Fracture Behavior of Long Fiber Reinforced Geopolymer Composites at Different Operating Temperatures

Abstract

:1. Introduction

- SKOBIFIX 30—geopolymer foam dedicated for heating systems, produced by Skoberne, Pfungstadt, Germany;

- Nu-Core®A2FR—fireproof geopolymer composite panels, produced by Nu-core®, Canberra, Australia;

- Ino-Flamm®—fire resistant geopolymer paint, produced by INOMAT, Neunkirchen, Germany;

- Desil Al—binder systems to the foundry industry, produced by Vodnis Klo, Prague, Czech Republic.

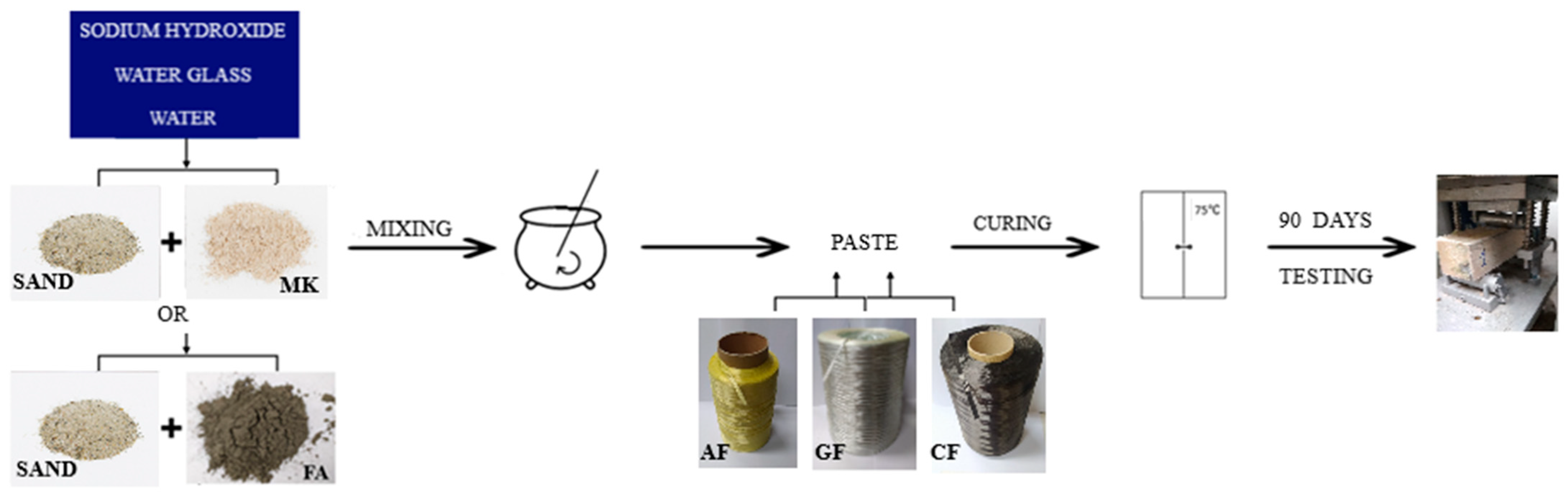

2. Materials and Methods

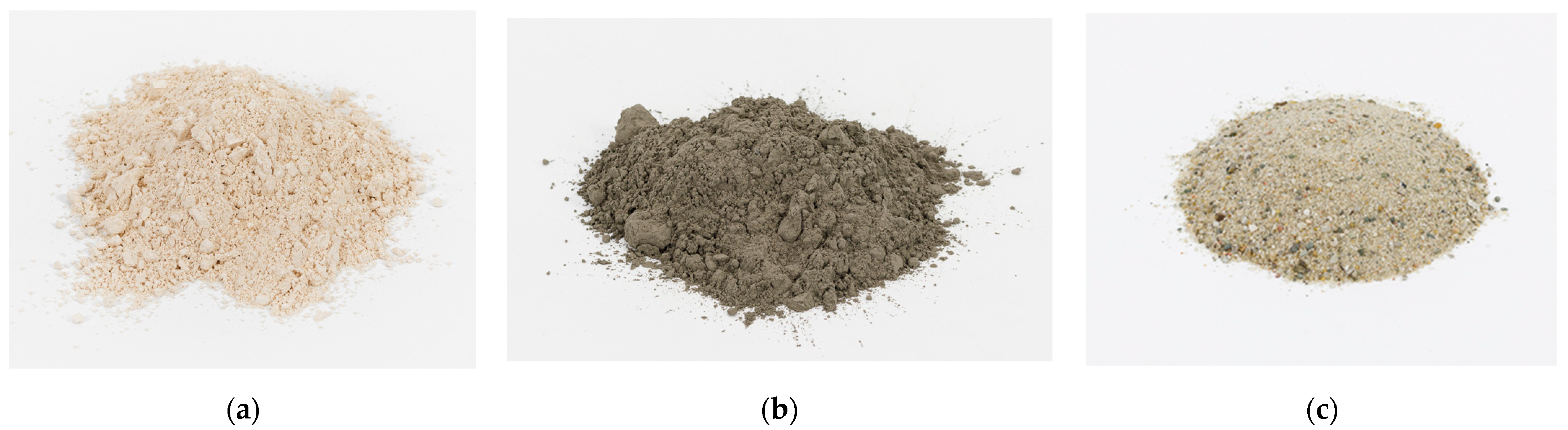

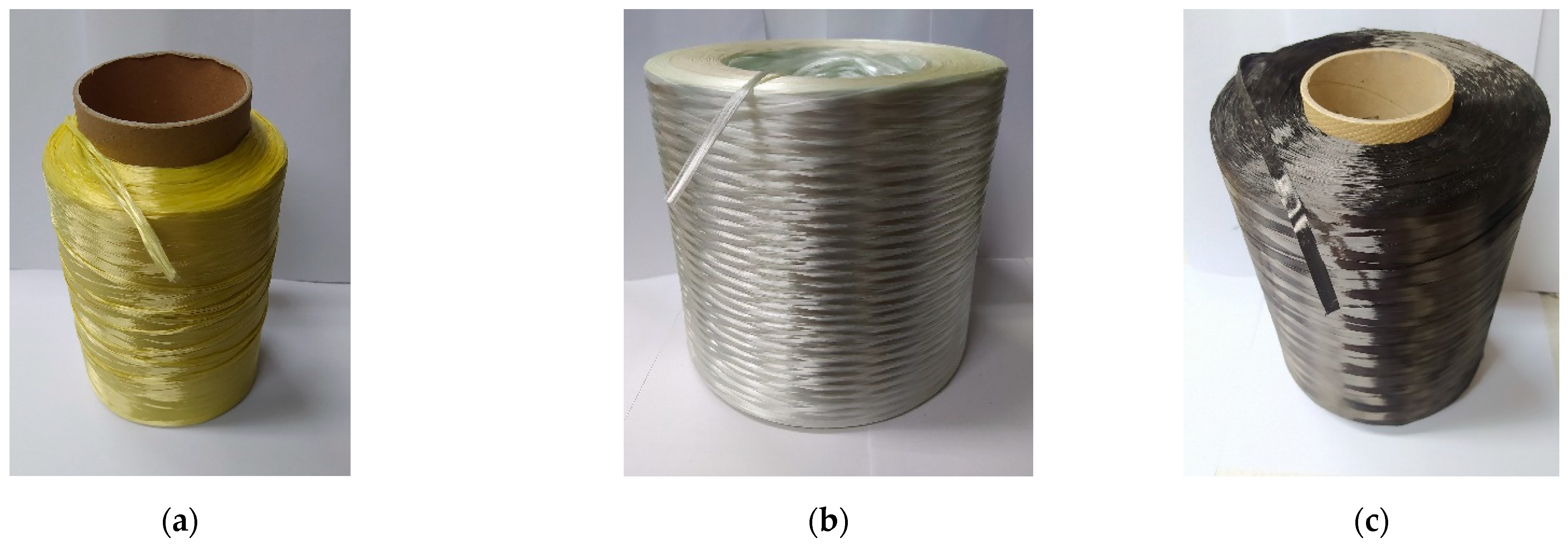

2.1. Materials

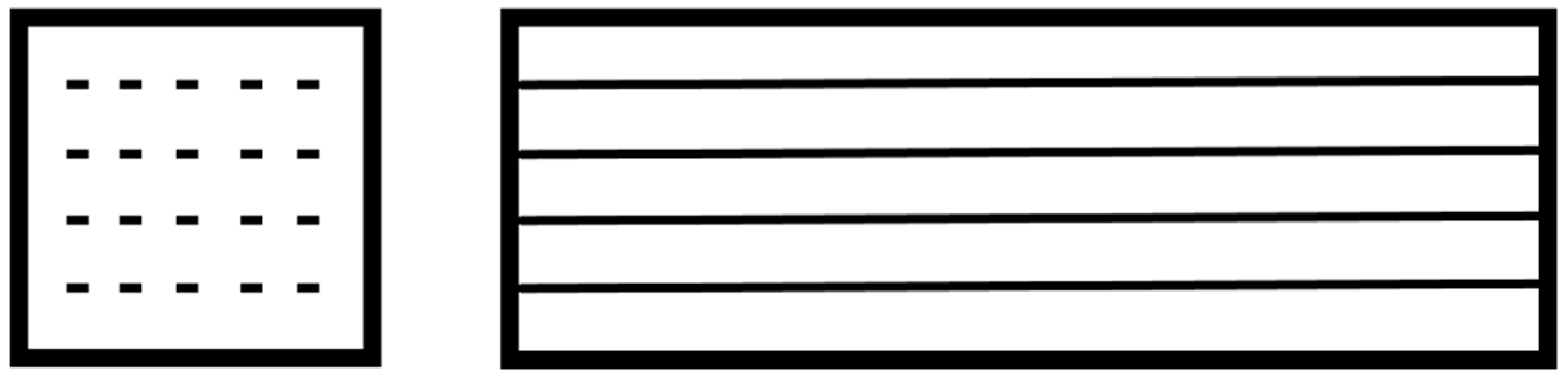

2.2. Sample Preparation

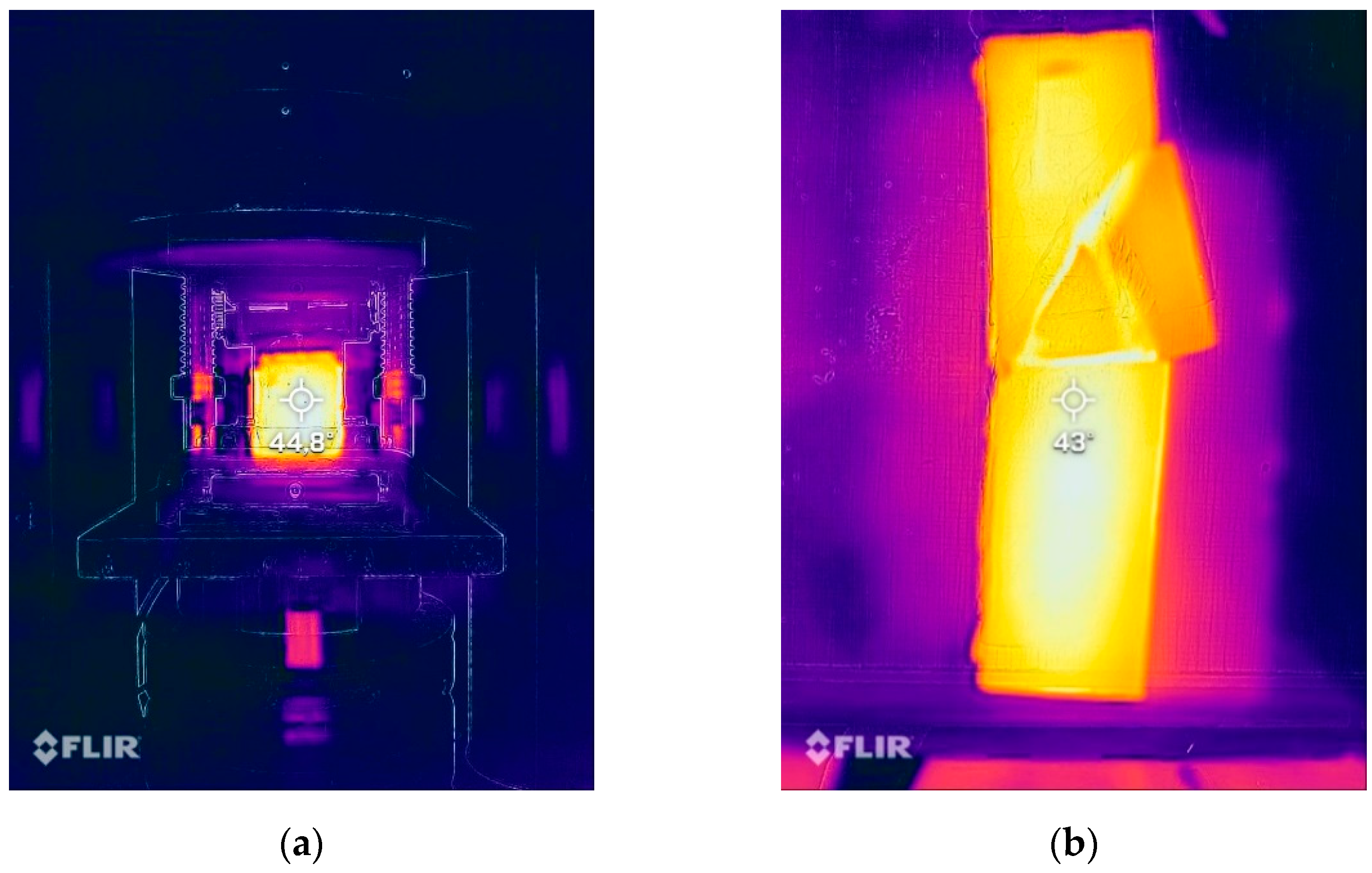

2.3. Methods

3. Results

3.1. Density

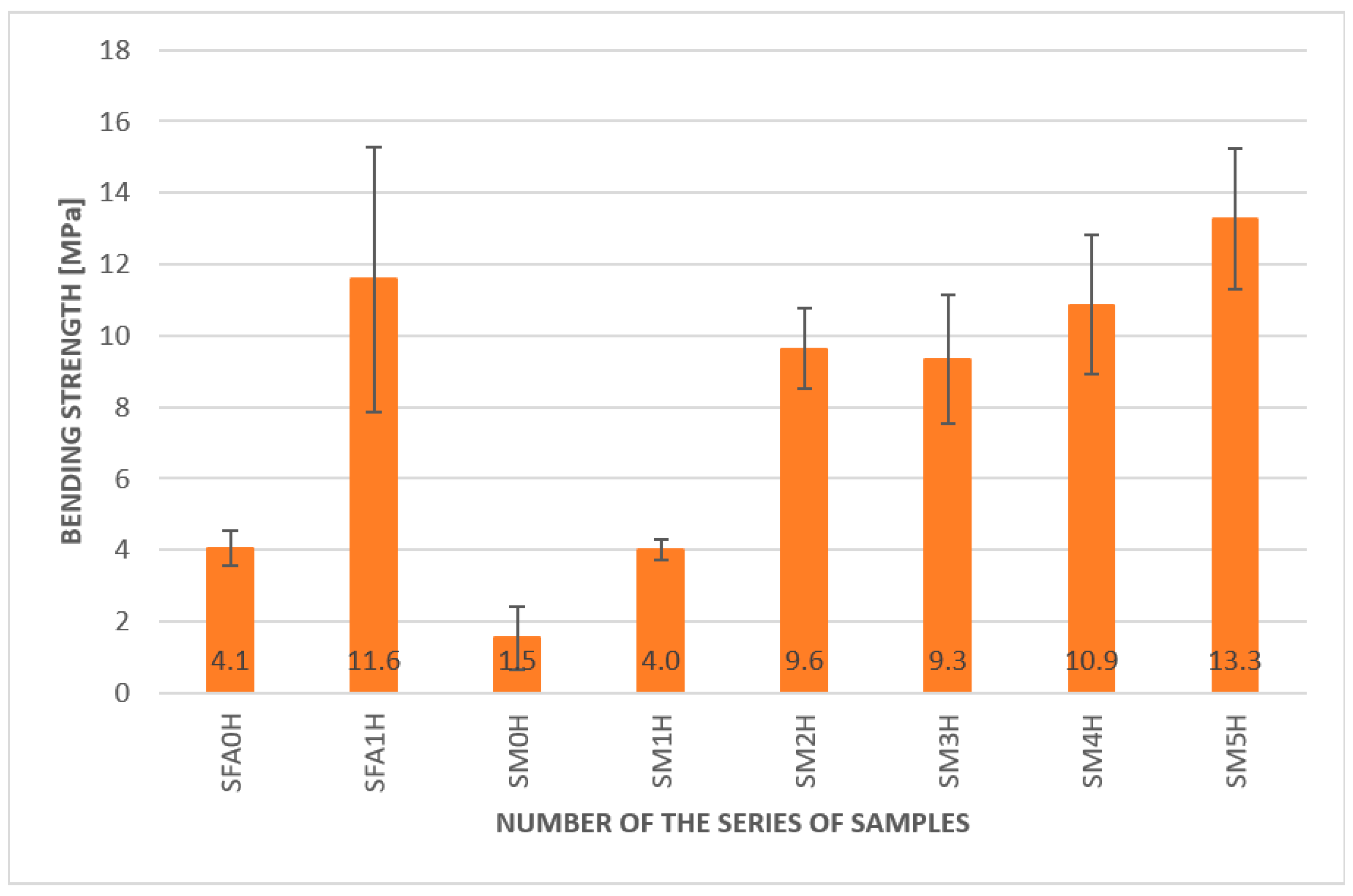

