Comparison of Testing Methods for Evaluating the Resistance of Alkali-Activated Blast Furnace Slag Systems to Sulfur Dioxide

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation and Composition of Mortars

2.3. Testing of Resistance to Sulfur Dioxide

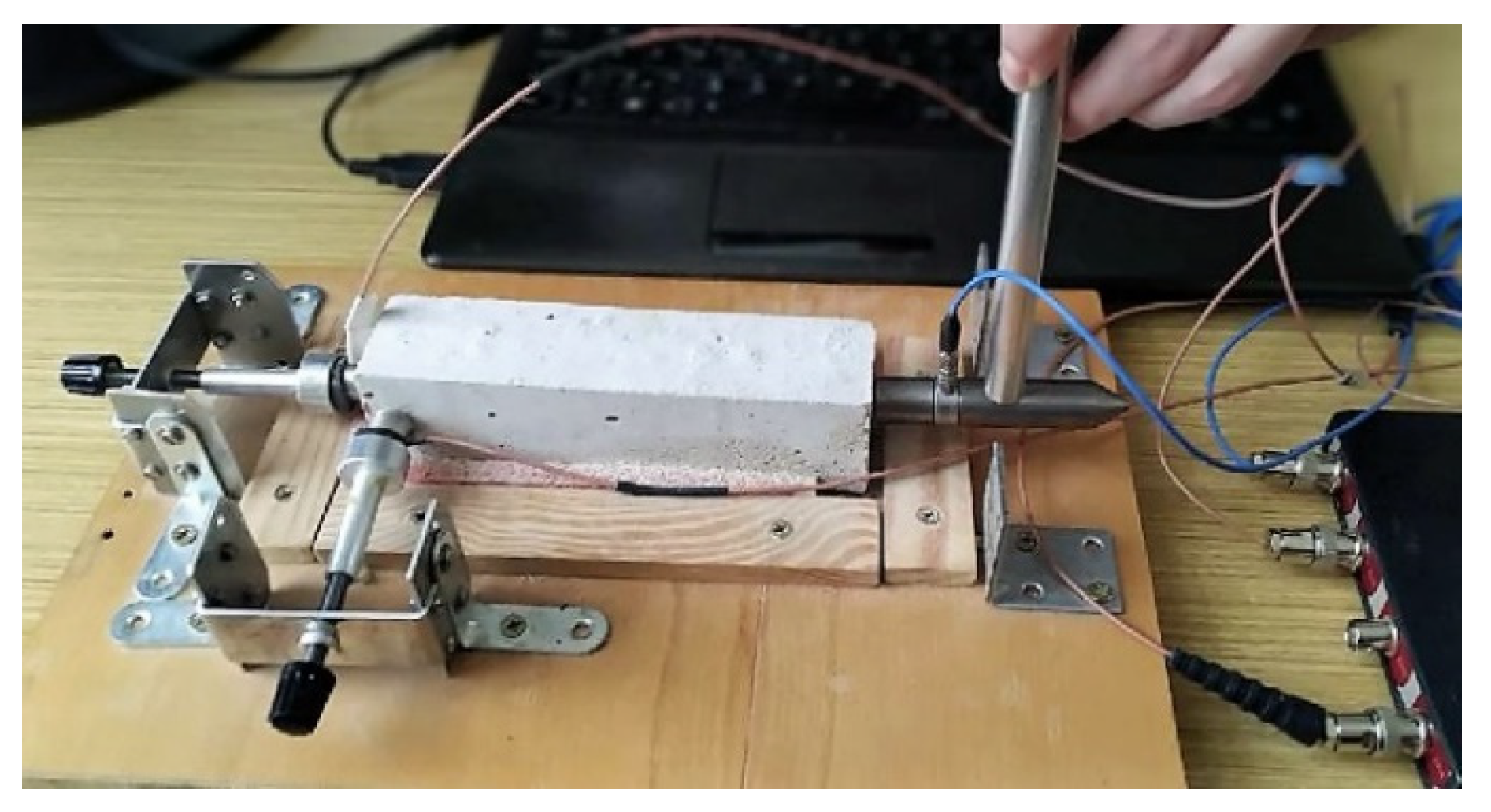

2.4. Testing Methods

3. Result and Discussion

