Organosilicon-Based Plasma Nanocoating on Crust Leather for Water-Repellent Footwear

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

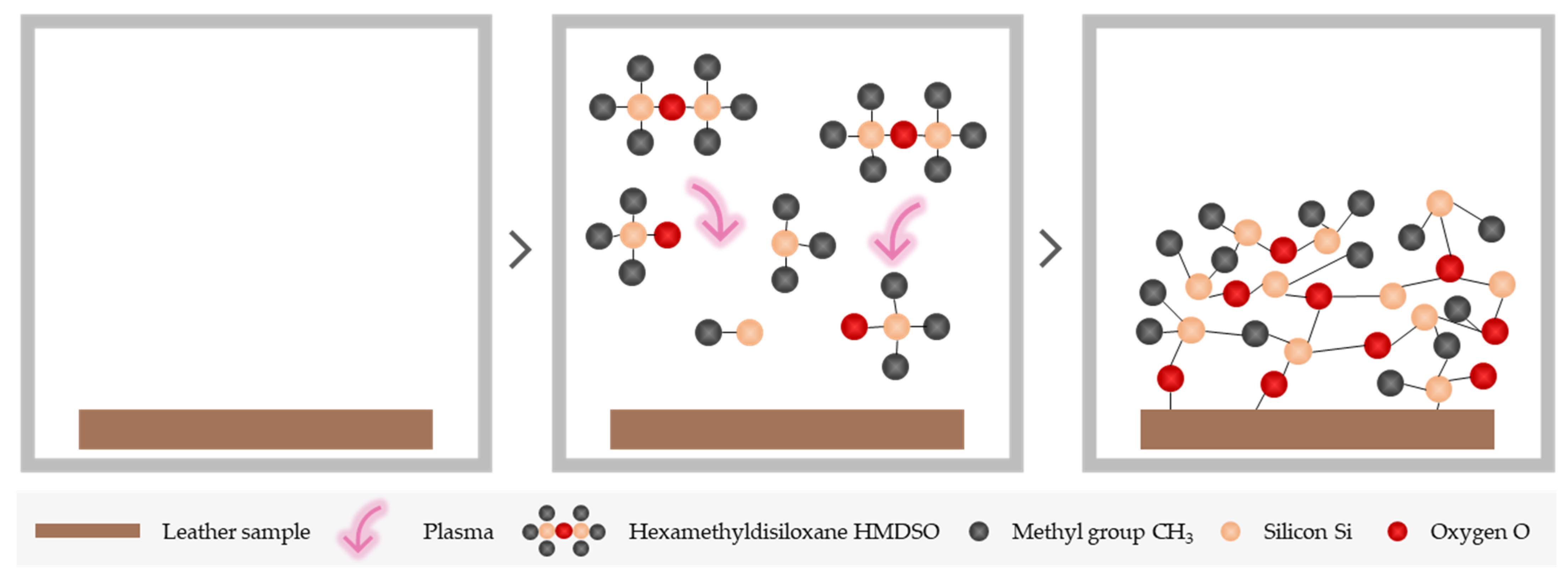

2.2. Plasma Polymerisation Coating Process

2.3. Characterisation Techniques

2.3.1. Fourier Transform Infrared Spectroscopy (FTIR)

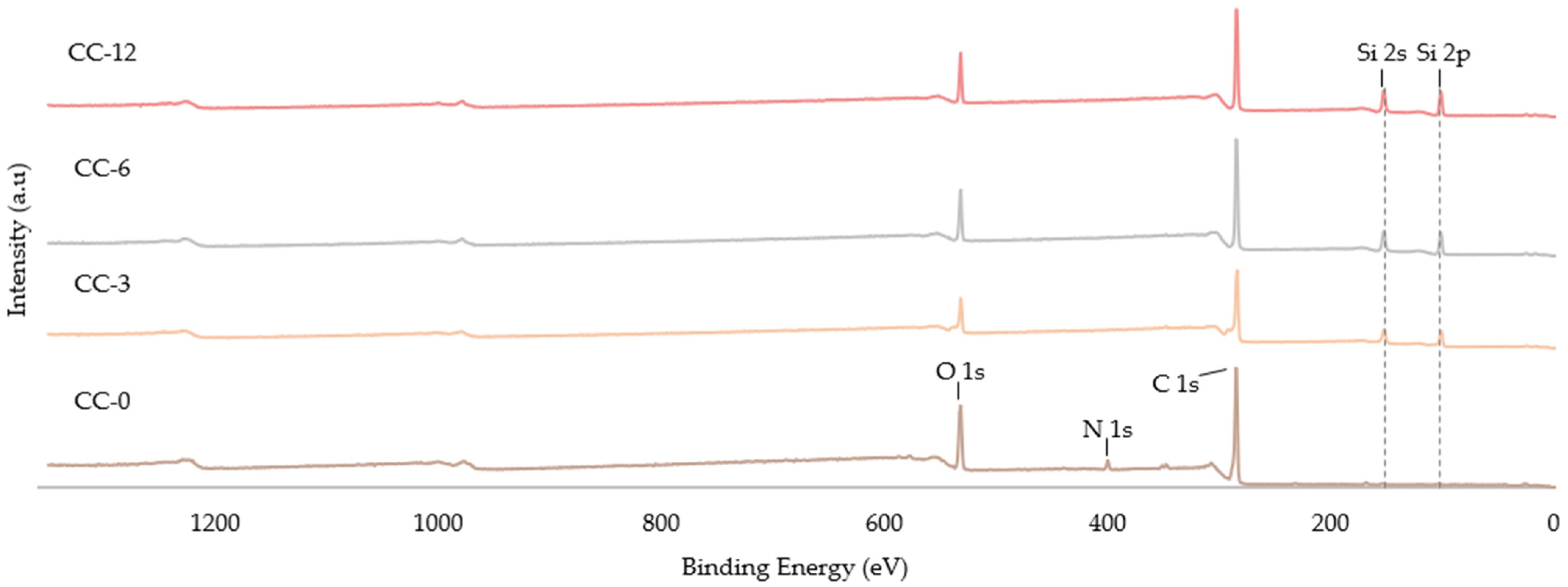

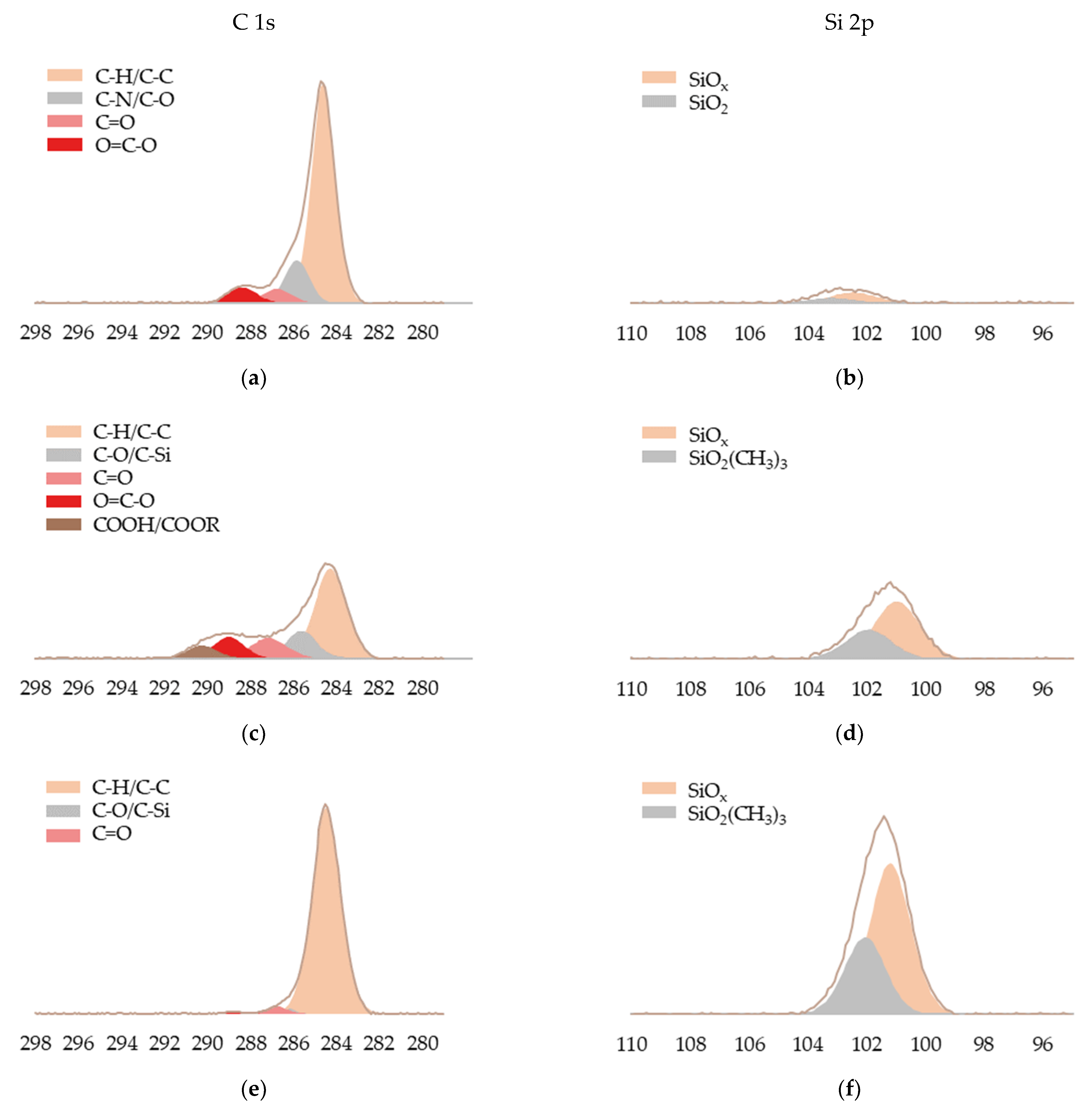

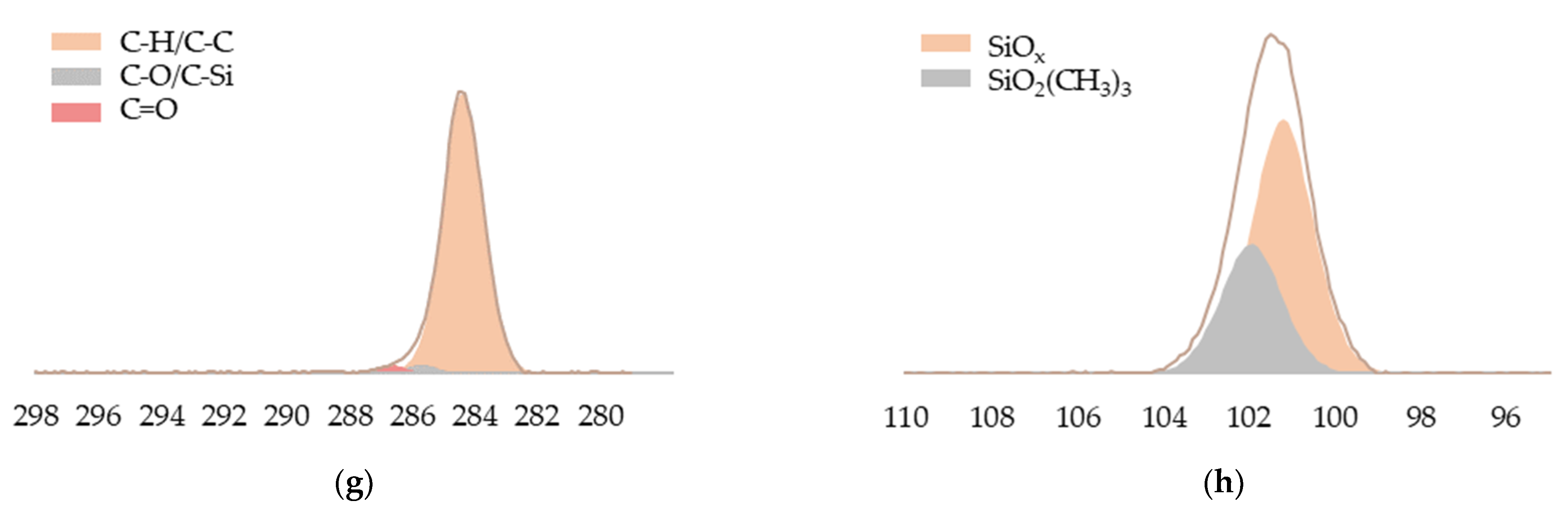

2.3.2. X-ray Photoelectron Spectroscopy (XPS)

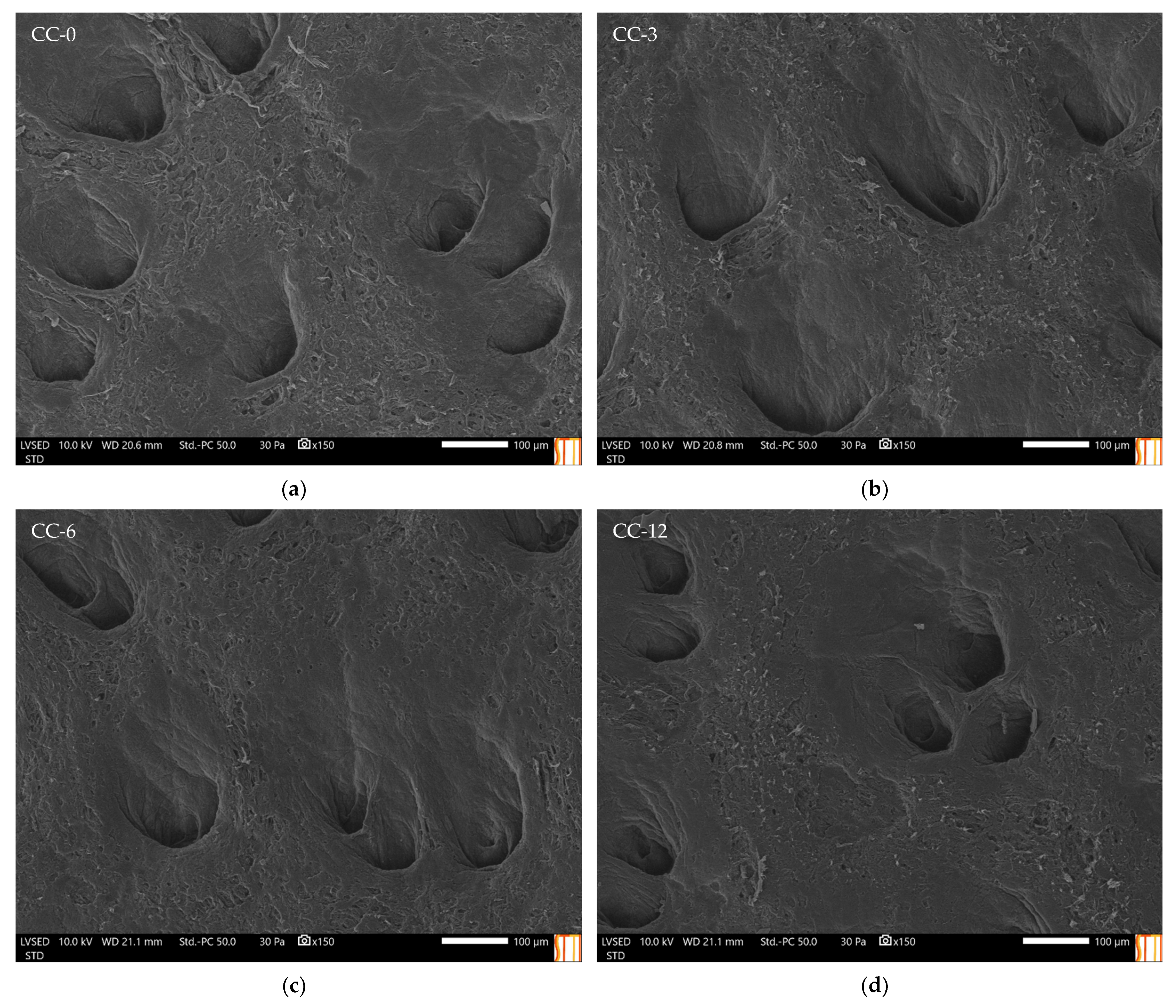

2.3.3. Scanning Electron Microscopy (SEM)

2.3.4. Colour Difference

2.3.5. Water Repellency Properties

2.3.6. Surface Wetting Resistance

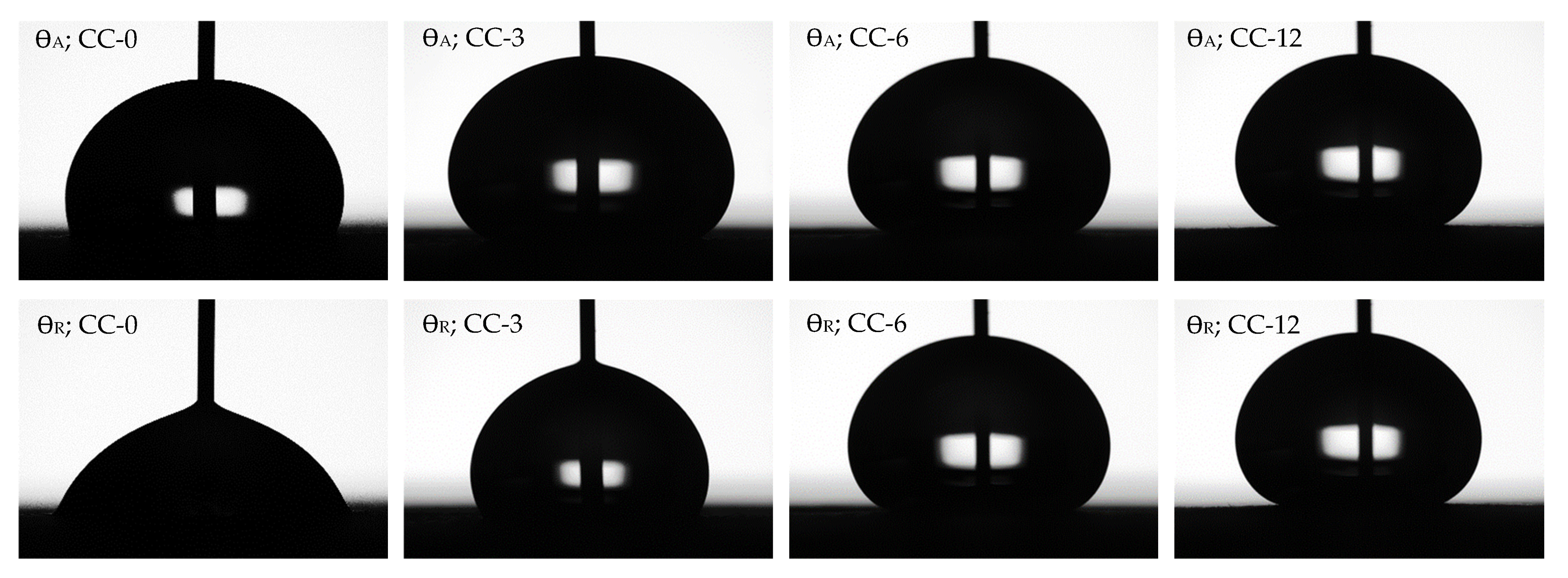

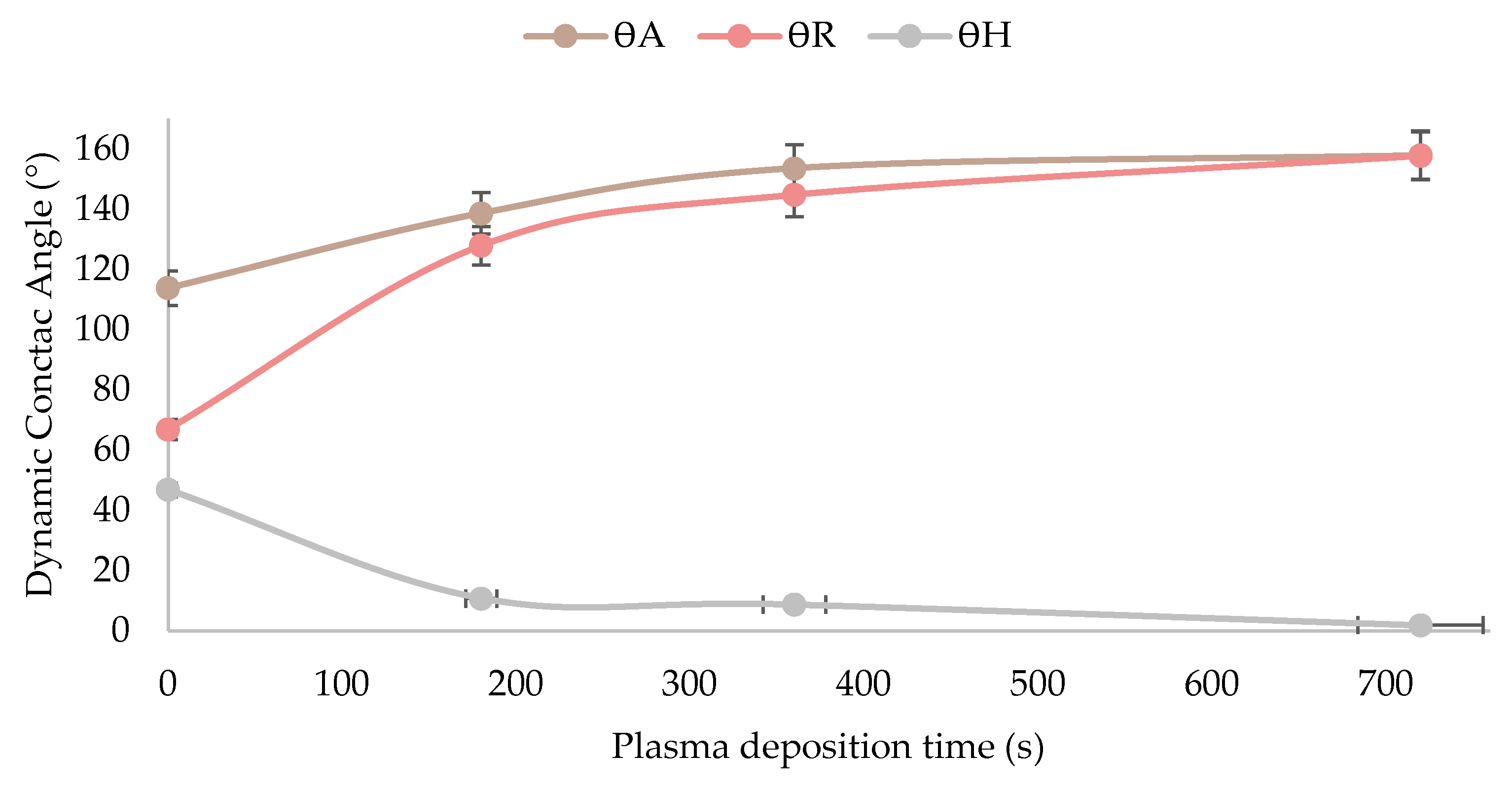

2.3.7. Dynamic Water Contact Angles (DWCA)

3. Results and Discussion

3.1. Chemical Properties Characterisation of the HMDSO Plasma Polymerised Coated Leather Samples

3.2. Physical Properties Characterisation of the HMDSO Plasma Polymerised Coated Leather Samples

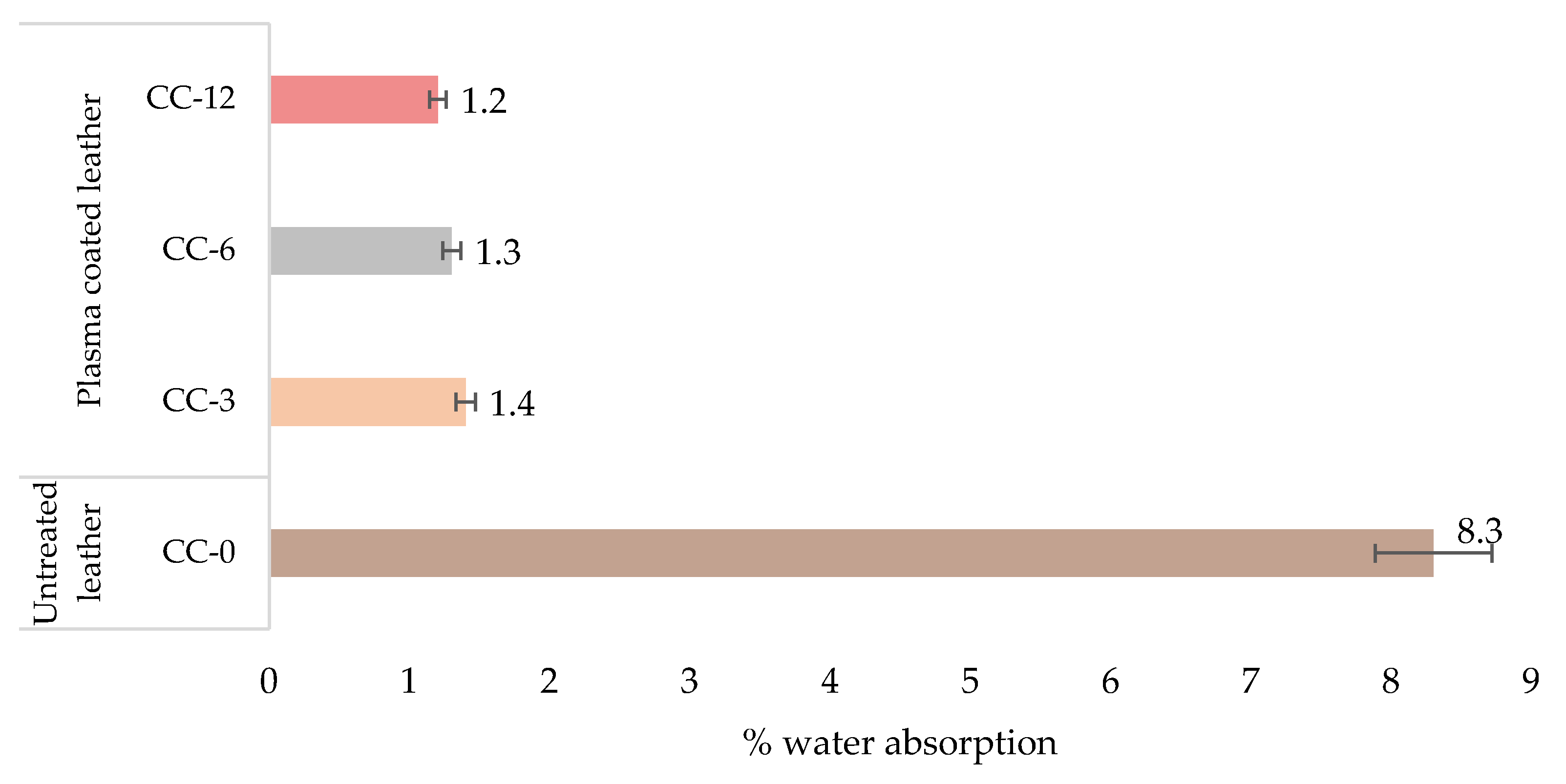

