Enhanced N-Type Bismuth-Telluride-Based Thermoelectric Fibers via Thermal Drawing and Bridgman Annealing

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Fabrication

2.2. Measurements

3. Results and Discussion

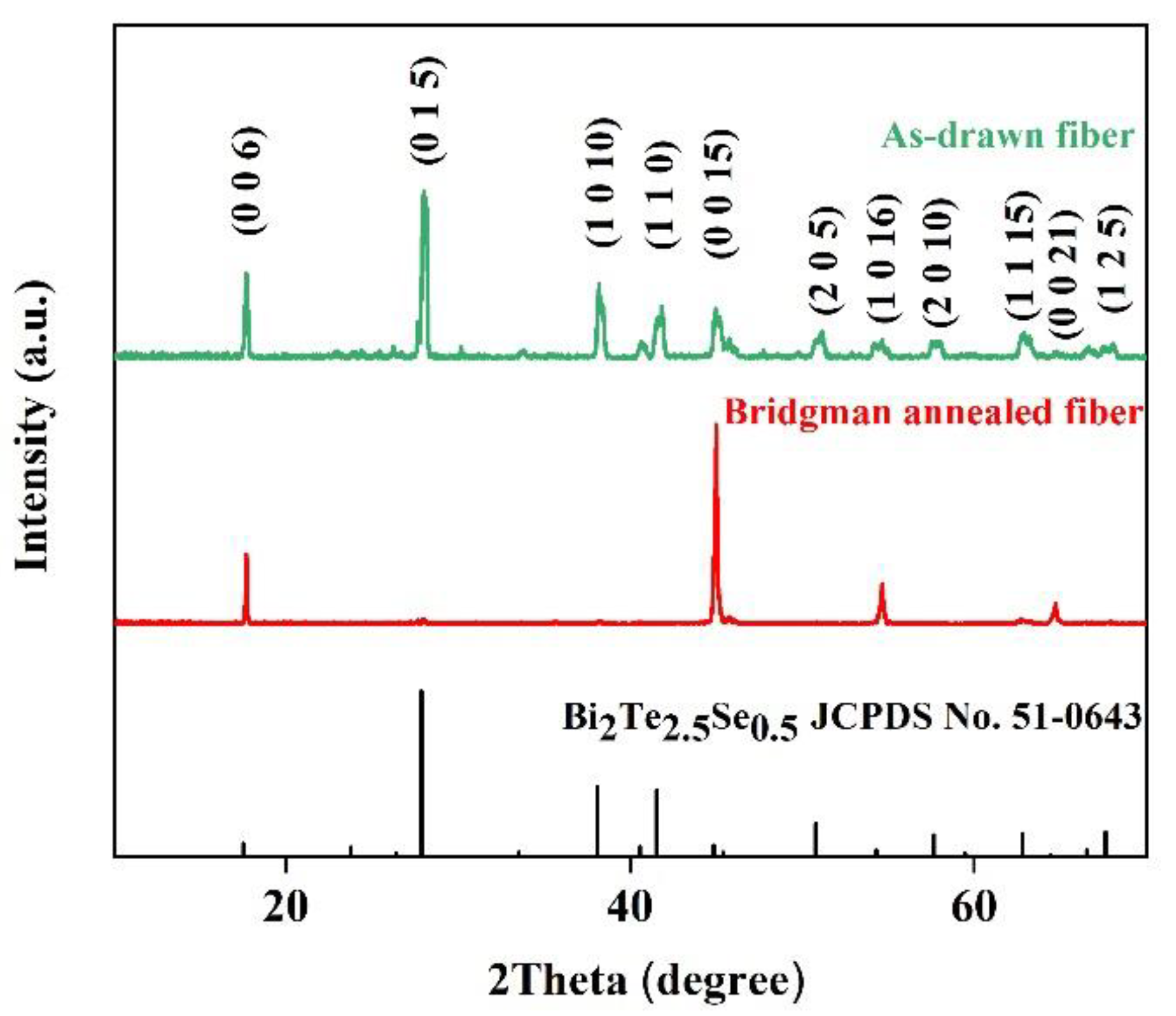

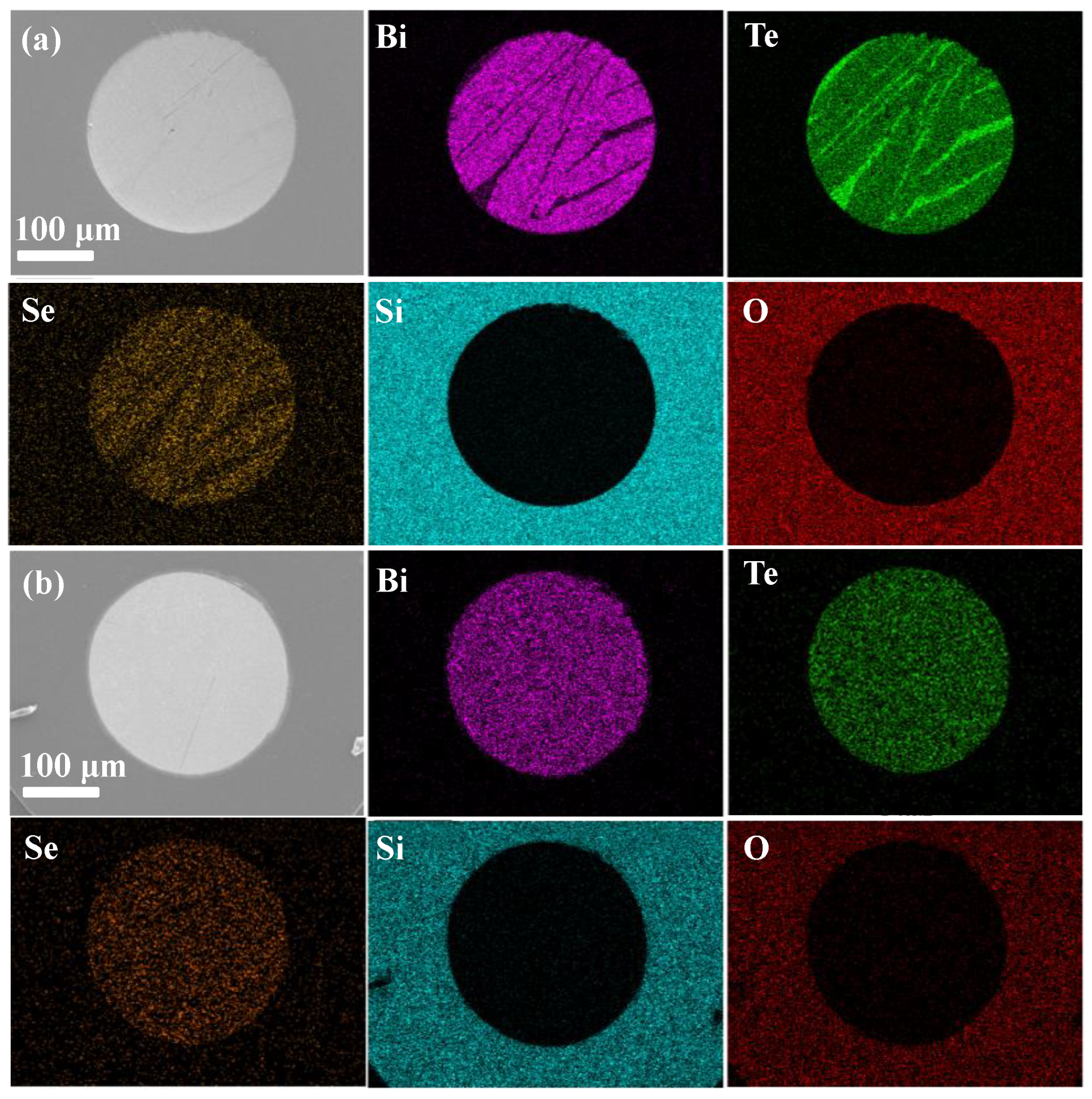

3.1. Microstructure

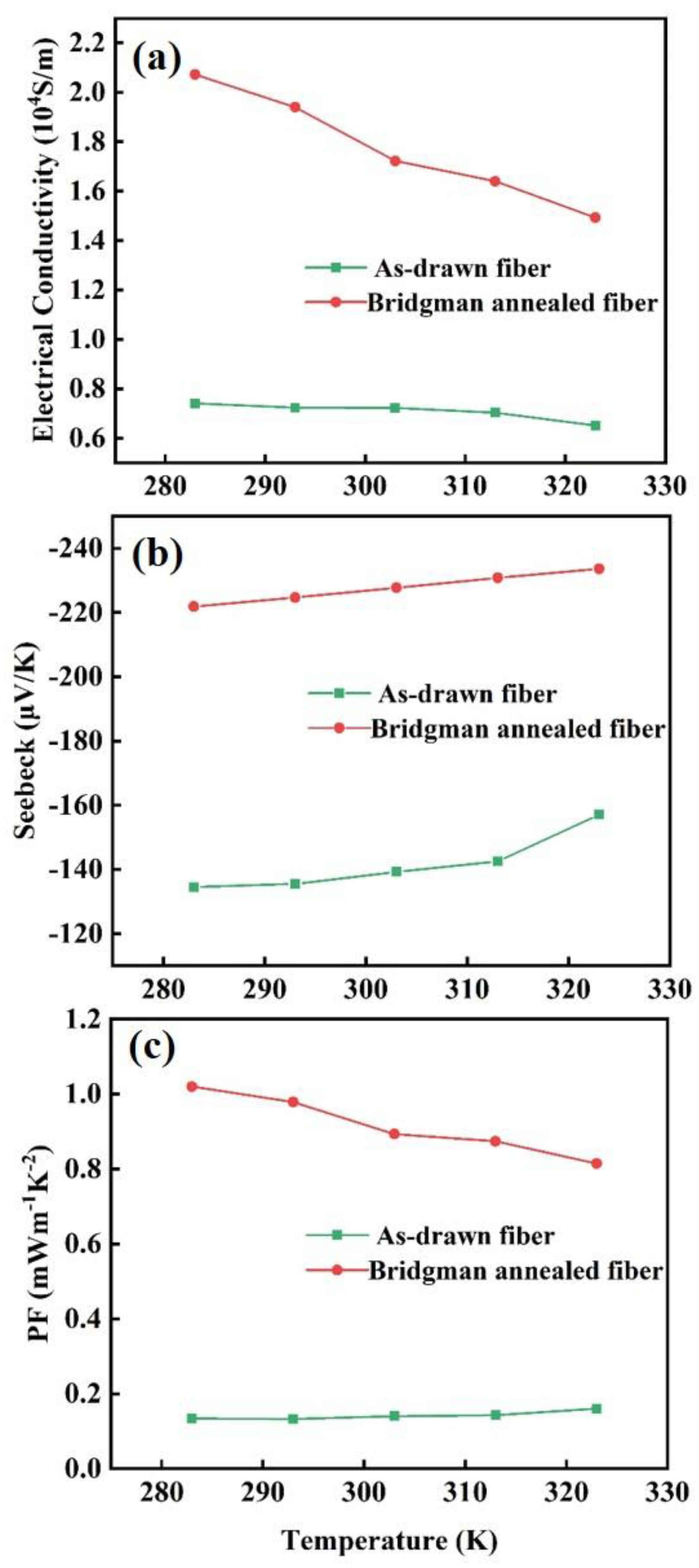

3.2. TE Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, C.; Souchay, D.; Kneiß, M.; Bogner, M.; Wei, H.M.; Lorenz, M.; Oeckler, O.; Benstetter, G.; Fu, Y.Q.; Grundmann, M. Transparent flexible thermoelectric material based on non-toxic earth-abundant p-type copper iodide thin film. Nat. Commun. Commun. 