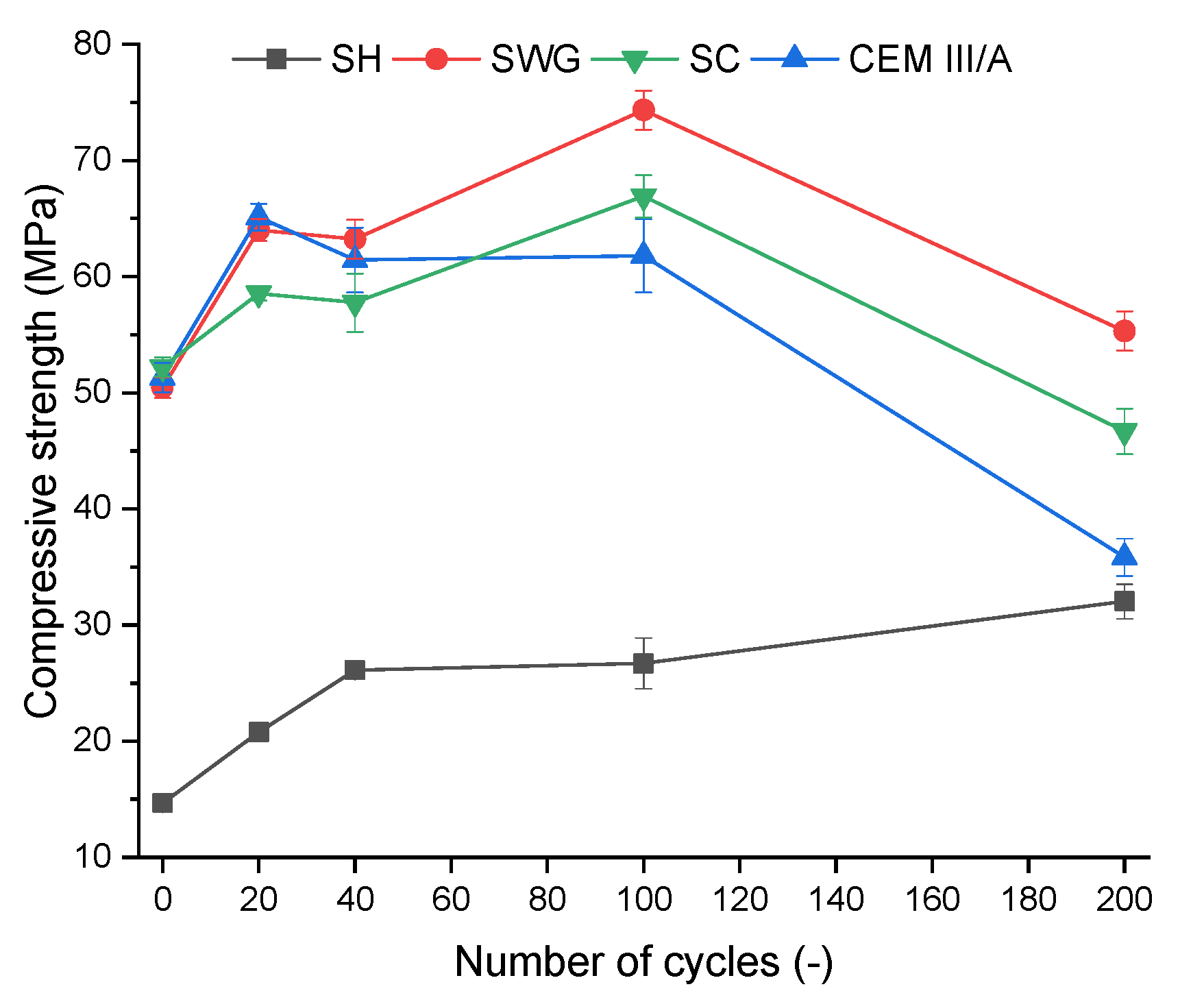

3.1. Compressive Strength Evaluation

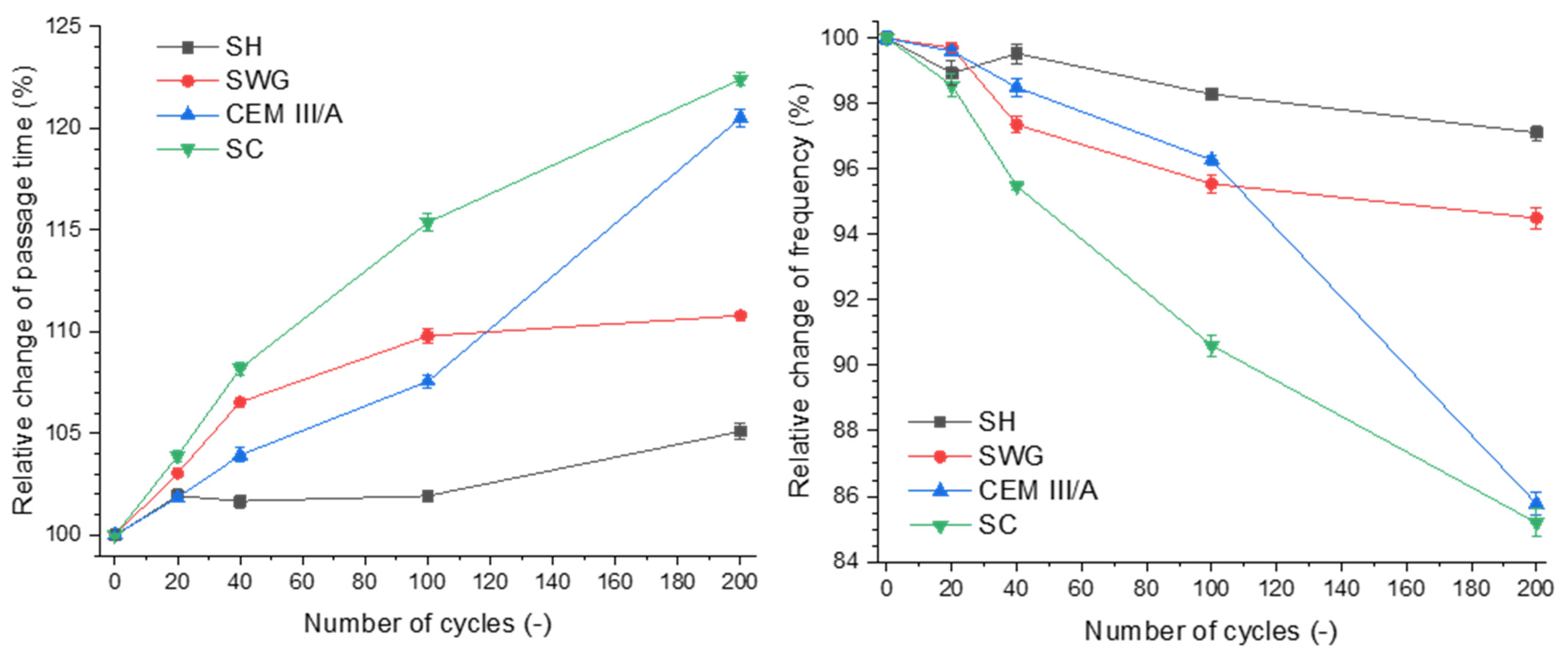

3.2. Ultrasound and Impact-Echo Evaluation Techniques

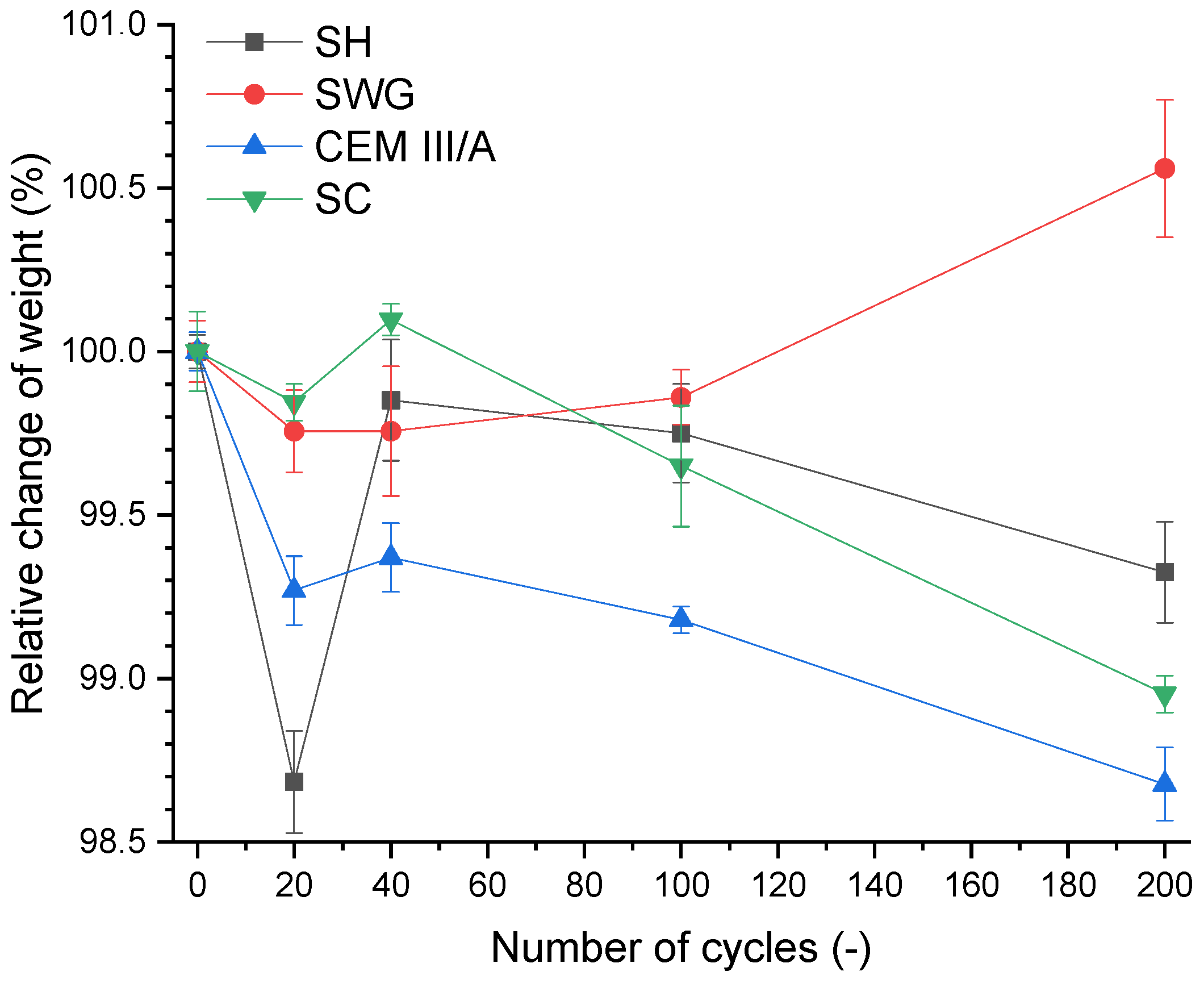

3.3. Weight Change Evaluation

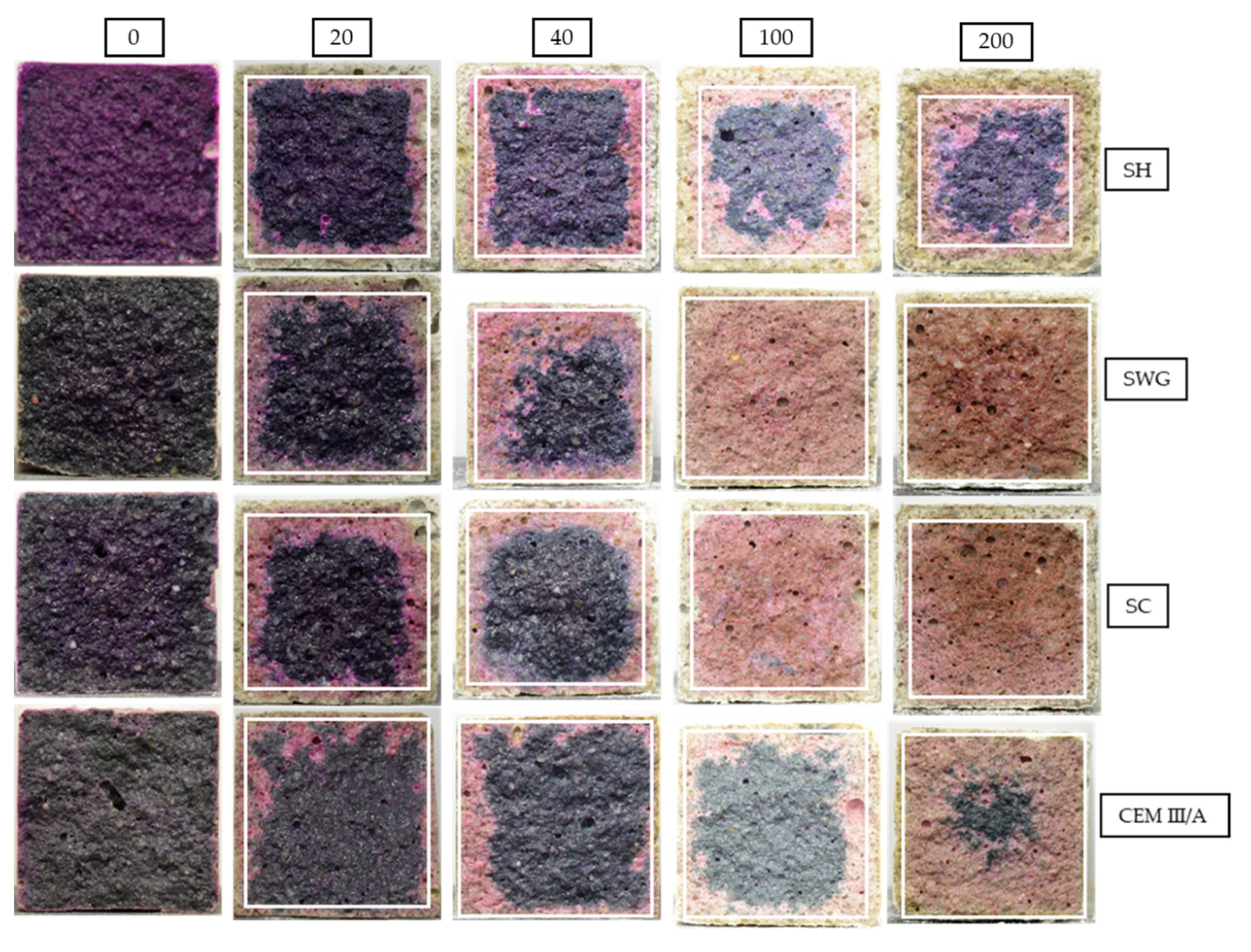

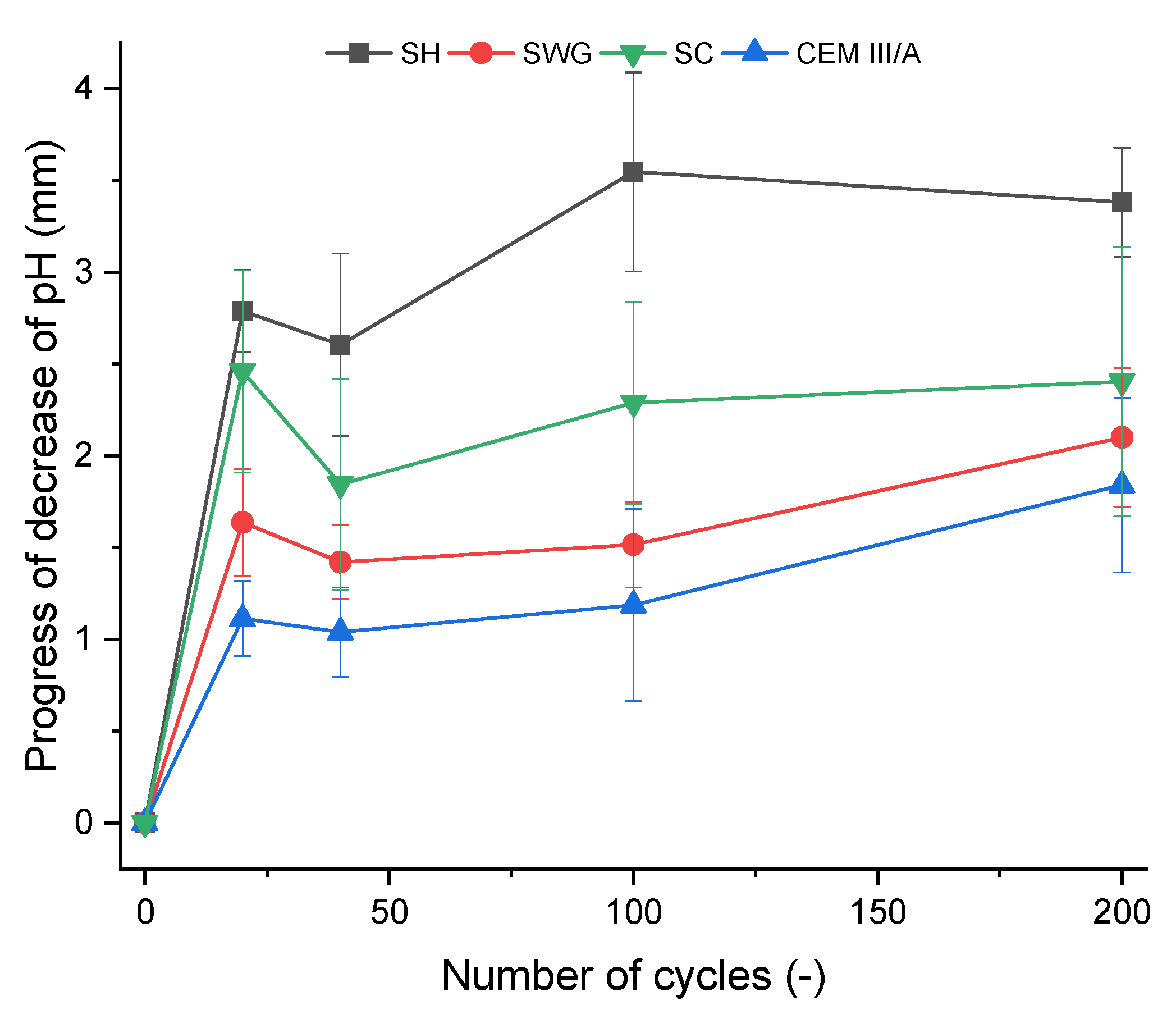

3.4. Visual Appearance/Phenolphthalein Technique

