Different Fiber Reinforcement Effects on Fly Ash-Based Geopolymer Long-Term Deflection in Three-Point Bending and Microstructure

Abstract

1. Introduction

2. Materials and Methods

- 1.

- Day 1—10 M NaOH solution preparation. Alkali solution is prepared by mixing NaOH flakes with water. As the chemical reaction is exothermic, the container with the solution after mixing is placed in cold water for one hour to reduce the temperature. Then, the R-145 sodium silicate is added to the sodium hydroxide and mixed until the solution has an even consistency. The solution is left until the next morning to settle.

- 2.

- Day 2—Geopolymer specimen preparation.

- 2.1.

- Specimen dry mix is prepared by mixing quartz sand and fly ash together. The sand and fly ash content ratios are 1:1 by mass. Sand and fly ash are mixed in a mixer for 5 min at the machine’s lowest speed.

- 2.2.

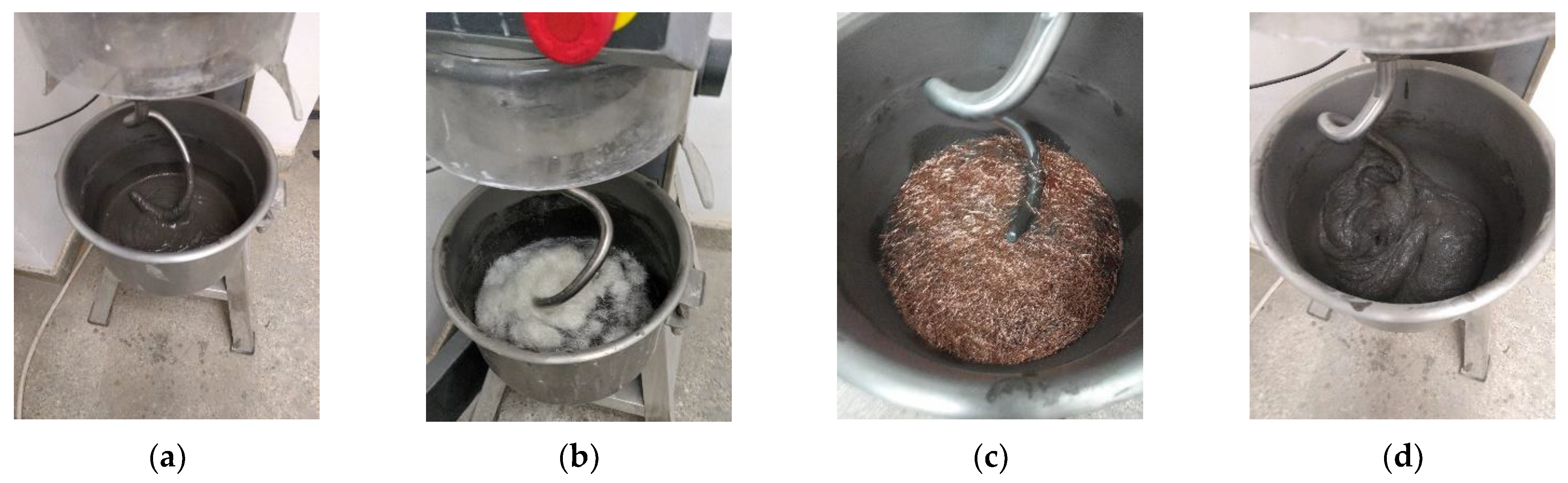

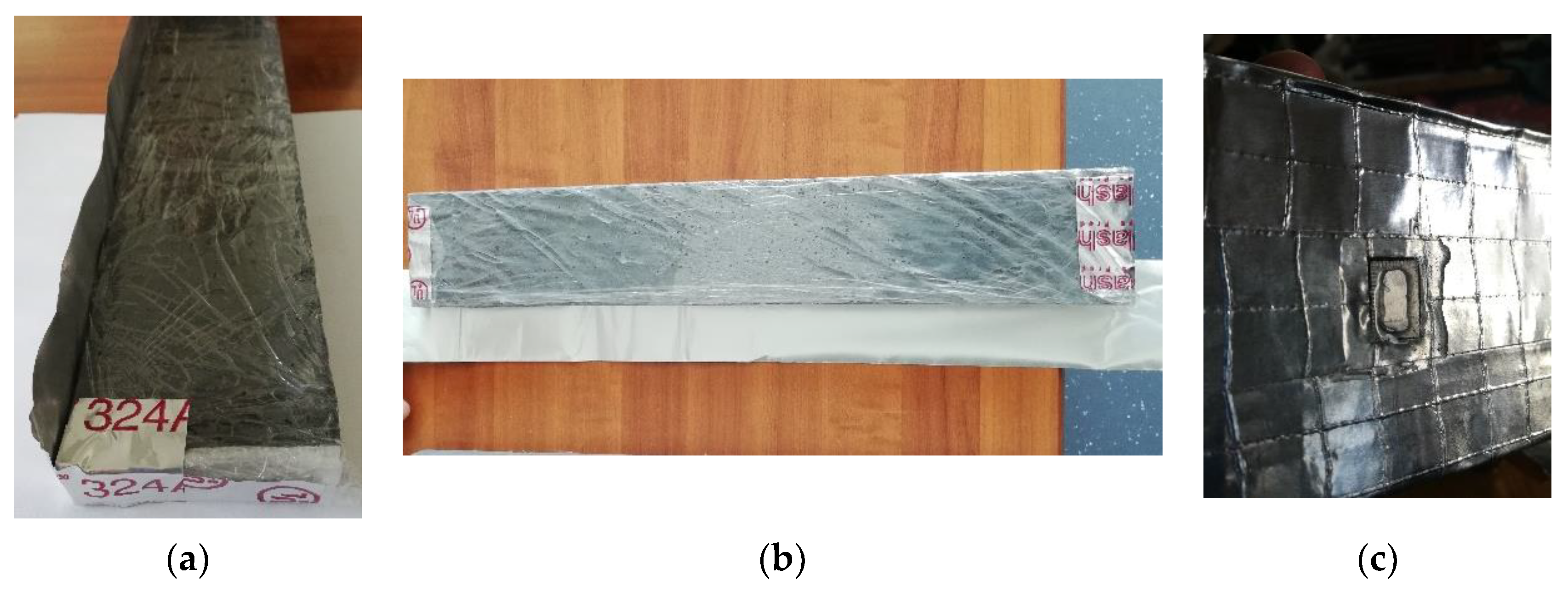

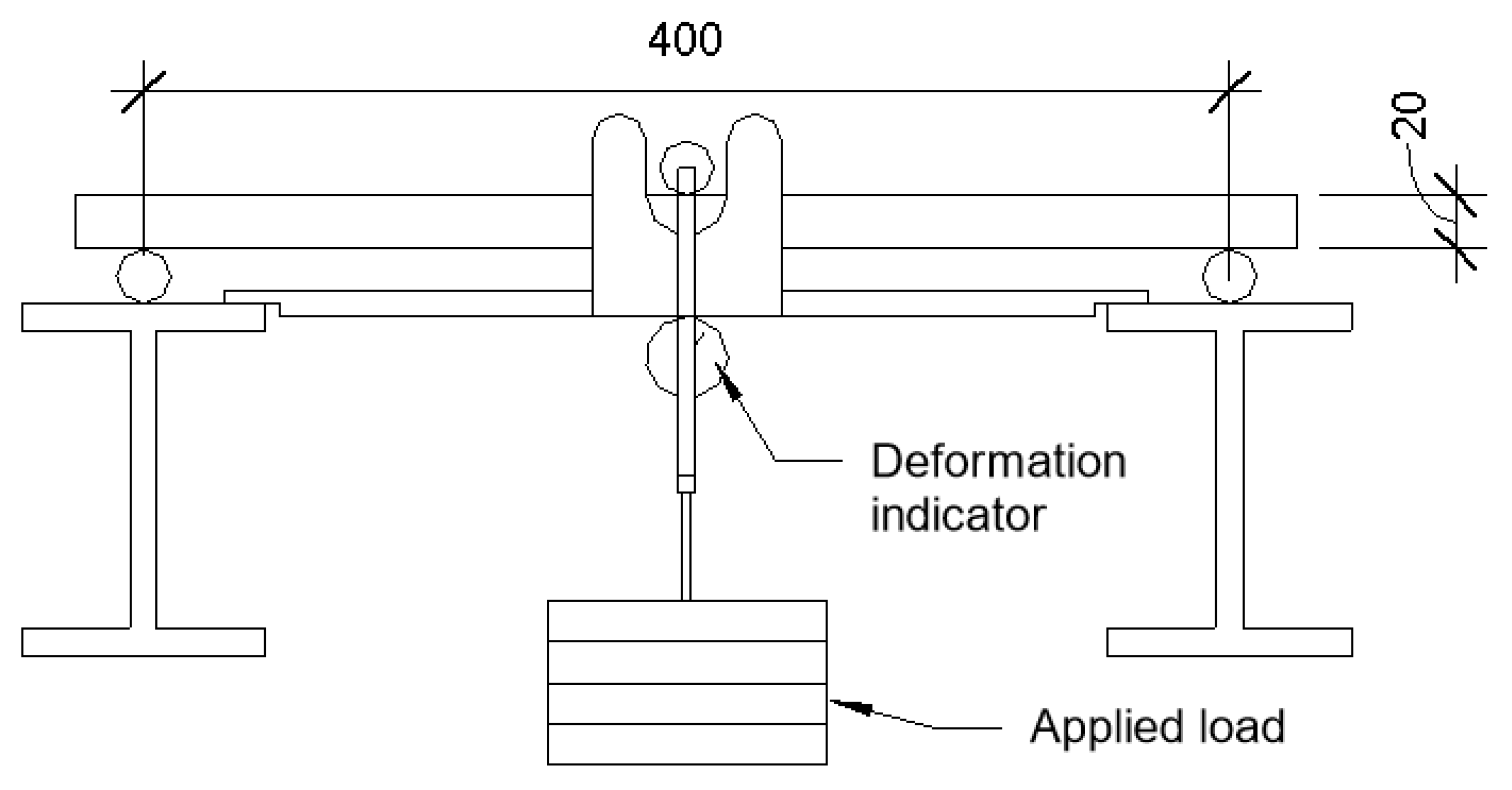

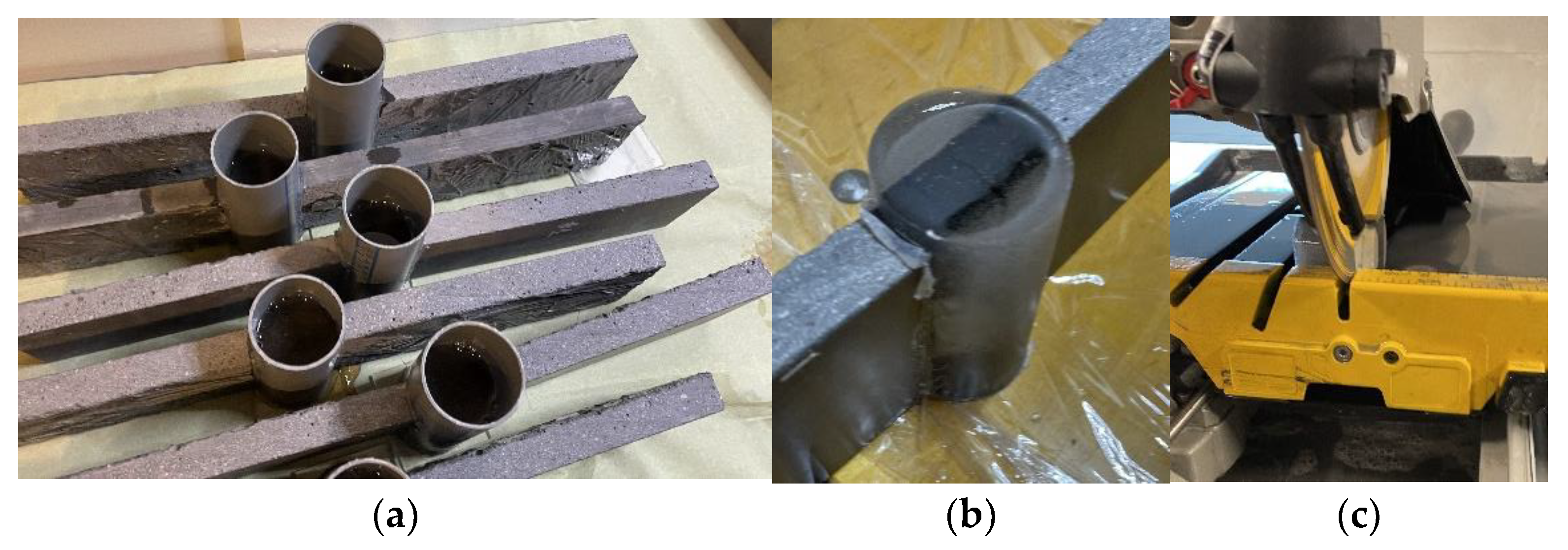

- After dry mix preparation, the previously prepared alkali solution is added to the dry mix and mixed until the geopolymer achieves a