Method for an Effective Selection of Tools and Cutting Conditions during Precise Turning of Non-Alloy Quality Steel C45

Abstract

:1. Introduction

- (1)

- The technical and economic indicators’ system of quality for metal-cutting tools taking into account uncertainty of the information for certain production conditions was created;

- (2)

- The method for determining the adhesive component for the cutting friction coefficient in terms of use as contact surfaces those of the cylinder made of the processed material, and as target surfaces, directly applied surfaces of the tool blades were improved, which allows avoiding the destruction of the tool cutting part, as well as determining the frictional characteristics of the interaction of the processed material with the purchased tool, including with an unknown coating;

- (3)

- Tools for quantitative assessment of the turning inserts quality based on simulation of the cutting process, considering the tribological interaction of tool and machined materials, and the tool edge radius were developed and implemented practically;

- (4)

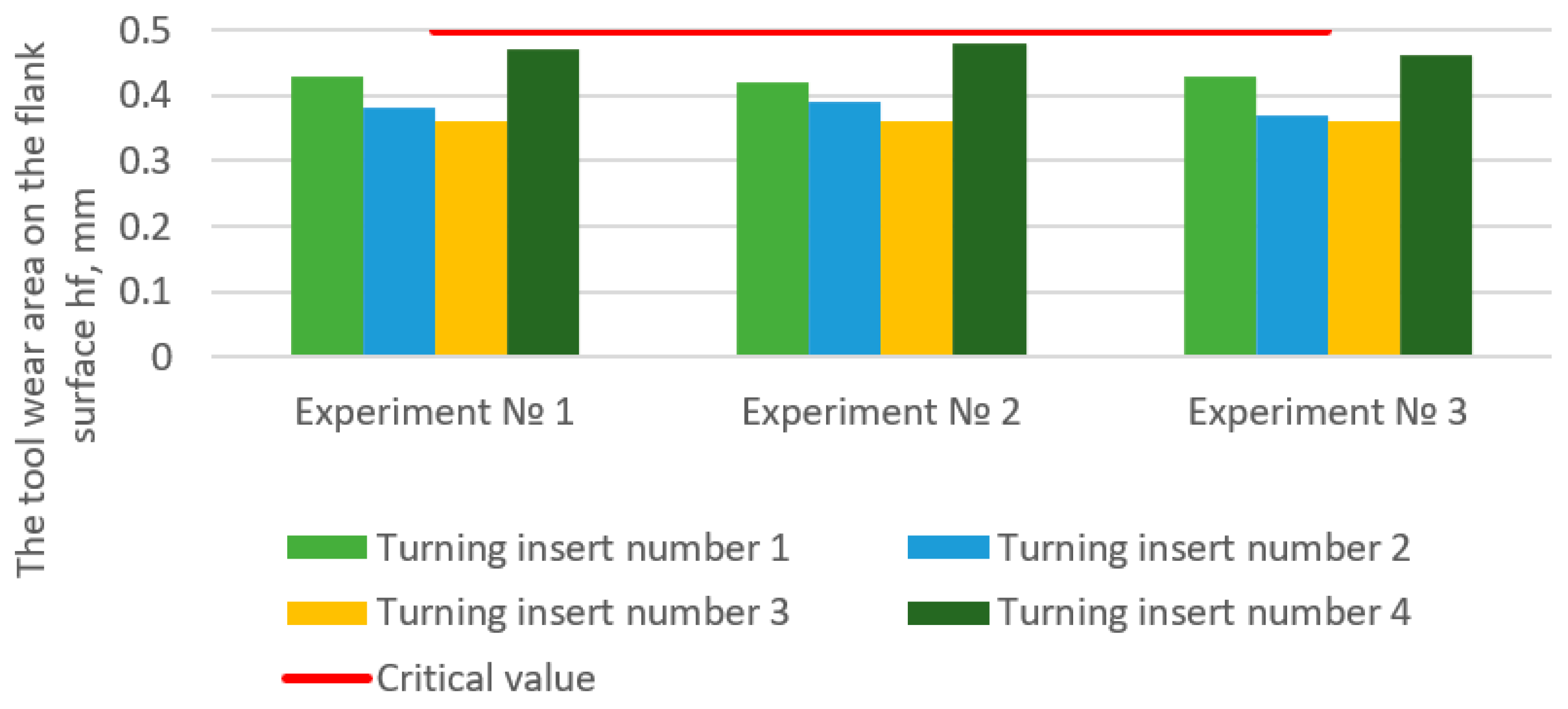

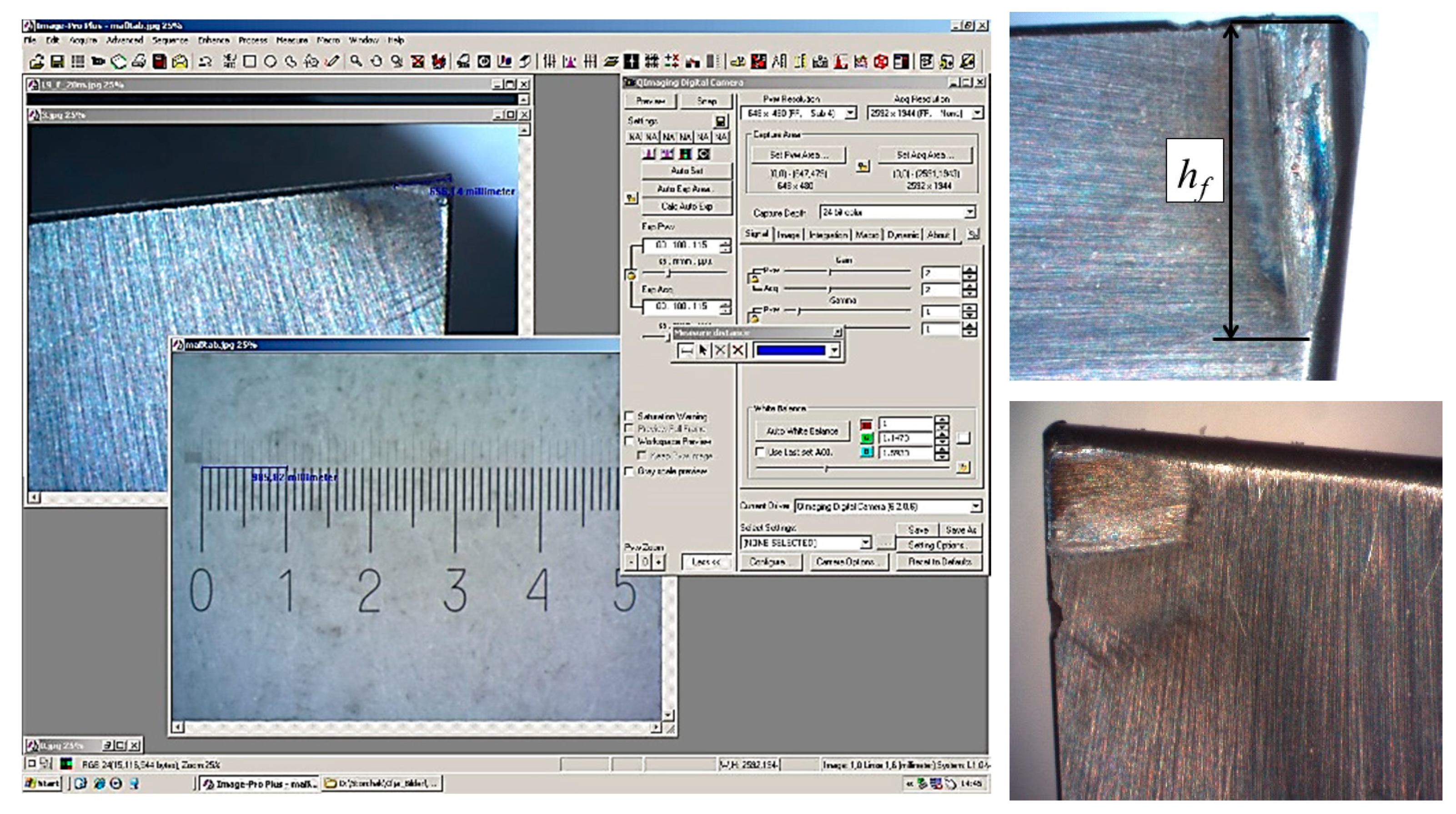

- The method for determining the intensity of cutting tool wear by cutting blade analysis with an electron microscope, an interferometer, and a dynamometer to determine the change in forces under machining was developed.