3.2. Bending Strength—Ambient Temperature

3.3. Bending Strength—High Temperature

3.4. Bending Strength—Low Temperature

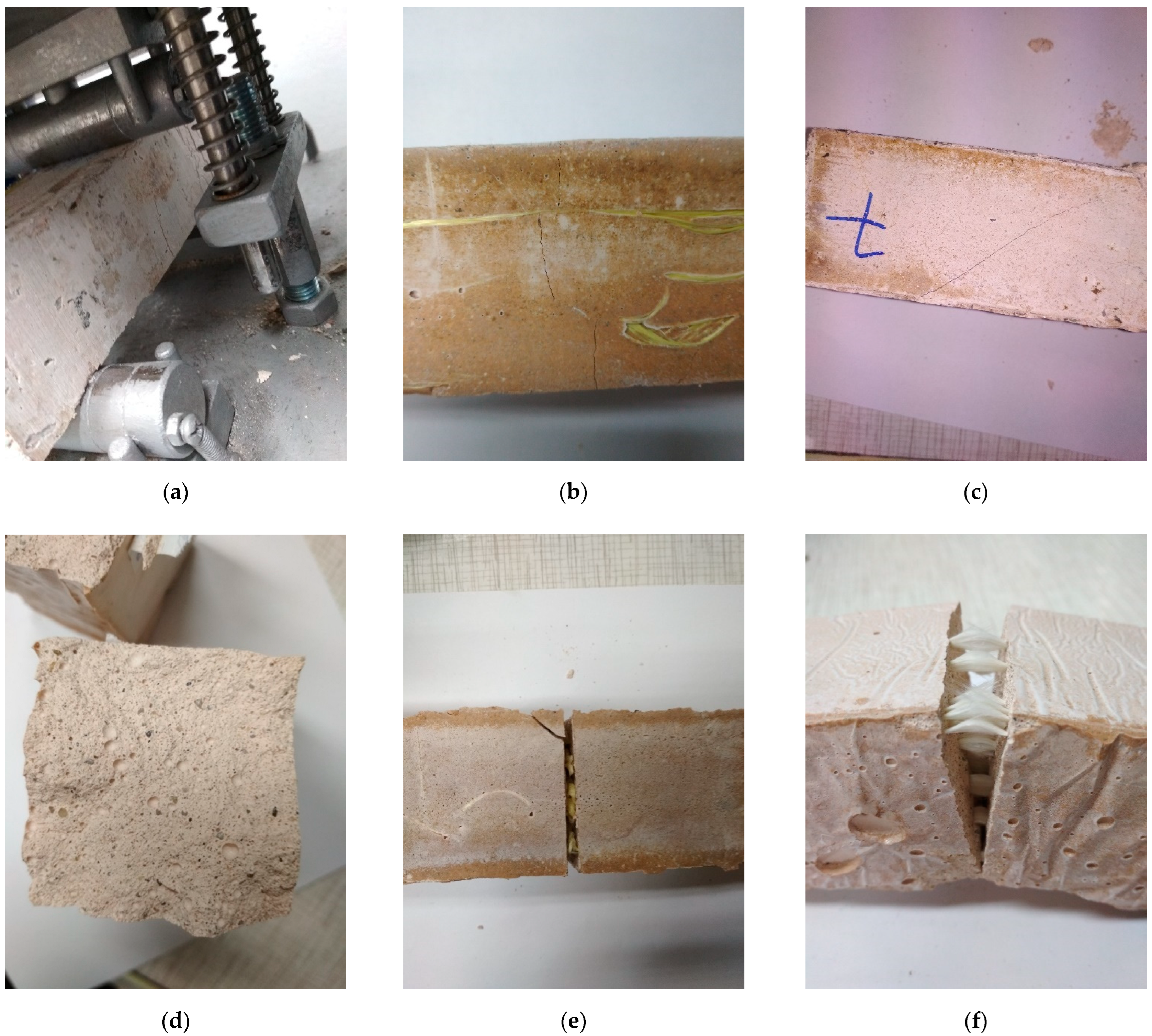

3.5. Study of the Fracture Mechanism

4. Discussion

5. Conclusions

- Density changes are not significant, taking into account fiber addition. This value is comparable to the standard geopolymer created using sand as a fine aggregate, where the density value was usually between 1.4 and 1.70 g/cm3.

- The samples with fibers in the case of the geopolymer matrix based on metakaolin and fly ash showed higher values of bending strength than the pure matrix. The best results were achieved for the 2.0% addition of aramid fibers. The overall tendency of material behavior in the temperature of approximately 50 °C was similar to results obtained for ambient temperature. The best result was obtained for the geopolymer based on metakaolin with a 2.0% addition of aramid fibers—13.3 MPa.