moldable consistency. Mixing is performed for 15 min at the machine’s lowest speed [22,23]. For the fiber-reinforced specimens, after the first 15 min of mixing, the previously prepared and weighed fiber reinforcement (Figure 1) is added, and the whole geopolymer composition is mixed for 5 min. Whole geopolymer mixing is shown in Figure 2.

- 2.3.

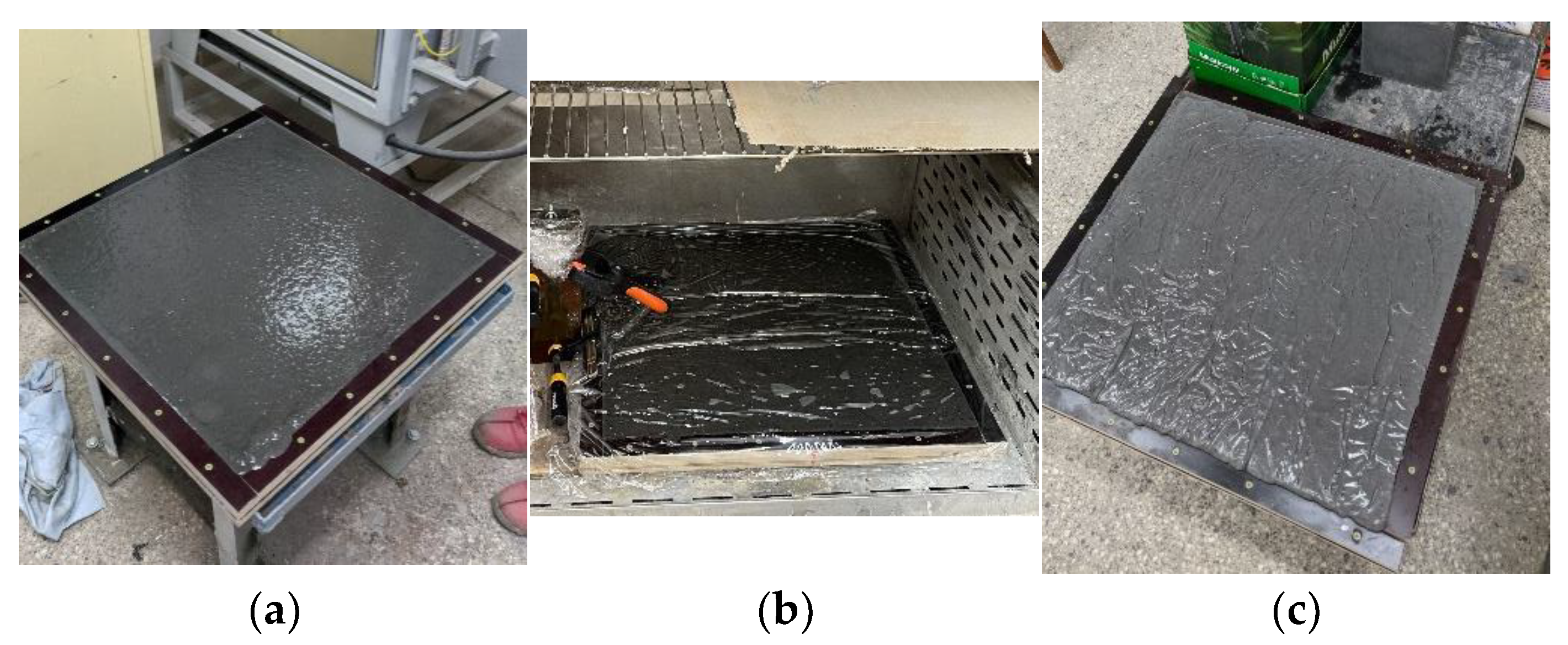

- The geopolymer mixture is poured into previously oiled plywood molds. The molds are vibrated to release entrapped air and covered with plastic film, then placed into a heat chamber at 75 °C for 24 h.

