High Thermoelectric Performance Achieved in Sb-Doped GeTe by Manipulating Carrier Concentration and Nanoscale Twin Grains

Abstract

:1. Introduction

2. Materials and Methods

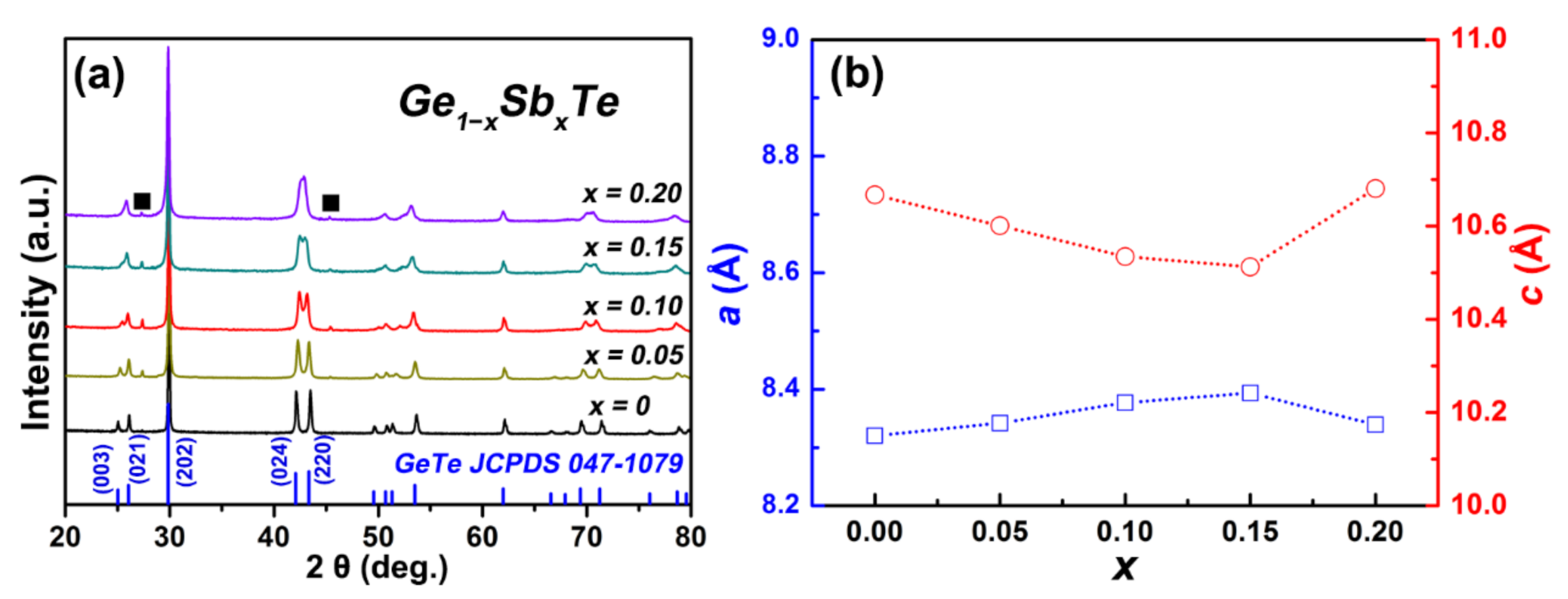

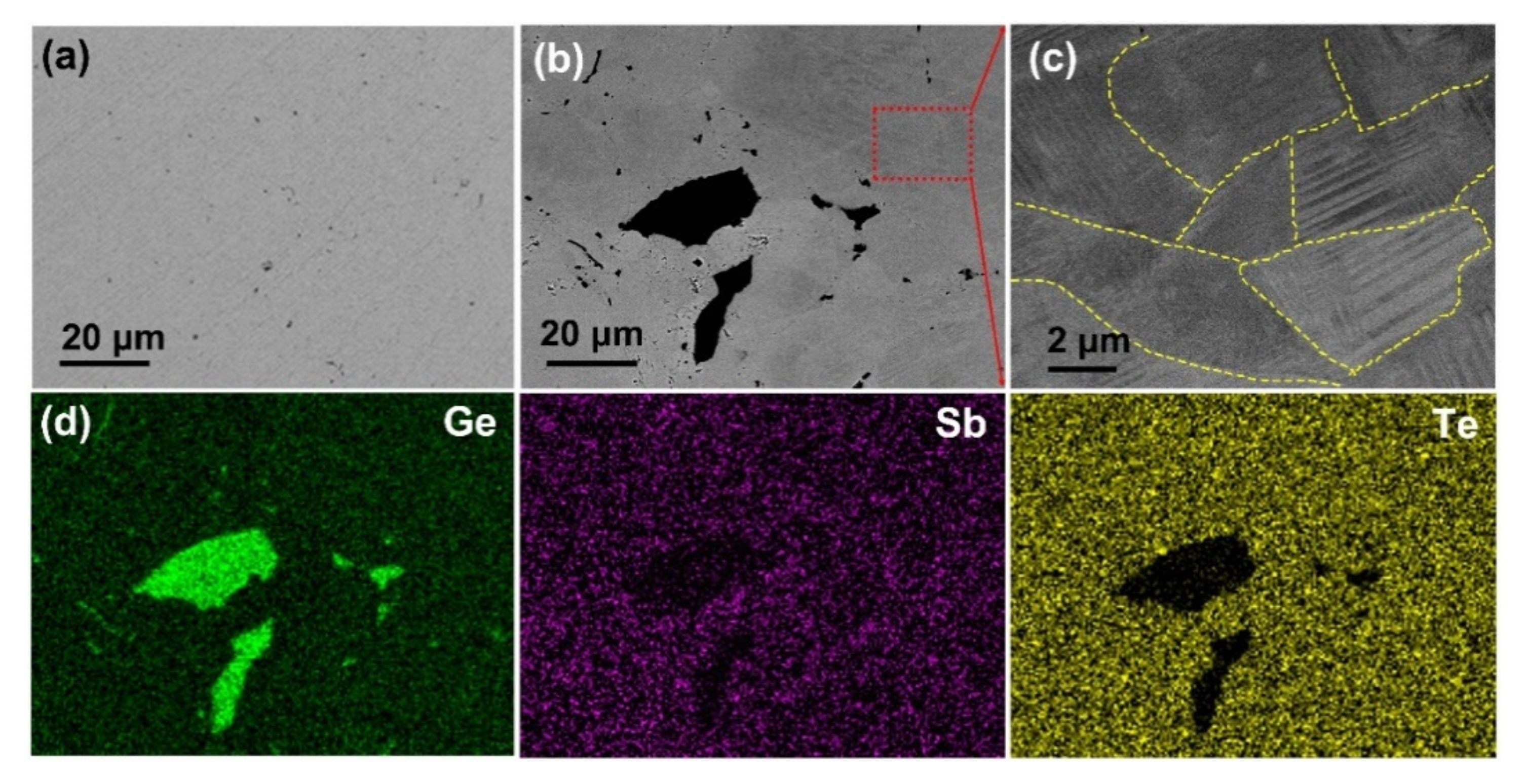

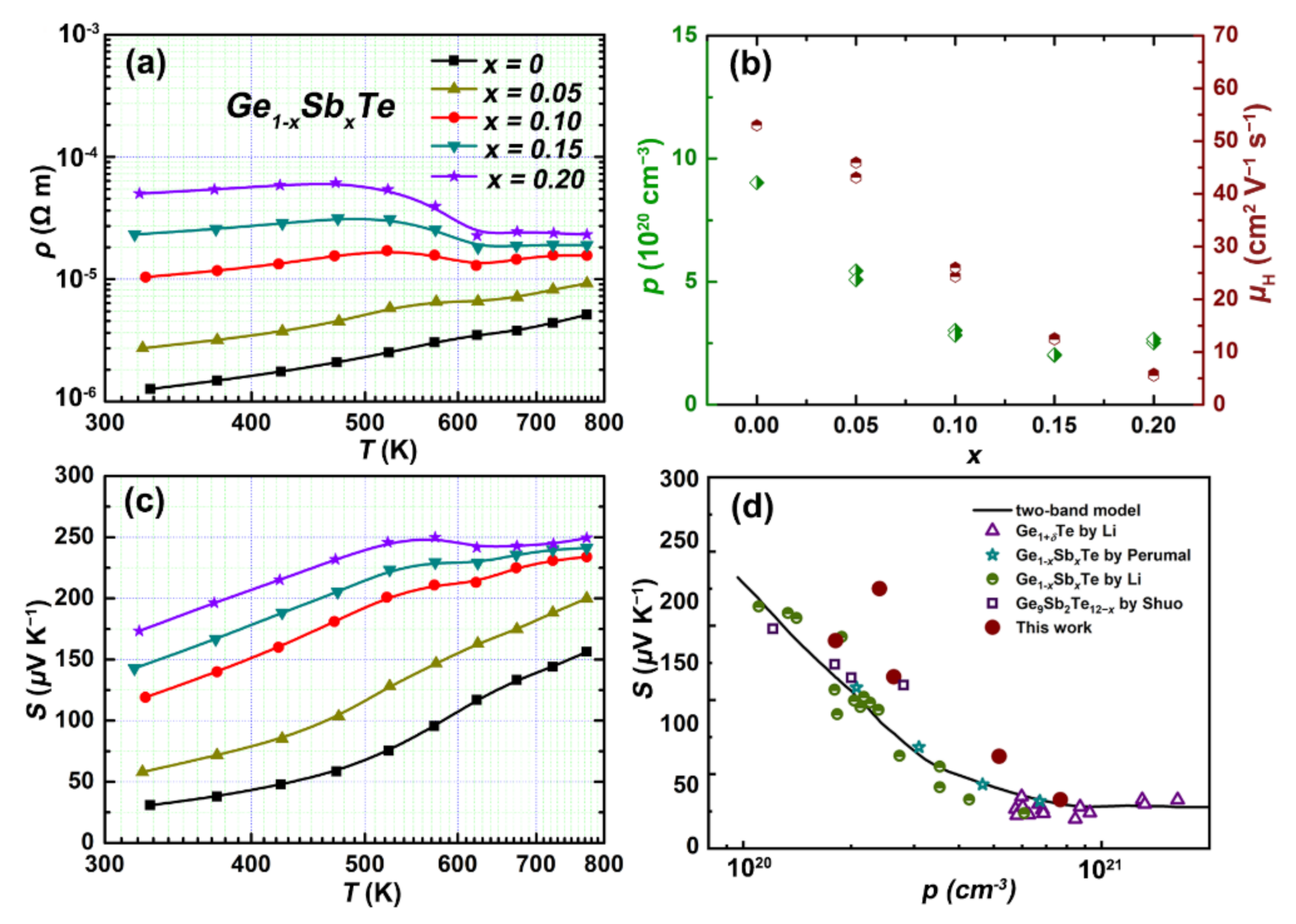