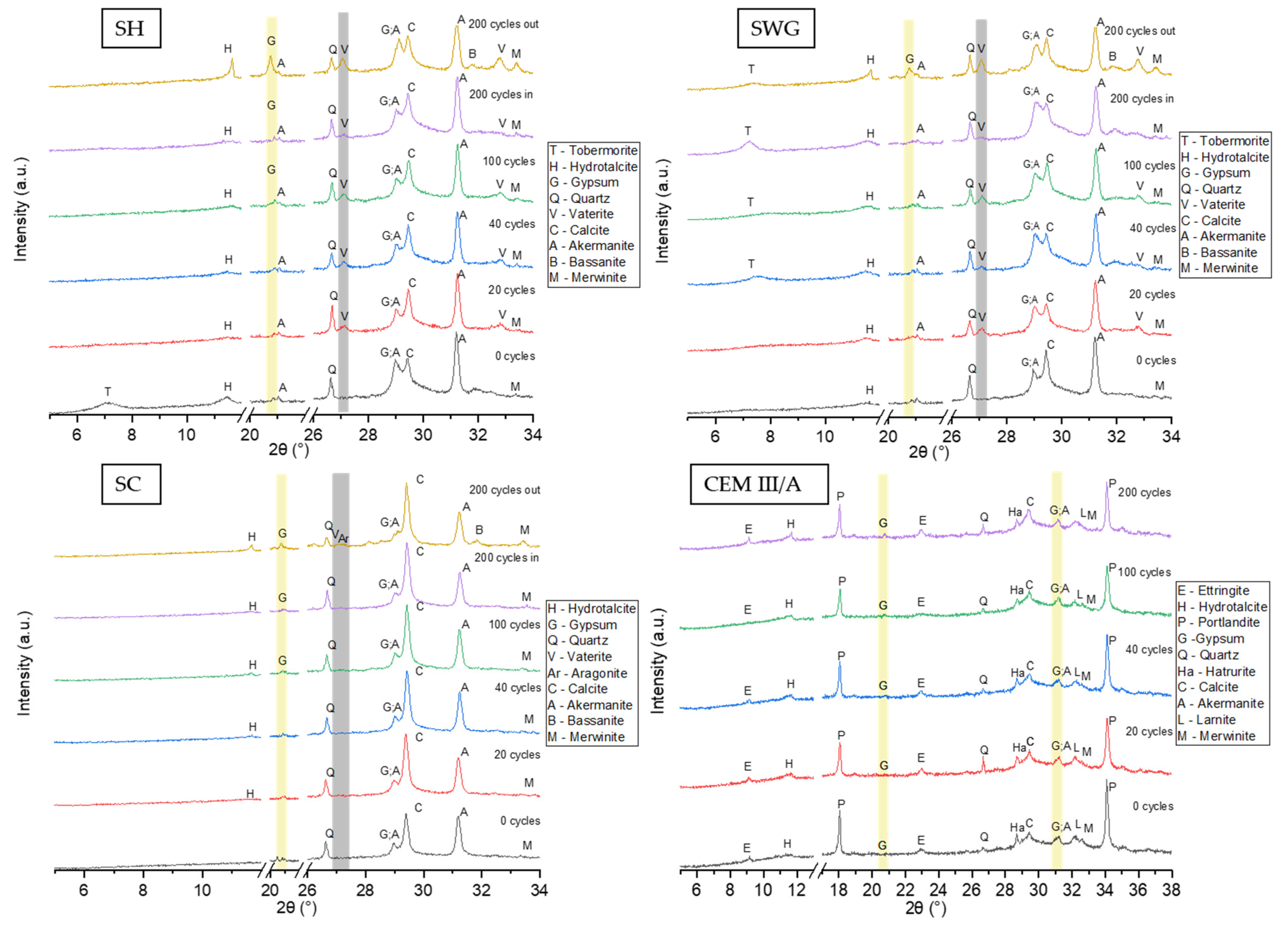

3.5. X-ray Powder Diffraction (XRD) and Elemental Analysis

4. Conclusions

- •

- The decrease of compressive strength during the standard testing of SO2 resistance according to CSN EN ISO 3231 was found for the systems activated by SWG, SC activator, and for CEM III/A. Contrarily, SH-activated BFS systems did not show any decrease in compressive strength.

- •

- Both ultrasound and impact-echo seem to be suitable techniques for the characterization of the progress of degradation. The usage of these methods is extremely beneficial for the evaluation of the state of building structures during service life.

- •

- The phenolphthalein technique indicating the loss of alkalinity of the matrix only showed a correlation with the XRD technique out of all characterization techniques.

- •

- The elemental analysis showed significant increase in sulfur content due to the SO2 cycling. The combination of XRD and elemental analysis seems to be suitable for the characterization of undergoing changes in phase composition and for the quantification of formed gypsum.