3. Results and Discussion

4. Conclusions

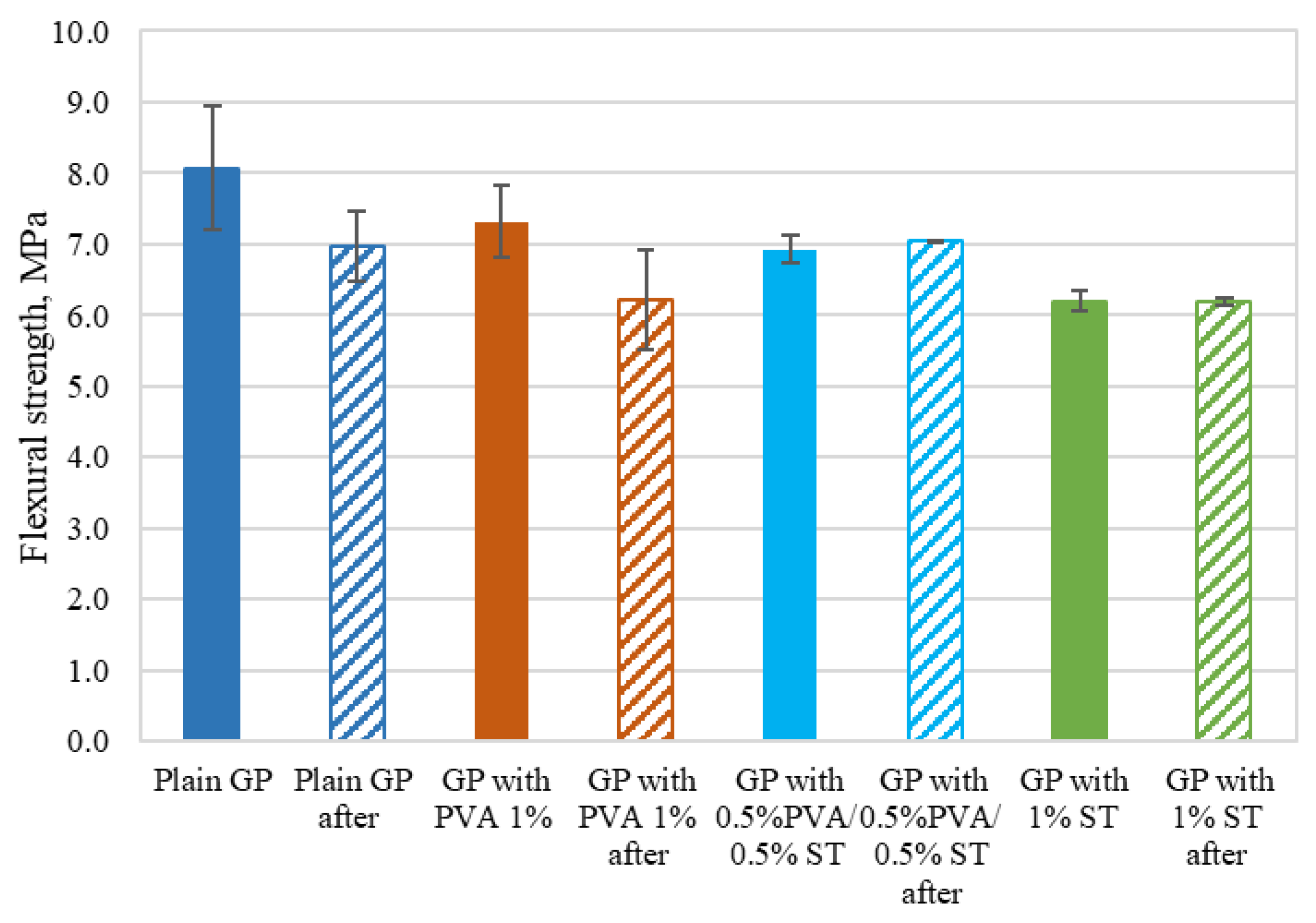

- The highest flexural strength before and after the tests is found in the plain geopolymer specimens. The 1% PVA fiber-reinforced and 0.5% PVA/0.5% steel fiber-reinforced specimens have 9% and 14.2% lower flexural strength, respectively. The 1% steel fiber-reinforced specimens have 23.2% lower flexural strength than the plain specimens. After long-term deflection tests, the flexural strength values from the plain specimens are 11.1% and 11.4% lower for 1% PVA and 1% steel fiber reinforcement and 0.9% higher for the specimens reinforced with 0.5% PVA/0.5% steel fibers;