2. Research Methodology

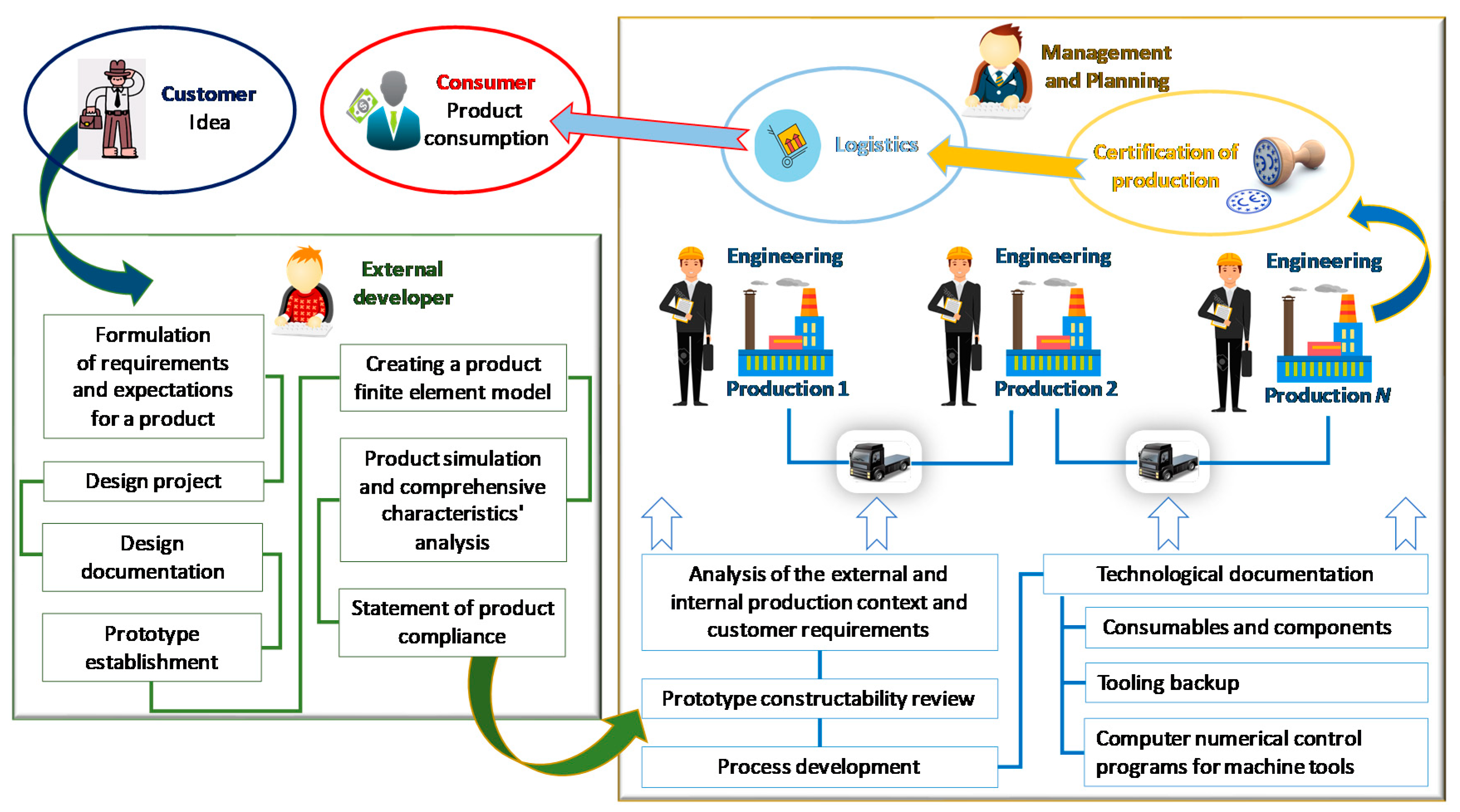

2.1. A General Model for Choosing an Edge Cutting Tool for Optimal Cutting Conditions

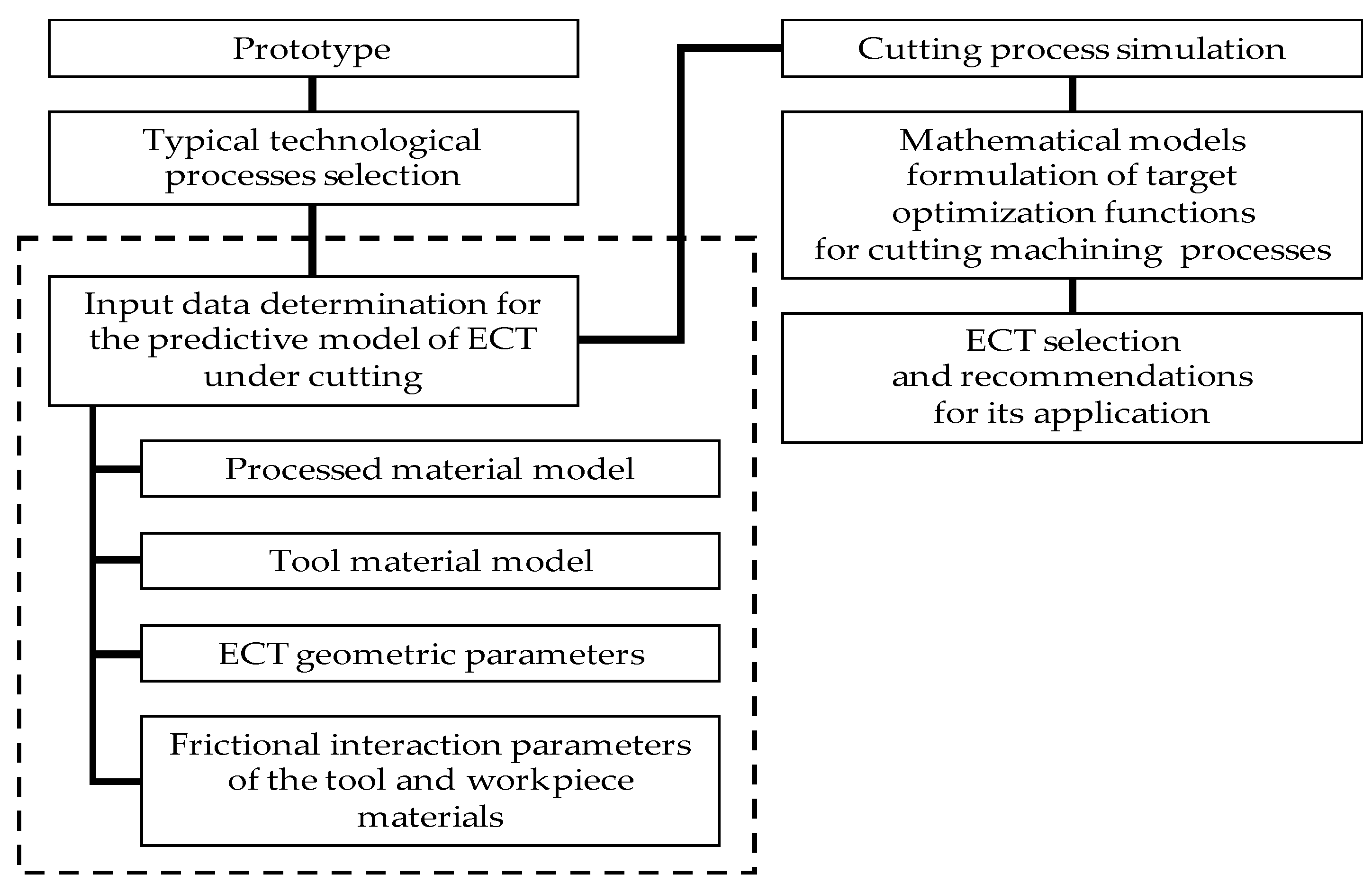

2.2. Simulation of Material Machining by Edge Cutting Tools

