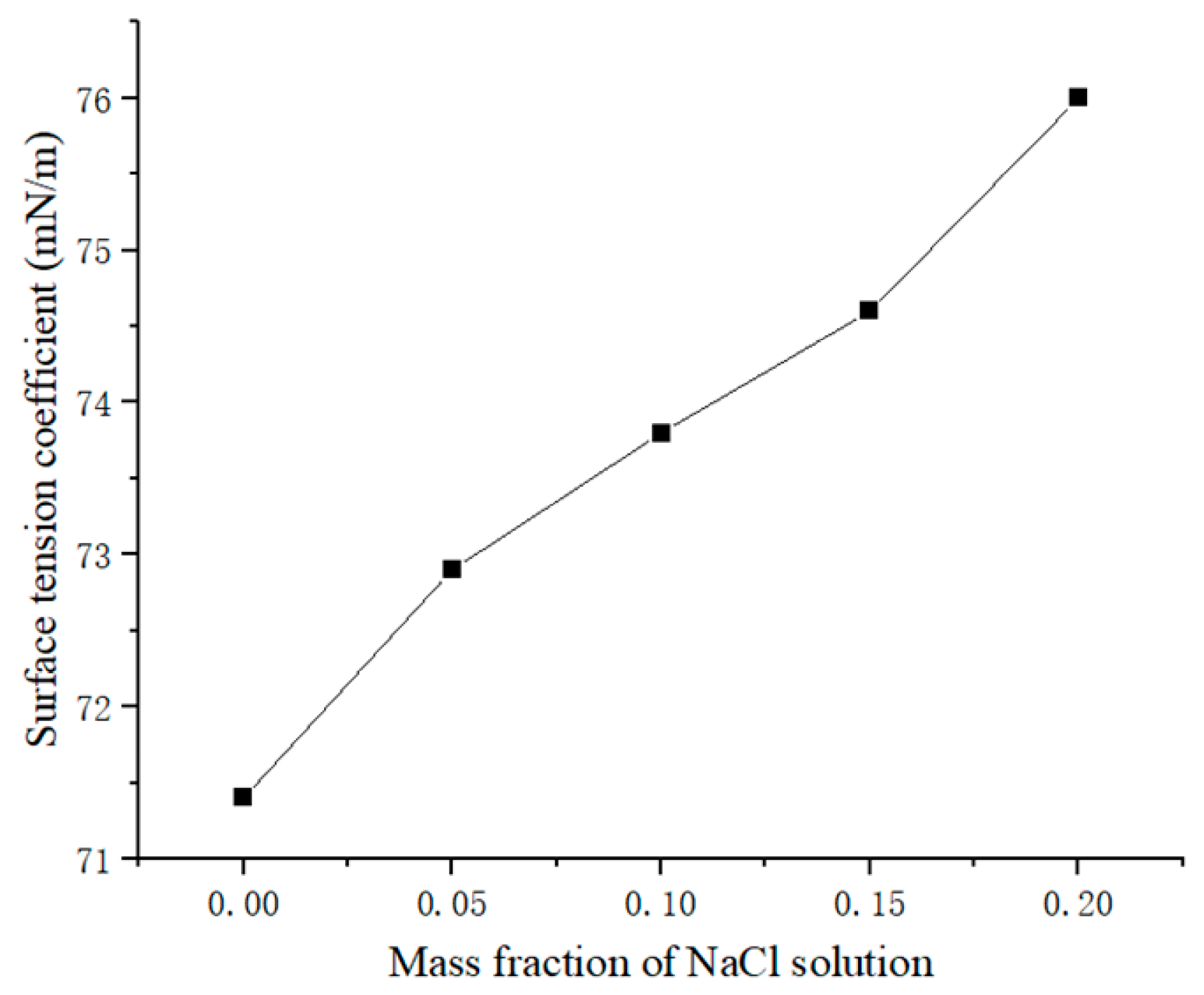

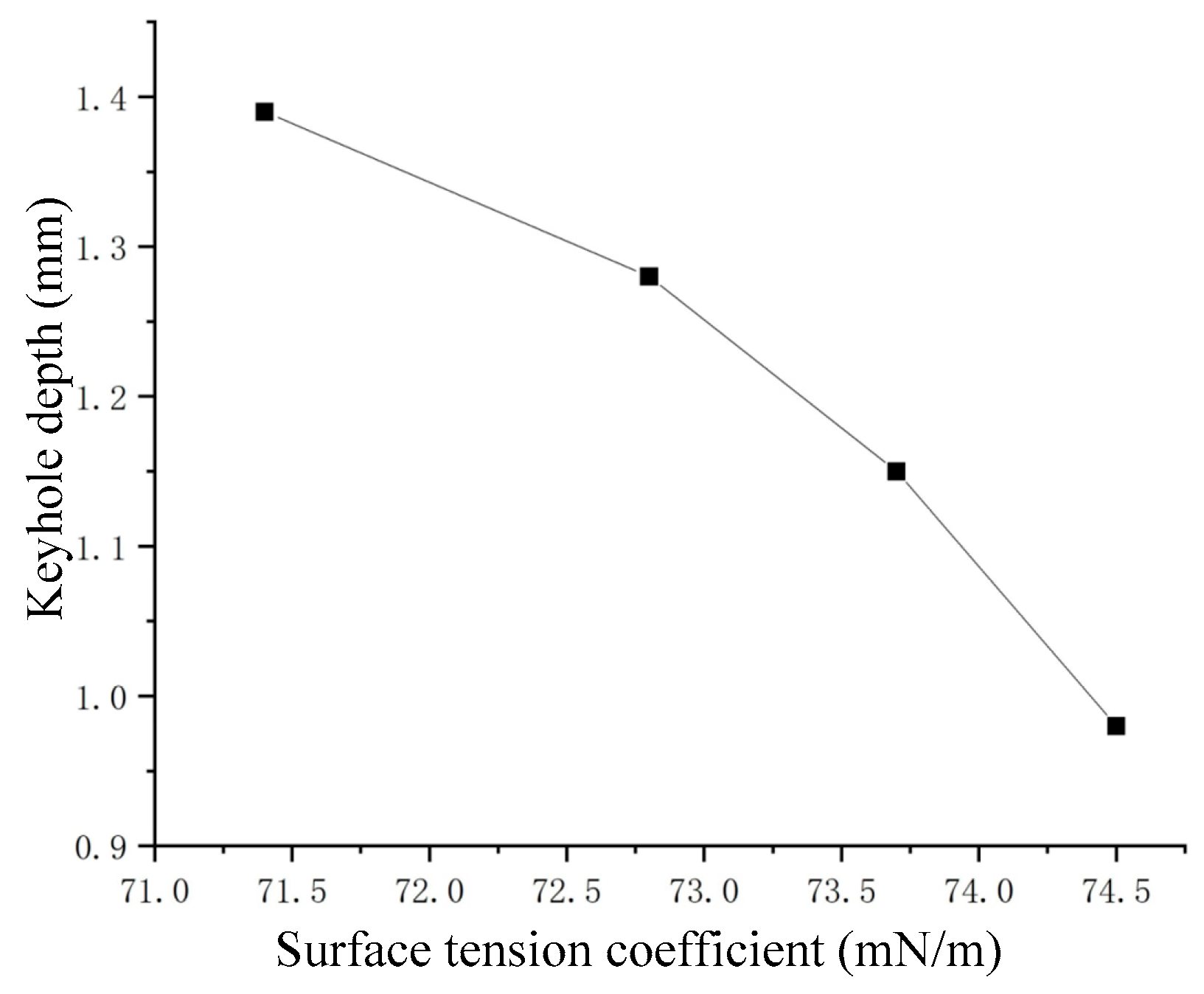

3.2.3. Effect of Material Properties on Keyhole

3.3. Keyhole in Real Deep Penetration Laser Welding with Sandwich Method

4. Conclusions

- (1)

- In the analogy welding and real deep penetration laser welding with the sandwich method, the pressure balance on the keyhole is similar in form. The gas dynamic pressure acting on the liquid in analogy welding and the vapor pressure caused by the evaporation of the laser irradiated material in deep penetration laser welding both promote the opening of the keyhole, while the hydrostatic pressure and surface tension promote the closing of the keyhole.

- (2)

- When the process parameters in the analogy welding and real laser welding are used to study the influence on the keyhole, the behavior of the keyhole in the analogy welding is similar to that obtained in the real deep penetration laser welding.