- •

- The resistance of various AAS against the action of SO2 according to the CSN EN ISO 3231 increases in the following order of activators: SC < SWG < SH.

- •

- SH-activated blast furnace slag showed the highest overall resistance to the action of SO2 of all tested binders.

- •

- Currently used standards are not applicable to the AAS. The wetting/drying cycles probably had more negative effects on the properties of tested binders than the effect of SO2. Therefore, the more appropriate method for the evaluation of SO2 resistance, which would take into account the characteristics of AAS, needs to be applied.

- •

- Further research should focus on the profound characterization of undergoing processes using other instrumental techniques. An innovative experimental design for the determination of the SO2 resistance suppressing the unsatisfactory aspects of the current one should be designed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pacheco-Torgal, F.; Abdollahnejad, Z.; Camões, A.; Jamshidi, M.; Ding, Y. Durability of alkali-activated binders: A clear advantage over Portland cement or an unproven issue? Constr. Build. Mater. 2012, 30, 400–405. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Scrivener, K.; Kirkpatrick, R.J. Innovation in use and research on cementitious material. Cem. Concr. Res. 2008, 38, 128–136. [Google Scholar] [CrossRef]

- Provis, J.L.; Van Deventer, J.S.J. Alkali Activated Materials: State-of-the-Art Report; Springer: Berlin/Heidelberg, Germany, 2014; p. 381. [Google Scholar]

- Shi, C.; Krivenko, P.; Roy, D. Alkali-Activated Cements and Concretes; Taylor & Francis: Abington, UK, 2006; p. 376. [Google Scholar]

- Madhuri, G.; Rao, S.K. Performance of alkali-activated slag concrete against sulphuric acidattack. Asian J. Civ. Eng. 2018, 1–11. [Google Scholar]

- Shi, C. Corrosion resistance of alkali-activated slag cement. Adv. Cem Res. 2003, 15, 77–81. [Google Scholar] [CrossRef]

- Bernal, S.; Rodriguez, E.; Gutiérrez, M.; Provis, J.L. Performance of alkali-activated slag mortars exposed to acids. J. Sustain. Cem-Based 2012, 1, 138–151. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.; Cheng, Y.-B. Sulfate attack on alkali-activated slag concrete. Cem. Concr. Res. 2002, 32, 211–216. [Google Scholar] [CrossRef]

- Rovnaník, P.; Bayer, P.; Rovnaníková, P. Characterization of alkali activated slag paste after exposure to high temperatures. Constr. Build. Mater. 2013, 47, 1479–1487. [Google Scholar] [CrossRef]

- Niu, J.; Wu, B.; Zhu, C.; Yang, P. Corrosion rules for ordinary concrete exposed to sulfur dioxide-containing environments. Toxicol. Environ. Chem. 2015, 97, 367–378. [Google Scholar] [CrossRef]

- Aliques-Granero, J.; Tognonvi, T.M.; Tagnit-Hamou, A. Durability test methods and their application to aams: Case of sulfu-ric-acid resistance. Mater. Struct. 2017, 50, 1–14. [Google Scholar] [CrossRef]

- Xie, Y.; Lin, X.; Ji, T.; Liang, Y.; Pan, W. Comparison of corrosion resistance mechanism between ordinary Portland concrete and alkali-activated concrete subjected to biogenic sulfuric acid attack. Constr. Build. Mater. 2019, 228, 117071. [Google Scholar] [CrossRef]

- Gu, L.; Bennett, T.; Visintin, P. Sulphuric acid exposure of conventional concrete and alkali-activated concrete: Assessment of test methodologies. Constr. Build. Mater. 2019, 197, 681–692. [Google Scholar] [CrossRef]

- Sturm, P.; Gluth, G.; Jäger, C.; Brouwers, H.; Kühne, H.-C. Sulfuric acid resistance of one-part alkali-activated mortars. Cem. Concr. Res. 2018, 109, 54–63. [Google Scholar] [CrossRef]

- Lee, N.; Lee, H. Influence of the slag content on the chloride and sulfuric acid resistances of alkali-activated fly ash/slag paste. Cem. Concr. Compos. 2016, 72, 168–179. [Google Scholar] [CrossRef]

- Hewayde, E.; Nehdi, M.; Allouche, E.; Nakhla, G. Effect of geopolymer cement on microstructure, compressive strength and sulphuric acid resistance of concrete. Mag. Concr. Res. 2006, 58, 321–331. [Google Scholar] [CrossRef]

- Allahverdi, A.; Skvara, F. Sulfuric acid attack on hardened paste of geopolymer cements-Part 1. Mechanism of corrosion at relatively high concentrations. Ceram. Silik. 2005, 49, 225–229. [Google Scholar]

- Vollertsen, J.; Nielsen, A.H.; Jensen, H.S.; Wium-Andersen, T.; Hvitved-Jacobsen, T. Corrosion of concrete sewers—The kinetics of hydrogen sulfide oxidation. Sci. Total Environ. 2008, 394, 162–170. [Google Scholar] [CrossRef]

- Lloyd, R.R.; Provis, J.L.; Van Deventer, J.S.J. Acid resistance of inorganic polymer binders. 1. Corrosion rate. Mater. Struct. 2011, 45, 1–14. [Google Scholar] [CrossRef]

- Office for Technical Standardization. Methods of Testing Cement-Part 1: Determination of Strength. CSN EN 196-1; Metrology and State Testing: Prague, Czech Republic, 2005; pp. 5–40. [Google Scholar]