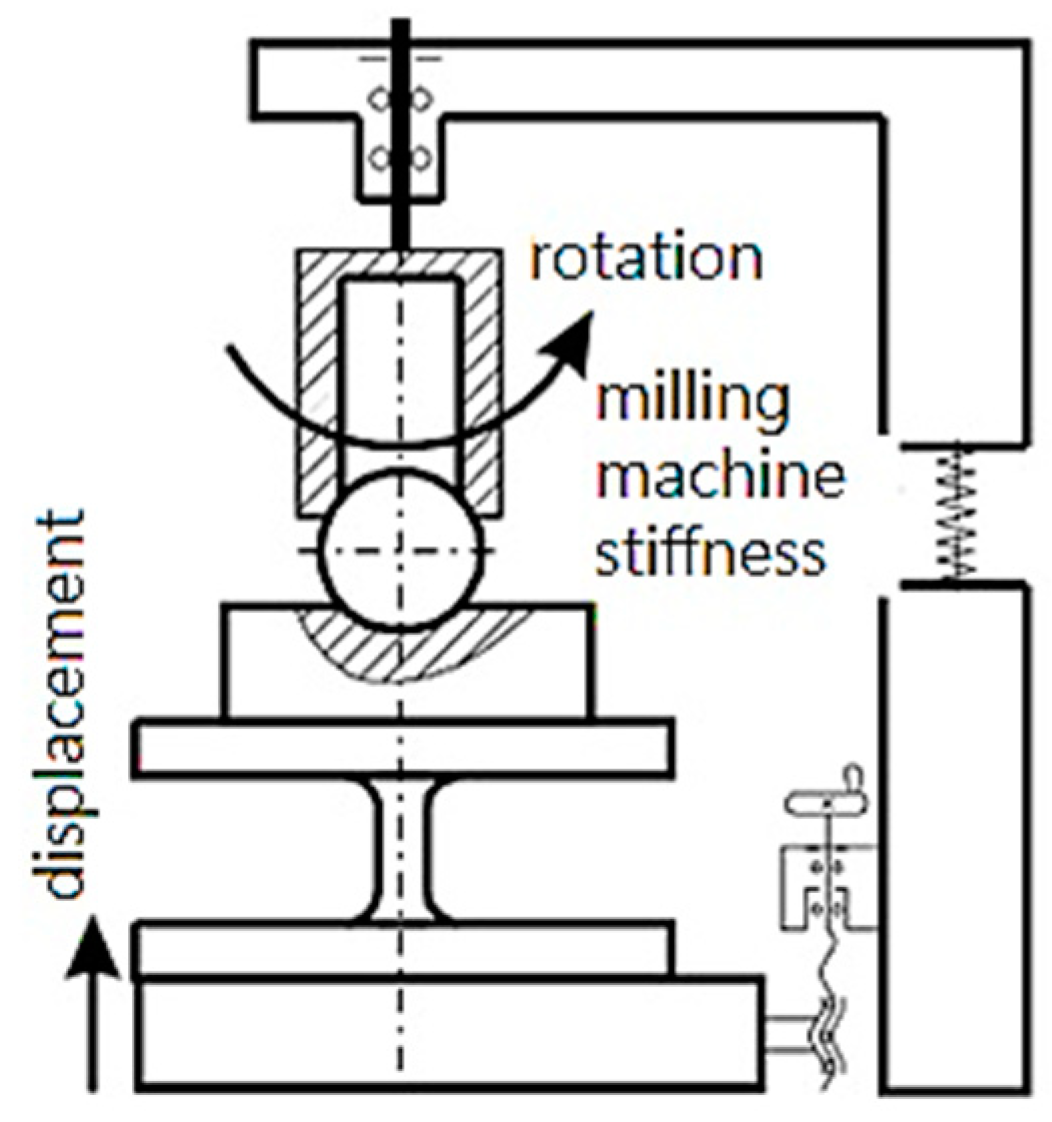

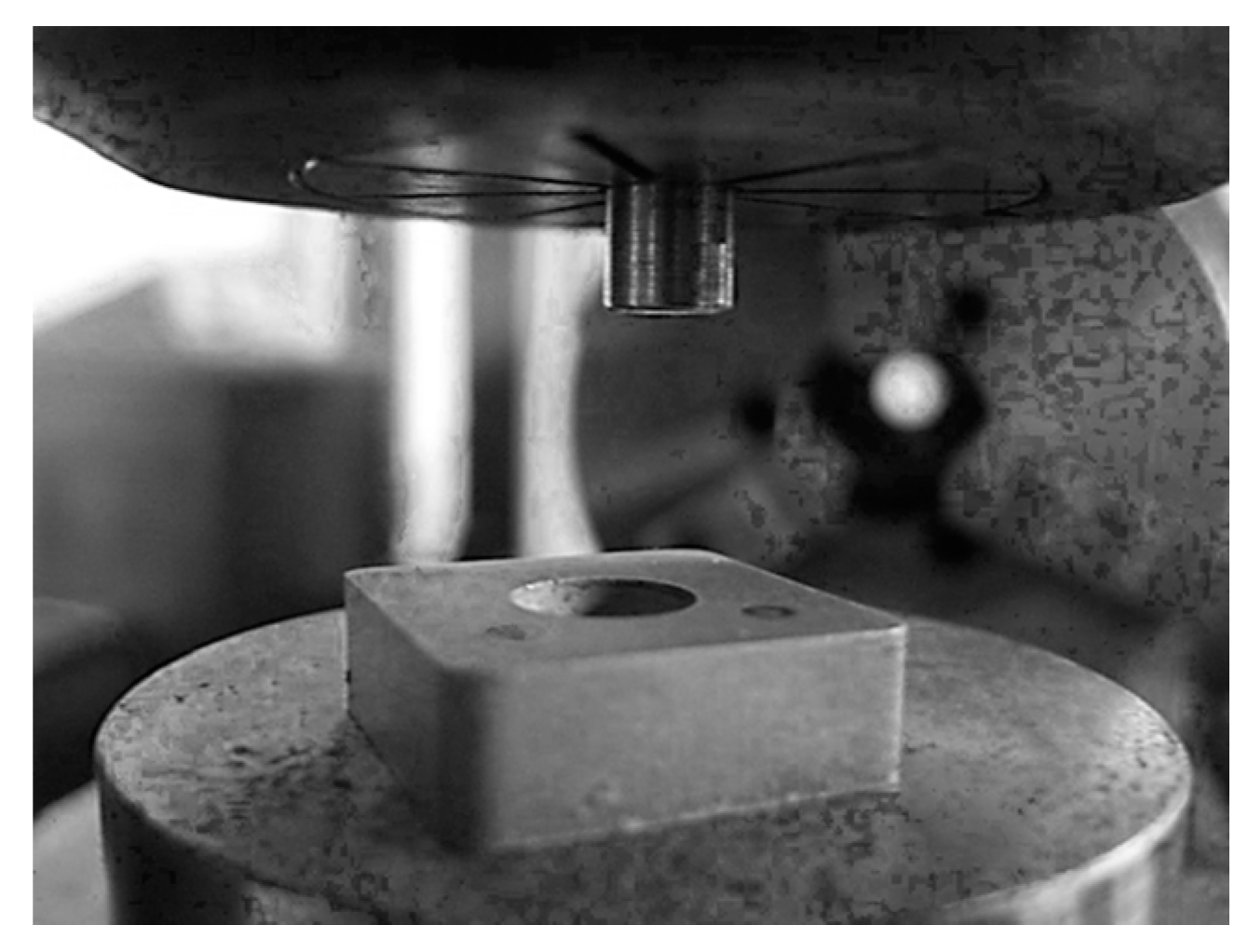

2.3. Method for Determining the Adhesion Component of the Average Friction Coefficient

2.4. Method for Determining the Surface Roughness of a Part after Machining

2.5. Influence of the Tool Edge Radius on the Cutting Process Performance

3. Results and Discussion

- − The adhesion component of the friction coefficient undercutting for a specific pair of machining and tool materials (or coating of tool material);