- (3)

- Studying the keyhole formation and maintenance principle in analogy welding may be helpful to deeply understand the keyhole formation and maintenance mechanism in real deep penetration laser welding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| T | Surface tension |

| σ | Surface tension coefficient |

| Lb | Total length of boundary |

| ∆P | Additional pressure |

| R1 | Radius of curvature |

| R2 | Radius of curvature |

| P | Comprehensive pressure on gas-liquid interface |

| Pa | Atmospheric pressure |

| Pd | Dynamic pressure generated by gas jet |

| PS | Hydrostatic pressure |

| p0 | Gas pressure in the nozzle |

| T0 | Gas temperature in the nozzle |

| ρ0 | Gas density in the nozzle |

| p1 | Gas pressure at the nozzle outlet |

| T1 | Gas temperature at the nozzle outlet |

| ρ1 | Gas density at the nozzle outlet |

| Tg | Temperature of jetted gas |

| ρg | Density of jetted gas |

| H | Distance between nozzle outlet and liquid level |

| h0 | Keyhole depth |

| R | Radius of curvature at the depth h on the keyhole wall |

| n | Normal of a point on the keyhole wall D Outlet diameter of the nozzle |

| vg | Velocity of the gas in the jet prior to the collision with the surface of the liquid |

| ρL | Density of liquid |

| σL | Surface tension coefficient of liquid |

| Rkh | Radius of curvature of the liquid surface at the keyhole depth h0 |

| Pw | Comprehensive pressure in keyhole in laser welding |

| Pv | Vapor pressure of the material |

| v | Movement speed |

| V | Gas velocity at the nozzle outlet |

| q | Gas flow rate |

| θ | Angle |

| vh | Moving speed of keyhole |

| vd | Drilling speed of keyhole |

| FH | The resultant force directions of the surface tension in the transverse direction |

| FL | The resultant force directions of the surface tension in longitudinal direction |

References

- Arata, Y.; Abe, N.; Oda, T. Fundamental Phenomena in High Power CO_2 Laser Welding (Report I): Atmospheric Laser Welding (Welding Physics, Process&Instrument). Trans. JWRI 1985, 14, 5–11. [Google Scholar]

- Dowden, J.; Postacioglu, N.; Davis, M.; Kapadia, P. A keyhole model in penetration welding with a laser. J. Phys. D Appl. Phys. 1987, 20, 36. [Google Scholar] [CrossRef]

- Postacioglu, N.; Kapadia, P.; Davis, M.; Dowden, J. Upwelling in the liquid region surrounding the keyhole in penetration welding with a laser. J. Phys. D Appl. Phys. 1987, 20, 340. [Google Scholar] [CrossRef]

- Dowden, J.; Kapadia, P.; Clucas, A.; Ducharme, R.; Steen, W.M. On the relation between fluid dynamic pressure and the formation of pores in laser keyhole welding. J. Laser Appl. 1996, 8, 183–190. [Google Scholar] [CrossRef]

- Postacioglu, N.; Kapadia, P.; Dowden, J.M. The thermal stress generated by a moving elliptical weldpool in the welding of thin metal sheets. J. Phys. D Appl. Phys. 1997, 30, 2304. [Google Scholar] [CrossRef]

- Dowden, J. Interaction of the keyhole and weld pool in laser keyhole welding. J. Laser Appl. 2002, 14, 204–209. [Google Scholar] [CrossRef]

- Semak, V.V.; Hopkins, J.A.; McCay, M.H.; McCay, T.D. Melt pool dynamics during laser welding. J. Phys. D Appl. Phys. 1995, 28, 2443. [Google Scholar] [CrossRef]

- Semak, V.; Matsunawa, A. The role of recoil pressure in energy balance during laser materials processing. J. Phys. D Appl. Phys. 1997, 30, 2541. [Google Scholar] [CrossRef]

- Kim, J.; Oh, S.; Ki, H. A study of keyhole geometry in laser welding of zinc-coated and uncoated steels using a coaxial observation method. J. Mater. Process. Technol. 2015, 225, 451–462. [Google Scholar] [CrossRef]

- Lankalapalli, K.N.; Tu, J.F.; Gartner, M. A model for estimating penetration depth of laser welding processes. J. Phys. D Appl. Phys. 1996, 29, 1831. [Google Scholar] [CrossRef]

- Solana, P.; Negro, G. A study of the effect of multiple reflections on the shape of the keyhole in the laser processing of materials. J. Phys. D Appl. Phys. 1997, 30, 3216. [Google Scholar] [CrossRef]

