Thermal and Stress Properties of Briquettes from Virginia Mallow Energetic Crops

Abstract

1. Introduction

2. Materials and Methods

2.1. Rod Sample Preparation

- diameter: 25 mm

- length: 100 mm.

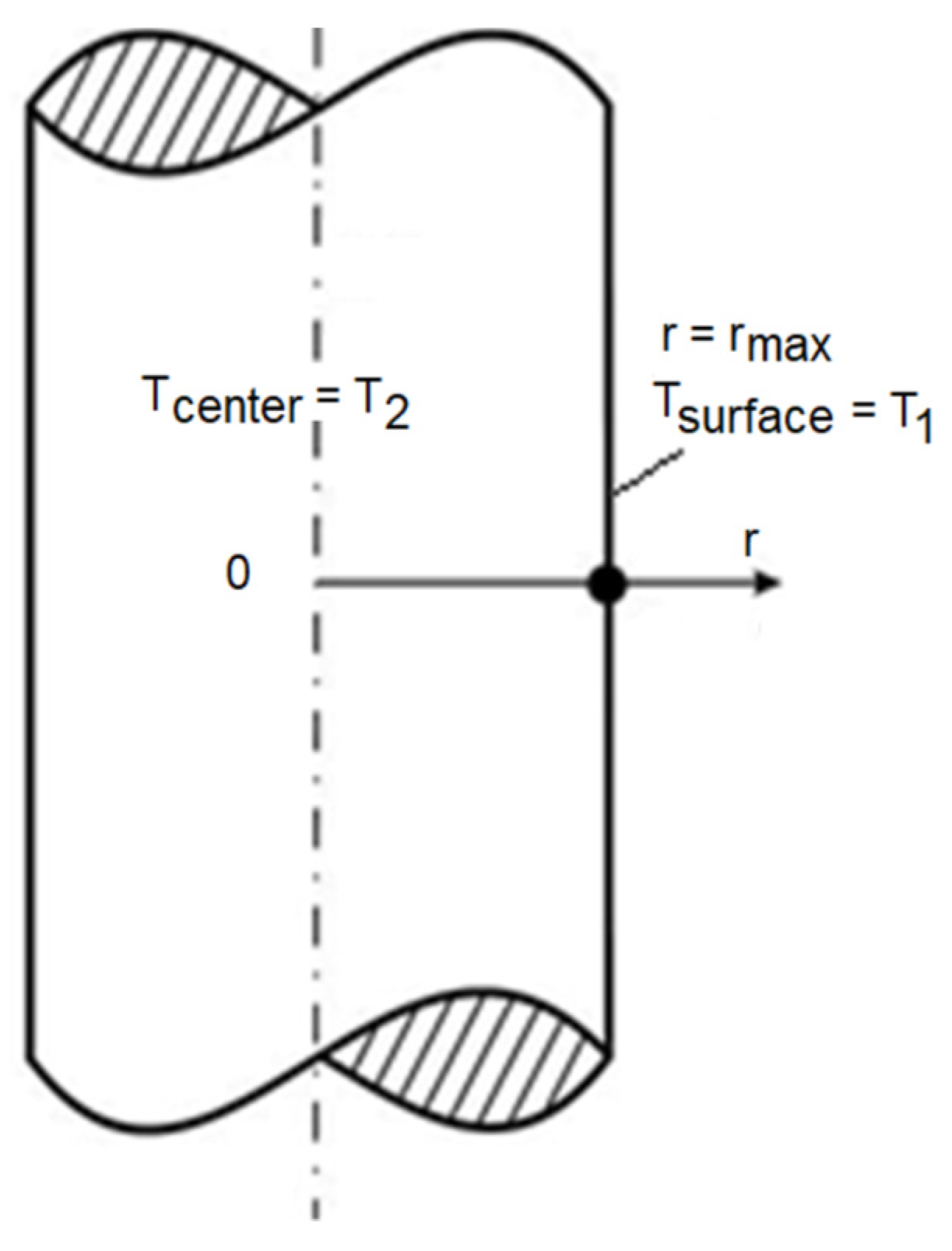

2.2. Methodology for Thermal Conductivity Determination

- The heat flux q” (W/m2) was calculated from the conductivity Equation (1) assuming the temperature gradient inside the rod close to the rod surface

- The heat flux was constant across the pellet

- kmean is the material conductivity determined by Equation (2), calculated for the temperature gradient inside the rod close to the rod surface

- Ts represents the temperature taken from the endpoint near the surface of the rod at quasi-steady-state conditions. This means conditions under which the temperature has been stabilized, whereas Ts−1 is the temperature inside the rod at a distance of a single step in the discrete mesh

- The contact resistance between the thermocouple and the material surface has been ignored

- Surface temperature changing with time (measured by the thermocouple surface):

- The initial conditions are as follows:

2.2.1. Test Procedure

2.2.2. Heating and Cooling Tests

- Tinitial represents the temperature for t = 0,

- T∞ represents the final temperature after the rod has reached steady-state conditions.

