1. Introduction

High-speed (HS) electrical machine (EM) technologies offer a viable solution for the needs of future electromechanical energy conversion systems. A key benefit of high-speed technology is its higher power density, which decreases the size of high-speed systems and reduces the need of raw materials. Moreover, high-speed machines exhibit greater efficiency than electrical machines with lower rotational speeds [

1]. Typical applications for HS-EM are, for example, gas turbines, flywheel energy storage systems, high-speed spindle applications, turbomolecular pumps, gas compressor applications, as well as industrial air compressors and air blowers [

2]. An important aspect of electromagnetic design and manufacturing of such high-speed technology is rotor dynamics, which influences robustness and efficiency, and consequently the economics of the rotating electrical machine. High-speed rotating electrical machines are electrical machines with rotor surface speed greater than 100 m/s [

3] and high rotational speed with respect to the power of the electrical machine [

2]. The maximum operation speed of a HS-EM is governed by the mechanical robustness of its rotor at high speeds [

4], thermal losses in the rotor and in the stator occurring at high switching frequencies [

5], and gas friction losses at rotor surface speed over 300 m/s [

6].

Typically, high-speed electrical machines can be classified by machine type and rotor structure into induction machines (IM), permanent magnet synchronous machines (PMSM) and switched reluctance machines (SRM) [

7]. Synchronous homopolar machines [

8] and synchronous reluctance motors (SynRM) [

9] are also applicable to be used in high-speed applications.

Each of the high-speed electrical machine types listed above has a unique rotor structure which makes the machine particularly suitable for specific application. The strengths and weaknesses of the various high-speed electrical machine types are described in [

4]. As a summary, it can be concluded that induction machines are generally suited for high-speed applications due to the mechanical robustness of the IM rotor. However, the efficiency of the IM rotor is decreased by rotor joule losses. Switched reluctance machine rotors are simple and robust constructions, but the requirement of a large airgap reduces their efficiency. Permanent magnet synchronous machines have high power density and efficiency; however, the mechanical robustness of the rotor, which is affected by the magnet encapsulation, may be a limiting factor in high-speed applications.

