Mesosphere of Carbon-Shelled Copper Nanoparticles with High Conductivity and Thermal Stability via Direct Carbonization of Polymer Soft Templates

Abstract

1. Introduction

2. Materials and Methods

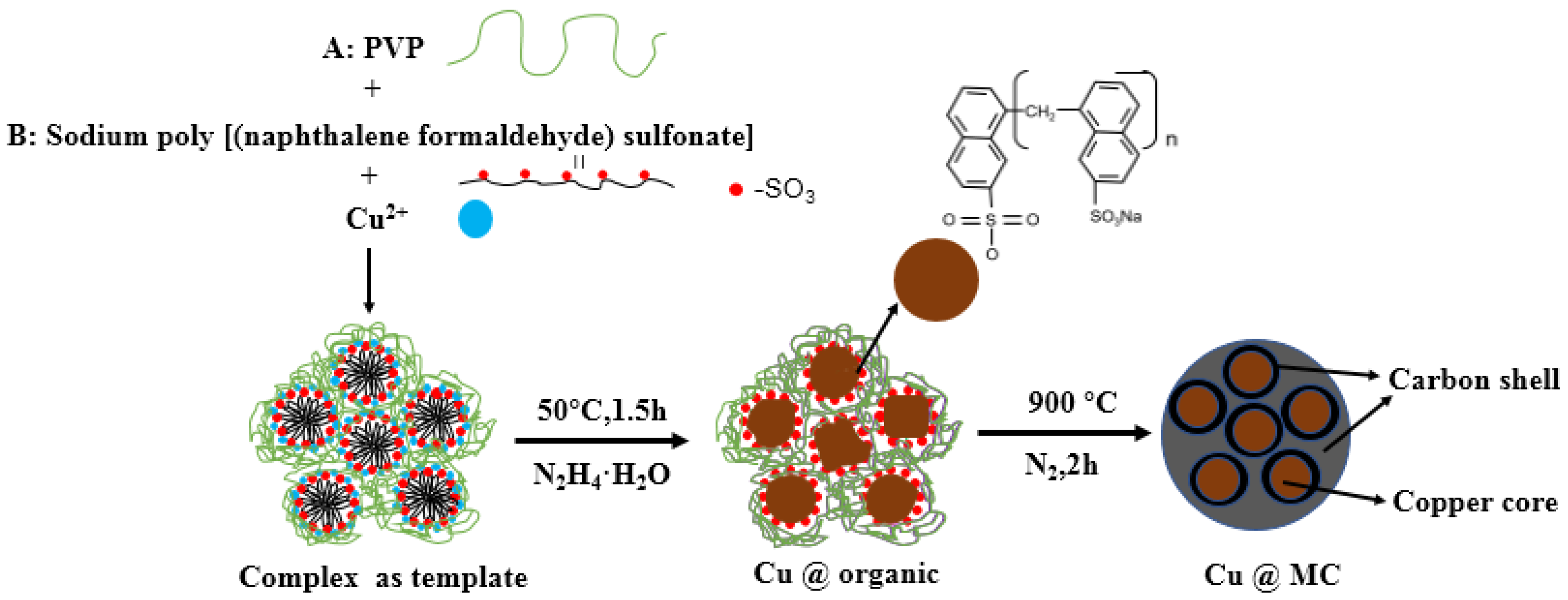

2.1. Preparation of Copper Nanoparticles Capped with Organic Layers (Cu@organic)