- Tinitial represents the temperature for time t = 0,

- T∞ represents the temperature after the rod has reached steady-state conditions.

2.3. Methodology for Stress Analysis

- force acting on the sample

- sample deformation

- 200 ± 1 °C

- ambient temperature (approximately 20 ± 0.5 °C)

2.4. Compressive Strength Test

- Δh represents the change in height of the sample during compaction under a given pressure,

- hp represents the initial sample height before compaction.

3. Results and Discussion

3.1. Results from Conductivity Tests

- for cooling tests: k = 0.048 ± 0.001 W/(K∙m)

- for heating tests: k = 0.049 ± 0.003 W/(K∙m)

3.2. Stress Analysis

4. Conclusions

- The average thermal conductivity was calculated from the equation of heat conduction in the unsteady state for cylindrical coordinates. The obtained thermal conductivity was 0.048 ± 0.001 W/(K∙m). As mentioned in Section 1, thermal conductivity determined by others was between 0.030 and 0.039 W/(K∙m) for various biomasses densified at various pressures.

- The cooling experiment for thermal conductivity determination allowed for a more precise adjustment of the theoretical temperature to the experimental data. This can be caused by the lower impact of the thermocouple wiring system on heat conduction and additionally, the impact of the heat convection may be marginal.

- The proposed methodology for determining the thermal conductivity for biomass-based briquettes can be considered a useful tool for other low-conductivity materials.

- The destructive force is strictly in line with the compaction pressure.

- The temperature of the compaction process of 200 °C can be considered optimal regarding direct briquetting after the torrefaction process has taken place at a typical temperature range between 200 and 260 °C.

- The compaction pressure of 200 bar has been proposed as an optimal compaction pressure due to economic considerations related to the energy required for the compaction process.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Li, Q.; Quan, H.; Xu, X.; Wang, Q.; Ni, S. Assessment on the Properties of Biomass-Aggregate Geopolymer Concrete. Appl. Sci. 2022, 12, 3561. [Google Scholar] [CrossRef]

- Gorzelany, J.; Zardzewiały, M.; Murawski, P.; Matłok, N. Analysis of Selected Quality Features of Wood Pellets. Agric. Eng. 2020, 24, 25–34. [Google Scholar] [CrossRef]

- Sova, D.; Porojan, M.; Bedelean, B.; Huminic, G. Effective Thermal Conductivity Models Applied to Wood Briquettes. Int. J. Therm. Sci. 2018, 124, 1–12. [Google Scholar] [CrossRef]

- Rbihi, S.; Laallam, L.; Sajieddine, M.; Jouaiti, A. Characterization and Thermal Conductivity of Cellulose Based Composite Xerogels. Heliyon 2019, 5, e01704. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Hou, S.; Shen, Z.; Wen, J.; Qi, C. Thermal Characteristics and Simulation of Enzymatic Lignin Isolated from Chinese Fir and Birch. Forests 2022, 13, 914. [Google Scholar] [CrossRef]

- Markowski, J. Assessment of the Susceptibility of Biomass to Attempts at Improving the Durability of Pellets. Nafta-Gaz 2020, 76, 965–968. [Google Scholar] [CrossRef]

- Dyjakon, A.; Sobol, Ł.; Krotowski, M.; Mudryk, K.; Kawa, K. The Impact of Particles Comminution on Mechanical Durability of Wheat Straw Briquettes. Energies 2020, 13, 6186. [Google Scholar] [CrossRef]

- Lemos, L.R.; da Rocha, S.H.F.S.; de Castro, L.F.A.; Assunção, G.B.M.; Silva, G.L.R. da Mechanical Strength of Briquettes for Use in Blast Furnaces. REM-Int. Eng. J. 2019, 72, 63–69. [Google Scholar] [CrossRef][Green Version]

- Bembenek, M. Badania Wpływu Kształtu Powierzchni Roboczej Walców Na Efekty Pracy Prasy Walcowej; Praca dokt.; Akademia Górniczo-Hutnicza im. St.Staszica w Krakowie: Kraków, Poland, 2010. [Google Scholar]

- Borowski, G. Porównanie Dwóch Sposobów Określenia Wytrzymałości Brykietów z MateriałóW Drobnoziarnistych. Postępy Nauk. i Tech. 2012, 12, 115–121. [Google Scholar]

- Niedziółka, I.; Szpryngiel, M. Wpływ Temperatury Na Gęstość i Trwałość Brykietów Wytworzonych w Brykieciarce Ślimakowej. Inżynieria Rol. 2013, 3, 301–310. [Google Scholar]