- − The influence of the tool edge radius on the performance of the cutting process of a particular material.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Badwelan, A.; Alatefi, M.; Ghaleb, A.M.; Alsamhan, A.M. Implementing IoT for the detection of production machine failures. In Proceedings of the International Conference on Industrial Engineering and Operations Management, IEOM Society International, Toronto, ON, Canada, 23–25 October 2019; pp. 858–866. [Google Scholar]

- Zawadzki, P.; Żywicki, K. Smart Product Design and Production Control for Effective Mass Customization in the Industry 4.0 Concept. Manag. Prod. Eng. Rev. 2016, 7, 105–112. [Google Scholar] [CrossRef]

- Araújo, A.F.; Varela, M.L.R.; Gomes, M.S.; Barreto, R.C.C.; Trojanowska, J. Development of an intelligent and automated system for lean industrial production adding maximum productivity and efficiency in the production process. In Advances in Manufacturing. Lecture Notes in Mechanical Engineering; Hamrol, A., Ciszak, O., Legutko, S., Jurczyk, M., Eds.; Springer: Cham, Switzerland, 2018; pp. 131–140. [Google Scholar]

- Doriat, C. Smart factory demonstrates principles of industry. Kunstst. Int. 2015, 105, 10–11. [Google Scholar]

- Gutierrez, C.; Garbajosa, J.; Diaz, J.; Yague, A. Providing a Consensus Definition for the Term Smart Product. In Proceedings of the 2013 20th IEEE International Conference and Workshops on Engineering of Computer Based Systems, IEEE, Scottsdale, AZ, USA, 22–24 April 2013; pp. 203–211. [Google Scholar] [CrossRef] [Green Version]

- Gurr, M.; Mülhaupt, R. Rapid Prototyping. Polym. Sci. A Compr. Ref. 2012, 8, 77–99. [Google Scholar] [CrossRef]

- Heisel, U. Cause Analysis of errors in FE prediction orthogonal cutting performances. In Proceedings of the 10th CIRP International Workshop on Modeling of Machining Operations, Rende, Italy, 27–28 August 2007; pp. 141–148. [Google Scholar]

- Wang, C.; Cheng, K.; Minton, T.; Rakowski, R. Development of a novel surface acoustic wave (SAW) based smart cutting tool in machining hybrid dissimilar material. Manuf. Lett. 2014, 2, 21–25. [Google Scholar] [CrossRef]

- Denkena, B.; Krödel, A.; Theuer, M. Novel continuous generating grinding process for the production of cutting tools. CIRP J. Manuf. Sci. Technol. 2020, 28, 1–7. [Google Scholar] [CrossRef]

- Kalchenko, V.; Kalchenko, V.; Sira, N.; Yeroshenko, A.; Kalchenko, D. Three-Dimensional Simulation of Machined, Tool Surfaces and Shaping Process with Two-Side Grinding of Cylindrical Parts Ends. In Advanced Manufacturing Processes. InterPartner-2019. Lecture Notes in Mechanical Engineering; Tonkonogyi, V., Ed.; Springer: Cham, Switzerland, 2020; pp. 118–127. [Google Scholar] [CrossRef]

- Klimenko, S.A.; Manokhin, A.S.; Mel’Nichuk, Y.A.; Kopieikina, M.Y.; Chumak, A.A.; Bakul, V. Contact stresses on the rake face of cutting tools with PCBN in turning of hardened steel. J. Eng. Sci. 2017, 4, F8–E14. [Google Scholar] [CrossRef]

- Karabegovic, I.; Karabegovic, E.; Mahmic, M.; Husak, E. The Role of Smart Sensors in Production Processes and the Implementation of Industry. J. Eng. Sci. 2019, 6, b8–b13. [Google Scholar] [CrossRef]

- Fujishima, M.; Ohno, K.; Nishikawa, S.; Nishimura, K.; Sakamoto, M.; Kawai, K. Study of sensing technologies for machine tools. CIRP J. Manuf. Sci. Technol. 2016, 14, 71–75. [Google Scholar] [CrossRef]