3.3. Hydrophobicity and Water Repellence Assessment

4. Conclusions

- –

- Organosilane and methyl-based chemical functional groups were introduced into the chemical structure of the leather surface due to the ionisation of the HMDSO monomer, which mainly offered and provided the materials with water repellent properties.

- –

- The physical characterization by different standardised tests revealed that the properties of the treated leather samples, such as colour or texture, were not modified. This is an advantage over conventional methods of functionalising and finishing leather, as the application of wet-end finishes sometimes modifies the perceived colour shades of the material.

- –

- Plasma coatings significantly increased the hydrophobic properties of all coated leather surfaces, but this was especially pronounced for specific parameter sets, as in sample CC-12, which showed the highest water resistance and water repellency.

- –

- The deposition time of the plasma coating process influenced the final performance obtained. Since a nano-sized film of polymer-functional plasma must be generated to coat the leather surface, long times (720 s) were more favourable for this purpose than short times (180 s).

- –

- Suitable performance of the chemical precursor HMDSO for use in LPP technology as a polymeric coating to impart water repellent and resistant properties to leather materials for footwear applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Covington, A.D. Tanning Chemistry: The Science of Leather; Royal Society of Chemistry: London, UK, 2009; ISBN 978-0-85404-170-1. [Google Scholar]

- Williams, J.T. Waterproof and Water Repellent Textiles and Clothing; Elsevier: Amsterdam, The Netherlands, 2018; ISBN 978-0-08-101212-3. [Google Scholar]

- Wu, X.; Wu, J.; Mu, C.; Wang, C.; Lin, W. Advances in Antimicrobial Polymer Coatings in the Leather Industry: A Comprehensive Review. Ind. Eng. Chem. Res. 2021, 60, 15004–15018. [Google Scholar] [CrossRef]

- Liang, F.; Wang, T.; Fan, H.; Xiang, J.; Chen, Y. A leather coating with self-healing characteristics. J. Leather Sci. Eng. 2020, 2, 5. [Google Scholar] [CrossRef]

