Effect of Annealing and Thickness of Co40Fe40Yb20 Thin Films on Various Physical Properties on a Glass Substrate

Abstract

1. Introduction

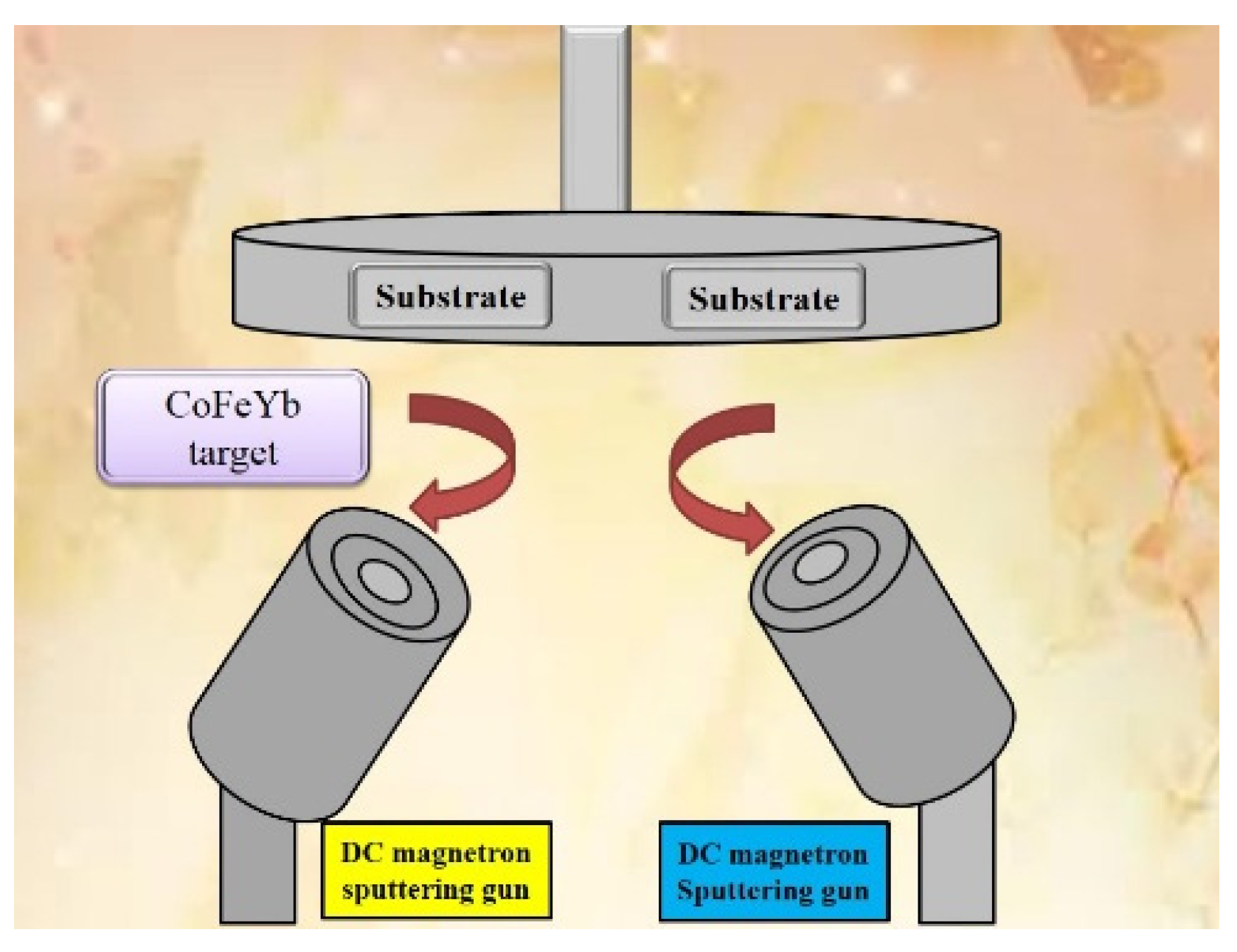

2. Materials and Methods

3. Results

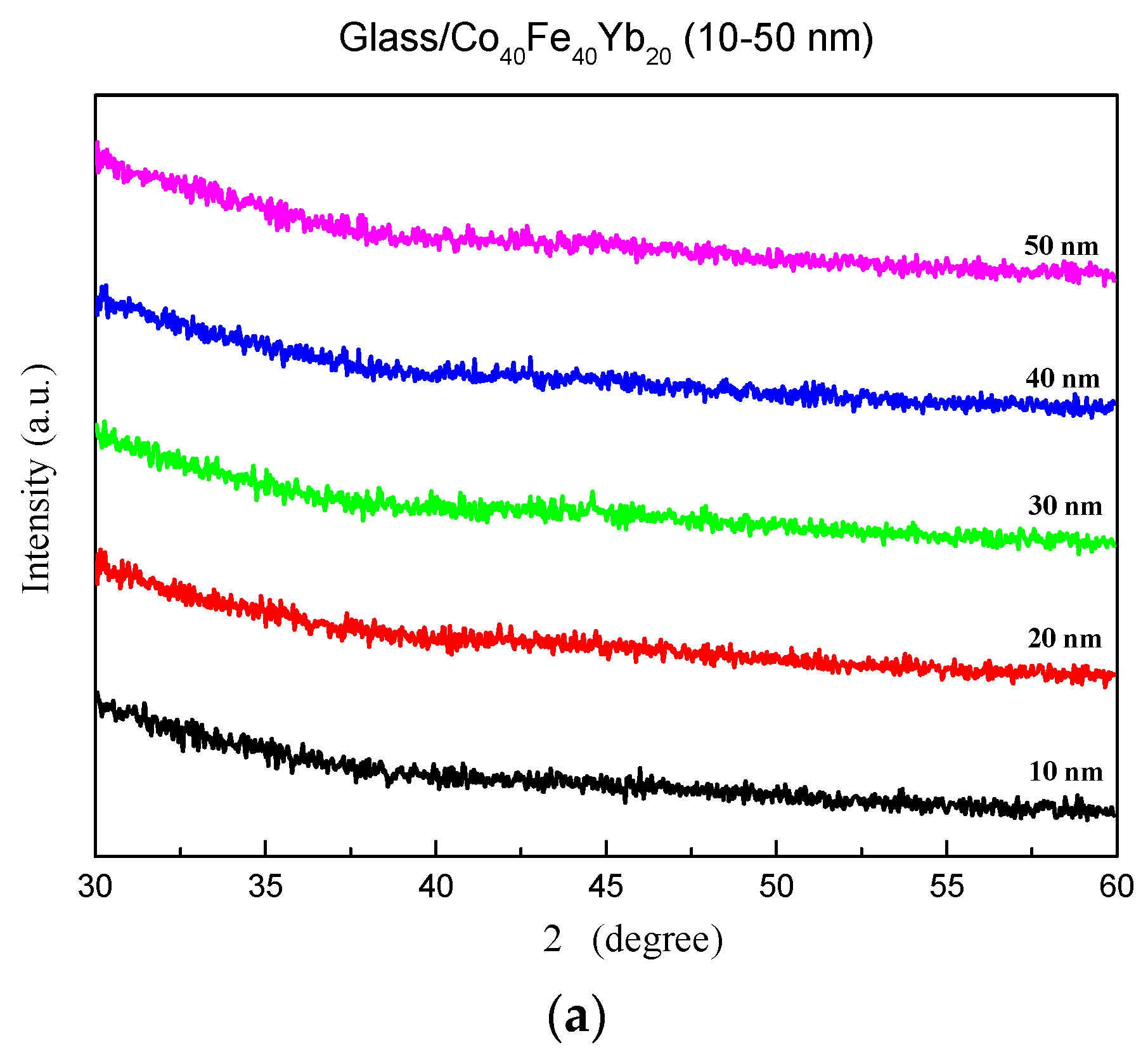

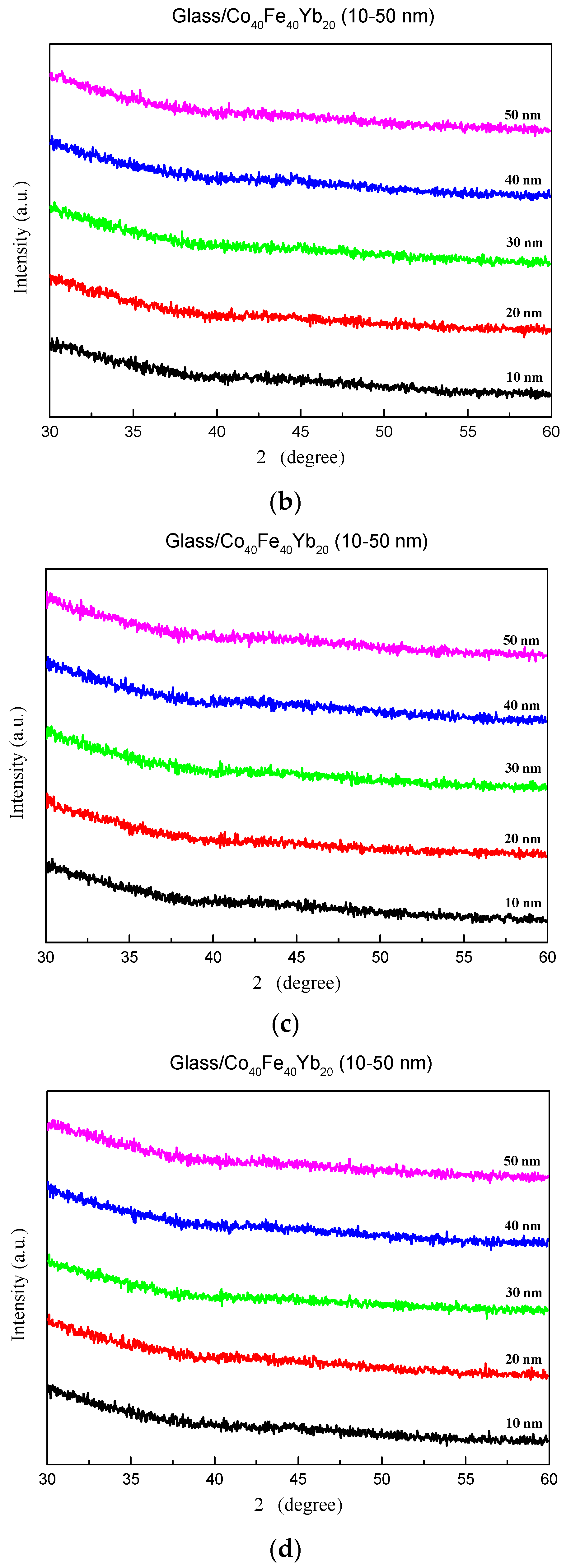

3.1. Structure

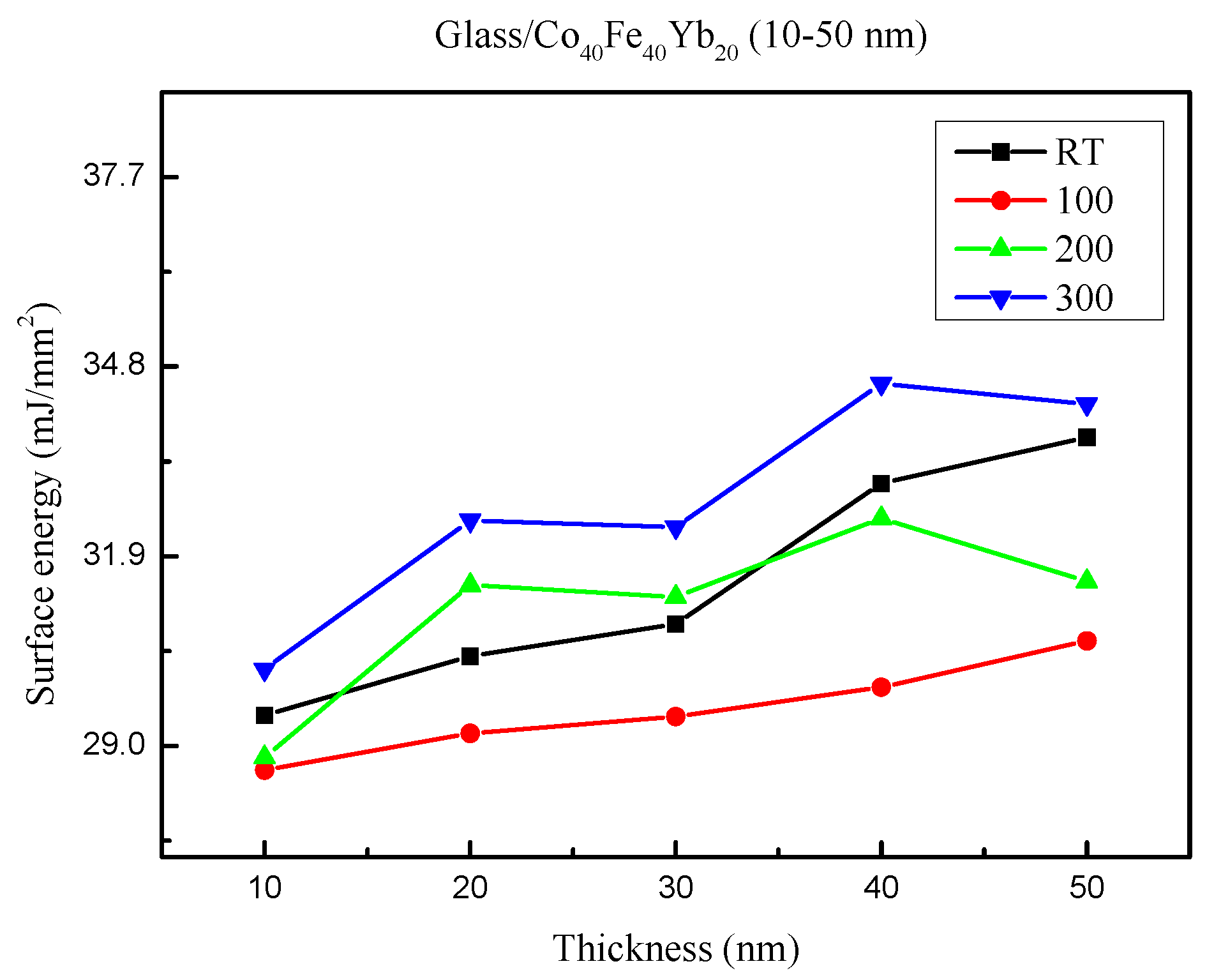

3.2. Analysis of Surface Energy and Adhesion

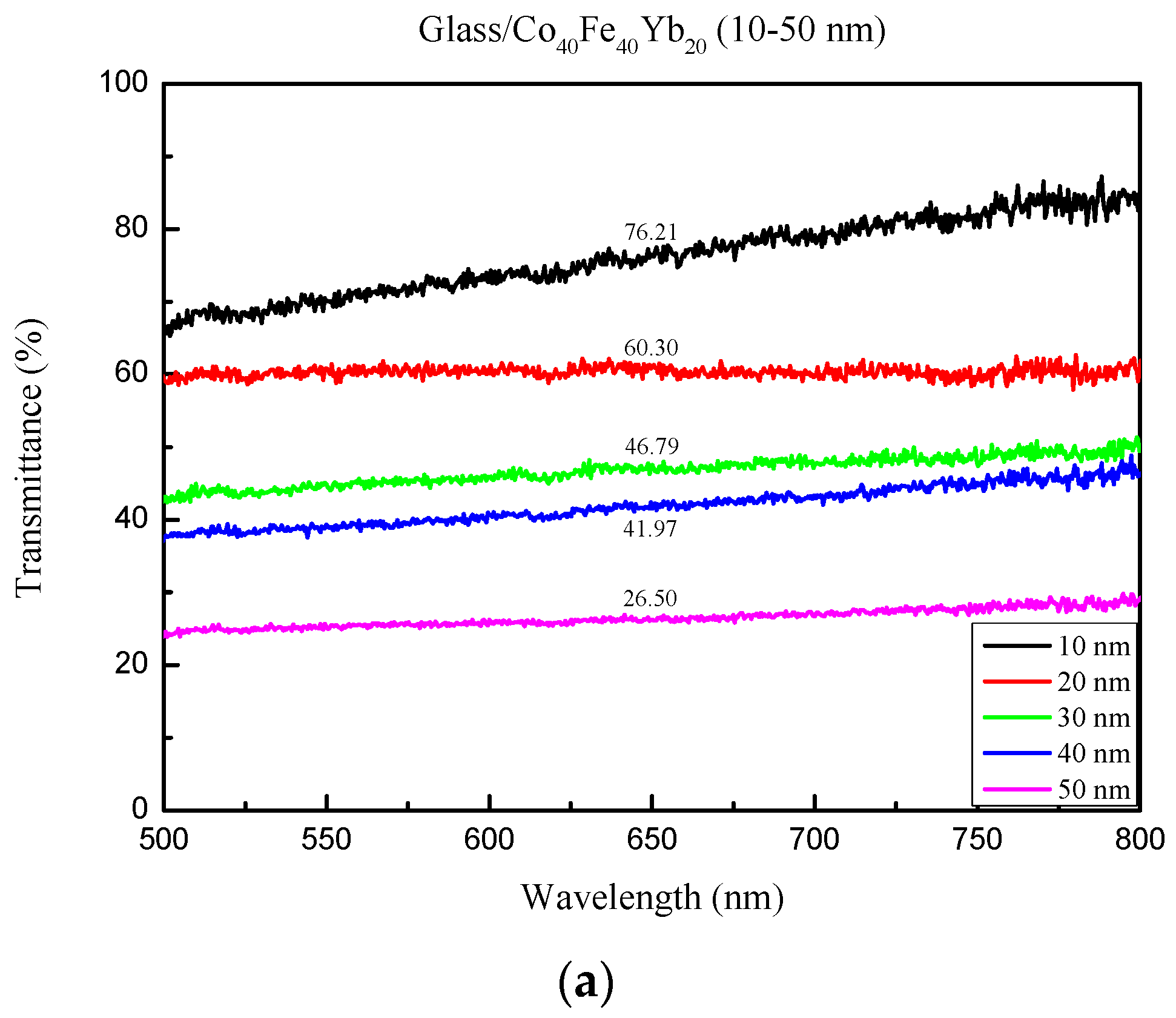

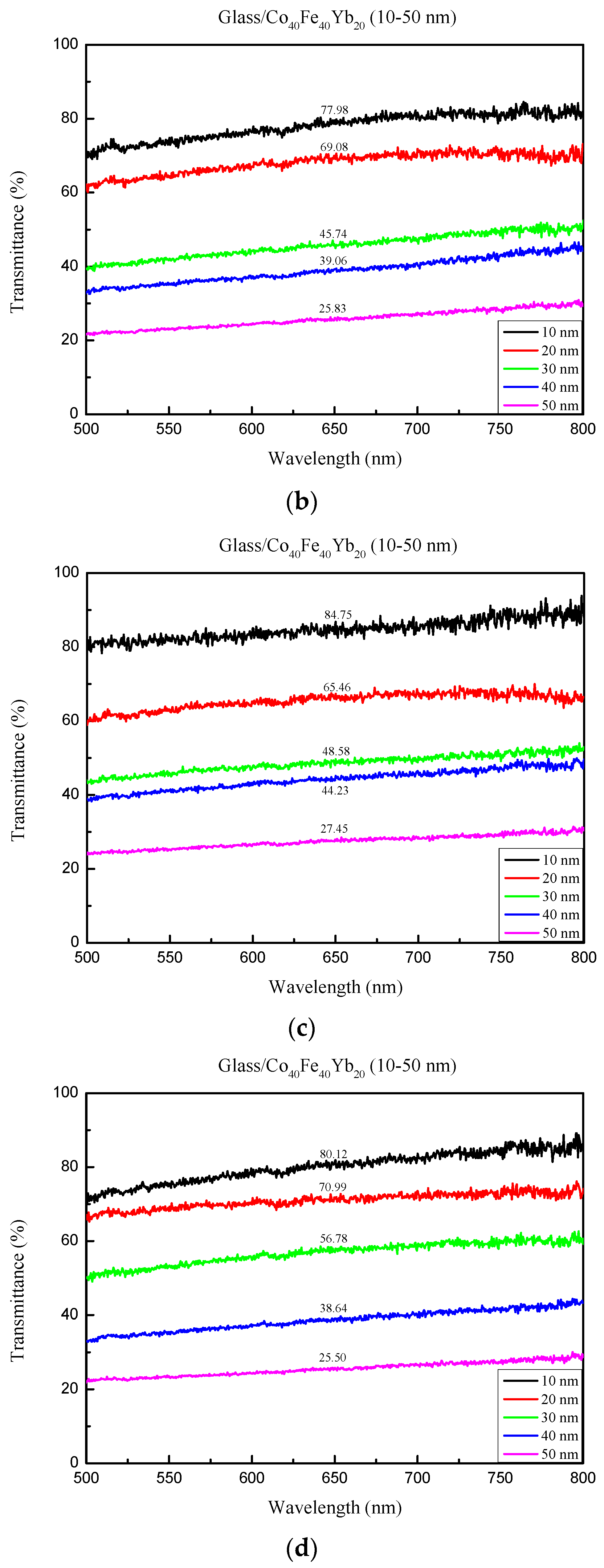

3.3. Examination of Optical Properties

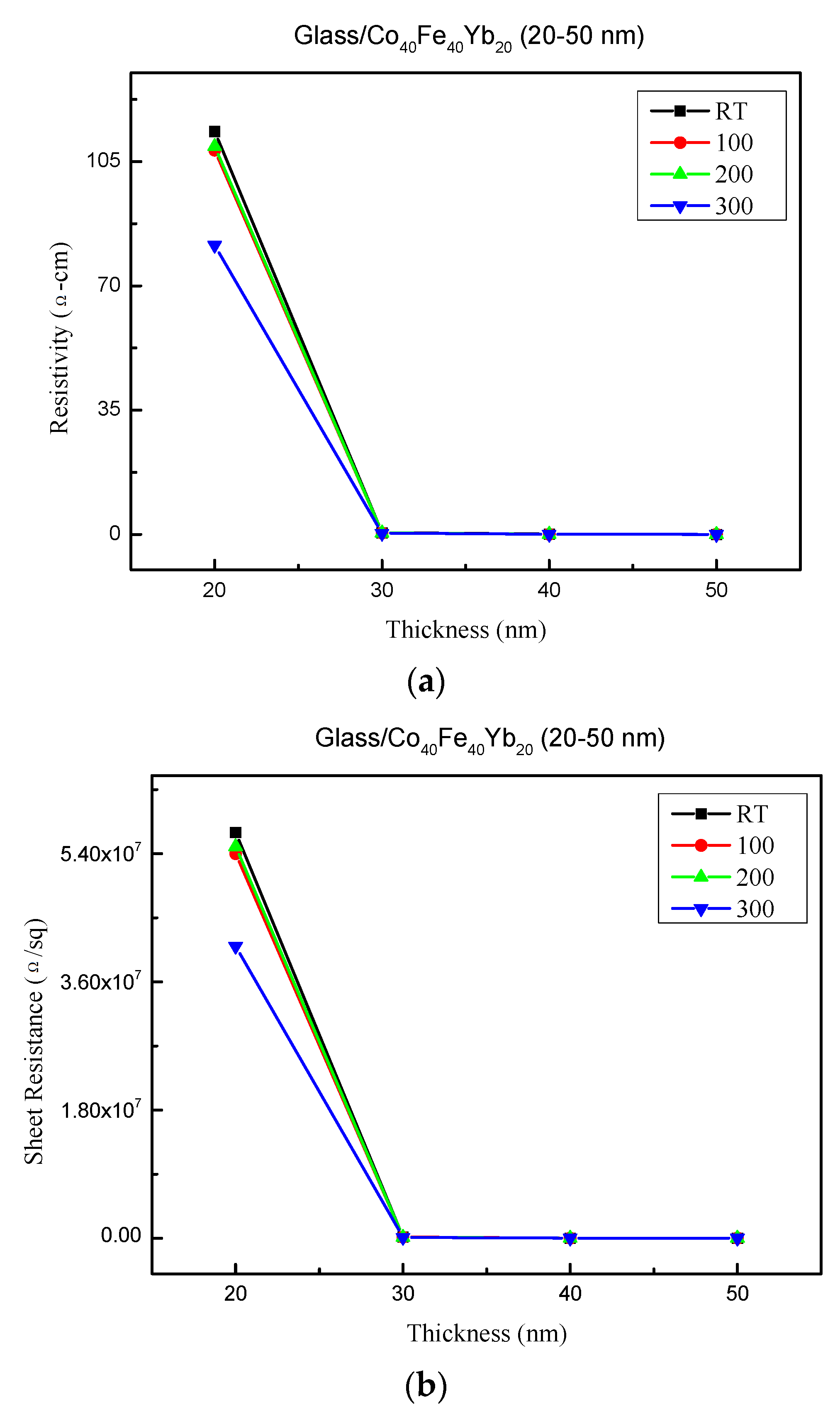

3.4. Electrical Analysis