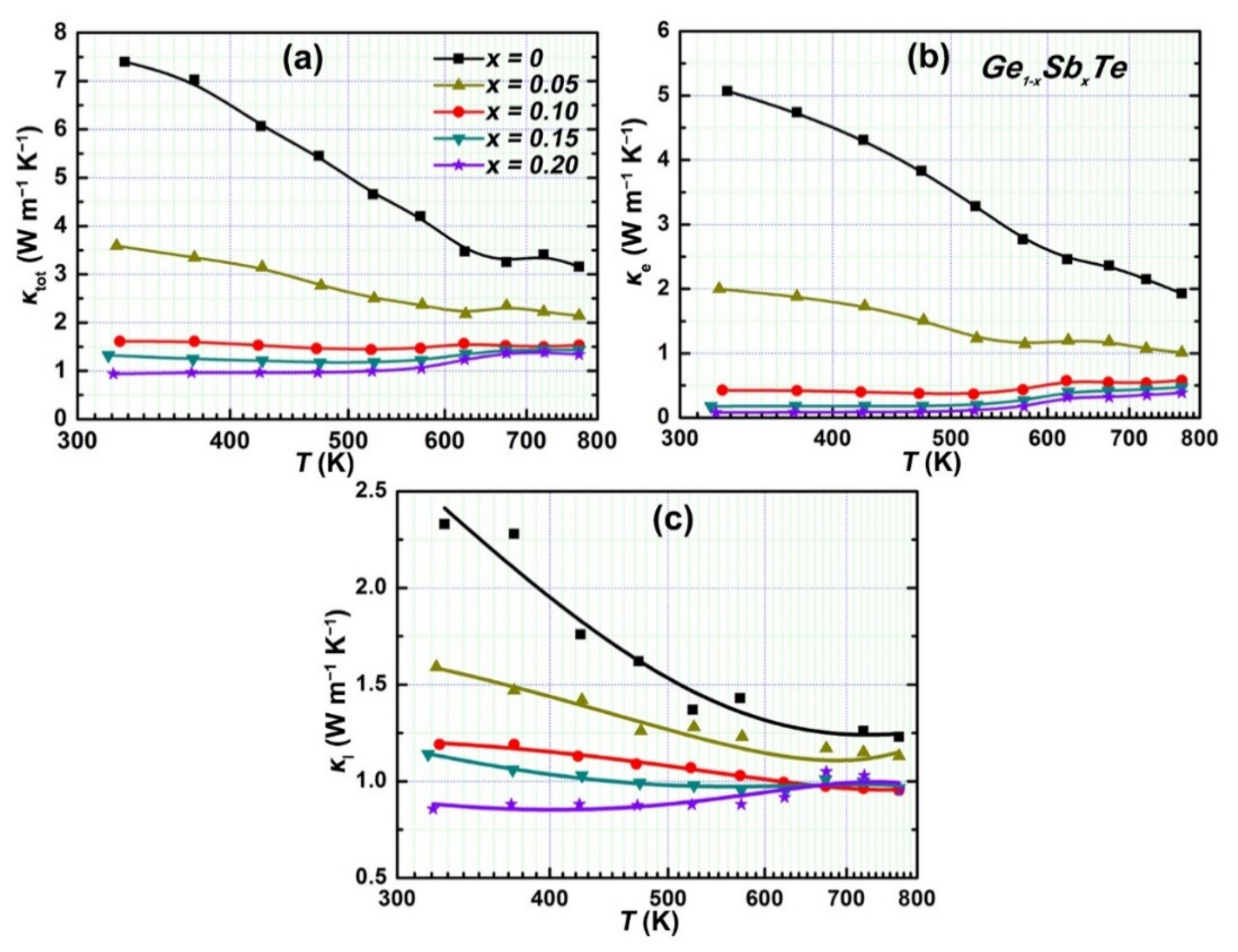

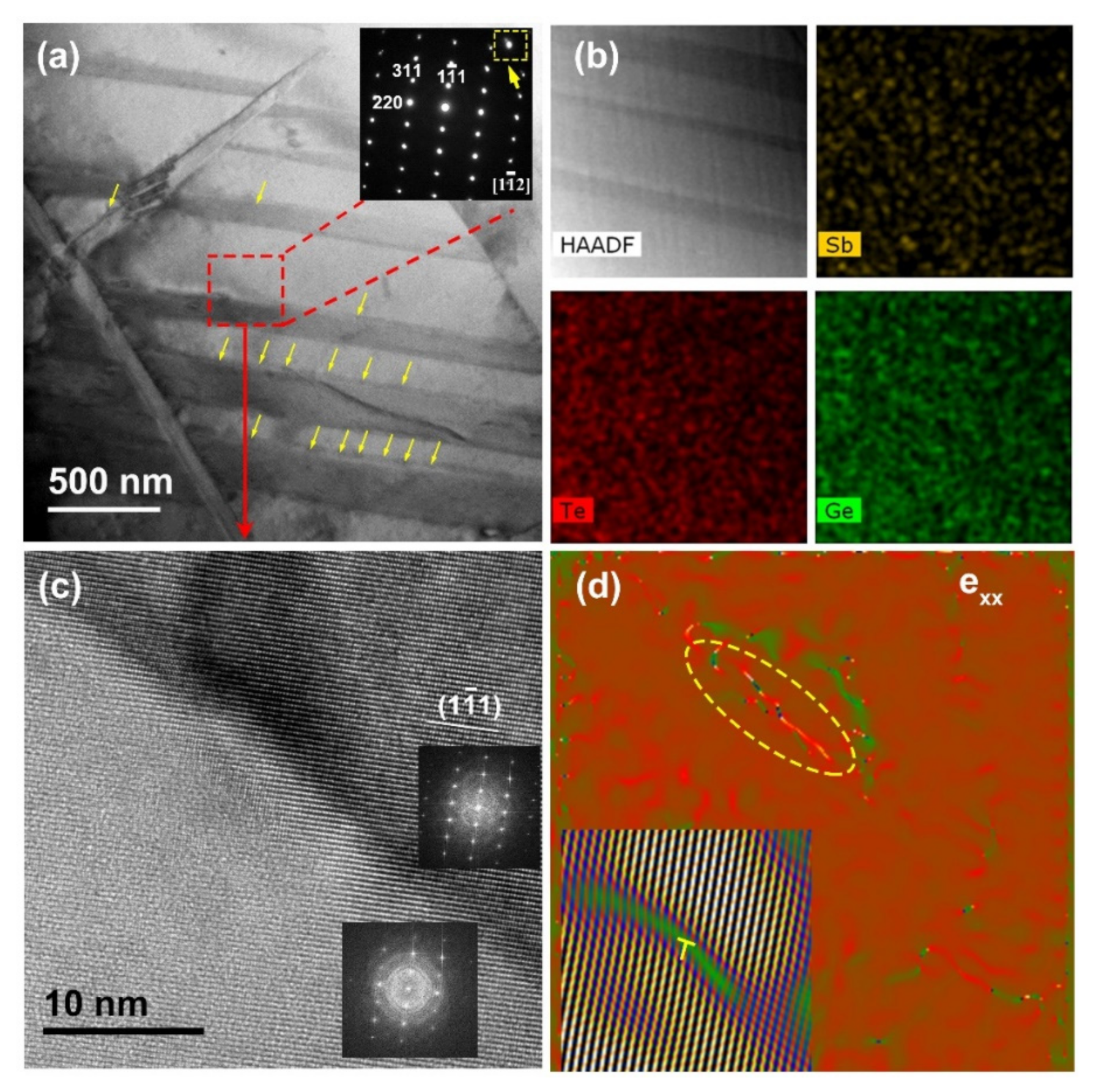

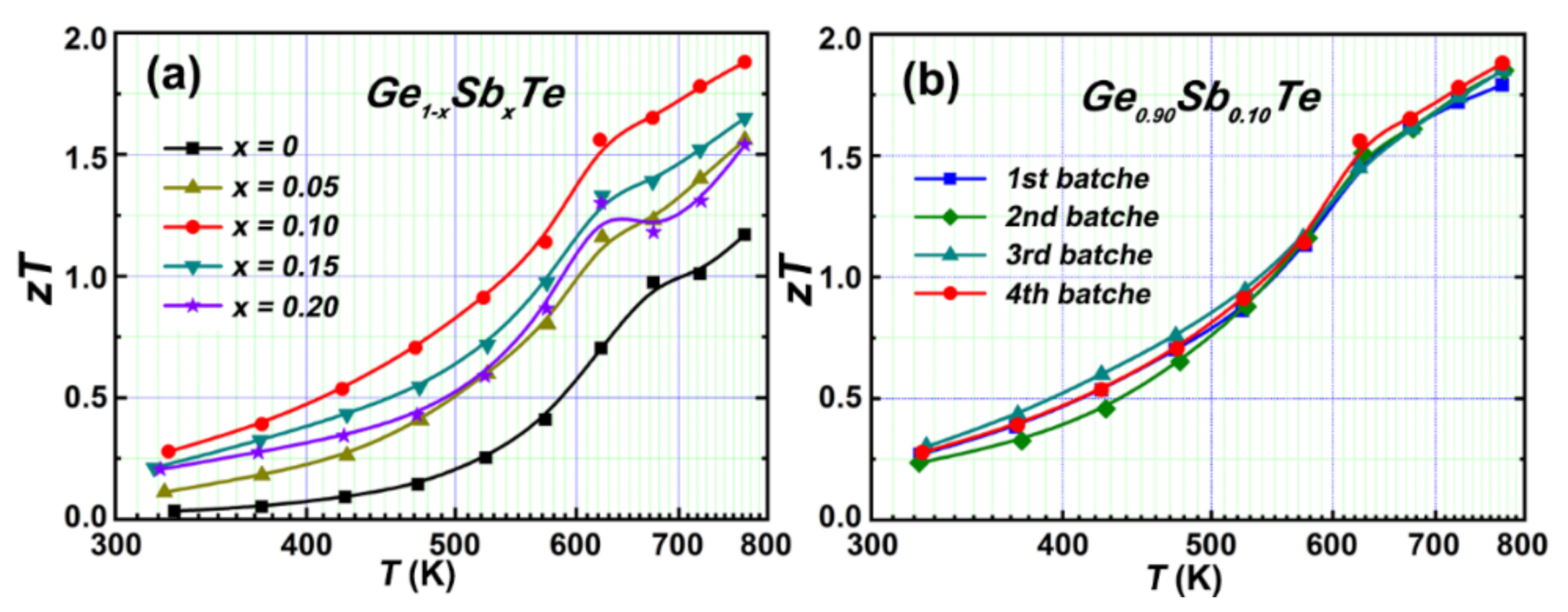

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Snyder, G.J.; Toberer, E.S. Complex thermoelectric materials. Nat. Mater. 2008, 7, 105–114. [Google Scholar] [CrossRef] [PubMed]