- The best result was obtained for the fly ash-based matrix with a 2.0% aramid fiber addition; it was 17 MPa, compared to 6.9 MPa for the pure fly ash-based matrix at ambient temperature.

- It was a fly ash-based geopolymer with a 2.0% addition of aramid fibers, a metakaolin-based geopolymer with a 2.0% addition of carbon fibers, and a metakaolin-based geopolymer with a 0.5% addition of aramid fibers. Among them, the highest values were obtained for the fly ash-based geopolymer with a 2.0% addition of aramid fibers, which seems to be a promising composite for applications in lower temperatures.

- Comparison of the results obtained in lowered temperature, approximately 3 °C, to the results obtained in the temperature of approximately 50 °C, showed that in all samples, the values of bending strength were higher in lower temperature. For most samples, this change was between 40 and 80%.

- The results obtained showed the highest values obtained for the metakaolin composite based on metakaolin with a 2.0% addition of aramid fibers. Even if the value for bending strength for this composition in elevated and lowered temperatures decreased compared to the obtained value in ambient temperature, it was still higher than for other compositions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Davidovits, J. Geopolymer Chemistry and Applications, 4th ed.; Geopolymer Institute: Saint-Quentin, France, 2015; p. 644. [Google Scholar]

- Provis, J.; Palomo, A.; Shi, C. Advances in understanding alkali-activated materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Palomo, A.; Krivenko, P.V.; Garcia-Lodeiro, I.; Kavalerova, E.; Maltseva, O.; Fernández-Jimenez, A.M. A review on alkaline activation: New analytical perspectives. Mater. Constr. 2014, 64, e022. [Google Scholar] [CrossRef] [Green Version]

- Singh, N. Fly Ash-Based Geopolymer Binder: A Future Construction Material. Minerals 2018, 8, 299. [Google Scholar] [CrossRef] [Green Version]

- Łach, M.; Korniejenko, K.; Mikuła, J. Thermal Insulation and Thermally Resistant Materials Made of Geopolymer Foams. Procedia Eng. 2016, 151, 410–416. [Google Scholar] [CrossRef] [Green Version]

- Davidovits, J. 30 Years of Successes and Failures in Geopolymer Applications. Market Trends and Potential Breakthroughs. In Proceedings of the Geopolymer 2002 Conference, Melbourne, VIC, Australia, 28–29 October 2002; Available online: https://www.geopolymer.org/wp-content/uploads/30YearsGEOP.pdf (accessed on 10 October 2021).