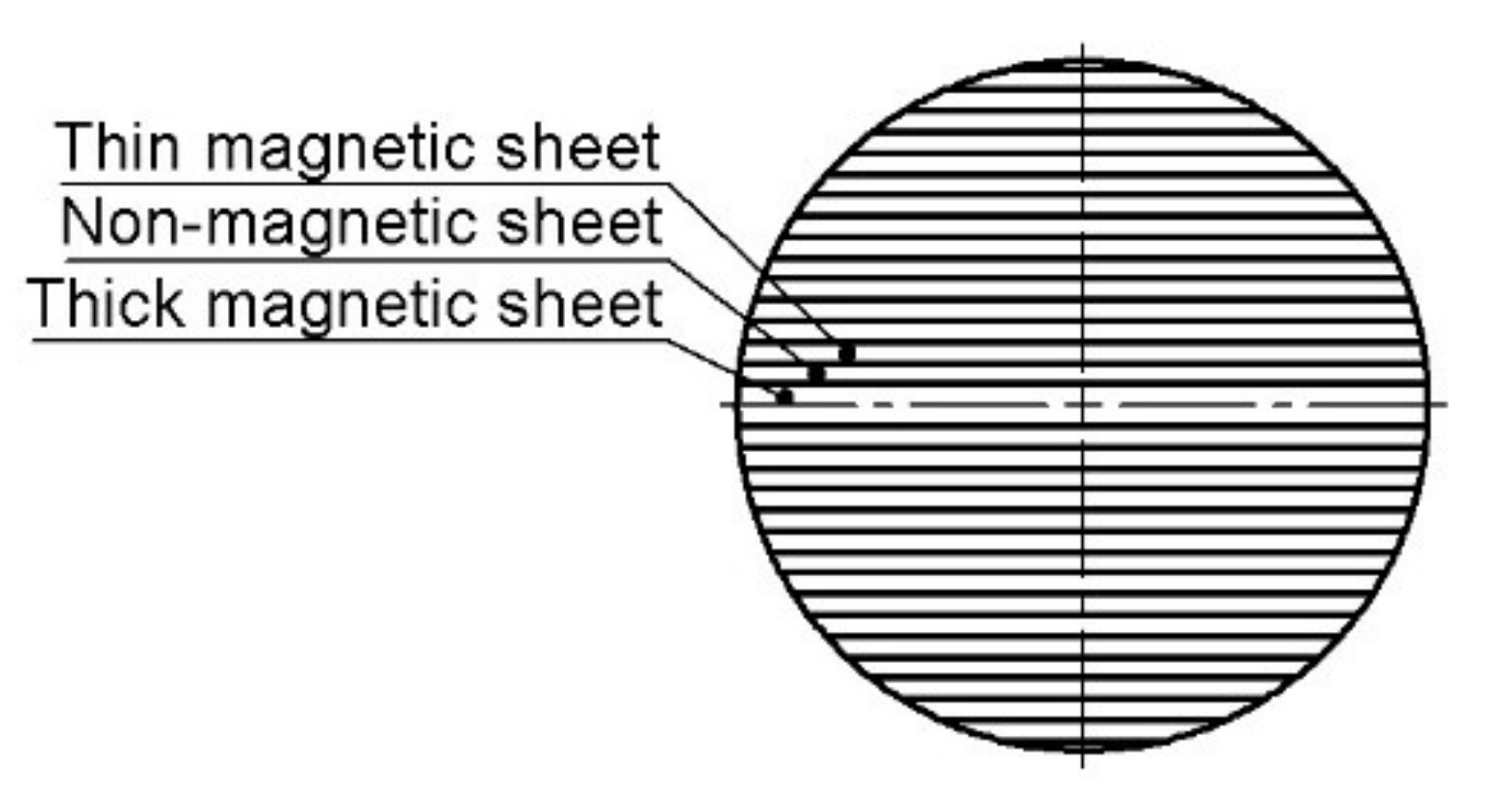

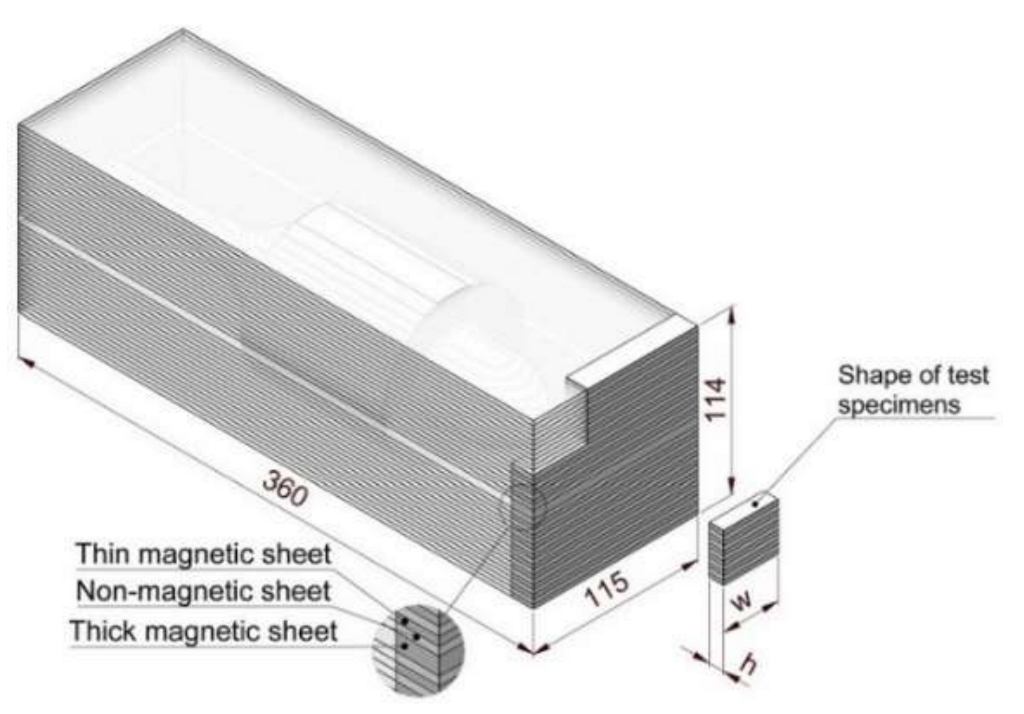

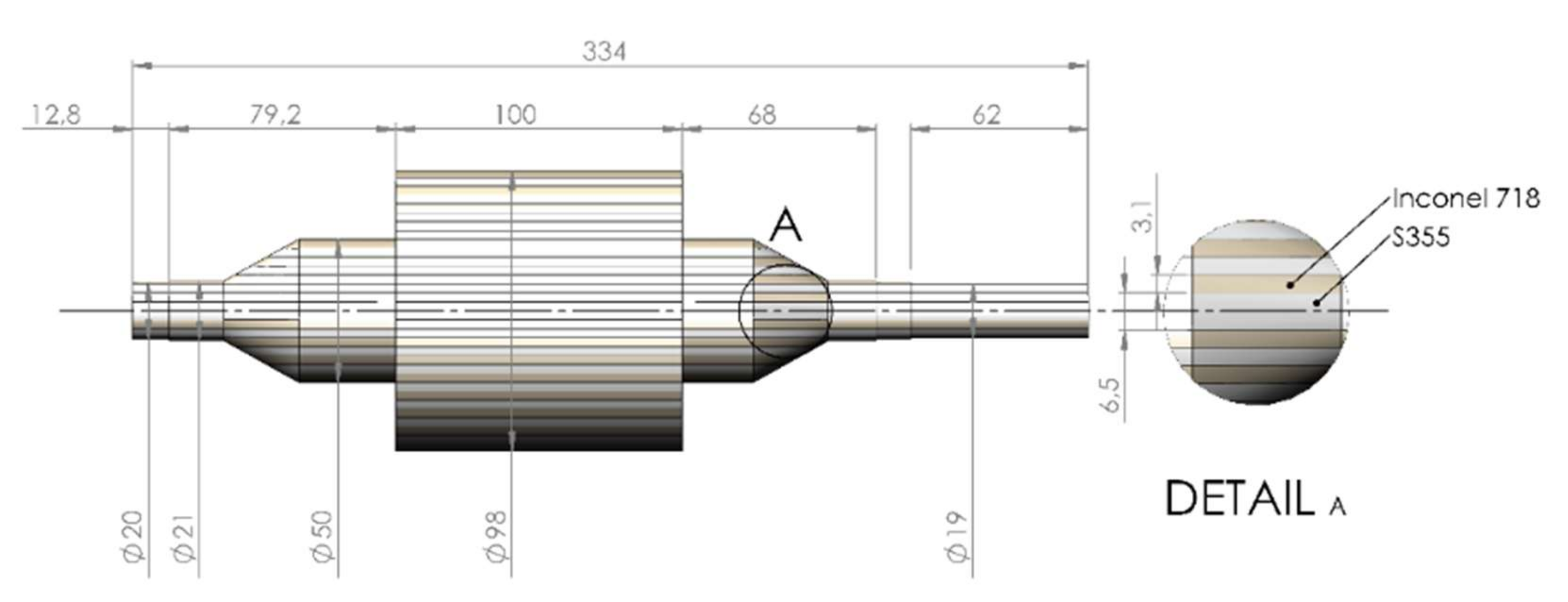

To overcome some of the limitations of conventional high-speed rotors noted above, an axially laminated anisotropic synchronous reluctance motor (ALA-SynRM) was presented in [

7]. The ALA-SynRM rotor is a solid rotor structure made from multiple alternating magnetic and non-magnetic metal sheets that provide the necessary flux paths for the electromagnetic field. A key benefit of the ALA-SynRM rotor is its simplicity. Unlike PMSM rotors, the ALA-SynRM rotor does not require rare earth permanent magnets. Moreover, there is no need for the complicated squirrel-cage structure found in IM rotors, which can limit the maximum rotational speed of the rotor by decreasing the rigidity of the rotor [

10].