- Silva, F.; Martins, R.; Gomes, M.; Silva, A.; Machado, J.; Novais, P.; Analide, C. Cloud computing environments for simulation of adaptable standardized work and electronic work instructions in industry 4.0. In Proceedings of the 16th International In-dustrial Simulation Conference, Ponta Delgada, Portugal, 6–8 June 2018; pp. 49–53. [Google Scholar]

- Saniuk, S.; Saniuk, A.; Cagáňová, D. Cyber Industry Networks as an environment of the Industry 4.0 implementation. Wirel. Netw. 2021, 27, 1649–1655. [Google Scholar] [CrossRef] [Green Version]

- Zaleski, K.; Skoczylas, A.; Ciecielag, K. The Investigations of the Surface Layer Properties of C45 Steel After Plasma Cutting and Centrifugal Shot Peening. In Industrial Measurements in Machining. IMM 2019. Lecture Notes in Mechanical Engineering; Królczyk, G., Niesłony, P., Królczyk, J., Eds.; Springer: Cham, Switzerland, 2020; pp. 172–185. [Google Scholar]

- Maruda, R.W.; Legutko, S.; Mrugalski, R.; Dębowski, D.; Wojciechowski, S. Analysis of Cutting Force and Power Under the Conditions of Minimized Cooling in the Process of Turning AISI-1045 Steel with the Use of the Parameter Space Investigation Method. In Industrial Measurements in Machining. IMM 2019. Lecture Notes in Mechanical Engineering; Królczyk, G., Niesłony, P., Królczyk, J., Eds.; Springer: Cham, Switzerland, 2020; pp. 151–162. [Google Scholar] [CrossRef]

- Dobrotvorskiy, S.; Balog, M.; Basova, Y.; Dobrovolska, L.; Zinchenko, A. Concept of the Software for Materials Selection Using .NET Technologies. In Advanced Manufacturing Processes. InterPartner-2019. Lecture Notes in Mechanical Engineering; Tonkonogyi, V., Ed.; Springer: Cham, Switzerland, 2020; pp. 32–43. [Google Scholar] [CrossRef]

- Kanwal, T.; Altaf, S.; Javed, M.K. Environmental Monitoring Smart System with Self-Sustaining Wireless Sensor Network Using Data Validation Algorithms. J. Eng. Sci. 2020, 7, E10–E19. [Google Scholar] [CrossRef]

- Fomin, O.; Derevianchenko, O. Improvement of the Quality of Cutting Tools States Recognition Using Cloud Technologies. In Advances in Design, Simulation and Manufacturing III. DSMIE-2020. Lecture Notes in Mechanical Engineering; Ivanov, V., Trojanowska, J., Pavlenko, I., Zajac, J., Peraković, D., Eds.; Vol. 1—Manufacturing and Materials Engineering; Springer: Cham, Switzerland, 2020; pp. 243–252. [Google Scholar] [CrossRef]

- Derevianchenko, O.; Fomin, O. Complex Recognition Approach for Cutting Part of Cutters in Finishing Turning. In Advances in Design, Simulation and Manufacturing IV. DSMIE-2021. Lecture Notes in Mechanical Engineering; Ivanov, V., Trojanowska, J., Pavlenko, I., Zajac, J., Peraković, D., Eds.; Vol. 1—Manufacturing and Materials Engineering; Springer: Cham, Switzerland, 2021; pp. 21–30. [Google Scholar]

- Tlhabadira, I.; Daniyan, I.A.; Machaka, R.; Machio, C.; Masu, L.; VanStaden, L.R. Modelling and optimization of surface roughness during AISI P20 milling process using Taguchi method. Int. J. Adv. Manuf. Technol. 2019, 102, 3707–3718. [Google Scholar] [CrossRef]

- Xu, L.-H.; Huang, C.-Z.; Niu, J.-H.; Wang, J.; Liu, H.-L.; Wang, X.-D. Prediction of cutting power and surface quality, and optimization of cutting parameters using new inference system in high-speed milling process. Adv. Manuf. 2021, 9, 388–402. [Google Scholar] [CrossRef]

- Cao, H.; Liu, L.; Wu, B.; Gao, Y.; Qu, D. Process optimization of high-speed dry milling UD-CF/PEEK laminates using GA-BP neural network. Compos. Part B Eng. 2021, 221, 109034. [Google Scholar] [CrossRef]

- Klocke, F.; Raedt, H.-W.; Hoppe, S. 2d-Fem Simulation of The Orthogonal High Speed Cutting Process. Mach. Sci. Technol. 2001, 5, 323–340. [Google Scholar] [CrossRef]

- Sartkulvanich, P.; Altan, T.; Göcmen, A. Effects of flow stress and friction models in finite element simulation of orthogonal cutting—A sensitivity analysis. Mach. Sci. Technol. 2005, 9, 1–26. [Google Scholar] [CrossRef]