- Shi, X.L.; Zou, J.; Chen, Z.G. Advanced Thermoelectric Design: From Materials and Structures to Devices. Chem. Rev. 2020, 120, 7399–7515. [Google Scholar] [CrossRef]

- Xiang, H.; Xing, Y.; Dai, F.Z.; Wang, H.; Su, L.; Miao, L.; Zhang, G.; Wang, Y.; Qi, X.; Yao, L.; et al. High-entropy ceramics: Present status, challenges, and a look forward. J. Adv. Ceram. 2021, 10, 385–441. [Google Scholar] [CrossRef]

- Liu, Z.-Y.; Zhu, J.-L.; Tong, X.; Niu, S.; Zhao, W.-Y. A review of CoSb3-based skutterudite thermoelectric materials. J. Adv. Ceram. 2020, 9, 647–673. [Google Scholar] [CrossRef]

- An, D.; Wang, J.; Zhang, J.; Zhai, X.; Kang, Z.; Fan, W.; Yan, J.; Liu, Y.; Lu, L.; Jia, C.-L.; et al. Retarding Ostwald ripening through Gibbs adsorption and interfacial complexions leads to high-performance SnTe thermoelectrics. Energy Environ. Sci. 2021, 14, 5469–5479. [Google Scholar] [CrossRef]

- Smorodin, B.L.; Velarde, M.G. Convective instability of an Ohmic liquid layer in an unsteady thermal field. Phys. Fluids 2008, 20, 44101. [Google Scholar] [CrossRef]

- Yu, Y.; Cagnoni, M.; Cojocaru-Mirédin, O.; Wuttig, M. Chalcogenide Thermoelectrics Empowered by an Unconventional Bonding Mechanism. Adv. Funct. Mater. 2019, 30, 1904862. [Google Scholar] [CrossRef] [Green Version]

- Xu, W.; Zhang, Z.; Liu, C.; Gao, J.; Ye, Z.; Chen, C.; Peng, Y.; Bai, X.; Miao, L. Substantial thermoelectric enhancement achieved by manipulating the band structure and dislocations in Ag and La co-doped SnTe. J. Adv. Ceram. 2021, 10, 860–870. [Google Scholar] [CrossRef]

- Tang, J.; Yao, Z.; Chen, Z.; Lin, S.; Zhang, X.; Xiong, F.; Li, W.; Chen, Y.; Pei, Y. Maximization of transporting bands for high-performance SnTe alloy thermoelectrics. Mater. Today Phys. 2019, 9, 100091. [Google Scholar] [CrossRef]

- Zhou, C.; Yu, Y.; Lee, Y.L.; Ge, B.; Lu, W.; Cojocaru-Miredin, O.; Im, J.; Cho, S.P.; Wuttig, M.; Shi, Z.; et al. Exceptionally High Average Power Factor and Thermoelectric Figure of Merit in n-type PbSe by the Dual Incorporation of Cu and Te. J. Am. Chem. Soc. 2020, 142, 15172–15186. [Google Scholar] [CrossRef]

- Pei, Y.; Shi, X.; LaLonde, A.; Wang, H.; Chen, L.; Snyder, G.J. Convergence of electronic bands for high performance bulk thermoelectrics. Nature 2011, 473, 66–69. [Google Scholar] [CrossRef] [PubMed]

- Kooi, B.J.; Wuttig, M. Chalcogenides by Design: Functionality through Metavalent Bonding and Confinement. Adv. Mater. 2020, 32, e1908302. [Google Scholar] [CrossRef] [Green Version]

- Korkosz, R.J.; Chasapis, T.C.; Lo, S.H.; Doak, J.W.; Kim, Y.J.; Wu, C.I.; Hatzikraniotis, E.; Hogan, T.P.; Seidman, D.N.; Wolverton, C.; et al. High ZT in p-Type (PbTe)(1-2x)(PbSe)x(PbS)xThermoelectric Materials. J. Am. Chem. Soc. 2014, 136, 3225–3237. [Google Scholar] [CrossRef] [PubMed]

- Pei, Y.; Tan, G.; Feng, D.; Zheng, L.; Tan, Q.; Xie, X.; Gong, S.; Chen, Y.; Li, J.-F.; He, J.; et al. Integrating Band Structure Engineering with All-Scale Hierarchical Structuring for High Thermoelectric Performance in PbTe System. Adv. Energy Mater. 2017, 7, 1601450. [Google Scholar] [CrossRef]