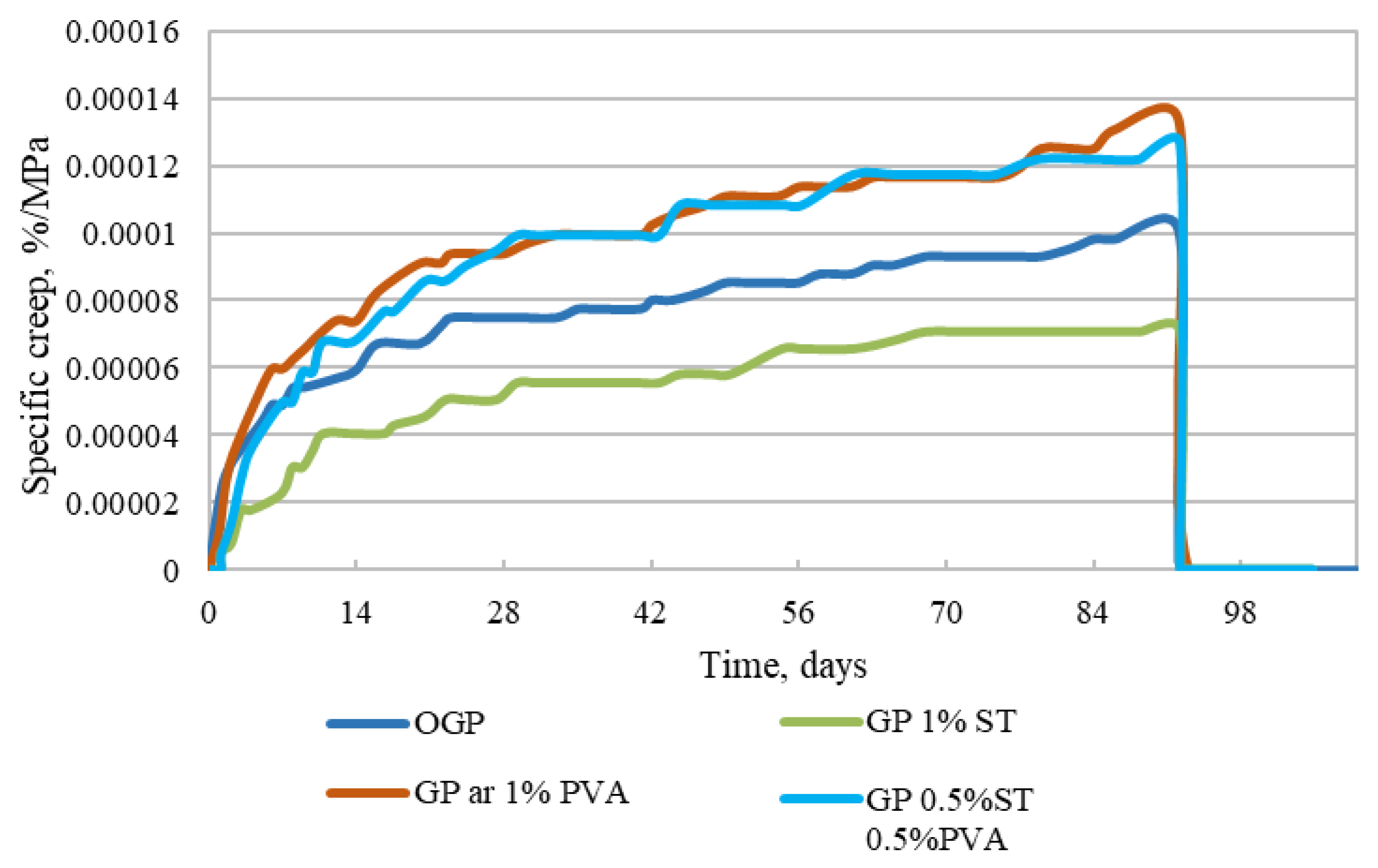

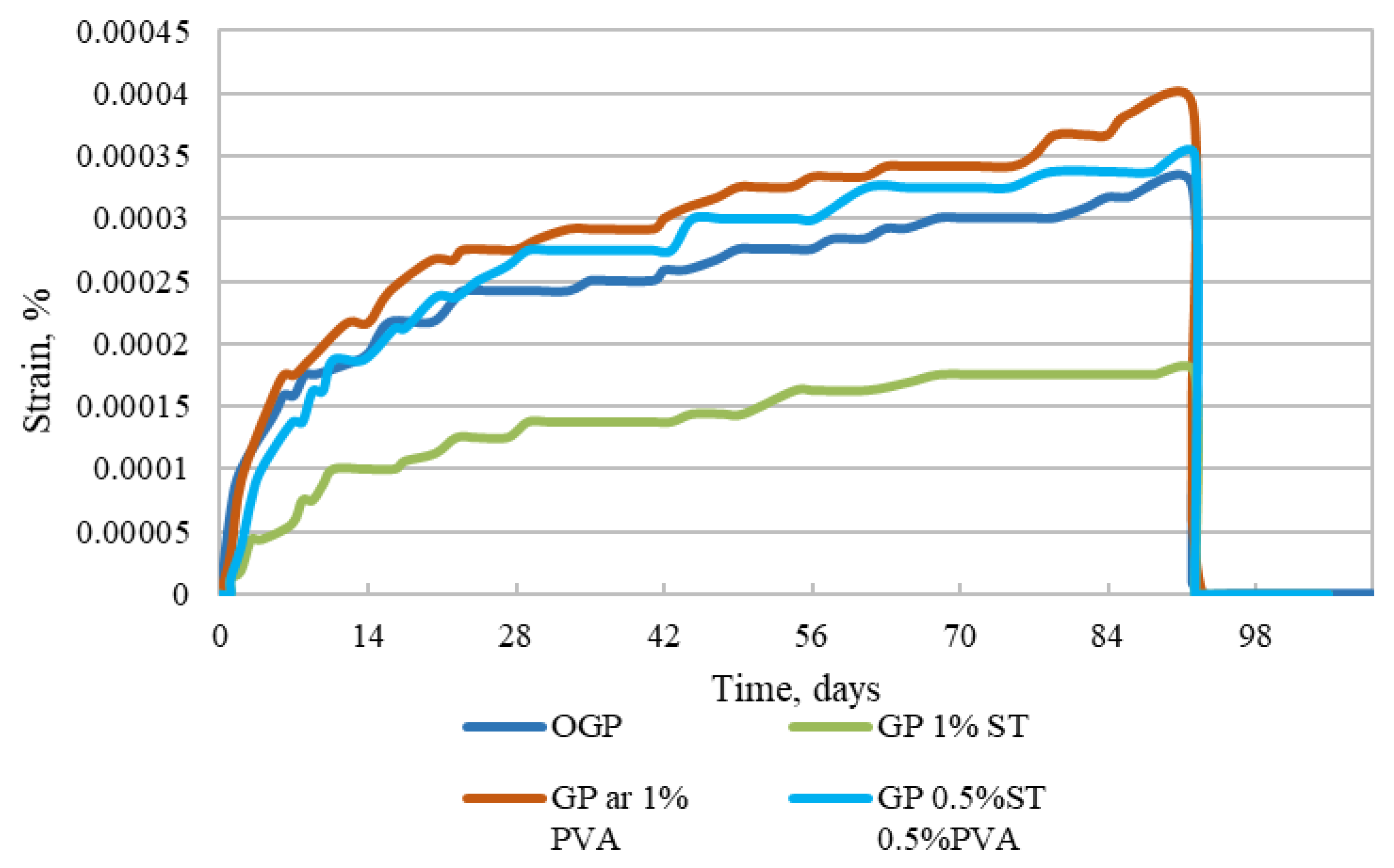

- The lowest long-term deflection in three-point bending is linked to the 1% steel fiber reinforced specimens. The 0.5% PVA/0.5% steel fiber-reinforced, plain, and 1% PVA fiber-reinforced specimens have 49.3%, 51.7%, and 60.6% higher long-term deflection, respectively;