- Bai, Z.; Wang, X.; Zheng, M.; Yue, O.; Xie, L.; Zha, S.; Dong, S.; Li, T.; Song, Y.; Huang, M.; et al. Leather for flexible multifunctional bio-based materials: A review. J. Leather. Sci. Eng. 2022, 4, 16. [Google Scholar] [CrossRef]

- Kredel, J.; Schmitt, D.; Schäfer, J.-L.; Biesalski, M.; Gallei, M. Cross-Linking Strategies for Fluorine-Containing Polymer Coatings for Durable Resistant Water- and Oil-Repellency. Polymers 2021, 13, 723. [Google Scholar] [CrossRef]

- Su, S.; Wang, J.; Li, C.; Yuan, J.; Pan, Z.; Pan, M. Short-Branched Fluorinated Polyurethane Coating Exhibiting Good Comprehensive Performance and Potential UV Degradation in Leather Waterproofing Modification. Coatings 2021, 11, 395. [Google Scholar] [CrossRef]

- Luo, Z.; Fan, H.; Lu, Y.; Shi, B. Fluorine-containing aqueous copolymer emulsion for waterproof leather. J. Soc. Leather Technol. Chem. 2008, 92, 107–113. [Google Scholar]

- Van der Veen, I.; Hanning, A.-C.; Stare, A.; Leonards, P.E.G.; De Boer, J.; Weiss, J.M. The effect of weathering on per-and polyfluoroalkyl substances (PFASs) from durable water repellent (DWR) clothing. Chemosphere 2020, 249, 126100. [Google Scholar] [CrossRef]

- Whittaker, M.H.; Heine, L. Toxicological and environmental issues associated with waterproofing and water repellent formulations. In Waterproof and Water Repellent Textiles and Clothing; Woodhead Publishing: Sawston, UK, 2018; pp. 89–120. [Google Scholar] [CrossRef]

- Palop, R. Química de la Fabricación del Cuero; Delta Publicaciones University: Cleveland, OH, USA, 2021; ISBN 978-84-17526-91-7. [Google Scholar]

- Tudoran, C.; Roşu, M.-C.; Coroş, M. A concise overview on plasma treatment for application on textile and leather materials. Plasma Process. Polym. 2020, 17, 2000046. [Google Scholar] [CrossRef]

- Regulation (EU) 2019/1021 of the European Parliament and of the Council of 20 June 2019 on Persistent Organic Pollutants. Available online: http://data.europa.eu/eli/reg/2019/1021/oj/eng (accessed on 15 June 2022).