- Sarkar, S.; Zhang, X.; Hao, S.; Hua, X.; Bailey, T.P.; Uher, C.; Wolverton, C.; Dravid, V.P.; Kanatzidis, M.G. Dual Alloying Strategy to Achieve a High Thermoelectric Figure of Merit and Lattice Hardening in p-Type Nanostructured PbTe. ACS Energy Lett. 2018, 3, 2593–2601. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H.; Cui, J.; Wang, D.; Fu, L.; Zhang, Y.; Chen, Y.; He, J.; Pennycook, S.J.; Zhao, L.-D. Realizing high performance n-type PbTe by synergistically optimizing effective mass and carrier mobility and suppressing bipolar thermal conductivity. Energy Environ. Sci. 2018, 11, 2486–2495. [Google Scholar] [CrossRef]

- Zhou, C.; Lee, Y.K.; Yu, Y.; Byun, S.; Luo, Z.Z.; Lee, H.; Ge, B.; Lee, Y.L.; Chen, X.; Lee, J.Y.; et al. Polycrystalline SnSe with a thermoelectric figure of merit greater than the single crystal. Nat. Mater. 2021, 20, 1378–1384. [Google Scholar] [CrossRef]

- Zhang, X.; Bu, Z.; Lin, S.; Chen, Z.; Li, W.; Pei, Y. GeTe Thermoelectrics. Joule 2020, 4, 986–1003. [Google Scholar] [CrossRef]

- Hong, M.; Zou, J.; Chen, Z.G. Thermoelectric GeTe with Diverse Degrees of Freedom Having Secured Superhigh Performance. Adv. Mater. 2019, 31, e1807071. [Google Scholar] [CrossRef]

- Bai, G.; Yu, Y.; Wu, X.; Li, J.; Xie, Y.; Hu, L.; Liu, F.; Wuttig, M.; Cojocaru-Mirédin, O.; Zhang, C. Boron Strengthened GeTe-Based Alloys for Robust Thermoelectric Devices with High Output Power Density. Adv. Energy Mater. 2021, 11, 2102012. [Google Scholar] [CrossRef]

- Tran, X.Q.; Hong, M.; Maeno, H.; Kawami, Y.; Toriyama, T.; Jack, K.; Chen, Z.-G.; Zou, J.; Matsumura, S.; Dargusch, M.S. Real-time observation of the thermally-induced phase transformation in GeTe and its thermal expansion properties. Acta Mater. 2019, 165, 327–335. [Google Scholar] [CrossRef]

- Hong, M.; Wang, Y.; Feng, T.; Sun, Q.; Xu, S.; Matsumura, S.; Pantelides, S.T.; Zou, J.; Chen, Z.G. Strong Phonon-Phonon Interactions Securing Extraordinary Thermoelectric Ge1-xSbxTe with Zn-Alloying-Induced Band Alignment. J. Am. Chem. Soc. 2019, 141, 1742–1748. [Google Scholar] [CrossRef]

- Zheng, Z.; Su, X.; Deng, R.; Stoumpos, C.; Xie, H.; Liu, W.; Yan, Y.; Hao, S.; Uher, C.; Wolverton, C.; et al. Rhombohedral to Cubic Conversion of GeTe via MnTe Alloying Leads to Ultralow Thermal Conductivity, Electronic Band Convergence, and High Thermoelectric Performance. J. Am. Chem. Soc. 2018, 140, 2673–2686. [Google Scholar] [CrossRef]

- Bu, Z.; Li, W.; Li, J.; Zhang, X.; Mao, J.; Chen, Y.; Pei, Y. Dilute Cu2Te-alloying enables extraordinary performance of r-GeTe thermoelectrics. Mater. Today Phys. 2019, 9, 100096. [Google Scholar] [CrossRef]

- Hong, M.; Wang, Y.; Liu, W.; Matsumura, S.; Wang, H.; Zou, J.; Chen, Z.-G. Arrays of Planar Vacancies in Superior ThermoelectricGe1−x−yCdxBiyTe with Band Convergence. Adv. Energy Mater. 2018, 8, 1801837. [Google Scholar] [CrossRef]

- Yue, L.; Fang, T.; Zheng, S.; Cui, W.; Wu, Y.; Chang, S.; Wang, L.; Bai, P.; Zhao, H. Cu/Sb Codoping for Tuning Carrier Concentration and Thermoelectric Performance of GeTe-Based Alloys with Ultralow Lattice Thermal Conductivity. ACS Appl. Energy Mater. 2019, 2, 2596–2603. [Google Scholar] [CrossRef]

- Li, P.; Ding, T.; Li, J.; Zhang, C.; Dou, Y.; Li, Y.; Hu, L.; Liu, F.; Zhang, C. Positive Effect of Ge Vacancies on Facilitating Band Convergence and Suppressing Bipolar Transport in GeTe-Based Alloys for High Thermoelectric Performance. Adv. Funct. Mater. 2020, 30, 1910059. [Google Scholar] [CrossRef]

- Zhang, X.; Li, J.; Wang, X.; Chen, Z.; Mao, J.; Chen, Y.; Pei, Y. Vacancy Manipulation for Thermoelectric Enhancements in GeTe Alloys. J. Am. Chem. Soc. 2018, 140, 15883–15888. [Google Scholar] [CrossRef]

- Levin, E.M.; Besser, M.F.; Hanus, R. Electronic and thermal transport in GeTe: A versatile base for thermoelectric materials. J. Appl Phys. 2013, 114, 083713. [Google Scholar] [CrossRef]