Typical methods for bonding dissimilar metals sheets includes brazing and high and low temperature solid-state welding processes, such as explosion welding and hot isostatic pressing (HIP), all of which can be used to manufacture ALA-SynRM rotors [

11]. The brazing process is described as a process where the parent materials to be bonded are heated to a temperature that is lower than the melting temperature of the parent materials but higher than the melting temperature of the braze alloy [

12]. As the braze alloy melts in the joint, capillary forces and the wetting action cause the braze alloy to flow throughout the joint area and, on cooling, to create a permanent bond between the workpieces. In the explosion welding process, an explosive charge is used to accelerate the parts to be bonded to high speeds of up to several hundreds of meters per second. The parts collide with each other and solid bonding of the two metal pieces occurs at the point of impact [

13]. The HIP process is used as a solid-state diffusion welding process to bond dissimilar materials and to sinter powder metal components with fully isotropic material parameters [

14]. The joint is formed by deforming and diffusing the joint area using high temperature and pressure [

15].

Recently, the electromagnetic properties of ALA-SynRM rotors manufactured by mechanically bonding the laminated rotor structure have been studied in [

16,

17,

18] and all aforementioned researchers highlight similar or higher rotor efficiency compared to other rotor structures. These studies, however, consider only ALA-SynRM rotors manufactured by mechanically joining, e.g., with screws, the alternating magnetic and non-magnetic metallic sheets. Using external elements to construct the ALA-SynRM rotor can lead to a complicated construction process in terms of manufacturing and may compromise the structural integrity of the rotor in high-speed applications [

19]. The utilization of metal-to-metal bonding methods, i.e., brazing, explosion welding and hot isostatic pressing, to manufacture ALA-SynRM rotor structures has not been widely studied. While the feasibility of a brazed ALA-SynRM rotor was studied in [

20], it was primarily focused on describing the electromagnetic performance of the brazed ALA-SynRM rotor with little consideration given to joint strength and structure.

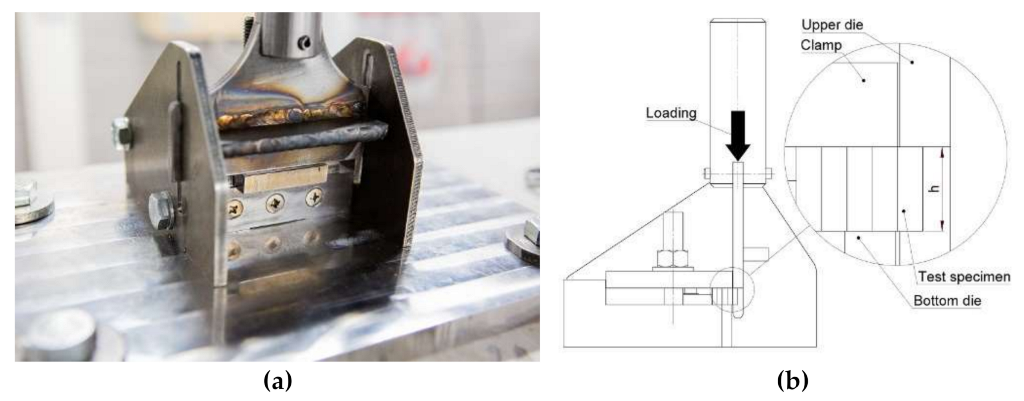

The detailed analysis of EM rotors structural performance and its applicability in high-speed operations in [

21] highlighted the importance of effective bonding of the dissimilar materials. Accordingly, this article investigates dissimilar metal joints suitable for use in construction of the rotor of an ALA-SynRM. The mechanical properties, such as shear strength, and microstructural aspects of the joints made from several different materials are studied. The paper begins by giving an overview of the structure of an ALA-SynRM rotor. The subsequent section introduces the experimental methods used to determine the shear strength of the joints followed by finite element analysis of the stresses that the rotor is subjected to during its operation. Finally, the shear strength measurements and the corresponding microstructural aspects are discussed. The paper concludes by reprising key findings from the work.