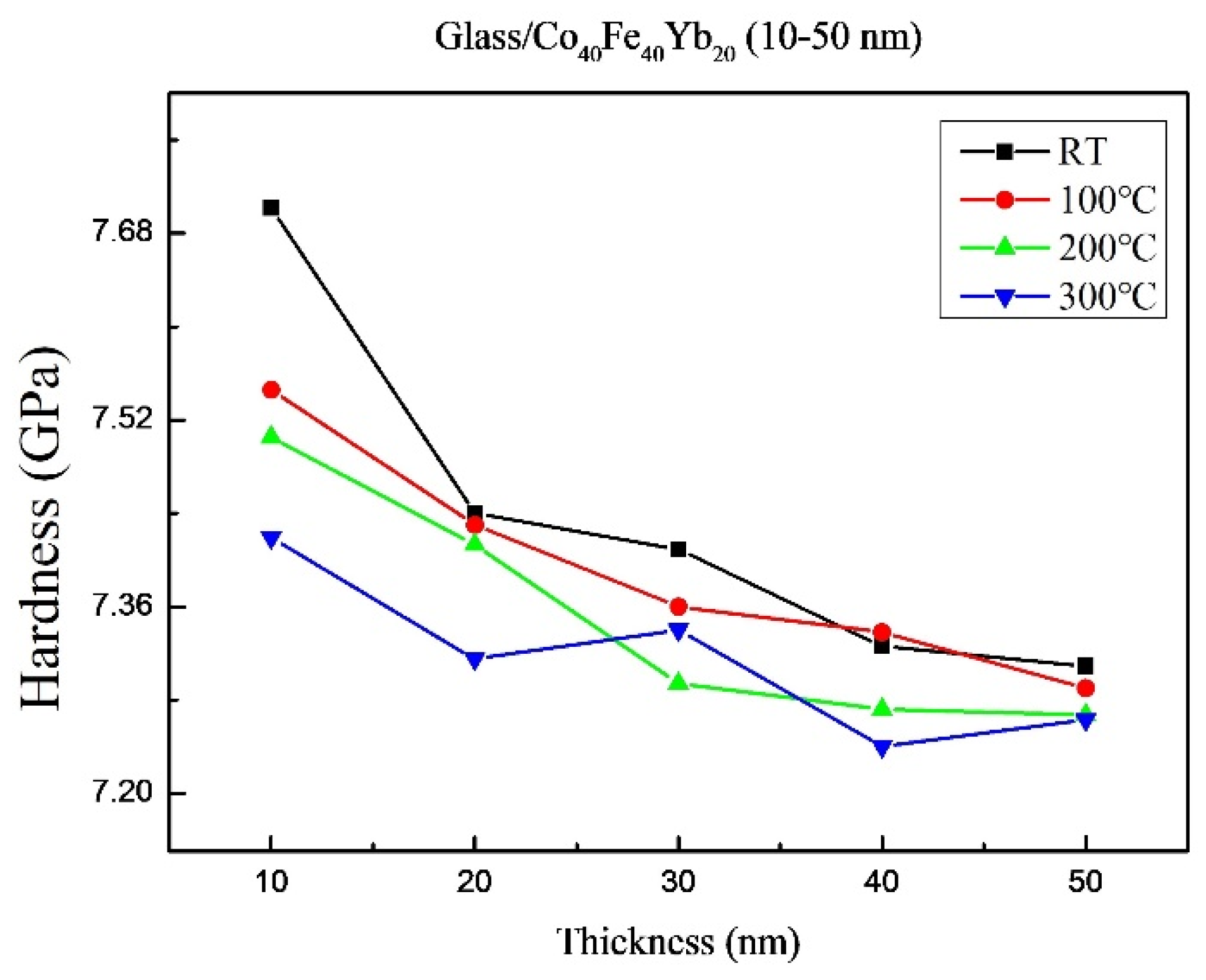

3.5. Hardness Analysis

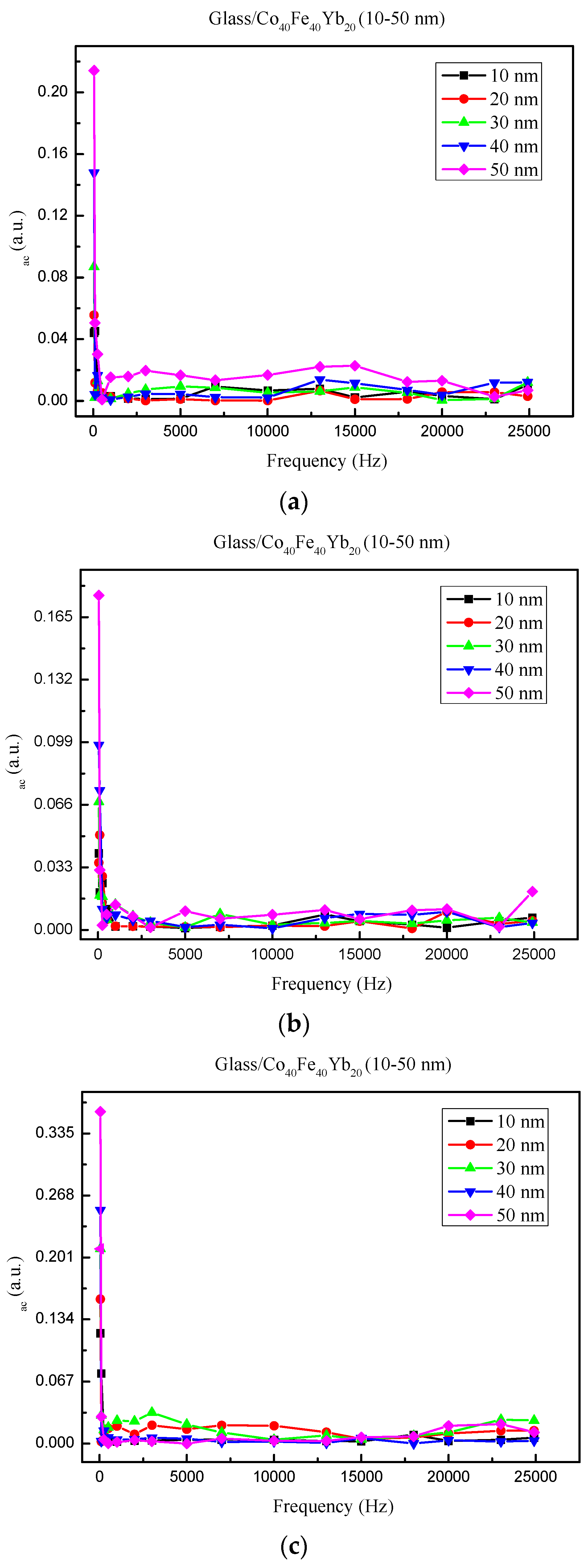

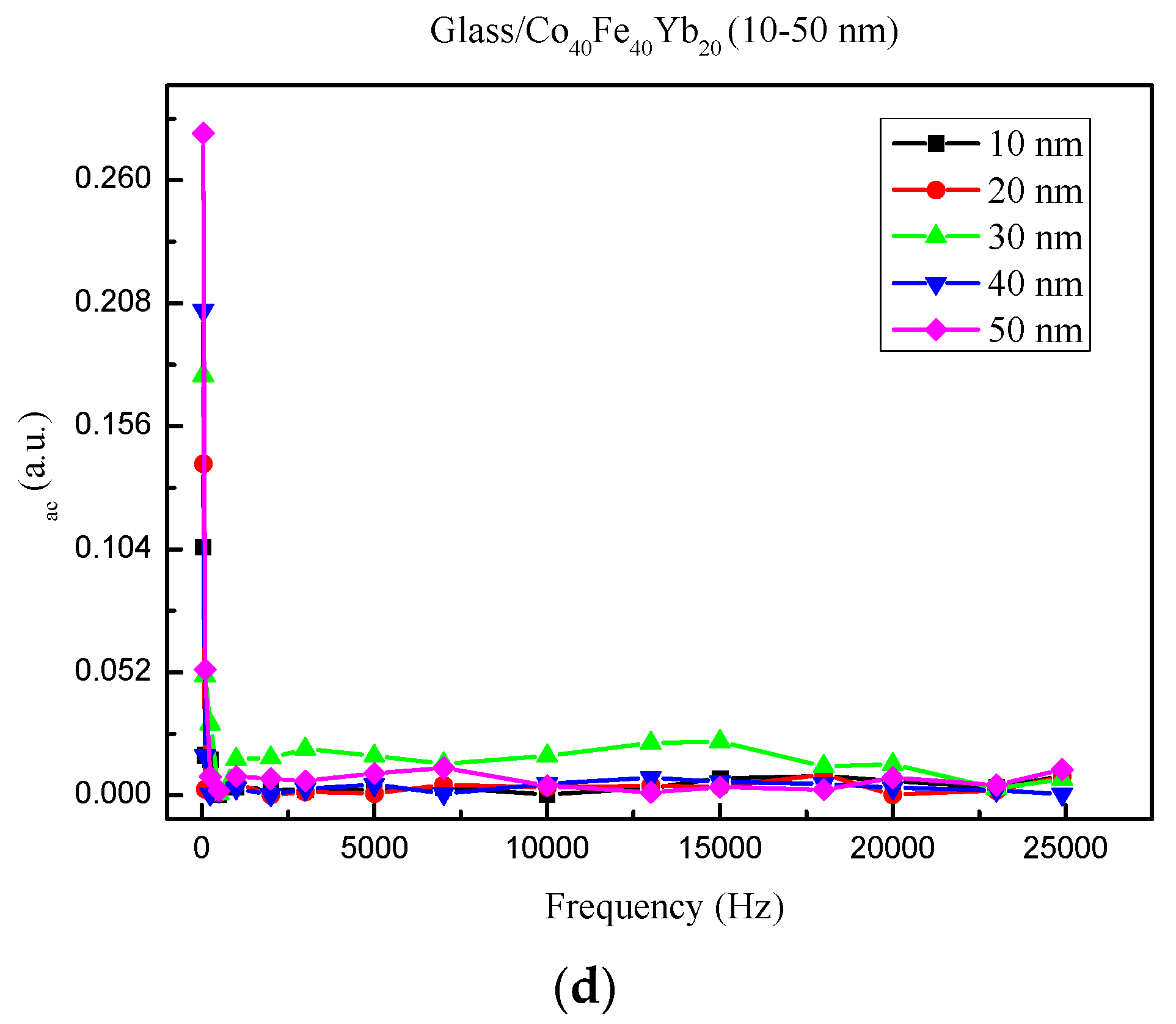

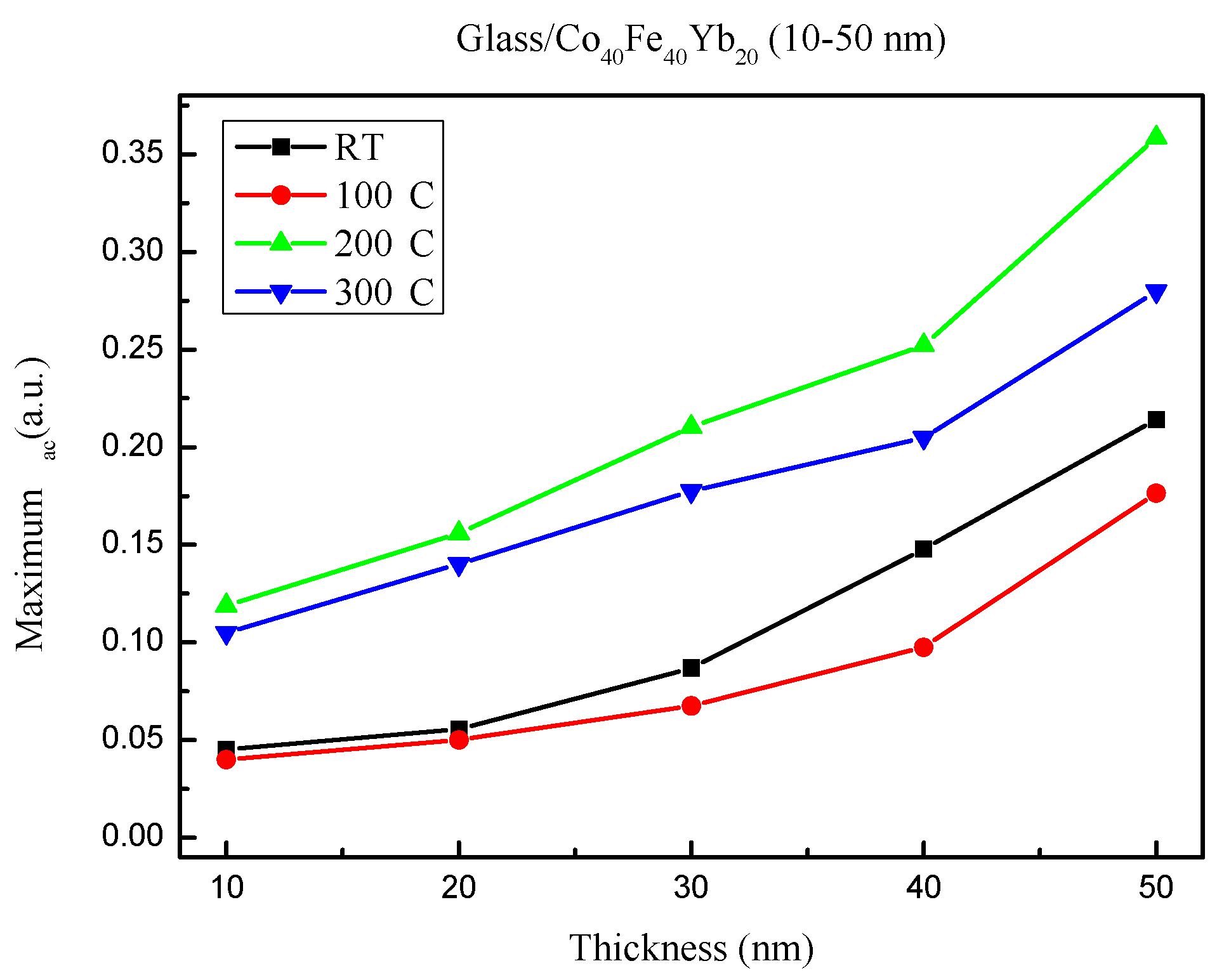

3.6. Magnetic Analysis

3.7. Challenges and Prospects

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Zeng, F.; Zhang, S.S.-L.; Shin, H.; Saglam, H.; Karakas, V.; Ozatay, O.; Pearson, J.E.; Heinonen, O.G.; Wu, Y.; et al. Giant Anisotropy of Gilbert Damping in Epitaxial CoFe Films. Phys. Rev. Lett. 2019, 122, 117203. [Google Scholar] [CrossRef]