- Saffari, M.-R.; Kamali Miab, R. Antibacterial property of PLA textiles coated by nano-TiO2 through eco-friendly low-temperature plasma. Int. J. Cloth. Sci. Technol. 2016, 28, 830–840. [Google Scholar] [CrossRef]

- Diener Electronic GmbH + Co. KG. Plasma Technology, 4th ed.; Diener Electronic GmbH + Co. KG: Ebhausen, Germany, 2011. [Google Scholar]

- Hegemann, D.; Hossain, M.M.; Körner, E.; Balazs, D.J. Macroscopic Description of Plasma Polymerization. Plasma Process. Polym. 2007, 4, 229–238. [Google Scholar] [CrossRef]

- Levchenko, I.; Xu, S.; Baranov, O.; Bazaka, O.; Ivanova, E.P.; Bazaka, K. Plasma and Polymers: Recent Progress and Trends. Molecules 2021, 26, 4091. [Google Scholar] [CrossRef] [PubMed]

- Lippens, P. Low-pressure cold plasma processing technology. In Plasma Technologies for Textiles; Woodhead Publishing Limited: Cambridge, UK, 2007; p. 64. [Google Scholar]

- Iqbal, M.; Dinh, D.K.; Abbas, Q.; Imran, M.; Sattar, H.; Ul Ahmad, A. Controlled Surface Wettability by Plasma Polymer Surface Modification. Surfaces 2019, 2, 349–371. [Google Scholar] [CrossRef]

- Legein, F.; Loulidi, S. Plasma Nanocoating of Nonwovens: Industrial applications of low pressure plasma technology to boost functional performance of nonwovens. Vak. Forsch. Prax. 2022, 34, 36–39. [Google Scholar] [CrossRef]

- Dimitrakellis, P.; Gogolides, E. Hydrophobic and superhydrophobic surfaces fabricated using atmospheric pressure cold plasma technology: A review. Adv. Colloid Interface Sci. 2018, 254, 1–21. [Google Scholar] [CrossRef] [PubMed]

- Holmquist, H.; Schellenberger, S.; Van der Veen, I.; Peters, G.M.; Leonards, P.E.G.; Cousins, I.T. Properties, performance and associated hazards of state-of-the-art durable water repellent (DWR) chemistry for textile finishing. Environ. Int. 2016, 91, 251–264. [Google Scholar] [CrossRef] [PubMed]

- Ziya Özek, H. Silicone-based water repellents. In Waterproof and Water Repellent Textiles and Clothing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 153–189. ISBN 978-0-08-101212-3. [Google Scholar]

- de Freitas, A.S.M.; Maciel, C.C.; Rodrigues, J.S.; Ribeiro, R.P.; Delgado-Silva, A.O.; Rangel, E.C. Organosilicon films deposited in low-pressure plasma from hexamethyldisiloxane—A review. Vacuum 2021, 194, 110556. [Google Scholar] [CrossRef]

- Hegemann, D.; Bülbül, E.; Hanselmann, B.; Schütz, U.; Amberg, M.; Gaiser, S. Plasma polymerization of hexamethyldisiloxane: Revisited. Plasma Process. Polym. 2021, 18, 2000176. [Google Scholar] [CrossRef]

- Siow, K.S. Low pressure plasma modifications for the generation of hydrophobic coatings for biomaterials applications. Plasma Process. Polym. 2018, 15, 1800059. [Google Scholar] [CrossRef]

- Gengenbach, T.R.; Griesser, H.J. Post-deposition ageing reactions differ markedly between plasma polymers deposited from siloxane and silazane monomers. Polymer 1999, 40, 5079–5094. [Google Scholar] [CrossRef]

- Wulf, G.; Mayer, B.; Lommatzsch, U. Plasma Co-Polymerization of HMDSO and Limonene with an Atmospheric Pressure Plasma Jet. Plasma 2022, 5, 44–59. [Google Scholar] [CrossRef]

- Chaiwong, C.; Rachtanapun, P.; Sarapirom, S.; Boonyawan, D. Plasma polymerization of hexamethyldisiloxane: Investigation of the effect of carrier gas related to the film properties. Surf. Coat. Technol. 2013, 229, 12–17. [Google Scholar] [CrossRef]

- West, J.O.F.; Critchlow, G.W.; Lake, D.R.; Banks, R. Development of a superhydrophobic polyurethane-based coating from a two-step plasma-fluoroalkyl silane treatment. Int. J. Adhes. Adhes. 2016, 68, 195–204. [Google Scholar] [CrossRef]

- Kayaoğlu, B.K.; Öztürk, E. Imparting hydrophobicity to natural leather through plasma polymerization for easy care effect. Fibers Polym. 2013, 14, 1706–1713. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, J.; Liu, F.; Zhang, Z.; Li, Z.; Yang, M.; Li, L. The effects of surface modification using O2 low temperature plasma on chrome tanning properties of natural leather. J. Ind. Text. 2019, 49, 534–547. [Google Scholar] [CrossRef]

- Hyuk Choi, J.; Suok Lee, E.; Koo Baik, H.; Lee, S.-J.; Moon Song, K.; Keun Hwang, M.; Su Huh, C. Surface modification of natural leather using low-pressure parallel plate plasma. Surf. Coat. Technol. 2003, 171, 257–263. [Google Scholar] [CrossRef]

- Štěpánová, V.; Kelar, J.; Slavíček, P.; Chlupová, S.; Stupavská, M.; Jurmanová, J.; Černák, M. Surface modification of natural leather using diffuse ambient air plasma. Int. J. Adhes. Adhes. 2017, 77, 198–203. [Google Scholar] [CrossRef]

- Arán-Ais, F.; Ruzafa-Silvestre, C.; Carbonell-Blasco, M.; Pérez-Limiñana, M.; Orgilés-Calpena, E. Sustainable adhesives and adhesion processes for the footwear industry. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2020, 235, 585–596. [Google Scholar] [CrossRef]