4. Discussion

None of the bonded test specimens A, B, and C achieved the same level of ultimate shear strength as the parent materials (

Table 5). For S1100MC, the theoretical shear strength considering the von Mises yield criterion is about 790 MPa in its as-delivery state. With the same considerations, the shear strengths of Inconel

® 600 and Inconel

® 718 are about 400 MPa and 510 MPa, respectively. Therefore, the shear strength of the joints was lower than that of the parent materials, i.e., the measured shear strength of S355MCD (

Table 5) and the theoretical shear strength of other parent materials in their delivery state. Moreover, it is noteworthy that the ultimate shear strength of the joint in S1100-IN718 (test specimen B) and S355-IN718 (test specimen C) is only 30 MPa higher in test specimen B although the strength of the parent material S1100 is much higher in the delivery state as compared to the S355 used in test specimen C.

In a study focused on describing the optimal vacuum brazing temperature of Inconel

® 600 alloy when using AgCuTi braze alloy [

25], it was stated that the shear strength reached the highest value of 223.32 MPa at a brazing temperature of 865 °C if Inconel

® 600 is bonded by vacuum brazing. The study also drew attention to the profound effect of the process parameters, mainly brazing temperature, on the strength of the joint. It is noteworthy that the shear strength of 230.1 MPa of the vacuum brazed S355-IN600 joint shows that the shear strength of IN600 is not affected significantly by joining with S355 steel, although the braze alloy compositions and brazing process variables in the present study and in [

25] are different. In [

23], the ultimate tensile strength for a vacuum brazed S355J0-Inconel

® 600 joint was found to be 283 MPa. Vacuum brazing Inconel

® 718 was studied in [

33] by examining γ-TiAl alloy/Inconel

® 718 vacuum brazed joints. In the work, it is claimed that vacuum brazing IN718 is possible with a suitable braze alloy. The braze alloy used contained silver, copper, indium, and titanium, and the average shear strength achieved in the study was 228 ± 83 MPa at a brazing temperature of 730 °C.

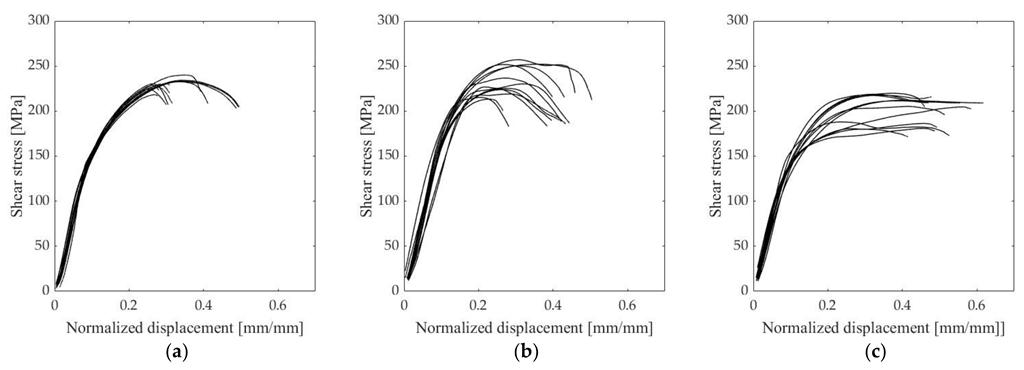

The shear stress-normalized displacement curves (

Figure 5) showed that there is some variation in the ductility of the joint since test specimen C shows different behavior compared to test specimens A and B. The behavior of test specimen C changes from linear elastic behavior to plastic region at lower shear stress. Overall, the ductility of test specimen C is higher than the ductility of test specimens A and B, as rupture occurred at a higher plastic strain. However, the ultimate shear strength of test specimen C is lower compared to other test specimens. These findings need thus to be interpreted with caution since this behavior could not be verified by actual measurement of the yield point with the test setup used in this study. The failure of the specimens observed in

Figure 5 can be further confirmed by the study of the fracture surfaces (

Appendix B). By observing the fractured specimens, it can be stated that test specimen A has failed by brittle fracture which is indicated by the very flat fracture surface. Test specimen B has failed by mixed fracture mode, which is noticeable by mildly slanted edges and partly flat fracture surface in the center of the specimen. Observing fracture surface of test specimen C, it can be stated that the failure mode is ductile failure due to the highly slanted edges of the fractured specimen.

