Tribological Properties of Ti-TiC Composite Coatings on Titanium Alloys

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Treatment

2.2. Composition and Structural Analysis

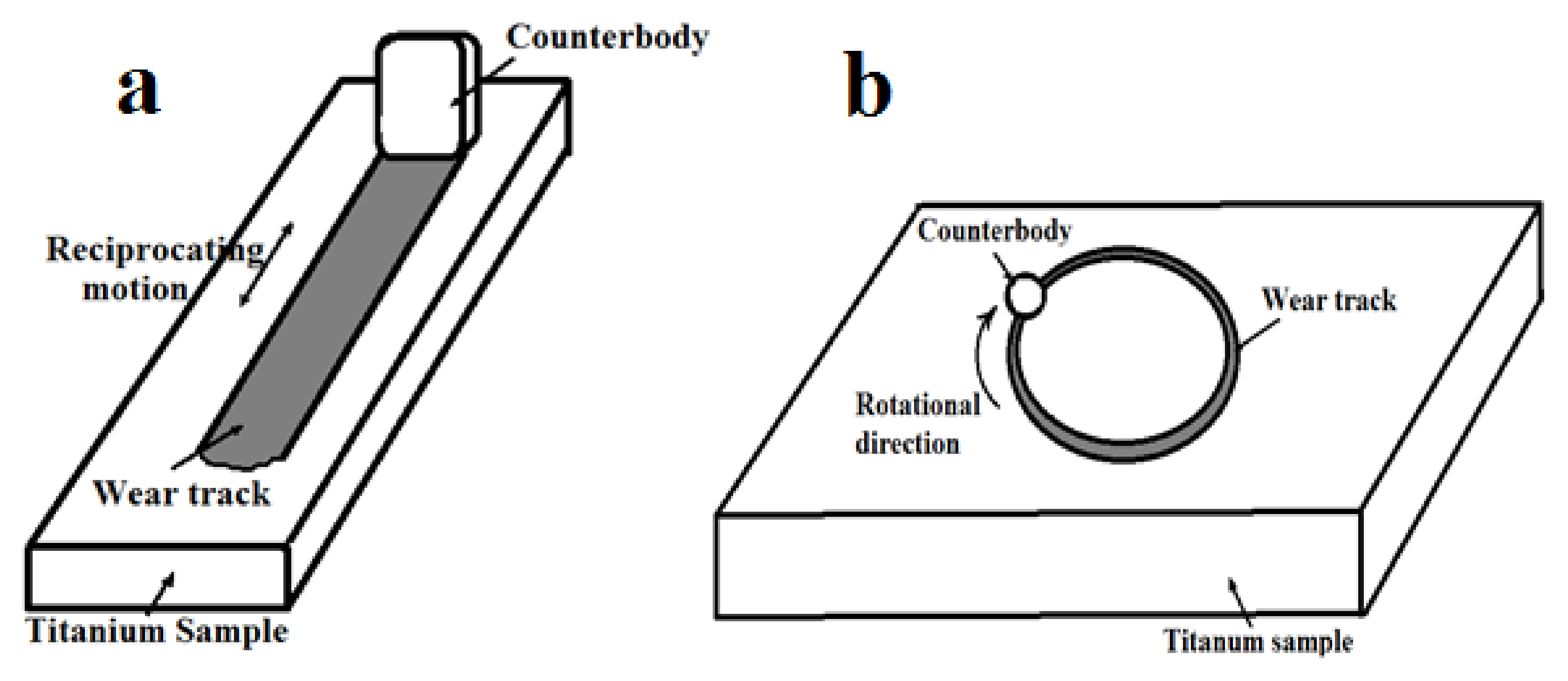

2.3. Mechanical and Tribological Evaluation

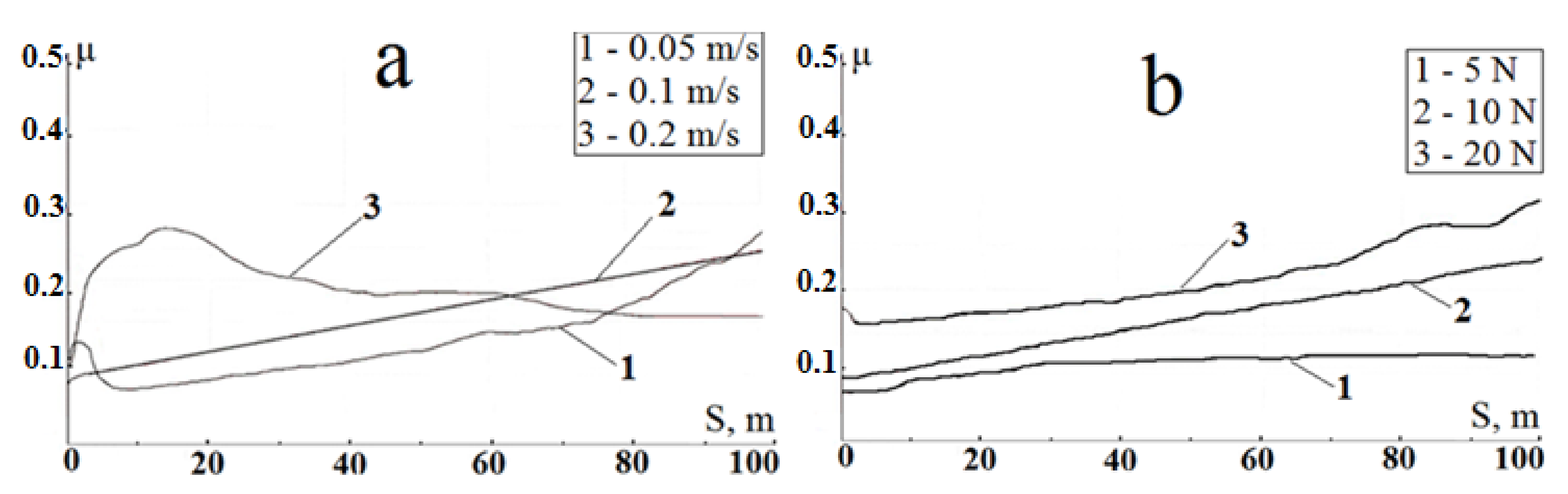

- (1)

- At a constant load of 10 N and variable sliding velocities—0.05, 0.1, and 0.2 m/s;

- (2)

- At a constant sliding velocity of 0.1 m/s and variable loads—5, 10, and 20 N. Sliding distance—100 m. The friction was dry in air. The disc-shaped samples were used.