- Ruzafa-Silvestre, C.; Carbonell-Blasco, P.; Orgiles-Calpena, E.; Aran Ais, F. Low-pressure plasma treatment applied to polymeric materials for a sustainable footwear industry. In Proceedings of the 8th International Conference on Advanced Materials and Systems, Bucharest, Romania, 1–3 October 2020; pp. 455–460. [Google Scholar]

- Ruzafa-Silvestre, C.; Carbonell-Blasco, M.P.; Pérez-Limiñana, M.A.; Arán-Ais, F.; Orgilés-Calpena, E. Robotised atmospheric plasma treatment to improve the adhesion of vulcanised and thermoplastic rubber materials for a more sustainable footwear. Int. J. Adhes. Adhes. 2021, 117, 103010. [Google Scholar] [CrossRef]

- Sánchez Navarro, M.M.; Escoto Palacios, M.J.; Arán Ais, F.; Roig Orts, M.; Orgilés Barceló, C.; Puche Albert, C. Leather functionalisation by means of MLSE technology. J. AQEIC 2016, 67, 85. [Google Scholar]

- Silvestre, C.R.; Blasco, M.P.C.; López, S.R.; Aguilar, H.P.; Limiñana, M.Á.P.; Gil, E.B.; Calpena, E.O.; Ais, F.A. Hydrophobic Leather Coating for Footwear Applications by a Low-Pressure Plasma Polymerisation Process. Polymers 2021, 13, 3549. [Google Scholar] [CrossRef] [PubMed]

- Abdul Moktadir, M.; Badri Ahmadi, H.; Sultana, R.; Zohra, F.-T.; James, J.H.L.; Rezaei, J. Circular economy practices in the leather industry: A practical step towards sustainable development. J. Clean. Prod. 2020, 251, 119737. [Google Scholar] [CrossRef]

- Cai, S.; Fang, J.; Yu, X. Plasma polymerization of organosiloxanes. J. Appl. Polym. Sci. 1992, 44, 135–141. [Google Scholar] [CrossRef]

- Randhawa, H. Review of plasma-assisted deposition processes. Thin Solid Film. 1991, 196, 329–349. [Google Scholar] [CrossRef]

- ISO 22700:2019; Leather—Measuring the Colour and Colour Difference of Finished Leather. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 23232:2009; Textiles—Aqueous Liquid Repellency—Water/Alcohol Solution Resistance Test. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 17231:2017; Leather—Physical and Mechanical Tests—Determination of Water Repellency of Garment Leather. International Organization for Standardization: Geneva, Switzerland, 2017.

- Kozbial, A.; Trouba, C.; Liu, H.; Li, L. Characterization of the Intrinsic Water Wettability of Graphite Using Contact Angle Measurements: Effect of Defects on Static and Dynamic Contact Angles. Langmuir 2017, 33, 959–967. [Google Scholar] [CrossRef] [PubMed]

- Strobel, M.; Lyons, C.S. An Essay on Contact Angle Measurements. Plasma Process. Polym. 2011, 8, 8–13. [Google Scholar] [CrossRef]

- ISO 19403-6:2017; Paints and Varnishes—Wettability—Part 6: Measurement of Dynamic Contact Angle. International Organization for Standardization: Geneva, Switzerland, 2017.

- You, X.; Gou, L.; Tong, X. Improvement in surface hydrophilicity and resistance to deformation of natural leather through O2/H2O low-temperature plasma treatment. Appl. Surf. Sci. 2016, 360, 398–402. [Google Scholar] [CrossRef]

- Launer, P.J.; Arkles, B. Infrared Analysis of Organosilicon Compounds: Spectra-Structure Relationships. In Silicon Compounds: Silanes and Silicones; Gelest Inc.: Morrisville, PA, USA, 2013. [Google Scholar]

- Kurosawa, S.; Choi, B.-G.; Park, J.-W.; Aizawa, H.; Shim, K.-B.; Yamamoto, K. Synthesis and characterization of plasma-polymerized hexamethyldisiloxane films. Thin Solid Film. 2006, 506–507, 176–179. [Google Scholar] [CrossRef]

- Maurau, R.; Boscher, N.D.; Guillot, J.; Choquet, P. Nitrogen Introduction in pp-HMDSO Thin Films Deposited by Atmospheric Pressure Dielectric Barrier Discharge: An XPS Study. Plasma Process. Polym. 2012, 9, 316–323. [Google Scholar] [CrossRef]

- Rügner, K.; Reuter, R.; Ellerweg, D.; de los Arcos, T.; von Keudell, A.; Benedikt, J. Insight into the Reaction Scheme of SiO2 Film Deposition at Atmospheric Pressure: Insight into the Reaction Scheme of SiO2 Film Deposition. Plasma Process. Polym. 2013, 10, 1061–1073. [Google Scholar] [CrossRef]

- Dakroub, G.; Duguet, T.; Esvan, J.; Lacaze-Dufaure, C.; Roualdes, S.; Rouessac, V. Comparative study of bulk and surface compositions of plasma polymerized organosilicon thin films. Surf. Interface. 2021, 25, 101256. [Google Scholar] [CrossRef]

- Cho, S.C.; Hong, Y.C.; Cho, S.G.; Ji, Y.Y.; Han, C.S.; Uhm, H.S. Surface modification of polyimide films, filter papers, and cotton clothes by HMDSO/toluene plasma at low pressure and its wettability. Curr. Appl. Phys. 2009, 9, 1223–1226. [Google Scholar] [CrossRef]

- Balkova, R.; Zemek, J.; Cech, V.; Vanek, J.; Prikryl, R. XPS study of siloxane plasma polymer films. Surf. Coat. Technol. 2003, 174–175, 1159–1163. [Google Scholar] [CrossRef]

- Kan, C.-W.; Kwong, C.-H.; Ng, S.-P. Atmospheric Pressure Plasma Surface Treatment of Rayon Flock Synthetic Leather with Tetramethylsilane. Appl. Sci. 2016, 6, 59. [Google Scholar] [CrossRef]

- Kaygusuz, M.; Meyer, M.; Junghans, F.; Aslan, A. Modification of Leather Surface with Atmospheric Pressure Plasma and Nanofinishing. Polym.-Plast. Technol. Eng. 2018, 57, 260–268. [Google Scholar] [CrossRef]