The FE analysis described in

Section 3 indicates a maximum permissible shear stress not to be greater than 37 MPa using the initial S355MC-Inconel

® 718 material pair in the studied ALA-SynRM rotor structure at the nominal rotational speed and at operational temperature. Other material pair with S1100 and Inconel

® 600 (material pairs A and B) yields greater shear stresses, although no greater than 60 MPa. It is noticeable in

Table 7 that the location of maximum stresses changes between the magnetic center laminate layer and non-magnetic laminate layer with different material pairs, as illustrated for S355MC-Inconel

® 718 pair in

Figure 11. Magnetic steels S355 and S1100 have very similar material properties, as indicated in

Table 4. The similar stress distributions in the laminate layers with material pairs B and C can be explained by the presence of Inconel

® 718, as indicated in

Table 7. In all material pairs, the material with a lower coefficient of thermal expansion is under the greatest tensile stress. Since the relative change in the density is smaller than the relative change in the coefficient of thermal expansion, it can be concluded that the main contribution to the simulated stresses is due to thermal strain. The shear strength values from the experimental tests support vacuum brazing and hot isostatic pressing methods as suitable bonding processes for ALA-SynRM rotors since both methods can achieve higher shear stress strength than the value predicted by FE analysis.

The microstructure and composition of the S355MC-IN600 vacuum brazed joint shows little or no diffusion of the main elements of the respective parent materials to their counterparts across the joint interface (

Figure 8a,c). Additionally, a distinctive copper layer is present because of the copper braze alloy (

Figure 8b). Manganese (

Figure 8e) and silicon (

Figure 8f) show good diffusion to the copper braze alloy. In addition, nickel shows some diffusion to the copper braze alloy (

Figure 8c) whereas chromium (

Figure 8d) and iron (

Figure 8a) have slightly less diffusion to the copper braze alloy. A thin line of a nickel (

Figure 8c) and chromium (

Figure 8d) enriched area has also formed near the joint face of the S355MC. Additionally, on the joint face of IN600, precipitates of Cr and Cu have formed as indicated by the strong presence of chromium and copper in the same location in which dark spots are visible in the micrograph (arrow in

Figure 8a). These Cr-Cu precipitates form alongside γ′ (Ni

3Al, Ni

3Ti) precipitates, whose presence is confirmed by the precipitate-like morphologies seen in the Ni-rich region (arrow in

Figure 8d).

