Erosion Resistance of Valve Core Surface Combined with WC-10Co-4Cr Coating Process under Different Pretreatments

Abstract

:1. Introduction

2. Experimental Design

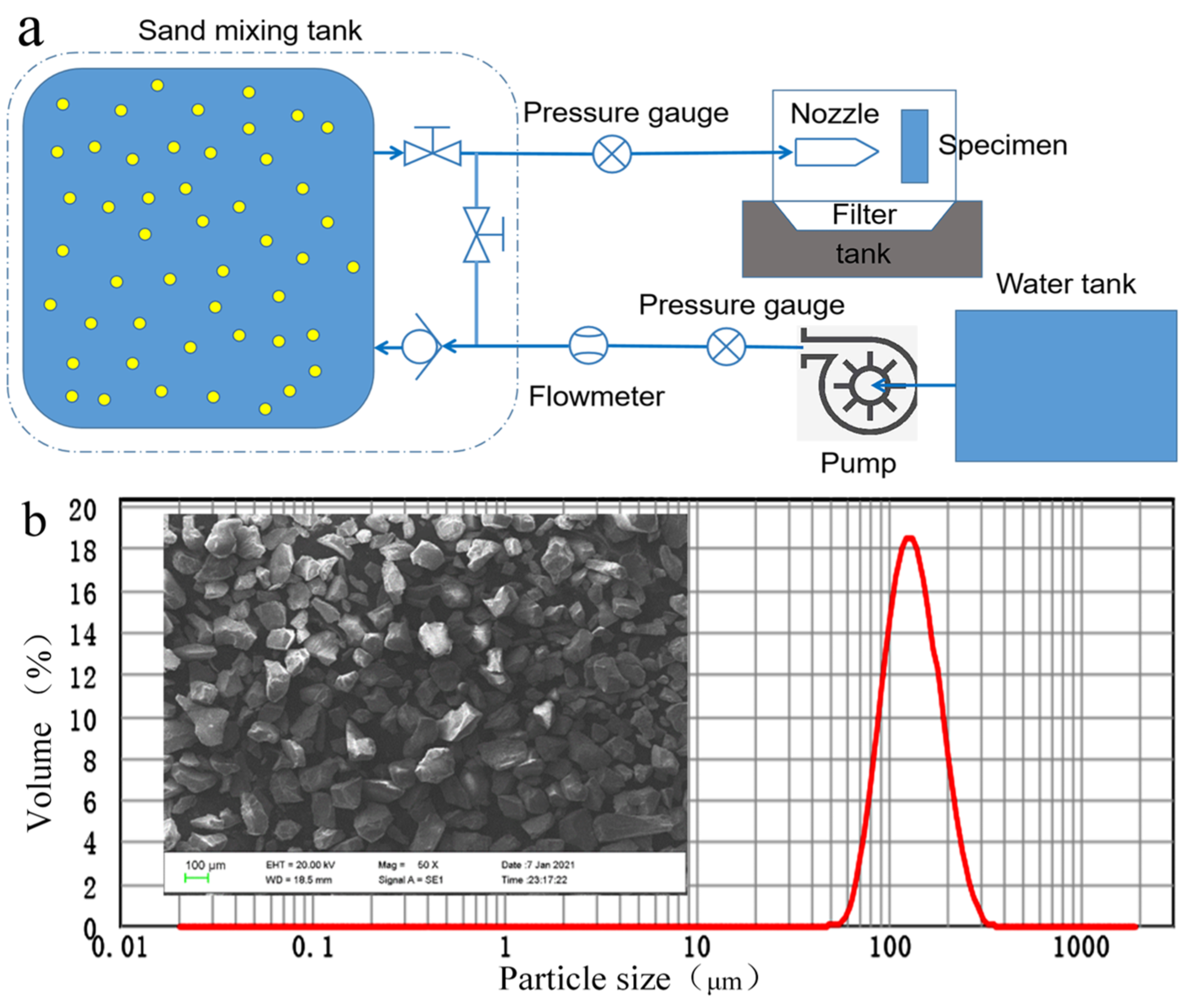

2.1. Unit Erosion Test Design of WC