- Özel, T.; Zeren, E. Determination of work material flow stress and friction for FEA of machining using orthogonal cutting tests. J. Mater. Process. Technol. 2004, 153-154, 1019–1025. [Google Scholar] [CrossRef]

- Habak, M.; Lebrun, J.L.; Levet, D.B. Effect of the microstructure on the tool/chip tribological contact in hard turning of 100Cr6 bearing steel. In Proceedings of the 10th CIRP International Workshop on Modeling of Machining Operations, Atlanta, GA, USA, 19 May 1998. [Google Scholar]

- Chandrasekaran, H.; Kapoor, S.G. Photoelastic analysis of tool-chip interface stresses. Trans. ASME 1965, 87, 78–91. [Google Scholar] [CrossRef]

- Ivchenko, O.; Zhyhylii, D.; Zaloha, O.; Zaloga, V.; Dehtiarenko, O. Resolution of the Friction Coefficient of Adhesion Under Cutting. In Advanced Manufacturing Processes. InterPartner-2019. Lecture Notes in Mechanical Engineering; Tonkonogyi, V., Ed.; Springer: Cham, Switzerland, 2020; pp. 98–107. [Google Scholar]

- Zaloga, V.; Krivoruchko, D.V.; Lebedev, V.Y. The effect of the nitrogen ion-beam implantation on adhesiveness of the WC-8Co hard alloy. J. Superhard Mater. 2012, 34, 44–48. [Google Scholar] [CrossRef]

- Storchak, M.; Rupp, P.; Möhring, H.-C.; Stehle, T. Determination of Johnson–Cook constitutive parameters for cutting sim-ulations. Metals 2019, 9, 473. [Google Scholar] [CrossRef] [Green Version]

- Kaščák, J.; Gašpár, Š.; Paško, J.; Husár, J.; Knapčíková, L. Polylactic Acid and Its Cellulose Based Composite as a Significant Tool for the Production of Optimized Models Modified for Additive Manufacturing. Sustainability 2021, 13, 1256. [Google Scholar] [CrossRef]

| Turning Insert Number | Recommended * | Simulation Results ** | Optimality Simulations Results *** | Optimality Criteria **** | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Vmax, m/min | Vmin, m/min | Smax, mm/rev | Smin, mm/rev | Vmax, m/min | Vmin, m/min | Smax, mm/rev | Smin, mm/rev | t, mm | SV, mm/rev | VS, m/min | Cmin, USD | ∏F, mm2/min | |

| 1 | 460 | 365 | 0.25 | 0.10 | 456 | 345 | 0.20 | 0.07 | 0.6 | 0.20 | 395 | 93.35 | 74.8 |

| 2 | 445 | 435 | 0.25 | 0.15 | 423 | 413 | 0.20 | 0.12 | 0.6 | 0.25 | 435 | 12.13 | 62.3 |

| 3 | 525 | 440 | 0.20 | 0.10 | 446 | 374 | 0.15 | 0.07 | 0.6 | 0.15 | 465 | 201.4 | 43.5 |

| 4 | 368 | 198 | 0.50 | 0.18 | 332 | 178 | 0.35 | 0.15 | 0.6 | 0.20 | 283 | 115.8 | 63.0 |

| Base value | 93.35 | 74.8 | |||||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivchenko, O.; Ivanov, V.; Trojanowska, J.; Zhyhylii, D.; Ciszak, O.; Zaloha, O.; Pavlenko, I.; Hladyshev, D. Method for an Effective Selection of Tools and Cutting Conditions during Precise Turning of Non-Alloy Quality Steel C45. Materials 2022, 15, 505. https://doi.org/10.3390/ma15020505

Ivchenko O, Ivanov V, Trojanowska J, Zhyhylii D, Ciszak O, Zaloha O, Pavlenko I, Hladyshev D. Method for an Effective Selection of Tools and Cutting Conditions during Precise Turning of Non-Alloy Quality Steel C45. Materials. 2022; 15(2):505. https://doi.org/10.3390/ma15020505

Chicago/Turabian StyleIvchenko, Oleksandr, Vitalii Ivanov, Justyna Trojanowska, Dmytro Zhyhylii, Olaf Ciszak, Olha Zaloha, Ivan Pavlenko, and Dmytro Hladyshev. 2022. "Method for an Effective Selection of Tools and Cutting Conditions during Precise Turning of Non-Alloy Quality Steel C45" Materials 15, no. 2: 505. https://doi.org/10.3390/ma15020505

APA StyleIvchenko, O., Ivanov, V., Trojanowska, J., Zhyhylii, D., Ciszak, O., Zaloha, O., Pavlenko, I., & Hladyshev, D. (2022). Method for an Effective Selection of Tools and Cutting Conditions during Precise Turning of Non-Alloy Quality Steel C45. Materials, 15(2), 505. https://doi.org/10.3390/ma15020505