- Łach, M. Geopolymer Foams—Will They Ever Become a Viable Alternative to Popular Insulation Materials?—A Critical Opinion. Materials 2021, 14, 3568. [Google Scholar] [CrossRef]

- Furtos, G.; Molnar, L.; Silaghi-Dumitrescu, L.; Pascuta, P.; Korniejenko, K. Mechanical and thermal properties of wood fiber reinforced geopolymer composites. J. Nat. Fibers 2021, 1–16. [Google Scholar] [CrossRef]

- Novais, R.M.; Ascensão, G.; Buruberri, L.; Senff, L.; Labrincha, J. Influence of blowing agent on the fresh- and hardened-state properties of lightweight geopolymers. Mater. Des. 2016, 108, 551–559. [Google Scholar] [CrossRef]

- Novais, R.M.; Seabra, M.; Labrincha, J. Ceramic tiles with controlled porosity and low thermal conductivity by using pore-forming agents. Ceram. Int. 2014, 40, 11637–11648. [Google Scholar] [CrossRef]

- Novais, R.M.; Ascensão, G.; Seabra, M.; Labrincha, J. Lightweight dense/porous PCM-ceramic tiles for indoor temperature control. Energy Build. 2015, 108, 205–214. [Google Scholar] [CrossRef]

- Sarazin, J.; Davy, C.A.; Bourbigot, S.; Tricot, G.; Hosdez, J.; Lambertin, D.; Fontaine, G. Flame resistance of geopolymer foam coatings for the fire protection of steel. Compos. Part B Eng. 2021, 222, 109045. [Google Scholar] [CrossRef]

- Pasupathy, K.; Sanjayan, J.; Rajeev, P. Evaluation of alkalinity changes and carbonation of geopolymer concrete exposed to wetting and drying. J. Build. Eng. 2020, 35, 102029. [Google Scholar] [CrossRef]

- Pasupathy, K.; Cheema, D.S.; Sanjayan, J. Durability performance of fly ash-based geopolymer concrete buried in saline environment for 10 years. Constr. Build. Mater. 2021, 281, 122596. [Google Scholar] [CrossRef]

- Korniejenko, K.; Łach, M.; Mikuła, J. The Influence of Short Coir, Glass and Carbon Fibers on the Properties of Composites with Geopolymer Matrix. Materials 2021, 14, 4599. [Google Scholar] [CrossRef]

- Sitarz, M.; Hager, I.; Kochanek, J. Effect of High Temperature on Mechanical Properties of Geopolymer Mortar. MATEC Web Conf. 2018, 163, 06004. [Google Scholar] [CrossRef]

- Figiela, B.; Šimonová, H.; Korniejenko, K. State-of-the-Art, Challenges and Emerging trends: Geopolymer Composite Reinforced by Dispersed Steel Fibers. Rev. Adv. Mater. Sci. 2021, 60. accepted for publication. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Hosan, A. Mechanical properties of steel fibre reinforced geopolymer concretes at elevated temperatures. Constr. Build. Mater. 2016, 114, 15–28. [Google Scholar] [CrossRef]

- Shaikh, F.; Haque, S. Behaviour of Carbon and Basalt Fibres Reinforced Fly Ash Geopolymer at Elevated Temperatures. Int. J. Concr. Struct. Mater. 2018, 12, 35. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.-Y.; Hao, X.; Fan, W. Experimental Study on High Temperature Properties of Carbon Fiber Sheets Strengthened Concrete Cylinders Using Geopolymer as Adhesive. Procedia Eng. 2016, 135, 47–55. [Google Scholar] [CrossRef]

- Behera, P.; Baheti, V.; Militky, J.; Naeem, S. Microstructure and mechanical properties of carbon microfiber reinforced geopolymers at elevated temperatures. Constr. Build. Mater. 2018, 160, 733–743. [Google Scholar] [CrossRef]

- Behera, P.; Baheti, V.; Militky, J.; Louda, P. Elevated temperature properties of basalt microfibril filled geopolymer composites. Constr. Build. Mater. 2018, 163, 850–860. [Google Scholar] [CrossRef]