- Pecharapa, W.; Kar, A. Effects of phase changes on weld pool shape in laser welding. J. Phys. D Appl. Phys. 1997, 30, 3322. [Google Scholar] [CrossRef]

- Strömbeck, P.; Kar, A. Self-focusing and beam attenuation in laser materials processing. J. Phys. D Appl. Phys. 1998, 31, 1438. [Google Scholar] [CrossRef]

- Fabbro, R.; Chouf, K. Keyhole modeling during laser welding. J. Appl. Phys. 2000, 87, 4075–4083. [Google Scholar] [CrossRef]

- Fabbro, R.; Slimani, S.; Coste, F.; Briand, F. Analysis of the Various Melt Pool Hydrodynamic Regimes Observed during cw nd-yag Deep Penetration Laser Welding. In Proceedings of the 26th International Congress on Applications of Lasers and Electro-Optics, Orlando, FL, USA, 29 October–1 November 2007. [Google Scholar]

- Fabbro, R.; Slimani, S.; Coste, F.; Briand, F. Characteristic Melt Pool Hydrodynamic Behaviors for CW Nd-YAG Deep Penetration Laser Welding. In Proceedings of the 3rd Pacific International Conference on Applications of Lasers and Optics, Beijing, China, 16–18 April 2008. [Google Scholar]

- Fabbro, R. Melt pool and keyhole behaviour analysis for deep penetration laser welding. J. Phys. D Appl. Phys. 2010, 43, 445501. [Google Scholar] [CrossRef]

- Fabbro, R. Scaling laws for the laser welding process in keyhole mode. J. Mater. Process. Technol. 2019, 264, 346–351. [Google Scholar] [CrossRef]

- Jin, X.; Li, L.; Zhang, Y. A heat transfer model for deep penetration laser welding based on an actual keyhole. Int. J. Heat Mass Transf. 2003, 46, 15–22. [Google Scholar] [CrossRef]

- Li, L.; Jin, X.; Zhang, Y. A Theoretical and Experimental Study on Keyhole Effects in Laser Deep-Penetration Welding. In Proceedings of the Lasers in Material Processing and Manufacturing, Shanghai, China, 14–18 October 2002. [Google Scholar]

- Jin, X.Z.; Li, L.J. A conduction model for deep penetration laser welding based on an actual keyhole. Opt. Laser Technol. 2003, 35, 5–12. [Google Scholar] [CrossRef]

- Jin, X.; Berger, P.; Graf, T. Multiple reflections and Fresnel absorption in an actual 3D keyhole during deep penetration laser welding. J. Phys. D Appl. Phys. 2006, 39, 4703. [Google Scholar] [CrossRef]

- Jin, X.; Li, L. An experimental study on the keyhole shapes in laser deep penetration welding. Opt. Laser Eng. 2004, 41, 779–790. [Google Scholar] [CrossRef]

- Jin, X. A three-dimensional model of multiple reflections for high-speed deep penetration laser welding based on an actual keyhole. Opt. Lasers Eng. 2008, 46, 83–93. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, G.; Wei, H.; Zhang, J. A novel “sandwich” method for observation of the keyhole in deep penetration laser welding. Opt. Lasers Eng. 2008, 46, 133–139. [Google Scholar] [CrossRef]

- Cheng, Y.; Jin, X.; Li, S.; Zeng, L. Fresnel absorption and inverse bremsstrahlung absorption in an actual 3D keyhole during deep penetration CO2 laser welding of aluminum 6016. Opt. Laser Technol. 2012, 44, 1426–1436. [Google Scholar] [CrossRef]

- Jin, X.; Zeng, L.; Cheng, Y. Direct observation of keyhole plasma characteristics in deep penetration laser welding of aluminum alloy 6016. J. Phys. D Appl. Phys. 2012, 45, 245205. [Google Scholar] [CrossRef]

- Li, S.; Chen, G.; Zhang, M.; Zhou, Y.; Zhang, Y. Dynamic keyhole profile during high-power deep-penetration laser welding. J. Mater. Process. Technol. 2014, 214, 565–570. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, Q.; Yin, X.; Li, S.; Deng, J. Experimental research on the dynamic behaviors of the keyhole and molten pool in laser deep-penetration welding. J. Phys. D Appl. Phys. 2018, 51, 145602. [Google Scholar] [CrossRef]