2.2. Preparation of Mesosphere of Carbon-Shelled Copper Nanoparticle (Cu@MC)

2.3. Preparation of Copper Nanoparticle-Based Conductive Paste (Cu Paste)

2.4. Characterization

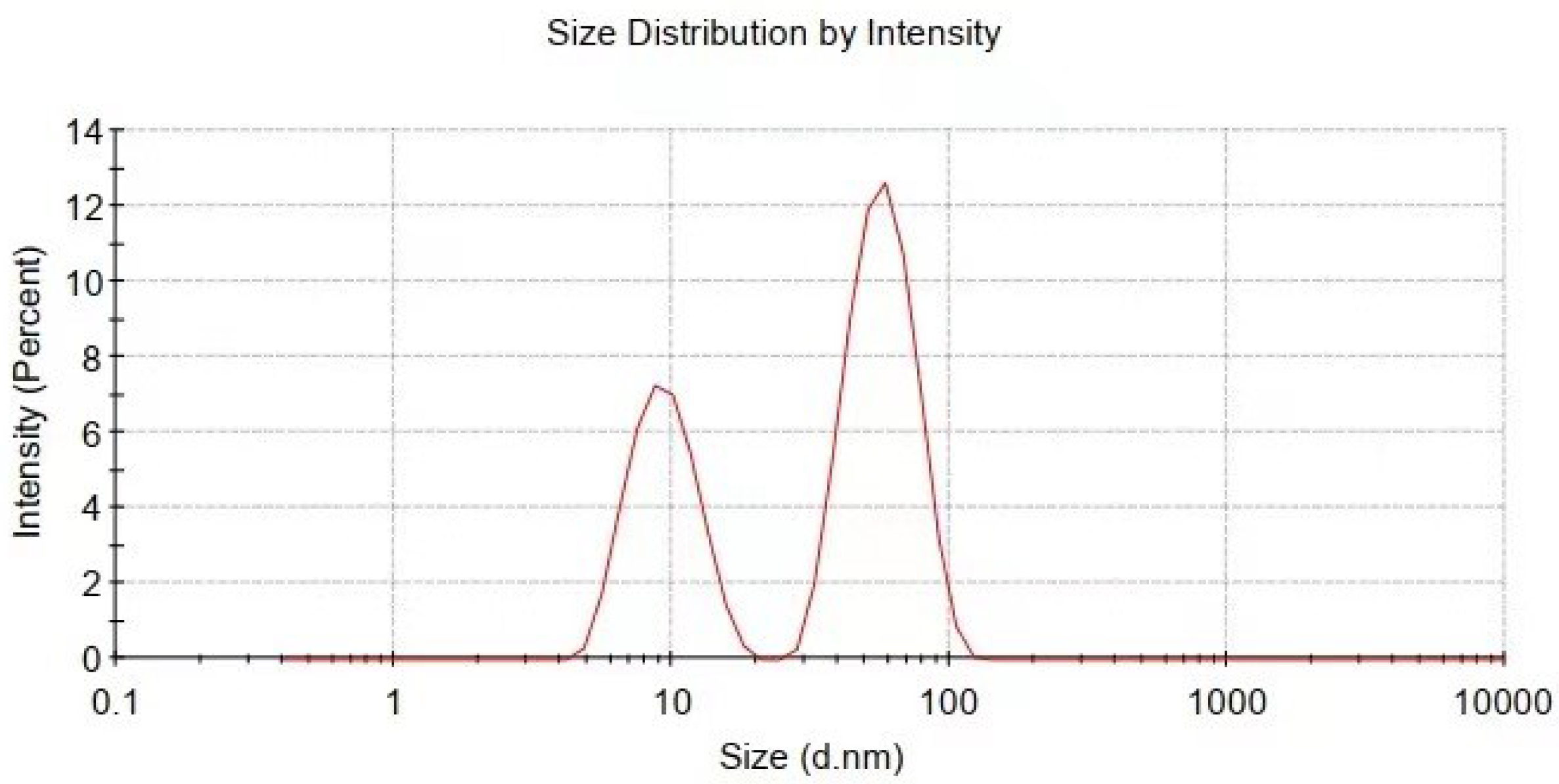

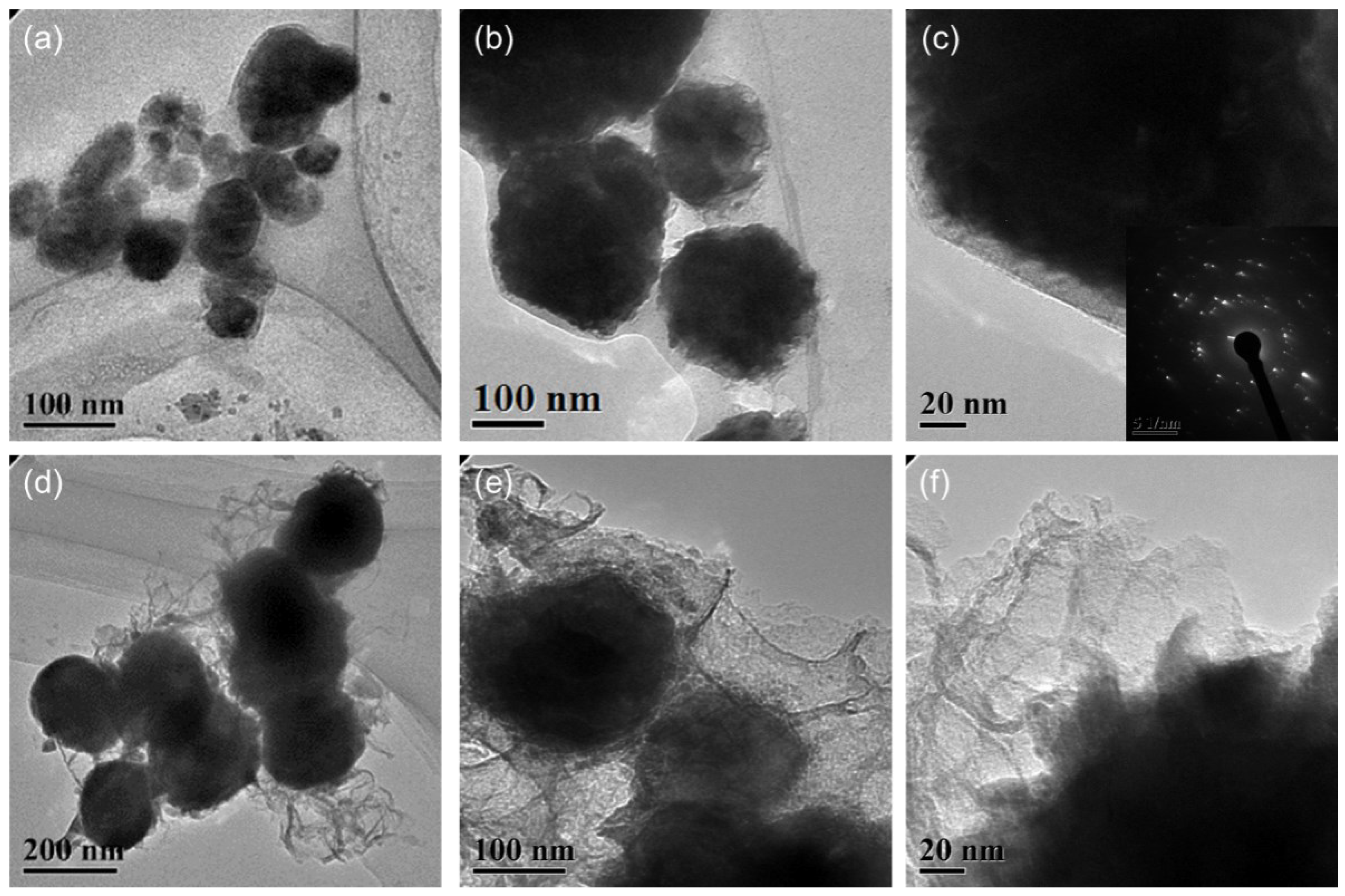