Coating Coupon under Different Pretreatment

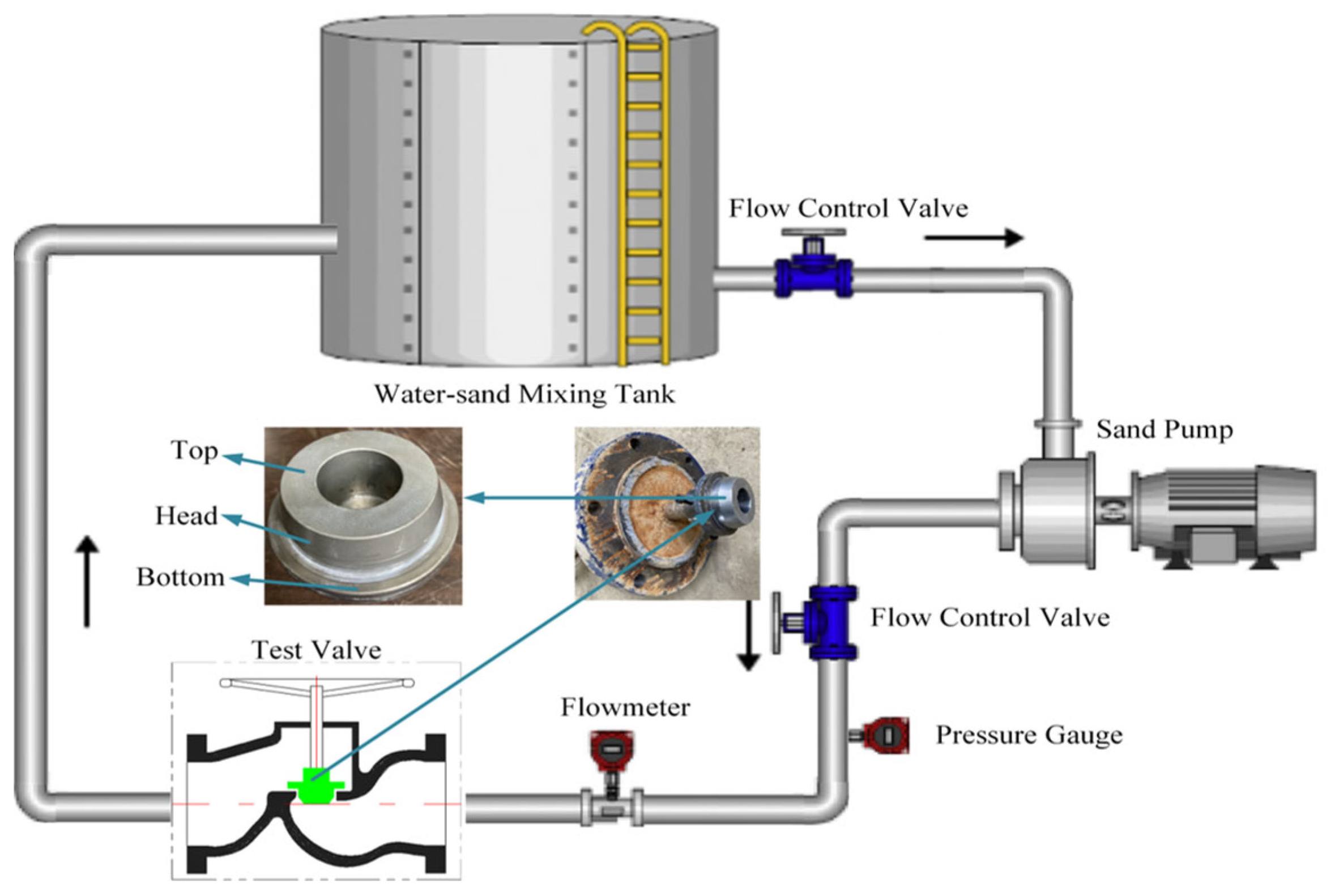

2.2. Valve Erosion Test Design of Valve Core under Different Pretreatment

3. Result and Discussion

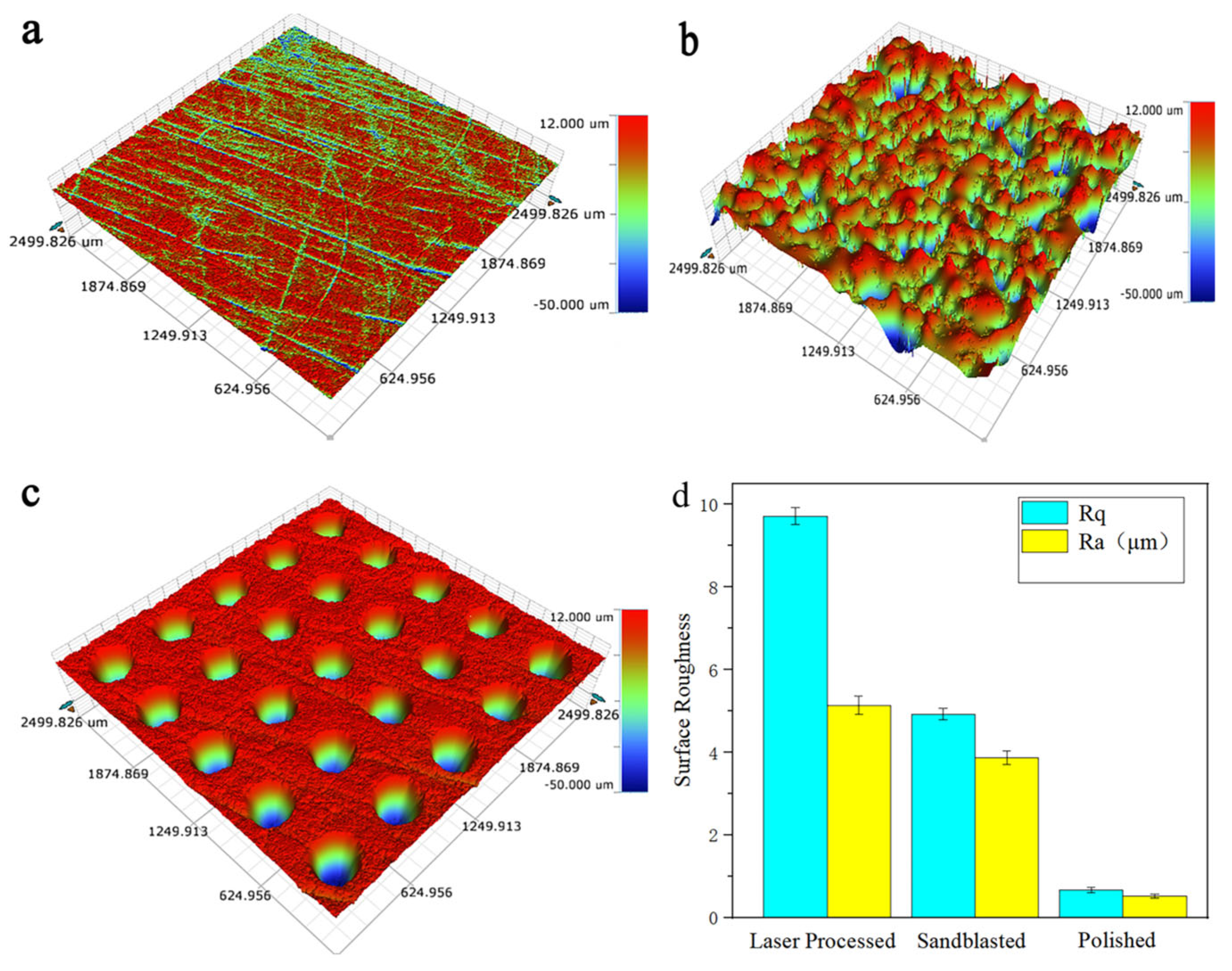