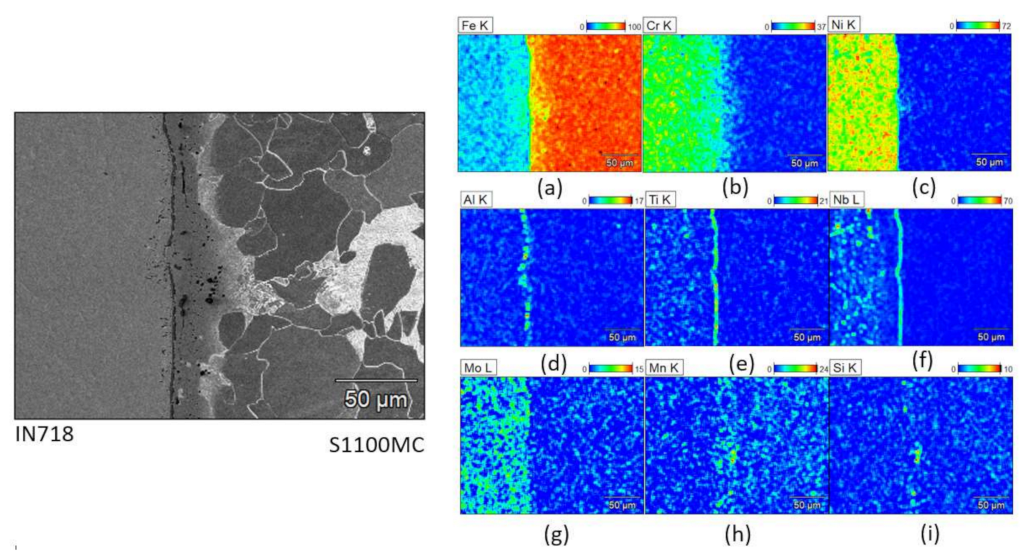

In the S1100MC-IN718 joint, significant levels of aluminum, titanium, and niobium (

Figure 9d–f), which are the main elements of minor phases, viz. γ′ (Ni

3Al, Ni

3Ti) and γ″ (Ni

3Nb) precipitates [

32], are seen along the joint face of IN718, indicating the formation of these precipitates. γ′ and γ″ precipitates form in the joint area almost along a straight line as seen in

Figure 9d–f. The dark precipitates in S1100MC near the joint could be MnS and SiC, based on the high intensity of Mn and Si visible in the respective composition plots (

Figure 9h,i).

In the S355MC-IN718 joint, the main elements of each parent material show very little diffusion in the joint area (

Figure 10a–c) and some aluminum, titanium, and niobium enriched areas are present in the form of γ′ and γ″ precipitates. Γ’ precipitates form along a straight line near the joint surface more prominently than the γ″ precipitates (

Figure 10d–f).

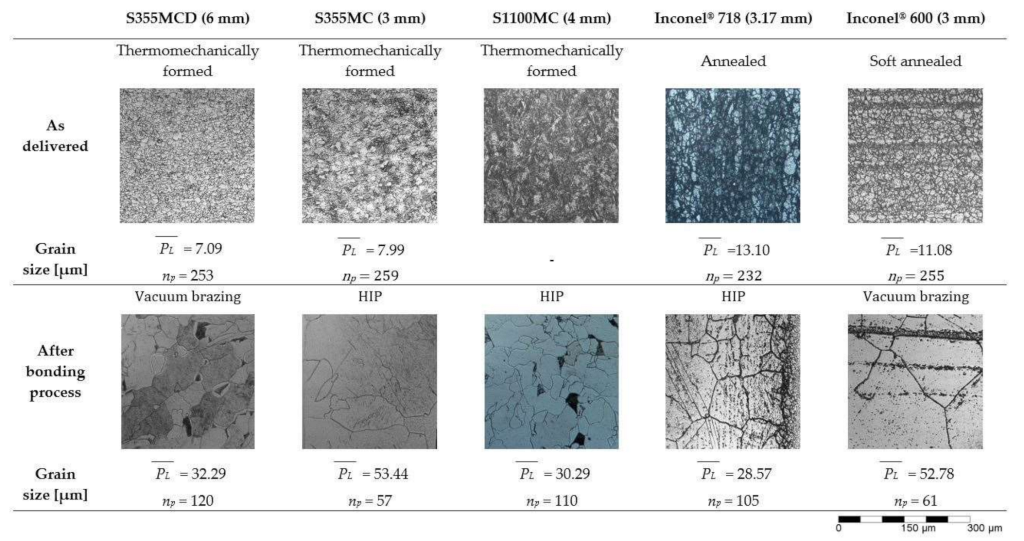

The results in this study show that the long high temperature exposure during bonding processes affects the microstructure of the materials in a significant manner. The long exposure to temperatures above the recrystallization temperatures has caused changes in the microstructure and mechanical properties. The structural steels (S355MC, S1100MC) had reduced ultimate strength, whereas the ultimate strength of the Inconel

® grades was higher than the values specified by the manufacturers in the delivery state (

Table 6).