- Zhang, D.; Wang, M.; Shu, C.; Zhang, Y.; Wu, D.; Ye, Y. Dynamic keyhole behavior and keyhole instability in high power fiber laser welding of stainless steel. Opt. Laser Technol. 2019, 114, 1–9. [Google Scholar] [CrossRef]

- Wang, H.; Shi, Y.; Gong, S. Numerical simulation of laser keyhole welding processes based on control volume methods. J. Phys. D Appl. Phys. 2006, 39, 4722. [Google Scholar] [CrossRef]

- Cho, J.H.; Farson, D.F.; Milewski, J.O.; Hollis, K.J. Weld pool flows during initial stages of keyhole formation in laser welding. J. Phys. D Appl. Phys. 2009, 42, 175502. [Google Scholar] [CrossRef]

- Huang, B.; Chen, X.; Pang, S.; Hu, R. A three-dimensional model of coupling dynamics of keyhole and weld pool during electron beam welding. Int. J. Heat Mass Transf. 2017, 115, 159–173. [Google Scholar] [CrossRef]

- Bedenko, D.V.; Kovalev, O.B.; Krivtsun, I.V. Simulation of plasma dynamics in a keyhole during laser welding of metal with deep penetration. J. Phys. D Appl. Phys. 2010, 43, 105501. [Google Scholar] [CrossRef]

- Pang, S.; Chen, X.; Shao, X.; Gong, S.; Xiao, J. Dynamics of vapor plume in transient keyhole during laser welding of stainless steel: Local evaporation, plume swing and gas entrapment into porosity. Opt. Lasers Eng. 2016, 82, 28–40. [Google Scholar] [CrossRef]

- Li, L.; Peng, G.; Wang, J.; Gong, J.; Meng, S. Numerical and experimental study on keyhole and melt flow dynamics during laser welding of aluminium alloys under subatmospheric pressures. Int. J. Heat Mass Transf. 2019, 133, 812–826. [Google Scholar] [CrossRef]

- Cunningham, R.; Zhao, C.; Parab, N.; Kantzos, C.; Pauza, J.; Fezzaa, K.; Sun, T.; Rollett, A.D. Keyhole threshold and morphology in laser melting revealed by ultrahigh-speed x-ray imaging. Science 2019, 363, 849–852. [Google Scholar] [CrossRef] [PubMed]

- Mayi, Y.A.; Dal, M.; Peyre, P.; Bellet, M.; Metton, C.; Moriconi, C.; Fabbro, R. Transient dynamics and stability of keyhole at threshold in laser powder bed fusion regime investigated by finite element modeling. J. Laser Appl. 2021, 33, 012024. [Google Scholar] [CrossRef]

- Zou, J.; Ha, N.; Xiao, R.; Wu, Q.; Zhang, Q. Interaction between the laser beam and keyhole wall during high power fiber laser keyhole welding. Opt. Express 2017, 25, 17650–17656. [Google Scholar] [CrossRef]

- Li, Z.; Yu, G.; He, X.; Li, S.; Tian, C.; Dong, B. Analysis of surface tension driven flow and solidification behavior in laser linear welding of stainless steel. Opt. Laser Technol. 2020, 123, 105914. [Google Scholar] [CrossRef]

- Seidgazov, R.D. Analysis of The Main Hydrodynamic Mechanisms in Laser Induced Keyhole Welding. In Proceedings of the IEEE 8th International Conference on Advanced Optoelectronics and Lasers, Sozopol, Bulgaria, 6–8 September 2019. [Google Scholar]

- Wu, D.; Hua, X.; Huang, L.; Li, F.; Cai, Y. Observation of the keyhole behavior, spatter, and keyhole-induced bubble formation in laser welding of a steel/glass sandwich. Weld. World 2019, 63, 815–823. [Google Scholar] [CrossRef]

- Huang, Y.; Shen, C.; Ji, X.; Li, F.; Zhang, Y.; Hua, X. Correlation between gas-dynamic behaviour of a vapour plume and oscillation of keyhole size during laser welding of 5083 Al-alloy. J. Mater. Process. Technol. 2020, 283, 116721. [Google Scholar] [CrossRef]

- Hao, Z.; Chen, H.; Jin, X.; Yu, X.; Liu, Z. Direct observation of keyhole with an innovative layer-by-layer imaging method during deep penetration laser welding. Opt. Laser Technol. 2022, 152, 108142. [Google Scholar] [CrossRef]