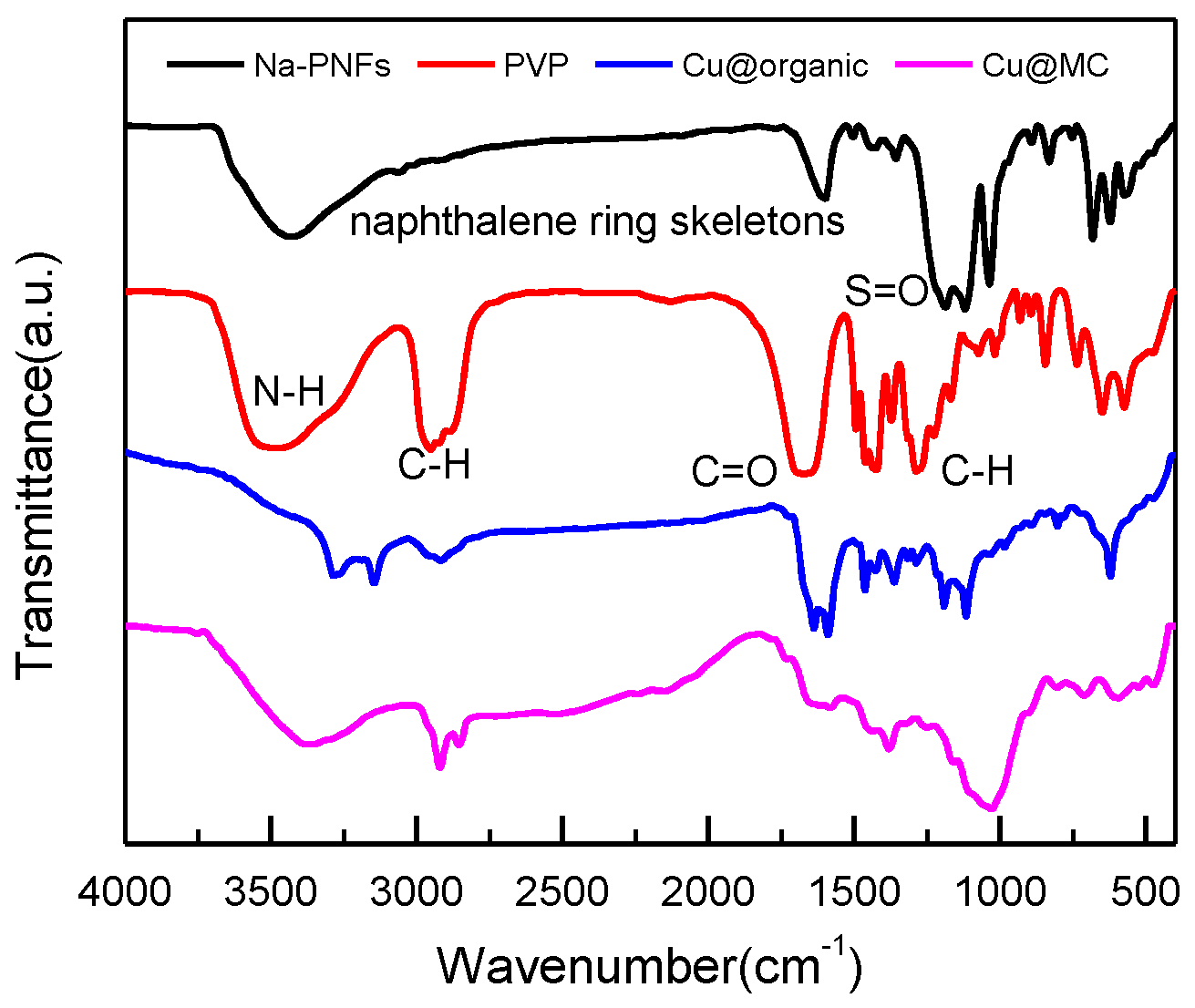

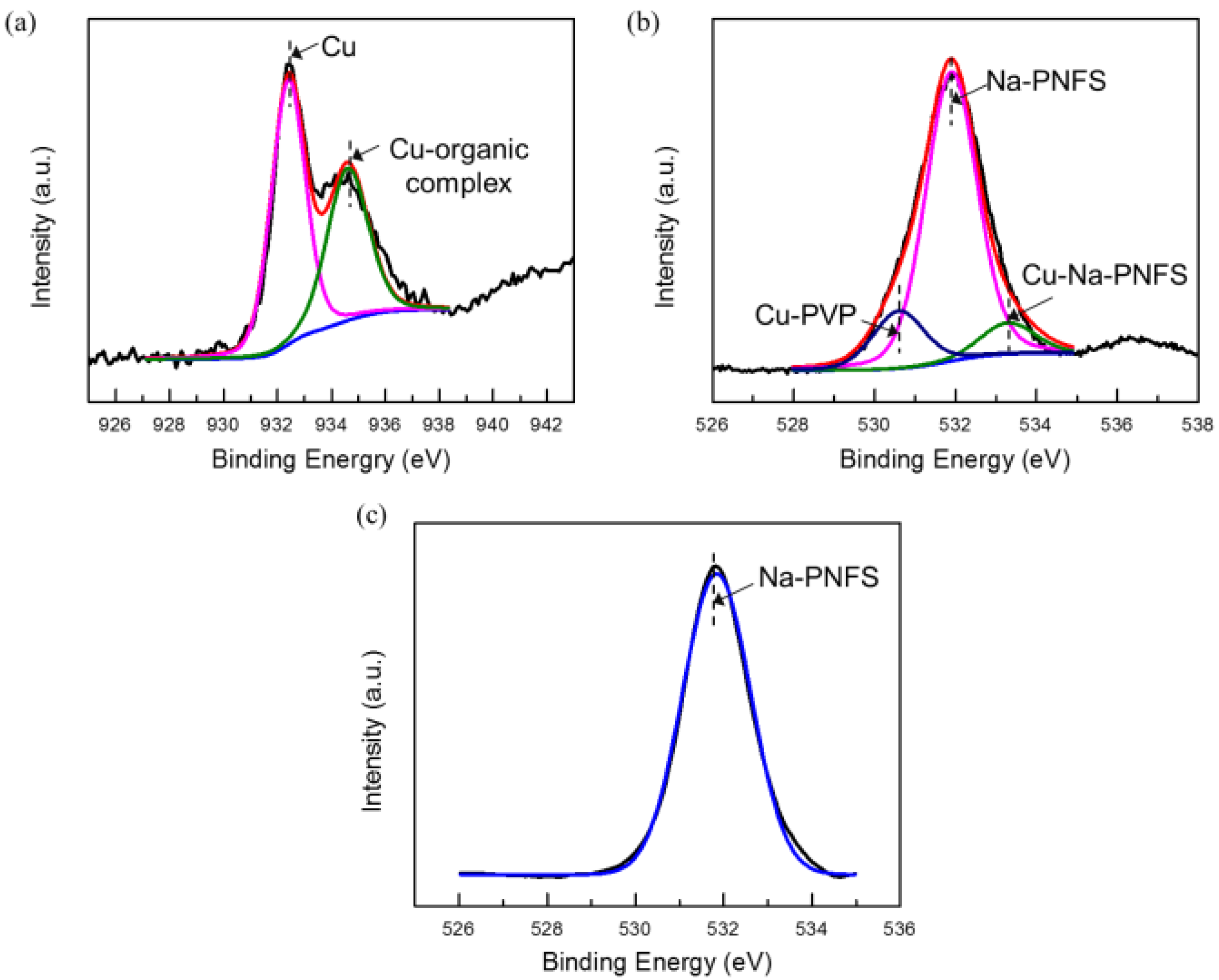

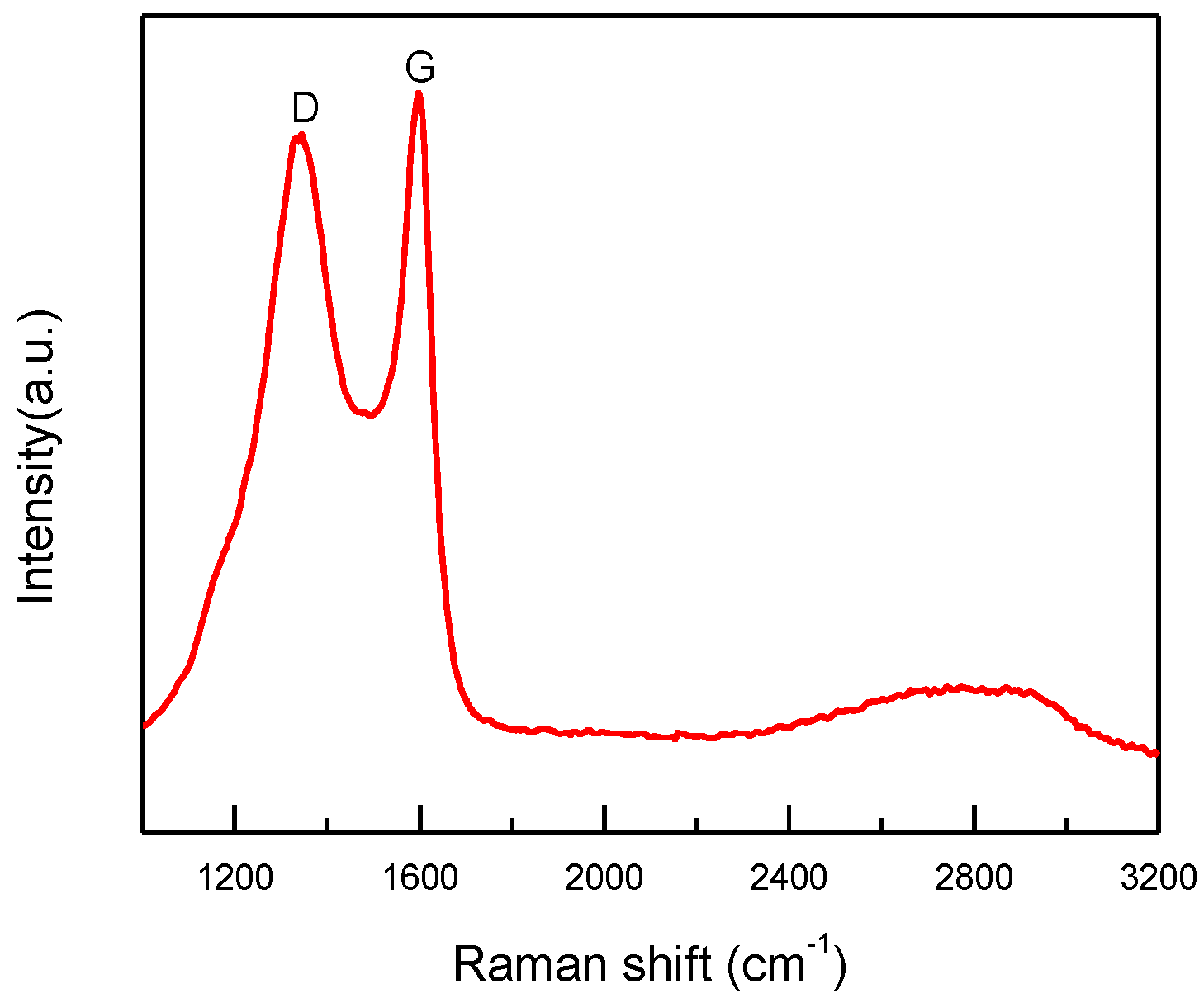

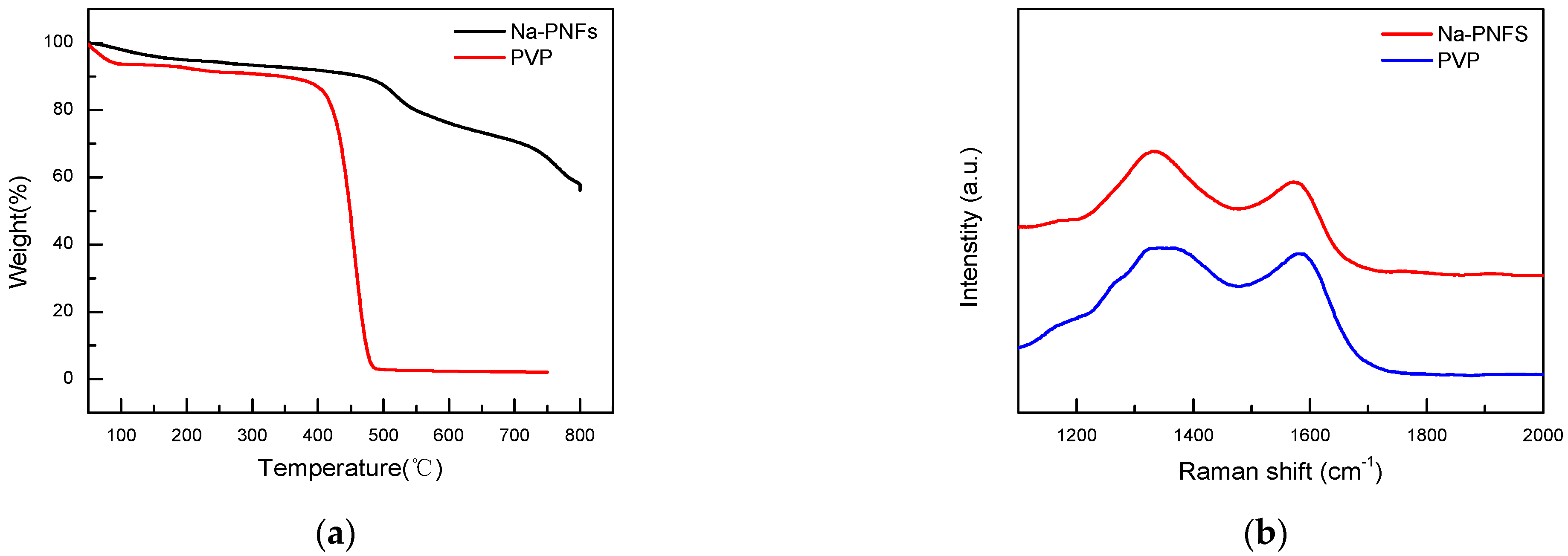

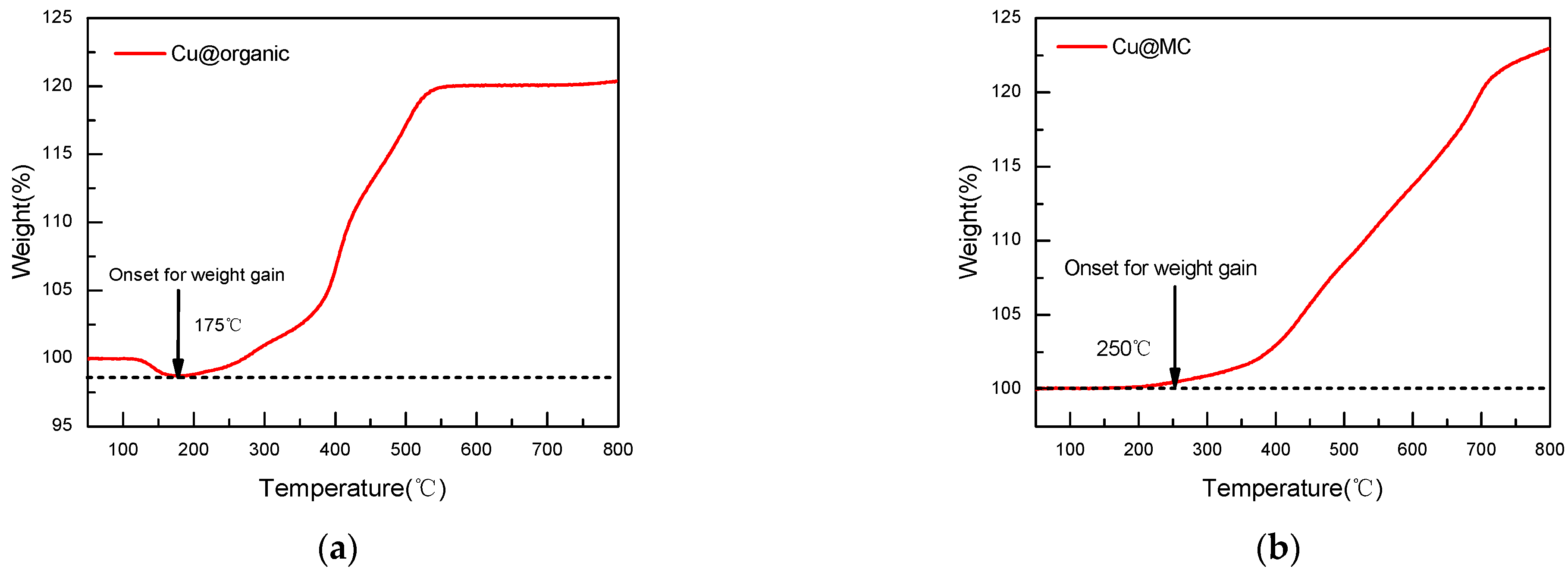

3. Results

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Magdassi, S.; Grouchko, M.; Kamyshny, A. Copper Nanoparticles for Printed Electronics: Routes Towards Achieving Oxidation Stability. Materials 2010, 3, 4626–4638. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Kim, N.R.; Koo, J.; Lee, Y.J.; Lee, H.M. Cu-Ag core–shell nanoparticles with enhanced oxidation stability for printed electronics. Nanotechnology 2015, 26, 455601. [Google Scholar] [CrossRef] [PubMed]

- Kim, N.R.; Shin, K.; Jung, I.; Shim, M.; Lee, H.M. Ag–Cu bimetallic nanoparticles with enhanced resistance to oxidation, a combined experi-mental and theoretical study. J. Phys. Chem. C 2014, 18, 26324–26331. [Google Scholar] [CrossRef]

- Yu, X.; Li, J.; Shi, T.; Cheng, C.; Liao, G.; Fan, J.; Tang, Z. A green approach of synthesizing of Cu-Ag core-shell nanoparticles and their sintering behaviour for printed electronics. J. Alloy. Compd. 2017, 724, 365–372. [Google Scholar] [CrossRef]