All materials have exhibited grain growth due to the high temperature exposure. For example, for Inconel

® 600, grain growth begins at a temperature of 980 °C by coalescing carbides in the microstructure. Exposure for 1–2 h at temperatures of 1090–1150 °C will completely dissolve carbides and result in an increased grain size [

28].

As the HIP process is carried out at 1150 °C for 5 h (

Table 2), high strength phases such as martensite and bainite revert to austenite, which then transforms to ferrite and pearlite during the slow cooling of the joint. Moreover, at such high temperatures, significant grain growth occurs. The sharp drop in hardness of S1100MC after the joining process (

Figure 6b) is attributed to the large austenite grain sizes and change in phase composition, i.e., from high strength and hard phases such as martensite and bainite to a relatively soft coarse-grained ferrite–pearlite mixture. Despite the loss of the lath martensitic structure due to the long-time high temperature exposure during HIP, the shear strength of the S1100MC-IN718 joint is slightly higher than the shear strength of the S355MC-IN718 joint and almost the same as the strength of the S355MC-IN600 joint.

Although the HIP process temperatures for S1100-IN718 and S355-IN718 joints are the same (1150 °C), the dwell time of the S1100-IN718 joint is longer compared to the other joint (

Table 2). This longer process time used for the S1100-IN718 joint enables the diffusion of alloying elements, such as Al, Nb, Ti, much closer towards the joint region. This gives rise to the formation and concentration of γ′ and γ″ precipitates very near to the joint region rather than in regions that are slightly farther away from the joint (

Figure 9). Consequently, this leads to depletion of alloying elements (Ti, Al, Nb) and a lack of evenly distributed precipitates in the regions that are slightly farther away from the joint, thereby giving rise to the observed sudden variations in the hardness of IN718 near the joint (

Figure 6b). In the S355-IN718 joint, due to a relatively lower dwell time, the alloying elements, such as Al, Ti, Nb are more evenly distributed in IN718, consequently leading to even distribution of the precipitates (

Figure 10d–f). Therefore, no sudden drop in hardness near the joint is observed (

Figure 6c).

5. Conclusions

In this work, dissimilar metal joints which can be used to bond alternating magnetic and non-magnetic metal sheets to manufacture a high-speed ALA-SynRM rotor were studied. The material pairs and bonding types selected for study were vacuum-brazed S355MCD-Inconel® 600 and hot isostatically pressed S1100MC-Inconel® 718, and S355MC-Inconel® 718. Shear stress tests were performed to determine the shear strength of the joints. Additionally, finite element analysis (FEA) of the ALA-SynRM rotor was performed to predict the required strength of the joints at the nominal rotation speed of the proposed rotor geometry. FEA showed that the material parameters (density, elastic modulus, and thermal expansion ratio) affect the stresses that the rotor experiences during operation. Material pair S355-IN718 generated the lowest stresses in this study. FEA showed that the joints should have a shear strength of at least 60 MPa, 60 MPa, and 37 MPa for S355-IN600, S1100-IN718, and S355-IN718, respectively. FEA also showed that the parent materials should have a minimum yield stress of at least 137 MPa, 117 MPa, and 77 MPa in S355-IN600, S1100-IN718, and S355-IN718, respectively.

In the experimental tests, the hot isostatic pressed S1100MC-IN718 joint achieved the highest ultimate shear strength (233.3 MPa) followed by the vacuum-brazed S355MCD-IN600 joint (230.1 MPa) and the HIP S355-IN718 (203.5 MPa) joint. It is noteworthy that the strength of ultra-high strength structural steels, like S1100MC, cannot be utilized when using bonding processes that require long exposure to high temperature as the heat input affects the microstructure of the parent material. However, the loss in strength and hardness of S1100MC after bonding does not seem to affect the overall ultimate shear strength of the S1100MC-IN718 joint compared to that of the S355MCD-IN600 joint. In conclusion, all test specimens of the study meet the requirements set by the operation conditions and geometry of the studied ALA-SynRM rotor. Therefore, it can be concluded that vacuum brazing and hot isostatic pressing can be considered viable bonding methods to fabricate high-speed ALA-SynRM rotors.