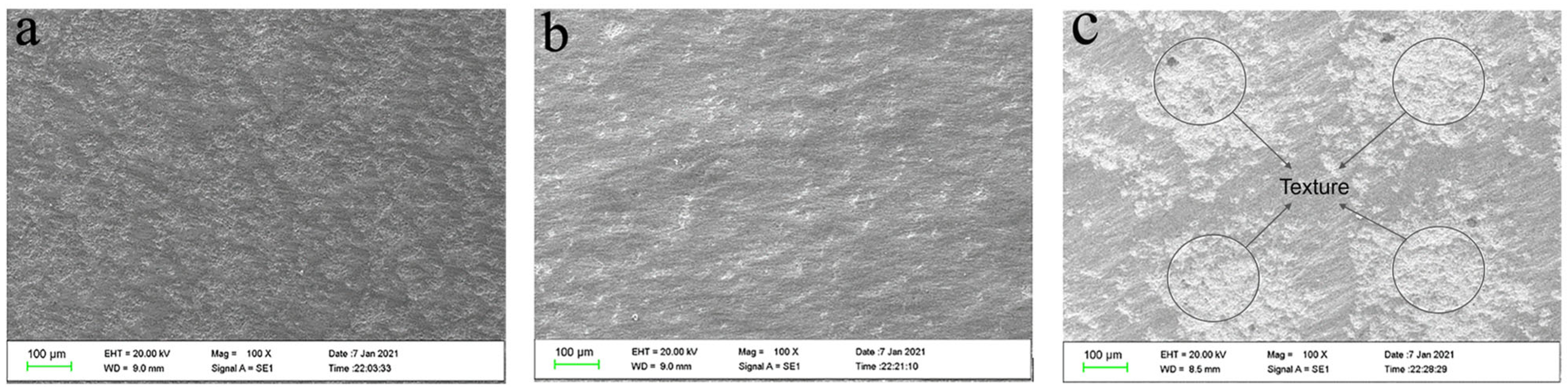

3.1. Three-Dimensional Morphology Characterization of Substrate Coupons under Different Pretreatments

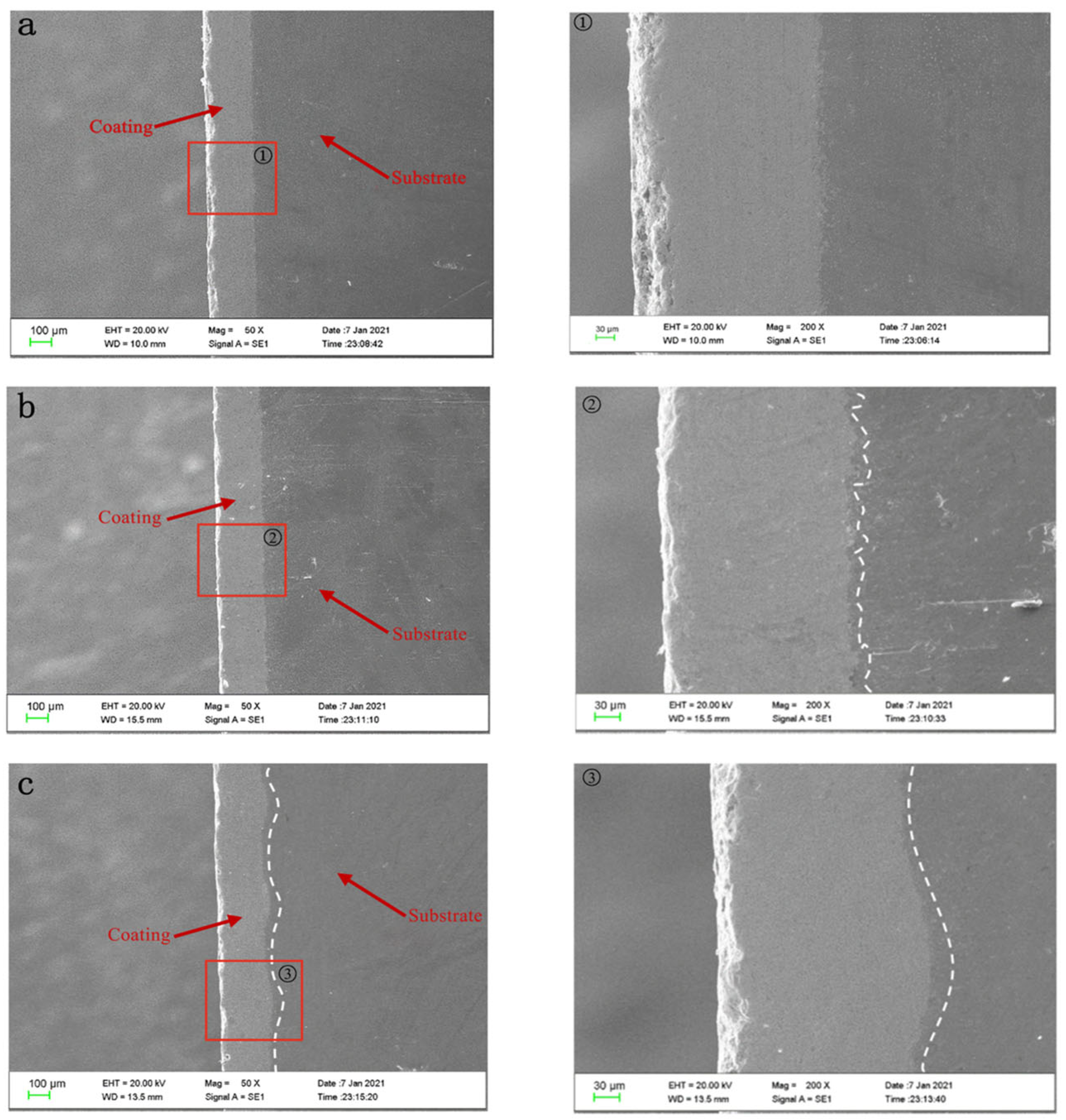

3.2. Characterization of the Bonding Properties of WC-10Co-4Cr Coatings