2017, 8, 16076. [Google Scholar] [CrossRef] [PubMed]

- Tarancón, A. Powering the IoT revolution with heat. Nat. Electron. 2019, 2, 270–271. [Google Scholar] [CrossRef]

- Yang, G.; Niu, R.; Sang, L.; Liao, X.; Mitchell, D.R.G.; Ye, N.; Pei, J.; Li, J.; Wang, X. Ultra-High Thermoelectric Performance in Bulk BiSbTe/Amorphous Boron Composites with Nano-Defect Architectures. Adv. Energy Mater. 2020, 10, 2000757. [Google Scholar] [CrossRef]

- Pei, J.; Cai, B.; Zhuang, H.-L.; Li, J.-F. Bi2Te3-based applied thermoelectric materials: Research advances and new challenges. Natl. Sci. Rev. 2020, 7, 1856–1858. [Google Scholar] [CrossRef]

- Saberi, Y.; Sajjadi, S.A.; Mansouri, H. Comparison of thermoelectric properties of Bi2Te3 and Bi2Se0.3Te2.7 thin film materials synthesized by hydrothermal process and thermal evaporation. Ceram. Int. 2021, 47, 11547–11559. [Google Scholar] [CrossRef]

- Zhu, B.; Liu, X.; Wang, Q.; Qiu, Y.; Shu, Z.; Guo, Z.; Tong, Y.; Cui, J.; Gu, M.; He, J. Realizing record high performance in n-type Bi2Te3-based thermoelectric materials. Energy Environ. Sci. 2020, 13, 2106–2114. [Google Scholar] [CrossRef]