3. Results and Discussion

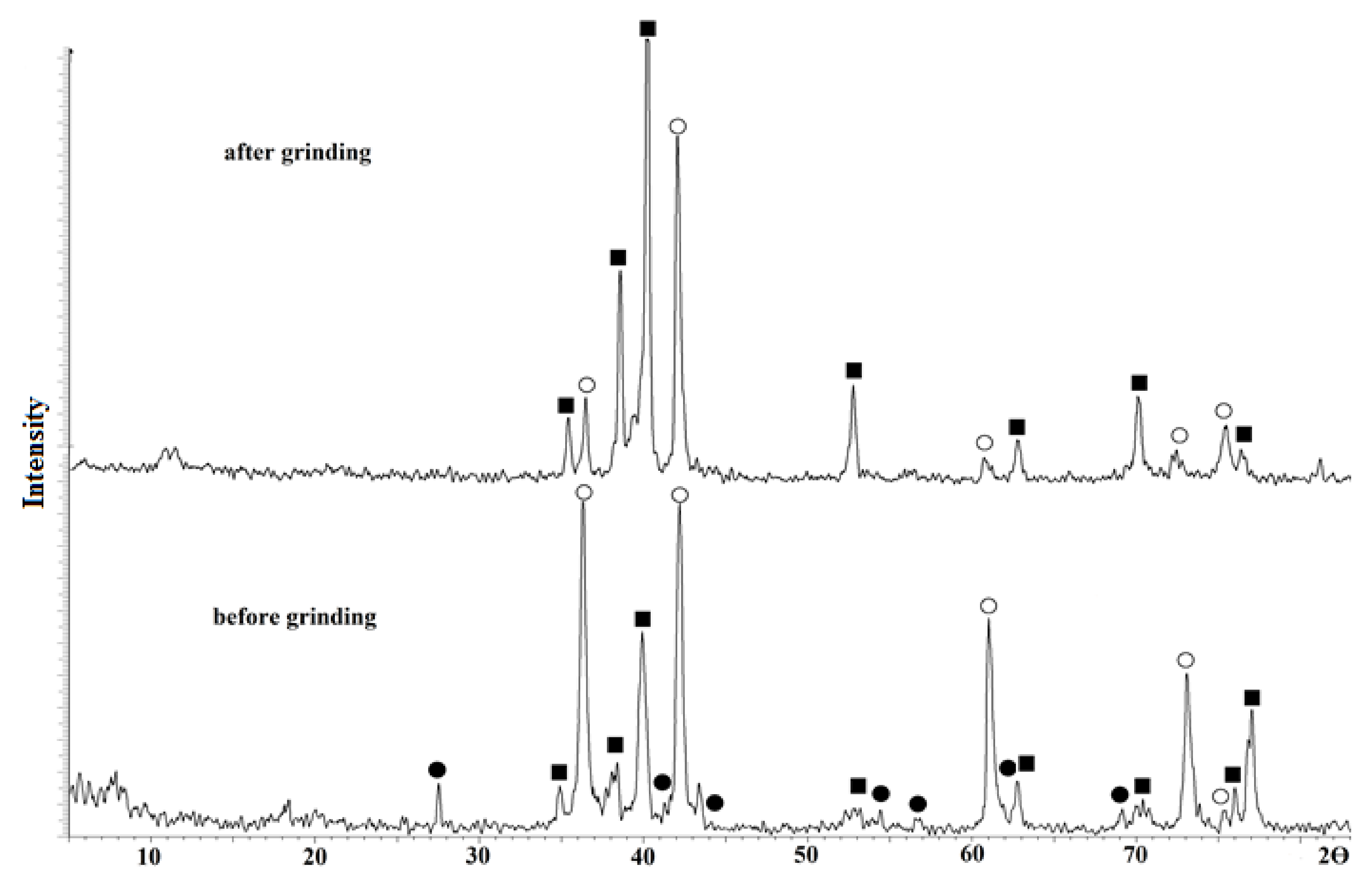

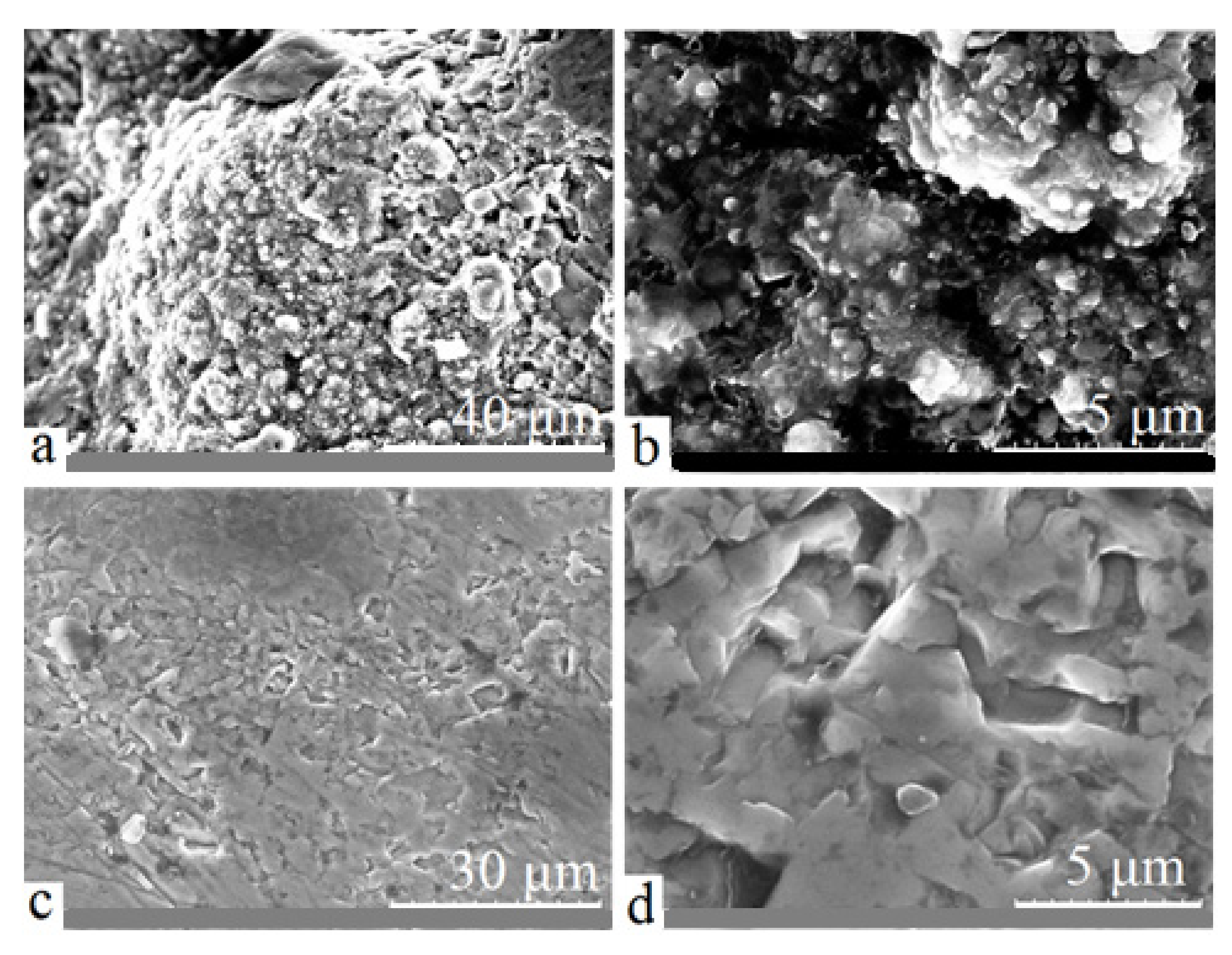

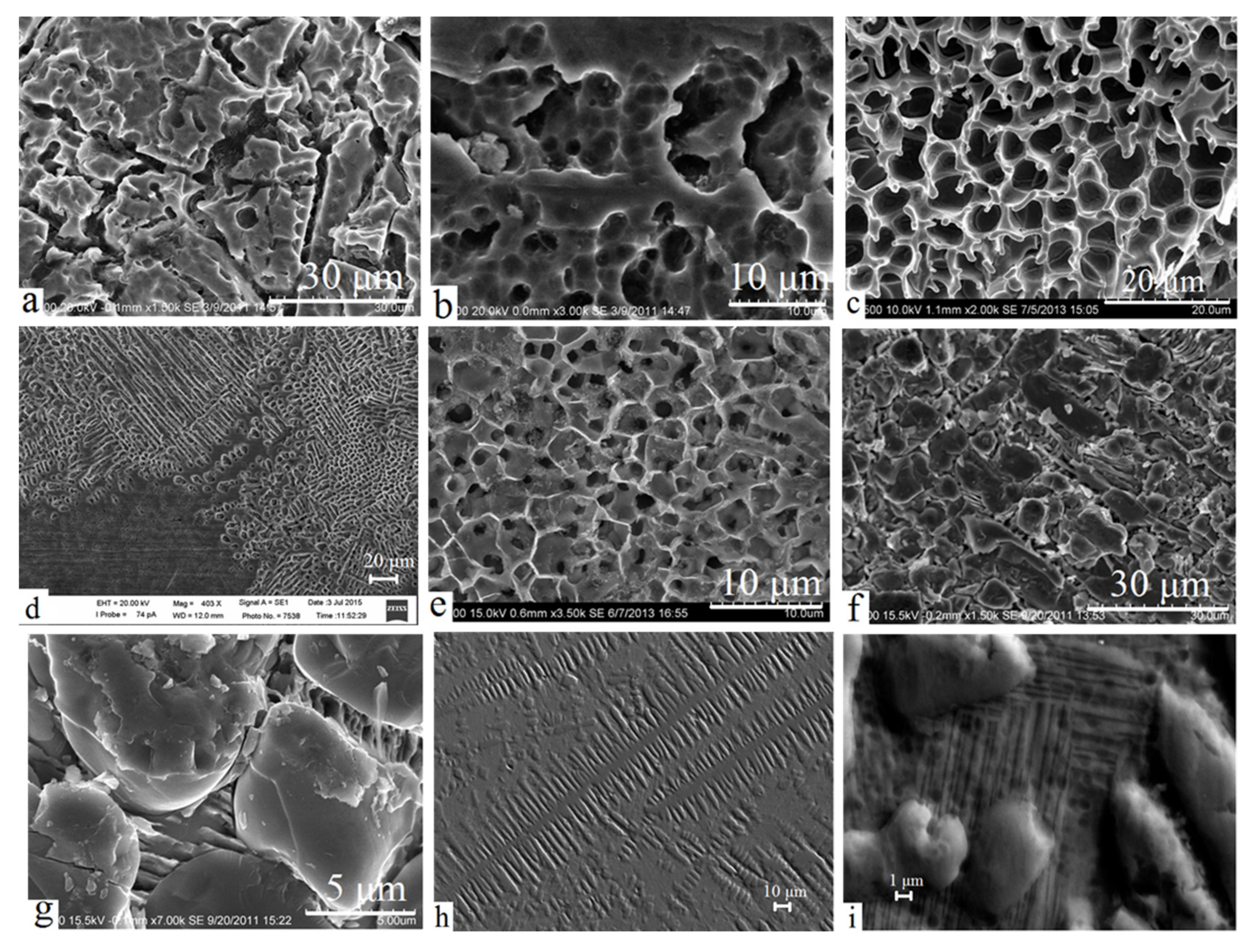

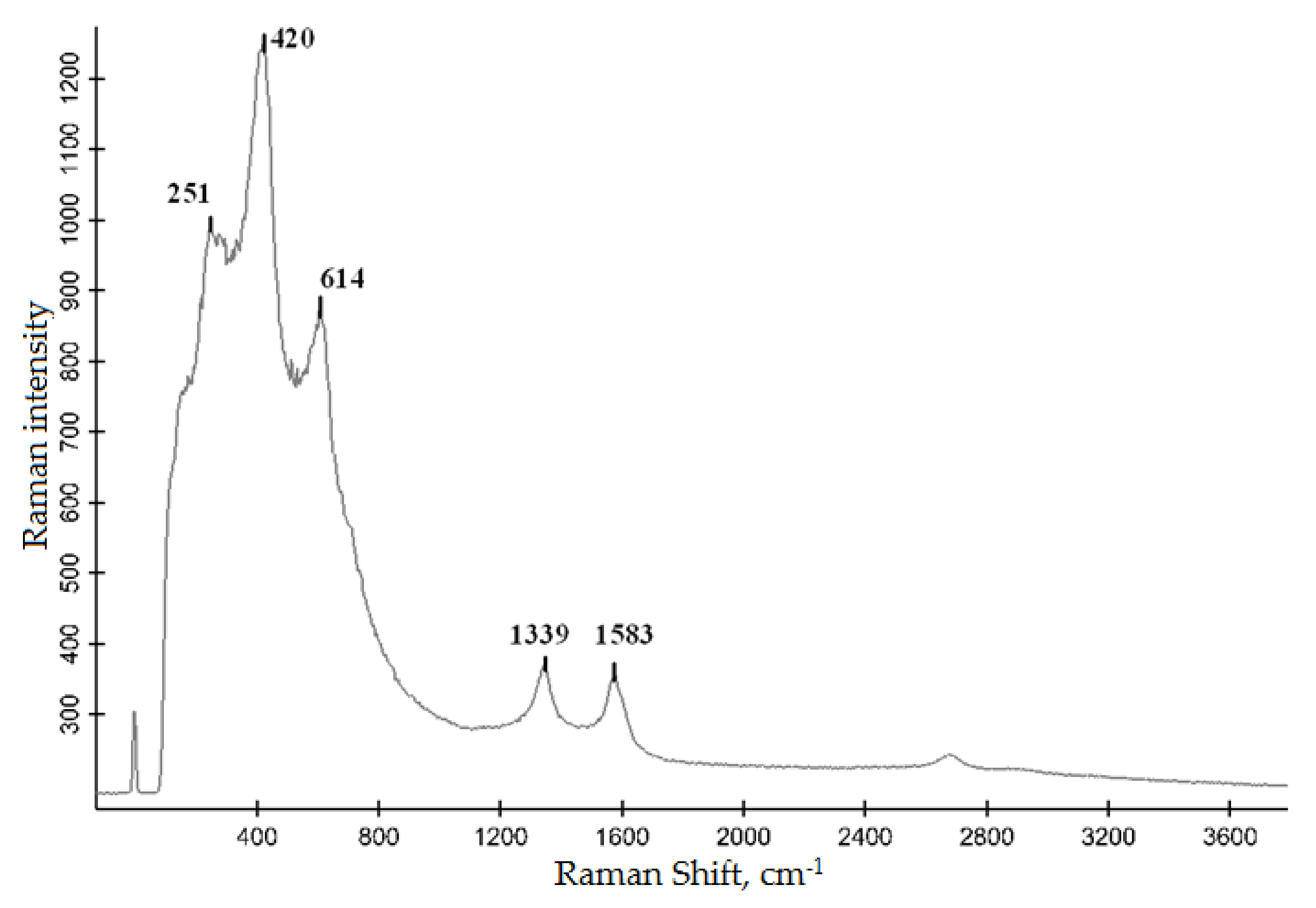

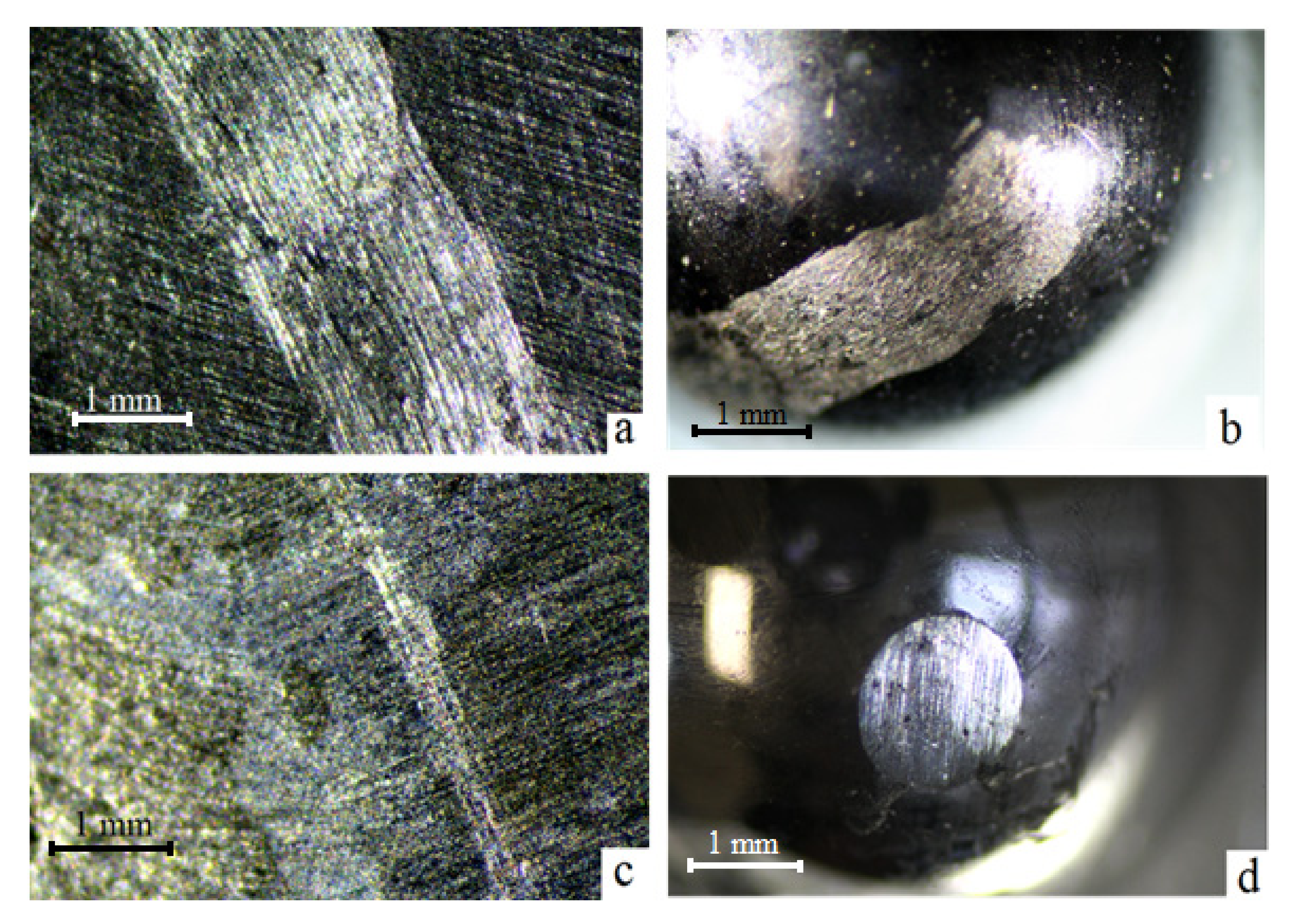

3.1. Composition and Structure

3.2. Micro-Hardness

3.3. Tribological Performance

4. Conclusions

- In the process of electroarc discharge treatment of titanium alloys in an aqueous electrolyte using a graphite anode, the titanium-based composite microstructure with TiC grains without oxygen is formed in the alloy surface layer.

- When moving from the central treatment zone to the periphery, the size and morphology of carbide grains changes from granular (1–10 microns in size) to dendritic (10–150 microns in size). There is free carbon in the amorphous state in the surface layer.