- Li, W.; Hu, D.; Li, L.; Li, C.-F.; Jiu, J.; Chen, C.; Ishina, T.; Sugahara, T.; Suganuma, K. Printable and Flexible Copper–Silver Alloy Electrodes with High Conductivity and Ultrahigh Oxidation Resistance. ACS Appl. Mater. Interfaces 2017, 9, 24711–24721. [Google Scholar] [CrossRef] [PubMed]

- Jianfeng, Y.; Guisheng, Z.; Anming, H.; Zhou, Y.N. Preparation of PVP coated Cu NPs and the application for low-temperature bonding. J. Mater. Chem. 2011, 21, 15981–15986. [Google Scholar] [CrossRef]

- Jeong, S.; Woo, K.; Kim, D.; Lim, S.; Kim, J.S.; Shin, H.; Moon, J. Controlling the thickness of the surface oxide layer on Cu nanoparticles for the fabrication of conductive structures by ink-jet printing. Adv. Funct. Mater. 2008, 18, 679–686. [Google Scholar] [CrossRef]

- Li, Y.; Li, D.; Li, C.; Wang, H.; Shen, D.; Liu, L.; Zou, G. Annealing-induced highly-conductive and stable Cu–organic composite nanoparticles with hierarchical structures. J. Alloy. Compd. 2015, 636, 1–7. [Google Scholar] [CrossRef]

- Ma, L.; Yu, B.; Wang, S.; Su, G.; Huang, H.; Chen, H.; He, Y.; Zou, J. Controlled synthesis and optical properties of Cu/C core/shell nanoparticles. J. Nanoparticle Res. 2014, 16, 2545. [Google Scholar] [CrossRef]

- Yue, R.; Ren, F.; Wang, C.; Xu, J.; Du, Y. Facile preparation of flower-like graphene-nanosheet clusters with the assistance of copper particles and their application in supercapacitors. RSC Adv. 2013, 4, 500–504. [Google Scholar] [CrossRef]

- Liu, B.; Jin, L.; Zheng, H.; Yao, H.; Wu, Y.; Lopes, A.; He, J. Ultrafine Co-based Nanoparticle@Mesoporous Carbon Nanospheres toward High-Performance Supercapacitors. ACS Appl. Mater. Interfaces 2017, 9, 1746–1758. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wei, R.; Zhang, B.; Lv, H.; Xu, D.; Hao, Q.; Liu, B. Template-Assisted Self-Sulfuration Formation of MoS2 Nanosheets Embedded in Ordered Mesoporous Carbon for Lithium Storage. ACS Appl. Energy Mater. 2019, 2, 6158–6162. [Google Scholar] [CrossRef]

- Liu, B.; Yao, H.; Daniels, R.A.; Song, W.; Zheng, H.; Jin, L.; He, J. A Facile synthesis of Fe3C@mesoporous carbon nitride nanospheres with superior electro-catalytic activity. Nanoscale 2016, 8, 5441–5445. [Google Scholar] [CrossRef] [PubMed]

- Luechinger, N.A.; Athanassiou, E.K.; Stark, W.J. Graphene-stabilized copper nanoparticles as an air-stable substitute for silver and gold in low-cost ink-jet printable electronics. Nanotechnology 2008, 19, 445201. [Google Scholar] [CrossRef]

- Athanassiou, E.K.; Grass, R.N.; Stark, W.J. Stark, Large-scale production of carbon-coated copper nanoparticles for sensor applications. Nanotechnology 2006, 17, 1668. [Google Scholar] [CrossRef]

- Wang, S.; Huang, X.; He, Y.; Huang, H.; Wu, Y.; Hou, L.; Liu, X.; Yang, T.; Zou, J.; Huang, B. Synthesis, growth mechanism and thermal stability of copper nanoparticles encapsulated by multi-layer graphene. Carbon 2012, 50, 2119–2125. [Google Scholar] [CrossRef]

- Tseng, C.A.; Chen, C.C.; Ulaganathan, R.K.; Lee, C.P.; Chiang, H.C.; Chang, C.F.; Chen, Y.T. One-step synthesis of anti-oxidative graphene-wrapped copper nanoparticles on flexible substrates for electronic and electro-catalytic applications. ACS Appl. Mater. Interfaces 2017, 9, 25067–25072. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Hong, J.; Koo, J.H.; Lee, H.; Lee, S.; Choi, T.; Jung, H.; Koo, B.; Park, J.; Kim, H.; et al. Synthesis of Few-Layered Graphene Nanoballs with Copper Cores Using Solid Carbon Source. ACS Appl. Mater. Interfaces 2013, 5, 2432–2437. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Huo, Y.; Li, C.; Xing, S.; Liu, L.; Zou, G. Thermal analysis of Cu-organic composite nanoparticles and fabrication of highly conductive copper films. J. Alloy. Compd. 2015, 649, 1156–1163. [Google Scholar] [CrossRef]

- Kwon, J.; Cho, H.; Eom, H.; Lee, H.; Suh, Y.D.; Moon, H.; Shin, J.; Hong, S.; Ko, S.H. Low-Temperature Oxidation-Free Selective Laser Sintering of Cu Nanoparticle Paste on a Polymer Substrate for the Flexible Touch Panel Applications. ACS Appl. Mater. Interfaces 2016, 8, 11575–11582. [Google Scholar] [CrossRef]