- Shen, Y.; Wang, C.; Yang, X.; Li, J.; Lu, R.; Li, R.; Zhang, L.; Chen, H.; Zheng, X.; Zhang, T. New Progress on Fiber-Based Thermoelectric Materials: Performance, Device Structures and Applications. Materials 2021, 14, 6306. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, S.; Liu, Z.; Mu, E.; Hu, Z. Thermoelectric converter: Strategies from materials to device application. Nano Energy 2021, 91, 106692. [Google Scholar] [CrossRef]

- Lee, J.A.; Aliev, A.E.; Bykova, J.S.; de Andrade, M.J.; Kim, D.; Sim, H.J.; Lepró, X.; Zakhidov, A.A.; Lee, J.; Spinks, G.M.; et al. Woven-yarn thermoelectric textiles. Adv. Mater. 2016, 28, 5038–5044. [Google Scholar] [CrossRef] [Green Version]

- Jin, Q.; Jiang, S.; Zhao, Y.; Wang, D.; Qiu, J.; Tang, D.-M.; Tan, J.; Sun, D.-M.; Hou, P.-X.; Chen, X.-Q.; et al. Flexible layer-structured Bi2Te3 thermoelectric on a carbon nanotube scaffold. Nat. Mater. 2019, 18, 62–68. [Google Scholar] [CrossRef] [PubMed]

- Rojas, J.P.; Conchouso, D.; Arevalo, A.; Singh, D.; Foulds, I.G.; Hussain, M.M. Paper-based origami flexible and foldable thermoelectric nanogenerator. Nano Energy 2017, 31, 296–301. [Google Scholar] [CrossRef] [Green Version]

- Yan, W.; Dong, C.; Xiang, Y.; Jiang, S.; Leber, A.; Loke, G.; Xu, W.; Hou, C.; Zhou, S.; Chen, M.; et al. Thermally drawn advanced functional fibers: New frontier of flexible electronics. Mater. Today 2020, 35, 168–194. [Google Scholar] [CrossRef]

- Tao, G.; Abouraddy, A.F.; Stolyarov, A.M. Multimaterial fibers [M]. In Lab-on-Fiber Technology; Springer: Berlin/Heidelberg, Germany, 2015; pp. 1–26. [Google Scholar]

- Cusano, A.; Consales, M.; Crescitelli, A.; Ricciardi, A. Recent progress and perspectives of thermally drawn multimaterial fiber electronics. Adv. Mater. 2020, 32, 1904911. [Google Scholar]

- Sun, M.; Tang, G.; Liu, W.; Qian, G.; Huang, K.; Chen, D.; Qian, Q.; Yang, Z. Sn-Se alloy core fibers. J. Alloy. Compd. 2017, 725, 242–247. [Google Scholar] [CrossRef]

- Zhang, T.; Li, K.; Zhang, J.; Chen, M.; Wang, Z.; Ma, S.; Zhang, N.; Wei, L. High-performance, flexible, and ultralong crystalline thermoelectric fibers. Nano Energy 2017, 41, 35–42. [Google Scholar] [CrossRef]

- Sun, M.; Qian, Q.; Tang, G.; Liu, W.; Qian, G.; Shi, Z.; Huang, K.; Chen, D.; Xu, S.; Yang, Z. Enhanced thermoelectric properties of polycrystalline Bi2Te3 core fibers with preferentially oriented nanosheets. APL Mater. 2018, 6, 036103. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Zhang, H.; Wang, Z.; Li, C.; Wang, Z.; Li, K.; Huang, X.; Chen, M.; Chen, Z.; Tian, Z.; et al. Single-crystal SnSe thermoelectric fibers via laser-induced directional crystallization: From 1D fibers to multidimensional fabrics. Adv. Mater. 2020, 32, 2002702. [Google Scholar] [CrossRef] [PubMed]

- Sun, M.; Tang, G.; Huang, B.; Chen, Z.; Zhao, Y.; Wang, H.; Zhao, Z.; Chen, D.; Qian, Q.; Yang, Z. Tailoring microstructure and electrical transportation through tensile stress in Bi2Te3 thermoelectric fibers. J. Mater. 2020, 6, 467–475. [Google Scholar] [CrossRef]

- Sun, M.; Tang, G.; Wang, H.; Zhang, T.; Zhang, P.; Han, B.; Yang, M.; Zhang, H.; Chen, Y.; Chen, J.; et al. Enhanced thermoelectric properties of Bi2Te3-based micro-nano fibers via thermal drawing and interface engineering. Adv. Mater. 2022, 2942. [Google Scholar] [CrossRef]