- The microhardness of the formed composite Ti-TiC-based structure varies from 7.6 to 29.5 GPa; the wear resistance of titanium samples after treatment increases by about 40 times; the friction coefficient of the composite Ti-TiC-layer paired with the steel counterbody gradually increases from 0.08 (min) to 0.3 (max) because of counterbody wear and an increase in the contact area.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Gorynin, I.V.; Ushkov, S.S.; Khatuntsev, A.N.; Loshakova, N.I. Titanium Alloys for Marine Machinery; Politekhnika: St.-Petersburg, Russia, 2007. (In Russian) [Google Scholar]

- Buravlev, I.; Shichalin, O.; Papynov, E.; Golub, A.; Gridasova, E.; Buravleva, A.; Yagofarov, V.; Dvornik, M.; Fedorets, A.; Reva, V.; et al. WC-5TiC-10Co hard metal alloy fabrication via mechanochemical and SPS techniques. Int. J. Refract. Met. Hard Mater. 2020, 94, 105385. [Google Scholar] [CrossRef]

- Shichalin, O.; Buravlev, I.; Portnyagin, A.; Dvornik, M.; Mikhailenko, E.; Golub, A.; Zakharenko, A.; Sukhorada, A.; Talskikh, K.; Buravleva, A.; et al. SPS hard metal alloy WC-8Ni-8Fe fabrication based on mechanochemical synthetic tungsten carbide powder. J. Alloys Compd. 2020, 816, 152547. [Google Scholar] [CrossRef]

- Buravleva, A.A.; Fedorets, A.N.; Vornovskikh, A.A.; Ognev, A.V.; Nepomnyushchaya, V.A.; Sakhnevich, V.N.; Lembikov, A.O.; Kornakova, Z.E.; Kapustina, O.V.; Tarabanova, A.E.; et al. Spark