- Zhang, Y.; Ivey, D.G. Electrodeposition of nanocrystalline CoFe soft magnetic thin films from citrate-stabilized baths. Mater. Chem. Phys. 2018, 204, 171–178. [Google Scholar] [CrossRef]

- Conte, R.L.; Gorchon, J.; Mougin, A.; Lambert, C.H.A.; Ghazaly, A.E.; Scholl, A.; Salahuddin, S.; Bokor, J. Electrically controlled switching of the magnetization state in multiferroic BaTiO3/CoFe submicrometer structures. Phys. Rev. Mater. 2018, 2, 091402. [Google Scholar]

- Gao, H.; Harumoto, T.; Luo, W.; Lan, R.; Feng, H.; Du, Y.; Nakamura, Y.; Shi, J. Room temperature perpendicular exchange bias in CoNi/(Co,Ni)O multilayers with perpendicular magnetic anisotropy directly induced by FM/AFM interface. J. Magn. Magn. Mater. 2018, 473, 490–494. [Google Scholar] [CrossRef]

- Iwasaki, S.; Nakamura, Y.; Ouchi, K. Perpendicular magnetic recording with a composite anisotropy film. IEEE Trans. Magn. 1979, 15, 1456–1458. [Google Scholar] [CrossRef]

- Li, M.; Yang, Z.; Zhang, Y.; Hu, D.; Lyu, X. Mesoporous CoFe alloy@SiO2 nanocapsules with controllable Co/Fe atomic ratio for highly efficient tunable electromagnetic wave absorption. J. Alloys Compd. 2019, 802, 41–49. [Google Scholar] [CrossRef]

- Soundararaj, A.; Mohanty, J. Impact of Deposition Potential on Structural and Magnetic Properties of Nano-Crystalline CoFe Alloy Thin Films. Surf. Eng. Appl. Electrochem. 