- Nozariasbmarz, A.; Krasinski, J.S.; Vashaee, D. N-type bismuth telluride nanocomposite materials optimization for thermoelectric generators in wearable applications. Materials 2019, 12, 1529. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Du, Y.; Meng, Q.; Xu, J.; Shen, S.Z. Effects of preparation methods on the thermoelectric performance of SWCNT/Bi2Te3 bulk composites. Materials 2020, 13, 2636. [Google Scholar] [CrossRef] [PubMed]

- Sattar, M.; Yeo, W.H. Recent Advances in Materials for Wearable Thermoelectric Generators and Biosensing Devices. Materials 2022, 15, 4315. [Google Scholar] [CrossRef]

- Luo, Q.; Tang, G.; Sun, M.; Qian, G.; Shi, Z.; Qian, Q.; Yang, Z. Single crystal tellurium semiconductor core optical fibers. Opt. Mater. Express 2020, 10, 1072–1082. [Google Scholar] [CrossRef]

- Han, B.; Luo, Q.; Zhang, P.; Zhang, T.; Tang, G.; Chen, Z.; Zhang, H.; Zhong, B.; Zeng, Y.; Sun, M.; et al. Multifunctional single-crystal tellurium core multimaterial fiber via thermal drawing and laser recrystallization. J. Am. Ceram. Soc. 2022, 105, 1640–1647. [Google Scholar] [CrossRef]

- Zhuang, H.; Pei, J.; Cai, B.; Dong, J.; Hu, H.; Sun, F.; Pan, Y.; Snyder, G.J.; Li, J. Thermoelectric performance enhancement in BiSbTe alloy by microstructure modulation via cyclic spark plasma sintering with liquid phase. Adv. Funct. Mater. 2021, 31, 2009681. [Google Scholar] [CrossRef]

- Qian, G.; Sun, M.; Tang, G.; Liu, W.; Shi, Z.; Qian, Q.; Zhang, Q.; Yang, Z. High-performance and high-stability bismuth selenide core thermoelectric fibers. Mater. Lett. 2018, 233, 63–66. [Google Scholar] [CrossRef]

- Peng, J.; Snyder, G.J. A figure of merit for flexibility. Science 2019, 366, 690–691. [Google Scholar] [CrossRef]

| Samples | Electrical Conductivity σ (S/cm) | Seebeck Coefficient S (μV/K) | Thermal Conductivity κ|| (W/mK) | ZT |

|---|---|---|---|---|

| Bridgman-annealed fiber | 180 ± 7 | −227 ± 11 | 0.64 ± 0.06 | 0.43 |

| As-drawn fiber | 71 ± 3 | −138 ± 6 | 0.39 ± 0.04 | 0.11 |

| Bi2Se3 fiber [16] | 763 ± 35 | −92 ± 6 | 0.84 ± 0.08 | 0.23 |

| Bi2Se3 core fiber [27] | 319 ± 15 | −150 ± 7 | 1.25 ± 0.12 | 0.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Zhang, P.; Li, Q.; Tang, G.; Zhang, T.; Chen, D.; Qian, Q. Enhanced N-Type Bismuth-Telluride-Based Thermoelectric Fibers via Thermal Drawing and Bridgman Annealing. Materials 2022, 15, 5331. https://doi.org/10.3390/ma15155331

Sun M, Zhang P, Li Q, Tang G, Zhang T, Chen D, Qian Q. Enhanced N-Type Bismuth-Telluride-Based Thermoelectric Fibers via Thermal Drawing and Bridgman Annealing. Materials. 2022; 15(15):5331. https://doi.org/10.3390/ma15155331

Chicago/Turabian StyleSun, Min, Pengyu Zhang, Qingmin Li, Guowu Tang, Ting Zhang, Dongdan Chen, and Qi Qian. 2022. "Enhanced N-Type Bismuth-Telluride-Based Thermoelectric Fibers via Thermal Drawing and Bridgman Annealing" Materials 15, no. 15: 5331. https://doi.org/10.3390/ma15155331

APA StyleSun, M., Zhang, P., Li, Q., Tang, G., Zhang, T., Chen, D., & Qian, Q. (2022). Enhanced N-Type Bismuth-Telluride-Based Thermoelectric Fibers via Thermal Drawing and Bridgman Annealing. Materials, 15(15), 5331. https://doi.org/10.3390/ma15155331