- Chin, O.C.; Siddiqui, K.M. Characteristics of Some Biomass Briquettes Prepared under Modest Die Pressures. Biomass Bioenergy 2000, 18, 223–228. [Google Scholar] [CrossRef]

- O’Dogerty, M.J. A Review of the Mechanical Behaviour of Straw When Compressed to High Densities. J. Agric. Engng. Res. 1989, 44, 241–265. [Google Scholar] [CrossRef]

- Nikiforov, A.S.; Prikhodko, E.V.; Kinzhibekova, A.K.; Nurkina, S.M. Study of Strength Characteristics of Fuel Briquettes from Organic Waste. AIP Conf. Proc. 2020. [Google Scholar] [CrossRef]

- Plíštil, D.; Brožek, M.; Malaťák, J.; Roy, A.; Hutla, P. Mechanical Characteristics of Standard Fuel Briquettes on Biomass Basis. Res. Agric. Eng. 2012, 51, 66–72. [Google Scholar] [CrossRef]

- Rahman, A.N.E.; Aziz Masood, M.; Prasad, C.S.N.; Venkatesham, M. Influence of Size and Shape on the Strength of Briquettes. Fuel Process. Technol. 1989, 23, 185–195. [Google Scholar] [CrossRef]

- Kaliyan, N.; Vance Morey, R. Factors Affecting Strength and Durability of Densified Biomass Products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Chłopek, M. Ciśnieniowa Aglomeracja Kompozytowych Paliw Stałych; Rozprawa d.; Akademia Górniczo-Hutnicza im. Stanisława Staszica: Kraków, Poland, 2015. [Google Scholar]

- Roman, K. The Characteristics of Briquetting Process with Resistance Sensors Usage. Przegląd Elektrotechniczny 2019, 1, 100–103. [Google Scholar] [CrossRef]

- Rejdak, M.; Czardybon, A.; Ignasiak, K.; Sobolewski, A.; Robak, J. Compaction Studies of Torrefied Willow. J. Ecol. Eng. 2017, 18, 183–192. [Google Scholar] [CrossRef]

- Swietochowski, A.; Lisowski, A.; Dabrowska-Salwin, M. Strength of Briquettes and Pellets from Energy Crops. In Proceedings of the 15th Internal Scientific Conference “Engineering for Rural Development”, Latvia University of Agriculture, Jelgava, Latvia, 25–27 May 2016; pp. 547–551. [Google Scholar]

- Temmerman, M.; Rabier, F.; Jensen, P. Comparative Study of Durability Test Methods for Pellets and Briquettes. Biomass Bioenergy 2006, 30, 964–972. [Google Scholar] [CrossRef]

- Jablonowski, N.D.; Kollmann, T.; Meiller, M.; Dohrn, M.; Müller, M.; Nabel, M.; Zapp, P.; Schonhoff, A.; Schrey, S.D. Full Assessment of Sida (Sida Hermaphrodita) Biomass as a Solid Fuel. GCB Bioenergy 2020, 12, 618–635. [Google Scholar] [CrossRef]

- Kitczak, T.; Jarnuszewski, G.; Łazar, E.; Malinowski, R. Sida Hermaphrodita Cultivation on Light Soil—A Closer Look at Fertilization and Sowing Density. Agronomy 2022, 12, 2715. [Google Scholar] [CrossRef]

| Coefficient a | Coefficient b | R2 | |

|---|---|---|---|

| Briquettes at T = 200 °C | 195 | −496 | 0.997 |

| Briquettes at T = 20 °C | 128 | −239 | 0.997 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kurtyka, M.; Szwaja, M.; Piotrowski, A.; Tora, B.; Szwaja, S. Thermal and Stress Properties of Briquettes from Virginia Mallow Energetic Crops. Materials 2022, 15, 8458. https://doi.org/10.3390/ma15238458

Kurtyka M, Szwaja M, Piotrowski A, Tora B, Szwaja S. Thermal and Stress Properties of Briquettes from Virginia Mallow Energetic Crops. Materials. 2022; 15(23):8458. https://doi.org/10.3390/ma15238458

Chicago/Turabian StyleKurtyka, Marek, Magdalena Szwaja, Andrzej Piotrowski, Barbara Tora, and Stanislaw Szwaja. 2022. "Thermal and Stress Properties of Briquettes from Virginia Mallow Energetic Crops" Materials 15, no. 23: 8458. https://doi.org/10.3390/ma15238458

APA StyleKurtyka, M., Szwaja, M., Piotrowski, A., Tora, B., & Szwaja, S. (2022). Thermal and Stress Properties of Briquettes from Virginia Mallow Energetic Crops. Materials, 15(23), 8458. https://doi.org/10.3390/ma15238458