2020, 56, 159–165. [Google Scholar] [CrossRef]

- Ha, N.D.; Phan, M.-H.; Kim, C.-O. Influences of rapid annealing and substrate temperature on the magnetic properties of Co-Fe-V films. J. Appl. Phys. 2006, 99, 08F105. [Google Scholar] [CrossRef]

- Galimberti, P.; Lay, S.; Antoni-Zdziobek, A.; Coindeau, S.; Veron, M.; Bley, F.; De Boissieu, M. Precipitation and hardening behaviour of the Fe20Co18W alloy aged at 800 °C. Intermetallics 2011, 19, 556–562. [Google Scholar] [CrossRef]

- Noce, R.D.; Benedetti, A.V.; Magnani, M.; Passamani, E.C.; Kumar, H.; Cornejo, D.R.; Ospina, C.A. Structural, morphological and magnetic characterization of electrodeposited Co–Fe–W alloys. J. Alloys Compd. 2014, 611, 243–248. [Google Scholar] [CrossRef]

- Prentice, J.J.; Grant-Jacob, J.A.; Shepherd, D.P.; Eason, R.W.; Mackenzie, J.I. Yb-doped mixed-sesquioxide films grown by pulsed laser deposition. J. Cryst. Growth 2018, 491, 51–56. [Google Scholar] [CrossRef]

- Sharma, D.K.; Varshney, M.; Shukla, S.; Sharma, K.K.; Kumar, V.; Sharma, A. Assimilation of Yb defect states in ZnO: Structural, optical and magnetic investigations. Vacuum 2020, 179, 109522. [Google Scholar] [CrossRef]