Plasma Sintering of WC-Based 10wt%Co Hard Alloy: A Study of Sintering Kinetics and Solid-Phase Processes. Materials 2022, 15, 1091. [Google Scholar] [CrossRef] [PubMed]

- Zhevtun, I.; Gordienko, P.; Kulchin, Y.; Nikitin, A.; Pivovarov, D.; Yarusova, S.; Golub, A.; Nikiforov, P.; Timchenko, V. Influence of Titanium Surface Porosity on Adhesive Strength of Coatings Containing Calcium Silicate. Materials 2020, 13, 4493. [Google Scholar] [CrossRef] [PubMed]

- Shichalin, O.; Buravlev, I.; Papynov, E.; Golub, A.; Belov, A.; Buravleva, A.; Sakhnevich, V.; Dvornik, M.; Vlasova, N.; Gerasimenko, A.; et al. Comparative study of WC-based hard alloys fabrication via spark plasma sintering using Co, Fe, Ni, Cr, and Ti binders. Int. J. Refract. Met. Hard Mater. 2022, 102, 105725. [Google Scholar] [CrossRef]

- Shichalin, O.O.; Sakhnevich, V.N.; Buravlev, I.Y.; Lembikov, A.O.; Buravleva, A.A.; Azon, S.A.; Yarusova, S.B.; Danilova, S.N.; Fedorets, A.N.; Belov, A.A.; et al. Synthesis of Ti-Cu Multiphase Alloy by Spark Plasma Sintering: Mechanical and Corrosion Properties. Metals 2022, 12, 1089. [Google Scholar] [CrossRef]

- Zwicker, U. Titan und Titanlegierungen; Springer: Berlin/Heidelberg, Germany, 1974. [Google Scholar] [CrossRef]

- Wooster, W.A.; Macdonald, G.L. Smears of Titanium Metal. Nature 1947, 160, 260. [Google Scholar] [CrossRef]

- Farokhzadeh, K.; Edrisy, A. Transition between mild and severe wear in titanium alloys. Tribol. Int. 2016, 94, 98–111. [Google Scholar] [CrossRef]