Sprayed on Coupons under Different Pretreatments

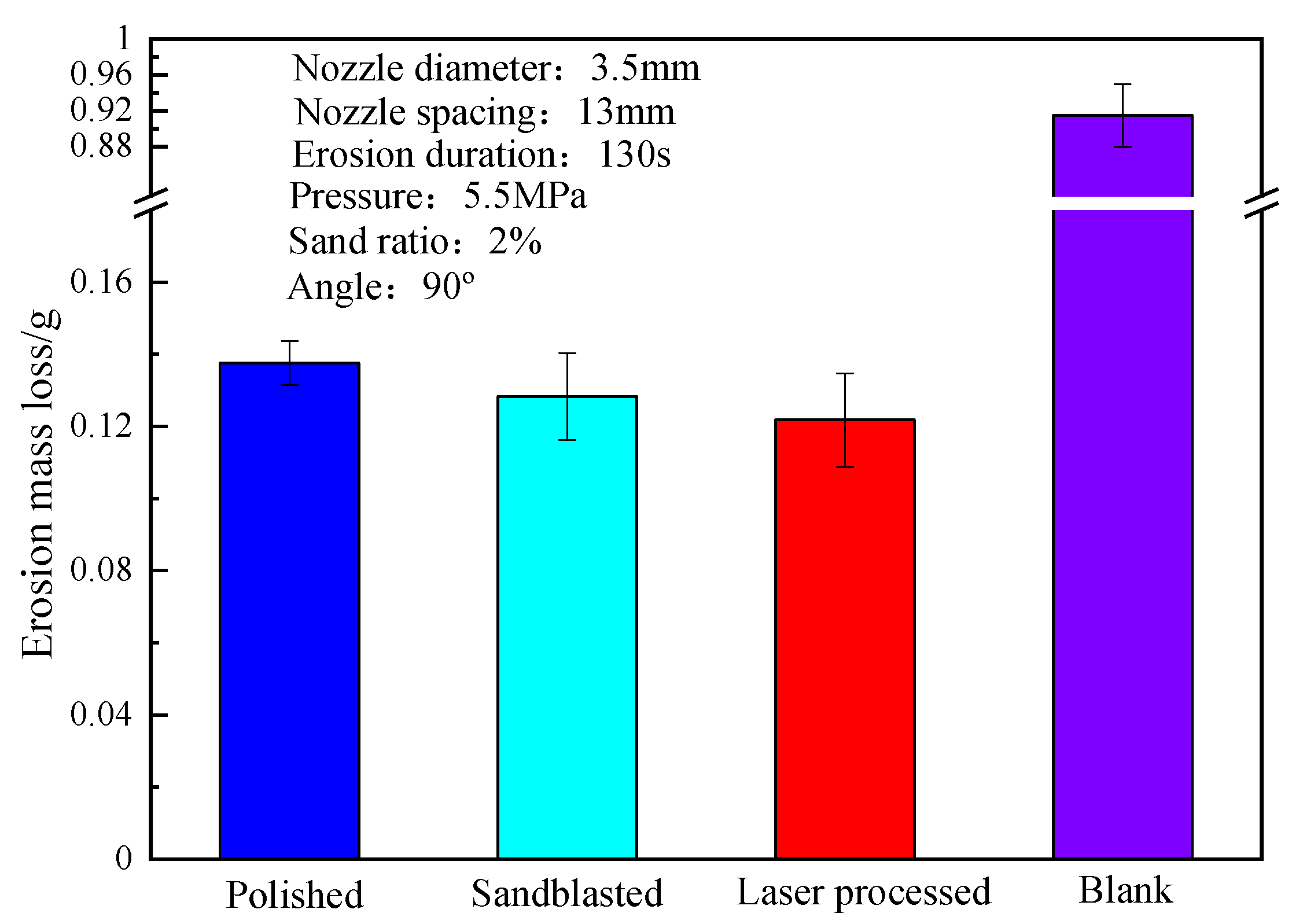

3.3. Erosion Performance Analysis of WC-10Co-4Cr Coating Coupons under Different Pretreatments

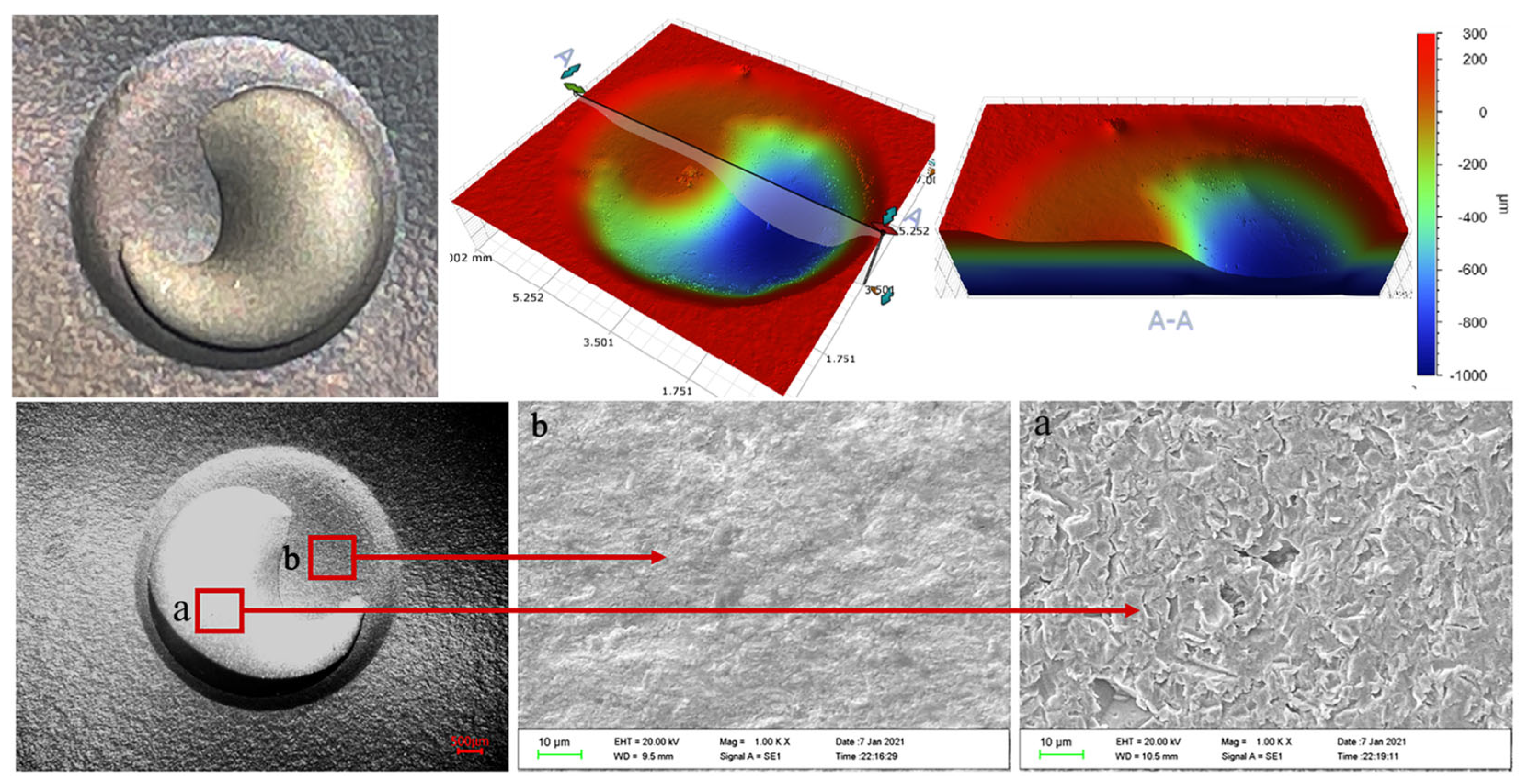