- Thangeeswari, T.; Parthipan, G.; Gowtham, S. Impact of rare earth (Dy and Yb) ions doping on magnetic and optical properties of ZnO nanoparticles. AIP Conf. Proc. 2019, 2105, 020003. [Google Scholar] [CrossRef]

- Diaz-Torres, L.; De la Rosa, E.; Salas, P.; Desirena, H. Enhanced cooperative absorption and upconversion in Yb3+doped YAG nanophosphors. Opt. Mater. 2005, 27, 1305–1310. [Google Scholar] [CrossRef]

- Liu, W.J.; Ou, S.L.; Chang, Y.H.; Chen, Y.T.; Chiang, M.R.; Hsu, S.C.; Chu, C.L. Adhesive characteristic, surface morphology, and optical properties of Co40Fe40V20 films. Opt.-Int. J. Light and Electron Optics 2020, 216, 164587. [Google Scholar] [CrossRef]

- Liu, W.-J.; Chen, Y.-T.; Chang, Y.-H.; Chiang, M.-R.; Li, W.-H.; Tseng, J.-Y.; Chi, P.-W.; Wu, T.-H. Structure and Magnetic Properties of Co40Fe40V20 Thin Films. J. Nanosci. Nanotechnol. 2019, 19, 5974–5978. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.J.; Chang, Y.H.; Ou, S.L.; Chen, Y.T.; Li, W.H.; Jhou, T.Y.; Chu, C.C.; Wu, T.H.; Tseng, S.W. Effect of annealing on the structural, magnetic, surface energy and optical properties of Co32Fe30W38 films deposited by direct-current magnetron sputtering. Coatings 2020, 10, 1028. [Google Scholar] [CrossRef]

- Ma, K.; Chung, T.S.; Good, R.J. Surface energy of thermotropic liquid crystalline polyesters and polyesteramide. J. Polym. Sci. 1998, 36, 2327–2337. [Google Scholar] [CrossRef]

- Owens, D.K.; Wendt, R.C. Estimation of the surface free energy of polymers. J. Appl. Polym. Sci. 1969, 13, 1741–1747. [Google Scholar] [CrossRef]

- Kaelble, D.H.; Uy, K.C. A Reinterpretation of Organic Liquid-Polytetrafluoroethylene Surface Interactions. J. Adhes. 1970, 2, 50–60. [Google Scholar] [CrossRef]

- Li, L.; Wang, T.; Wang, Y.; Zhang, C.-C.; Lv, H.; Lin, H.; Yu, W.-B.; Huang, C.-J. Effects of ytterbium addition and heat treatment on the mechanical properties and biocorrosion behaviors of Mg–Zn–Zr alloy. J. Magnes. Alloy. 2020, 8, 499–509. [Google Scholar] [CrossRef]

- Eckert, J.; Holzer, J.C.; Johnson, W.L. Thermal stability and grain growth behavior of mechanically alloyed nanocrystalline Fe-Cu alloys. J. Appl. Phys. 1993, 73, 131–141. [Google Scholar] [CrossRef]

- Kube, S.A.; Xing, W.; Kalidindi, A.; Sohn, S.; Datye, A.; Amram, D.; Schuh, C.A.; Schroers, J. Combinatorial study of thermal stability in ternary nanocrystalline alloys. Acta Mater. 2020, 188, 40–48. [Google Scholar] [CrossRef]

- Peng, H.; Huang, L.; Liu, F. A thermo-kinetic correlation for grain growth in nanocrystalline alloys. Mater. Lett. 2018, 219, 276–279. [Google Scholar] [CrossRef]

- Pachchigar, V.; Ranjan, M.; Mukherjee, S. Role of Hierarchical Protrusions in Water Repellent Superhydrophobic PTFE Surface Produced by Low Energy Ion Beam Irradiation. Sci. Rep. 2019, 9, 8675. [Google Scholar] [CrossRef]

- Romero, R.; Martin, F.; Ramos-Barrado, J.; Leinen, D. Synthesis and characterization of nanostructured nickel oxide thin films prepared with chemical spray pyrolysis. Thin Solid Film. 2009, 518, 4499–4502. [Google Scholar] [CrossRef]

- Tavakoli, M.M.; Dastjerdi, H.T.; Zhao, J.; Shulenberger, K.E.; Carbonera, C.; Po, R.; Cominetti, A.; Bianchi, G.; Klein, N.D.; Bawendi, M.G.; et al. Light Management in Organic Photovoltaics Processed in Ambient Conditions Using ZnO Nanowire and Antireflection Layer with Nanocone Array. Small 2019, 15, e1900508. [Google Scholar] [CrossRef]

- Kapustianyk, V.; Turko, B.; Kostruba, A.; Sofiani, Z.; Derkowska, B.; Dabos-Seignon, S.; Barwiński, B.; Eliyashevskyi, Y.; Sahraoui, B. Influence of size effect and sputtering conditions on the crystallinity and optical properties of ZnO thin films. Opt. Commun. 2007, 269, 346–350. [Google Scholar] [CrossRef]

- Shaaban, E. Optical constants and fitted transmittance spectra of varies thickness of polycrystalline ZnSe thin films in terms of spectroscopic ellipsometry. J. Alloys Compd. 2013, 563, 274–279. [Google Scholar] [CrossRef]

- Chen, H.-L.; Lu, Y.-M.; Hwang, W.-S. Thickness dependence of electrical and optical properties of sputtered nickel oxide films. Thin Solid Film. 2006, 498, 266–270. [Google Scholar] [CrossRef]

- Jassim, S.A.-J.; Zumaila, A.A.R.A.; Al Waly, G.A.A. Influence of substrate temperature on the structural, optical and electrical properties of CdS thin films deposited by thermal evaporation. Results Phys. 2013, 3, 173–178. [Google Scholar] [CrossRef]

- Redjdal, N.; Salah, H.; Hauet, T.; Menari, H.; Chérif, S.; Gabouze, N.; Azzaz, M. Microstructural, electrical and magnetic properties of Fe35Co65 thin films grown by thermal evaporation from mechanically alloyed powders. Thin Solid Film. 2014, 552, 164–169. [Google Scholar] [CrossRef][Green Version]

- Wen, T.; Gong, J.; Peng, Z.; Jiang, D.; Wang, C.; Fu, Z.; Miao, H. Analysis of continuous stiffness data measured during nanoindentation of titanium films on glass substrate. Mater. Chem. Phys. 2011, 125, 500–504. [Google Scholar] [CrossRef]

- Wei, P.-J.; Lin, J.-F. A new method developed to evaluate both the hardness and elastic modulus of a coating–substrate system. Surf. Coat. Technol. 2005, 200, 2489–2496. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Venkatraman, R.; Bravman, J.C. Separation of film thickness and grain boundary strengthening effects in Al thin films on Si. J. Mater. Res. 1992, 7, 2040–2048. [Google Scholar] [CrossRef]

- Beegan, D.; Laugier, M. Application of composite hardness models to copper thin film hardness measurement. Surf. Coat. Technol. 2005, 199, 32–37. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, D.; Fu, Y.; Du, H. Recent advances of superhard nanocomposite coatings: A review. Surf. Coat. Technol. 2003, 167, 113–119. [Google Scholar] [CrossRef]