- Cheng, J.; Li, F.; Qiao, Z.; Zhu, S.; Yang, J.; Liu, W. The role of oxidation and counterface in the high temperature tribological properties of TiAl intermetallics. Mater. Des. 2015, 84, 245–253. [Google Scholar] [CrossRef]

- Long, M.; Rack, H. Friction and surface behavior of selected titanium alloys during reciprocating-sliding motion. Wear 2001, 249, 157–167. [Google Scholar] [CrossRef]

- Mao, Y.; Wang, L.; Chen, K.; Wang, S.; Cui, X. Tribo-layer and its role in dry sliding wear of Ti–6Al–4V alloy. Wear 2013, 297, 1032–1039. [Google Scholar] [CrossRef]

- Rabinovitz, E. Frictional Properties of Titanium and Its Alloys. Met. Prog. 1954, 65, 107–110. [Google Scholar]

- Yang, Y.; Zhang, C.; Wang, Y.; Dai, Y.; Luo, J. Friction and wear performance of titanium alloy against tungsten carbide lubricated with phosphate ester. Tribol. Int. 2016, 95, 27–34. [Google Scholar] [CrossRef]

- Budinski, K.G. Tribological properties of titanium alloys. Wear 1991, 151, 203–217. [Google Scholar] [CrossRef]

- Umeda, J.; Fugetsu, B.; Nishida, E.; Miyaji, H.; Kondoh, K. Friction behavior of network-structured CNT coating on pure titanium plate. Appl. Surf. Sci. 2015, 357, 721–727. [Google Scholar] [CrossRef]

- Qin, Y.; Xiong, D.; Li, J. Tribological properties of laser surface textured and plasma electrolytic oxidation duplex-treated Ti6Al4V alloy deposited with MoS2 film. Surf. Coat. Technol. 2015, 269, 266–272. [Google Scholar] [CrossRef]

- Wang, S.; Ma, Z.; Liao, Z.; Song, J.; Yang, K.; Liu, W. Study on improved tribological properties by alloying copper to CP-Ti and Ti–6Al–4V alloy. Mater. Sci. Eng. C 2015, 57, 123–132. [Google Scholar] [CrossRef]

- Kaptyug, I.S.; Syshchikov, V.I. Effect of alloy content on fractional properties of titanium. Met. Sci. Heat Treat. Met. 1959, 4, 27–32. [Google Scholar] [CrossRef]

- Aniołek, K.; Kupka, M.; Barylski, A.; Dercz, G. Mechanical and tribological properties of oxide layers obtained on titanium in the thermal oxidation process. Appl. Surf. Sci. 2015, 357, 1419–1426. [Google Scholar] [CrossRef]

- Kümmel, D.; Schneider, J.; Gumbsch, P. Influence of Interstitial Oxygen on the Tribology of Ti6Al4V. Tribol. Lett. 2020, 68, 96. [Google Scholar] [CrossRef]

- Lai, F.; Wu, T.; Wu, J. Surface modification of Ti-6Al-4V alloy by salt cyaniding and nitriding. Surf. Coat. Technol. 1993, 58, 79–81. [Google Scholar] [CrossRef]

- Kumar, S.A.; Raman, S.G.S.; Narayanan, T.S.; Gnanamoorthy, R. Influence of counterbody material on fretting wear behaviour of surface mechanical attrition treated Ti–6Al–4V. Tribol. Int. 2013, 57, 107–114. [Google Scholar] [CrossRef]

- Hong, X.; Tan, Y.; Zhou, C.; Xu, T.; Zhang, Z. Microstructure and tribological properties of Zr-based amorphous-nanocrystalline coatings deposited on the surface of titanium alloys by Electrospark Deposition. Appl. Surf. Sci. 2015, 356, 1244–1251. [Google Scholar] [CrossRef]

- Yerokhin, A.; Nie, X.; Leyland, A.; Matthews, A. Characterisation of oxide films produced by plasma electrolytic oxidation of a Ti–6Al–4V alloy. Surf. Coat. Technol. 2000, 130, 195–206. [Google Scholar] [CrossRef]

- Ayers, J. Wear behavior of carbide-injected titanium and aluminum alloys. Wear 1984, 97, 249–266. [Google Scholar] [CrossRef]

- Zhao, Y.; Lu, M.; Fan, Z.; Huang, S.; Huang, H. Laser deposition of wear-resistant titanium oxynitride/titanium composite coatings on Ti-6Al-4V alloy. Appl. Surf. Sci. 2020, 531, 147212. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Steel, K.; Veidt, M.; Heitzmann, M.T. Wear behaviour of polymeric materials reinforced with man-made fibres: A comprehensive review about fibre volume fraction influence on wear performance. J. Reinf. Plast. Compos. 2021, 41, 215–241. [Google Scholar] [CrossRef]

- Zaghloul, M.M.Y.; Zaghloul, M.Y.M.; Zaghloul, M.M.Y. Experimental and modeling analysis of mechanical-electrical behaviors of polypropylene composites filled with graphite and MWCNT fillers. Polym. Test. 2017, 63, 467–474. [Google Scholar] [CrossRef]