- Perumal, S.; Roychowdhury, S.; Negi, D.S.; Datta, R.; Biswas, K. High Thermoelectric Performance and Enhanced Mechanical Stability of p-type Ge1–xSbxTe. Chem. Mater. 2015, 27, 7171–7178. [Google Scholar] [CrossRef]

- Wu, D.; Zhao, L.D.; Hao, S.; Jiang, Q.; Zheng, F.; Doak, J.W.; Wu, H.; Chi, H.; Gelbstein, Y.; Uher, C.; et al. Origin of the high performance in GeTe-based thermoelectric materials upon Bi2Te3 doping. J. Am. Chem. Soc. 2014, 136, 11412–11419. [Google Scholar] [CrossRef] [PubMed]

- Perumal, S.; Roychowdhury, S.; Biswas, K. Reduction of thermal conductivity through nanostructuring enhances the thermoelectric figure of merit in Ge1−xBixTe. Inorg. Chem. Front. 2016, 3, 125–132. [Google Scholar] [CrossRef]

- Gao, W.; Liu, Z.; Zhang, W.; Sato, N.; Guo, Q.; Mori, T. Improved thermoelectric performance of GeTe via efficient yttrium doping. Appl. Phys. Lett. 2021, 118, 33901. [Google Scholar] [CrossRef]

- Perumal, S.; Samanta, M.; Ghosh, T.; Shenoy, U.S.; Bohra, A.K.; Bhattacharya, S.; Singh, A.; Waghmare, U.V.; Biswas, K. Realization of High Thermoelectric Figure of Merit in GeTe by Complementary Co-doping of Bi and In. Joule 2019, 3, 2565–2580. [Google Scholar] [CrossRef]

- Srinivasan, B.; Gellé, A.; Gucci, F.; Boussard-Pledel, C.; Fontaine, B.; Gautier, R.; Halet, J.-F.; Reece, M.J.; Bureau, B. Realizing a stable high thermoelectric zT ∼ 2 over a broad temperature range in Ge1−x−yGaxSbyTe via band engineering and hybrid flash-SPS processing. Inorg. Chem. Front. 2019, 6, 63–73. [Google Scholar] [CrossRef]

- Li, M.; Hong, M.; Tang, X.; Sun, Q.; Lyu, W.-Y.; Xu, S.-D.; Kou, L.-Z.; Dargusch, M.; Zou, J.; Chen, Z.-G. Crystal symmetry induced structure and bonding manipulation boosting thermoelectric performance of GeTe. Nano Energy 2020, 73, 104740. [Google Scholar] [CrossRef]

- Wu, L.; Li, X.; Wang, S.; Zhang, T.; Yang, J.; Zhang, W.; Chen, L.; Yang, J. Resonant level-induced high thermoelectric response in indium-doped GeTe. NPG Asia Mater. 2017, 9, e343. [Google Scholar] [CrossRef]

- Shuai, J.; Sun, Y.; Tan, X.; Mori, T. Manipulating the Ge Vacancies and Ge Precipitates through Cr Doping for Realizing the High-Performance GeTe Thermoelectric Material. Small 2020, 16, e1906921. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Chen, Z.; Lin, S.; Li, W.; Shen, J.; Witting, I.T.; Faghaninia, A.; Chen, Y.; Jain, A.; et al. Low-Symmetry Rhombohedral GeTe Thermoelectrics. Joule 2018, 2, 976–987. [Google Scholar] [CrossRef]

- Carruthers, P. Scattering of Phonons by Elastic Strain Fields and the Thermal Resistance of Dislocations. Phys. Rev. 1959, 114, 995–1001. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Lin, S.; Chen, Z.; Pei, Y. Realizing the High Thermoelectric Performance of GeTe by Sb-Doping and Se-Alloying. Chem. Mater. 2016, 29, 605–611. [Google Scholar] [CrossRef]

- Xu, X.; Xie, L.; Lou, Q.; Wu, D.; He, J. Boosting the Thermoelectric Performance of Pseudo-Layered Sb2Te3(GeTe) n via Vacancy Engineering. Adv. Sci. 2018, 5, 1801514. [Google Scholar] [CrossRef]

- Li, J.; Zhang, X.; Wang, X.; Bu, Z.; Zheng, L.; Zhou, B.; Xiong, F.; Chen, Y.; Pei, Y. High-Performance GeTe Thermoelectrics in Both Rhombohedral and Cubic Phases. J. Am. Chem. Soc. 2018, 140, 16190–16197. [Google Scholar] [CrossRef] [PubMed]

- Wu, D.; Feng, D.; Xu, X.; He, M.; Xu, J.; He, J. Realizing high figure of merit plateau in Ge Bi Te via enhanced Bi solution and Ge precipitation. J. Alloy Compd. 2019, 805, 831–839. [Google Scholar] [CrossRef]

- Li, J.; Chen, Z.; Zhang, X.; Yu, H.; Wu, Z.; Xie, H.; Chen, Y.; Pei, Y. Simultaneous Optimization of Carrier Concentration and Alloy Scattering for Ultrahigh Performance GeTe Thermoelectrics. Adv. Sci. 2017, 4, 1700341. [Google Scholar] [CrossRef]