- Liu, S.; Zhao, B.; Jiang, L.; Zhu, Y.W.; Fu, X.Z.; Sun, R.; Wong, C.P. Core-shell Cu@rGO hybrids filled in epoxy composites with high thermal conduction. J. Mater. Chem. C 2018, 6, 257–265. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Resonant Raman spectroscopy of disordered, amorphous, and diamondlike carbon. Phys. Rev. B 2001, 64, 075414. [Google Scholar] [CrossRef]

- Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S.; Cançado, L.G.; Jorio, A.; Saito, R. Studying disorder in graphite-based systems by Raman spectroscopy. Phys. Chem. Chem. Phys. 2007, 9, 1276–1290. [Google Scholar] [CrossRef]

- Sun, Z.; Yan, Z.; Yao, J.; Beitler, E.; Zhu, Y.; Tour, J.M. Growth of graphene from solid carbon sources. Nature 2010, 468, 549–552. [Google Scholar] [CrossRef] [PubMed]

- Guo, Z.; Gui, Q.; Zhang, B.; Ren, S.; Zhang, S.; Li, X.; Ren, T. Application of polycarboxylate and naphthalene sulfonate dispersants in high concentration suspension concentrate. Chem. J. Chin. Univ. 2017, 38, 1278–1285. [Google Scholar]

- Li, Y.; Tang, X.; Zhang, Y.; Li, J.; Lv, C.; Meng, X.; Huang, Y.; Hang, C.; Wang, C. Cu nanoparticles of low polydispersity synthesized by a double-template method and their stability. Colloid Polym. Sci. 2013, 292, 715–722. [Google Scholar] [CrossRef]

- Byun, S.-J.; Lim, H.; Shin, G.-Y.; Han, T.-H.; Oh, S.H.; Ahn, J.-H.; Choi, H.C.; Lee, T.-W. Graphenes Converted from Polymers. J. Phys. Chem. Lett. 2011, 2, 493–497. [Google Scholar] [CrossRef]

- Zheng, M.; Takei, K.; Hsia, B.; Fang, H.; Zhang, X.; Ferralis, N.; Javey, A. Metal-catalysed crystallization of amorphous carbon to graphene. Appl. Phys. Lett. 2010, 96, 063110–063113. [Google Scholar] [CrossRef]

- Kim, C.; Lee, G.; Rhee, C.; Lee, M. Expeditious low-temperature sintering of copper nanoparticles with thin defective carbon shells. Nanoscale 2015, 7, 6627–6635. [Google Scholar] [CrossRef]

- Aditya, T.; Jana, J.; Pal, A.; Pal, T. One-Pot Fabrication of Perforated Graphitic Carbon Nitride Nanosheets Decorated with Copper Oxide by Controlled Ammonia and Sulfur Trioxide Release for Enhanced Catalytic Activity. ACS Omega 2018, 3, 9318–9332. [Google Scholar] [CrossRef]

- Aditya, T.; Jana, J.; Singh, N.K.; Pal, A.; Pal, T. Remarkable facet selective reduction of 4-nitrophenol by morphologically tailored (111) faceted Cu2O nanocatalyst. ACS Omega 2017, 2, 1968–1984. [Google Scholar] [CrossRef] [PubMed]

| Sample | Resistance | Volume Resistivity | Pressure | Thickness | Machine |

|---|---|---|---|---|---|

| C/Cu | 595 μΩ | 7.27 × 10−3 Ω·cm | 20 MPa | 0.64 mm | FT-300I |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, M.; Cao, X.; Zhang, J.; Liu, H.; Lu, J.; Yi, D.; Ma, Y. Mesosphere of Carbon-Shelled Copper Nanoparticles with High Conductivity and Thermal Stability via Direct Carbonization of Polymer Soft Templates. Materials 2022, 15, 7536. https://doi.org/10.3390/ma15217536

Huang M, Cao X, Zhang J, Liu H, Lu J, Yi D, Ma Y. Mesosphere of Carbon-Shelled Copper Nanoparticles with High Conductivity and Thermal Stability via Direct Carbonization of Polymer Soft Templates. Materials. 2022; 15(21):7536. https://doi.org/10.3390/ma15217536

Chicago/Turabian StyleHuang, Min, Xinyu Cao, Jingnan Zhang, Huiqun Liu, Jiaxin Lu, Danqing Yi, and Yongmei Ma. 2022. "Mesosphere of Carbon-Shelled Copper Nanoparticles with High Conductivity and Thermal Stability via Direct Carbonization of Polymer Soft Templates" Materials 15, no. 21: 7536. https://doi.org/10.3390/ma15217536

APA StyleHuang, M., Cao, X., Zhang, J., Liu, H., Lu, J., Yi, D., & Ma, Y. (2022). Mesosphere of Carbon-Shelled Copper Nanoparticles with High Conductivity and Thermal Stability via Direct Carbonization of Polymer Soft Templates. Materials, 15(21), 7536. https://doi.org/10.3390/ma15217536