- Specimens reinforced with 1% steel fibers or those with the lowest specific creep are less likely to deform under three-point bending, followed by plain specimens, 0.5% PVA/0.5% steel fiber-reinforced specimens, and 1% PVA fiber-reinforced specimens, by 37.1%, 43.3%, and 53.5%, respectively;

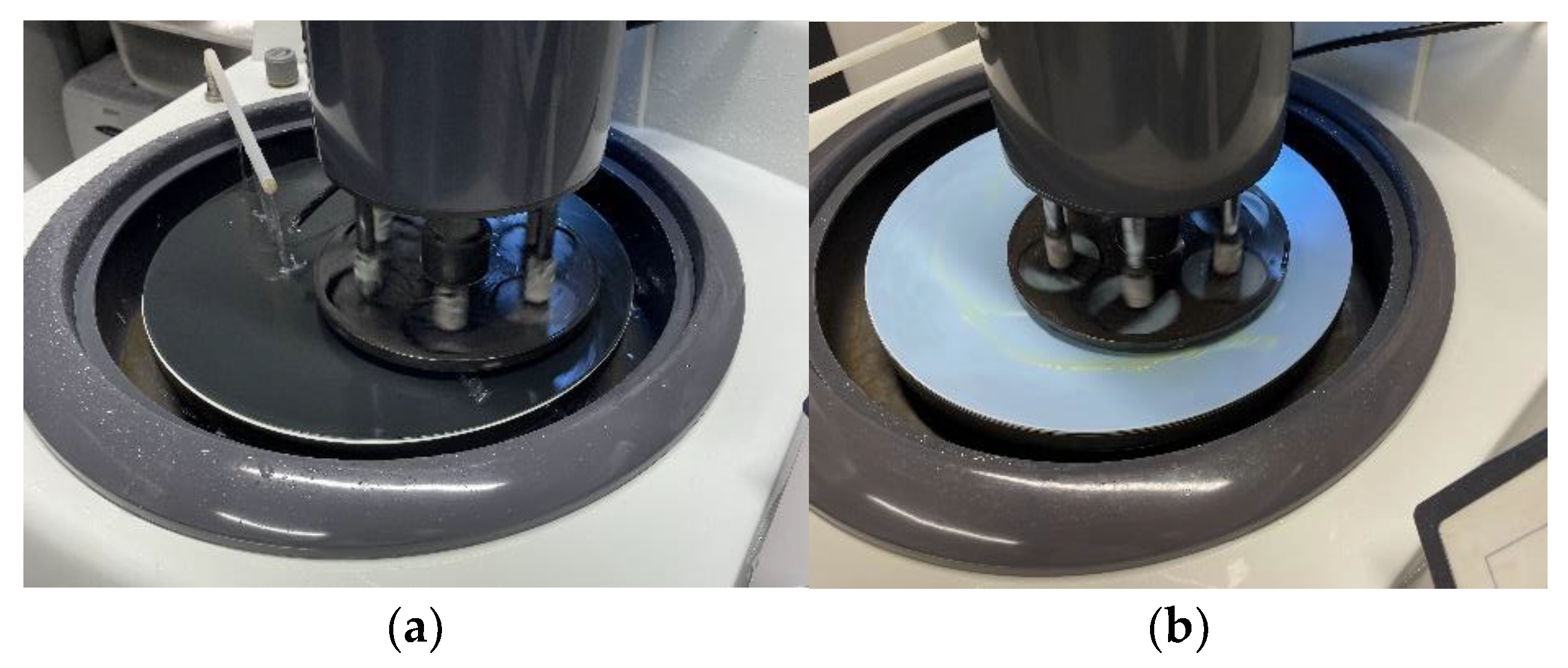

- The microstructure quantitative analysis of long-term deflection test specimens shows that specimens with 1% PVA fiber reinforcement have two times higher detected fiber reinforcement amount than all the other fiber-reinforced specimens, while air void amounts for the 1% PVA fiber reinforced specimens are 1.51 and 1.37 times higher than 0.5% PVA/0.5% steel, and 1% steel fiber-reinforced specimens. The flexural strength test specimen microstructure quantitative analysis showed 5.52% and 7.50% lower air void and crack amount linked to 1% steel fiber and 0.5% PVA/0.5% steel fiber-reinforced specimens than to 1% PVA fiber reinforced specimens, showing that these specimens have lower plasticity than those reinforced with 1% PVA fibers;

- Overall, it is apparent that beam-shaped specimens with random fiber distribution throughout have lower deflection strength. Moreover, steel fiber incorporation into geopolymer specimens seems to be most beneficial for reducing long-term deflection. It can be concluded that for the bent specimens, not only the lowest bending strength and its reduction while exposed to the long-term load application, but also the lowest long-term deflection and specific creep is linked to the specimens with 1% steel fiber incorporation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Villa, C.; Pecina, E.T.; Torres, R.; Gómez, L. Geopolymer synthesis using alkaline activation of natural zeolite. Constr. Build. Mater. 2010, 24, 2084–2090. [Google Scholar] [CrossRef]

- Hassan, A.; Arif, M.; Shariq, M. A review of properties and behaviour of reinforced geopolymer concrete structural elements—A clean technology option for sustainable development. J. Clean. Prod. 2020, 245, 118762. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G.; Sagoe-Crentsil, K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Sarfaraz Ali, M.; Sachan, A.K. A review on the durability and applicability of Geopolymer concrete from the recent research studies. Mater. Today Proc. 2021, 52, 911–922. [Google Scholar] [CrossRef]

- Almutairi, A.L.; Tayeh, B.A.; Adesina, A.; Isleem, H.F.; Zeyad, A.M. Potential applications of geopolymer concrete in construction: A review. Case Stud. Constr. Mater. 2021, 15, e00733. [Google Scholar] [CrossRef]