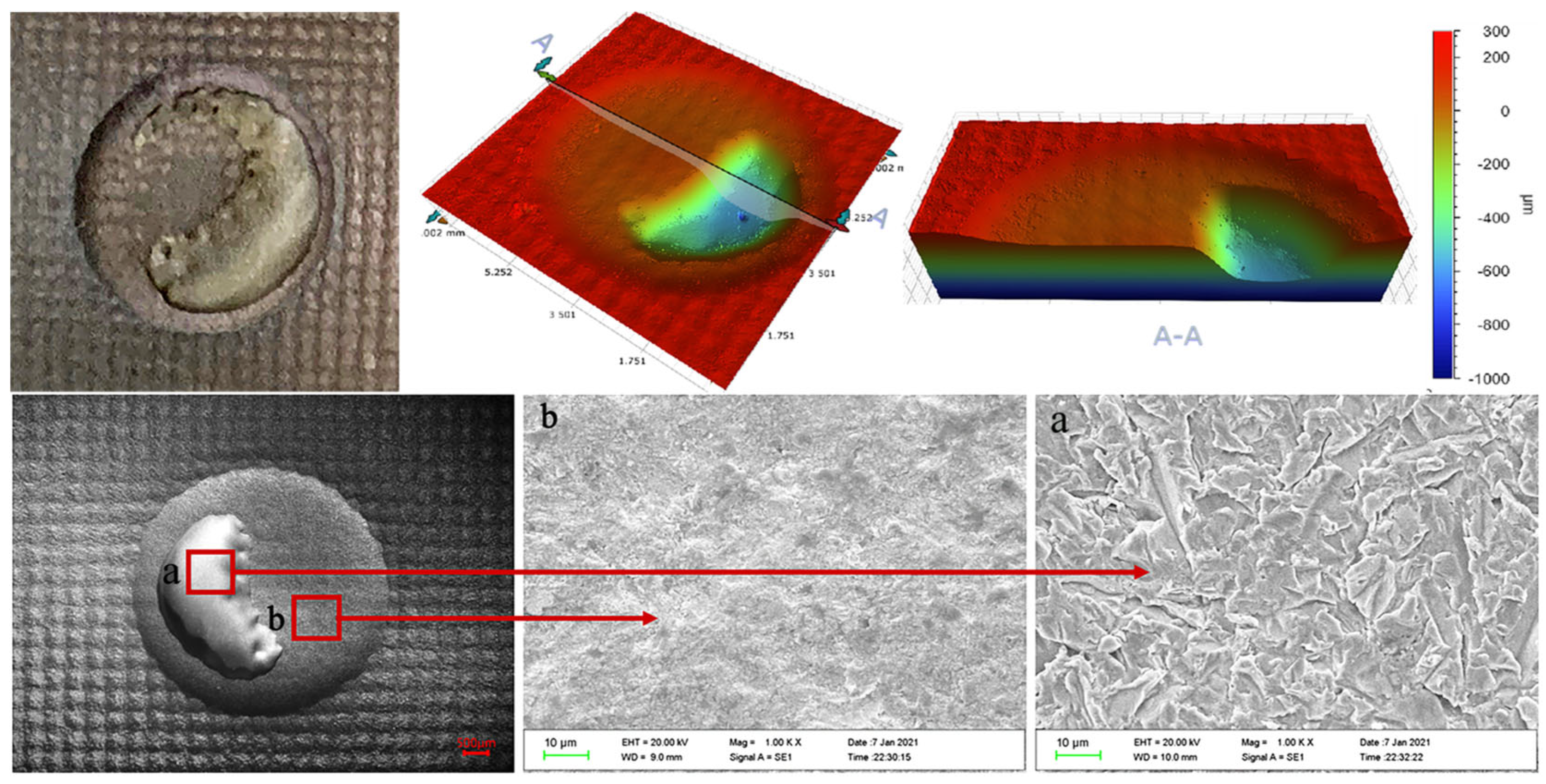

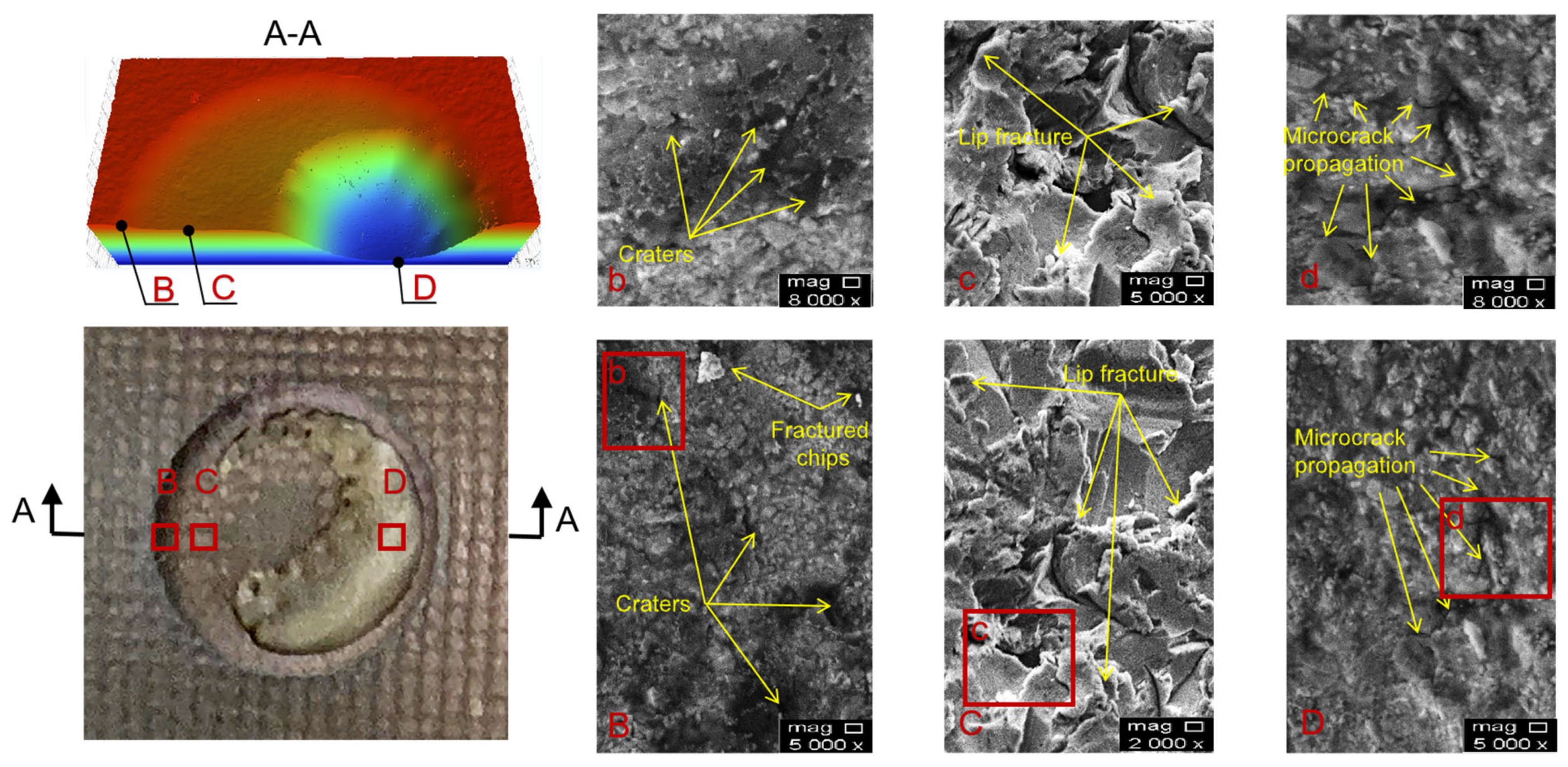

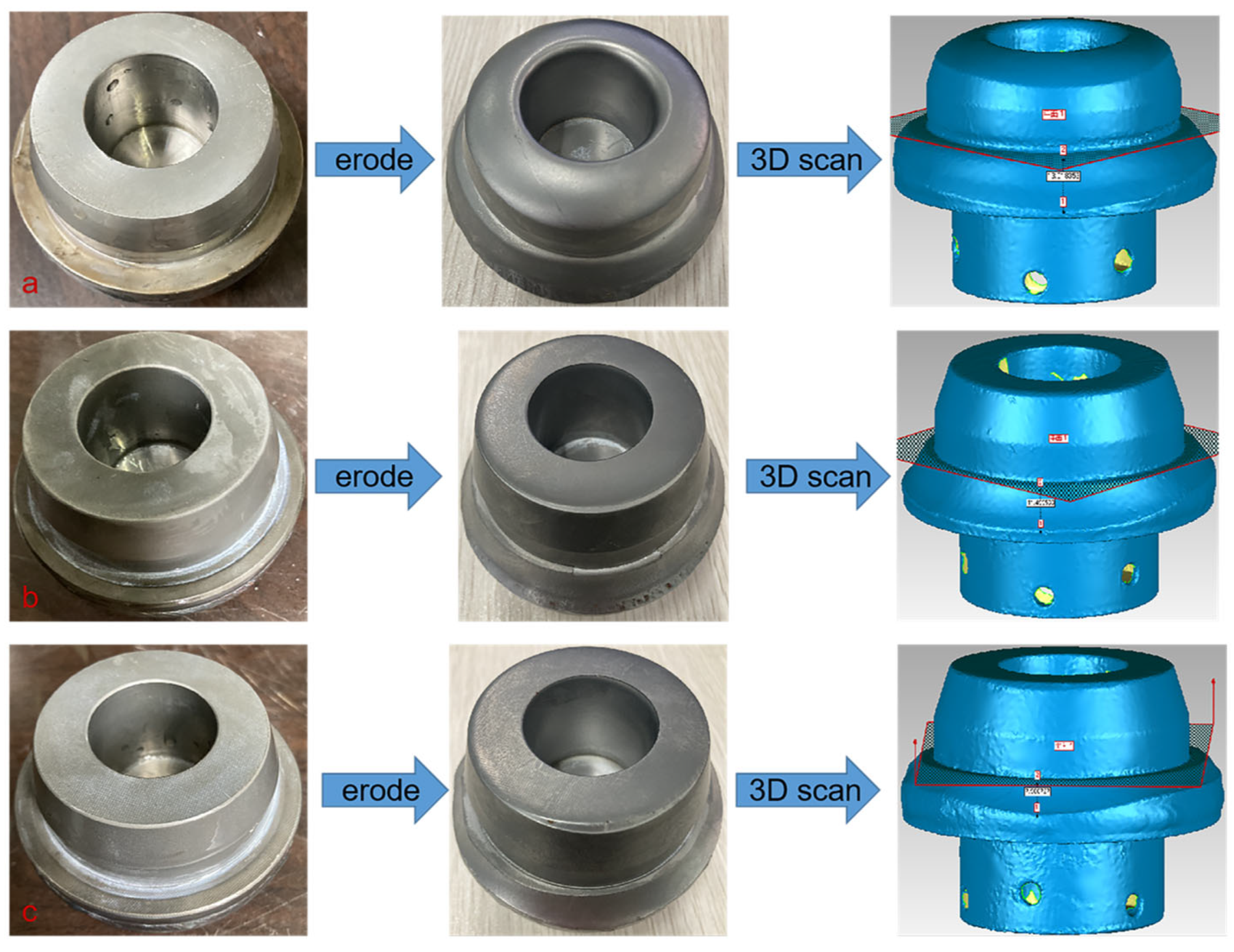

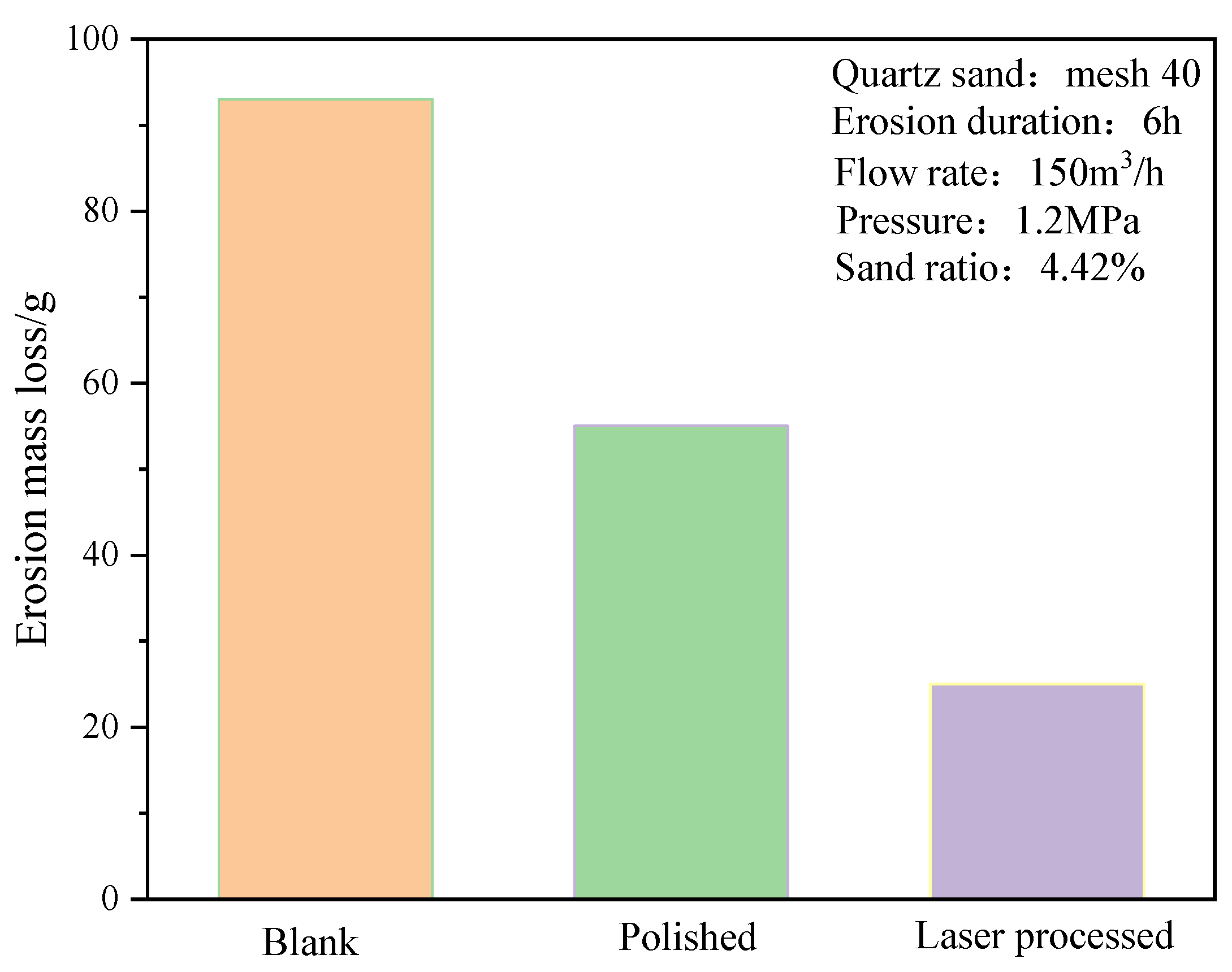

3.4. Erosion Test of Texture Coating Valve Core

4. Conclusions

- (1)

- The bonding interface of the texture coating samples is wavy, and the roughness of the textured substrate is higher than that of the polishing or grit blasting treatment substrate, which effectively increases the bonding area between the coating and the substrate.