- Chen, S.; Bai, H.; Li, J.; Pan, W.; Jiang, X.; Li, Z.; Chen, Z.; Yan, Y.; Su, X.; Wu, J.; et al. Vacancy-Based Defect Regulation for High Thermoelectric Performance in Ge9Sb2Te12-x Compounds. ACS Appl Mater. Interfaces 2020, 12, 19664–19673. [Google Scholar] [CrossRef] [PubMed]

- Sun, Q.; Li, M.; Shi, X.L.; Xu, S.D.; Liu, W.D.; Hong, M.; Lyu Wy Yin, Y.; Dargusch, M.; Zou, J.; Chen, Z.G. Versatile Vanadium Doping Induces High Thermoelectric Performance in GeTe via Band Alignment and Structural Modulation. Adv. Energy Mater. 2021, 11, 2100544. [Google Scholar] [CrossRef]

- Lee, H.S.; Kim, B.-S.; Cho, C.-W.; Oh, M.-W.; Min, B.-K.; Park, S.-D.; Lee, H.-W. Herringbone structure in GeTe-based thermoelectric materials. Acta Mater. 2015, 91, 83–90. [Google Scholar] [CrossRef]

- Bayikadi, K.S.; Sankar, R.; Wu, C.T.; Xia, C.; Chen, Y.; Chen, L.-C.; Chen, K.-H.; Chou, F.-C. Enhanced thermoelectric performance of GeTe through in situ microdomain and Ge-vacancy control. J. Mater. Chem. A 2019, 7, 15181–15189. [Google Scholar] [CrossRef]

- Bayikadi, K.S.; Wu, C.T.; Chen, L.-C.; Chen, K.-H.; Chou, F.-C.; Sankar, R. Synergistic optimization of thermoelectric performance of Sb doped GeTe with a strained domain and domain boundaries. J. Mater. Chem. A 2020, 8, 5332–5341. [Google Scholar] [CrossRef]

- Nevskii, S.; Sarychev, V.; Konovalov, S.; Granovskii, A.; Gromov, V. Formation Mechanism of Micro- and Nanocrystalline Surface Layers in Titanium and Aluminum Alloys in Electron Beam Irradiation. Metals 2020, 10, 1399. [Google Scholar] [CrossRef]

- Abdellaoui, L.; Chen, Z.; Yu, Y.; Luo, T.; Hanus, R.; Schwarz, T.; Bueno Villoro, R.; Cojocaru-Mirédin, O.; Snyder, G.J.; Raabe, D.; et al. Parallel Dislocation Networks and Cottrell Atmospheres Reduce Thermal Conductivity of PbTe Thermoelectrics. Adv. Funct. Mater. 2021, 31, 2101214. [Google Scholar] [CrossRef]

- Zhu, M.; Cojocaru-Miredin, O.; Mio, A.M.; Keutgen, J.; Kupers, M.; Yu, Y.; Cho, J.Y.; Dronskowski, R.; Wuttig, M. Unique Bond Breaking in Crystalline Phase Change Materials and the Quest for Metavalent Bonding. Adv. Mater. 2018, 30, e1706735. [Google Scholar] [CrossRef]

- Yu, Y.; He, D.-S.; Zhang, S.; Cojocaru-Mirédin, O.; Schwarz, T.; Stoffers, A.; Wang, X.-Y.; Zheng, S.; Zhu, B.; Scheu, C.; et al. Simultaneous optimization of electrical and thermal transport properties of Bi 0.5 Sb 1.5 Te 3 thermoelectric alloy by twin boundary engineering. Nano Energy 2017, 37, 203–213. [Google Scholar] [CrossRef]

- Shuai, J.; Tan, X.J.; Guo, Q.; Xu, J.T.; Gellé, A.; Gautier, R.; Halet, J.F.; Failamani, F.; Jiang, J.; Mori, T. Enhanced thermoelectric performance through crystal field engineering in transition metal–doped GeTe. Mater. Today Phys. 2019, 9, 100094. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Song, H.; Dai, Z.; Zhao, Z.; Liu, C.; Yang, H.; Cui, C.; Miao, L. High Thermoelectric Performance Achieved in Sb-Doped GeTe by Manipulating Carrier Concentration and Nanoscale Twin Grains. Materials 2022, 15, 406. https://doi.org/10.3390/ma15020406

Li C, Song H, Dai Z, Zhao Z, Liu C, Yang H, Cui C, Miao L. High Thermoelectric Performance Achieved in Sb-Doped GeTe by Manipulating Carrier Concentration and Nanoscale Twin Grains. Materials. 2022; 15(2):406. https://doi.org/10.3390/ma15020406

Chicago/Turabian StyleLi, Chao, Haili Song, Zongbei Dai, Zhenbo Zhao, Chengyan Liu, Hengquan Yang, Chengqiang Cui, and Lei Miao. 2022. "High Thermoelectric Performance Achieved in Sb-Doped GeTe by Manipulating Carrier Concentration and Nanoscale Twin Grains" Materials 15, no. 2: 406. https://doi.org/10.3390/ma15020406

APA StyleLi, C., Song, H., Dai, Z., Zhao, Z., Liu, C., Yang, H., Cui, C., & Miao, L. (2022). High Thermoelectric Performance Achieved in Sb-Doped GeTe by Manipulating Carrier Concentration and Nanoscale Twin Grains. Materials, 15(2), 406. https://doi.org/10.3390/ma15020406