- Hardjito, D.; Wallah, S.E.; Sumajouw, D.M.; Rangan, B.V. On the Development of Fly Ash-Based Geopolymer Concrete. ACI Mater. J. 2004, 101, 467–472. [Google Scholar] [CrossRef]

- Liu, M.Y.J.; Alengaram, U.J.; Santhanam, M.; Jumaat, M.Z.; Mo, K.H. Microstructural investigations of palm oil fuel ash and fly ash based binders in lightweight aggregate foamed geopolymer concrete. Constr. Build. Mater. 2016, 120, 112–122. [Google Scholar] [CrossRef]

- Robayo-Salazar, R.; Mejía-Arcila, J.; Mejía de Gutiérrez, R.; Martínez, E. Life cycle assessment (LCA) of an alkali-activated binary concrete based on natural volcanic pozzolan: A comparative analysis to OPC concrete. Constr. Build. Mater. 2018, 176, 103–111. [Google Scholar] [CrossRef]

- Assi, L.N.; Carter, K.; Deaver, E.; Ziehl, P. Review of availability of source materials for geopolymer/sustainable concrete. J. Clean. Prod. 2020, 263, 121477. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Bhutta, A.; Borges, P.H.R.; Zanotti, C.; Farooq, M.; Banthia, N. Flexural behavior of geopolymer composites reinforced with steel and polypropylene macro fibers. Cem. Concr. Compos. 2017, 80, 31–40. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Pongsopha, P.; Chindaprasirt, P.; Songpiriyakij, S. Flexural performance and toughness of hybrid steel and polypropylene fibre reinforced geopolymer. Constr. Build. Mater. 2018, 161, 37–44. [Google Scholar] [CrossRef]

- Farooq, M.; Bhutta, A.; Banthia, N. Tensile performance of eco-friendly ductile geopolymer composites (EDGC) incorporating different micro-fibers. Cem. Concr. Compos. 2019, 103, 183–192. [Google Scholar] [CrossRef]

- Meng, Q.; Wu, C.; Hao, H.; Li, J.; Wu, P.; Yang, Y.; Wang, Z. Steel fibre reinforced alkali-activated geopolymer concrete slabs subjected to natural gas explosion in buried utility tunnel. Constr. Build. Mater. 2020, 246, 118447. [Google Scholar] [CrossRef]

- Mu, B.; Meyer, C.; Shimanovich, S. Improving the interface bond between f iber mesh and cementitious matrix. Cem. Concr. Res. 2002, 32, 783–787. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of polypropylene fiber geometry on plastic shrinkage cracking in concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Redon, C.; Li, V.C.; Wu, C.; Hoshiro, H.; Saito, T.; Ogawa, A. Measuring and modifying interface properties of PVA fibers in ECC matrix. J. Mater. Civ. Eng. 2001, 13, 399–406. Available online: https://deepblue.lib.umich.edu/bitstream/handle/2027.42/84898/redon_JMCE01.pdf?sequence=1 (accessed on 21 September 2022). [CrossRef]

- Li, V.C.; Wu, C.; Wang, S.; Ogawa, A.; Saito, T. Interface tailoring for strain-hardening polyvinyl alcohol-engineered cementitious composite (PVA-ECC). ACI Mater. J. 2002, 99, 463–472. Available online: https://www.researchgate.net/profile/Victor-Li-15/publication/280224066_Interface_Tailoring_for_Strain-hardening_PVA-ECC/links/58c6f9afa6fdccde55e4134d/Interface-Tailoring-for-Strain-hardening-PVA-ECC.pdf (accessed on 21 September 2022).

- Segui, P.; Aubert, J.E.; Husson, B.; Measson, M. Characterization of wastepaper sludge ash for its valorization as a component of hydraulic binders. Appl. Clay Sci. 2012, 57, 79–85. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Murali, G.; Avudaiappan, S.; Ozbakkaloglu, T. Fly Ash-Based Eco-Efficient Concretes: A Comprehensive Review of the Short-Term Properties. Materials 2021, 14, 4264. [Google Scholar] [CrossRef]

- Un, C.H.; Sanjayan, J.G.; San Nicolas, R.; Van Deventer, J.S.J. Predictions of long-term deflection of geopolymer concrete beams. Constr. Build. Mater. 2015, 94, 10–19. [Google Scholar] [CrossRef]

- Korniejenko, K. Geopolymers for Increasing Durability for Marine Infrastructure. Spec. Publ. 2018, 326, 20.1–20.10. [Google Scholar]

- Łach, M.; Mikuła, J.; Hebda, M. Thermal analysis of the by-products of waste combustion. J. Therm. Anal. Calorim. 2016, 125, 1035–1045. [Google Scholar] [CrossRef][Green Version]

- Gailitis, R.; Sprince, A.; Pakrastins, L.; Korniejenko, K.; Kozlovskis, T. Reinforced and Plain Geopolymer Concrete Specimen Cross-Section Composition Influence on Creep Strains. In Proceedings of the 4th International Rilem Conference on Microstructure Related Durability of Cementitious Composites, Online, 29 April–25 May 2021; pp. 739–746. [Google Scholar]

- Gailitis, R.; Sprince, A.; Pakrastins, L.; Korniejenko, K.; Kozlovskis, T. Plain Geopolymer Concrete Cross-Section Surface Analysis after Creep and Shrinkage Tests in Compression and Tension; Springer International Publishing: New York, NY, USA, 2021; pp. 13–24. ISBN 9783030729219. [Google Scholar]

- Nazari, A.; Maghsoudpour, A.; Sanjayan, J.G. Flexural strength of plain and fibre-reinforced boroaluminosilicate geopolymer. Constr. Build. Mater. 2015, 76, 207–213. [Google Scholar] [CrossRef]