- Celik, A.; Yilmaz, K.; Canpolat, O.; Al-Mashhadani, M.M.; Aygörmez, Y.; Uysal, M. High-temperature behavior and mechanical characteristics of boron waste additive metakaolin based geopolymer composites reinforced with synthetic fibers. Constr. Build. Mater. 2018, 187, 1190–1203. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.; Low, I.M. Characterisation of cotton fibre-reinforced geopolymer composites. Compos. Part B Eng. 2013, 50, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Alomayri, T.; Shaikh, F.; Low, I. Mechanical and thermal properties of ambient cured cotton fabric-reinforced fly ash-based geopolymer composites. Ceram. Int. 2014, 40, 14019–14028. [Google Scholar] [CrossRef]

- Constancio Trindade, A.C.; Alcamand, H.A.; Ribeiro Borges, P.H.; de Andrade Silva, F. Influence of Elevated Temperatures on the Mechanical Behavior of Jute-Textile-Reinforced Geopolymers. J. Ceram. Sci. Technol. 2017, 8, 389–398. [Google Scholar] [CrossRef]

- Teixeira-Pinto, A.; Varela, B.; Shrotri, K.; Panandiker, R.S.P.; Lawson, J. Geopolymer-Jute Composite: A Novel Environmentally Friendly Compposite with Fire Resistant Properties. In Development in Porous, Biological and Geopolymer Ceramics; Brito, M., Case, E., Kriven, W.M., Eds.; Wiley-Interscience: Hoboken, NJ, USA, 2008; pp. 338–345. [Google Scholar]

- Bindiganavile, V.; Goncalves, J.R.; Boluk, Y. Crack Growth Resistance in Fibre Reinforced Geopolymer Concrete Exposed to Sustained Extreme Temperatures. Key Eng. Mater. 2016, 711, 511–518. [Google Scholar] [CrossRef]

- Aygörmez, Y.; Canpolat, O.; Al-Mashhadani, M.M.; Uysal, M. Elevated temperature, freezing-thawing and wetting-drying effects on polypropylene fiber reinforced metakaolin based geopolymer composites. Constr. Build. Mater. 2019, 235, 117502. [Google Scholar] [CrossRef]

- Bazan, P.; Kozub, B.; Łach, M.; Korniejenko, K. Evaluation of Hybrid Melamine and Steel Fiber Reinforced Geopolymers Composites. Materials 2020, 13, 5548. [Google Scholar] [CrossRef] [PubMed]

- Łach, M.; Korniejenko, K.; Hebdowska-Krupa, M.; Mikuła, J. The Effect of Additives on the Properties of Metakaolin and Fly Ash Based Geopolymers. MATEC Web Conf. 2018, 163, 06005. [Google Scholar] [CrossRef]

- Korniejenko, K.; Figiela, B.; Miernik, K.; Ziejewska, C.; Marczyk, J.; Hebda, M.; Cheng, A.; Lin, W.-T. Mechanical and Fracture Properties of Long Fiber Reinforced Geopolymer Composites. Materials 2021, 14, 5183. [Google Scholar] [CrossRef] [PubMed]

- Łach, M.; Mierzwiński, D.; Korniejenko, K.; Stanek, A.; Mikuła, J. The behaviour of alkali activated materials based on calcium clay at elevated temperatures. MATEC Web Conf. 2018, 247, 00054. [Google Scholar] [CrossRef] [Green Version]

- Prałat, K.; Ciemnicka, J.; Koper, A.; Buczkowska, K.; Łoś, P. Comparison of the Thermal Properties of Geopolymer and Modified Gypsum. Polymers 2021, 13, 1220. [Google Scholar] [CrossRef]

- Kozub, B.; Bazan, P.; Mierzwiński, D.; Korniejenko, K. Fly-Ash-Based Geopolymers Reinforced by Melamine Fibers. Materials 2021, 14, 400. [Google Scholar] [CrossRef] [PubMed]

- Baziak, A.; Pławecka, K.; Hager, I.; Castel, A.; Korniejenko, K. Development and Characterization of Lightweight Geopolymer Composite Reinforced with Hybrid Carbon and Steel Fibers. Materials 2021, 14, 5741. [Google Scholar] [CrossRef]

- Le, V.S.; Louda, P.; Tran, H.N.; Nguyen, P.D.; Bakalova, T.; Buczkowska, K.E.; Dufkova, I. Study on Temperature-Dependent Properties and Fire Resistance of Metakaolin-Based Geopolymer Foams. Polymers 2020, 12, 2994. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Kodur, V.; Qi, S.L.; Cao, L.; Wu, B. Development of metakaolin–fly ash based geopolymers for fire resistance applications. Constr. Build. Mater. 2014, 55, 38–45. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; Abdullah, M.M.A.B.; Hussin, K.; Ismail, K.N.; Binhussain, M. Mechanical and Microstructural Evaluations of Lightweight Aggregate Geopolymer Concrete before and after Exposed to Elevated Temperatures. Materials 2013, 6, 4450–4461. [Google Scholar] [CrossRef] [Green Version]

- Elimbi, A.; Tchakoute, H.; Kondoh, M.; Manga, J.D. Thermal behavior and characteristics of fired geopolymers produced from local Cameroonian metakaolin. Ceram. Int. 2014, 40, 4515–4520. [Google Scholar] [CrossRef]