- Office for Technical Standardization. Paints and Varnishes—Determination of Resistance to Humid Atmospheres Containing Sulfur Dioxide. CSN EN ISO 3231; Office for Technical Standardization, Metrology and State Testing: Prague, Czech Republic, 1998; pp. 1–5. [Google Scholar]

- Gade, S.O.; Alaca, B.B.; Sause, M.G.R. Determination of Crack Surface Orientation in Carbon Fibre Reinforced Polymers by Measuring Electromagnetic Emission. J. Nondestruct. Evaluation 2017, 36, 1–7. [Google Scholar] [CrossRef]

- Plšková, I.; Topolář, L.; Komárková, T.; Matysík, M.; Chobola, Z.; Stoniš, P. Verification of the ability of selected acoustic methods to detect the amount of steel fibers in concrete. In Proceedings of the Advances and Trends in Engineering Sciences and Technologies III, 12–14 September 2018, Tatranské Matliare, Slovak Republic; CRC Press: Boca Raton, FL, USA, 2019; pp. 217–221. [Google Scholar]

- Kopec, B. Nedestruktivní Zkoušení Materiálů a Konstrukcí; Akademické nakladatelství CERM: Brno, Czech Republic, 2008; Volume 1. (In Czech) [Google Scholar]

- Office for Technical Standardization. Zkoušení Betonu v Konstrukcích—Část 1: Vývrty—Odběr, Vyšetření a Zkoušení v Tlaku. CSN EN 12504-1 (731303); Office for Technical Standardization, Metrology and State Testing: Prague, Czech Republic, 2021; pp. 1–12. [Google Scholar]

- Plšková, I.; Matysík, M.; Topolář, L.; Bílek, V. Influence of alkali-activated materials placement during curing on their dynamic parameters. MATEC Web Conf. 2020, 313, 00039. [Google Scholar] [CrossRef][Green Version]

- Majhi, S.; Mukherjee, A.; George, N.; Uy, B. Corrosion detection in steel bar: A time-frequency approach. NDT E Int. 2019, 107. [Google Scholar] [CrossRef]

- Matysik, M.; Plšková, I.; Chobola, Z. Assessment of the impact-echo method for monitoring the long-standing frost resistance of ceramic tiles. Mater. Teh. 2015, 49, 639–643. [Google Scholar] [CrossRef]

- Garbacz, A.; Piotrowski, T.; Courard, L.; Kwaśniewski, L. On the evaluation of interface quality in concrete repair system by means of impact-echo signal analysis. Constr. Build. Mater. 2017, 134, 311–323. [Google Scholar] [CrossRef]

- Office for Technical Standardization. Nedestruktivní Zkoušení Betonu—Rezonanční Metoda Zkoušení Betonu. CSN EN 73 1372 (731372); Office for Technical Standardization, Metrology and State Testing: Prague, Czech Republic, 2012; pp. 1–16. (In Czech) [Google Scholar]

- Özbay, E.; Erdemir, M.; Durmuş, H.I. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar] [CrossRef]

- Oner, A.; Akyuz, S. An experimental study on optimum usage of GGBS for the compressive strength of concrete. Cem. Concr. Compos. 2007, 29, 505–514. [Google Scholar] [CrossRef]

- Tao, J.; Wei, X. Effect of ground granulated blast-furnace slag on the hydration and properties of cement paste. Adv. Cem. Res. 2019, 31, 251–260. [Google Scholar] [CrossRef]

- Kalina, L.; Bílek, V.; Bartoníčková, E.; Kalina, M.; Hajzler, J.; Novotný, R. Doubts over capillary pressure theory in context with drying and autogenous shrinkage of alkali-activated materials. Constr. Build. Mater. 2020, 248, 118620. [Google Scholar] [CrossRef]

- Bilek, V.; Kalina, L.; Novotny, R.; Tkacz, J.; Parizek, L. Some issues of shrinkage-reducing admixtures application in alka-li-activated slag systems. Materials 2016, 9, 462. [Google Scholar] [CrossRef]

- Neto, A.M.; Cincotto, M.A.; Repette, W. Drying and autogenous shrinkage of pastes and mortars with activated slag cement. Cem. Concr. Res. 2008, 38, 565–574. [Google Scholar] [CrossRef]

- Wittmann, F.H.; Beltzung, F.; Zhao, T.J. Shrinkage mechanisms, crack formation and service life of reinforced concrete structures. Int. J. Struct. Eng. 2009, 1, 13. [Google Scholar] [CrossRef]

- Collins, F.; Sanjayan, J.G. Effect of pore size distribution on drying shrinkage of alkali-activated slag concrete. Cement Concrete Res. 2000, 30, 1401–1406. [Google Scholar] [CrossRef]

- Palacios, M.; Puertas, F. Effect of shrinkage-reducing admixtures on the properties of alkali-activated slag mortars and pastes. Cem. Concr. Res. 2007, 37, 691–702. [Google Scholar] [CrossRef]

- Mohamed, O.A. A Review of Durability and Strength Characteristics of Alkali-Activated Slag Concrete. Materials 2019, 12, 1198. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.J.; Thomas, J.J.; Jennings, H.M. Decalcification shrinkage of cement paste. Cem. Concr. Res. 2006, 36, 801–809. [Google Scholar] [CrossRef]

- Komljenović, M.M.; Baščarević, Z.; Marjanović, N.; Nikolić, V. Decalcification resistance of alkali-activated slag. J. Hazard. Mater. 2012, 233-234, 112–121. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.; Cheng, Y.-B. Resistance of alkali-activated slag concrete to carbonation. Cem. Concr. Res. 2001, 31, 1277–1283. [Google Scholar] [CrossRef]