- Constâncio Trindade, A.C.; Liebscher, M.; Curosu, I.; de Andrade Silva, F.; Mechtcherine, V. Influence of elevated temperatures on the residual and quasi in-situ flexural strength of strain-hardening geopolymer composites (SHGC) reinforced with PVA and PE fibers. Constr. Build. Mater. 2022, 314, 125649. [Google Scholar] [CrossRef]

- Alsaif, A.S.; Abdulrahman, S.; Albidah, A. Compressive and flexural characteristics of geopolymer rubberized concrete reinforced with recycled tires steel fibers. Mater. Today Proc. 2022, 65, 1230–1236. [Google Scholar] [CrossRef]

- Ahmed, H.Q.; Jaf, D.K.; Yaseen, S.A. Flexural strength and failure of geopolymer concrete beams reinforced with carbon fibre-reinforced polymer bars. Constr. Build. Mater. 2020, 231, 117185. [Google Scholar] [CrossRef]

- Junwei, Z.; Shijie, L.; Hongjian, P. Experimental investigation of multiscale hybrid fibres on the mechanical properties of high-performance concrete. Constr. Build. Mater. 2021, 299, 123895. [Google Scholar] [CrossRef]

- Sprince, A.; Gailitis, R.; Pakrastins, L.; Kozlovskis, T.; Vatin, N. Long-term properties of cement mortar under compression, tension, and 3-point bending. Mag. Civ. Eng. 2021, 105, 3–12. [Google Scholar] [CrossRef]

- Haddaji, Y.; Majdoubi, H.; Mansouri, S.; Alomayri, T.S.; Allaoui, D.; Manoun, B.; Oumam, M.; Hannache, H. Microstructure and flexural performances of glass fibers reinforced phosphate sludge based geopolymers at elevated temperatures. Case Stud. Constr. Mater. 2022, 16, e00928. [Google Scholar] [CrossRef]

- Deng, Z.; Yang, Z.; Bian, J.; Lin, J.; Long, Z.; Hong, G.; Yang, Z.; Ye, Y. Advantages and disadvantages of PVA-fibre-reinforced slag-and fly ash-blended geopolymer composites: Engineering properties and microstructure. Constr. Build. Mater. 2022, 349, 128690. [Google Scholar] [CrossRef]

| Alkali Solution | Dry Mix | ||

|---|---|---|---|

| Constituent | Weight (g) | Constituent | Weight Ratio |

| NaOH flakes | 400 | Quartz sand | 1.00 |

| Water | 1000 | Fly ash | 1.00 |

| R-145 Na2O + SiO2 solution (molar module 2.5, density 1.45 g/cm3) | 3500 | Fibers | 0.01 |

| Fiber Parameter | PVA Mesofibers (MasterFiber 400/401) | Steel Fibers (La Graminga GOLD) |

|---|---|---|

| Length (mm) | 18.00 | 20.00 |

| Diameter (mm) | 0.16 | 0.30 |

| Tensile strength (MPa) | 790–1160 | 2635–3565 |

| Geopolymer Composite Type | Age 28 Days | Age 274 Days | ||

|---|---|---|---|---|

| Flexural Strength (MPa) | Coefficient of Variation | Flexural Strength (MPa) | Coefficient of Variation | |

| Plain GP | 8.07 | 10.67 | 6.98 | 7.05 |

| 1% PVA GP | 7.32 | 6.93 | 6.21 | 11.25 |

| 0.5% PVA/0.5% St GP | 6.93 | 2.85 | 7.05 | 1.34 |

| 1% Steel GP | 6.20 | 2.27 | 6.18 | 0.87 |

| Geopolymer Composite Type | Matrix (%) | Filler (%) | Air Voids (%) | Fiber Reinforcement (%) |

|---|---|---|---|---|

| Plain GP | 75.93 | 19.05 | 5.02 | - |

| 1% PVA GP | 74.58 | 19.62 | 4.64 | 1.16 |

| 0.5% PVA/0.5% St GP | 77.76 | 18.12 | 3.65 | 0.47 |

| 1% Steel GP | 77.50 | 17.28 | 4.62 | 0.60 |

| Geopolymer Composite Type | Matrix (%) | Filler (%) | Air Voids, Cracks (%) | Fiber Reinforcement (%) |

|---|---|---|---|---|

| Plain GP | 65.10 | 16.33 | 18.57 | - |

| 1% PVA GP | 61.02 | 16.04 | 22.00 | 0.94 |

| 0.5% PVA/0.5% St GP | 69.09 | 15.99 | 14.50 | 0.42 |

| 1% Steel GP | 67.87 | 15.12 | 16.48 | 0.52 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gailitis, R.; Pakrastins, L.; Sprince, A.; Radina, L.; Sakale, G.; Miernik, K. Different Fiber Reinforcement Effects on Fly Ash-Based Geopolymer Long-Term Deflection in Three-Point Bending and Microstructure. Materials 2022, 15, 8512. https://doi.org/10.3390/ma15238512

Gailitis R, Pakrastins L, Sprince A, Radina L, Sakale G, Miernik K. Different Fiber Reinforcement Effects on Fly Ash-Based Geopolymer Long-Term Deflection in Three-Point Bending and Microstructure. Materials. 2022; 15(23):8512. https://doi.org/10.3390/ma15238512

Chicago/Turabian StyleGailitis, Rihards, Leonids Pakrastins, Andina Sprince, Liga Radina, Gita Sakale, and Krzysztof Miernik. 2022. "Different Fiber Reinforcement Effects on Fly Ash-Based Geopolymer Long-Term Deflection in Three-Point Bending and Microstructure" Materials 15, no. 23: 8512. https://doi.org/10.3390/ma15238512

APA StyleGailitis, R., Pakrastins, L., Sprince, A., Radina, L., Sakale, G., & Miernik, K. (2022). Different Fiber Reinforcement Effects on Fly Ash-Based Geopolymer Long-Term Deflection in Three-Point Bending and Microstructure. Materials, 15(23), 8512. https://doi.org/10.3390/ma15238512