- (2)

- The erosion test data of different pretreated WC-10Co-4Cr coating coupons show that, compared with polishing or grit blasting pretreatment, the volume loss is reduced by about 31.98% and 11.27%, respectively. Therefore, the texture coupling coating process on the surface of the substrate effectively improves the erosion resistance of coating specimens.

- (3)

- The valve erosion data of the full-size texture coating valve core show that, compared with the polishing or grit blasting pretreatment valve core, the volume loss depth of the bottom surface of the texture coating pretreatment valve core is reduced by 5.04 mm and 3.6 mm, respectively. This study verifies the feasibility of the laser texture treatment coupling coating process as a way to improve the erosion resistance of coating specimens, and it provides experimental support for its application.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shetty, D.K.; Wright, I.G.; Clauer, A.H. Effects of composition and microstructure on the slurry erosion of WC-Co cermets. Wear 1987, 114, 1–18. [Google Scholar] [CrossRef]

- Pugsley, V.A.; Allen, C. Microstructure/property relationships in the slurry erosion of tungsten carbide–Cobalt. Wear 1999, 225–229, 1017–1024. [Google Scholar] [CrossRef]

- Li, F.U.; Chen, X.M.; Ma, H.H.; Liu, W.; Meng, J.B. Performance of anti-erosion coating sprayed by explosive spraying on fluid machinery. Mater. Sci. Eng. Powder Metall. 2019, 24, 75–79. [Google Scholar] [CrossRef]

- Yang, Q.; Seo, D.Y.; Zhao, L.R.; Zeng, X.T. Erosion resistance performance of magnetron sputtering deposited TiAlN coatings. Surf. Coat. Technol. 2005, 188, 168–173. [Google Scholar] [CrossRef]

- Huang, D.; He, W.; Lyu, C.; Cao, X.; Liao, B.; Wang, S. Effects of ions implantation on adhesion strength and sand erosion resistance of TiN/Ti coatings on TC4 titanium alloy. Surf. Technol. 2020, 49, 184–191. [Google Scholar] [CrossRef]

- Wang, H.R.; Zhang, G.H.; Li, S.; Liu, Y. Study on Sandwear-withstand Test with HVOF Spraying WC-10Co-4Cr Coating. Dongfang Electr. Rev. 2011, 25, 41–47. [Google Scholar] [CrossRef]

- Yang, Z.X.; Liu, M.; Deng, C.M.; Deng, C.M.; Che, X.Z. Review on the Pretreatment of Substrate for Thermal Spray Process. China Surf. Eng. 2012, 25, 8–14. [Google Scholar] [CrossRef]

- Zhang, K.D.; Guo, X.H.; Wang, C.Y.; Liu, F.; Sun, L.N. Effect of plasma-assisted laser pretreatment of hard coatings surface on the physical and chemical bonding between PVD soft and hard coatings and its resulting properties. Appl. Surf. Sci. 2020, 509, 145342. [Google Scholar] [CrossRef]

- Zhang, X.C.; Gong, J.M.; Tu, S.D.; Kong, F.Y. Study on the Effect of Coating Defects on the Coating Failure and Corrosion Behavior of Substrate. China Surf. Eng. 2003, 21, 922–926. [Google Scholar]

- Ji, Z.H.; Wang, H.Y.; Sun, Z.; Ding, K.Y. Effect of interfacial bonding properties of WC-17Co / Ti-6Al-4V after roughening on the face of substrate. Trans. China Weld. Inst. 2018, 39, 77–81+132. [Google Scholar]

- Jiang, X.Y.; Wan, Y.P.; Herman, H.; Sampath, S. Role of condensates and adsorbates on substrate surface on fragmentation of impinging molten droplets during thermal spray. Thin Solid Films 2001, 385, 132–141. [Google Scholar] [CrossRef]

- Kromer, R.; Costil, S.; Cormier, J.; Courapied, D.; Berthe, L.; Peyre, P.; Boustie, M. Laser surface patterning to enhance adhesion of plasma sprayed coatings. Surf. Coat. Technol. 2015, 278, 171–182. [Google Scholar] [CrossRef]

- Neves, D.; Diniz, A.E.; Lima, M.S.F. Microstructural analyses and wear behavior of the cemented carbide tools after laser surface treatment and PVD coating. Appl. Surf. Sci. 2013, 282, 680–688. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Deng, J.X.; Zhang, G.L.; Ge, D.L.; Wang, W.; Liu, Y.Y. Research on Effect from Nano Texturing of Matrix Surface to Coalescent Force of AlCrN Coating Tool. Tool Eng. 2017, 51, 17–21. [Google Scholar]

- Zhang, K.; Deng, J.; Guo, X.; Sun, L.; Lei, S. Study on the adhesion and tribological behavior of PVD TiAlN coatings with a multi-scale textured substrate surface. Int. J. Refract. Metals Hard Mater. 2018, 72, 292–305. [Google Scholar] [CrossRef]

- Tang, P.; Liu, L.X.; Cao, D.P.; Gao, X.; Liu, X.S.; Tao, J.F. Review on Adhesion Mechanism and Adhesion Enhancement of Organic Coatings. Mater. Prot. 2020, 53, 126–135. [Google Scholar] [CrossRef]

- Lamraoui, A.; Costil, S.; Langlade, C.; Coddet, C. Laser surface texturing (LST) treatment before thermal spraying: A new process to improve the substrate-coating adherence. Surf. Coat. Technol. 2010, 205, S164–S167. [Google Scholar] [CrossRef]

- Feng, A.X.; Wang, B.; He, Y.; Yang, R.; Liu, Y.; Zhong, G.Q. Study on Influence of Laser Micro-texture on Bonding Properties of Cemented Carbide Ti AlN Coating. Hot Work. Technol. 2017, 46, 155–158. [Google Scholar] [CrossRef]

- Bao, Y.M.; Wang, C.W.; Jin, Z.W.; Wu, X.; Bao, J. Textured Surface on a Bioceramic Coating via a Femtosecond Laser and its Friction and Wear Properties. Chin. J. Lasers 2019, 46, 77–85. [Google Scholar]

- Qi, P.H.; Tong, Z.; Liu, Q.; Li, Y.; Dong, G.N. Tribological Properties of DLC Coated Textured Surfaces under Grease Lubrication. Surf. Technol. 2021, 50, 296–304. [Google Scholar] [CrossRef]

- Wahab, J.A.; Ghazali, M.J. Erosion resistance of laser textured plasma-sprayed Al2o3-13%Tio2 coatings on mild steel. Wear 2019, 432–433, 202–937. [Google Scholar] [CrossRef]

- Zhang, K.D.; Deng, J.X.; Meng, R.; Lei, S.T.; Yu, X.M. Influence of laser substrate pretreatment on anti-adhesive wear properties of WC/Co-based TiAlN coatings against AISI 316 stainless steel. Int. J. Refract. Metals Hard Mater. 2016, 57, 101–114. [Google Scholar] [CrossRef]