- Ji, Y.-Y.; Hong, Y.-C.; Lee, S.-H.; Kim, S.-D.; Kim, S.-S. Formation of super-hydrophobic and water-repellency surface with hexamethyldisiloxane (HMDSO) coating on polyethyleneteraphtalate fiber by atmosperic pressure plasma polymerization. Surf. Coat. Technol. 2008, 202, 5663–5667. [Google Scholar] [CrossRef]

- Mossotti, R.; Lopardo, G.; Innocenti, R. Characterization of Plasma-coated Wool Fabrics. Text. Res. J. 2009, 79, 853–861. [Google Scholar] [CrossRef]

- Türk, M.; Ehrmann, A.; Mahltig, B. Water-, oil-, and soil-repellent treatment of textiles, artificial leather, and leather. J. Text. Inst. 2015, 106, 611–620. [Google Scholar] [CrossRef]

- Jankauskaitė, V.; Jiyembetova, I.; Gulbinienė, A.; Širvaitytė, J.; Beleška, K.; Urbelis, V. Comparable Evaluation of Leather Waterproofing Behaviour upon Hide Quality. I. Influence of Retanning and Fatliqouring Agents on Leather Structure and Properties. Mater. Sci. 2012, 18, 150–157. [Google Scholar] [CrossRef][Green Version]

- Maghsoudi, K.; Vazirinasab, E.; Momen, G.; Jafari, R. Icephobicity and durability assessment of superhydrophobic surfaces: The role of surface roughness and the ice adhesion measurement technique. J. Mater. Process. Technol. 2021, 288, 116883. [Google Scholar] [CrossRef]

- Asadollahi, S.; Profili, J.; Farzaneh, M.; Stafford, L. Development of Organosilicon-Based Superhydrophobic Coatings through Atmospheric Pressure Plasma Polymerization of HMDSO in Nitrogen Plasma. Materials 2019, 12, 219. [Google Scholar] [CrossRef] [PubMed]

- Kan, C.-W.; Man, W.-S. Parametric Study of Effects of Atmospheric Pressure Plasma Treatment on the Wettability of Cotton Fabric. Polymers 2018, 10, 233. [Google Scholar] [CrossRef] [PubMed]

- COM/2019/640 Final; Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions the European Green Deal. EUR-Lex: Luxembourg, 2019.

| Leather Samples | Monomer | Time (s) | Power (W) |

|---|---|---|---|

| CC-0 | - | - | - |

| CC-3 | HMDSO | 180 | 100 |

| CC-6 | HMDSO | 360 | 100 |

| CC-12 | HMDSO | 720 | 100 |

| Element | Leather Samples | |||

|---|---|---|---|---|

| CC-0 | CC-3 | CC-6 | CC-12 | |

| C | 75.52 | 84.09 | 74.20 | 70.44 |

| O | 20.41 | 8.94 | 13.26 | 13.63 |

| N | 3.12 | 0.00 | 0.00 | 0.00 |

| Si | 0.95 | 6.98 | 12.57 | 15.92 |

| Si/C | 0.01 | 0.08 | 0.17 | 0.23 |

| Si/O | 0.05 | 0.78 | 0.95 | 1.17 |

| Element | Species | Binding Energy (eV) | CC-0 | CC-3 | CC-6 | CC-12 |

|---|---|---|---|---|---|---|

| C 1s | C-H/C-C | 284.6 | 55.17 | 44.44 | 71.05 | 67.79 |

| C-N/C-O/C-Si | 286.0 | 11.23 | 11.66 | 0.66 | 1.48 | |

| C=O | 286.9 | 4.26 | 11.68 | 1.59 | 1.03 | |

| O=C-O | 288.7 | 4.86 | 10.07 | 0.65 | - | |

| COOH/COOR | 291.5 | - | 6.24 | - | 0.14 | |

| Si 2p | SiOx | 101.3 | - | 6.98 | 12.57 | 15.92 |

| SiOx | 102.2 | 0.95 | - | - | - | |

| SiO2/SiO2(CH3)3 | 103.2 | - | - | - | - |

| Water Repellency | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sample/Solutions | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 |

| CC-0 | A | B | C | D | |||||

| CC-3 | A | A | A | B | D | ||||

| CC-6 | A | A | A | B | C | C | D | ||

| CC-12 | A | A | A | A | B | C | C | D | |

| Dynamic Water Contact Angle (DWCA)/(° Grades) | Leather Samples | |||

|---|---|---|---|---|

| CC-0 | CC-3 | CC-6 | CC-12 | |

| ϴA | 114 ± 1 | 139 ± 3 | 154 ± 3 | 158 ± 2 |

| ϴR | 67 ± 2 | 128 ± 4 | 145 ± 3 | 158 ± 4 |

| ϴH | 47 ± 2 | 11 ± 1 | 9 ± 2 | 2 ± 0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ruzafa-Silvestre, C.; Juan-Fernández, B.; Carbonell-Blasco, M.P.; Bañón-Gil, E.; Orgilés-Calpena, E.; Arán-Ais, F. Organosilicon-Based Plasma Nanocoating on Crust Leather for Water-Repellent Footwear. Materials 2022, 15, 7255. https://doi.org/10.3390/ma15207255

Ruzafa-Silvestre C, Juan-Fernández B, Carbonell-Blasco MP, Bañón-Gil E, Orgilés-Calpena E, Arán-Ais F. Organosilicon-Based Plasma Nanocoating on Crust Leather for Water-Repellent Footwear. Materials. 2022; 15(20):7255. https://doi.org/10.3390/ma15207255

Chicago/Turabian StyleRuzafa-Silvestre, Carlos, Blanca Juan-Fernández, María Pilar Carbonell-Blasco, Elena Bañón-Gil, Elena Orgilés-Calpena, and Francisca Arán-Ais. 2022. "Organosilicon-Based Plasma Nanocoating on Crust Leather for Water-Repellent Footwear" Materials 15, no. 20: 7255. https://doi.org/10.3390/ma15207255

APA StyleRuzafa-Silvestre, C., Juan-Fernández, B., Carbonell-Blasco, M. P., Bañón-Gil, E., Orgilés-Calpena, E., & Arán-Ais, F. (2022). Organosilicon-Based Plasma Nanocoating on Crust Leather for Water-Repellent Footwear. Materials, 15(20), 7255. https://doi.org/10.3390/ma15207255