- Gordienko, P.S.; Zhevtun, I.G.; Dostovalov, V.A.; Kuryavyi, V.G.; Barinov, N.N. Composition and structure of carbon-rich local sections formed on titanium alloys in electrolytes. Russ. Eng. Res. 2012, 32, 158–161. [Google Scholar] [CrossRef]

- Storms, E.K. The Refractory Carbides; Academic Press: New York, NY, USA, 1967. [Google Scholar]

- Zhevtun, I.G.; Gordienko, P.S.; Yarusova, S.B. Formation of Wear-Resistant Composite Coatings on Titanium Alloys during Electric Arc Treatment in Aqueous Electrolytes; RIOR: Moscow, Russia, 2018. [Google Scholar]

- Zhevtun, I.G.; Gordienko, P.S.; Kul’Chin, Y.N.; Subbotin, E.P.; Yarusova, S.B.; Golub, A.V. Effects of Doping of Composite Ti–TiC Coatings with Transition and Valve Metals on Their Structure and Mechanical Properties. Phys. Met. Met. 2019, 120, 25–31. [Google Scholar] [CrossRef]

- Kiparisov, S.S.; Levinskiy, Y.V.; Petrov, A.P. Titanium Carbide. Production, Properties and Applications; Metallurgia: Moscow, Russia, 1987. (In Russian) [Google Scholar]

- Lohse, B.H.; Calka, A.; Wexler, D. Raman spectroscopy as a tool to study TiC formation during controlled ball milling. J. Appl. Phys. 2005, 97, 114912. [Google Scholar] [CrossRef]

- Amer, M.; Barsoum, M.W.; El-Raghy, T.; Weiss, I.; Leclair, S.; Liptak, D. The Raman spectrum of Ti3SiC2. J. Appl. Phys. 1998, 84, 5817–5819. [Google Scholar] [CrossRef]

- Lubarskiy, I.M.; Palatnik L, S. Physics of Metal Friction; Metallurgia: Moscow, Russia, 1976. (In Russian) [Google Scholar]

- Semenov, A.P.; Posdnyakov, V.V. Methods and results of the study of friction and adhesive interactions at high temperatures in vacuum and in gaseous environments. In The Structure and Properties of Heat Resistant Metal Materials; Nauka: Moscow, Russia, 1967. (In Russian) [Google Scholar]

- Buckley, D.H. Influence of Various Physical Properties of Metals on Their Friction and Wear Behavior in Vacuum. Met. Eng. Q. 1967, 7, 44–53. [Google Scholar]

| No. | Before Grinding | After Grinding | ||||||

|---|---|---|---|---|---|---|---|---|

| Ti | C | O | Others | Ti | C | O | Others | |

| 1 | 30.07 | 32.76 | 37.16 | 0.01 | 63.77 | 35.54 | 0.69 | - |

| 2 | 29.87 | 27.65 | 42.46 | 0.02 | 65.25 | 34.75 | - | - |

| 3 | 38.03 | 39.63 | 22.34 | - | 64.08 | 35.92 | - | - |

| 4 | 27.15 | 4.69 | 68.15 | 0.01 | 66.11 | 32.59 | 1.3 | - |

| 5 | 23.69 | 19.59 | 56.72 | - | 61.44 | 37.34 | 1.22 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhevtun, I.G.; Gordienko, P.S.; Mashtalyar, D.V.; Kulchin, Y.N.; Yarusova, S.B.; Nepomnyushchaya, V.A.; Kornakova, Z.E.; Gribanova, S.S.; Gritsuk, D.V.; Nikitin, A.I. Tribological Properties of Ti-TiC Composite Coatings on Titanium Alloys. Materials 2022, 15, 8941. https://doi.org/10.3390/ma15248941

Zhevtun IG, Gordienko PS, Mashtalyar DV, Kulchin YN, Yarusova SB, Nepomnyushchaya VA, Kornakova ZE, Gribanova SS, Gritsuk DV, Nikitin AI. Tribological Properties of Ti-TiC Composite Coatings on Titanium Alloys. Materials. 2022; 15(24):8941. https://doi.org/10.3390/ma15248941

Chicago/Turabian StyleZhevtun, Ivan G., Pavel S. Gordienko, Dmitriy V. Mashtalyar, Yuriy N. Kulchin, Sofia B. Yarusova, Valeria A. Nepomnyushchaya, Zlata E. Kornakova, Sofia S. Gribanova, Danil V. Gritsuk, and Alexander I. Nikitin. 2022. "Tribological Properties of Ti-TiC Composite Coatings on Titanium Alloys" Materials 15, no. 24: 8941. https://doi.org/10.3390/ma15248941

APA StyleZhevtun, I. G., Gordienko, P. S., Mashtalyar, D. V., Kulchin, Y. N., Yarusova, S. B., Nepomnyushchaya, V. A., Kornakova, Z. E., Gribanova, S. S., Gritsuk, D. V., & Nikitin, A. I. (2022). Tribological Properties of Ti-TiC Composite Coatings on Titanium Alloys. Materials, 15(24), 8941. https://doi.org/10.3390/ma15248941