- Fu, X.; Jiang, J.; Jiang, X. Research Progress in Interfacial Characteristics and Strengthening Mechanisms of Rare Earth Metal Oxide-Reinforced Copper Matrix Composites. Materials 2022, 15, 5350. [Google Scholar] [CrossRef] [PubMed]

- Wang, K.; Xu, Z.; Huang, Y.; Qiu, Y.; Dong, S. Magnetic, thermal, electrical properties and crystallization kinetics of Co60Fe20B20 alloy films. Sci. China Mater. 2016, 59, 639–647. [Google Scholar] [CrossRef]

- Yang, S.Y.; Chien, J.J.; Wang, W.C.; Yu, C.Y.; Hing, N.S.; Hong, H.E.; Hong, C.Y.; Yang, H.C.; Chang, C.F.; Lin, H.Y. Magnetic nanoparticles for high-sensitivity detection on nucleicacids via superconducting quantum-interference device basedimmunomagnetic reduction assay. J. Magn. Magn. Mater. 2011, 323, 681–685. [Google Scholar] [CrossRef]

- Bhatt, R.C.; Ye, L.-X.; Hai, N.T.; Wu, J.-C.; Wu, T.-H. Spin-flop led peculiar behavior of temperature-dependent anomalous Hall effect in Hf/Gd-Fe-Co. J. Magn. Magn. Mater. 2021, 537, 168196. [Google Scholar] [CrossRef]

- Kharmouche, A.; Ch´erif, S.M.; Bourzami, A.; Layadi, A.; Schmerber, G. Structural and magnetic properties of evaporated Co/Si(100) and Co/glass thin films. J. Phys. D Appl. Phys. 2004, 37, 2583–2587. [Google Scholar] [CrossRef]

| Abbreviation | Full Name |

|---|---|

| XRD | X-ray diffraction |

| χac | low-frequency alternative-current magnetic susceptibility |

| ƒres | optimal resonance frequency |

| MS | saturation magnetization |

| MRAM | magnetic random-access memory |

| PMA | perpendicular magnetic anisotropy |

| Ku | magnetic anisotropy constant |

| CoFe | cobalt iron |

| Hc | coercivity |

| Tc | Curie temperature |

| Hk | magnetic anisotropy field |

| RE | rare-earth |

| Yb | ytterbium |

| YAG | yttrium aluminum Garnet |

| MTJ | magnetic tunneling junction |

| TMR | tunneling magnetoresistance |

| B | boron |

| RT | room temperature |

| DC | direct current |

| Ar | argon |

| GIXRD | grazing incidence X-ray diffraction |

| θ | contact angle |

| DI | deionized |

| MTS | mechanical testing and simulation |

| CSM | continuous stiffness measurement |

| AGM | alternating gradient magnetometer |

| Hext | external magnetic field |

| Materials | Maximum χac (a.u.) | Surface Energy (mJ/mm2) |

|---|---|---|

| Glass/Co40Fe40V20 [15,16] 10–100 nm at RT | 0.02–0.04 | 27.8–45.4 |

| Glass/Co32Fe30W38 [17] 10–50 nm at RT and annealed conditions | 0.02–0.52 | 22.3–28.4 |

| Glass/Co40Fe40Yb20 10–50 nm at RT and annealed conditions (Current research) | 0.04–0.35 | 28.6–34.5 |

| Process | Thickness | Contact Angle with DI Water (θ) | Contact Angle with Glycerol (θ) | Surface Energy (mJ/mm2) |

|---|---|---|---|---|

| As-deposited | 10 nm | 76.5° | 70.9° | 29.47 |

| 20 nm | 74.4° | 67.9° | 30.37 | |

| 30 nm | 74.6° | 67.1° | 30.86 | |

| 40 nm | 69.9° | 65.3° | 33.02 | |

| 50 nm | 68.8° | 65.1° | 33.72 | |

| Post-annealing 100 °C | 10 nm | 81.3° | 71.4° | 28.63 |

| 20 nm | 84.0° | 72.5° | 29.19 | |

| 30 nm | 79.1° | 71.6° | 29.45 | |

| 40 nm | 74.1° | 72.0° | 29.90 | |

| 50 nm | 79.8° | 69.1° | 30.61 | |

| Post-annealing 200 °C | 10 nm | 82.5° | 71.9° | 28.82 |

| 20 nm | 86.4° | 72.8° | 31.46 | |

| 30 nm | 71.8° | 69.6° | 31.28 | |

| 40 nm | 70.9° | 70.4° | 32.48 | |

| 50 nm | 74.8° | 66.3° | 31.52 | |

| Post-annealing 300 °C | 10 nm | 79.7° | 71.8° | 30.17 |

| 20 nm | 71.1° | 68.3° | 32.45 | |

| 30 nm | 77.5° | 67.7° | 32.35 | |

| 40 nm | 77.1° | 64.7° | 34.54 | |

| 50 nm | 74.8° | 63.7° | 34.23 |

| Thickness (nm) | As-Deposited Optimal Resonance Frequency (Hz) | Post-Annealing at 100 °C of Optimal Resonance Frequency (Hz) | Post-Annealing at 200 °C of Optimal Resonance Frequency (Hz) | Post-Annealing at 300 °C of Optimal Resonance Frequency (Hz) |

|---|---|---|---|---|

| 10 | 100 | 50 | 50 | 50 |

| 20 | 50 | 100 | 50 | 50 |

| 30 | 50 | 50 | 50 | 50 |

| 40 | 50 | 50 | 50 | 50 |

| 50 | 50 | 50 | 50 | 50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.-J.; Chang, Y.-H.; Chiang, C.-C.; Fern, C.-L.; Chen, Y.-T.; Chen, Y.-H.; Liao, H.-W.; Wu, T.-H.; Lin, S.-H.; Lin, K.-W.; et al. Effect of Annealing and Thickness of Co40Fe40Yb20 Thin Films on Various Physical Properties on a Glass Substrate. Materials 2022, 15, 8509. https://doi.org/10.3390/ma15238509

Liu W-J, Chang Y-H, Chiang C-C, Fern C-L, Chen Y-T, Chen Y-H, Liao H-W, Wu T-H, Lin S-H, Lin K-W, et al. Effect of Annealing and Thickness of Co40Fe40Yb20 Thin Films on Various Physical Properties on a Glass Substrate. Materials. 2022; 15(23):8509. https://doi.org/10.3390/ma15238509

Chicago/Turabian StyleLiu, Wen-Jen, Yung-Huang Chang, Chia-Chin Chiang, Chi-Lon Fern, Yuan-Tsung Chen, Ying-Hsuan Chen, Hao-Wen Liao, Te-Ho Wu, Shih-Hung Lin, Ko-Wei Lin, and et al. 2022. "Effect of Annealing and Thickness of Co40Fe40Yb20 Thin Films on Various Physical Properties on a Glass Substrate" Materials 15, no. 23: 8509. https://doi.org/10.3390/ma15238509

APA StyleLiu, W.-J., Chang, Y.-H., Chiang, C.-C., Fern, C.-L., Chen, Y.-T., Chen, Y.-H., Liao, H.-W., Wu, T.-H., Lin, S.-H., Lin, K.-W., & Chi, P.-W. (2022). Effect of Annealing and Thickness of Co40Fe40Yb20 Thin Films on Various Physical Properties on a Glass Substrate. Materials, 15(23), 8509. https://doi.org/10.3390/ma15238509