- Olivares, O.; Elias, A.; Sanchez, R.; Díaz-Cruz, M.; Morales, R.D. Physical and mathematical models of gas-liquid fluid dynamics in LD converters. Steel Res. 2002, 73, 44–51. [Google Scholar] [CrossRef]

- Vafaei, S.; Wen, D. Modification of the Young–Laplace equation and prediction of bubble interface in the presence of nanoparticles. Adv. Colloid Interface Sci. 2015, 225, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Banks, R.B.; Chandrasekhara, D.V. Experimental investigation of the penetration of a high-velocity gas jet through a liquid surface. J. Fluid Mech. 1963, 15, 13–34. [Google Scholar] [CrossRef]

- Banks, R.B.; Bhavamai, A. Experimental study of the impingement of a liquid jet on the surface of a heavier liquid. J. Fluid Mech. 1965, 23, 229–240. [Google Scholar] [CrossRef]

- Mordasov, M.M.; Savenkov, A.P.; Chechetov, K.E. Method for analyzing the gas jet impinging on a liquid surface. Technol. Phys. 2016, 61, 659–668. [Google Scholar] [CrossRef]

- Szymanski, Z.; Hoffman, J.; Kurzyna, J.; Kolasa, A.; Jakubowski, J. Oscillations of keyhole pressure and plasma radiation during cw CO2 laser welding. Laser Technol. VI Appl. 2000, 4238, 186–198. [Google Scholar]

- Vargaftik, N.B.; Volkov, B.N.; Voljak, L.D. International tables of the surface tension of water. J. Phys. Chem. Ref. Data 1983, 12, 817–820. [Google Scholar] [CrossRef]

- Hwang, H.Y.; Irons, G.A. Mathematical modeling of impinging gas jets on liquid surfaces. Metall. Mater. Trans. B 2011, 42, 575–591. [Google Scholar] [CrossRef]

- Kestin, J.; Khalifa, H.E.; Correia, R.J. Tables of the dynamic and kinematic viscosity of aqueous NaCl solutions in the temperature range 20–150 C and the pressure range 0.1–35 MPa. J. Phys. Chem. Ref. Data 1981, 10, 71–88. [Google Scholar] [CrossRef]

- dos Santos, A.P.; Diehl, A.; Levin, Y. Surface tensions, surface potentials, and the Hofmeister series of electrolyte solutions. Langmuir 2010, 26, 10778–10783. [Google Scholar] [CrossRef]

- Plevachuk, Y.; Sklyarchuk, V.; Eckert, S.; Gerbeth, G.; Novakovic, R. Thermophysical properties of the liquid Ga–In–Sn eutectic alloy. J. Chem. Eng. Data 2014, 59, 757–763. [Google Scholar] [CrossRef]

- Ek, M.; Sichen, D. Study of penetration depth and droplet behavior in the case of a gas jet impinging on the surface of molten metal using liquid Ga–In–Sn. Steel Res. Int. 2012, 83, 678–685. [Google Scholar] [CrossRef]

- Liu, Q.; Chen, W.; Hu, L.; Xie, H.; Fu, X. Experimental investigation of cavity stability for a gas-jet penetrating into a liquid sheet. Phys. Fluids 2015, 27, 082106. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hao, Z.; Chen, H.; Jin, X.; Liu, Z. Comparative Study on the Behavior of Keyhole in Analogy Welding and Real Deep Penetration Laser Welding. Materials 2022, 15, 9001. https://doi.org/10.3390/ma15249001

Hao Z, Chen H, Jin X, Liu Z. Comparative Study on the Behavior of Keyhole in Analogy Welding and Real Deep Penetration Laser Welding. Materials. 2022; 15(24):9001. https://doi.org/10.3390/ma15249001

Chicago/Turabian StyleHao, Zhongjia, Huiyang Chen, Xiangzhong Jin, and Zuguo Liu. 2022. "Comparative Study on the Behavior of Keyhole in Analogy Welding and Real Deep Penetration Laser Welding" Materials 15, no. 24: 9001. https://doi.org/10.3390/ma15249001

APA StyleHao, Z., Chen, H., Jin, X., & Liu, Z. (2022). Comparative Study on the Behavior of Keyhole in Analogy Welding and Real Deep Penetration Laser Welding. Materials, 15(24), 9001. https://doi.org/10.3390/ma15249001