- Han, Z.W.; Zhang, J.Q.; Ge, C.; Wang, C.F.; Ren, Q.L. Gas-solid erosion wear on bionic configuration surface. J. Jilin Univ. (Eng. Technol. Ed.) 2009, 6, 1512–1515. [Google Scholar] [CrossRef]

- Wang, L.; Guo, S.; Wei, Y.; Yuan, G.; Geng, H. Optimization research on the lubrication characteristics for friction pairs surface of journal bearings with micro texture. Meccanica 2019, 54, 1135–1148. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, S.; Zhang, H.; Lin, J.; Chen, G. Effect of grit blasting pre-treatment on bond strength of TiAl-Nb/NiCrAl coatings sprayed by high velocity oxyfuel. Trans. Mater. Heat Treat. 2011, 32, 105–109. [Google Scholar]

- Qiao, J.; Zhu, L.; Yue, W.; Fu, Z.; Kang, J.; Wang, C. The effect of attributes of micro-shapes of laser surface texture on the wettability of WC-CrCo metal ceramic coatings. Surf. Coat. Technol. 2018, 334, 429–437. [Google Scholar] [CrossRef]

- Liu, X.B.; Kang, J.J.; Yue, W.; Fu, Z.Q.; Zhu, L.N.; Wang, C.B. Research Status of Erosion Failure Behavior of HVOF Sprayed Cermet Coatings. Mater. Rep. 2018, 32, 312–316. [Google Scholar]

- Han, Z.W.; Yin, W.; Zhang, J.Q.; Jiang, J.L.; Niu, S.C.; Ren, L.Q. Erosion-Resistant Surfaces Inspired by Tamarisk. J. Bionics Eng. 2013, 10, 479–487. [Google Scholar] [CrossRef]

- Bansal, A.; Goyal, D.K.; Singh, P.; Singla, A.K.; Gupta, M.K.; Bala, N.; Kolte, J.; Setia, G. Erosive wear behaviour of HVOF-sprayed Ni-20Cr2O3 coating on pipeline materials. Int. J. Refract. Metals Hard Mater. 2020, 92, 105332. [Google Scholar] [CrossRef]

- Sapate, S.G.; Tangselwar, N.; Paul, S.N.; Rathod, R.C.; Mehar, S.; Gowtam, D.S.; Roy, M. Effect of Coating Thickness on the Slurry Erosion Resistance of HVOF-Sprayed WC-10Co-4Cr Coatings. J. Therm. Spray Techn. 2021, 30, 1365–1379. [Google Scholar] [CrossRef]

- Wang, Y.J.; Hao, E.K.; An, Y.L.; Chen, J.M.; Zhou, H.D. Effects of microstructure and mechanical properties on cavitation erosion resistance of NiCrWMoCuCBFe coatings. Appl. Surf. Sci. 2021, 547, 149125. [Google Scholar] [CrossRef]

- Bao, Y.F.; Guo, L.P.; Zhong, C.H.; Song, Q.N.; Yang, K.; Jiang, Y.F.; Wang, Z.R. Effects of WC on the cavitation erosion resistance of FeCoCrNiB0.2 high entropy alloy coating prepared by laser cladding. Mater. Today Commun. 2021, 26, 102154. [Google Scholar] [CrossRef]

- Cai, L.X.; Li, Y.; Wang, S.S.; He, Y.; Li, F.; Liu, Z.K. Investigation of the Erosion Damage Mechanism and Erosion Prediction of Boronized Coatings at Elevated Temperatures. Materials 2021, 14, 123. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.C.; Li, G.L.; Wang, H.D.; Kang, J.J.; Lin, L. Microstructure and Erosion Wear of Supersonic Plasma Sprayed NiCr-Cr3C2 Coatings. Surf. Technol. 2016, 45, 32–37. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.; Duan, D.L.; Li, S. Slurry Erosion Behavior of HVOF Sprayed WC-Co-Cr Coatings at Different Impingement Angle. China Surf. Eng. 2011, 24, 11–18. [Google Scholar]

- Li, Z.; Farhat, Z.; Islam, M.A. Investigation of Single-Particle Erosion Behavior of Electroless Ni-P-Ti Composite Coatings. J. Mater. Eng. Perform. 2020, 29, 1671–1685. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Laser | MOPA adjustable pulse width fiber laser |

| Wavelength(nm) | 1064 |

| Laser frequency(kHz) | 800 |

| Power(W) | 10.5 |

| Scanning speed(mm/s) | 300 |

| Processing times(times) | 5 |

| Parameter | Value |

|---|---|

| Inlet water temperature | 15.3 °C |

| Outlet water temperature | 33 °C |

| Combustion chamber pressure (MPa) | 0.73 |

| Oxygen pressure (MPa) | 0.99 |

| Kerosene pressure (MPa) | 0.9 |

| Water flow (L/min) | 27 |

| Oxygen flow (m3/h) | 36 |

| Air pressure (MPa) | 0.8 |

| Powder delivery rate (g/min) | 50 |

| Spray distance (mm) | 230 |

| Fuel | Kerosene |

| powder | Tafa1350VM |

| Parameter | Value |

|---|---|

| Pressure (MPa) | 5.5 |

| Nozzle diameter (mm) | 3.5 |

| Nozzle distance (mm) | 13 |

| Volume sand ratio | 2% |

| Erosion duration (s) | 130 |

| Erosion angle | 90° |

| Parameter | Value |

|---|---|

| Pressure (MPa) | 1.2 |

| Flow rate (m3/h) | 15 |

| Mass sand ratio | 4.42% |

| Erosion duration (h) | 6 |

| Quartz sand (mesh) | 40 |

| Valve opening | 3 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhong, L.; Li, Z.; Wang, G.; He, H.; Wei, G.; Zheng, S.; Feng, G.; Xie, N.; Zhang, R. Erosion Resistance of Valve Core Surface Combined with WC-10Co-4Cr Coating Process under Different Pretreatments. Materials 2022, 15, 8140. https://doi.org/10.3390/ma15228140

Zhong L, Li Z, Wang G, He H, Wei G, Zheng S, Feng G, Xie N, Zhang R. Erosion Resistance of Valve Core Surface Combined with WC-10Co-4Cr Coating Process under Different Pretreatments. Materials. 2022; 15(22):8140. https://doi.org/10.3390/ma15228140

Chicago/Turabian StyleZhong, Lin, Zhichao Li, Guorong Wang, Haiyang He, Gang Wei, Sijia Zheng, Guihong Feng, Nana Xie, and Rongyao Zhang. 2022. "Erosion Resistance of Valve Core Surface Combined with WC-10Co-4Cr Coating Process under Different Pretreatments" Materials 15, no. 22: 8140. https://doi.org/10.3390/ma15228140

APA StyleZhong, L., Li, Z., Wang, G., He, H., Wei, G., Zheng, S., Feng, G., Xie, N., & Zhang, R. (2022). Erosion Resistance of Valve Core Surface Combined with WC-10Co-4Cr Coating Process under Different Pretreatments. Materials, 15(22), 8140. https://doi.org/10.3390/ma15228140