- Bakharev, T.; Sanjayan, J.; Cheng, Y.-B. Alkali activation of Australian slag cements. Cem. Concr. Res. 1999, 29, 113–120. [Google Scholar] [CrossRef]

- Atiş, C.D.; Bilim, C.; Çelik, Ö.; Karahan, O. Influence of activator on the strength and drying shrinkage of alkali-activated slag mortar. Constr. Build. Mater. 2009, 23, 548–555. [Google Scholar] [CrossRef]

- Puertas, F.; Palacios, M.; Vázquez, T. Carbonation process of alkali-activated slag mortars. J. Mater. Sci. 2006, 41, 3071–3082. [Google Scholar] [CrossRef]

- Dvorak, R.; Topolar, L.; Bilek, V.; Hruby, P. Study of Latent Self-healing Ability of Sodium Hydroxide Activated Blast Furnace Slag Systems via Non-destructive Measurement. In Advances in Intelligent Information Hiding and Multimedia Signal Processing; Springer International Publishing: New York, NY, USA, 2020; pp. 915–926. [Google Scholar] [CrossRef]

- Lothenbach, B.; Gruskovnjak, A. Hydration of alkali-activated slag: Thermodynamic modelling. Adv. Cem. Res. 2007, 19, 81–92. [Google Scholar] [CrossRef]

- Cornec, D.L.; Wang, Q.; Galoisy, L.; Renaudin, G.; Izoret, L.; Calas, G. Greening effect in slag cement materials. Cem. Concr. Compos. 2017, 84, 93–98. [Google Scholar] [CrossRef]

- Chaouche, M.; Gao, X.X.; Cyr, M.; Cotte, M.; Frouin, L. On the origin of the blue/green color of blast-furnace slag-based ma-terials: Sulfur k-edge xanes investigation. J. Am. Ceram. Soc. 2017, 100, 1707–1716. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, C.; Zhang, Z.; Ou, Z. Durability of alkali-activated materials in aggressive environments: A review on recent studies. Constr. Build. Mater. 2017, 152, 598–613. [Google Scholar] [CrossRef]

- Mainier, F.B.; Almeida, P.C.F.; Nani, B.; Fernandes, L.H.; Reis, M.F. Corrosion Caused by Sulfur Dioxide in Reinforced Concrete. Open J. Civ. Eng. 2015, 5, 379–389. [Google Scholar] [CrossRef][Green Version]

| Chemical Composition in wt.% | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | MgO | Al2O3 | SO3 | TiO2 | K2O | MnO | Na2O | Fe2O3 | LOI | |

| BFS | 37.0 | 39.4 | 8.6 | 8.1 | 1.4 | 0.3 | 1.2 | 0.9 | 0.4 | 0.7 | 2 |

| CEM III/A | 45.6 | 31.6 | 5.8 | 7.4 | 3.3 | 0.4 | 0.8 | 0.6 | 0.3 | 1.4 | 2.8 |

| BFS | CEM III/A 32.5R | Sand | 50% NaOH | Sodium Water Glass (Ms = 0.5) | Na2CO3 | H2O | |

|---|---|---|---|---|---|---|---|

| SH | 22.2 | – | 66.5 | 3.4 | – | – | 7.9 |

| SWG | 22.0 | – | 66.1 | – | 4.6 | – | 7.2 |

| SC | 22.0 | – | 66.2 | – | – | 2.3 | 9.5 |

| CEM III/A | – | 22.5 | 67.4 | – | – | – | 10.1 |

| Sulfur Content in wt.% | |||

|---|---|---|---|

| 0 Cycles | 200 Cycles In | 200 Cycles Out | |

| SH | 0.411 ± 0.039 | 0.423 ± 0.046 | 2.201 ± 0.031 |

| SWG | 0.362 ± 0.004 | 1.150 ± 0.020 | 2.542 ± 0.040 |

| SC | 0.319 ± 0.008 | 0.931 ± 0.011 | 2.964 ± 0.011 |

| CEM III/A | 1.031 ± 0.007 | 1.491 ± 0.055 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hrubý, P.; Kalina, L.; Bílek, V., Jr.; Keprdova, S.; Másilko, J.; Plšková, I.; Koplík, J.; Topolář, L. Comparison of Testing Methods for Evaluating the Resistance of Alkali-Activated Blast Furnace Slag Systems to Sulfur Dioxide. Materials 2022, 15, 1344. https://doi.org/10.3390/ma15041344

Hrubý P, Kalina L, Bílek V Jr., Keprdova S, Másilko J, Plšková I, Koplík J, Topolář L. Comparison of Testing Methods for Evaluating the Resistance of Alkali-Activated Blast Furnace Slag Systems to Sulfur Dioxide. Materials. 2022; 15(4):1344. https://doi.org/10.3390/ma15041344

Chicago/Turabian StyleHrubý, Petr, Lukáš Kalina, Vlastimil Bílek, Jr., Sarka Keprdova, Jiří Másilko, Iveta Plšková, Jan Koplík, and Libor Topolář. 2022. "Comparison of Testing Methods for Evaluating the Resistance of Alkali-Activated Blast Furnace Slag Systems to Sulfur Dioxide" Materials 15, no. 4: 1344. https://doi.org/10.3390/ma15041344

APA StyleHrubý, P., Kalina, L., Bílek, V., Jr., Keprdova, S., Másilko, J., Plšková, I., Koplík, J., & Topolář, L. (2022). Comparison of Testing Methods for Evaluating the Resistance of Alkali-Activated Blast Furnace Slag Systems to Sulfur Dioxide. Materials, 15(4), 1344. https://doi.org/10.3390/ma15041344