- Ciemnicka, J.; Prałat, K.; Koper, A.; Makomaski, G.; Majewski, L.; Wójcicka, K.; Buczkowska, K. Changes in the Strength Properties and Phase Transition of Gypsum Modified with Microspheres, Aerogel and HEMC Polymer. Materials 2021, 14, 3486. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; Al Bakri, A.M.; Kamarudin, H.; Nizar, I.K.; Saif, A.A. Effects of elevated temperatures on the thermal behavior and mechanical performance of fly ash geopolymer paste, mortar and lightweight concrete. Constr. Build. Mater. 2014, 50, 377–387. [Google Scholar] [CrossRef]

- Vogt, O.; Ukrainczyk, N.; Ballschmiede, C.; Koenders, E. Reactivity and Microstructure of Metakaolin Based Geopolymers: Effect of Fly Ash and Liquid/Solid Contents. Materials 2019, 12, 3485. [Google Scholar] [CrossRef] [Green Version]

- Tchakouté, H.K.; Rüscher, C.H.; Kong, S.; Kamseu, E.; Leonelli, C. Thermal Behavior of Metakaolin-Based Geopolymer Cements Using Sodium Waterglass from Rice Husk Ash and Waste Glass as Alternative Activators. Waste Biomass-Valorization 2016, 8, 573–584. [Google Scholar] [CrossRef]

- Pilehvar, S.; Szczotok, A.M.; Rodríguez, J.F.; Valentini, L.; Lanzón, M.; Pamies, R.; Kjøniksen, A.-L. Effect of freeze-thaw cycles on the mechanical behavior of geopolymer concrete and Portland cement concrete containing micro-encapsulated phase change materials. Constr. Build. Mater. 2018, 200, 94–103. [Google Scholar] [CrossRef]

| Sample Designation | Matrix | Reinforcement |

|---|---|---|

| SFA0 | Fly ash and sand | - |

| SFA1 | Fly ash and sand | Aramid fiber 2.0% wt. |

| SM0 | Metakaolin and sand | - |

| SM1 | Metakaolin and sand | Fiberglass 2.0% wt. |

| SM2 | Metakaolin and sand | Carbon fiber 2.0% wt. |

| SM3 | Metakaolin and sand | Aramid fiber 0.5% wt. |

| SM4 | Metakaolin and sand | Aramid fiber 1.0% wt. |

| SM5 | Metakaolin and sand | Aramid fiber 2.0% wt. |

| Sample | Ambient Temperature [MPa] | High Temperature [MPa] | % Change Compare to Ambient Temperature | Low Temperature [MPa] | % Change Compare to Ambient Temperature |

|---|---|---|---|---|---|

| SFA0 | 7.9 | 4.1 | 51.90 | 6.9 | 87.34 |

| SFA1 | 8.8 | 11.6 | 131.82 | 17.2 | 195.45 |

| SM0 | 5.1 | 1.5 | 29.41 | 7.7 | 150.98 |

| SM1 | 8.2 | 4.0 | 48.78 | 6.8 | 82.93 |

| SM2 | 7.1 | 9.6 | 135.21 | 10.2 | 143.66 |

| SM3 | 8.9 | 9.8 | 110.11 | 13.9 | 156.18 |

| SM4 | 11.3 | 10.9 | 96.46 | 15.8 | 139.82 |

| SM5 | 17.0 | 13.3 | 78.24 | 16.0 | 94.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Korniejenko, K.; Figiela, B.; Ziejewska, C.; Marczyk, J.; Bazan, P.; Hebda, M.; Choińska, M.; Lin, W.-T. Fracture Behavior of Long Fiber Reinforced Geopolymer Composites at Different Operating Temperatures. Materials 2022, 15, 482. https://doi.org/10.3390/ma15020482

Korniejenko K, Figiela B, Ziejewska C, Marczyk J, Bazan P, Hebda M, Choińska M, Lin W-T. Fracture Behavior of Long Fiber Reinforced Geopolymer Composites at Different Operating Temperatures. Materials. 2022; 15(2):482. https://doi.org/10.3390/ma15020482

Chicago/Turabian StyleKorniejenko, Kinga, Beata Figiela, Celina Ziejewska, Joanna Marczyk, Patrycja Bazan, Marek Hebda, Marta Choińska, and Wei-Ting Lin. 2022. "Fracture Behavior of Long Fiber Reinforced Geopolymer Composites at Different Operating Temperatures" Materials 15, no. 2: 482. https://doi.org/10.3390/ma15020482

APA StyleKorniejenko, K., Figiela, B., Ziejewska, C., Marczyk, J., Bazan, P., Hebda, M., Choińska, M., & Lin, W.-T. (2022). Fracture Behavior of Long Fiber Reinforced Geopolymer Composites at Different Operating Temperatures. Materials, 15(2), 482. https://doi.org/10.3390/ma15020482